Stearns 87800 Series Parts List

®

Spring-Set Disc Brakes

P/N 8-078-927-08

effective 10/06/10

Installation, Service Instructions and Parts List for

87,800 Series, Division 2 (rev. B)

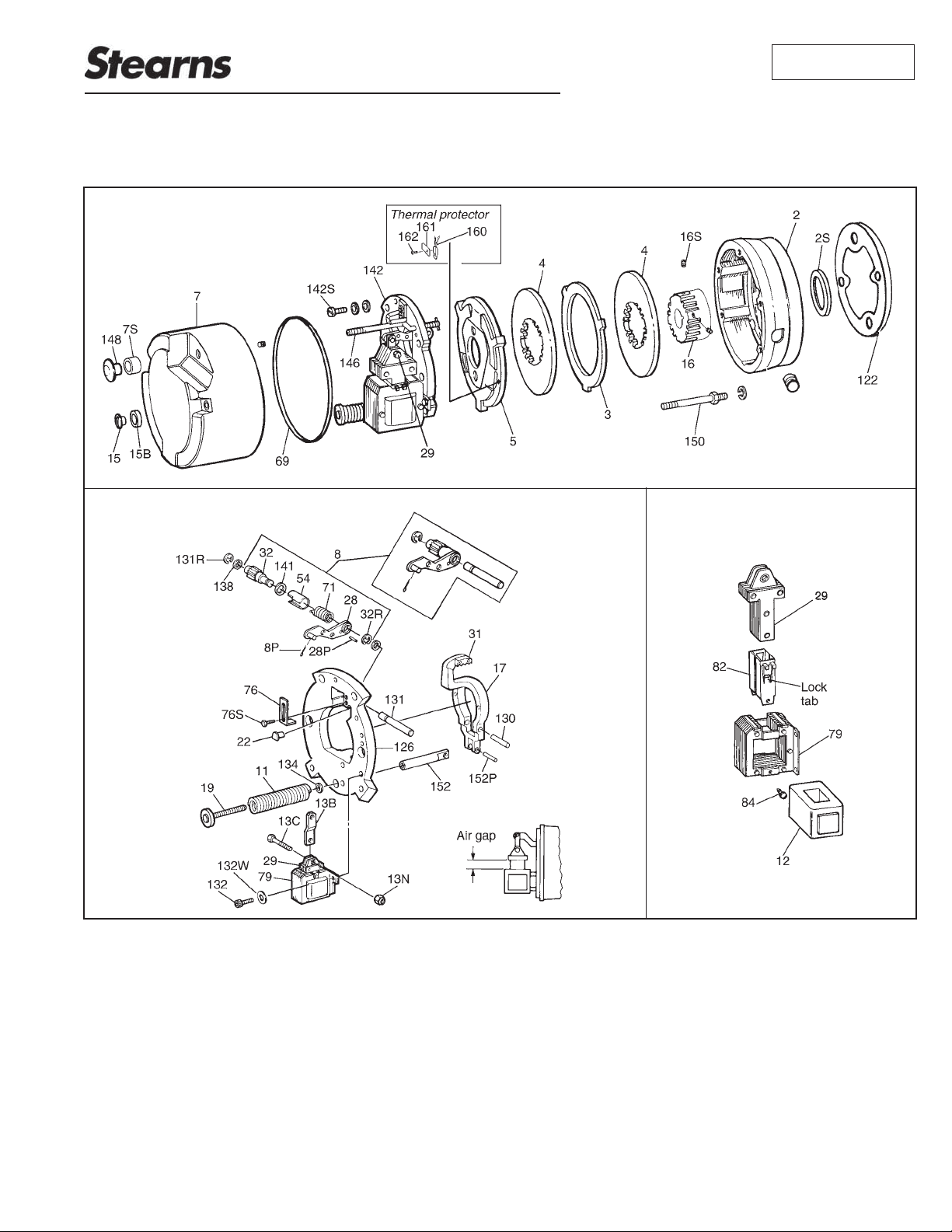

Figure 1

Important

Please read these instructions carefully

before installing, operating or servicing your

Stearns Brake. Failure to comply with these

instructions could cause injury to personnel

and/or damage to property if the brake

is installed or operated incorrectly. For

definition of limited warranty/liability, contact

Rexnord Industries, Inc.,

(414) 272-1100.

Caution

1. Installation and servicing must be

made in compliance with all local safety

codes including Occupational Safety

and Health Act (OSHA). All wiring and

electrical connections must comply

with the National Electric Code (NEC)

and local electric codes in effect. For

additional information refer to the

Underwriters Laboratory (UL) website

at: http:/ul.com/hazloc/codes.html

This brake may not be suitable for 2.

use in certain atmospheres containing

explosive gases and dusts. HazLoc

inspection authorities are responsible

for verifying and authorizing the use of

suitably designed and installed HazLoc

equipment. When questions arise consult

local Authority Having Jurisdiction (AHJ).

To prevent ignition of hazardous atmospheres, disconnect product from supply

circuit before opening. Keep assembly

tightly closed when in operation.

Also, to prevent an electrical hazard,

disconnect power source before

working on the brake. If power

disconnect point is out of sight, lock

disconnect in the off position and tag to

prevent accidental application of power.

Make certain power source conforms to 3.

the requirements specified on the brake

nameplate.

Be careful when touching the exterior 4.

of an operating brake. Allow sufficient

time for the brake to cool before

disassembly. Surfaces may be hot

enough to be painful or cause injury.

Do not operate brake in hazardous 5.

atmosphere with housing removed and

supply circuit connected.

Ins6. tallation and maintenance should be

performed only by qualified personnel

familiar with the construction and

operation of the brake.

For proper performance and operation, 7.

only genuine Stearns parts should be

used for repairs and replacements.

After usage, the brake interior will 8.

contain burnt and degraded friction

material dust. This dust must be

removed before servicing or adjusting

the brake.

DO NOT BLOW OFF DUST using

an air hose. It is important to avoid

dispersing dust into the air or inhaling

it, as this may be dangerous to your

health.

a) Wear a filtered mask or a respirator

while removing dust from the inside of

a brake.

b) Use a vacuum cleaner or a soft brush

to remove dust from the brake. When

brushing, avoid causing the dust to

become airborne. Collect the dust in a

container, such as a bag, which can be

sealed off.

Do not run motor with the brake in 9.

the manual release position to avoid

overheating of friction disc.

Do not lubricate any parts of the brake.10.

Do not adjust brake torque. The normal 11.

static torque is factory pre-set and

should not be altered.

General Description

The 87,800 Series, Division 2 is a springset, electrically released disc brake for

controlled stopping and holding of a load.

It is self-adjusting for friction disc wear and

mounts directly to a NEMA C-face motor

with 8-1/2” (AK) register and a 7-1/4” (AJ)

bolt circle.

The brake is Listed by Underwriters

Laboratories, Incorporated for Division

2 - normally not hazardous location. The

Class and Group designation is shown on

nameplate. The listing includes brakes for

attachment to TENV or TEFC motor.

The listing marks on the brake apply only to

the brake, not to the driving equipment. In

the case of another mounted brake, neither

brake nor motor are Listed unless both are

Listed. The listing marks of both the brake

and the motor must be in agreement as to

the Class and Group rating.

Note: Fanguard-mounted brakes requiring

IP54 & IP55 protection may require additional

sealing measures beyond seals provided with

this brake. Pressurized sprays aimed at the

fan and brake hub surfaces can result in fluid

migration along the motor shaft and keyway,

and into the brake. The use of an appropriate

sealant, such as RTV, or a forsheda seal is

advised.

The brake has a single-phase solenoid

coil for operating on alternating current.

The nominal static torque is factory set.

Standard NEMA voltage coils are available

in Class A style only.

Operation

Each brake assembly consists of one to

three molded friction discs fitted over a

hub attached to or driven by a motor shaft.

The friction disc(s) are located alternately

between an endplate, stationary disc(s) and

a pressure plate. The stationary disc(s) and

pressure plate are restrained from rotating

by the endplate. A solenoid, lever system,

and a pressure spring are located on a

support plate. A fitted housing, attached to

the endplate, encloses the working parts.

The housing also provides location and

support for a manual release rod.

The release of the brake occurs when

the solenoid coil is energized, causing

the solenoid plunger to travel a specified

distance and, through the lever system,

overcome the pressure spring force. The

lever system in its travel disengages from

the pressure plate which permits the friction

discs to rotate when the motor is energized.

When the motor and solenoid coil are

de-energized, the pressure spring moves

the lever system toward the pressure plate,

applying a force to stop the rotation of the

friction discs.

The brake is equipped with a manual

release rod, which, when activated,

sufficiently releases the brake without

energizing the solenoid coil, permitting

manual movement of the drive system,

however drag may be noted. When the

solenoid is energized, the manual release

rod returns to its initial position or may

be manually reset and permits the brake

to set when the solenoid coil is again

de-energized.

Note: The motor should not be run with

the brake in the manual release position to

avoid overheating of friction discs.

Installation Procedure - 87,800

Re1. move manual release knob (148) (0n

pull type), housing nuts (15) & housing (7).

Depress sol2. enoid plunger (29) and pull

release rod (146) back to lock brake

mechanism in manual release position

or wire the plunger (29) to frame (79).

Note: For proper operation in the

horizontal position, mount brake so

that solenoid plunger (29) is above

the frame (79) when installed. The

brake may be mounted, if specifically

modified, vertically above or vertically

below the motor. A one disc brake

vertically below is not modified. If motor

is to be ceiling or horizontally wall

mounted, brake must be oriented so

the solenoid plunger is above frame

when motor is installed.

Disconnect solenoid coil lead wires 3.

at solenoid. If brake is supplied

with heater it will be necessary to

disconnect heater lead wires.

Remove entire support plate 4.

assembly (142) by evenly unscrewing

and removing screws, conical

spring washers, and flat washers

(142S, 142W, and 142X). Optional

switch TSW1, if installed, may be

Page 2

disconnected at this time as support

plate assembly (126) is being

separated from the endplate.

Disconnect motor cut off thermal 5.

protector TSW2 (160). Remove

pressure plate (5), friction disc(s) (4),

stationary disc(s) (3) and the hub

(16). Take note of position of the

protector(s).

Attach endplate (2) to NEMA C-face of 6.

motor using four 1/2” diameter socket

head cap screws (not supplied) torque

per manufacturer’s specifications

(545 lb-in for cast iron). (Head of cap

screws must not project above friction

surface.) C-face mounted brakes must

be carefully aligned within .004” on

concentricity and face runout. Shaft

runout should be within .002” T.I.R.

Maximum permissible shaft endfloat is

.020”.

Note 1: Vertically mounted brake will

have special pins which guide spacer

springs and, in some cases, spring

washers. Note color coded sequence of

springs and location of washers,if used.

Note 2: If motor is to be ceiling

mounted after assembly, entire brake

will have to be rotated 180° or “upside

down” so it will be positioned with

solenoid plunger (29) above frame

when final assembly is mounted on

ceiling. Similarly, for horizontal wall

mounting, rotate 90°.

Note 3: The brake nameplate states

mounting position; “horizontal, vertical

above or vertical below.” The brake

must be mounted in that position.

Horizontal brakes rated 35 lb-ft and

less do not require modification to be

mounted vertical below.

Note 4: A dimple drilled into the motor

shaft for the hub set screw (16S),

90° from the key is recommended for

vertical mounting.

Position hub (16) and key (by 7.

customer) on the motor shaft so

outboard face of hub will protrude

approximately 1/32” to 1/16” beyond

face of last outboard friction disc.

(Position man be determined by

assembling friction disc(s) and stationary

disc(s) onto hub, noting hub position,

and removing disc(s).

Torque set screw (16S) as follows: 3/8

dia. - 24 ft-lb & 1/2 diameter - 52 ft-lb.

Assemble friction discs, stationary 8.

discs and pressure plate in correct

sequence and position. If vertical style,

reassemble springs plus spacers in

proper position and sequence.

Note: Friction discs must be free to

slide on hub and the stationary disc(s)

and pressure plate must be free to

slide in endplate. I.D. of friction discs

may require filling to avoid binding on

the hub.

Reconnect motor cut off thermal

protector TSW2 and optional TSW1.

Be sure wires are not pulled tight,

and carefully reroute all wires when

mounting support plate, as originally

installed.

Mount support plate assembly (142) 9.

to endplate using screws and conical

spring washers (142S and 142W). Flat

washer (142X) is installed under the

conical spring washer. Torque these

screws (142S) to 50 lb-in nominal. Be

sure the assembly is mounted with the

solenoid plunger above the solenoid

frame on horizontally installed brakes.

(See Installation Procedure, Item 2

Note.)

Using tie wrap provided, install tie 10.

wrap so that wires are held away from

pressure plate.

Disengage manual release rod by 11.

depressing plunger sufficiently, to allow

release rod to retract or remove plunger

tie down.

Note: If release rod is not in manual

release position and has allowed the

mechanism to overadjust, the support

plate will not seat against the endplate.

It will have to be reset. In this case the

lever arm (17) throat will be near, or

touching, the pinion (32) teeth. Loosen

pressure spring nut (19) until pressure

spring (11) is free. Mount support

plate and retighten spring nut, do not

overtighten. Lift plunger to maximum

travel and release.

Manually depress solenoid plunger 12.

into the solenoid frame and release,

allowing it to snap up. Repeat this

process several times to set solenoid

air gap. (See Self-Adjust Maintenance

Section for proper air gap measurement

or corrective action for improper gap.)

Replace and/or remake connections

on all internal electrical hardware, as

originally installed. (See Section on

Electrical Connection of Brake.)

Complete external electrical connection. 13.

(See Section on Electrical Connection

of Brake).

Check that friction disc(s) rotates freely 14.

when the solenoid plunger is held firmly

against the solenoid frame. If binding or

sticking occurs, recheck Steps 6, 7 & 8.

Reinstall housing (7) and housing 15.

gasket (69) to endplate (2), being

careful to guide the manual release rod

(146) through seal (7S) in the housing.

Do not hang the housing from the

release rod, as this may bend the rod

making it inoperable. Install the housing

screws (15) and O-rings (15B).

Note: To meet the requirements for Class

II, Division 2 enclosure, the 87,800 Series

Brake must include the following seals and

gaskets shown in Figure 1:

a) Manual release rod seal (7S) pressed into

brake housing (7).

b) O-rings (15B) assembled between

housing (7) and housing screws (15).

c) Housing gasket (69) installed between

endplate (2) and housing (7).

d)Hub seal (2S) pressed into endplate (2).

e)Brake - motor gasket (122) positioned

between brake and motor.

When brake is disassembled or had been

used for a long period of time, replace

deformed or damaged seals and gaskets.

Electrical Connection of the Brake

CAUTION: Inverter Motor and Special

Control Systems This brake contains

either a single phase AC coil or DC coil

that requires instantaneous power within ±

10% of rating at the coil. A separate power

source is required when this brake is used

in conjunction with a motor or control system

that limits voltage or current input (i.e.

inverter motors) or causes a ramping of the

power supply.

Note 1: Be sure lead wires to coil are not

tight or pinched, and that leads will not be

rubbed by friction disc, trapped between

solenoid plunger and frame, caught between

lever arm and endplate, or by linkage.

Note 2: On brakes with space heater,

connect to appropriate power source. Heater

is to be energized continuously, even during

storage, to prevent condensation and

potential rusting.

The Series 87,800 Brake is equipped with

an AC single-phase coil. Connect single

voltage coil to any two leads on single or

three-phase motor of the same voltage

as the brake. Refer to brake nameplate

and coil number for correct voltage and

frequency. The brake can also be wired to

external switch contacts, providing proper

voltage other than that used to control the

motor with the motor and brake contacts

interlocked.

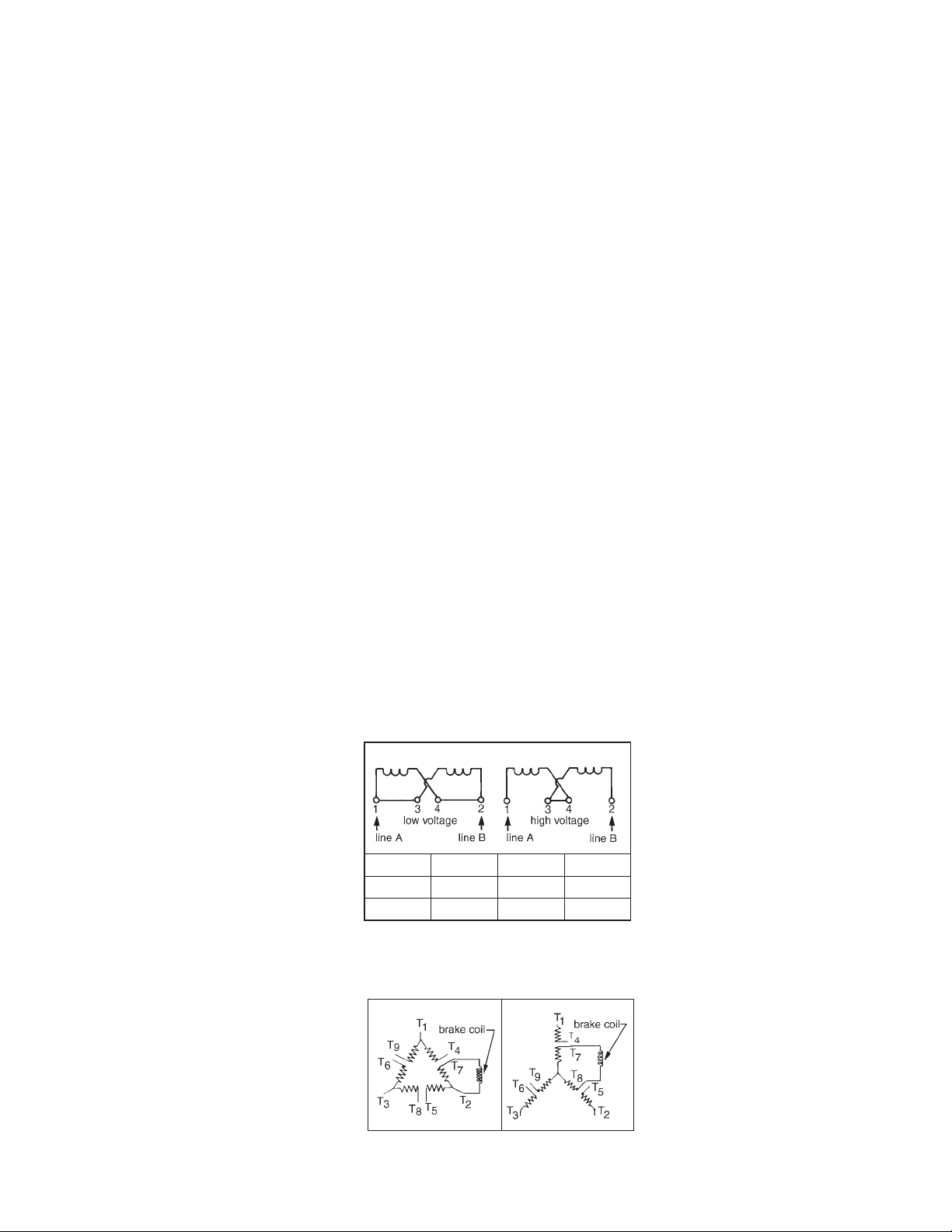

Method of connecting a dual voltage coil for

use on low or high voltage is shown in

Figure 2. Connect power source to coil

terminals.

Connecting AC solenoid coils to dual

voltage three-phase motors.

To connect a dual voltage coil through the

windings of a dual voltage motor, configure

the cil to match the low voltage rating of the

motor as shown in Figure 2. (Single voltage

coils should be equal to the low voltage

Class H Coil (colored)

For

Low voltage

High voltage 1 2 3 and 4

Power LIne

A

1 and 3

rating of the motor) Connect the brake coil

across the motor windings as shown in

Figure 3. Operation of the motor at either

voltage will properly operate the brake coil.

Figure 3

Power LIne

B

2 and 4

Tie Leads

—

The 87,800 Series Brake, Division 2 is built

for attachment to TENV or TEFC motors.

Brake operation should not exceed 2 or 5

cycles per minute respectively.

See Figure 4 (on next page) for proper

connections of protector switch TSW2,

optional warning switch TSW1, optional

heater and optional microswitches.

General Maintenance

Warning! Any mechanism or load held in

position by the brake should be secured to

prevent possible injury or damage to equipment before any disassembly of the brake

is attempted of the manual release knob is

operated on the brake. Observe all cautions

listed at the beginning of manual.

Note 1: Do not lubricate any parts of the

brake.

A. Coil replacement

For housing removal see 1. Installation

Procedure.

Disconnect coil leads.2.

For 10, 15, 25, and 50 lb-ft brakes, 3.

remove solenoid link screw (13C), nut

(13N) and lift out solenoid plunger (29).

a) For 35, 75 and 105 lb-ft brakes,

remove three mounting screws (132),

and lock washers (132W). A hex key

with shortened leg is helpful.

For metallic plunger guides (82), 4.

remove plunger guide screw(s) (84).

Remove both plunger guides (82) by

prying up on the flanges. Replace

plunger guides if worn or damaged.

S5. lide coil (12) out from solenoid frame

(79) in the direction of the coil terminals.

If necessary, tap coil lightly with a soft

hammer. If solenoid coil had burned out,

be sure to remove all foreign material

from the solenoid plunger (29) and

solenoid frame (79).

I6. nstall new coil (12) into solenoid frame

with same relative position as old coil.

Assemble new metallic plunger guides

(82) and plunger guide screws(s) (84).

Install plunger guide screw(s) (84).

R7. eassemble plunger into solenoid by

reversing Step 3.

a) For 35, 75 and 105 lb-ft brakes, slide

solenoid frame with the installed coil

over solenoid plunger (29) and attach to

support plate assembly (142) with three

mounting screws (132) and lock washers

(132W). Before tightening mounting

screws, align solenoid plunger and

solenoid frame so that mating surfaces

are parallel. This can be accomplished by

manually pulling the plunger down into its

sealed position.

b) Tighten the three mounting screws

(132) to 50-55 lb-in torque. Be certain

that three lock washers (132W) are

used.

O8. n dual voltage coils observe the

lead numbering sequence for proper

connection. (See Electrical Connection).

B9. e sure lead wires to coil are not tight

or pinched; leads must not be rubbed by

friction disc; leads must not be trapped

between solenoid plunger and frame.

C10. heck air gap per Self Adjust

Maintenance.

Page 3

Loading...

Loading...