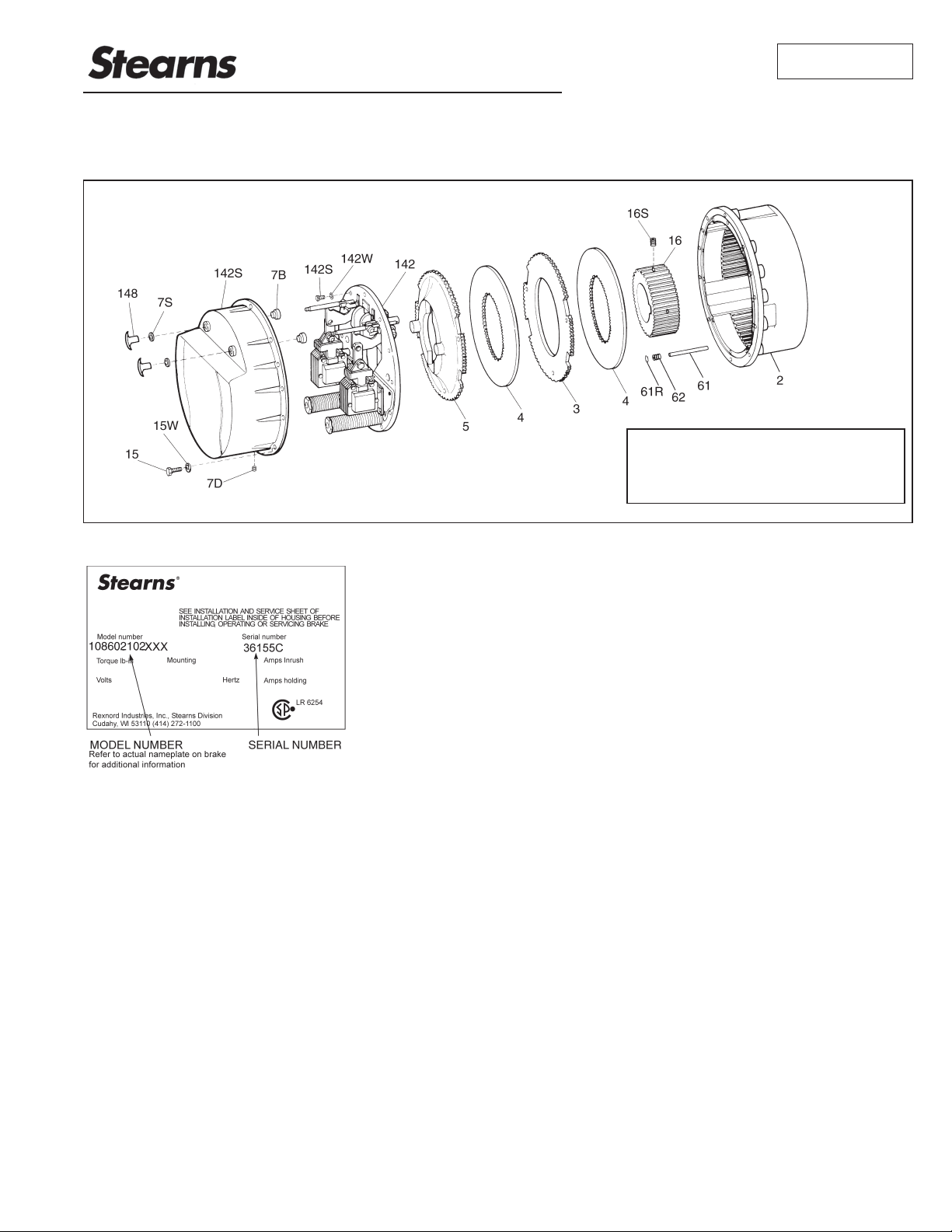

Stearns 86000 Series Installation and Service Instructions

®

Spring-Set Disc Brakes

Installation and Service Instructions

for 86,000 Series Self-Adjust Brakes

P/N 8-078-926-00

effective 06/28/12

Tools required for installation and servicing:

3/8” hex wrench 5/16” nut driver

5/16” hex wrench 1/4” screwdriver

3/16” hex wrench 8” adjustable wrench

Typical Nameplate

IMPORTANT

Please read these instructions carefully before

installing, operating, or servicing your Stearns

Brake. Failure to comply with these instructions

could cause injury to personnel and/or damage

to property if the brake is installed or operated

incorrectly. For definition of limited warranty/

liability, contact

Cudahy, WI

53110, (414) 272-1100.

Caution

1. Installation and servicing must be made

in compliance with all local safety codes

including Occupational Safety and Health Act

(OSHA). All wiring and electrical connections

must comply with the National Electric Code

(NEC) and local electric codes in effect.

2. Use of this brake in atmospheres containing

explosive gases and dusts must be in

accordance with NEC article 501. This

brake is not suitable for use in certain

atmospheres containing explosive gases

and dusts. HazLoc inspection authorities are

responsible for verifying and authorizing the

use of suitably designed and installed HazLoc

equipment. When questions arise consult

local Authority Having Jurisdiction (AHJ).

3. To prevent an electrical hazard, disconnect

power source before working on the brake.

If power disconnect point is out of sight,

lock disconnect in the off position and tag to

prevent accidental application of power.

4. Make certain power source conforms to

the requirements specified on the brake

nameplate.

5. Be careful when touching the exterior of an

operating brake. Allow sufficient time for brake

to cool before disassembly. Surfaces may be

hot enough to be painful or cause injury.

6. Do not operate brake with housing removed.

All moving parts should be guarded.

7. Installation and servicing should be performed

only by qualified personnel familiar with the

construction and operation of the brake.

8. For proper performance and operation, only

genuine Stearns parts should be used for

repairs and replacements.

9. After usage, the brake interior will contain

burnt and degraded friction material dust. This

dust must be removed before servicing or

adjusting the brake.

DO NOT BLOW OFF DUST using an air

hose. It is important to avoid dispersing dust

into the air or inhaling it, as this may be

dangerous to your health.

a) Wear a filtered mask or a respirator while

removing dust from the inside of a brake.

b) Use a vacuum cleaner or a soft brush to

remove dust from the brake. When brushing,

avoid causing the dust to become airborne.

Collect the dust in a container, such as a bag,

which can be sealed off.

10. Caution! While the brake is equipped with

manual releases to allow manual shaft

rotation, the motor should not be run with

the manual releases engaged, to avoid

overheating the friction disc(s).

General Description

This series of brakes is spring-set, electrically

released. They contain two to four rotating friction

discs (4) driven by a hub (16) mounted on the

motor or other shaft.

Note: Fan-guard mounted brakes requiring IP54

& IP55 protection may require additional sealing

measures beyond seals provided with this brake.

Pressurized sprays aimed at the fan and brake

hub surfaces can result in fluid migration along the

motor shaft and keyway, and into the brake. The

use of an appropriate sealant such as RTV or a

forsheda seal is advised.

Operating Principle

This series contain two or more friction discs

(4) assembled alternately between the endplate

(2) friction surface, stationary disc(s) (3) and

pressure plate (5). The stationary components

are restrained from rotating by being keyed into

the endplate. With the brake released, all disc

pack components are free to slide axially and the

friction disc(s) to rotate.

Brake release occurs when the solenoid coils

are electrically energized, causing the solenoid

plungers to travel a specified distance and through

a lever system, overcoming the pressure spring

force. This action releases the clamping force on

the disc pack, thereby allowing the friction disc(s)

and brake hub to rotate.

Brake sets and torque is produced when electric

current to the solenoid coils are interrupted,

thereby collapsing the solenoid magnetic fields.

The solenoid plungers return to their original

de-energized position allowing the lever arms to

move forward by virtue of the compressed torque

springs. This action compresses the disc pack

components which applies a retarding torque to

the brake hub and ultimately restores the brake to

a spring-set static condition.

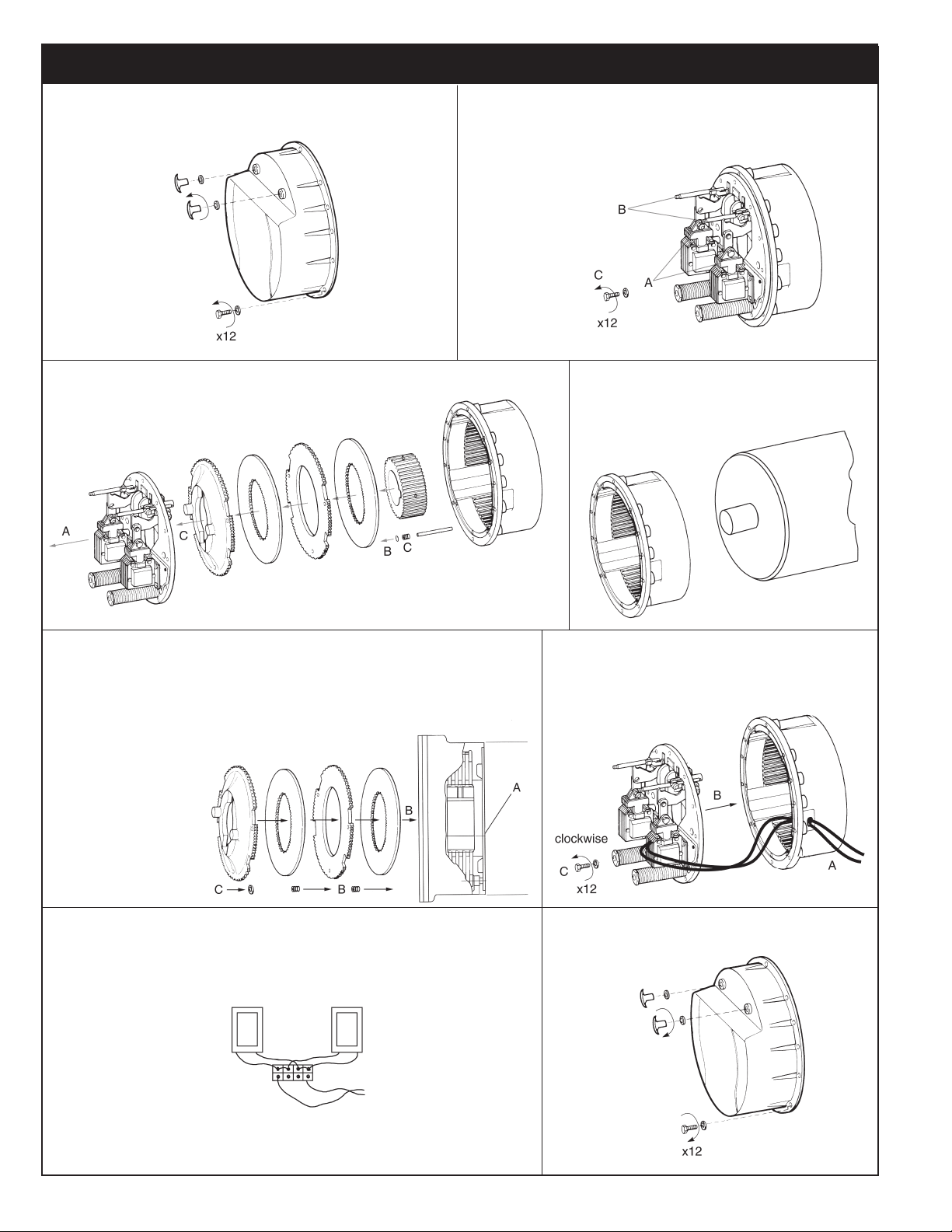

BRAKE MOUNTING

Remove manual release knobs.

Remove housing screws.

Remove housing.

counterclockwise

A. Lift off support plate.

B. Remove retaining clips.

C. Remove disc pack and centralizing springs.

A. Push plungers down.

B. Pull manual releases to hold plungers.

C. Remove support plate screws.

counterclockwise

A. Position endplate on motor register.

B. Insert four mounting bolts and tighten.

(Torque per manufacturer specification)

A. Position hub on shaft so that the inner spline

surface is flush with machined friction surface.

Torque to: 1/2” diameter – 620 lb-in (70 Nm)

5/8” diameter – 1325 lb-in (150 Nm)

3/4” diameter – 2150 lb-in (240 Nm)

7/8” diameter – 5200 lb-in (585 Nm)

1” diameter – 7100 lb-in (800Nm)

B. Reassemble disc pack in reverse order of removal.

C. Reinstall retaining clips.

For vertical

*

brakes, refer

to Service

Instruction Sheet

8-078-936-05.

AC coils are 50/60 hz, single phase rated. Power supply

to coil must not have current or frequency limiting output

that is less then the coil requirement. Voltage supply to

the coil must be within ±10% of nameplate rating.*

Caution: Keep

wiring away from

pinch points.

Coils are wired

in parallel with

a jumper on the

terminal strip on

the support plate.

* For DC voltages see sheet 8-078-950-00.

*

Power

Source

A. Route lead wires through conduit hole.

B. Position support plate on endplate.

C. Insert three mounting screws;

tighten to 85-100 lb-in.

Replace housing.

Tighten housing screws to 130 lb-in and

release knob to 50 lb-in.

clockwise

2

General Maintenance

Warning! Any mechanism or load held in

position by the brake should be secured

to prevent possible injury to personnel

or damage to equipment before any

disassembly of the brake is attempted or

before the manual release knob or lever is

operated on the brake. Observe all cautions

listed at the beginning of this manual.

Note: Do not lubricate any part of the brake

as this may cause malfunction and/or a loss

of torque.

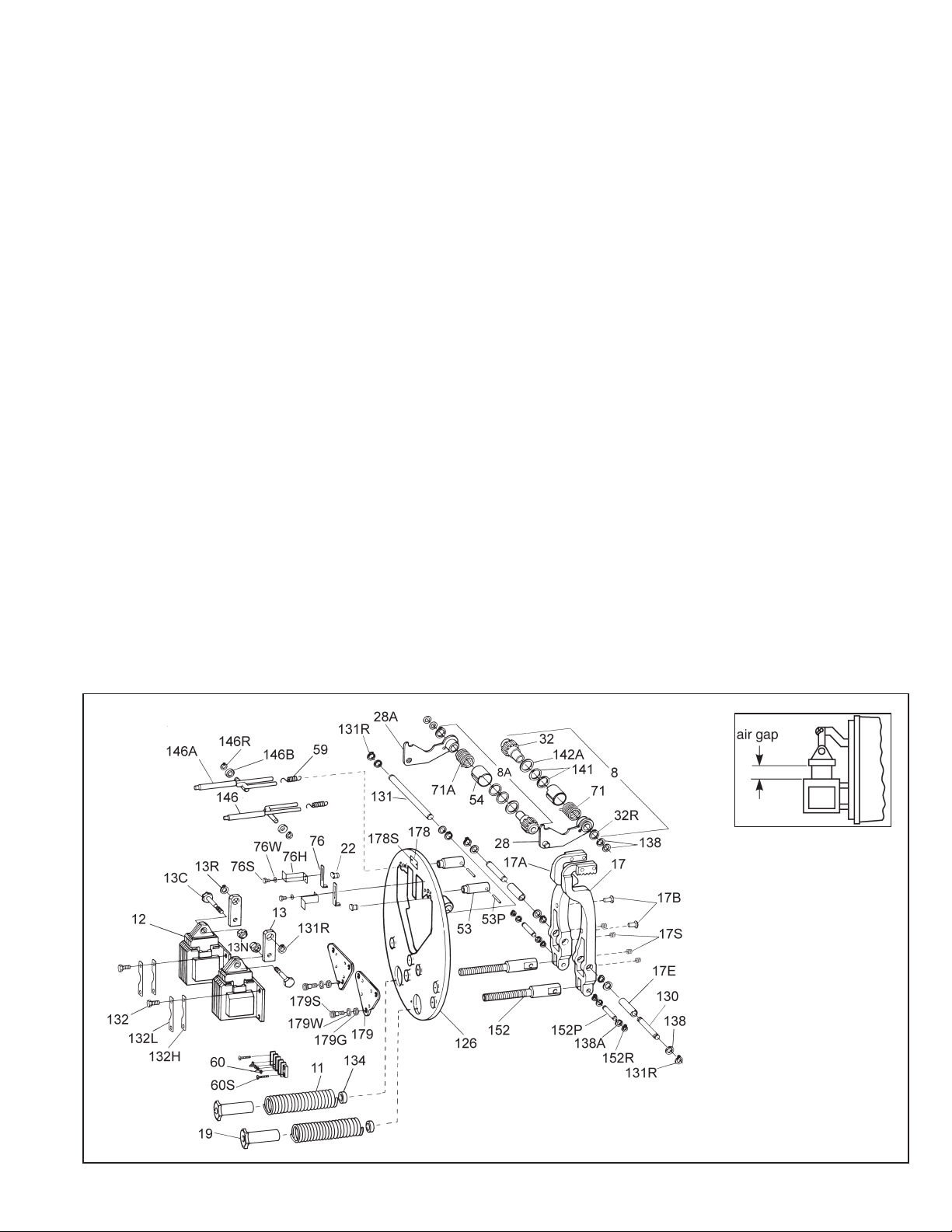

Troubleshooting

A. If brake does not stop properly,

coasts or overheats:

1. Check that manual release knobs are

not in released mode.

2. Check for excessively worn, charred or

broken friction discs.

3. Check that hub has not loosened and

shifted on motor shaft.

4. Check that friction discs slide freely over

hub. Clean hub and/or file burrs and

nicks if required.

5. Check that stationary disc(s) and/

or pressure plate can move freely in

endplate and that they are not warped

from overheating.

6. Check endplate slots for wear in the

areas where stationary disc(s) and/or

pressure plate make contact. Grooves

in slots can prevent free disc movement

and result in torque loss, stationary disc

or friction disc breakage.

7. On vertically mounted brakes, check

that springs are installed correctly and

that stationary disc(s) can slide freely

over vertical mounting pins. Check for

wear on plunger guide bracket.

8. Check that pressure spring nut (19) was

properly tightened. Correct compressed

spring height should be approximately

5-5/32” with new friction discs.

Measurement is from top face of support

plate to bottom of the spring nut.

9. Check solenoid air gap and other items

per Self-Adjust Maintenance, Section

III-C. Adjust if necessary

10. Check that solenoid linkages can move

freely. It requires approximately 28 lbs

of pressure to seat solenoid plunger to

frame on a correctly functioning brake.

11. Check voltage reading at coil terminals

against coil voltage rating.

12. Check that brake coils are energized at

the same time as, or prior to, motor and

de-energized at the same time, or after,

motor.

13. If stopping time exceeds 1 second, or if

the application requires more than five

stops per minute, check the thermal

requirements to stop load against the

thermal capacity of the brake.

14. Check for excessive voltage drop in

motor line when motor is started. Check

wire gauge of supply line against motor

starting current and solenoid inrush

current. Measure voltage drop at solenoid

coil terminals during maximum inrush

current condition. To accomplish this,

insert a block of wood, or other nonmagnetic material, between solenoid

plunger and frame. Block thickness

should approximately equal solenoid

air gap. Energize motor and brake

simultaneously, take reading and

immediately shut down. This is to prevent

motor, brake, or solenoid burnup.

B. If brake hums, solenoid pulls in

slowly, or coil burns out:

1. Check Items A-7, A-9, A-11 and A-14.

2. Check if shading coils are broken.

3. Check for worn plunger guides or

if plunger rubs on solenoid frame

laminations.

4. Check for worn solenoid plunger and

frame.

5. Check if solenoid is dirty.

6. Check if solenoid mounting screws have

loosened.

7. Check for worn or binding linkage.

For normal pressure required to seat

solenoid plunger to frame see A-10.

C. If brake is noisy during stopping

and/or friction discs shatter:

1. Check for worn motor bearings allowing

shaft runout.

2. On foot mounted brakes, recheck

alignment.

3. Check hub position on shaft. The

outboard face of hub should protrude

3/32” to 1/8” beyond face of outboard

friction disc.

4. Check motor shaft endfloat. It should not

exceed 0.020”.

5. Check concentricity of endplate and

C-face register. Alignment must be within

.007” concentricity and face runout. Shaft

runout should be within .002” TIR.

Vertical Spring Assembly

Refer to service sheet 8-078-936-05 for

proper spring and spacer positions when

brake is assembled for vertical orientation.

3

Loading...

Loading...