Stearns Series 320 Catalog Page

Series 320 Armature Actuated Brakes

Maintained

manual

release option

(Shown with and without

maintained manual release)

BACK TO T ABLE OF CONTENTS

• Torque rating 3 to 50 lb-in / (.34 to 5.6 NM)

• UR and CUR Recognized insulation system,

E-125303 and sizes 1.8, 2.8 brakes with internal

power supply File E-71115

Class B temperature rise with Class H mag wire

• Available for holding (H) or dynamic (D) stopping

applications

• Corrosion resistance

• Optional “double D” friction discs are available in

3-7 lb-in dynamic and 3-15 lb-in holding brakes. DD

shafts fit the brake directly without a brake hub, no

shaft keyway cost and simplify assembly

• Optional maintained manual release

• Optional mounting plates to make conversion over

to the superior Stearns product easy

• Optional AC Rectifiers - internal or external in-line

• Optional band seal (not available for 1.2 size)

• Installation and Service Instructions:

P/N 8-078-889-00

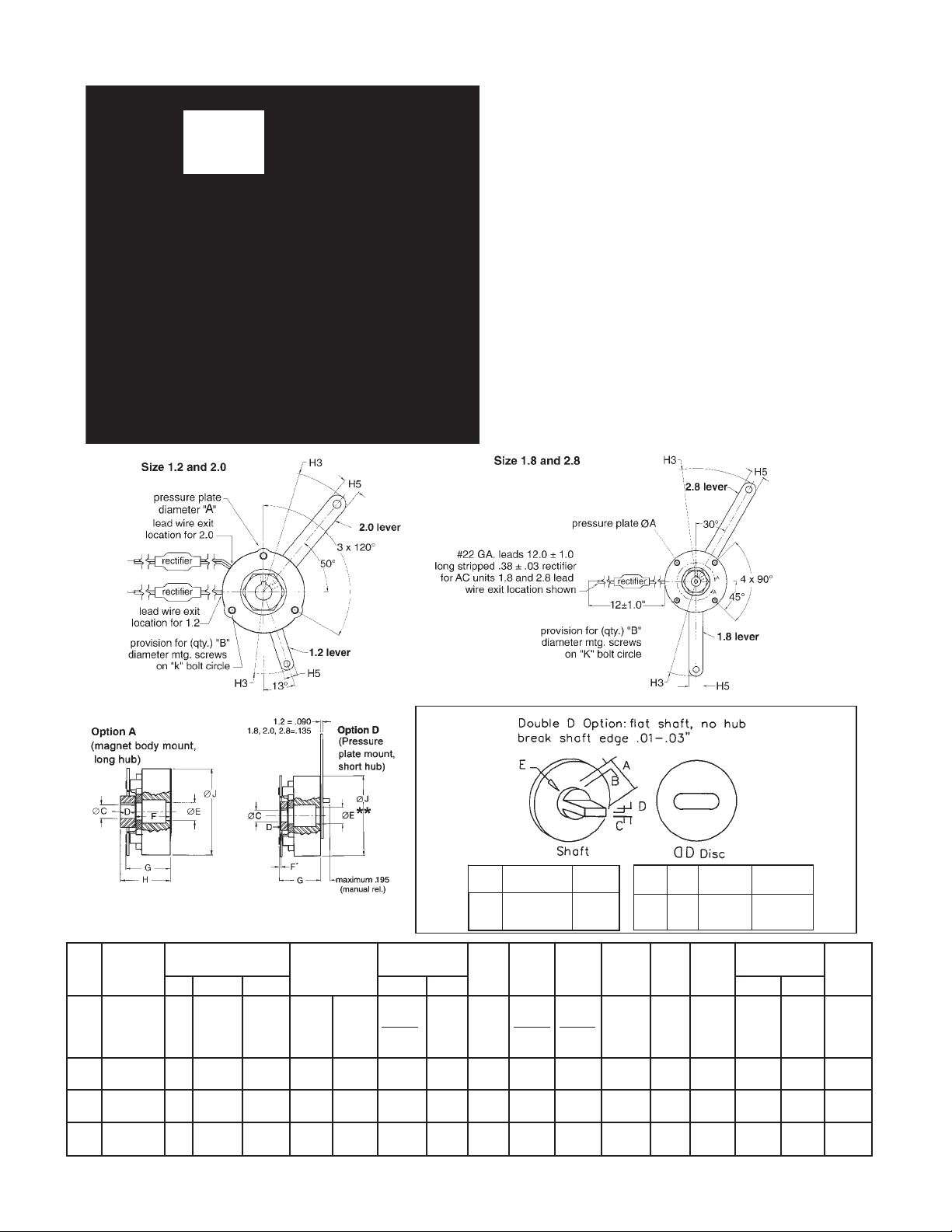

Dimensional Data

Model

Size

1.2D

1.2H

1.8D

1.8H

2.0D

2.0H

2.8D

2.8H

Number

3-20-2401G

3-20-2501G

3-20-4401G

3-20-4501G

3-20-5401G

3-20-5501G

3-20-7401G

3-20-7501G

Qty. B K F F` Long Short

3

4

3

4

Mounting Screw

Ø.140

#4, (M3)

Ø.177

#6 (M3.5)

Ø.145

#6 (M3)

Ø.188

#8 (M4)

Optional Manual

Release Shown

Maximum Shaft

Length (Manual

Release Units)

Ø1.545

(39.243)

Ø2.125

(53.975)

Ø2.220

(56.388)

Ø2.844

(72.738)

.300 (7.62)

.430 (10.92)

.430 (10.92)

.490

(12.45)

Hub Location

.685

(17.40)

.860

(21.84)

.995

(25.27)

.933

(23.70)

.954

(24.23)

.015

(.381)

.015

(.381)

.015

(.381)

.050*

(1.27)

Brake

Size

1.2

1.8

E** G

.410

(10.41

.450

(11.43)

.530

(13.46)

1.10

(27.94)

.25 + .05/-.00

.30 + .13/-.00

.890

(22.60)

1.065

(27.05)

1.260

(32.00)

1.190

(30.23)

1.415

(35.94)

.075 max.

.075

max.

H

Long

Hub

1.065

(27.05)

1.240

(31.50)

1.405

(35.69)

1.623

(41.22)

1.364

(34.64)

Shaft

BA

Size

5/16

3/8

H3 H5 J

2.5

(63.5)

3.775

(95.885)

3.775

(95.885)

4.5

(95.885)

.052

.063

.40

(10.16)

.55

(10.16)

.55

(10.16)

.55

(10.16)

DC

.105 /.103

.126 /.124

1.77

(44.96)

2.43

(61.72)

2.50

(63.5)

3.25

(82.55)

E

.3135 /.3115

.376 /.374

D Hub Lengths

.38

(9.65)

.410

(10.41)

.69

(17.53)

.410

(10.41)

.19

(4.83)

.25

(6.35)

.31

(7.87)

*

*Size 2.8 can be pressure plate mounted using the long hub. The F` dimension shown for size 2.8 is for pressure plate mount using the long hub.

** No thru bore with manual release option.

A

1.925

(48.90)

2.55

(64.77)

2.50

(63.50)

3.32

(84.33)

71

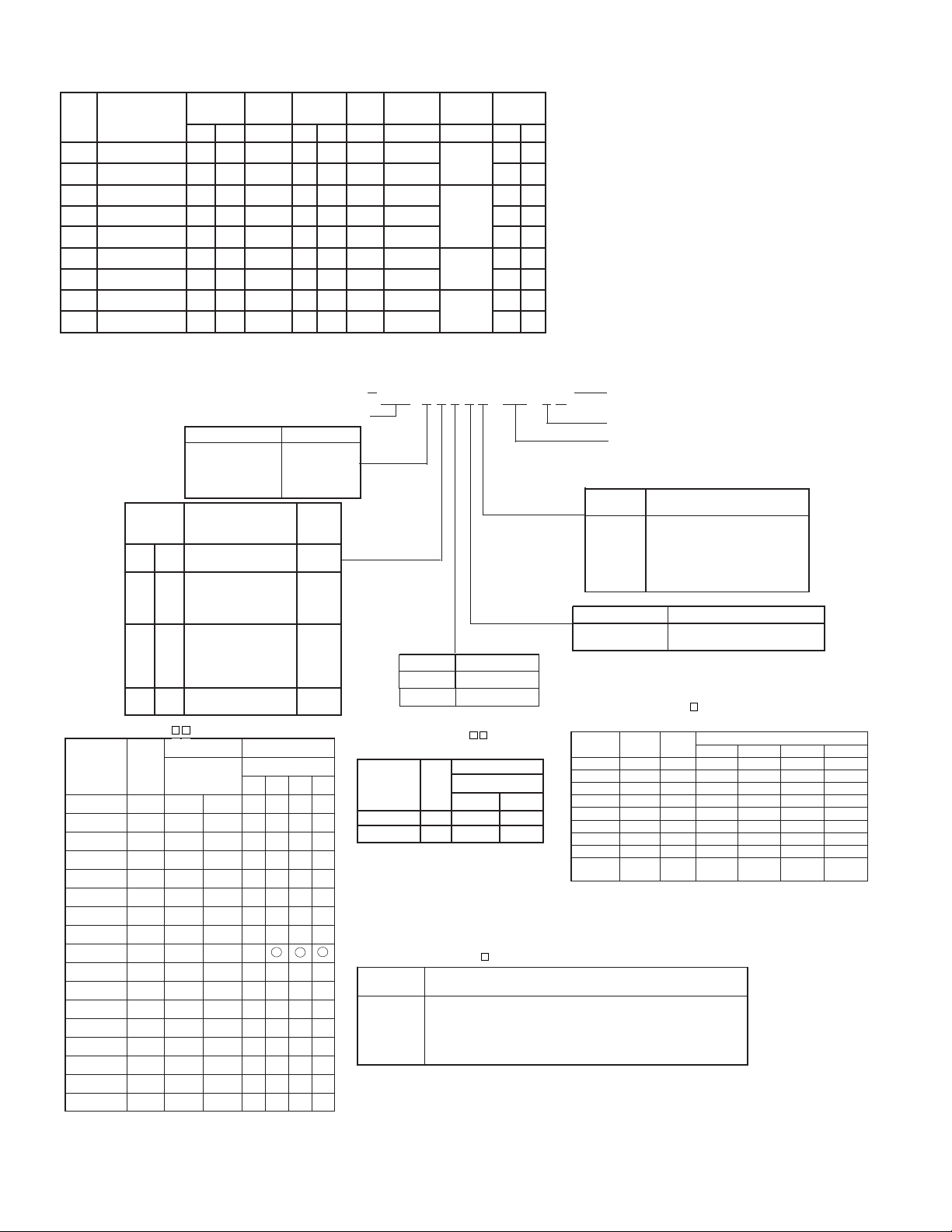

Series 320 Continued

Engineering Specifications

Nominal

Size Part Number

1.2D 3-20-2401G-XX-XX 3 .34 Dynamic .4 .181 7 7.02 x 10

3-20-2501G-XX-XX

1.2H

1.8D 3-20-4401G-XX-XX 7 .79 Dynamic 1.1 .499 10 4.8 x 10

3-20-4501G-XX-XX

1.8H

1.8D 3-20-4601G-XX-XX 15 1.69 Dynamic 1.1 .499 10 4.8 x 10

2.0D 3-20-5401G-XX-XX 18 2.03 Dynamic 1.2 .544 12.5 2.23 x 10

3-20-5501G-XX-XX

2.0H

2.8D 3-20-7401G-XX-XX 35 3.95 Dynamic 2.0 .91 17 2.3 x 10

3-20-7501G-XX-XX

2.8H

For holding applications only. Set Screws located 120° from keyway.

Static

Torque

lb-in Nm Type lbs kg (watts) oz-in-sec

5

15

30

50

.56

1.69

3.39

5.65

Friction

Material

Holding

Holding

Holding

Holding

Approx

Electric

Weight

.4 .181 9 7.02 x 10

1.1 .499 10 4.8 x 10

1.2 .544 12.5 2.23 x 10

2.0 .91 17 2.3 x 10

Power

Hub and

Disc Inertia

Thermal

Capacity

2

HP-sec/min in mm

-5

Consult

Factory

-5

-4

-4

-4

-3

-3

-3

-3

.26

.32

.17

1/2

1/2

1/2

1/2

1/2

Maximum

Bore

3/8 9

3/8 9

12

12

12

1/2 12

1/2 12

12

12

BACK TO T ABLE OF CONTENTS

Ordering

Information

Character

Size

1.245

4

Size

6

1.8

9

5

4

5

Size

3

2.0

6

7

Size

2.845

Table 1: 320-44010 - -JD

Characters

to insert

0A

0B

0C

0D

0E

0F

0G

0H

0J

05

06

07

08

09

10

11

12

Set screws located 120° from keyway.

Hubs are provided without keyway.

*Keyseats made to ANSI B17.1 standard.

72

Bore

3/16

3/16

1/4

1/4

5/16

5/16

3/8

3/8

1/2

5

6

7

8

9

10

11

12

* *

Keyway Size*

Width (in.) x

Depth (in.)

Group “3” Armature Acting Brake.

320 = For AAB-R Models

AAB-R Unit Sizes Part Number

1.2

1.8

2.0

2.8

Nominal Static Torque

(lb-in)

3 Dynamic

5 Holding

7 Dynamic

15 Dynamic

9 Dynamic

15 Holding

18 Dynamic

30 Holding

15 Dynamic

25 Holding

7 Dynamic

35 Dynamic

50 Holding

Bores Available

Mag Body Size

1.8 2.01.2

X

N/AN/A

1/321/16

X

N/AN/A

1/321/16

X

N/AN/A

1/321/16

X

N/AN/A

3/643/32

1/161/8

1 mm2 mm

1 mm2 mm

1 mm2 mm

1 mm2 mm

1.4 mm3 mm

1.4 mm3 mm

1.8 mm4 mm

1.8 mm4 mm

2

4

5

7

List

Adder

---

---

--$20.00

$10.00

---

---

---

---

---

---

---

---

2.8

X

X

X

X

X

X

X

X

X

X

1

1

1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

320-4401G-0H-JD

Options – Table 3

Voltages – Table 2

Hub bore and Keyway – Table 1

For Double “D” Bores See Table 1A

Numeral

Enclosure type

Characters

to insert

E

Brake release indicator (NC)

F

Brake release indicator (NO)

G

Standard - GGA Friction Material

J

CCW manual release rotation

S

Carrier ring friction disc

Numeral or Letter

1

A-Z

Modification

Options

Standard Unit

Reserved for Mounting Plates

0 None

2 Band seal

Table 1A: 320-44010 - -JX

(Double “D” Bores)

Characters

to insert

Bore

*

*

Bores Available

Mag Body Size

1.2 1.8H

0F 5/16 X X

0H 3/8 X X

NOTE: Can be used up to 15 lb-in for

holding.

Table 3:

Options 320-44010-0H-J

A

Basic Brake, Magnet Body Mounted, Long Hub

D*

Basic Brake, Pressure Plate Mounted, Short Hub*

G*

Short Hub, Pressure Plate Mounted with Maintained Manual Release*

H

Long Hub with Maintained Manual Release, Size 2.8 Only

X

Double “D” Friction Disc, 1.2H, 1.2D, 1.8H

Y

*Short hub not required for size 2.8 pressure plate mount.

Option X with Maintained Manual Release Pressure Plate Mounted

*

Table 2: 320-44010-0H- D

Standard Coil Voltage

Character

*For external in-line rectifier

(for internal rectifier, add $30.00 list)

NOTE: 65

in-line rectifiers

OptionsCharacters

Voltage

to Insert

C 12 Vdc - .632 .826 1.04 1.37

E 24 Vdc - .307 .421 .53 .70

G 48 Vdc - .158 .216 .27 .36

J 90 Vdc - .076 .123 .13 .17

K 103 Vdc - .085 .115 .121 .140

L 180 Vdc - .039 .060 .069 .09

N 115 Vac $50.00 .085 .115 .140 .140

P 230 Vac $50.00 .044 .059 .075 .097

115/230

Z

Vac

o

C maximum ambient temperature for all external

*

List

Adder*

$50.00 .085/.044 .115/.059 .140/.075 .140/.097

Current Rating in Amps

Size 1.2 Size 1.8 Size 2.0 Size 2.8

NOTE: Final part number may change due to specifications or options selected or

other product design considerations. A number such as a 2, 3, 4 etc., in the 12

position is used to designate a unique brake (custom) and can only be assigned by

Stearns Design Engineering Department.

Modifications are available - see AAB Modification Section.

th

Loading...

Loading...