Page 1

®

OWNER’S MANUAL

Safety, Installation, Maintenance, and Operation

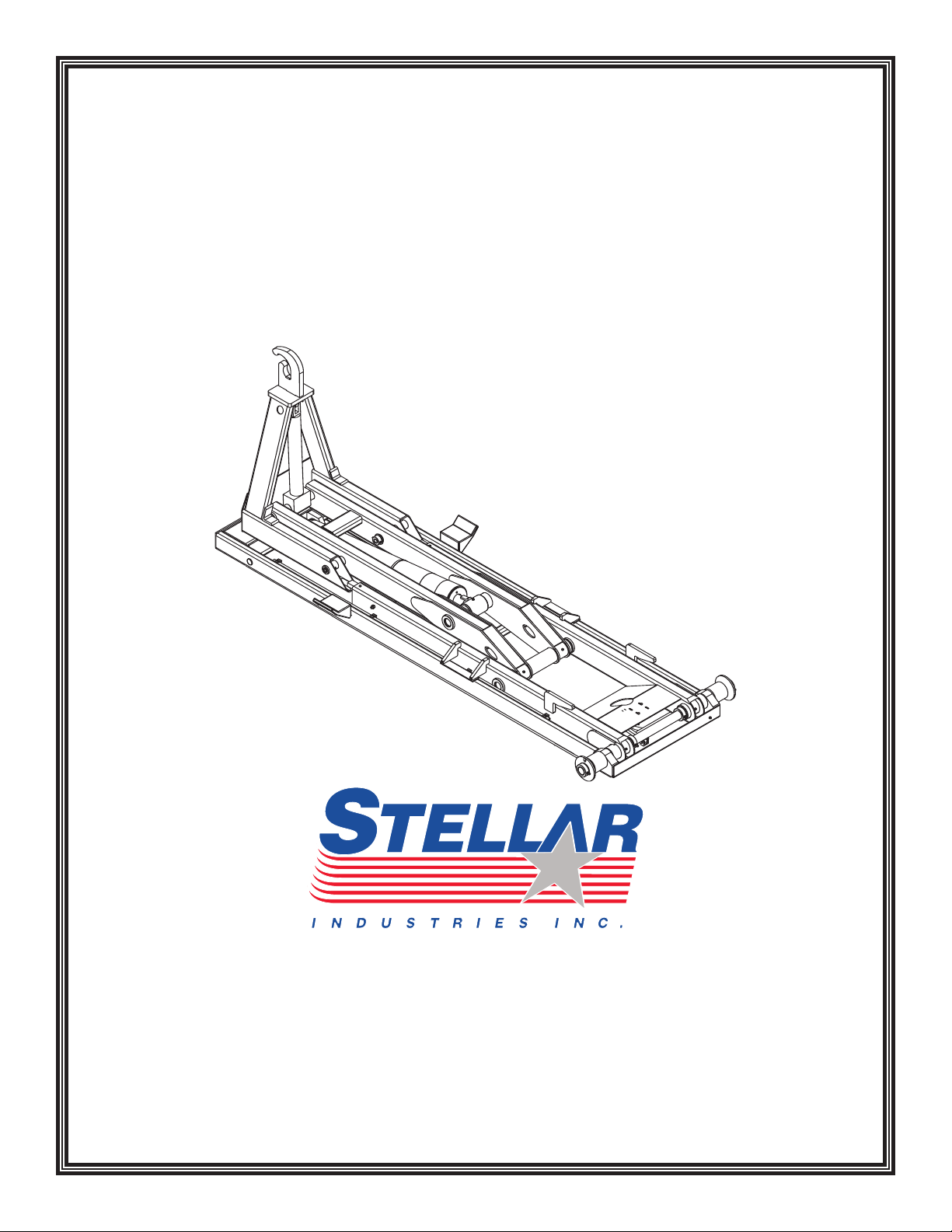

Stellar Flex36 Hooklift

Models

60-8

84-10

108-12

120-14

Subject to Change without Notification.

© 2007 Stellar Industries, Inc.

Stellar Industries, Inc.

190 State Street

PO Box 169

Garner, IA 50438

800-321-3741

Fax: 641-923-2811

www.stellarindustries.com

Manual Part No. 35551

Last Revision: 10/03/07

Page 2

Flex36 Hooklift Manual Revisions

Date of Revision

August 27, 2007

Section Revised

Chapter 6 - Installation

Description of Revision

Updated Reservoir Assembly Drawing (PN 35883) to reflect

engineering changes.

Page 3

Table of Contents

Table of Contents i

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Stellar Flex Hooklift Nomenclature . . . . . . .iv

Chapter 1 - Safety . . . . . . . . . . . . . . . . . . . . . .1

General Safety . . . . . . . . . . . . . . . . . . . . . . .1

Personal Safety . . . . . . . . . . . . . . . . . . . . . . .1

Maintenance Safety . . . . . . . . . . . . . . . . . .1

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Load Safety . . . . . . . . . . . . . . . . . . . . . . . . . .2

Environment . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 2 - Operation . . . . . . . . . . . . . . . . . . .3

Job-Site Set-Up . . . . . . . . . . . . . . . . . . . . . . .3

Operator Requirements . . . . . . . . . . . . . . . .3

Operator Conduct . . . . . . . . . . . . . . . . . . . .3

Hooklift Controls . . . . . . . . . . . . . . . . . . . . . .4

Operation Overview . . . . . . . . . . . . . . . . . . .4

Unloading Operation . . . . . . . . . . . . . . . . . .5

Loading Operation . . . . . . . . . . . . . . . . . . . .6

Dumping Operation . . . . . . . . . . . . . . . . . . .7

Chapter 3 - Maintenance . . . . . . . . . . . . . . . .9

Maintenance Procedures . . . . . . . . . . . . . .9

Periodic Inspection . . . . . . . . . . . . . . . . .9

Daily Inspection

Monthly Inspection . . . . . . . . . . . . . . . . .9

General Service . . . . . . . . . . . . . . . . . . . .9

Choice Lubricants for DX Bearings . . . . . .10

Chapter 4 - Specifications . . . . . . . . . . . . . .11

Stellar Flex36 Model 60-8

Hydraulic Hooklift Specifications . . . . .12

Stellar Flex36 Model 84-10

Hydraulic Hooklift Specifications

Stellar Flex36 Model 108-12

Hydraulic Hooklift Specifications . . . . .14

Stellar Flex36 Model 120-14

Hydraulic Hooklift Specifications . . . . .15

Chapter 5 - Decals . . . . . . . . . . . . . . . . . . . .17

Decals of Note . . . . . . . . . . . . . . . . . . . . . .17

Decal Kit Placement - PN 35559 . . . . . . . .18

Chapter 6 - Installation . . . . . . . . . . . . . . . . .19

Basic Installation Overview

Installation Steps - Basic Guidelines

Mounting Kit (Model 60-8) - PN 33320 . . .22

Mounting Kit (Models 84-10, 108-12,

120-14) - PN 23700

Rotary Valve

(All Models) - PN 37741 . . . . . . . . . . . . .24

Reservoir Assembly - PN 35883 . . . . . . . . .25

Setting System Relief Pressure . . . . . . . . .26

Installation Instructions for the

. . . . . . . . . . . . . . . . . . . .9

. . . . .

. . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . .

13

19

20

23

Power Beyond VDM8 Valve . . . . . . . . .28

Port Side Relief Installation . . . . . . . . . . . . .29

Controller Assembly - PN 38841 . . . . . . . .30

Dump Light Kit Installation . . . . . . . . . . . . .31

Hydraulic Schematic

(Model 60-8) - PN 34616 . . . . . . . . . . . .32

Hydraulic Schematic

(Model 84-10)- PN 34617 . . . . . . . . . . . .33

Hydraulic Schematic

(Model 108-12) - PN 34618 . . . . . . . . . .34

Hydraulic Schematic

(Model 120-14)- PN 34619 . . . . . . . . . . .35

Subframe Model 60-8 . . . . . . . . . . . . . . . . .36

Subframe Model 84-10 . . . . . . . . . . . . . . . .37

Subframe Model 108-12 . . . . . . . . . . . . . . .38

Subframe Model 120-14 . . . . . . . . . . . . . . .39

Chapter 7 - Assembly Drawings . . . . . . . . . .41

Base Assembly (60-8) - PN 31823 . . . . . . .41

Base Assembly (84-10) - PN 33337 . . . . . .42

Base Assembly (108-12) - PN 34245 . . . . .43

Base Assembly (120-14) - PN 33419 . . . . .44

Dump Assembly (60-8) - PN 31824

Dump Assembly (84-10) - PN 33339 . . . . .46

Dump Assembly (108-12) - PN 34247 . . . .47

Dump Assembly (120-14) - PN 33417 . . . .48

Secondary Assembly

(60-8) - PN 33047 . . . . . . . . . . . . . . . . . .49

Secondary Assembly

(84-10) - PN 33341 . . . . . . . . . . . . . . . . .50

Secondary Assembly

(108-12) - PN 34249 . . . . . . . . . . . . . . . .51

Secondary Assembly

(120-14) - PN 33415 . . . . . . . . . . . . . . . .52

Tilt Assembly

(All Flex36 Models) - PN 33049 . . . . . . .53

Tilt Assembly

(Optional Tall Tilt) - PN 35032 . . . . . . . .54

Tilt Cylinder Assembly

(All Flex36 Models) - PN 23460

Main Cylinder Assembly

(60-8) - PN 27116 . . . . . . . . . . . . . . . . . .56

Main Cylinder Assembly

(84-10)- PN 33404

Main Cylinder Assembly

(108-12, 120-14)- PN 33462 . . . . . . . . . .58

Chapter 8 - Replacement Parts . . . . . . . . . .59

Chapter 9 - Troubleshooting . . . . . . . . . . . . .61

Warranty Information . . . . . . . . . . . . . . . . . . .62

. . . . . . . . . . . . . . . . . .

. . . . . .45

. . . . . . .

55

57

Page 4

ii Flex36 Owner’s Manual

AN OVERVIEW TO OWNER, OPERATOR AND

SERVICE PERSONNEL ABOUT SAFETY

As the owner or employer, it is your responsibility to instruct the operator in the safe operation of this equipment and to provide the operator with properly maintained equipment.

FAILURE TO READ THIS MANUAL BY ANYONE WHO WILL OPERATE, SERVICE, OR WORK

AROUND THIS HOOKLIFT IS A MISUSE OF THE EQUIPMENT. DEATH OR SERIOUS INJURY WILL

RESULT FROM IMPROPER USE OR MAINTENANCE OF THIS MACHINE.

Occupational safety is a prime concern of Stellar Industries in the design and production

of this hooklift. Our goal in writing this manual was the safety of the operator and others

who work around this equipment.

It is your responsibility to know the specific requirements, governmental regulations, precautions and work hazards that exist in the operation and maintenance of this hooklift.

You shall make these available and known to all personnel working with and around the

equipment, so that all of you will take the necessary and requir

FAILURE TO HEED THESE INSTRUCTIONS CAN RESULT IN SERIOUS INJURY OR DEATH.

ed safety precautions.

It is also your responsibility to operate and maintain your hooklift with caution, skill, and

good judgment. Following the recognized safety procedures will help you avoid accidents. Modification to any part of his hooklift can create a safety hazard and therefore

shall not be made without the manufacturer’s written approval. Use only factory

approved accessories, options, and parts on this equipment. The rebuilding or remounting

of this equipment requires the mounting procedures and retesting to be in accordance

with factory instructions. Safety covers and devices must remain installed and maintained

in proper working condition. Safety decals must be maintained, be completely legible,

and be properly located. If safety covers, devices, or decals are missing, they must be

replaced with the proper designated Stellar part.

Be capable, careful, and concerned! Make safety your everyday business!

Attention!

According to Federal Law (49 cfr part 571),

each final-stage manufacturer shall complete the vehicle in such a manner that it

conforms to the standar

date of manufacture of the incomplete

vehicle, the date of final completion, or a

date between those two dates. This requirement shall, however, be superseded by any

conflicting provisions of a standard that

applies by its terms to vehicles manufactured in two or more stages.

Therefore, the installer of Stellar hooklifts is

considered one of the manufacturers of the

vehicle. As such a manufacturer

ds in ef

fect on the

, the

installer is responsible for compliance with

all applicable federal and state regulations.

They are required to certify that the vehicle

is in compliance with the Federal Motor

Vehicle Safety Standards and other regulations issued under the National Traffic and

Motor Vehicle Safety Act.

ence the Code of Federal

Please r

Regulations, title 49 - Transportation,

Volume 5 (400-999), for further information,

or visit

www.gpoaccess.gov/nara/index.html for

the full text of Code of Federal Regulations.

efer

Page 5

Introduction

Introduction iii

Stellar Hooklifts are designed to provide safe

and dependable service for a variety of

operations. With proper use and

maintenance, these hooklifts will operate at

peak performance for many years.

To promote this longevity, carefully study the

information contained in this manual before

putting the equipment into service. Though

it is not intended to be a training manual for

beginners, this manual should provide solid

guidelines for the safe and proper usage of

the hooklift.

Once you feel comfortable with the

material contained in this manual, strive to

cise your knowledge as you safely

exer

operate and maintain the hooklift. This

process is vital to the proper use of the unit.

A few notes on this manual:

A copy of this manual is provided with every

hooklift and shall remain with the hooklift at

all times. Information contained within this

manual does not cover all maintenance,

operating, or repair instructions pertinent to

all possible situations.

Please be awar

manual contain information pertaining to

e that some sections of this

Stellar manufactured hooklifts in general

and may or may not apply to your specific

model.

This manual is not binding. Stellar Industries,

Inc. reserves the right to change, at any

time, any or all of the items, components,

and parts deemed necessary for product

improvement or commercial/production

purposes. This right is kept with no

requirement or obligation for immediate

mandatory updating of this manual.

In closing:

If more information is required or technical

assistance is needed, or if you feel that any

part of this manual is unclear or incorrect,

please contact the Stellar Customer Service

Department by phone at 800-321-3741 or

email at service@stellarindustries.com.

ATTENTION

Failure to adhere to the

instructions could result in

property damage or even serious

bodily injury to the operator or

others close to the hooklift.

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information service@stellarindustries.com

Order Parts parts@stellarindustries.com

Warranty Information warranty@stellarindustries.com

Page 6

iv Flex36 Owner’s Manual

HOOKLIFT

BASE

DUMP

SECONDARY

TILT

Stellar Flex Hooklift Nomenclature

The Stellar Flex is a hydraulic, body-loading device when mounted on a truck chassis.

When mounted, the Stellar Flex can handle a variety of bodies ranging from flatbeds to

recycling containers to dump bodies.

Two independently controlled cylinders operate all the functions of the Stellar Flex. By

varying the cylinder operation, the Stellar Flex can be used to dump or unload a body.

The Stellar Flex consists of four basic parts: The base, dump, secondary, and tilt sections.

Familiarize yourself with the various components of this hooklift and the names of those

components. Knowing the proper terminology is necessary to get full benefit from this

manual

Page 7

Chapter 1 - Safety

Safety 1

Please Read the Following Carefully! This

portion of the manual contains information

regarding all Stellar manufactured hooklifts.

Some items contained within this chapter

may not apply to your specific equipment.

Safety should be the number one thought

on every operator’s mind. Three factors

should exist for safe operation: a qualified

operator, well-maintained equipment, and

the proper use of this equipment. The

following information should be read and

understood completely by everyone

working with or near the hooklift before

putting the unit into operation.

Please take note that Stellar Industries, Inc.

is not liable for accidents incurred by the

hooklift because of non-fulfillment from the

operator’s side of current rules, laws, and

regulations.

General Safety

It is the responsibility of the owner to instruct

the operator in the safe operation of your

equipment and to provide the operator with

properly maintained equipment.

anti-noise headphones, protective glasses,

breathing apparatus, and reflective jackets.

Consult your employer regarding current

safety regulations and accident-prevention

equipment.

Do not wear rings, wristwatch, jewelry, loosefitting or hanging clothing such as ties, torn

garments, scarves, unbuttoned jackets or

unzipped overalls, which could get caught

up in the moving parts of the hooklift.

Keep a first-aid box and a fire extinguisher

readily available on the truck. Regularly

check to make sure the fire extinguisher is

fully charged and the first-aid kit is stocked.

Do not use controls and hoses as handholds.

These parts move and cannot provide stable support.

Do not allow unauthorized personnel or

equipment to enter within 10 feet of hooklift

operating area.

Never allow anyone to ride the hooklift or

load.

Trainees or untrained persons shall be under

the direct supervision of qualified persons.

Do not operate equipment under the

adverse influence of alcohol, drugs, or medication.

Read all Danger and Caution decals on the

equipment and understand their meaning.

Personal Safety

Keep clear of all moving parts.

Always wear the pr

devices.

Always wear appr

clothing such as: protective helmets, antislip shoes with steel toes, protective gloves,

escribed personal safety

oved accident-prevention

Maintenance Safety

Never modify or alter any of the equipment,

whether mechanical, electrical, or hydraulic,

without Stellar Industries’ approval.

Do not perform any maintenance or repair

work on the hooklift unless authorized and

trained to do so.

Release system pressure before attempting

to make adjustments or repairs.

Do not attempt service or repair when PTO is

engaged.

Decals are considered safety equipment.

They must be maintained, as would other

safety devices. Do not remove any decals.

Page 8

2 Flex36 Owner’s Manual

Replace any decals that are missing, damaged, or not

legible.

The safety instruction plates, notices, load

charts and any other sticker applied to the

hooklift must be kept legible and in good

condition. If necessary, replace them.

Keep all surfaces of the hooklift free of oil

and grease to avoid slippery surfaces and

aid in

inspections.

Stability

Know the hooklift components and their

capabilities and limitations. Overloading the

hooklift may result in serious damage of self,

others, equipment or the surroundings.

Never exceed manufacturer’s load ratings.

These ratings are based on the machine’s

hydraulic, mechanical, and structural design

rather than stability.

Load Safety

Full rated dump capacity assumes load will

decrease as dump angle increases. Do not

take full rated capacity to full dump angle

without some unloading of weight as it may

cause damage to the chassis and/or the

hooklift.

Move the control lever slow and smooth for

steady oil flow.

Avoid jerky or sudden movement of the controls.

weight can be lifted.

Keep everyone clear when loading, unloading, and dumping.

Do not push on fixed objects or bodies without rollers with the hooklift.

Do not permit loose objects on the hooklift.

Use a qualified person to assist in loading

when the load is not visible to the operator.

Do not leave hooklift unattended with suspended load.

Take care when operating in areas supported by vehicle tires, because of the cushioning effect of springs and tires.

Never use the drivetrain of the chassis to

assist the hydraulics in loading

Environment

Do not operate the hooklift during electrical

storms.

In extreme cold, allow adequate time to

warm the truck before engaging the PTO.

Do not rev the truck engine and over speed

the hydraulic pumps as permanent damage

to the pumps may occur. Follow the vehicle

owner’s manual regarding operating the

vehicle in such adverse conditions.

In extreme cold, operate the controls slowly

to allow for viscosity changes.

Be constantly aware of the hooklift position

when operating the controls.

Do not attempt to lift fixed loads.

Know the weight of your load to avoid overloading the equipment.

Deduct the weight of the body from the

maximum load rating to determine how

much

ATTENTION

Stellar Industries, Inc. is not liable

for accidents incurred by the

hooklift because of the

operator’s non-fulfillment of

current rules, laws and

regulations.

Page 9

Chapter 2 - Operation

Operation 3

Job-Site Set-Up

Thoroughly plan the lift before positioning

the vehicle. Consider the following:

1. The vehicle should be positioned in an

area free from overhead obstructions to

eliminate the need for repositioning.

2. Position the vehicle so that it is impossible

for any portion of the equipment to come

within the minimum required safe distance

of any power line. Maintain a clearance

of at least 10 feet between any part of

the hooklift, load line, or load, and any

electrical line or apparatus carrying up to

50,000 volts. One foot additional clearance is required for every additional

30,000 volts or less. Remember to allow

for winds that cause power lines to sway.

It is recommended that a signal person

be used when the vehicle is set-up near

power lines.

3. The vehicle should also be positioned on

a firm and level surface that will provide

adequate support for the body.

Operator Requirements

Operation is limited to the following people:

A. Qualified individual.

B. Trainees under direct supervision of the

qualified individual.

C. Test or maintenance individual.

D. Hooklift Inspector.

Operators must:

A. Demonstrate the ability to understand

all decals, the owner’s manual, and any

other information required for safe operation of the hooklift.

B. Be able to demonstrate the ability to

safely control the hooklift.

C. Know all safety r

D. Be responsible for maintenance require-

ments.

E. Understand and be fully capable of

implementing all emergency proce-

dures.

F. Understand the operating procedures as

outlined by this manual, Ansi B30.5 and

Federal/State Laws.

egulations.

4. The parking brake must be removed to

allow the truck to roll under the body

while loading.

CAUTION

1.

When loading and unloading

bodies, the tilt cylinder must be

fully extended before operating

the lift cylinder to prevent

damage to the latch systems.

2. When the PTO is engaged, do

not run the engine over 1400

RPM.

3. Do not hold the brakes while

performing operations.

Operator Conduct

1. Operators will not engage in any operation that would cause them to divert

attention away fr

the hooklift.

2. Operators are responsible for all opera

tions under their direct control.

3. Operators will not leave a suspended

load unattended.

4. Operators will be familiar with the equipment and the maintenance required for

oper care.

pr

om the operation of

-

Page 10

4 Flex36 Owner’s Manual

Hooklift Controls

1. Be familiar with the sequence and operation of the hooklift controls.

2. Each individual hooklift function should

have control function decals. Replace

them immediately if they are missing or

illegible.

3. Keep hands, feet and control levers free

from mud, grease and oil.

4. Be familiar with the control levers and

how they operate before attempting to

operate the hooklift.

5. Be prepared before beginning operation of the hooklift:

• All pr

•

• Be sure all safety devices provided are

• Be prepared for all situations. Keep

• Be sure all regular maintenance has

• Visually inspect all aspects of the

• Check for fluid leaks.

otective guards must be in place.

Be aware of the surroundings: low

branches, power lines, unstable

ground.

in place and in good operating condition.

fire extinguisher and first aid kit near.

been performed.

hooklift for physical damage.

Operation Overview

Unloading Operation

. Stop the truck at the location you wish to unload.

1

2. Put the truck in neutral and engage the PTO.

Run RPM as needed.

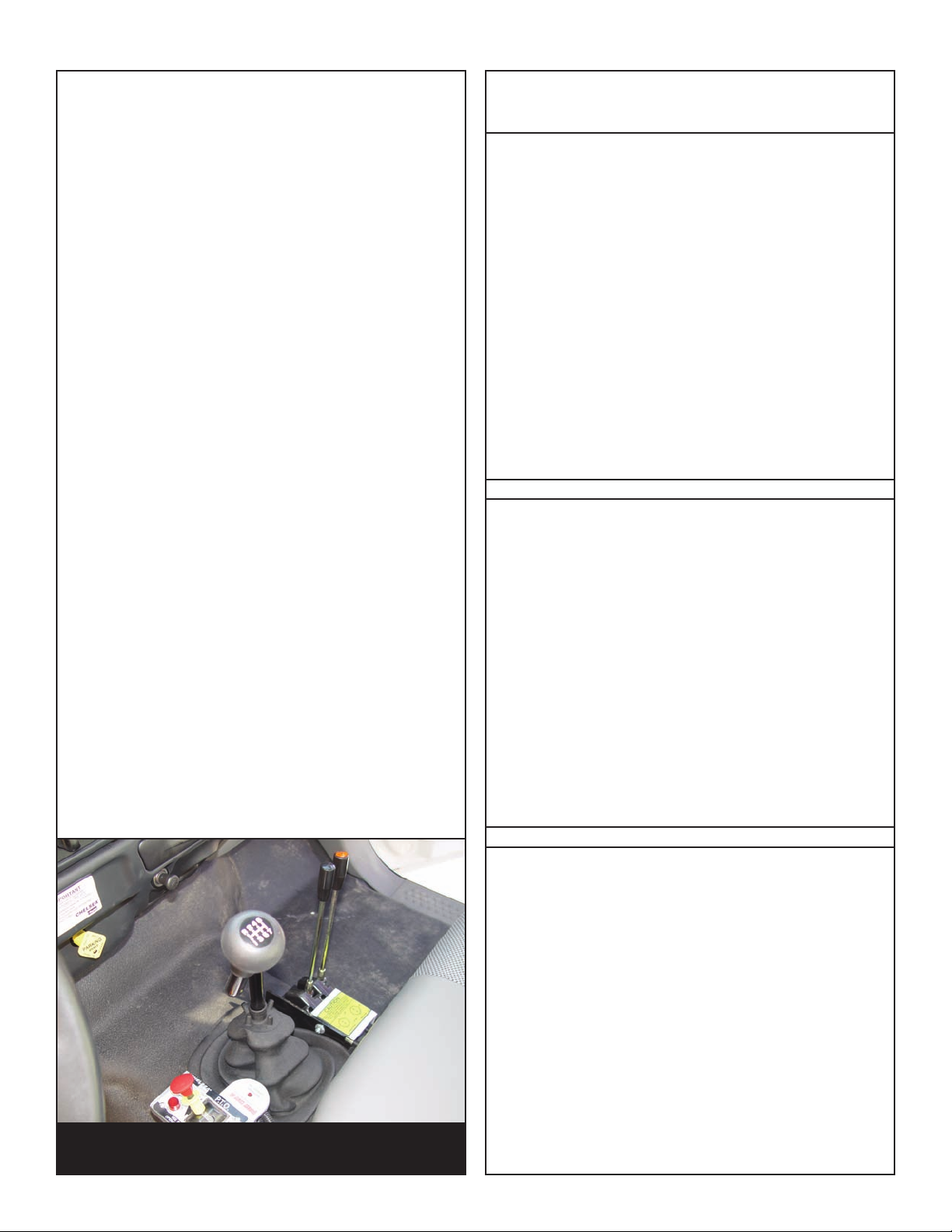

3. Locate the black control lever labeled tilt.

4. Pull the tilt lever until the cylinder is fully extended, thus releasing tabs.

5. Locate the red lever labeled lift.

6. Pull lift lever until the body is on the ground and

can be detached. Return the hooklift to the

stored position and disengage the PTO.

Loading Operation

1. Position the truck in line with the body you intent

to pick up.

2. Engage the hook to the body by maneuvering

the hooklift with the red(lift) lever. Run RPM as

needed.

3. Push the red(lift) lever until the main cylinder is

fully retracted.

4. Push the black(tilt) lever until the tilt is fully

extended.

5. Disengage the PTO.

NOTE: The controller assembly pictured in this

chapter may differ from model to model.

Dumping Operation

1. Stop the truck at the location you wish to dump

the load.

2. Put the truck in neutral and engage the PTO.

Run RPM as needed.

3. Locate the red lever labeled lift.

4. Pull the lever to dump the body.

5.Wait until dumping is complete, then push the

red(lift) lever until the main cylinder fully retracts.

6. Disengage the PTO.

Page 11

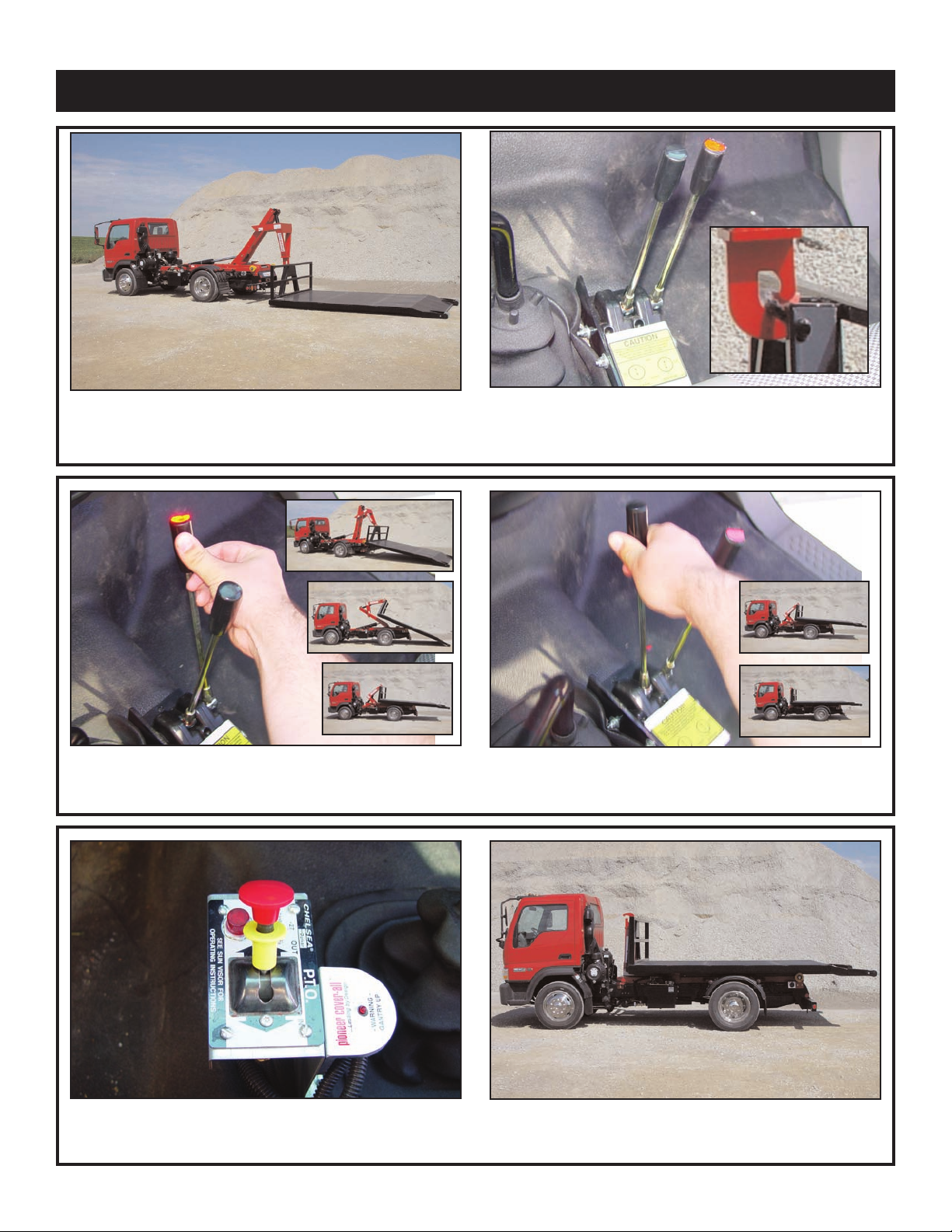

Unloading Operation

5Operation 5

1. Stop the truck at the location you wish to unload.

3. Locate the black control lever labeled tilt.

2. Put the truck in neutral and engage the PTO.

Run RPM as needed.

4. Pull the tilt lever until the cylinder is

fully extended, thus releasing tabs.

5. Locate the r

ed lever labeled lift.

6. Pull lift lever until the body is on the ground and

can be detached. Return the hooklift to the

stored position and disengage the PTO.

Page 12

6 Flex36 Owner’s Manual

Loading Operation

1. Position the truck in line with the

body you intent to pick up.

3. Push the red(lift) lever until the

main cylinder is fully retracted.

2. Engage the hook to the body by maneuvering

the hooklift with the red(lift) lever.

Run RPM as needed.

4. Push the black(tilt) lever until

the tilt is fully retracted.

5. Disengage the PTO.

Page 13

Dumping Operation

7Operation 7

1. Stop the truck at the location

you wish to dump the load.

3. Locate the red lever labeled lift.

2. Put the truck in neutral and engage the PTO.

Run RPM as needed.

4. Pull the lift lever to dump the body.

5. Wait until dumping is complete, then push the

ed(lift) lever until the main cylinder fully r

r

etracts.

6. Disengage the PTO.

Page 14

8 Flex36 Owner’s Manual

Page 15

Chapter 3 - Maintenance

9Maintenance 9

Please read the following before performing any

m

aintenance on the hooklift.

1. Only authorized service personnel are to perform

maintenance on the hooklift.

2. Disengage the PTO before any service or repair is

performed.

3. Do not disconnect hydraulic hoses while there is

still pressure in those components.

4. Before disconnecting hydraulic components,

shut off the engine, release any air pressure on

the hydraulic reservoir, and move control levers

repeatedly through their operating positions to

relieve all pressures.

Keep the hooklift clean and free from grease

5.

build-up, oil and dirt to prevent slippery conditions.

6. Perform all safety and maintenance checks

before each period of use.

7. Replace parts with Stellar Industries, Inc.

approved parts only.

8. Immediately repair or have repaired any components found to be inadequate.

Maintenance Procedures

1. Position the hooklift where it will be out of the way of

other operations or vehicles in the area.

2. Place all controls in the off position and secure operating features from inadvertent motion.

3. Relieve hydraulic oil pressure from all hydraulic circuits before loosening or removing hydraulic components.

4. Label or tag parts when disassembling.

Periodic Inspection

Periodic Inspection should occur while the hooklift is in

use. For the duration of the usage, inspect the hooklift

for all of the following:

1. Loose bolts and fasteners.

2. All pins, bushings, shafts, and gears for wear, cracks,

or distortion to include all pivot points, and bushings.

e.

Hydraulic systems for pr

3.

4. Main frame mount bolts.

5. Cylinders for:

A. Damaged rods.

B. Dented barrels.

C. Drift fr

D. Leaks at rod seals or holding valves.

6. PTO and hydraulic pump(s) for leaks.

Hydraulic hose and tubing for evidence of damage

7.

such as blistering, crushing, or abrasion.

esence of this owner’s manual.

8. Pr

Daily Inspection

Daily Inspection should occur each day before the

hooklift is put into use. Each day, inspect the hooklift for

all of the following:

om oil leaking inter

oper operating pr

nally.

essur

1. Hydraulic oil level.

2. Loose parts or damage to structures or weld.

3. Cylinder movement due to leakage.

4

. Hoses for evidence of oil leaks.

5. Controls for malfunction or adjustment.

6. Parking brake operation.

7. All securing hardware such as cotter pins, snap rings,

h

airpins, and pin keepers for proper installation.

8. All safety covers for proper installation.

9. Cylinder holding valves for proper operation.

10. Equipment for missing, illegible, or defaced operat-

ing decals and safety signs.

Monthly Inspection

Monthly Inspection should occur at the beginning of

every work month. Each month, inspect the hooklift for

all of the following:

1. Frame bolt tightness - turn barrel nuts and mounting

bolts during the first month of operation on new

machines and then quarterly thereafter.

2. Cylinders and valves for leaks.

3. Lubrication.

4. Tilt hook for cracks.

5. Structural weldments for bends, cracks, or breaks.

6. All pins and keepers for proper installation.

7. All control, safety, and capacity placards for read-

ability and secure attachment.

8. Inspect all electrical wires and connections for worn,

cut, or deteriorated insulation and bare wire.

Replace or repair wires as required.

10. Lubrication of all points requiring lubrication.

General Service

The following general suggestions should be helpful in

analyzing and servicing your hooklift. Using the following

systematic approach should be helpful in finding and

fixing problems:

1. Deter

2. List and record possible causes.

3. Devise checks.

4. Conduct checks in a logical order to determine the

5. Consider the remaining service life of components

6. Make the necessary repair.

7. Recheck to ensur

8. Functionally test the new part in its system.

mine the pr

cause.

against the cost of parts and labor necessary to

replace them.

oblem.

e that nothing has been overlooked.

Cleanliness

An important item in preserving the

long life of the hooklift is keeping dirt,

grime, and corrosive material out of

the working parts. Thoroughly wash

and grease the hooklift periodically.

Page 16

10 Flex36 Owner’s Manual

Choice Lubricants for DX Bearings

Type of Grease Description

Greases Recommended

Premium Quality

Multi-Purpose

Multi-Purpose Calcium Based, for General Automotive and Industrial Use

Anti-Friction Bearing Calcium Based with EP Additives

Extreme Pressure (EP) Lithium Based with EP Additives

High Temperature Modified Sodium Based, High Drop Point

Transmission Semi-Fluid, Calcium Based

Molybdenum Filled Lithium Based with 2% Molybdenum Disulfide

Graphite Filled Sodium Based with 2% Graphite

Block Grease Sodium Based Solid Grease

White Grease Aluminum Complex Based with Anti-Oxidant & Rust

Silicone Lithium Based with Silicone Oil Lubricant

Stabilized, Anti-Oxidant Lithium Base

Lithium Base with 3% Molybdenum Disulfide

High Drop Point

Calcium Grease, Water Stabilized, High Drop Point

Lithium Based

Sodium Based

Calcium Based with EP Additives

Inhibitors & Zinc Oxide Additives

Greases Not Recommended

Type of Grease Description

Cup Grease Light Service Calcium or Sodium Based Grease

Graphite Filled Greases with More than 10% Graphite

Molybdenum Filled Greases with More than 10% Molybdenum Disulfide

Fluorocarbon Low Molecular Weight Chlorofluoroethylene Polymer

with Inert Thickeners

White Grease Calcium Based, Zinc Oxide Filled

Page 17

Chapter 4 - Specifications

• Standard in-cab manual controls which allow for precise

metering of the manual hydraulic valve. Solenoid-activated

hydraulic control valve with electric remote control pendant

is optional.

• Ten (10) gallon capacity frame-mounted oil reservoir.

• Hydraulic flow shall not exceed 16-gallons per minute.

• Patented dump/load interface on double pivot models.

• Hydraulic locks to prevent cylinder movement in case of

pressure loss.

• Grease zerks at all points to allow purging of contaminates.

• Mechanical rear body tie-down latches.

• Resettable dump/tilt tabs.

11Specifications 11

• Hydraulic rotary valve to prevent front tilt movement when

the dump frame is raised.

• DX pre-lubricated bushings used at pivot points.

• Greaseable load rollers.

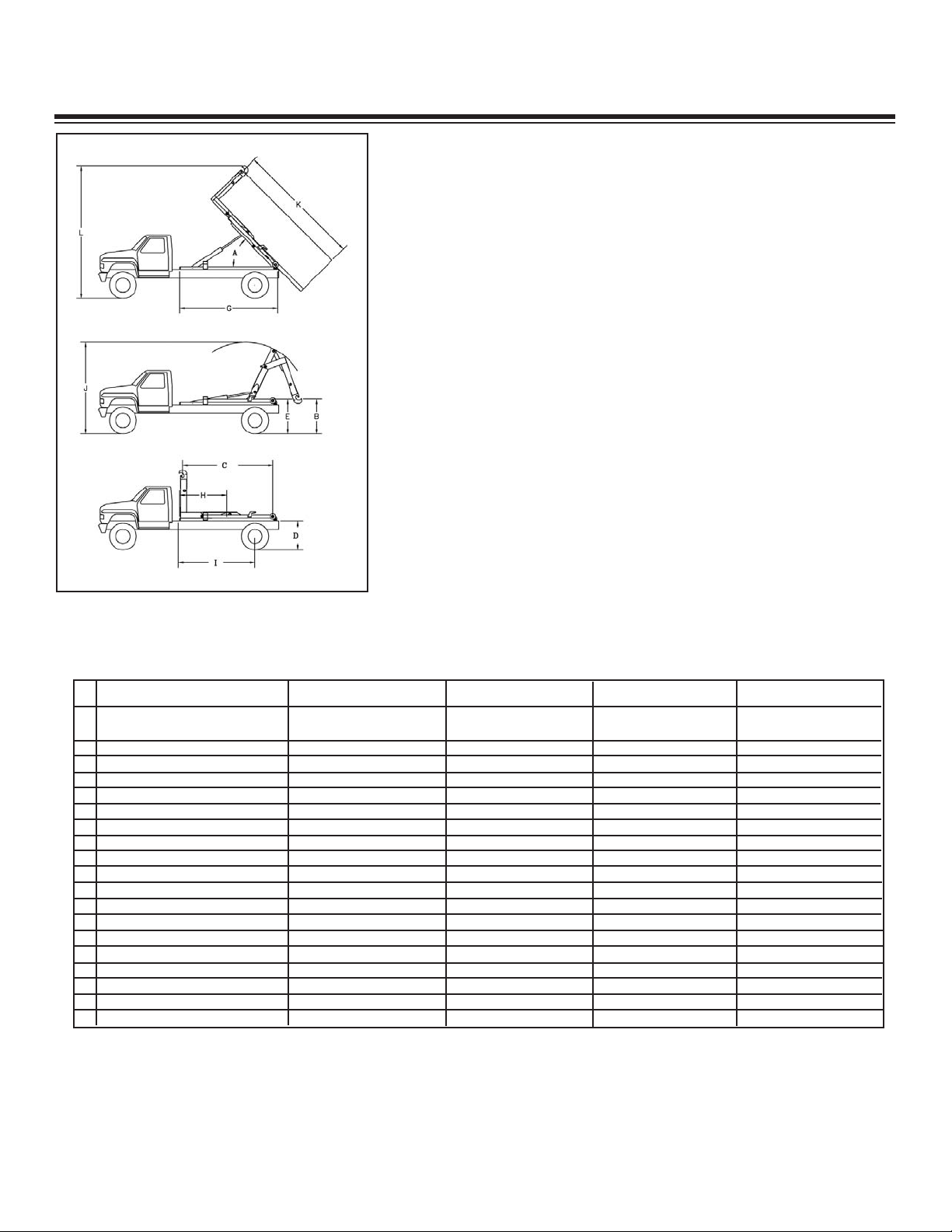

60-8 84-10 108-12 120-14

Lifting/Dumping Capacity Up to 9,000lbs

(4,082kg) (7,257kg) (7,257kg) (7,257kg)

A Dump Angle 54° 53° 54° 50°

B Lowest Hook Heigh 23.5” (60cm) 25” (63.5cm) 27” (68.5cm) 28” (71cm)

fective Length

Ef

C

D Truck Frame Height 34” (86cm) 36” (91.5cm) 36” (91.5cm) 36” (91.5cm)

E Hooklift Height 39.5” (100cm) 41.5” (105.5cm) 41.5” (105.5cm) 41.5” (105.5cm)

Hooklift Length 99.25” (252cm) 126” (320cm) 154” (391cm) 161” (409cm)

G

H Hooklift Center of Gravity 43” (109cm) 58” (147cm) 68” (173cm) 70” (178cm)

I Chassis Cab to Axle 60” (152.5cm) 84”-96” 108”-120” 120”-130”

J Max. Height When Loading 104” (264cm) 118” (300cm) 135” (343cm) 136” (345.5cm)

K Longest Body to Dump 120” (305cm) 144” (366cm) 180” (457cm) 192” (488cm)

L Max. Height When Dumping 141” (358cm) 162” (411.5cm) 185” (470cm) 187” (475cm)

Operating Pressure See table 1.1 See table 1.1 See table 1.1 See table 1.1

Shipping Weight 1,275lbs (578.5kg) 1,360lbs (617kg) 1,615lbs (733kg) 1,650lbs (748.5kg)

Hook Height

(from bottom of hook bar)

Shipping Dimensions 100”x49”x47” 126”x49”x47” 154”x49”x47” 161”x49”x47”

(LxHxW) (254x124.5x119.5cm) (320x124.5x119.5cm) (391x124.5x119.5cm) (409x124.5x119.5cm)

91” (231cm) 115” (292cm) 142” (361cm) 151” (383.5cm)

35.63” (90.5cm)

Up to 16,000lbs

(213.5cm-244cm)

35.63” (90.5cm)

Up to 16,000lbs Up to 16,000lbs

(274.5cm-305cm)

35.63” (90.5cm)

(305cm-330cm)

35.63” (90.5cm)

Page 18

12 Flex36 Owner’s Manual

Stellar Flex36 Model 60-8 Hydraulic Hooklift Specifications

ifting Capacity: Check table 1.1 for variable lifting capabilities.

L

ontainer Length: 8-foot through 9-foot. Longer bodies up to 10-feet may be accommodated if full dump angle is not required (may require

C

pecial body-mounted or extendable truck-mounted bumper and additional latches to meet the Federal Motor Carrier

s

afety Administration (FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134).

S

ody length does not include A-frame.

B

Maximum Dump Angle: 54°

Operating Pressure: See table 1.1 in Chapter 6: Installation for variable pressure settings.

Weight of Hooklift: Hooklift weight not to exceed 1,275 pounds.

Height of Hooklift: Hooklift height not to exceed 5.5" as measured from top of truck frame to top of hooklift rollers.

Hook Height: 35.63-inches from bottom of skid rails to bottom of hook bar. Hooklift must be able to pick up body

10-inches below grade, when mounted on a 34” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Contro

ontrols: D

C

Tilting Hook Assembly: Hooklift must have pivoting type front tilt section (jib) to provide a low degree loading/unloading angle and also to provide

Tilt Cylinder: Cylinder must be double acting (4” Bore x 2” Rod x 17” Stroke) and include dual integral pilot-operated counterbalance

Tilt Section Operation: Hooklift must include a hydraulic lock-out device to prevent operation of the tilt section while hooklift is in the dumping

Lift/Dump Cylinder: Cylinder must be double acting and include dual pilot-operated counterbalance valves to prevent cylinder movement in

Dump/Tilt Interlock: Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length 25” wide frame to

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body to the hooklift through all ranges of

Rear Dump Hinge Pin: 2-inch diameter type 304 or 17-4 stainless steel minimum.

l Valve: Hydraulic valve mounted directly onto the oil reservoir with power beyond capabilities.

ual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all hooklift functions.

a wider stance for side to side stability.

valves to prevent cylinder collapse in case of hose failure. Cylinder must be fully retracted when in the transport mode to

prevent exposure of cylinder rod to corrosive road salts.

mode.

case of pressure loss.

provide support for the container while in the dump mode. These sections form this frame without the use of mechanical

latches which rely on gravity, springs, or container/body mounted latches. The system must be protected from out of

sequence operation.

the dump mode. This must be accomplished without the use of steel springs and/or hydraulic/air cylinders.

Pins:

Bushings:

Hoses & Hyd. Fittings: All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized wherever possible.

Electrical: All electrical wiring to be protected by full length steel conduit fastened into the hooklift framework.

Technical Documentation: All hooklifts shall come with documentation on operation, maintenance, safety and a parts manual.

Regulations: Hooklift shall be designed and manufactured to all local, state and federal regulations.

Origin of Manufacture: Hooklift to be designed and manufactured in the United States of America.

All pins to be type 304 or 17-4 stainless steel.

All bushings to be of the DX pr

in heavy containment and corrosive environments.

ed steel hydraulic tubing to be used whenever possible.

Secur

e-lubricated variety, used with grease fittings. Bronze bushings not allowed due to survivability

Page 19

Specifications 13

Stellar Flex36 Model 84-10 Hydraulic Hooklift Specifications

ifting Capacity: Check table 1.1 for variable lifting capabilities.

L

ontainer Length: 10-foot through 12-foot. Longer bodies up to 13-feet may be accommodated if full dump angle is not required (may require

C

pecial body-mounted or extendable truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety

s

dministration (FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134). Body

A

ength does not include A-frame.

l

Maximum Dump Angle: 53°

Operating Pressure: See table 1.1 in Chapter 6: Installation for variable pressure settings.

Weight of Hooklift: Hooklift weight not to exceed 1,360 pounds.

Height of Hooklift: Hooklift height not to exceed 5.5" as measured from top of truck frame to top of hooklift rollers.

Hook Height: 35.63-inches from bottom of skid rails to bottom of hook bar. Hooklift must be able to pick up body

10-inches below grade, when mounted on a 36” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Contro

ontrols: D

C

Tilting Hook Assembly: Hooklift must have pivoting type front tilt section (jib) to provide a low degree loading/unloading angle and also to provide a

Tilt Cylinder: Cylinder must be double acting (4” Bore x 2” Rod x 17” Stroke) and include dual integral pilot-operated counterbalance

Tilt Section Operation: Hooklift must include a hydraulic lock-out device to prevent operation of the tilt section while hooklift is in the dumping mode.

Lift/Dump Cylinder: Cylinder must be double acting and include dual pilot-operated counterbalance valves to prevent cylinder movement in

Dump/Tilt Interlock: Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length 25” wide frame to

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body to the hooklift through all ranges of

Rear Dump Hinge Pin: 2-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

l Valve: Hydraulic valve mounted directly onto the oil reservoir with power beyond capabilities.

ual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all hooklift functions.

wider stance for side to side stability.

valves to prevent cylinder collapse in case of hose failure. Cylinder must be fully retracted when in the transport mode to pre-

vent exposure of cylinder rod to corrosive road salts.

case of pressure loss.

provide support for the container while in the dump mode. These sections form this frame without the use of mechanical

latches which rely on gravity, springs, or container/body mounted latches. The system must be protected from out of

sequence operation.

the dump mode. This must be accomplished without the use of steel springs and/or hydraulic/air cylinders.

Bushings: All bushings to be of the DX pre-lubricated variety, used with grease fittings. Bronze bushings not allowed due to survivability in

heavy containment and corr

Hoses & Hyd. Fittings: All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized wherever possible.

Secured steel hydraulic tubing to be used whenever possible.

Electrical:

Technical Documentation: All hooklifts shall come with documentation on operation, maintenance, safety and a parts manual.

Regulations:

Origin of Manufacture: Hooklift to be designed and manufactured in the United States of America.

All electrical wiring to be protected by full length steel conduit fastened into the hooklift framework.

Hooklift shall be designed and manufactured to all local, state and federal regulations.

osive envir

onments.

Page 20

14 Flex36 Owner’s Manual

Stellar Flex36 Model 108-12 Hydraulic Hooklift Specifications

ifting Capacity: Check table 1.1 for variable lifting capabilities.

L

ontainer Length: 12-foot through 14-foot. Longer bodies up to 16-feet may be accommodated if full dump angle is not required (may require

C

pecial body-mounted or extendable truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety

s

dministration (FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134). Body

A

ength does not include A-frame.

l

Maximum Dump Angle: 54°

Operating Pressure: See table 1.1 in Chapter 6: Installation for variable pressure settings.

Weight of Hooklift: Hooklift weight not to exceed 1,615 pounds.

Height of Hooklift: Hooklift height not to exceed 5.5" as measured from top of truck frame to top of hooklift rollers.

Hook Height: 35.63-inches from bottom of skid rails to bottom of hook bar. Hooklift must be able to pick up body

10-inches below grade, when mounted on a 36” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Contro

ontrols: D

C

Tilting Hook Assembly: Hooklift must have pivoting type front tilt section (jib) to provide a low degree loading/unloading angle and also to provide a

Tilt Cylinder: Cylinder must be double acting (4” Bore x 2” Rod x 17” Stroke) and include dual integral pilot-operated counterbalance

Tilt Section Operation: Hooklift must include a hydraulic lock-out device to prevent operation of the tilt section while hooklift is in the dumping mode.

Lift/Dump Cylinder: Cylinder must be double acting and include dual pilot-operated counterbalance valves to prevent cylinder movement in

Dump/Tilt Interlock: Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length 25” wide frame to

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body to the hooklift through all ranges of

Rear Dump Hinge Pin: 2-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

l Valve: Hydraulic valve mounted directly onto the oil reservoir with power beyond capabilities.

ual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all hooklift functions.

wider stance for side to side stability.

valves to prevent cylinder collapse in case of hose failure. Cylinder must be fully retracted when in the transport mode to pre-

vent exposure of cylinder rod to corrosive road salts.

case of pressure loss.

provide support for the container while in the dump mode. These sections form this frame without the use of mechanical

latches which rely on gravity, springs, or container/body mounted latches. The system must be protected from out of

sequence operation.

the dump mode. This must be accomplished without the use of steel springs and/or hydraulic/air cylinders.

Bushings: All bushings to be of the DX pre-lubricated variety, used with grease fittings. Bronze bushings not allowed due to survivability in

heavy containment and corr

Hoses & Hyd. Fittings: All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized wherever possible.

Secured steel hydraulic tubing to be used whenever possible.

Electrical:

Technical Documentation: All hooklifts shall come with documentation on operation, maintenance, safety and a parts manual.

Regulations:

Origin of Manufacture: Hooklift to be designed and manufactured in the United States of America.

All electrical wiring to be protected by full length steel conduit fastened into the hooklift framework.

Hooklift shall be designed and manufactured to all local, state and federal regulations.

osive envir

onments.

Page 21

Specifications 15

Stellar Flex36 Model 120-14 Hydraulic Hooklift Specifications

ifting Capacity: Check table 1.1 for variable lifting capabilities.

L

ontainer Length: 13-foot through 15-foot. Longer bodies up to 16-feet may be accommodated if full dump angle is not required (may require

C

pecial body-mounted or extendable truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety

s

dministration (FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134). Body

A

ength does not include A-frame.

l

Maximum Dump Angle: 50°

Operating Pressure: See table 1.1 in Chapter 6: Installation for variable pressure settings.

Weight of Hooklift: Hooklift weight not to exceed 1,650 pounds.

Height of Hooklift: Hooklift height not to exceed 5.5" as measured from top of truck frame to top of hooklift rollers.

Hook Height: 35.63-inches from bottom of skid rails to bottom of hook bar. Hooklift must be able to pick up body

10-inches below grade, when mounted on a 36” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Contro

ontrols: D

C

Tilting Hook Assembly: Hooklift must have pivoting type front tilt section (jib) to provide a low degree loading/unloading angle and also to provide a

Tilt Cylinder: Cylinder must be double acting (4” Bore x 2” Rod x 17” Stroke) and include dual integral pilot-operated counterbalance

Tilt Section Operation: Hooklift must include a hydraulic lock-out device to prevent operation of the tilt section while hooklift is in the dumping mode.

Lift/Dump Cylinder: Cylinder must be double acting and include dual pilot-operated counterbalance valves to prevent cylinder movement in

Dump/Tilt Interlock: Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length 25” wide frame to

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body to the hooklift through all ranges of

Rear Dump Hinge Pin: 2-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

l Valve: Hydraulic valve mounted directly onto the oil reservoir with power beyond capabilities.

ual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all hooklift functions.

wider stance for side to side stability.

valves to prevent cylinder collapse in case of hose failure. Cylinder must be fully retracted when in the transport mode to pre-

vent exposure of cylinder rod to corrosive road salts.

case of pressure loss.

provide support for the container while in the dump mode. These sections form this frame without the use of mechanical

latches which rely on gravity, springs, or container/body mounted latches. The system must be protected from out of

sequence operation.

the dump mode. This must be accomplished without the use of steel springs and/or hydraulic/air cylinders.

Bushings: All bushings to be of the DX pre-lubricated variety, used with grease fittings. Bronze bushings not allowed due to survivability in

heavy containment and corr

Hoses & Hyd. Fittings: All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized wherever possible.

Secured steel hydraulic tubing to be used whenever possible.

Electrical:

Technical Documentation: All hooklifts shall come with documentation on operation, maintenance, safety and a parts manual.

Regulations:

Origin of Manufacture: Hooklift to be designed and manufactured in the United States of America.

All electrical wiring to be protected by full length steel conduit fastened into the hooklift framework.

Hooklift shall be designed and manufactured to all local, state and federal regulations.

osive envir

onments.

Page 22

16 Flex36 Owner’s Manual

Page 23

Chapter 5 - Decals

Decals of Note

17Decals 17

Electrocution Hazard Decal

Location: On each side of the tilt base.

Function: To inform the operator of the hazard

associated with electrocution, the possible

consequences should the hazard occur, and

how to avoid the hazard.

PN: C1179

Hands Clear Decal

Location: On each side of the tilt base.

Function: To inform the operator of the

hazard associated with tilt operation, the

possible consequences should the haz-

ard occur, and how to avoid the hazard

PN: C0865

.

Operation Hazard Decal

Location: Truck Frame

Function: To inform the operator of the

need for proper training, familiarity with

safe operating pr

possible consequences without training.

PN: C4540

ocedures and , the

Operation Hazard Decal

Location: Truck Frame

Function: To inform the operator and other

personnel in the work area of the hazard

associated with improper maintenance and

unauthorized modifications, the possible

consequences should the hazard occur, and

how to avoid the hazard. PN: 4190

Page 24

18 Flex36 Owner’s Manual

PN 35559

Decal Kit Placement - PN 35559

Page 25

Installation

Chapter 6 - Installation

Every hooklift installation is unique. However, certain guidelines exist that apply to every

model. Listed below is a general set of chronological steps that may be followed when

installing a Stellar Hooklift. If any questions arise during the installation process, feel free to

contact your local dealer or Stellar Customer Service at 800-321-3741.

Chapter Contents

Basic Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Installation Steps - Basic Guidelines . . . . . . . . . . . . . . . . . . . . . . . .20

Mounting Kit (Model 60-8) - PN 33320 . . . . . . . . . . . . . . . . . . . . . .22

Mounting Kit (Models 84-10, 108-12, 120-14) - PN 23700 . . . . . . .23

Rotary Valve (All Models) - PN 37741 . . . . . . . . . . . . . . . . . . . . . . .24

Reservoir Assembly - PN 35883 . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Setting System Relief Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-27

Installation Instructions for the Power Beyond VDM8 Valve . . . .28

Port Side Relief Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Controller Assembly - PN 38841 . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Dump Light Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Hydraulic Schematic (Model 60-8) - PN 34616

Hydraulic Schematic (Model 84-10)- PN 34617 . . . . . . . . . . . . . .33

Hydraulic Schematic (Model 108-12) - PN 34618 . . . . . . . . . . . . .34

Hydraulic Schematic (Model 120-14)- PN 34619 . . . . . . . . . . . . .35

Subframe Model 60-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subframe Model 84-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Subframe Model 108-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Subframe Model 120-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

. . . . . . . . . . . . . . .32

36

19

19

Basic Installation Overview

1. Clear the truck frame.

2. Set the Flex on the truck frame.

3. Shorten the truck frame to within 2” from the rear of the loader.

4. Install bumper.

5. Install tie down channels. (See corresponding Mounting Kit Drawing in this chapter)

6. Install tarper tower (If applicable).

7. Install cab and PTO controls.

8. Mount hydraulic reservoir tank and valve bank.

9. Mount PTO and Pump.

10. Run hydraulic hoses.

11. Connect suction and pressure to the reservoir tank and valve bank.

12. Install mud flaps and fenders.

13. Run Flex.

Page 26

20 Flex36 Owner’s Manual

Installation Steps - Basic Guidelines

1. Clear the truck frame.

2. Set the Flex on the truck frame.

a. The front plate of the base needs to be at least 2” behind the cab or any equip-

ment mounted behind the cab.

b. Be sure to square the Flex on the truck frame.

c. Take a visual and look for any potential issues. For example: Clearance problems,

cross members extending too high, insufficient room in front of the Flex for tarpers,

exhaust manifolds, etc, or insufficient room in the rear to allow for bumper selec-

tion. Feel free to space up if needed.

3. Shorten the truck frame to within 2” from the rear of the loader.

4. Install bumper.

a. See Government Regulations for acceptable placement.

5. Install tie down channels. (See corresponding Mounting Kit Drawing in this chapter)

a. Move anything on the truck frame that may be in the way of the tie down chan-

nels.

b. Place a tie down channel on either side of the base, within 2” of the front plate.

c. Place a tie down channel on either side of the base, within 7” of the rear of the

hooklift.

d. The final channels should be placed in the approximate position shown in the cor-

responding mounting diagram. The top of the lower channel should be flush with

the top of the chassis frame rail.

e. Using the channels as a guide, drill six (6) 11/16” holes through the truck frame.

(Note: For Flex36 Model 60-8, you only need to drill four (4) holes.)

f. Using 5/8” bolts, washers, and nuts, secure all tie down channels to the truck

frame. All bolts should be torqued to 160 ft-lbs.

h. Weld the upper tie down channels to the hooklift base. Use 5/8” washers to

space the channels up. Remove washers when finished.

g. Using 5/8” bolts, washers, and nuts, fasten two (2) tie-down channels together with

the narrow faces toward each other. Do this with all of the channels.

6. Install tarper tower (If applicable).

a. See brand specific installation instructions.

Page 27

7. Install cab and PTO controls.

a. Use PTO brand specific installation instructions.

b. See Controller Assembly Drawing (PN 38841) for details.

c. See Dump Light Kit Installation

8. Mount hydraulic reservoir tank and valve bank.

a. Make sure the tank isn’t too far away if cables are being used.

b. Don’t raise the tank above the frame height.

c. See Power Beyond Installation guide for valve bank details.

d. See Reservoir Assembly Drawing PN 35883 for details.

9. Mount PTO and Pump.

a. Be sure to check the rotation of the pump to ensure proper installation.

b. Use brand specific installation instructions.

Installation 21

10. Run hydraulic hoses.

a. Run hoses between the pump and reservoir tank.

b. Run hoses between the PTO and valve bank.

c. Protect these lines with hose wrap when necessary.

d. Keep these lines away from sharp edges.

e. Keep these lines away from the exhaust or other temperature extreme items.

f. Keep these lines away from the driveshaft or other moving items.

g. See hydraulic schematics for details.

11. Connect suction and pressure to the reservoir tank and valve bank.

a. Fittings on the valve bank should be 3” lower than the long sills.

b. Fill reservoir to site gauge, within 3” from the top (Roughly 10 Gallons).

c. Petro-Canada Hydrex 32 (ISO 32) hydraulic oil is recommended.

d. When connections are secure, turn reservoir on.

12. Install mud flaps and fenders.

3. Run Flex.

a. Bleed the air out of the hydraulic system.

b. Check the oil level and add oil if needed.

c. Calibrate rotary valve.

d. Calibrate dump light system.

e. Be sure to check all clearances.

f. Set/check relief pressure no higher than 4200 PSI (see chart/diagram).

Page 28

22 Flex36 Owner’s Manual

PN 33320

ITEM PART DESCRIPTION QTY.

1D0143 TIE DOW N CHANNEL 8

2C1025 CAP SCR 0.63-11X2.00 HHGR8 ZY 8

3C1038 WASHER 0.63 FLAT 16

424868 NUT 0.63-11 HH NYLOC 8

5D0045 BACKUP ALARM .97 DECIBAL 1

Mounting Kit (Model 60-8) - PN 33320

Page 29

Installation 23

3

2

2

3

1

2

3

1

4

3

4

2

3

1

3

4

5

.YT

QN

OITPIRC

S

E

D

TR

A

P

ME

TI

21LEN

NA

HC

N

WOD EIT

341

0D

1

21YZ 8RGHH 00.2X11-36.0 RCS P

A

C

5

201

C

2

42TALF 36.0 REHSA

W

8301C3

21COLYN HH 11-36.0 TU

N

868424

1LABIC

ED 79

. MR

ALA

PUKC

AB5

400D5

PN 23700

Mounting Kit (Models 84-10, 108-12, 120-14) - PN 23700

Page 30

24 Flex36 Owner’s Manual

6

5

4

3

10

1

11

8

7

2

9

6

7

13

12

7

.

YTQNOITPIRCSEDTR

APMETI

1MSA EVLAV YRATOR654221

2 22450 WLDMT ROTARY VALVE ECCENTRIC 1

3D1638 O'RING 1.12X1.38X0.12 568-216 1

4 3748 WASHER ROTARY VALVE 1

5 0480 CAP SCR 0.25-20X1.00 HHGR5 1

6 0353 CAP SCR 0.38-16X2.00 HHGR5 3

7 0347 NUT 0.38-16 HH NYLOC 3

8 0977 O'RING 1.00X1.25X0.12 568-214 1

9 22449 PLATE ROTARY VALVE ARM 1

10 0482 CAP SCR 0.25-20 X 3.00 HHGR5 2

11 0333 NUT 0.25-20 HHGR5 NYLOC 2

12 7350 FTG ST RUN TEE 8R5OLO 2

13 D1535 PLUG STR HOLLOW HEX 0.50 8-HP5ON 2

37741

Rotary Valve (All Models) - PN 37741

To adjust rotary valve move hooklift into

stowed position. Loosen the bolts that are

attaching the valve block to the dump

section. Adjust rotary arm so that it is in

contact with the dump plate. Push the

rotary arm up as you pull the valve block

back towards the rear of the loader.

Tighten valve block bolts while making

sure valve block is snug. Note: It should

engage between 4 and 10 degrees.

Page 31

3

4

2

7

3

5

7

6

1

25

25

21

20

19

20

9

8

2

14

15

15

17

16

12

11

10

22

28

29

1

8

13

23

26

27

.YTQNOITPIRCSEDTRAP

M

E

T

I

1 26455 RSRVR ASM 10GAL K MODEL 1

2 1115 FTG NIPPLE HEX MALE 010 1-20-20 1

3 c2242 ST EL 0.75 90 DEG BLK 2

4 3320 NIPPLE 0.75X12.00 PIPE 1

1

D

AEH RE

TLIF6226c5

6 C6229 FILTER LARGE AE-10L 1

7 C6014 FTG ADAPT 8-12 FOLO-S 1

1

5

2.1 LLAB

E

VLA

V

1155C8

9 C2282 FTG 1.25 NPT TO 1.25 BARB 1

10 24611 VB 2-SECTION VDM8 1

3KCOL 52.0 RE

HSAW1

25011

12 0339 CAP SCR 0.25-20X2.50 HHGR5 3

.YTQNOITPIRCSE

D

TRA

PMETI

13 C4227 FTG MF/MSTR 90 8-12 C5OLO-S 1

14 26731 HOSE 0.50(381-JC-J9-8-8-8-18-0) 1

15 0352 WASHER 0.50 USS FLAT ZINC 8

16 C6106 NUT 0.50-13 HHGR5 NYLOC 4

17 0506 CAP SCR 0.50-13X4.00 HHGR5 4

18 D0549 FTG ADAPT 16-8 F5OG5-S 1

19 17767 HOSE SUCT 1.25 10FT 1

20 C1123 HOSE CLAMP 88 DB-20 2

21 C4747 NIPPLE O'RING 45 4603-20-16 1

22 10094 GAUGE OIL LF 2.5" 0-500 BM 1

23 9892 SPACER TANK MOUNTING 10 GAL 2

24 16145 GAUGE PRES FILTER SERVICE CI20 1

.YTQNOITPIRCSE

DT

RAPMETI

25 25630 FTG ADAPT 10-1/4 F5OG 1

26 C2252 FTG ADAPT 8-10-F5OLO-S 5

27 C2376 FTG ADAPT 8-C6LO-S 1

28 31676 HOSE 0.50(471TC-JC-JC-8-8-8-120) 1

29 1554 FTG ADAPT 8-F5OLO-S 1

PN 35883

Reservoir Assembly - PN 35883

Installation 25

Page 32

26 Flex36 Owner’s Manual

4500

5500

6500

7500

8500

9500

10500

11500

12500

13500

14500

15500

2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 4200 4400

SYSTEM RELIEF PRESSURE (P.S.I.)

LOADER CAP

ACITY (POUNDS)

60 CA

84 CA

108 CA

120 CA

Pressure vs. Capacity

60 CA

84 CA

108 CA

120 CA

Setting System Relief Pressure

Table 1.1*

Instruction Overview:

See next page for details.

1. Engage the PTO. Run truck at

1300 RPM.

2. Push the red (lift) lever until the

boom bottoms out. Keep pushing

the lever forward until the pressure

is set.

Never Exceed the

Maximum

Pressure of 4200 psi.

Never adjust System Relief Pressure to allow Loader

Capacity to exceed chassis GVW and always per-

form a weight distribution before installation and

after System Relief Pressure adjustments to confirm

Loader Capacity and chassis compatibility.

3. Release the jam nut using a 13

mm wrench.

4. Adjust the system r

elief pressure

using 4 mm allen wrench.

5. Once system pressure is set,

tighten the jam nut to lock system

pressure. No per

lock may be used

manent thread

Page 33

Setting System Relief Pressure Continued

27Installation 27

1. Engage the PTO. Run the truck at 1300 RPM.

3. Release the jam nut using a 13 mm wrench.

2. Push the red (lift) lever until the boom bottoms out.

Keep pushing the lever forward until steps 3-5 are

complete.

-

4. Adjust the system relief pressure using 4 mm allen

wrench. Clockwise increases pressure, counter clockwise decreases pressure.

+

5. Once system pressure is set, tighten the jam nut to

e. Permanent thread lock should

lock system pr

not be used.

essur

6. Release all functions and disengage the PTO. Snap

tamper cap into position over the jam nut. The br

away clip will be destroyed if the cap is removed.

eak

Page 34

28 Flex36 Owner’s Manual

Installation Instructions for the Power Beyond VDM8 Valve

These instructions ar intended for correct installation of power beyond on a Salami VDM8

valve bank. If any hydraulic component is integrated after this valve the power beyond

must be installed correctly, or serious damage may incur to the hydraulic system.

1. Remove cover/access plug to reveal the power

beyond access point. Can also be used as the

Return/Tank port.

3. The Power Beyond feature is now activated and will

divert oil to alternate system via the port shown.

2. Install a 3/8” straight thread pipe plug into lower portion of cavity to activate the power beyond feature.

Use thread sealer (tape sealers not recommended.

Note:

1. The return/tank line must be connected to the

top or the side port, labeled “T”.

2. Using the return line to run auxiliary equipment will

directly result in a failure and will not in any circumstance be covered under warranty.

3. A standard Stellar hooklift will have 6 hydraulic

lines attached to the valve. A Stellar hooklift with

Power Beyond will have 7 hydraulic lines

attached to the valve.

Page 35

MAIN CYLINDER

RETRACT PORT

PLUG

PORT SIDE RELIEF

MAIN RELIEF

VALVE BANK

• For some options, port side relief is required.

• To install port side relief:

1. Remove plug.

2. Insert relief.

3. Replace plug

• Relief can be installed on the retract or extend side of the valve bank.

Port Side Relief Installation

Installation 29

Page 36

30 Flex36 Owner’s Manual

17

7

1

2

6

15

4

CONTROLLER CABLES

TO VALVE BANK

5

.YTQNOITPIRCSEDTRAPMETI

137474 CONTROLLER CTR LOCK RIGHT BEND 1

237475 CONTROLLER CTR LOCK LEFT BEND 1

1TNM MRALA BAT ETALP392623

437470 VALVE CTRL CONSOLE 2LEVER RVC 1

50491 CAP SCR 0.31-18X4.00 HHGR5 2

60343WASHER 0.31 USS FLAT ZINC 4

2COLYN HH 81-13.0 TUN24307

826031 BACKUP ALARM PIEZO JAMECO 123537 1

926135 DECAL NOTICE FIX TABS 1

10 D1711 CAP SCR #10-24X0.50 BTNHD SS 1

11 C6072 RELAY BOSCH 20-30 AMP 1

12 26288 LIGHT INDICATOR RED FORCE PTO 1

13 31806 DUMP UP LIGHT KIT BUYERS SK10 1

15 25933 BRKT CONTROLLER DECAL 1

1 COLYN HH 42-01# TUN4306261

18 37469 CABLE CONN. KIT FOR VD8A/VDM8 2

28MDV TCES-2 BV1164291

20 26291 WIRE HARNESS TAB ALARM 1

21 26289 WIRE HARNESS PROXIMITY SWITCH 1

17 37471 CONTROL CABLE 96" WESCON 2

NOTE: CONTROL LEVER, HA NDLES, CONSOLE,

AND CONTROLLER CABLES ARE INCLUDED

WITH THE HYDRA ULIC CONTROL VAL VE.

19

18

9

10

1

1

12

16

3

13

13

8

PN 38841

Controller Assembly - PN 38841

Page 37

• Bolt L-bracket to front of base, drilling and tapping holes in appropriate area.

• Attach dump light switch to L-bracket.

• Drill and tap ¼-20 hole in bottom of secondary tube. Hole should be located

directly above dump light switch when secondary is in lowered position.

• Screw in elevator bolt, and adjust so that switch is engaged when secondary is in

lowered position.

• Install light in bracket provided with control console.

• Complete the wiring; following instructions provided with dump light kit.

Elevator bolt

L-bracket

Dump light switch

Detail A

Scale 1 : 8

Dump Light Kit Installation

31Installation 31

Page 38

32 Flex36 Owner’s Manual

V

ALVE

R

OTARY

R

ETRACT

EXTEND

MAIN

R

ETRACT

E

XTEND

T

ILT

HOSE .38 X 91.00

H

OSE .50 X 60.00

H

OSE .38 X 41.00

H

OSE ASM 9-16M LOADERS

HOSE .38 X 60.00

PART No.ITEM

34646

34644

1

8169

3

4645

3

464701

0

2

03

0

4

05

QTY

DESCRIPTION

2

2ref

2

ref

2

ref

1

6

0.00

STELLAR #34644- (471TC-J0-J9-8-8-6-60")

C

0562(HOSE-.38)

3

4651

6392

QTY - 2

FUNCTION: TILT VB TO PORT TUBES

C2773(HOSE-.50)

STELLAR #18169 - (471TC-JC-J9-8-8-8-60")

6

0.00

FUNCTION: MAIN CYLINDER

C

1558

QTY - 2

C1559

C0562(HOSE-.38)

91.00

STELLAR #34646 - (471TC-JC-J9-8-6-6-91")

FUNCTION: TILT ROTARY VAVLVE TO CYLINDER

6391

QTY -2

0546

STELLAR #34645 - (471TC-JC-J0-8-8-6-41")

4

1.00

C0562(HOSE-.38)

3

4651

FUNCTION: PORT TUBES TO ROTARY VALVE

QTY - 2

6391

3

2

3

2

5

5

4

4

T

ILT RETRACT

MAIN RETRACT

PRESSURE FROM PUMP

T

ILT EXTEND

MAIN EXTEND

NOTE: IF RESERVOIR IS MOUNTED ON CS

HOSES 3 AND 4 ARE REVERSED

RETURN

TO TANK

PN 34616

Hydraulic Schematic (Model 60-8) - PN 34616

Page 39

V

ALVE

R

OTARY

R

ETRACT

EXTEND

M

AIN

RETRACT

E

XTEND

T

ILT

HOSE .38 X 115.00

HOSE .50 X 60.00

HOSE .38 X 41.00

H

OSE ASM 9-16M LOADERS

H

OSE .38 X 60.00

PART No.ITEM

34648

3

4644

18169

34645

3

464701

02

0

3

04

05

QTY

D

ESCRIPTION

2

2

ref

2ref

2ref

1

6

0.00

STELLAR #34644- (471TC-J0-J9-8-8-6-60")

C

0562(HOSE-.38)

34651

6392

QTY - 2

FUNCTION: TILT VB TO PORT TUBES

C2773(HOSE-.50)

STELLAR #18169 - (471TC-JC-J9-8-8-8-60")

6

0.00

FUNCTION: MAIN CYLINDER

C

1558

QTY - 2

C

1559

C0562(HOSE-.38)

115.00

STELLAR #34648 - (471TC-JC-J9-8-6-6-115")

FUNCTION: TILT ROTARY VAVLVE TO CYLINDER

6

391

QTY -2

0

546

STELLAR #34645 - (471TC-J0-JC-8-8-6-41")

41.00

C0562(HOSE-.38)

3

4651

FUNCTION: PORT TUBES TO ROTA RY VALVE

QTY - 2

6391

3

2

3

2

5

5

4

4

T

ILT RETRACT

MAIN RETRACT

PRESSURE FROM PUMP

TILT EXTEND

M

AIN EXTEND

NOTE: IF RESERVOIR IS MOUNTED ON CS

HOSES 3 AND 4 ARE REVERSED

RETURN

TO TANK

PN 34617

Hydraulic Schematic (Model 84-10)- PN 34617

33Installation 33

Page 40

34 Flex36 Owner’s Manual

VALVE

R

OTARY

RETRACT

EXTEND

M

AIN

R

ETRACT

EXTEND

TILT

HOSE .38 X 145.00

HOSE .50 X 60.00

HOSE .38 X 41.00

H

OSE ASM 9-16M LOADERS

HOSE .38 X 60.00

P

ART No.ITEM

34649

34644

18169

34645

3

464701

02

03

04

05

Q

TY

DESCRIPTION

2

2ref

2ref

2ref

1

60.00

STELLAR #34644- (471TC-J0-J9-8-8-6-60")

C0562(HOSE-.38)

3

4651

6

392

QTY - 2

FUNCTION: TILT VB TO PORT TUBES

C2773(HOSE-.50)

S

TELLAR #18169 - (HTB-JC-J9-8-8-8-60")

60.00

FUNCTION: MAIN CYLINDER

C1558

QTY - 2

C

1559

C

0562(HOSE-.38)

1

45.00

STELLAR #34649 - (471TC-JC-J9-8-6-6-145")

FUNCTION: TILT ROTARY VAVLVE TO CYLINDER

6391

QTY -2

0546

STELLAR #34645 - (471TC-JC-J0-8-8-6-41")

41.00

C0562(HOSE-.38)

34651

FUNCTION: PORT TUBES TO ROTA RY VALVE

QTY - 2

6391

3

2

3

2

5

5

4

4

T

ILT RETRACT

MAIN RETRACT

PRESSURE FROM PUMP

T

ILT EXTEND

MAIN EXTEND

NOTE: IF RESERVOIR IS MOUNTED ON CS

HOSES 3 AND 4 ARE REVERSED

RETURN

TO TANK

PN 34618

Hydraulic Schematic (Model 108-12) - PN 34618

Page 41

Installation 35

VALVE

ROTARY

RETRACT

E

XTEND

M

AIN

RETRACT

EXTEND

TILT

HOSE .38 X 150.00

H

OSE .50 X 60.00

HOSE .38 X 41.00

H

OSE ASM 9-16M LOADERS

H

OSE .38 X 60.00

PART No.ITEM

34650

3

4644

1

8169

34645

3

464701

0

2

0

3

04

05

QTY

D

ESCRIPTION

2

2

ref

2

ref

2ref

1

6

0.00

STELLAR #34644- (471TC-J0-J9-8-8-6-60")

C

0562(HOSE-.38)

3

4651

6392

QTY - 2

FUNCTION: TILT VB TO PORT TUBES

C

2773(HOSE-.50)

STELLAR #18169 - (471TC-JC-J9-8-8-8-60")

6

0.00

FUNCTION: MAIN CYLINDER

C

1558

QTY - 2

C1559

C0562(HOSE-.38)

150.00

STELLAR #34650 - (471TC-JC-J9-8-6-6-150")

FUNCTION: TILT ROTARY VAVLVE TO CYLINDER

6

391

QTY -2

0

546

STELLAR #34645 - (471TC-JC-J0-8-8-6-41")

4

1.00

C

0562(HOSE-.38)

34651

FUNCTION: PORT TUBES TO ROTA RY VALVE

QTY - 2

6391

3

2

3

2

5

5

4

4

TILT RETRACT

MAIN RETRACT

PRESSURE FROM PUMP

TILT EXTEND

MAIN EXTEND

RETURN

TO TANK

PN 34619

Hydraulic Schematic (Model 120-14)- PN 34619

Page 42

36 Flex36 Owner’s Manual

(multi-lift only)

Subframe Model 60-8

Page 43

Subframe Model 84-10

Installation 37

Page 44

38 Flex36 Owner’s Manual

Subframe Model 108-12

Page 45

Subframe Model 120-14

Installation 39

Page 46

40 Flex36 Owner’s Manual

Page 47

Chapter 7 - Assembly Drawings

PN 31823

ITEM PART DESCRIPTION QTY. ITEM PART DESCRIPTION QTY.

1 31815 BASE WLDMT 60- 8 FLEX36 1 12 C0953 CAP SCR 0.38-16X4.00 HHGR5 4

2 4381 BUSHING 32DXR32 2.00X2.00 GARLOCK 4 13 0347 NUT 0.38-16 HH NYLOC 4

3 19291 ROLLER 4" OD 2 14 c1592 ZERK 1/8 NPT STRAIGHT 2

4 1546 THRUST W ASHER 2.01DIA UHMW .12THK 6 15 C0078 HOSE CLAMP #8 RU BBER COATED 1

5 8819 BUSHING QSI-3235-16 2 16 0479 CAP SCR 0.25-20X0.75 HHGR5 1

6 24766 PIN 2.00X47.00 1 17 0333 NUT 0.25-20 HHGR5 NYLOC 1

7 23699 BUSHING 32DXR20 2.00X1.25 2 18 8622 CLAMP HO SE/TUBE AG-2 8

8 33741 PIN 2.00X10.19 SR 1 19 34415 TUBE ASM 0.50X65.25 2

9 0427 MACHY WASHER 2.00ID 10GA 2 20 0220 CAP SCR 0.25-20 X 1.50 HHGR5 4

10 0108 SNAP RING 2.00 7200-200 2 21 0340 WASHER 0.25 FLAT 4

11 22764 COLLAR 2.01X3.00X1.00 4 22 34622 PLUG PLASTIC 1.25X0.19 CCF1.5-14-20 4

Base Assembly (60-8) - PN 31823

41Assembly Drawings 41

Page 48

42 Flex36 Owner’s Manual

PN 33337

ITEM PART DESCRIPTION QTY. ITEM PART DESCRIPTION QTY.

1 33338 BASE WLDMT 84-10 FLEX36 1 12 c1592 ZERK 1/8 NPT STRAIGHT 2

2 4381 BUSHING 32DXR32 2.00X2.00 GARLOCK 4 13 C0078 HOSE CLAMP #8 RUBBER COATED 1

3 19291 ROLLER 4" OD 2 14 0479 CAP SCR 0.25-20X0.75 HHGR5 1

4 1546 THRUST W ASHER 2.01DIA UHMW .12THK 6 15 0333 NUT 0.25-20 HHGR5 NYLOC 1

5 8819 BUSHING QSI-3235-16 2 16 0427 MACHY WASHER 2.00ID 10GA 2

6 24766 PIN 2.00X47.00 1 17 0108 SNAP RING 2.00 7200-200 2

723699 BUSHING 32DXR20 2.00X1.25 2 18 8622 CLAMP HOSE/TUBE AG-2 10

8 34411 PIN 2.00X10.31 SR 1 19 34418 TUBE ASM 0.50X95.00 2

9 22764 COLLAR 2.01X3.00X1.00 4 20 0340 WASHER 0.25 FLAT 5

10 0532 CAP SCR 0.38-16X3.75 HHGR5 4 21 0220 CAP SCR 0.25-20 X 1.50 HHGR5 5

11 0347 NUT 0.38-16 HH NYLOC 4 22 34622 PLUG PLASTIC 1.25X0.19 CCF1.5-14-20 4

Base Assembly (84-10) - PN 33337

Page 49

Assembly Drawings 43

PN 34245

ITEM PART DESCRIPTION QTY. ITEM PART DESCRIPTION QTY.

1 34246 BASE WLDMT 108-12 FLEX36 1 12 0532 CAP SCR 0.38-16X3.75 HHGR5 4

2 4381 BUSHING 32DXR32 2.00X2.00 GARLOCK 4 13 0347 NUT 0.38-16 HH NYLOC 4

3 19291 ROLLER 4" OD 2 14 c1592 ZERK 1/8 NPT STRAIGHT 2

4 1546 THRUST WASHER 2.01DIA UHMW .12THK 6 15 C0078 HOSE CLAMP #8 RU BBER COATED 1

5 8819 BUSHING QSI-3235-16 2 16 0479 CAP SCR 0.25-20X0.75 HHGR5 1

6 23699 BUSHING 32DXR20 2.00X1.25 2 17 0333 NUT 0.25-20 HHGR5 NYLOC 1

7 33741 PIN 2.00X10.19 SR 1 18 0220 CAP SCR 0.25-20 X 1.50 HHGR5 5

8 0427 MACHY WASHER 2.00ID 10GA 2 19 0340 W ASHER 0.25 FLAT 5

90108 SNAP RING 2.00 7200-200 2 20 8622 CLAMP HOSE/TUBE AG-2 10

10 24766 PIN 2.00X47.00 1 21 34641 TUBE ASM 0.50X122.50 2

11 22764 COLLAR 2.01X3.00X1.00 4 22 34622 PLUG PLASTIC 1.25X0.19 CCF1.5-14-20 4

Base Assembly (108-12) - PN 34245

Page 50