Page 1

®

OWNER’S MANUAL

Safety, Installation, Maintenance, and Operation

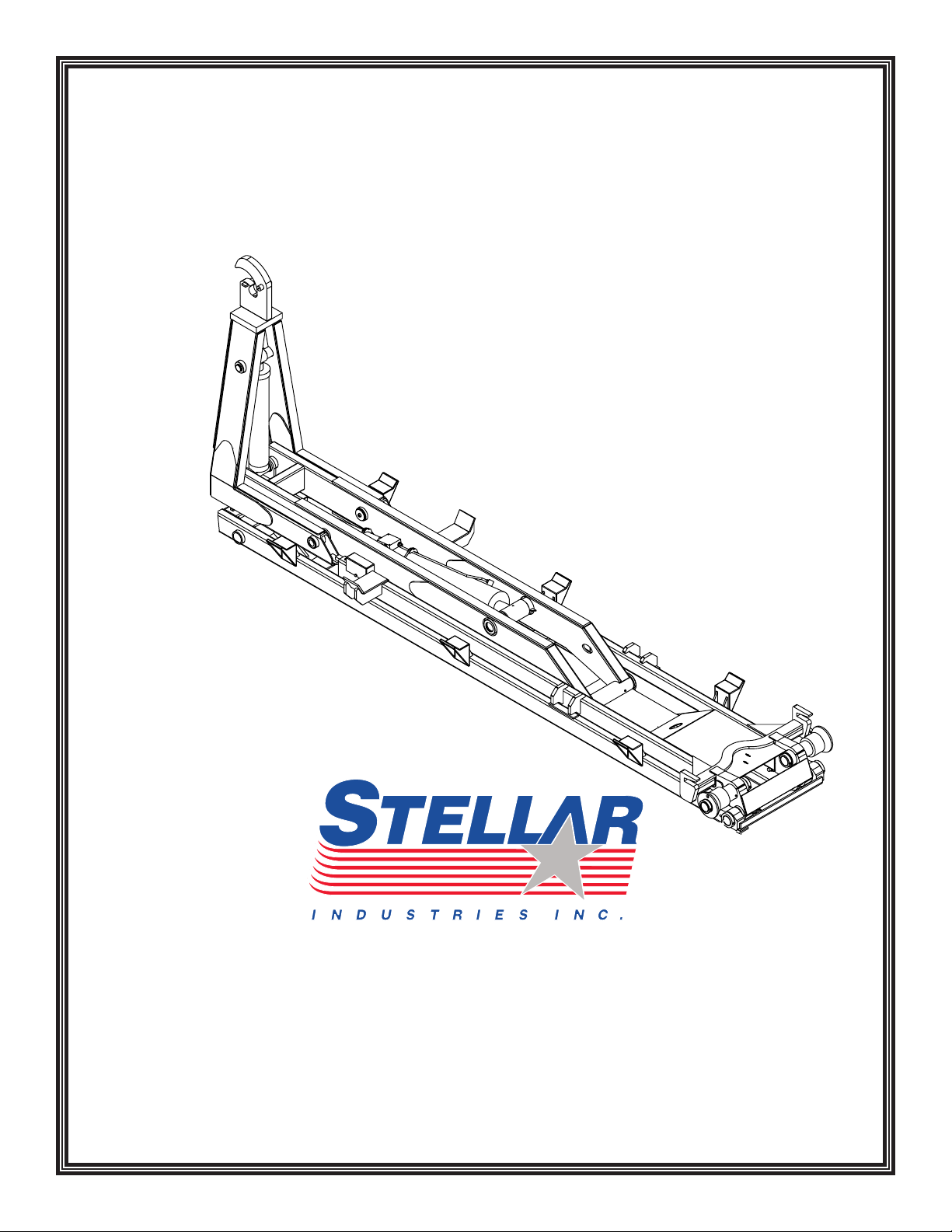

Stellar Shuttle Hooklifts

Models

138-18-52

174-20-52

190-24-52

138-18-65

174-20-65

190-24-65

Subject to Change without Notification.

© 2007 Stellar Industries, Inc.

Stellar Industries, Inc.

190 State Street

PO Box 169

Garner, IA 50438

800-321-3741

Fax: 641-923-2811

www.stellarindustries.com

Manual Part No. 43502

Last Revision: 12/18/07

Page 2

52K/65K Hooklift Manual Revisions

Date of Revision Description of RevisionSection Revised

Page 3

Table of Contents

Table of Contents i

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Stellar Shuttle Hooklift Nomenclature . . . . .iv

Chapter 1 - Safety . . . . . . . . . . . . . . . . . . . . . . .1

General Safety . . . . . . . . . . . . . . . . . . . . . . .1

Personal Safety . . . . . . . . . . . . . . . . . . . . . . .1

Maintenance Safety . . . . . . . . . . . . . . . . . . .1

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Load Safety . . . . . . . . . . . . . . . . . . . . . . . . . .2

Environment . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 2 - Operation . . . . . . . . . . . . . . . . . . . .3

Operator Requirements . . . . . . . . . . . . . . . .3

Operator Conduct . . . . . . . . . . . . . . . . . . . .3

Job-Site Set-Up . . . . . . . . . . . . . . . . . . . . . . .3

Operation Overview . . . . . . . . . . . . . . . . . . .4

Hooklift Controls . . . . . . . . . . . . . . . . . . . . . . .4

Unloading Operation . . . . . . . . . . . . . . . . . .5

Loading Operation . . . . . . . . . . . . . . . . . . . .6

Dumping Operation . . . . . . . . . . . . . . . . . . .7

Chapter 3 - Maintenance . . . . . . . . . . . . . . . . .9

Choice Lubricants for DX Bearings . . . . . .10

Chapter 4 - Specifications . . . . . . . . . . . . . . . .11

Model 138-18-52 Specifications . . . . . . . . .12

Model 174-20-52 Specifications . . . . . . . . .13

Model 190-24-52 Specifications . . . . . . . . .14

Model 138-18-65 Specifications . . . . . . . . .15

Model 174-20-65 Specifications . . . . . . . . .16

Model 190-24-65 Specifications . . . . . . . . .17

Chapter 5 - Decals . . . . . . . . . . . . . . . . . . . . . .19

Decals of Note . . . . . . . . . . . . . . . . . . . . . . .19

Decal Kit Placement - PN D0779 . . . . . . . .20

Chapter 6 - Installation

Basic Installation Overview . . . . . . . . . . . .21

52K Installation Steps - Basic Guidelines . .22

Installation Steps - Basic Guidelines

65K

Power Beyond VDM8 Valve . . . . . . . . . . . .26

Mounting Kit (All 52K Shuttles)

PN 17803 . . . . . . . . . . . . . . . . . . . . . . . . .27

Mounting Kit (All 65K Shuttles)

PN 16561 . . . . . . . . . . . . . . . . . . . . . . . . .28

Rotary Valve (All 52K Shuttles)

PN 24040

Rotary Valve (All 65K Shuttles)

PN D0000

Reservoir Assembly - PN 25927

Subframe - PN 3118

(138-18-52, 138-18-65) . . . . . . . . . . . . . .32

Subframe - PN 3117

. . . . . . . . . . . . . . . . . . . . . . . . .29

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .21

2

. .

30

. . . . . . . . . .

31

(174-20-52, 174-20-65, 190-24-65, 190-24-52) . . . . . .33

Dump Light Kit Installation . . . . . . . . . . . . .34

Controller Assembly Part 1 - PN 38841 . . .35

Controller Assembly Part 2 - PN 38841 . . .36

Hose Kit (138-18-52) - PN 17017 . . . . . . . . .37

Hose Kit (174-20-52) - PN 17794 . . . . . . . . .38

Hose Kit (190-24-52) - PN 17822 . . . . . . . . .39

Hose Kit (138-18-65) - PN 16624 . . . . . . . . .40

Hose Kit (174-20-65) - PN 32677 . . . . . . . . .41

Hose Kit (190-24-65) - PN 16708 . . . . . . . . .42

Chapter 7 - Assembly Drawings . . . . . . . . . . .43

Base (138-18-52) - PN 27196 . . . . . . . . . . . .43

Base (174-20-52) - PN 26862 . . . . . . . . . . . .44

Base (190-24-52) - PN 27244 . . . . . . . . . . . .45

Base (138-18-65) - PN 16570 . . . . . . . . . . . .46

Base (174-20-65) - PN 16648 . . . . . . . . . . . .47

Base (190-24-65) - PN 16705 . . . . . . . . . . . .48

Dump (138-18-52) - PN 27198 . . . . . . . . . . .49

Dump (174-20-52) - PN 26866 . . . . . . . . . . .50

Dump (190-24-52) - PN 27246 . . . . . . . . . . .51

Dump (138-18-65) - PN 16621 . . . . . . . . . . .52

Dump (174-20-65) - PN 16649 . . . . . . . . . . .53

Dump (190-24-65) - PN 16706 . . . . . . . . . . .54

Secondary (138-18-52) - PN 27200 . . . . . .55

Secondary (174-20-52) - PN 26870 . . . . . .56

Secondary (190-24-52) - PN 27248 . . . . . .57

Secondary (138-18-65) - PN 16623 . . . . . .58

Secondary (174-20-65) - PN 16650 . . . . . .59

Secondary (190-24-65) - PN 16650 . . . . . .60

Tilt (138-18-52) - PN 26874 . . . . . . . . . . . . . .61

ilt (174-20-52) - PN 26874 . . . . . . . . . . . . . .62

T

Tilt (190-24-52) - PN 26874 . . . . . . . . . . . . . .63

Tilt (138-18-65) - PN 16523 . . . . . . . . . . . . . .64

4

ilt (174-20-65) - PN 16523

T

Tilt (190-24-65) - PN 16707 . . . . . . . . . . . . . .66

Main Cylinder (138-18-52) - PN 27231 . . . .67

Main Cylinder (174-20-52) - PN 18064 . . . .68

Main Cylinder (190-24-52) - PN 27239

Main Cylinder (138-18-65) - PN 18397 . . . .70

Main Cylinder (174-20-65) - PN 19070 . . . .71

Main Cylinder (190-24-65) - PN 19070

Roller Assembly (138-16-65) - PN 22738 . .73

Roller Assembly (174-20-65) - PN 22747

Roller Assembly (190-24-65) - PN 22738

Chapter 8 - Troubleshooting . . . . . . . . . . . . . .77

Warranty Information . . . . . . . . . . . . . . . . . . . .78

. . . . . . . . . . . . . .

6

6

. . . .

. . . .72

74

. .

7

. .

5

9

5

Manual PN 43502

Page 4

ii Shuttle Owner’s Manual - PN 43502

AN OVERVIEW TO OWNER, OPERATOR AND

SERVICE PERSONNEL ABOUT SAFETY

As the owner or employer, it is your responsibility to instruct the operator in the safe operation of this equipment and to provide the operator with properly maintained equipment.

FAILURE TO READ THIS MANUAL BY ANYONE WHO WILL OPERATE, SERVICE, OR WORK

AROUND THIS HOOKLIFT IS A MISUSE OF THE EQUIPMENT. DEATH OR SERIOUS INJURY WILL

RESULT FROM IMPROPER USE OR MAINTENANCE OF THIS MACHINE.

Occupational safety is a prime concern of Stellar Industries in the design and production

of this hooklift. Our goal in writing this manual was the safety of the operator and others

who work around this equipment.

It is your responsibility to know the specific requirements, governmental regulations, precautions and work hazards that exist in the operation and maintenance of this hooklift.

You shall make these available and known to all personnel working with and around the

equipment, so that all of you will take the necessary and requir

FAILURE TO HEED THESE INSTRUCTIONS CAN RESULT IN SERIOUS INJURY OR DEATH.

ed safety precautions.

It is also your responsibility to operate and maintain your hooklift with caution, skill, and

good judgment. Following the recognized safety procedures will help you avoid accidents. Modification to any part of his hooklift can create a safety hazard and therefore

shall not be made without the manufactur

approved accessories, options, and parts on this equipment. The rebuilding or remounting

of this equipment requires the mounting procedures and retesting to be in accordance

with factory instructions. Safety covers and devices must remain installed and maintained

in proper working condition. Safety decals must be maintained, be completely legible,

and be properly located. If safety covers, devices, or decals are missing, they must be

replaced with the proper designated Stellar part.

Be capable, careful, and concerned! Make safety your everyday business!

er’s written approval. Use only factory

Attention!

According to Federal Law (49 cfr part 571),

each final-stage manufacturer shall complete the vehicle in such a manner that it

conforms to the standar

date of manufacture of the incomplete

vehicle, the date of final completion, or a

date between those two dates. This requirement shall, however, be superseded by any

conflicting provisions of a standard that

applies by its terms to vehicles manufactured in two or more stages.

Therefore, the installer of Stellar hooklifts is

considered one of the manufacturers of the

vehicle. As such a manufacturer

ds in ef

fect on the

, the

installer is responsible for compliance with

all applicable federal and state regulations.

They are required to certify that the vehicle

is in compliance with the Federal Motor

Vehicle Safety Standards and other regulations issued under the National Traffic and

Motor Vehicle Safety Act.

ence the Code of Federal

Please r

Regulations, title 49 - Transportation,

Volume 5 (400-999), for further information,

or visit

www.gpoaccess.gov/nara/index.html for

the full text of Code of Federal Regulations.

efer

Page 5

Introduction

Introduction iii

Stellar Hooklifts are designed to provide safe

and dependable service for a variety of

operations. With proper use and

maintenance, these hooklifts will operate at

peak performance for many years.

To promote this longevity, carefully study the

information contained in this manual before

putting the equipment into service. Though

it is not intended to be a training manual for

beginners, this manual should provide solid

guidelines for the safe and proper usage of

the hooklift.

Once you feel comfortable with the

material contained in this manual, strive to

cise your knowledge as you safely

exer

operate and maintain the hooklift. This

process is vital to the proper use of the unit.

A few notes on this manual:

A copy of this manual is provided with every

hooklift and shall remain with the hooklift at

all times. Information contained within this

manual does not cover all maintenance,

operating, or repair instructions pertinent to

all possible situations.

Please be awar

manual contain information pertaining to

e that some sections of this

Stellar manufactured hooklifts in general

and may or may not apply to your specific

model.

This manual is not binding. Stellar Industries,

Inc. reserves the right to change, at any

time, any or all of the items, components,

and parts deemed necessary for product

improvement or commercial/production

purposes. This right is kept with no

requirement or obligation for immediate

mandatory updating of this manual.

In closing:

If more information is required or technical

assistance is needed, or if you feel that any

part of this manual is unclear or incorrect,

please contact the Stellar Customer Service

Department by phone at 800-321-3741 or

email at service@stellarindustries.com.

ATTENTION

Failure to adhere to the

instructions could result in

property damage or even serious

bodily injury to the operator or

others close to the hooklift.

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information service@stellarindustries.com

Order Parts parts@stellarindustries.com

Warranty Information warranty@stellarindustries.com

Manual PN 43502

Page 6

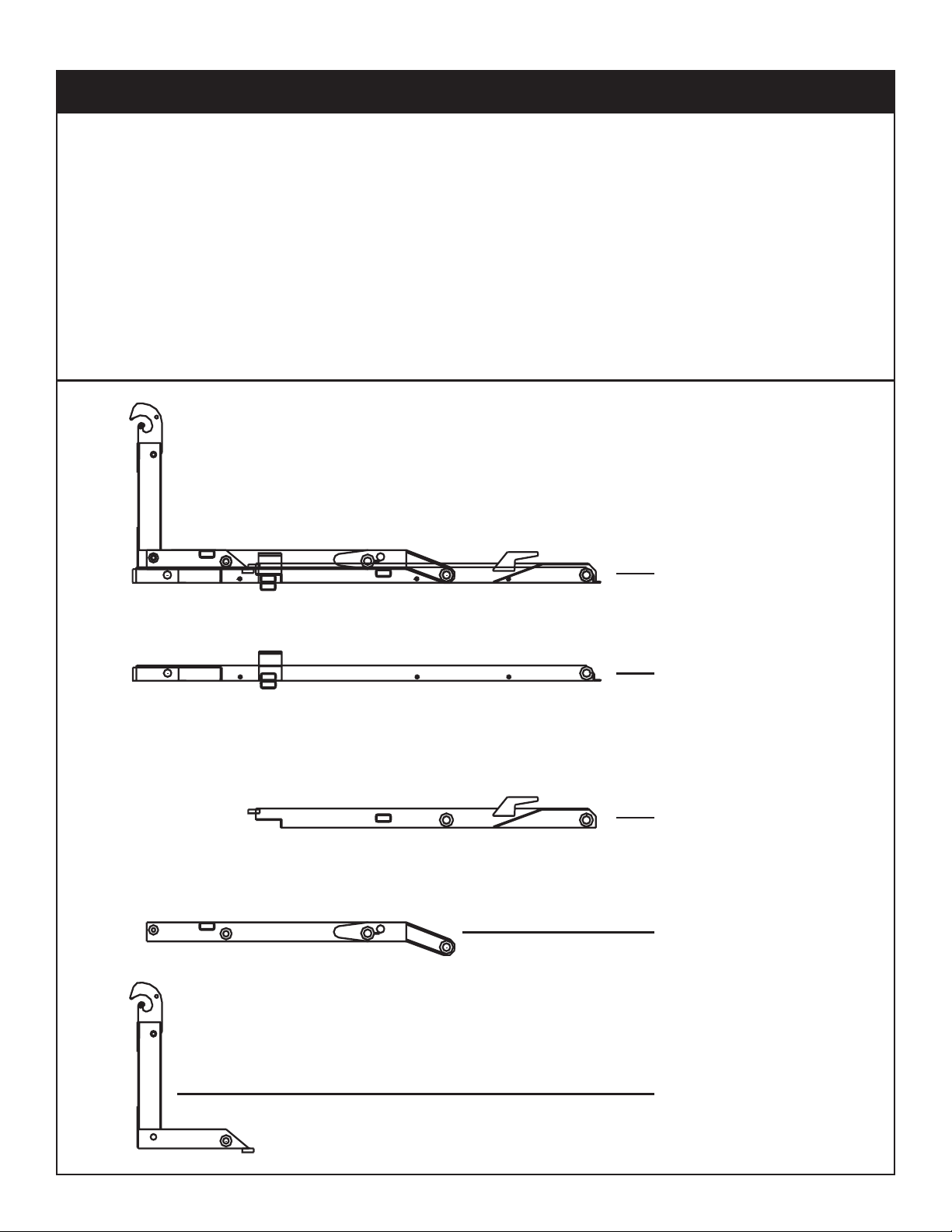

iv Shuttle Owner’s Manual - PN 43502

HOOKLIFT

BASE

DUMP

SECONDARY

TILT

Stellar Shuttle Hooklift Nomenclature

The Stellar Shuttle is a hydraulic, body-loading device when mounted on a truck chassis.

When mounted, the Stellar Shuttle can handle a variety of bodies ranging from flatbeds

to recycling containers to dump bodies.

Two independently controlled cylinders operate all the functions of the Stellar Shuttle. By

varying the cylinder operation, the Stellar Flex can be used to dump or unload a body.

The Stellar Shuttle consists of four basic parts: The base, dump, secondary, and tilt sections. Familiarize yourself with the various components of this hooklift and the names of

those components. Knowing the proper terminology is necessary to get full benefit from

this manual

Page 7

Chapter 1 - Safety

Safety 1

Please Read the Following Carefully! This

portion of the manual contains information

regarding all Stellar manufactured hooklifts.

Some items contained within this chapter

may not apply to your specific equipment.

Safety should be the number one thought

on every operator’s mind. Three factors

should exist for safe operation: a qualified

operator, well-maintained equipment, and

the proper use of this equipment. The

following information should be read and

understood completely by everyone

working with or near the hooklift before

putting the unit into operation.

Please take note that Stellar Industries, Inc.

is not liable for accidents incurred by the

hooklift because of non-fulfillment from the

operator’s side of current rules, laws, and

regulations.

General Safety

It is the responsibility of the owner to instruct

the operator in the safe operation of your

equipment and to provide the operator with

properly maintained equipment.

anti-noise headphones, protective glasses,

breathing apparatus, and reflective jackets.

Consult your employer regarding current

safety regulations and accident-prevention

equipment.

Do not wear rings, wristwatch, jewelry, loosefitting or hanging clothing such as ties, torn

garments, scarves, unbuttoned jackets or

unzipped overalls, which could get caught

up in the moving parts of the hooklift.

Keep a first-aid box and a fire extinguisher

readily available on the truck. Regularly

check to make sure the fire extinguisher is

fully charged and the first-aid kit is stocked.

Do not use controls and hoses as handholds.

These parts move and cannot provide stable support.

Do not allow unauthorized personnel or

equipment to enter within 10 feet of hooklift

operating area.

Never allow anyone to ride the hooklift or

load.

Trainees or untrained persons shall be under

the direct supervision of qualified persons.

Do not operate equipment under the

adverse influence of alcohol, drugs, or medication.

Read all Danger and Caution decals on the

equipment and understand their meaning.

Personal Safety

Keep clear of all moving parts.

Always wear the pr

devices.

Always wear appr

clothing such as: protective helmets, antislip shoes with steel toes, protective gloves,

escribed personal safety

oved accident-prevention

Maintenance Safety

Never modify or alter any of the equipment,

whether mechanical, electrical, or hydraulic,

without Stellar Industries’ approval.

Do not perform any maintenance or repair

work on the hooklift unless authorized and

trained to do so.

Release system pressure before attempting

to make adjustments or repairs.

Do not attempt service or repair when PTO is

engaged.

Decals are considered safety equipment.

They must be maintained, as would other

safety devices. Do not remove any decals.

Manual PN 43502

Page 8

2 Shuttle Owner’s Manual - PN 43502

Replace any decals that are missing, damaged, or not

legible.

The safety instruction plates, notices, load

charts and any other sticker applied to the

hooklift must be kept legible and in good

condition. If necessary, replace them.

Keep all surfaces of the hooklift free of oil

and grease to avoid slippery surfaces and

aid in

inspections.

Stability

Know the hooklift components and their

capabilities and limitations. Overloading the

hooklift may result in serious damage of self,

others, equipment or the surroundings.

Never exceed manufacturer’s load ratings.

These ratings are based on the machine’s

hydraulic, mechanical, and structural design

rather than stability.

Load Safety

Full rated dump capacity assumes load will

decrease as dump angle increases. Do not

take full rated capacity to full dump angle

without some unloading of weight as it may

cause damage to the chassis and/or the

hooklift.

Move the control lever slow and smooth for

steady oil flow.

Avoid jerky or sudden movement of the controls.

weight can be lifted.

Keep everyone clear when loading, unloading, and dumping.

Do not push on fixed objects or bodies without rollers with the hooklift.

Do not permit loose objects on the hooklift.

Use a qualified person to assist in loading

when the load is not visible to the operator.

Do not leave hooklift unattended with suspended load.

Take care when operating in areas supported by vehicle tires, because of the cushioning effect of springs and tires.

Never use the drivetrain of the chassis to

assist the hydraulics in loading

Environment

Do not operate the hooklift during electrical

storms.

In extreme cold, allow adequate time to

warm the truck before engaging the PTO.

Do not rev the truck engine and over speed

the hydraulic pumps as permanent damage

to the pumps may occur. Follow the vehicle

owner’s manual regarding operating the

vehicle in such adverse conditions.

In extreme cold, operate the controls slowly

to allow for viscosity changes.

Be constantly aware of the hooklift position

when operating the controls.

Do not attempt to lift fixed loads.

Know the weight of your load to avoid overloading the equipment.

Deduct the weight of the body from the

maximum load rating to determine how

much

ATTENTION

Stellar Industries, Inc. is not liable

for accidents incurred by the

hooklift because of the

operator’s non-fulfillment of

current rules, laws and

regulations.

Page 9

Chapter 2 - Operation

Operation 3

Job-Site Set-Up

Thoroughly plan the lift before positioning

the vehicle. Consider the following:

1. The vehicle should be positioned in an

area free from overhead obstructions to

eliminate the need for repositioning.

2. Position the vehicle so that it is impossible

for any portion of the equipment to come

within the minimum required safe distance

of any power line. Maintain a clearance

of at least 10 feet between any part of

the hooklift, load line, or load, and any

electrical line or apparatus carrying up to

50,000 volts. One foot additional clearance is required for every additional

30,000 volts or less. Remember to allow

for winds that cause power lines to sway.

It is recommended that a signal person

be used when the vehicle is set-up near

power lines.

3. The vehicle should also be positioned on

a firm and level surface that will provide

adequate support for the body.

Operator Requirements

Operation is limited to the following people:

A. Qualified individual.

B. Trainees under direct supervision of the

qualified individual.

C. Test or maintenance individual.

D. Hooklift Inspector.

Operators must:

A. Demonstrate the ability to understand

all decals, the owner’s manual, and any

other information required for safe operation of the hooklift.

B. Be able to demonstrate the ability to

safely control the hooklift.

C. Know all safety r

D. Be responsible for maintenance require-

ments.

E. Understand and be fully capable of

implementing all emergency proce-

dures.

F. Understand the operating procedures as

outlined by this manual, Ansi B30.5 and

Federal/State Laws.

egulations.

4. The parking brake must be removed to

allow the truck to roll under the body

while loading.

CAUTION

1.

When loading and unloading

bodies, the tilt cylinder must be

fully extended before operating

the lift cylinder to prevent

damage to the latch systems.

2. When the PTO is engaged, do

not run the engine over 1400

RPM.

3. Do not hold the brakes while

performing operations.

Operator Conduct

1. Operators will not engage in any operation that would cause them to divert

attention away fr

the hooklift.

2. Operators are responsible for all opera

tions under their direct control.

3. Operators will not leave a suspended

load unattended.

4. Operators will be familiar with the equipment and the maintenance required for

oper care.

pr

om the operation of

-

Manual PN 43502

Page 10

4 Shuttle Owner’s Manual - PN 43502

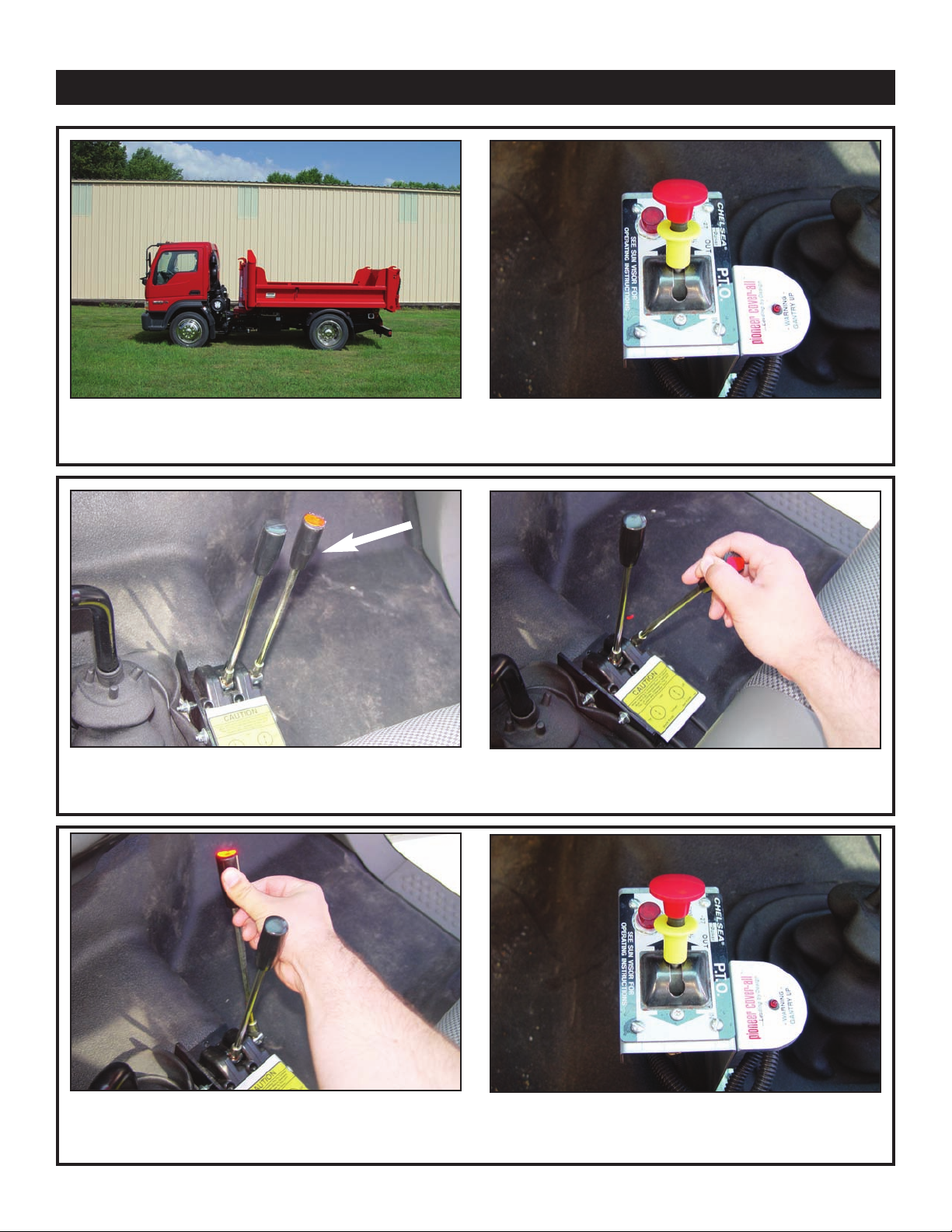

Hooklift Controls

1. Be familiar with the sequence and operation of the hooklift controls.

2. Each individual hooklift function should

have control function decals. Replace

them immediately if they are missing or

illegible.

3. Keep hands, feet and control levers free

from mud, grease and oil.

4. Be familiar with the control levers and

how they operate before attempting to

operate the hooklift.

5. Be prepared before beginning operation of the hooklift:

• All pr

•

• Be sure all safety devices provided are

• Be prepared for all situations. Keep

• Be sure all regular maintenance has

• Visually inspect all aspects of the

• Check for fluid leaks.

otective guards must be in place.

Be aware of the surroundings: low

branches, power lines, unstable

ground.

in place and in good operating condition.

fire extinguisher and first aid kit near.

been performed.

hooklift for physical damage.

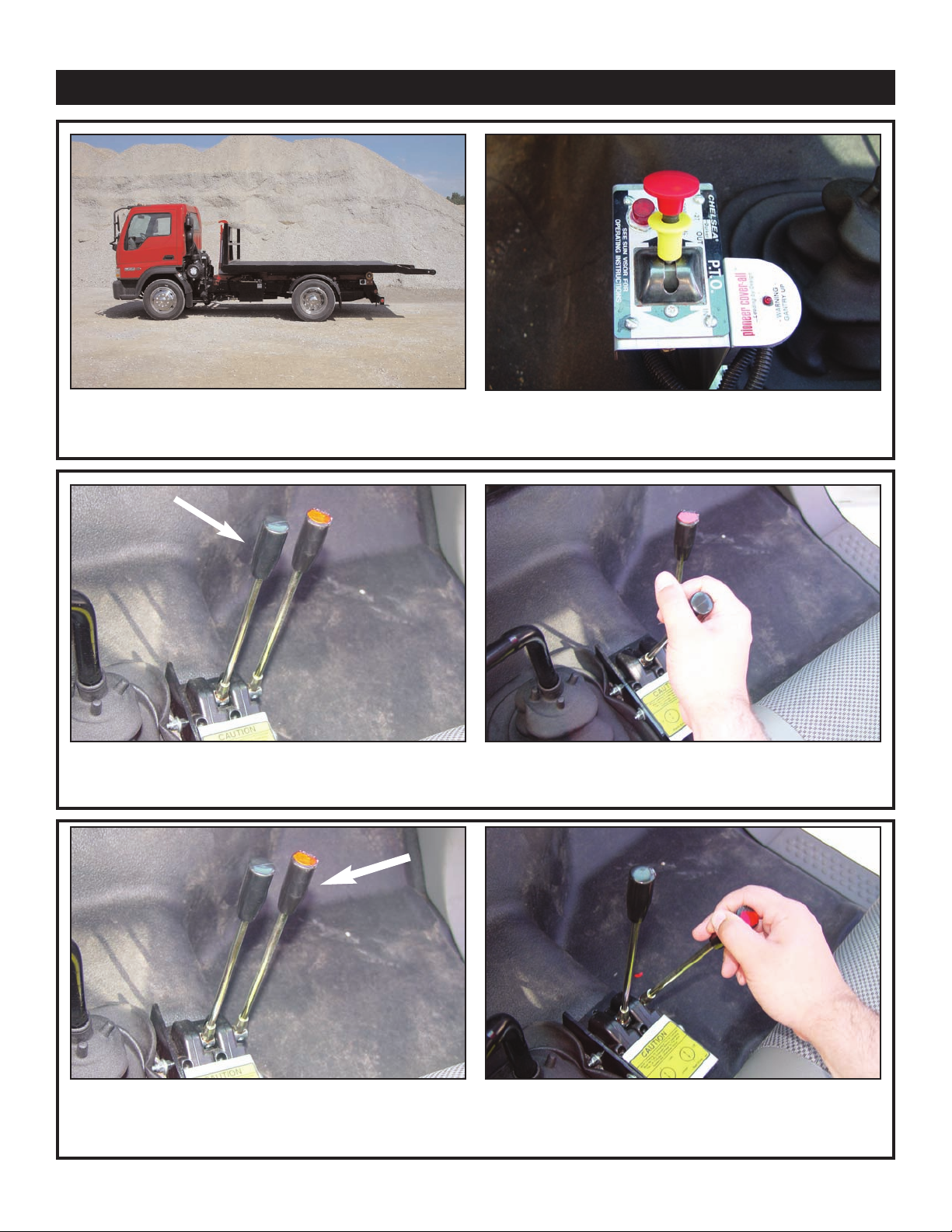

Operation Overview

Unloading Operation

. Stop the truck at the location you wish to unload.

1

2. Put the truck in neutral and engage the PTO.

Run RPM as needed.

3. Locate the black control lever labeled tilt.

4. Pull the tilt lever until the cylinder is fully extended, thus releasing tabs.

5. Locate the red lever labeled lift.

6. Pull lift lever until the body is on the ground and

can be detached. Return the hooklift to the

stored position and disengage the PTO.

Loading Operation

1. Position the truck in line with the body you intent

to pick up.

2. Engage the hook to the body by maneuvering

the hooklift with the red(lift) lever. Run RPM as

needed.

3. Push the red(lift) lever until the main cylinder is

fully retracted.

4. Push the black(tilt) lever until the tilt is fully

extended.

5. Disengage the PTO.

NOTE: The controller assembly pictured in this

chapter may differ from model to model.

Dumping Operation

1. Stop the truck at the location you wish to dump

the load.

2. Put the truck in neutral and engage the PTO.

Run RPM as needed.

3. Locate the red lever labeled lift.

4. Pull the lever to dump the body.

5.Wait until dumping is complete, then push the

red(lift) lever until the main cylinder fully retracts.

6. Disengage the PTO.

Page 11

Operation Operation 5

Unloading Operation

1. Stop the truck at the location you wish to unload.

3. Locate the black control lever labeled tilt.

2. Put the truck in neutral and engage the PTO.

4. Pull tilt lever until full stroke is reached,

thus releasing tabs.

5. Locate the r

ed lever labeled lift.

6. Pull lift lever until the body is on the ground and

can be detached. Return the hooklift to the

stored position and disengage the PTO.

Manual PN 43502

Page 12

6 Shuttle Owner’s Manual - PN 43502 Operation 6

Loading Operation

1. Perform the steps for unloading a container.

3. Push the red(lift) lever until the

main cylinder is fully retracted.

2. Engage the hook to the body by

maneuvering the hooklift with the red(lift)

lever and the black (tilt) lever..

4. Push the black(tilt) lever until

the tilt is fully retracted.

5. Disengage the PTO.

Page 13

Dumping Operation

Operation 7

1. Stop the truck at the location

you wish to dump the load.

3. Locate the red lever labeled lift.

2. Put the truck in neutral and engage the PTO.

4. Pull the lift lever to dump the body.

5. Wait until dumping is complete, then push the

ed(lift) lever until the main cylinder fully r

r

etracts.

6. Disengage the PTO.

Manual PN 43502

Page 14

8 Shuttle Owner’s Manual - PN 43502

Page 15

Chapter 3 - Maintenance

Maintenance 9

9

Please read the following before performing any maintenance on the hooklift.

1. Only authorized service personnel are to perform

maintenance on the hooklift.

2. Disengage the PTO before any service or repair is

performed.

3. Do not disconnect hydraulic hoses while there is still

pressure in those components.

4. Before disconnecting hydraulic components, shut

off the engine, release any air pressure on the

hydraulic reservoir, and move control levers repeatedly through their operating positions to relieve all

pressures.

5. Keep the hooklift clean and free from grease buildup, oil and dirt to prevent slippery conditions.

6. Perform all safety and maintenance checks before

each period of use.

7. Replace parts with Stellar Industries, Inc. approved

parts only.

8. Immediately repair or have repaired any components found to be inadequate.

Maintenance Procedures

1. Position the hooklift where it will be out of the way of

other operations or vehicles in the area.

2. Place all controls in the off position and secure operating features from inadvertent motion.

3. Relieve hydraulic oil pressure from all hydraulic circuits before loosening or removing hydraulic components.

4. Label or tag parts when disassembling.

Daily Inspection

Daily Inspection should occur each day before the

hooklift is put into use. Each day, inspect the hooklift

for all of the following:

1. Hydraulic oil level.

2. Loose parts or damage to structures or weld.

3. Cylinder movement due to leakage.

4. Hoses for evidence of oil leaks.

5. Controls for malfunction or adjustment.

6. Parking brake operation.

e such as cotter pins, snap

All securing har

7.

rings, hairpins, and pin keepers for proper installation.

8. All safety covers for proper installation.

9. Cylinder holding valves for proper operation.

Equipment for missing, illegible, or defaced operat

10.

ing decals and safety signs.

Periodic Inspection

Periodic Inspection should occur while the hooklift is in

use. For the duration of the usage, inspect the hooklift

for all of the following:

1. Loose bolts and fasteners.

All pins, bushings, shafts, and gears for wear

2.

or distortion to include all pivot points, and bushings.

3. Hydraulic systems for proper operating pressure.

dwar

, cracks,

4. Main frame mount bolts.

5. Cylinders for:

A. Damaged rods.

B. Dented barrels.

C. Drift from oil leaking internally.

D. Leaks at rod seals or holding valves.

6. PTO and hydraulic pump(s) for leaks.

7. Hydraulic hose and tubing for evidence of damage

such as blistering, crushing, or abrasion.

8. Presence of this owner’s manual.

Monthly Inspection

Monthly Inspection should occur at the beginning of

every work month. Each month, inspect the hooklift for

all of the following:

1. Frame bolt tightness - turn barrel nuts and mounting

bolts during the first month of operation on new

machines and then quarterly thereafter.

2. Cylinders and valves for leaks.

3. Lubrication.

4. Tilt hook for cracks.

5. Structural weldments for bends, cracks, or breaks.

6. All pins and keepers for proper installation.

7. All control, safety, and capacity placards for read-

ability and secure attachment.

8. Inspect all electrical wires and connections for worn,

cut, or deteriorated insulationand bare wire.

Replace or repair wires as required.

10. Lubrication of all points requiring lubrication.

Service

The following general suggestions should be helpful in

analyzing and servicing your hooklift. Using the following systematic approach should be helpful in finding

and fixing problems:

1. Determine the problem.

2. List and record possible causes.

3. Devise checks.

4. Conduct checks in a logical order to determine the

cause.

5. Consider the remaining service life of components

against the cost of parts and labor necessary to

eplace them.

r

6. Make the necessary repair.

7. Recheck to ensur

looked.

8. Functionally test the new part in its system.

-

e that nothing has been over

Stellar Industries recommends the first filter change

to occur after the first 250 hours of service.* The

second, and every subsequent change, should

occur after every 1,000 hours of service. By

following these guidelines, the hydraulic oil should

last up to 6,500 hours.

*Note: These recommendations are based on normal working

parameters. If operating in less than favorable conditions

(excessive dust, moisture, etc.), be sure to check the filter gauge

often for filter change notice.

-

Manual PN 43502

Page 16

10 Shuttle Owner’s Manual - PN 43502

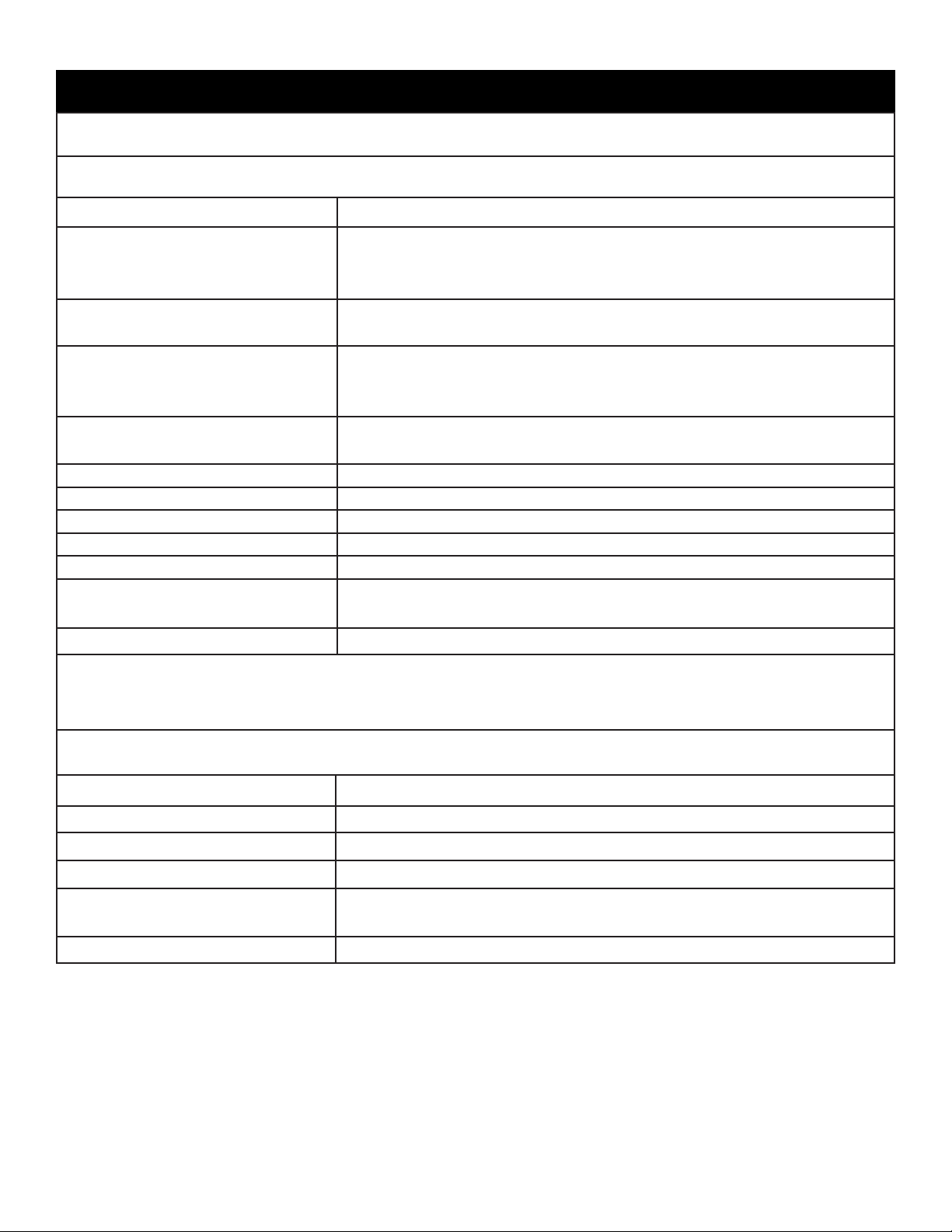

Choice Lubricants for DX Bearings

Greases Recommended

Type of Grease Description

Premium Quality

Multi-Purpose

Multi-Purpose Calcium Based, for General Automotive and Industrial Use

Anti-Friction Bearing Calcium Based with EP Additives

Extreme Pressure (EP) Lithium Based with EP Additives

High Temperature Modified Sodium Based, High Drop Point

Transmission Semi-Fluid, Calcium Based

Molybdenum Filled Lithium Based with 2% Molybdenum Disulfide

Graphite Filled Sodium Based with 2% Graphite

Block Grease Sodium Based Solid Grease

White Grease Aluminum Complex Based with Anti-Oxidant & Rust

Silicone Lithium Based with Silicone Oil Lubricant

Stabilized, Anti-Oxidant Lithium Base

Lithium Base with 3% Molybdenum Disulfide

High Drop Point

Calcium Grease, Water Stabilized, High Drop Point

Lithium Based

Sodium Based

Calcium Based with EP Additives

Inhibitors & Zinc Oxide Additives

Greases Not Recommended

Type of Grease Description

Cup Grease Light Service Calcium or Sodium Based Grease

Graphite Filled Greases with More than 10% Graphite

Molybdenum Filled Greases with More than 10% Molybdenum Disulfide

Fluorocarbon Low Molecular Weight Chlorofluoroethylene Polymer

with Inert Thickeners

White Grease Calcium Based, Zinc Oxide Filled

Page 17

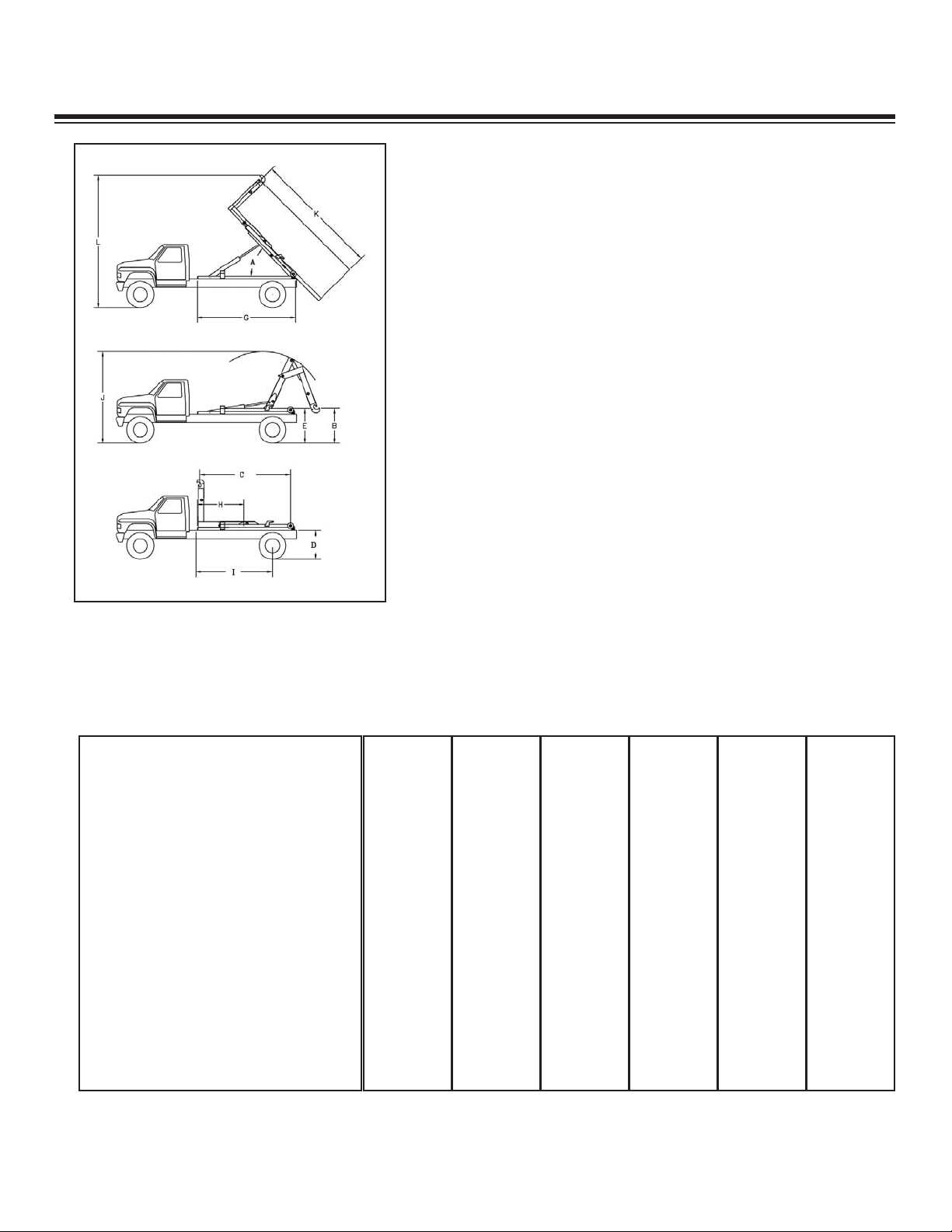

Chapter 4 - Specifications

• Will accommodate bodies from 15-feet up to 21.5-feet long and still

attain the maximum rated dump angle on a 41-inch high frame truck.

onger bodies may be accommodated with reduced dumping

L

capabilities.

• Transmission-mounted PTO and hydraulic pump required to power the

Hooklift loader.

Standard in-cab manual controls which allow for precise metering of

•

the manual stack-type hydraulic valve. Solenoid-activated hydraulic

control valve with electric remote control pendant is optional.

• Twenty-Five (25) gallon frame-mounted oil tank.

• Operating pressure is 4,200 psi.

• Hydraulic flow required is 20 gallons per minute (52,000 lbs models)

and 25-gallons per minute (65,000 lb models).

• Patented dump/load interface on double pivot models.

• Hydraulic locks to prevent cylinder collapse in case of hose failure.

Specifications 11

11

Lifting/Dumping Capacity (pounds)

Dump Angle

A

Lowest Hook Height

B

Effective Length

C

Truck Frame Height

D

Loader Height

E

Chassis Cab to Trunnion

F

Loader Length

G

Loader Center of Gravity

H

Max. Height When Loading

I

Longest Body to Dump

J

Max. Height When Dumping

K

Shipping Weight (pounds)

L

Hook Height (fr

Shipping Dimensions (LxHxW)

Min. Truck GVWR (pounds)

Load Angle w/Shortest Body Length

Recommended Body Lengths*

Recommended Body Lengths**

*(Assumes 3ft. overhang from center of rear roller pin)

(Bumper typically 12” fr

**(Assumes 5ft. overhang from center of rear roller pin)

equir

(May r

om bottom of hook bar)

om center of r

e bumper and latch options)

oller pin)

• Hook latch to prevent body from becoming detached prematurely.

• Mechanical rear body tie-down latches.

• Resettable dump/tilt tabs.

• Hydraulic rotary valve to prevent front tilt movement when the dump

frame is raised.

• Permanently lubricated and greaseless bushings used throughout.

138-18-52

52,000

50°

51”

176”

41”

53.06”

138” to 144”

190”

80”

170”

234”

237”

5,250

61.75”

190”x86”x49”

54,000

35°

15’ to 17.5’

To 19.5’

174-20-52

52,000

50°

36”

206”

41”

53.06”

160” to 174”

220”

92”

188”

264”

261”

5,500

61.75”

220”x86”x49”

54,000

33°

17.5’ to 20’

To 22’

190-24-52

52,000

50°

51”

223”

41”

53.06”

174” to 190”

237”

96”

195”

282”

273”

6,200

61.75”

237”x86”x49”

54,000

32°

19’ to 21.5’

To 23.5’

138.18-65

65,000

50°

45”

174”

41”

54”

138” to 144”

190”

82”

171”

234”

238”

6,300

61.75”

190”x86”x56”

65,000

34°

15’ to 17.5’

To 19.5’

174-20-65

65,000

51°

45”

204”

41”

54”

160” to 174”

220”

91”

188”

264”

262”

6,875

61.75”

220”x86”x56”

54,000

33°

17’ to 20’

To 22’

190-24-65

65,000

50°

42”

221”

41”

54”

174” to 190”

237”

96”

195”

282”

272”

7,300

61.75”

237”x86”x56”

54,000

29°

19’ to 21.5’

To 23.5’

Manual PN 43502

Page 18

12 Shuttle Owner’s Manual - PN 43502

Model 138-18-52 Specifications

ifting Capacity: 52,000 pounds gross weight evenly distributed in, or on, body.

L

Container Length: 15-foot through 17.5-foot from front A-frame to rear of skid rails. Longer bodies up to 19.5-feet may be

accommodated if full dump angle is not required (may require special body-mounted or extendable

truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety Administration

(FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134).

Maximum Dump Angle: 50°

Operating Pressure: 4200 PSI maximum.

Weight of Loader: Loader weight not to exceed 5,250 pounds.

Height of Loader: Loader height not to exceed 12.06" as measured from top of truck frame to top of loader rollers.

Hook Height: 61.75-inches from bottom of skid rails to bottom of hook bar. Loader must be able to pick up body 10-

inches below grade, when mounted on a 41” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Control Valve: Hydraulic valve mounted directly onto the oil reservoir.

Controls: Dual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all

loader functions.

Tilting Hook Assembly: Loader must have pivoting type front tilt section (jib) to provide a low degree

loading/unloading angle. Hook to include automatic mechanical safety latch which disengages only

when the container/body is in proper position to be picked up or dropped off.

Tilt Cylinder: Single 5-inch bore with 2.5-inch diameter rod cylinder. Cylinder must be double acting and

include dual integral pilot-operated counterbalance valves to prevent cylinder collapse in

case of hose failure. Cylinder must be fully retracted when in the transport mode to prevent

exposure of cylinder rod to corrosive road salts.

Tilt Section Operation: Loader must include a hydraulic lock-out device to prevent operation of the tilt section

while loader is in the dumping mode.

Lift/Dump Cylinder: Single 8-inch bore with 3.5-inch diameter rod cylinder. Cylinder must be double acting and include dual

integral pilot-operated counterbalance valves to pr

case of hose failure.

Dump/T

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body to the loader

ilt Interlock:

Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length

27” wide frame with front saddles to provide support for the container while in the dump mode. These

sections for

er/body mounted latches. The system must be protected from out of sequence operation.

ough all ranges of the dump mode. This must be accomplished without the use of steel springs and/or

thr

hydraulic/air cylinders. Loader must be compatible with containers manufactured to ANSI Z245.60 recommended standard for waste containers.

m this frame without the use of mechanical latches which r

event cylinder

ely on gravity, springs, or contain

collapse in

-

Rear Dump Hinge Pin: 3-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

Bushings: All bushings to be of the permanently lubricated variety.

Hoses & Hyd. Fittings:

Origin of Manufacture: Loader to be designed and manufactured in the United States of America.

All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized

wherever possible.

Page 19

Specifications 13

Model 174-20-52 Specifications

ifting Capacity: 52,000 pounds gross weight evenly distributed in, or on, body.

L

Container Length: 17.5-foot through 20-foot from front A-frame to rear of skid rails. Longer bodies up to 22-feet may be

accommodated if full dump angle is not required (may require special body-mounted or extendable

truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety Administration

(FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134).

Maximum Dump Angle: 50°

Operating Pressure: 4200 PSI maximum.

Weight of Loader: Loader weight not to exceed 5,500 pounds.

Height of Loader: Loader height not to exceed 12.06" as measured from top of truck frame to top of loader rollers.

Hook Height: 61.75-inches from bottom of skid rails to bottom of hook bar. Loader must be able to pick up body 10-

inches below grade, when mounted on a 41” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Control Valve: Hydraulic valve mounted directly onto the oil reservoir.

Controls: Dual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all

loader functions.

Tilting Hook Assembly: Loader must have pivoting type front tilt section (jib) to provide a low degree

loading/unloading angle. Hook to include automatic mechanical safety latch which disengages only

when the container/body is in proper position to be picked up or dropped off.

Tilt Cylinder: Single 5-inch bore with 2.5-inch diameter rod cylinder. Cylinder must be double acting and

include dual integral pilot-operated counterbalance valves to prevent cylinder collapse in

case of hose failure. Cylinder must be fully retracted when in the transport mode to prevent

exposure of cylinder rod to corrosive road salts.

Tilt Section Operation: Loader must include a hydraulic lock-out device to prevent operation of the tilt section

while loader is in the dumping mode.

Lift/Dump Cylinder: Single 8-inch bore with 3.5-inch diameter rod cylinder. Cylinder must be double acting

and include dual integral pilot-operated counterbalance valves to pr

collapse in case of hose failure.

Dump/T

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body

ilt Interlock:

Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length

27” wide frame with front saddles to provide support for the container while in the dump mode. These

sections for

er/body mounted latches. The system must be protected from out of sequence operation.

to the loader thr

use of steel springs and/or hydraulic/air cylinders. Loader must be compatible with containers manufactured to ANSI Z245.60 recommended standard for waste containers.

m this frame without the use of mechanical latches which r

ough all ranges of the dump mode. This must be accomplished without

event cylinder

ely on gravity, springs, or contain

the

-

Rear Dump Hinge Pin: 3-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

Bushings: All bushings to be of the permanently lubricated variety.

Hoses & Hyd. Fittings:

Origin of Manufacture: Loader to be designed and manufactured in the United States of America.

All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized

wherever possible.

Manual PN 43502

Page 20

14 Shuttle Owner’s Manual - PN 43502

Model 190-24-52 Specifications

ifting Capacity: 52,000 pounds gross weight evenly distributed in, or on, body.

L

Container Length: 19-foot through 21.5-foot from front A-frame to rear of skid rails. Longer bodies up to 23.5-feet may be

accommodated if full dump angle is not required (may require special body-mounted or extendable

truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety Administration

(FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134).

Maximum Dump Angle: 50°

Operating Pressure: 4200 PSI maximum.

Weight of Loader: Loader weight not to exceed 6,200 pounds.

Height of Loader: Loader height not to exceed 12.06" as measured from top of truck frame to top of loader rollers.

Hook Height: 61.75-inches from bottom of skid rails to bottom of hook bar. Loader must be able to pick up body 10-

inches below grade, when mounted on a 41” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Control Valve: Hydraulic valve mounted directly onto the oil reservoir.

Controls: Dual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all

loader functions.

Tilting Hook Assembly: Loader must have pivoting type front tilt section (jib) to provide a low degree

loading/unloading angle. Hook to include automatic mechanical safety latch which disengages only

when the container/body is in proper position to be picked up or dropped off.

Tilt Cylinder: Single 5-inch bore with 2.5-inch diameter rod cylinder. Cylinder must be double acting and

include dual integral pilot-operated counterbalance valves to prevent cylinder collapse in

case of hose failure. Cylinder must be fully retracted when in the transport mode to prevent

exposure of cylinder rod to corrosive road salts.

Tilt Section Operation: Loader must include a hydraulic lock-out device to prevent operation of the tilt section

while loader is in the dumping mode.

Lift/Dump Cylinder: Single 8-inch bore with 3.5-inch diameter rod cylinder. Cylinder must be double acting

and include dual integral pilot-operated counterbalance valves to pr

collapse in case of hose failure.

Dump/T

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body

ilt Interlock:

Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length

27” wide frame with front saddles to provide support for the container while in the dump mode. These

sections for

er/body mounted latches. The system must be protected from out of sequence operation.

to the loader thr

use of steel springs and/or hydraulic/air cylinders. Loader must be compatible with containers manufactured to ANSI Z245.60 recommended standard for waste containers.

m this frame without the use of mechanical latches which r

ough all ranges of the dump mode. This must be accomplished without

event cylinder

ely on gravity, springs, or contain

the

-

Rear Dump Hinge Pin: 3-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

Bushings: All bushings to be of the permanently lubricated variety.

Hoses & Hyd. Fittings:

Origin of Manufacture: Loader to be designed and manufactured in the United States of America.

All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized

wherever possible.

Page 21

Specifications 15

Model 138-18-65 Specifications

ifting Capacity: 65,000 pounds gross weight evenly distributed in, or on, body.

L

Container Length: 15-foot through 17.5-foot from front A-frame to rear of skid rails. Longer bodies up to 19.5-feet may be

accommodated if full dump angle is not required (may require special body-mounted or extendable

truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety Administration

(FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134).

Maximum Dump Angle: 50°

Operating Pressure: 4200 PSI maximum.

Weight of Loader: Loader weight not to exceed 6,300 pounds.

Height of Loader: Loader height not to exceed 13" as measured from top of truck frame to top of loader rollers.

Hook Height: 61.75-inches from bottom of skid rails to bottom of hook bar. Loader must be able to pick up body

10-inches below grade, when mounted on a 41” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Control Valve: Hydraulic valve mounted directly onto the oil reservoir.

Controls: Dual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all

loader functions.

Tilting Hook Assembly: Loader must have pivoting type front tilt section (jib) to provide a low degree

loading/unloading angle. Hook to include automatic mechanical safety latch which disengages only

when the container/body is in proper position to be picked up or dropped off.

Tilt Cylinder: Single 5-inch bore with 2.5-inch diameter rod cylinder. Cylinder must be double acting and

include dual integral pilot-operated counterbalance valves to prevent cylinder collapse in

case of hose failure. Cylinder must be fully retracted when in the transport mode to prevent

exposure of cylinder rod to corrosive road salts.

Tilt Section Operation: Loader must include a hydraulic lock-out device to prevent operation of the tilt section

while loader is in the dumping mode.

Lift/Dump Cylinder: Dual 7-inch bore with 3-inch diameter rod cylinder. Cylinders must be double acting

and include pilot-operated counterbalance valving to pr

hose failure.

Dump/T

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body

ilt Interlock:

Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length

34” wide frame with front saddles to provide support for the container while in the dump mode. These

sections for

er/body mounted latches. The system must be protected from out of sequence operation.

to the loader thr

the use of steel springs and/or hydraulic/air cylinders. Loader must be compatible with containers manufactured to ANSI Z245.60 recommended standard for waste containers.

m this frame without the use of mechanical latches which r

ough all ranges of the dump mode. This must be accomplished without

event cylinder collapse in case of

ely on gravity, springs, or contain

-

Rear Dump Hinge Pin: 3-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

Bushings: All bushings to be of the permanently lubricated variety.

Hoses & Hyd. Fittings:

Origin of Manufacture: Loader to be designed and manufactured in the United States of America.

All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized

wherever possible.

Manual PN 43502

Page 22

16 Shuttle Owner’s Manual - PN 43502

Model 174-20-65 Specifications

ifting Capacity: 65,000 pounds gross weight evenly distributed in, or on, body.

L

Container Length: 17-foot through 20-foot from front A-frame to rear of skid rails. Longer bodies up to 22-feet may be

accommodated if full dump angle is not required (may require special body-mounted or extendable

truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety Administration

(FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134).

Maximum Dump Angle: 51°

Operating Pressure: 4200 PSI maximum.

Weight of Loader: Loader weight not to exceed 6,875 pounds.

Height of Loader: Loader height not to exceed 13" as measured from top of truck frame to top of loader rollers.

Hook Height: 61.75-inches from bottom of skid rails to bottom of hook bar. Loader must be able to pick up body 10-

inches below grade, when mounted in a 41” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Control Valve: Hydraulic valve mounted directly onto the oil reservoir.

Controls: Dual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all

loader functions.

Tilting Hook Assembly: Loader must have pivoting type front tilt section (jib) to provide a low degree

loading/unloading angle. Hook to include automatic mechanical safety latch which disengages only

when the container/body is in proper position to be picked up or dropped off.

Tilt Cylinder: Single 5-inch bore with 2.5-inch diameter rod cylinder. Cylinder must be double acting and

include dual integral pilot-operated counterbalance valves to prevent cylinder collapse in

case of hose failure. Cylinder must be fully retracted when in the transport mode to prevent

exposure of cylinder rod to corrosive road salts.

Tilt Section Operation: Loader must include a hydraulic lock-out device to prevent operation of the tilt section

while loader is in the dumping mode.

Lift/Dump Cylinder: Dual 7-inch bore with 3-inch diameter rod cylinder. Cylinders must be double acting

and include pilot-operated counterbalance valving to pr

hose failure.

Dump/T

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body

ilt Interlock:

Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length

34” wide frame with front saddles to provide support for the container while in the dump mode. These

sections for

er/body mounted latches. The system must be protected from out of sequence operation.

to the loader thr

use of steel springs and/or hydraulic/air cylinders. Loader must be compatible with containers manufactured to ANSI Z245.60 recommended standard for waste containers.

m this frame without the use of mechanical latches which r

ough all ranges of the dump mode. This must be accomplished without

event cylinder collapse in case of

ely on gravity, springs, or contain

the

-

Rear Dump Hinge Pin: 3-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

Bushings: All bushings to be of the permanently lubricated variety.

Hoses & Hyd. Fittings:

Origin of Manufacture: Loader to be designed and manufactured in the United States of America.

All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized

wherever possible.

Page 23

Specifications 17

Model 190-24-65 Specifications

ifting Capacity: 65,000 pounds gross weight evenly distributed in, or on, body.

L

Container Length: 19-foot through 21.5-foot from front A-frame to rear of skid rails. Longer bodies up to 23.5-feet may be

accommodated if full dump angle is not required (may require special body-mounted or extendable

truck-mounted bumper and additional latches to meet the Federal Motor Carrier Safety Administration

(FMCSA) Rear End Protection regulation 393.86 and Securing Hooklift Containers regulation 393.134).

Maximum Dump Angle: 50°

Operating Pressure: 4200 PSI maximum.

Weight of Loader: Loader weight not to exceed 7,300 pounds.

Height of Loader: Loader height not to exceed 13" as measured from top of truck frame to top of loader rollers.

Hook Height: 61.75-inches from bottom of skid rails to bottom of hook bar. Loader must be able to pick up body 10-

inches below grade, when mounted on a 41” truck frame height.

Hydraulic Pump: Direct-coupled high-pressure gear pump.

Hydraulic Control Valve: Hydraulic valve mounted directly onto the oil reservoir.

Controls: Dual manual levers with sealed cable actuators mounted in the truck cab to allow full feathering of all

loader functions.

Tilting Hook Assembly: Loader must have pivoting type front tilt section (jib) to provide a low degree

loading/unloading angle. Hook to include automatic mechanical safety latch which disengages only

when the container/body is in proper position to be picked up or dropped off.

Tilt Cylinder: Single 5-inch bore with 2.5-inch diameter rod cylinder. Cylinder must be double acting and

include dual integral pilot-operated counterbalance valves to prevent cylinder collapse in

case of hose failure. Cylinder must be fully retracted when in the transport mode to prevent

exposure of cylinder rod to corrosive road salts.

Tilt Section Operation: Loader must include a hydraulic lock-out device to prevent operation of the tilt section

while loader is in the dumping mode.

Lift/Dump Cylinder: Dual 7-inch bore with 3-inch diameter rod cylinder. Cylinders must be double acting

and include pilot-operated counterbalance valving to pr

hose failure.

Dump/T

Rear Body Hold-downs: Dual fixed-position hold down devices mounted to the dump frame to secure the body

ilt Interlock:

Dumping must be accomplished through a rear pivot. Tilt and lift sections must lock into a rigid full length

34” wide frame with front saddles to provide support for the container while in the dump mode. These

sections for

er/body mounted latches. The system must be protected from out of sequence operation.

to the loader thr

use of steel springs and/or hydraulic/air cylinders. Loader must be compatible with containers manufactured to ANSI Z245.60 recommended standard for waste containers.

m this frame without the use of mechanical latches which r

ough all ranges of the dump mode. This must be accomplished without

event cylinder collapse in case of

ely on gravity, springs, or contain

the

-

Rear Dump Hinge Pin: 3-inch diameter type 304 or 17-4 stainless steel minimum.

Pins: All pins to be type 304 or 17-4 stainless steel.

Bushings: All bushings to be of the permanently lubricated variety.

Hoses & Hyd. Fittings:

Origin of Manufacture: Loader to be designed and manufactured in the United States of America.

All hoses and fittings are to be SAE; metrics are not to be allowed. O-ring face seal fittings to be utilized

wherever possible.

Manual PN 43502

Page 24

18 Shuttle Owner’s Manual - PN 43502

Page 25

Chapter 5 - Decals

Decals of Note

Moving Tilt Hazard Decal

Location: On each side of the tilt.

Function: To inform the operator of the

hazard associated with tilt operation, the

possible consequences should the haz-

ard occur, and how to avoid the hazard.

PN: C0865

Decals 19

19

Electrocution Hazard Decal

Location: Bottom of tilt.

Function: To inform the operator of the hazard

associated with electrocution, the possible

consequences should the hazar

how to avoid the hazard.

PN: C1179

d occur

, and

Misuse Hazard Decal

Location: Sides of the Breakaway Tabs.

Function: T

d associated with impr

ar

dump tabs, the possible consequences

should the hazar

the hazar

o infor

d. PN: 26134

m the operator of the haz

oper use of the

d occur, and how to avoid

-

Manual PN 43502

Page 26

20 Shuttle Owner’s Manual - PN 43502

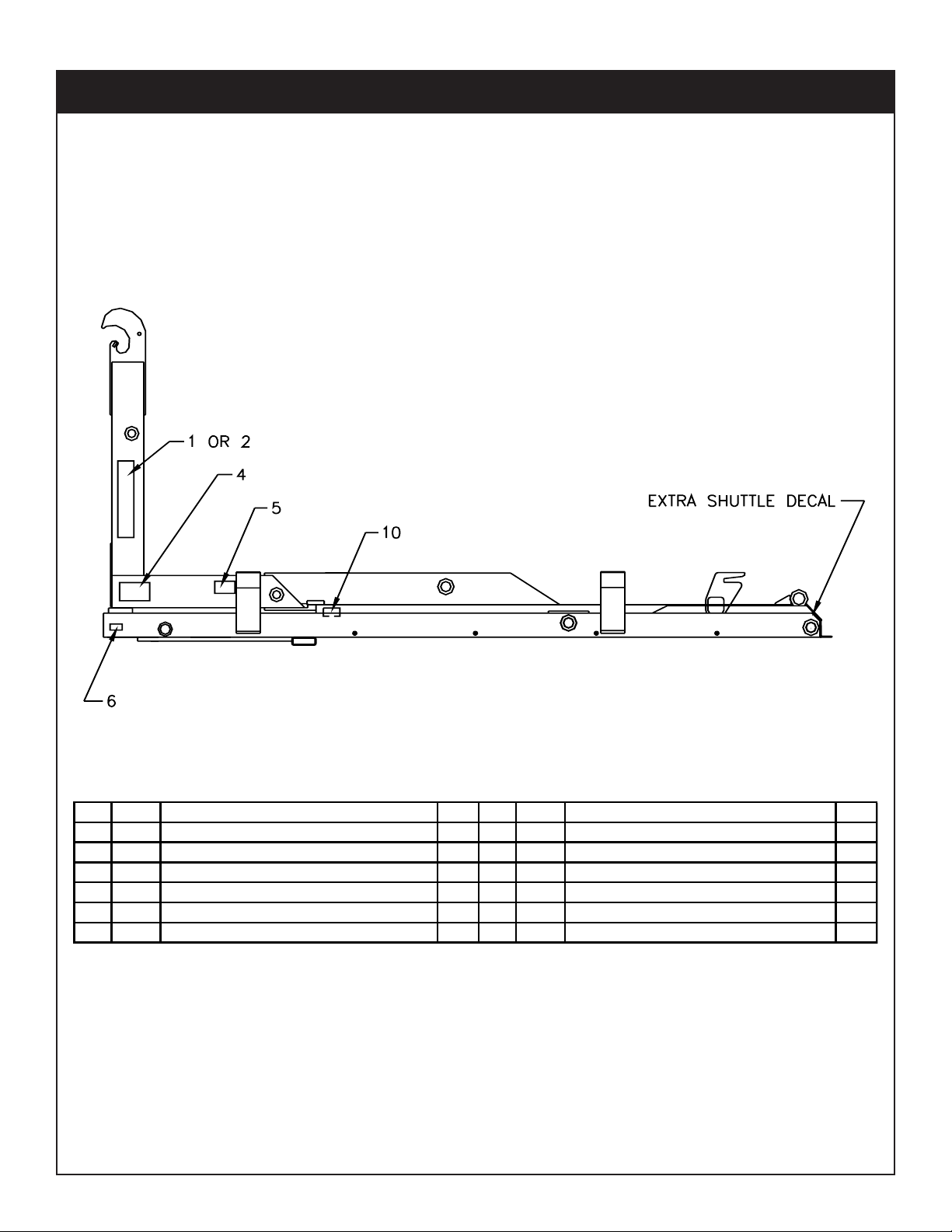

.YTQNOITPIRCSEDTRAPMETI.YTQNOITPIRCSEDTRAPMETI

1NOITAREPO LACED15607*2EGRAL ELTTUHS LACED8026C1

2C6207 DECAL SHUTTLE SMALL 2 *8 4190 DECAL DANGER OPERATION CONDITION 2

2REGNAD LACED0454C9*1NOITUCORTCELE REGNAD LACED5454C3*

4 C1179 DECAL DANGER ELECTROCUTION HORTL 2 10 26134 DECAL DANGER MISUSE HAZARD 4

5C0865 DECAL WARNING ARMS 2 *11 26135 DECAL NOTICE FIX TABS 1

6 4214 DECAL CONTACT STELLAR 1

PN D0779

Notes:

1. Leftover Shuttle decals should be mounted on back of hooklift and on truck frame.

2. Extra electrocution decals should be shipped loose.

3. Place one of 26134 & 26135 in cab on controller assembly.

* These decals not shown (Mount in cab or on truck frame).

Decal Kit Placement - PN D0779

Page 27

Installation 21

Chapter 6 - Installation

Every hooklift installation is unique. However, certain guidelines exist that apply to every

model. Listed below is a general set of chronological steps that may be followed when

installing a Stellar Hooklift. If any questions arise during the installation process, feel free to

contact your local dealer or Stellar Customer Service at 800-321-3741.

52K Model Installation Steps - Basic Guidelines . . . . . . . . 22

65K Model Installation Steps - Basic Guidelines . . . . . . . . 24

Power Beyond VDM8 Valve. . . . . . . . . . . . . . . . . . . . . . . . . 26

Mounting Kit (All 52K Shuttles) - PN 17803 . . . . . . . . . . . . . 27

Mounting Kit (All 65K Shuttles) - PN 16561 . . . . . . . . . . . . . 28

Rotary Valve (All 52K Shuttles) - PN 24040 . . . . . . . . . . . . . 29

Rotary Valve (All 65K Shuttles) - PN D0000 . . . . . . . . . . . . . 30

Reservoir Assembly - PN 25927 . . . . . . . . . . . . . . . . . . . . . . 31

Subframe - PN 3118

(138-18-52, 138-18-65) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Subframe - PN 3117

(174-20-52, 174-20-65, 190-24-65, 190-24-52). . . . . . . . . . . . . . . . . . . . 33

Dump Light Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Controller Assembly Part 1 - PN 38841 . . . . . . . . . . . . . . . . 35

Controller Assembly Part 2 - PN 38841 . . . . . . . . . . . . . . . . 36

Hose Kit (138-18-52) - PN 17017 . . . . . . . . . . . . . . . . . . . . . . 37

Hose Kit (174-20-52) - PN 17794 . . . . . . . . . . . . . . . . . . . . . . 38

Hose Kit (190-24-52) - PN 17822 . . . . . . . . . . . . . . . . . . . . . . 39

Hose Kit (138-18-65) - PN 16624 . . . . . . . . . . . . . . . . . . . . . . 40

Hose Kit (174-20-65) - PN 32677 . . . . . . . . . . . . . . . . . . . . . . 41

Hose Kit (190-24-65) - PN 16708 . . . . . . . . . . . . . . . . . . . . . . 42

21

Basic Installation Overview

1. Clear the truck frame.

2. Set the hooklift on the truck frame.

3. Shorten the truck frame so that it’s flush with the rear of the hooklift.

4. Install bumper.

5. Install tie down channels. (See corresponding Mounting Kit Drawing in this chapter)

6. Install tarper tower (If applicable).

7. Install cab and PTO controls.

8. Mount hydraulic reservoir tank and valve bank.

9. Mount PTO and Pump.

10. Run hydraulic hoses.

11. Connect suction and pressure to the reservoir tank and valve bank.

12. Install mud flaps and fenders.

13. Run hooklift.

Manual PN 43502

Page 28

22 Shuttle Owner’s Manual - PN 43502

52K Model Installation Steps - Basic Guidelines

1. Clear the truck frame.

2. Set the hooklift on the truck frame.

a. The front of the hooklift needs to be at least 2” behind the cab or any equipment

mounted behind the cab.

b. Be sure to square the hooklift on the truck frame.

c. Survey the chassis frame and look for any potential issues. For example:

Clearance problems, cross members extending too high, insufficient room in front

of the hooklift for tarpers, exhaust manifolds, etc, or insufficient room in the rear to

allow for bumper selection. Feel free to space up if needed.

3. Shorten the truck frame so that it’s flush with the rear of the hooklift.

4. Install bumper.

a. See Government Regulations for acceptable placement.

5. Install tie down channels. (See Mounting Kit Drawing 17803 on page 27)

a. Move anything on the truck frame that may be in the way of the tie down chan-

nels.

b. Using 1” bolts, washers, and nuts, fasten two (2) tie-down channels (PN 1425 &

1440) together with the narrow faces toward each other. Do this with all of the

channels.

c. Place a tie down channel (PN 1425) on both sides of the base, within 2” of the

front plate.

d. Place a tie down channel (PN D0143) on both sides of the base, underneath the

tabs at the rear. Drill an 11/16” hole in each of the rear tabs, using the channels as

a guide. Bolt these channels to the tab using 5/8” bolts, washers, and nuts.

e. The final tie down channels should be placed in the approximate position shown in

the corresponding mounting diagram. The top of the lower tie down should be

flush with the top of the chassis frame rail.

f. Place three shear plates (PN 3596) on each side of the base in the approximate

locations shown in the mounting diagram. The top of the plates should be approxi-

mately even with the bottom of the base tube.

g. Weld all of the shear plates to the base of the hooklift.

h. Using the channels as a guide, drill four (4) 1-1/16” holes and two (2) 11/16” holes

through the truck frame.

i. Drill two (2) 1-1/16” holes through each of the shear plates, and the truck frame.

j. Using 1” bolts, washers, and nuts, secure the front tie down channels to the truck

frame. Using 5/8” bolts, washers, and nuts, secure the rear tie down channels to

the truck frame. All 1” bolts must be torqued to 680 ft-lbs and all 5/8” bolts must be

torqued to 160 ft-lbs.

K. Weld the upper tie down channels (PN 1425) to the hooklift base.

Page 29

6. Install tarper tower (If applicable).

a. See brand specific installation instructions.

7. Install cab and PTO controls.

a. Use PTO brand specific installation instructions.

b. See Controller Assembly Drawing (PN 38841) for details.

c. See Dump Light Kit Installation

8. Mount hydraulic reservoir tank and valve bank.

a. Make sure the tank isn’t too far away if cables are being used.

b. Don’t raise the tank above the frame height.

c. See Power Beyond Installation guide for valve bank details.

d. See Reservoir Assembly Drawing PN 25629 for details.

9. Mount PTO and Pump.

a. Be sure to check the rotation of the pump to ensure proper installation.

b. Use brand specific installation instructions.

Installation 23

23

10. Run hydraulic hoses.

a. Run hoses between the pump and r

eservoir tank.

b. Run hoses between the valve bank and hooklift.

c. Protect these lines with hose wrap when necessary.

d. Keep these lines away from sharp edges.

e. Keep these lines away from the exhaust or other temperature extreme items.

f. Keep these lines away from the driveshaft or other moving items.

g. See hydraulic schematics for details.

11. Connect suction and pressure to the reservoir tank and valve bank.

a. Fittings on the valve bank should be 3” lower than the long sills.

b. Fill reservoir to site gauge, within 3” from the top (Roughly 10 Gallons).

c. Petro-Canada Hydrex 32 (ISO 32) hydraulic oil is recommended.

d. When connections are secure, turn reservoir on.

12. Install mud flaps and fenders.

13. Run Hooklift.

Bleed the air out of the hydraulic system.

a.

b. Check the oil level and add oil if needed.

c. Calibrate rotary valve.

d. Calibrate dump light system.

e. Be sure to check all clearances.

Manual PN 43502

Page 30

24 Shuttle Owner’s Manual - PN 43502

65K Model Installation Steps - Basic Guidelines

1. Clear the truck frame.

2. Set the hooklift on the truck frame.

a. The front of the hooklift needs to be at least 2” behind the cab or any equipment

mounted behind the cab.

b. Be sure to square the hooklift on the truck frame.

c. Take a survey of the chassis frame and look for any potential issues. For example:

Clearance problems, cross members extending too high, insufficient room in front

of the hooklift for tarpers, exhaust manifolds, etc, or insufficient room in the rear to

allow for bumper selection.

3. Shorten the truck frame to within 2” from the rear of the loader.

4. Install bumper.

a. See Government Regulations for acceptable placement.

Space the base up by 1/2”.

5. Install tie down channels. (See Mounting Kit Drawing 16561 on page 28)

a. Move anything on the truck frame that may be in the way of the tie downs.

b. Using 1” bolts, washers, and nuts, fasten two (2) tie-down channels (PN 2891 &

2874) together with the narrow faces toward each other. Do this with all of the

channels. Note: The hooklift should already have two tie down channels (PN

2874) welded on each side of the base.

c. The loose tie down channels should be placed in the approximate position shown

in the corresponding mounting diagram. The top of the lower tie down should be

flush with the top of the chassis frame rail.

d. Place two angles (PN 3238) on each side of the base in the approximate locations

shown in the mounting diagram. The back of the r

of the rear of the hooklift. The top flange of the angles should be touching the

bottom of the base tube and the other flange should touching the frame rail.

e. Weld all of the angles to the base of the hooklift.

f. Using the channels as a guide, drill six (6) 1-1/16” holes through the truck frame.

g. Drill three (3) 1-1/16” holes through each of the angles, and the truck frame.

h. Using 1” bolts, washers, and nuts, secure all tie downs to the truck frame. All 1”

bolts must be torqued to 680 ft-lbs.

i. Weld the upper tie down channels (PN 2874) to the hooklift base.

ear channels must be within 1”

6. Install tarper tower (If applicable).

a. See brand specific installation instructions.

Page 31

7. Install cab and PTO controls.

a. Use PTO brand specific installation instructions.

b. See Controller Assembly Drawing (PN 38841) for details.

c. See Dump Light Kit Installation

8. Mount hydraulic reservoir tank and valve bank.

a. Make sure the tank isn’t too far away if cables are being used.

b. Don’t raise the tank above the frame height.

c. See Power Beyond Installation guide for valve bank details.

d. See Reservoir Assembly Drawing PN 25629 for details.

9. Mount PTO and Pump.

a. Be sure to check the rotation of the pump to ensure proper installation.

b. Use brand specific installation instructions.

Installation 25

10. Run hydraulic hoses.

Run hoses between the pump and reservoir tank.

a.

b. Run hoses between the valve bank and hooklift.

c. Protect these lines with hose wrap when necessary.

d. Keep these lines away from sharp edges.

e. Keep these lines away from the exhaust or other temperature extreme items.

f. Keep these lines away from the driveshaft or other moving items.

g. See hydraulic schematics for details.

11. Connect suction and pressure to the reservoir tank and valve bank.

a. Fittings on the valve bank should be 3” lower than the long sills.

b. Fill reservoir to site gauge, within 3” from the top (Roughly 10 Gallons).

c. Petro-Canada Hydrex 32 (ISO 32) hydraulic oil is recommended.

d. When connections are secure, turn reservoir on.

12. Install mud flaps and fenders.

13. Run Hooklift.

a. Bleed the air out of the hydraulic system.

b. Check the oil level and add oil if needed.

c. Calibrate rotary valve.

d. Calibrate dump light system.

e. Be sure to check all clearances.

Manual PN 43502

Page 32

26 Shuttle Owner’s Manual - PN 43502

Power Beyond VDM8 Valve

These instructions ar intended for correct installation of power beyond on a Salami VDM8

valve bank. If any hydraulic component is integrated after this valve the power beyond

must be installed correctly, or serious damage may incur to the hydraulic system.

1. Remove cover/access plug to reveal the power

beyond access point. Can also be used as the

Return/Tank port.

3. The Power Beyond feature is now activated and will

divert oil to alternate system via the port shown.

2. Install a 3/8” straight thread pipe plug into lower portion of cavity to activate the power beyond feature.

Use thread sealer (tape sealers not recommended.

Note:

1. The return/tank line must be connected to the

top or the side port, labeled “T”.

2. Using the return line to run auxillary equipment will

directly result in a failure and will not in any circumstance be covered under warranty.

3. A standard Stellar hooklift will have 6 hydraulic

lines attached to the valve. A Stellar hooklift with

Power Beyond will have 7 hydraulic lines

attached to the valve.

Page 33

Installation 27

6

9

1

1

20

3

5

4

3

7

3

3

6

9

20

2

3

3

8

WELD HERE

10

9

19

ITEM PART DESCRIPTION QTY.

1 1440 TIE DOWN, 40000# 4

2 3596 PLATE 0.50X8.00X16.00 6

3 1443 WASHER 1.00 USS FLAT ZINC 40

4D0045 BACKUP ALARM .97 DECIBAL 1

5 12169 CAP SCR 1.00-8X3.50 HHGR8 4

6 5199 CAP SCR 1.00X8X3.00 HHGR8 ZY 16

7C1025 CAP SCR 0.63-11X2.00 HHGR8 ZY 2

824868 NUT 0.63-11 HHGR8 NYLOCK ZY 2

9 6294 NUT 1.00 HHGR8 NYLOC 20

10 C1038 WASHER 0.63 FLAT 4

18 26879 LOADER 174-20-52K 1

19 D0143 TIE DOWN CHANNEL 2

20 1425 TIE DOWN 40,000# 4

PN 17803

27

Mounting Kit (All 52K Shuttles) - PN 17803

Manual PN 43502

Page 34

28 Shuttle Owner’s Manual - PN 43502

6

1

2

FROM THE REAR OF THE LOADER

PLACE 1 INCH FORWARD

7

8

4

8

6

5

8

8

7

7

WELD BETWEEN OTHER

TWO TIE DOWN CHANNELS

.YTQN

O

ITPIRC

SE

DTR

A

PMETI

6

000,56 NWOD EI

T

198

2

1

2000,56 NWOD EIT47822

4 3238 ANGLE 4.00X6.00X.50WX36.00 4

512169 CAP SCR 1.00-8X3.50 HHGR8 6

65199 CAP SCR 1.00X8X3.00 HHGR8 ZY 24

7 6294 NUT 1.00 HHGR8 NYLOC 30

86538 WASHER 1.00 SAE FLAT YELLOW GR8 60

PN 16561

Mounting Kit (All 65K Shuttles) - PN 16561

Page 35

Installation 29

7

10

10

5

4

11

3

1

7

9

6

6

6

2

8

12

7

12

.YTQNOITPIRC

SE

D

TRAPME

TI

122456 ROTARY VALVE ASM 1

2 22450 WLDMT ROTARY VALVE ECCENTRIC 1

3 D1638 O'RING 1.12X1.38X0.12 568-216 1

43748 WASHER ROTARY VALVE 1

50480 CAP SCR 0.25-20X1.00 HHGR5 1

60353 CAP SCR 0.38-16X2.00 HHGR5 3

7 0347 NUT 0.38-16 HH NYLOC 3

8 0977 O'RING 1.00X1.25X0.12 568-214 1

9 24236 PLATE ROTARY VALVE ARM 1

10 0482 CAP SCR 0.25-20 X 3.00 HHGR5 2

11 0333 NUT 0.25-20 HHGR5 NYLOC 2

12 C1854 FTG ADAPT 6-8 F5OLO-S 4

PN 24040

Rotary Valve (All 52K Shuttles) - PN 24040

29

To adjust rotary valve move hooklift into stowed position. Loosen the bolts that are

attaching the valve block to the dump section. Adjust rotary arm so that it is in contact

with the dump plate. Pull valve block towards rear of hooklift until snug. Tighten valve

block bolts while making sure valve block is snug. Note: It should engage between 4

and 10 degrees.

Manual PN 43502

Page 36

30 Shuttle Owner’s Manual - PN 43502

6

5

4

9

9

1

0

1

0

1

3

7

8

2

41

41

1

1

31

31

11

41

41

21

.O

N

METI.

YT

Q.ONTRANP

OITP

IRCSED

11 77

8M0

SAEVLAVYRATOR

21 12

5T1

OV

IPEV

LAVYRATOR

31 7794012-86521.0X52.1X00.1GNIR

'O

41 8361

6D 12-86521.0X83.1X21.1GNIR'

O

51 847E3VLAVYRATO

RRE

HSAW

61 0

8

450

R

GH

H00.1X02-52.0RCSP

AC

71 35350RGHH00.2X61-83.0RCSPAC

81 743C0OLYNHH61-83.0TUN

92 2

8450RGHH00.3X02-52.0RCSPAC

012 333C0OLYN5RGHH02-52.0TUN

1

12 9

74N2IP61/

5D

RHT61/5EKOY

211 674)2MR(7BDRHT42-13.0DOR

3

12 8

742HH8

1-13.TU

N

4

14 31

160C.

1X490.

NIPRETT

OC

5

14 458

1SC-OLO5F

8-6

TPA

DAGTF

PN D0000

Rotary Valve (All 65K Shuttles) - PN D0000

Page 37

26

3

4

3

6

24

23

5

1

12

2

1

2

2

1

5

8

18

20

18

18

19

31

7

1

1

10

2

9

25

28

16

1

3

14

30

2

9

20

27

1

7

.YTQNOITPIRCSEDTRAPMET

I

1 26510 RSRVR ASM 25GAL K MODEL 1

2 7353 NIPPLE 2.00 HEX PIPE 2FF 1

3 C4694 ST EL 1.25 90 DEG BLK 2

4 D0024 NIPPLE 1.25X14.00 BLK 1

5 C6228 FILTER HEAD SF120-25 1.3 1

101-ES EGRAL RETLIF5226C6

1

00

.2

LLAB EVLAV0574C7

1

00

.2 BRA

B ES

OH GTF0374C