Page 1

Instruction Manual

RESIDENTIAL DIRECT VENT GAS W A TER HEATERS

NOT FOR USE IN MANUF ACTURED (MOBILE) HOMES

GAMA certification applies to

all residential gas water

heaters with capacities of 20

to 100 gallons with input rating

of 75,000 BTU/Hr. or less.

• For Your Safety •

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WA TER HEATER.

ALL TECHNICAL AND W ARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WA TER HEA TER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE WRITE TO THE COMPANY LISTED ON THE RATING PLA TE ON THE WA TER HEA TER.

KEEP THIS MANUAL IN THE POCKET ON HEA TER FOR FUTURE REFERENCE

PRINTED 1005 183774-001

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

1

Page 2

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very

important that the meaning of each safety message is understood by you and others who install, use or service this water heater.

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message and

how to avoid the risk of injury.

IMPORTANT DEFINITIONS

• Qualified Installer: A qualified installer must have ability equivalent to a licensed tradesman in the fields of plumbing,

air supply , venting and gas supply, including a thorough understanding of the requirements of the National Fuel Gas

Code as it relates to the installation of gas fired water heaters. The qualified installer must also be familiar with the

design features and use of flammable vapor ignition resistant water heaters, and have a thorough understanding of this

instruction manual.

• Service Agency: A service agency also must have ability equivalent to a licensed tradesman in the fields of plumbing,

air supply , venting and gas supply, including a thorough understanding of the requirements of the National Fuel Gas

Code as it relates to the installation of gas fired water heaters. The service agency must also have a thorough

understanding of this instruction manual, and be able to perform repairs strictly in accordance with the service guidelines

provided by the manufacturer.

• Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burning

appliances within this application. The gas supplier typically has responsibility for the inspection and code approval of

gas piping up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers also

offer service and inspection of appliances within the building.

• Piezo-Electric Spark Gas Ignition System: A combination of a piezo-electric spark generator , high voltage lead(s) and

a spark electrode(s) designed to ignite pilot burner gas at an appliance burner .

2

Page 3

GENERAL SAFETY

3

Page 4

TABLE OF CONTENTS

SAFE INSTALLA TION, USE AND SERVICE...............................2

GENERAL SAFETY ..................................................................3

T ABLE OF CONTENTS .............................................................. 4

INTRODUCTION ........................................................................4

Preparing for the New Installation...................................4

TYPICAL INST ALLA TION ...................................................... 5-6

LOCA TING THE NEW WA TER HEA TER..................................... 7

Facts to Consider About Location ............................... 7-8

Venting Clearances..........................................................8

Optional Wire Grill ............................................................9

Flue Extensions ................................................................ 9

Vertical Height (Extension Kit).......................................10

Horizontal (Extension Kit) .............................................. 10

Vent Inst allations .......................................................11-24

INST ALLING THE NEW WA TER HEATER ................................ 25

Water Piping ...................................................................25

T emperature-Pressure Relief V alve............................... 26

Filling the Water Heater............... .......... .......... .......... .....27

Gas Piping ................................................................ 27-28

Sediment Traps .............................................................. 28

Installation Checklist.......................................................29

LIGHTING & OPERA TING LABEL ............................................ 30

TEMPERA TURE REGULATION ................................................ 31

FOR YOUR INFORMATION .....................................................31

Start Up Conditions ........................................................ 31

Condensate ....................................................................32

Smoke/Odor....................................................................32

Thermal Expansion......................................................... 32

Strange Sounds..............................................................32

OPERATIONAL CONDITIONS..................................................32

Smelly Water .................................................................. 32

“Air” in Hot Water Faucets.............................................32

High T emperature Shut Of f System ............................... 32

PERIODIC MAINTENANCE ....................................................... 33

Venting System Inspection ............................................ 33

Burner Inspection...........................................................33

Burner Cleaning..............................................................33

Housekeeping ................................................................34

Anode Rod Inspection.................................................... 34

T emperature-Pressure Relief V alve Operation.............. 34

Draining ..........................................................................34

Drain Valve Washer Replacement................................. 35

LEAKAGE CHECKPOINTS ......................................................35

REPAIR P ARTS ....................................................................... 36

TROUBLESHOOTING .............................................................. 40

NOTES .............................................................................. 41-43

WARRANTY ..................................................................... Insert

INTRODUCTION

Thank Yo u for purchasing this water heater. Properly installed and

maintained, it should give you years of trouble free service.

Abbreviations Found In This Instruction Manual:

• CSA - Canadian Standards Association

• ANSI - American National Standards Institute

• NFPA - National Fire Protection Association

• ASME - American Society of Mechanical Engineers

• GAMA - Gas Appliance Manufacturer’s Association

This gas-fired water heater is design certified by CSA INTERNA TIONAL

under American National S tandard/CSA Standard for Gas W ater Heaters

ANSI Z21.10.1 • CSA 4.1 (current edition).

This gas-fired water heater is equipped with a piezo-electric spark

device used for pilot burner ignition, and complies with the St andard for

Manually-Operated Piezo-Electric Spark Gas Ignition Systems and

Components, ANSI Z21.77 • CGA 6.23.

PREPARING FOR THE INSTALLATION

1. Read the “General Safety” section, page 3 of this manual first and

then the entire manual carefully. If you don’t follow the safety rules,

the water heater will not operate properly . It could cause DEA TH,

SERIOUS BODIL Y INJURY AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, operation, and

maintenance of the gas-fired water heater. It also contains warnings

throughout the manual that you must read and be aware of. All

warnings and all instructions are essential to the proper operation

of the water heater and your safety . Since we cannot put everything

on the first few pages, READ THE ENTIRE MANUAL BEFORE

A TTEMPTING TO INST ALL OR OPERA TE THE WATER HEA TER.

2. The installation must conform with these instructions and the local

code authority having jurisdiction. In the absence of local codes,

installations shall comply with the National Fuel Gas Code ANSI

Z223.1/NFPA 54. This publication is available from the Canadian

Standards Association, 8501 East Pleasant V alley Rd., Cleveland

Ohio 44131, or The National Fire Protection Association, 1

Batterymarch Park, Quincy, MA 02269.

3. If after reading this manual you have any questions or do not

understand any portion of the instructions, call the local gas utility or

the manufacturer whose name appears on the rating plate.

4. Carefully plan the place where you are going to put the water heater.

Correct combustion, vent action and vent pipe installation are very

important in preventing death from possible carbon monoxide

poisoning and fires, see Figures 1 and 2.

Examine the location to ensure the water heater complies with the

“Locating the New Water Heater” section in this manual.

5. For California installation this water heater must be braced, anchored

or strapped to avoid falling or moving during an earthquake. See

instructions for correct installation procedures. Instructions may be

obtained from California Office of the St ate Architect, 400 P Street,

Sacramento, CA 95814.

6. Massachusetts Code requires this water heater to be installed in

accordance with Massachusetts 248-CMR 2.00: St ate Plumbing Code

and 248-CMR 5.00.

7. Complies with SCAQMD rule #1121 and districts having equivalent

NOx requirements.

4

Page 5

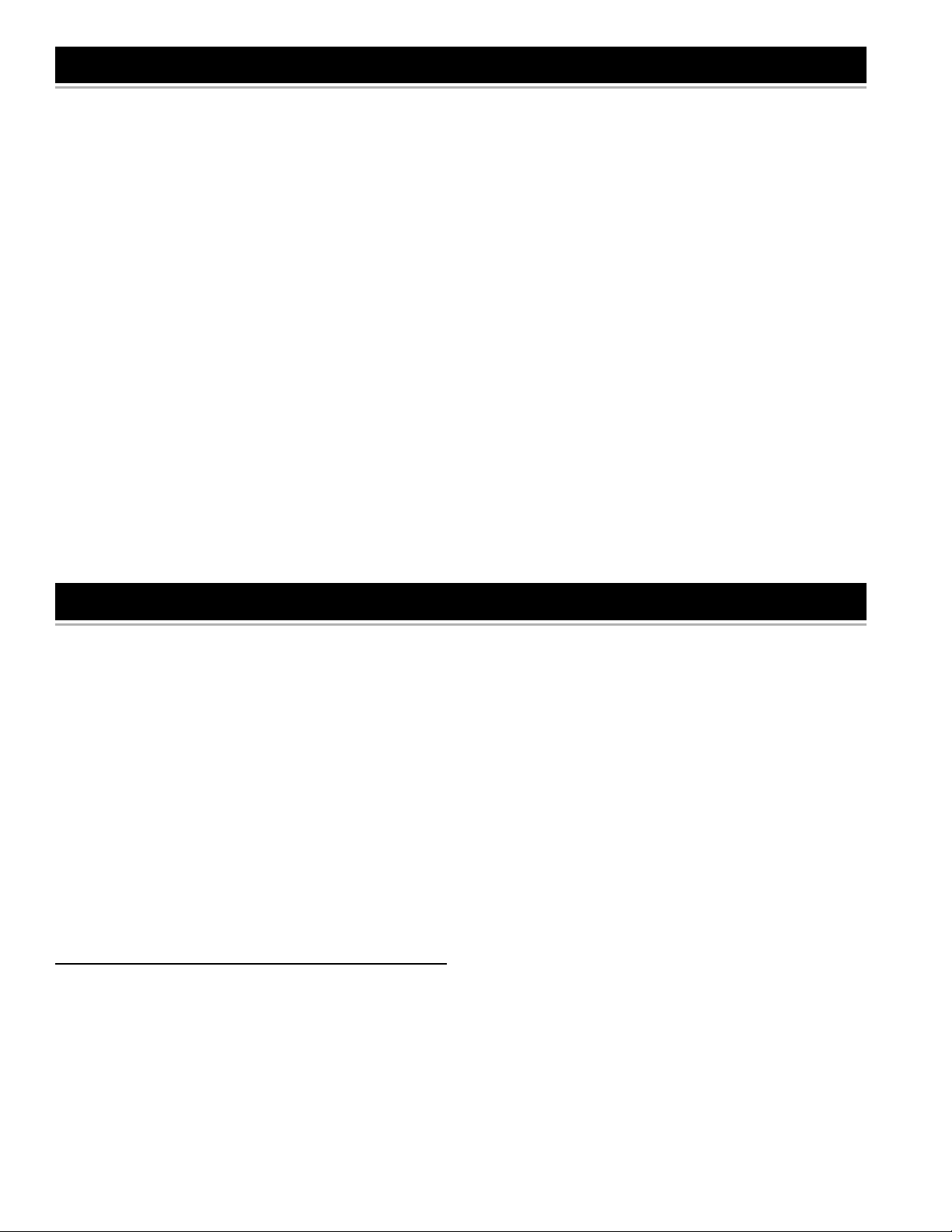

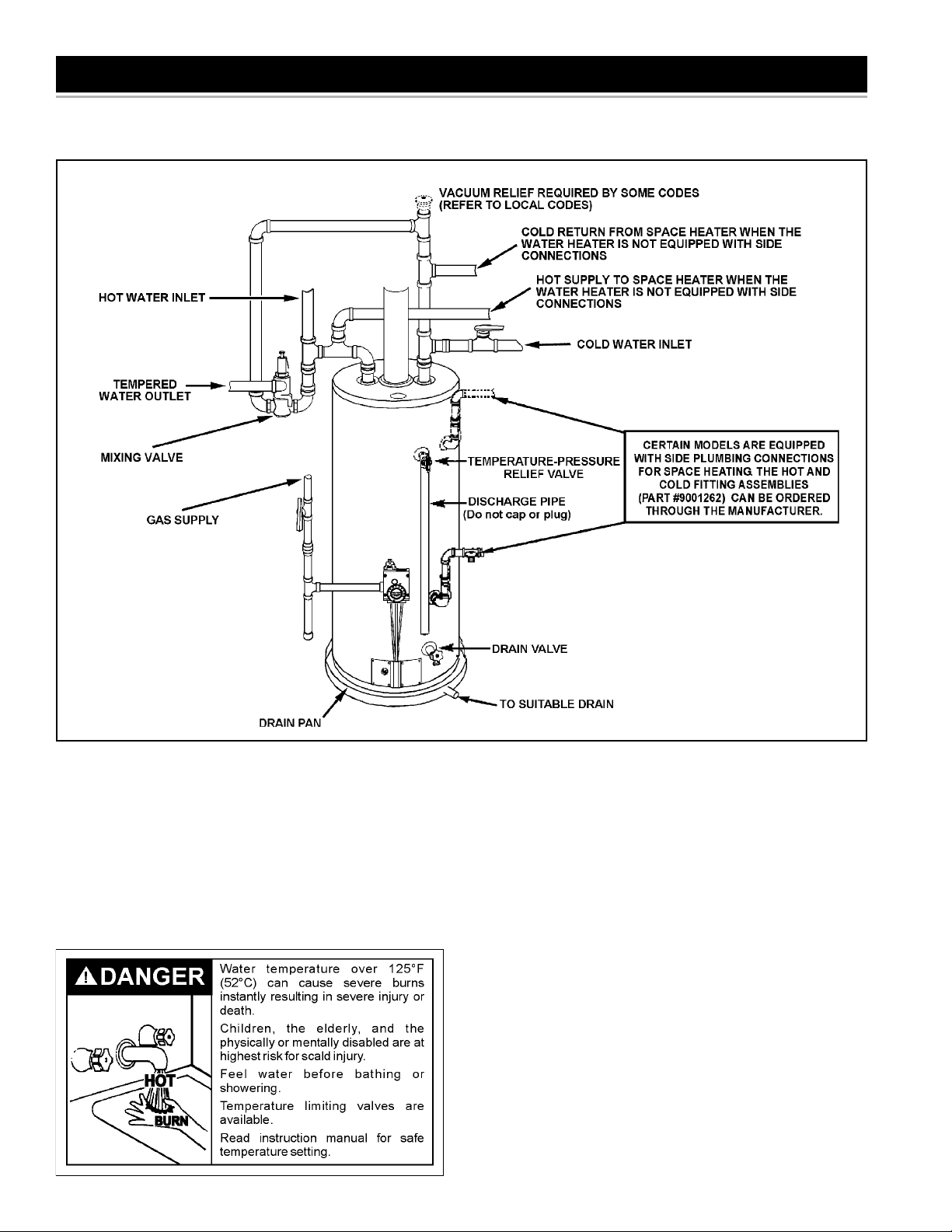

TYPICAL INSTALLATION

GET TO KNOW YOUR WATER HEATER - GAS MODELS

A Vent Assembly

B Flue Outlet

C Anode

D Hot Water Outlet

E Outlet

F Insulation

G Gas Supply

H Manual Gas Shut-off Valve

* INSTALL IN ACCORDANCE

WITH LOCAL CODES.

*DRIP LEG AS REQUIRED

BY LOCAL CODES.

I Ground Joint Union

J Drip Leg (Sediment Trap)

K Inner Door

L Outer Doors w ith Gaskets

M Union

N Inlet Water Shut-off Valve

O Cold Water Inlet

P Inlet Dip Tube

Q Temperature-Pressure Relief Valve

R Rating Plate

S Flue Baffle

T Thermostat

U Drain Valve

V Pilot and Main Burner

W Flue

X Drain Pan

Y Piezo Ignitor

Z Thermostat Shield (optional)

(V) PILOT & MAIN BURNER

(T) THERMOSTA T

*ALL PIPING MATERIALS TO BE

SUPPLIED BY CUSTOMERS.

FIGURE 1.

5

Page 6

TYPICAL INSTALLATION

MIXING VALVE USAGE

This appliance has been design certified as complying with Am erican N ational

Standard/CS A Standard for water heat ers and is considered suitable for:

Water (Potable) Heating: All models are “considered suitable for

water (potable) heating.”

Water (Potable) Heating and Space Heating: Certain models are

“considered suitable for water (potable) heating and space heating.”

Refer to the model and rating plate of the water heater.

FIGURE 2.

HOT WATER CAN SCALD:

Water heaters are intended to produce hot water. Water heated

to a temperature which will satisfy space heating, clothes

washing, dish washing, and other sanitizing needs can scald

and permanently injure you upon contact. Some people are

more likely to be permanently injured by hot water than others.

These include the elderly, children, the infirm or physically/

mentally handicapped. If anyone using hot water in your home

fits into one of these groups or if there is a local code or state

law requiring a certain temperature water at the hot water tap,

then you must take special precautions. In addition to using

the lowest possible temperature setting that satisfies your

hot water needs, a means such as a *Mixing Valve shall be

used at the hot water taps used by these people or at the

water heater. Mixing valves are available at plumbing supply

or hardware stores. Consult a Qualified Installer or Service

Agency. Follow mixing valve manufacturer ’s instructions for

installation of the valves. Before changing the factory setting

on the thermostat, read the “Temperature Regulation” section

in this manual, see Figures 109 and 110.

6

Page 7

LOCATING THE NEW WATER HEATER

FACTS TO CONSIDER ABOUT THE LOCA TION

Carefully choose an indoor location for the new water heater, because

the placement is a very important consideration for the safety of the

occupants in the building and for the most economical use of the

appliance. This water heater is not for use in manufactured

(mobile) homes or outdoor installation.

Whether replacing an old water heater or putting the water heater in a

new location, the following critical points must be observed:

1. The location selected should be indoors, as close as practical to the

outside wall through which the water heater vent is going to be

installed, and as centralized with the water piping system as possible.

The water heater, as all water heaters, will eventually leak. Do not

install without adequate drainage provisions where water flow will

cause damage.

2. Selected location must provide adequate clearances for servicing

and proper operation of the water heater.

Installation of the water heater must be accomplished in such a manner

that if the tank or any connections should leak, the flow will not cause

damage to the structure. For this reason, it is not advisable to install the

water heater in an attic or upper floor. When such locations cannot be

avoided, a suitable drain pan should be installed under the water heater.

Drain pans are available at your local hardware store. Such a drain

pan must have a minimum length and width of at least 2 inches (5.1 cm)

greater that the water heater dimensions and must be piped to an

adequate drain. Drain pan depth must allow for access to the outer

doors for servicing the pilot and burner.

INSTALLA TIONS IN AREAS WHERE FLAMMABLE LIQUIDS (VAPORS)

ARE LIKELY TO BE PRESENT OR STORED (GARAGES, STORAGE AND

UTILITY AREAS, ETC.): Flammable liquids (such as gasoline, solvent s,

propane [LP or butane, etc.] and other substances such as adhesives,

etc.) emit flammable vapors which can be ignited by a gas water heater’s

pilot light or main burner. The resulting flashback and fire can cause

death or serious burns to anyone in the area, as well as property damage.

If installation in such areas is your only option, then the installation must

be accomplished in a way that the pilot flame and main burner flame are

elevated from the floor at least 18 inches (45.7 cm). While this may

reduce the chances of flammable vapors, from a floor spill being ignited,

gasoline and other flammable substances should never be stored or

used in the same room or area containing a gas water heater or other

open flame or spark producing appliance. NOTE: Flammable vapors may

be drawn by air currents from other areas of the structure to the appliance.

Water heater life depends upon water quality, water pressure and

the environment in which the water heater is installed. Water heaters

are sometimes installed in locations where leakage may result in

property damage, even with the use of a drain pan piped to a drain.

However, unanticipated damage can be reduced or prevented by a

leak detector or water shut-off device used in conjunction with a

piped drain pan. These devices are available from some plumbing

supply wholesalers and retailers, and detect and react to leakage in

various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn off the

incoming water to the water heater when leakage is detected.

• Sensors mounted in the drain pan that turn off the water supply to

the entire home when water is detected in the drain pan.

• Water supply shut-off devices that activate based on the water

pressure differential between the cold water and hot water pipes

connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater while

at the same time shutting off its water supply .

7

Page 8

Also, the water heater must be located and/or protected so it is not

subject to physical damage by a moving vehicle.

This water heater must not be installed directly on carpeting. Carpeting

mu st be protected by metal or wood panel beneath the appliance

extending beyond the full width and depth of the appliance by

at least 3 inches (7.62 cm) in any direction, or if the appliance

is installed in an alcove or closet, the entire floor must be

co ve r ed by the panel. Failure to heed this warning may result in a

fire hazard.

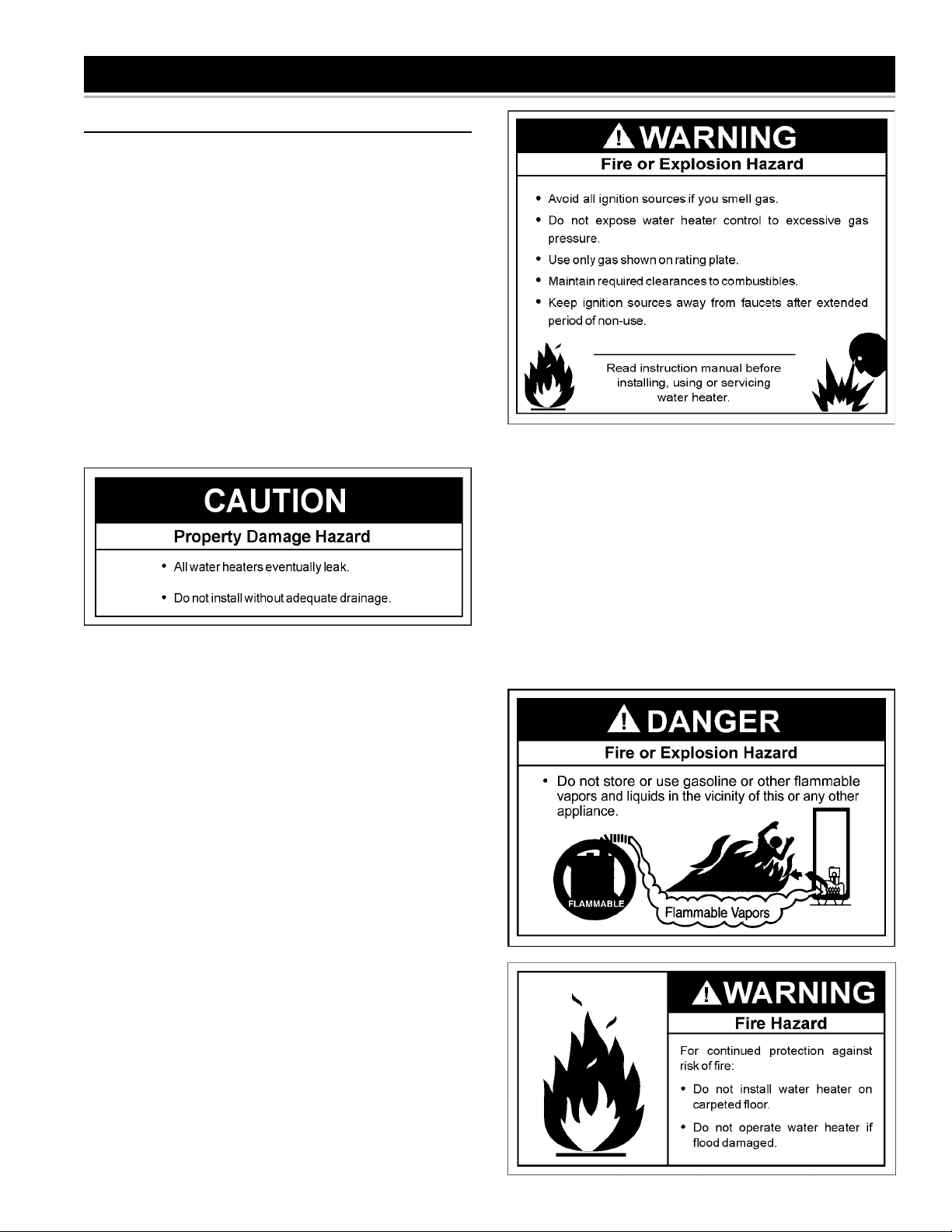

Minimum clearances between the water heater and combustible and

noncombustible construction are 0 inch at the sides, 0 inches from

back, 4”(10.2 cm) from front of jacket to closet door and 3”(7 .6 cm )

from top of jacket to combustible and noncombustible material. Minimum

vent clearance: 0 inches.

No vent damper , whether it is operated thermally or otherwise, is to

be installed on this direct vent water heater. Alteration of any p art

of the factory-furnished vent assembly could result in improper

operation due to restriction of flue gases and may cause carbon

monoxide poisoning.

Venting Clearances

When determining the installation location for a direct vent water heater ,

snow accumulation and drifting should be considered in areas where

applicable. See Figures 4 through 8 and items below.

• 18” minimum in all directions from any obstruction that may interfere.

• 18” minimum from the ground and 12 “ from ceiling overhangs.

• The direct vent terminal shall terminate at least 3 feet above any

forced air inlet located within 10 feet. See Figure 5.

• 9” minimum horizontally from or above any door, window or gravity

air inlet into the building (50,000 BtuH input or less.)

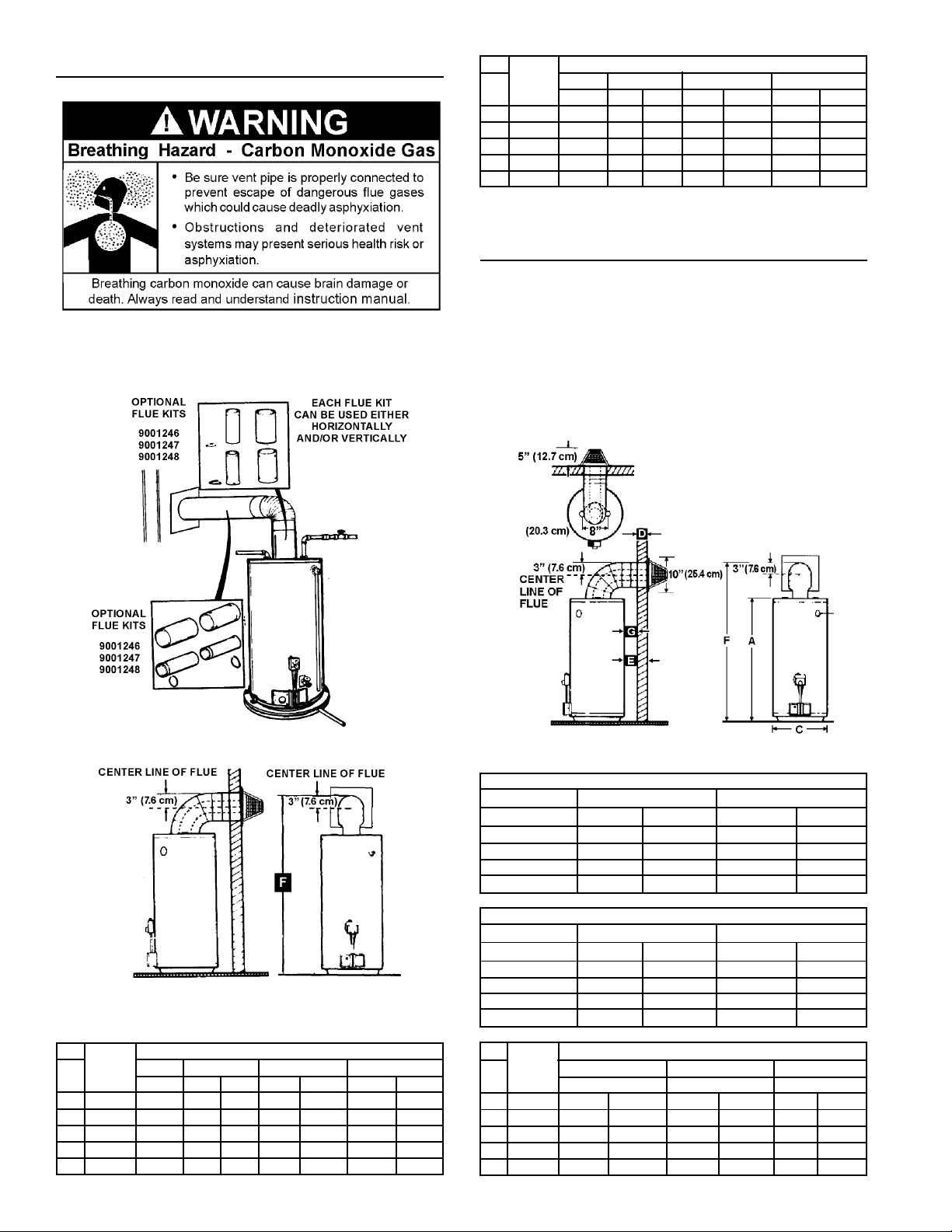

FIGURE 3.

NOTE: Provide 24 inches (61 cm) front clearance for servicing and

a adequate clearance between the jacket top and ceiling for servicing

the flue area.

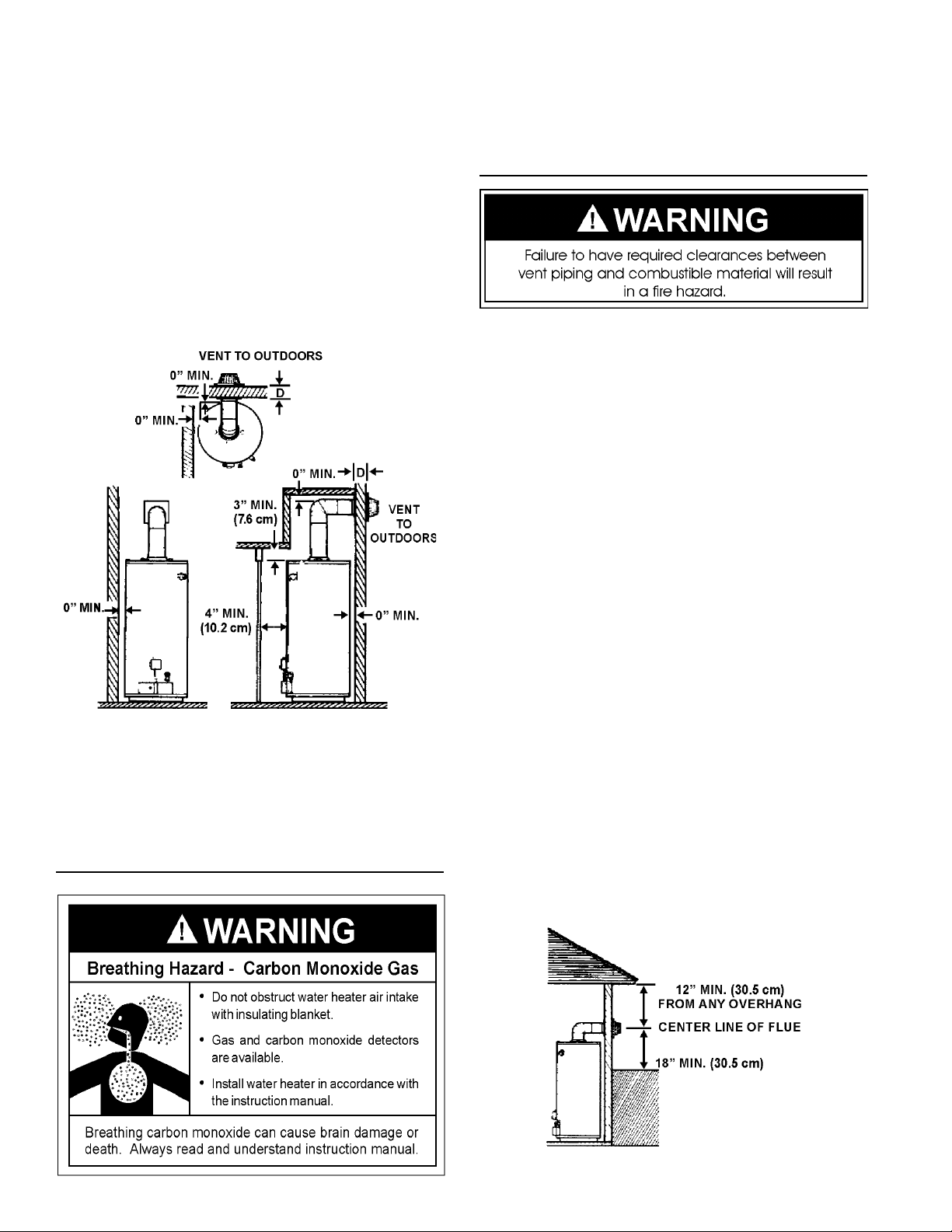

Combustion Air and Ventilation

• 12” minimum horizontally from or above any door, window or gravity

air inlet into the building (over 50,000 BtuH input).

• 12” minimum below any door, window or gravity air inlet into the

building (50,000 BtuH input or less).

• 18” minimum below any door, window or gravity air inlet into the

building (over 50,000 BtuH input).

• 18” minimum from other gravity or natural appliance outlet vents

when directly above or 135° to either side of center line. See Figure 6.

• 36” minimum from any outlet vents when directly below or 45° to

either side of center line. See Figure 7.

• 36” minimum in all directions from any other forced air appliance

outlet vent. See Figure 7.

• The location selection must provide clearances for servicing and

proper operation of the water heater. See Figure 8.

• Vent termination must not be within 4 feet of any items such as gas

meters, gas valves or other gas regulating equipment.

• Unless specified at time of ordering, a standard extension

kit (No. 9000687) is individually packaged and shipped with

the water heater.

FIGURE 4.

8

Page 9

FIGURE 5.

Some local codes may require a vent cap cover. Figure 9 shows the

optional wire vent cap protector available from the water heater

manufacturer.

A wire mesh chain link fence (see Figure 9) may be used instead of the

factory cover. Care should be t aken to maintain adequate ventilation

around the vent cap. If a chain link fence is installed, it must not be used

as a storage area for items that may block proper ventilation.

FIGURE 9.

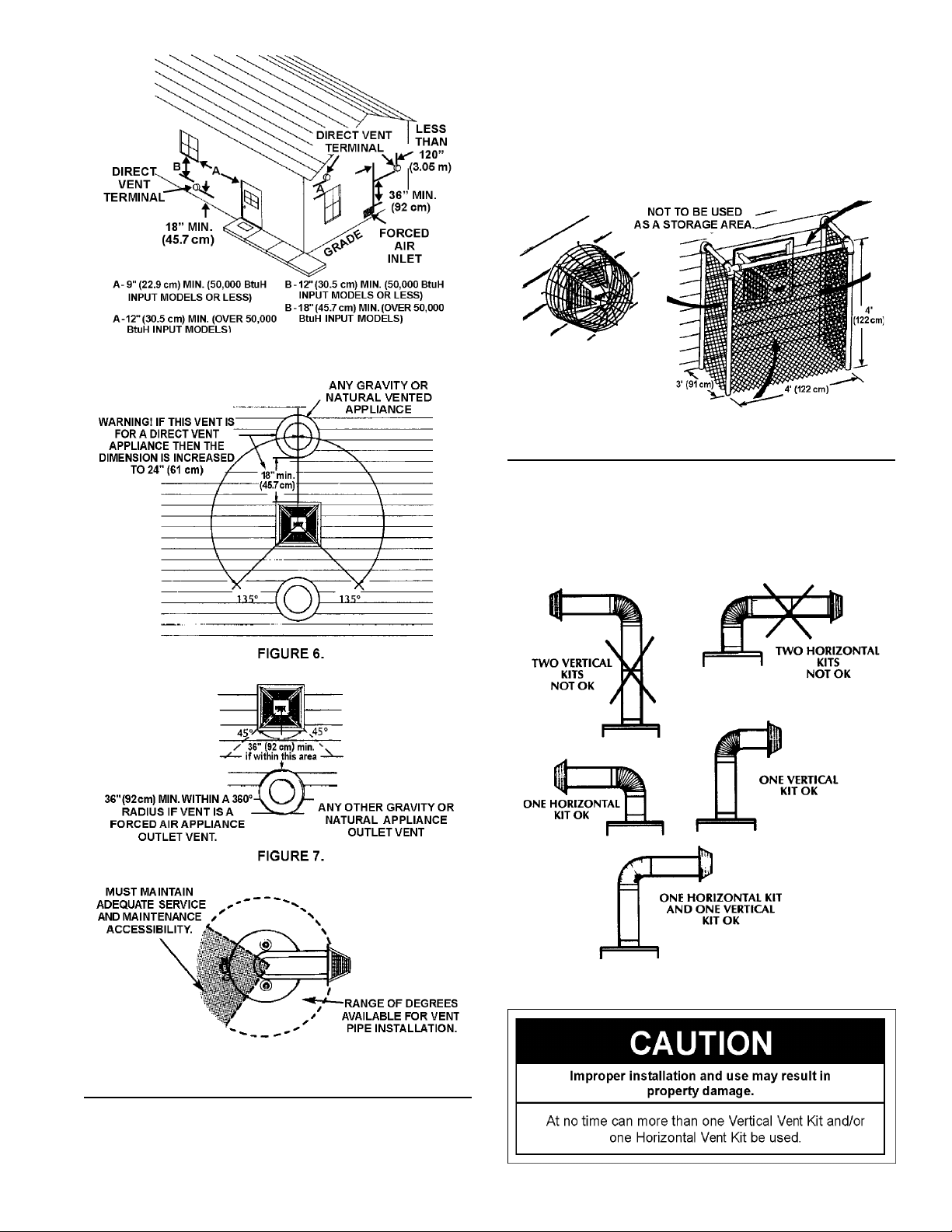

Flue Extensions

There are three optional extension kits available. Any combination of

the three kits can be chosen; however, only one kit can be used

vertically and/or horizontally, see Figures 10 & 11.

Unless otherwise specified at the time of ordering, a standard extension kit (9000687) is individually packaged and shipped within the water

heater carton.

FIGURE 10.

FIGURE 8.

Optional Wire Grill

When the water heater vent cap is low enough to be touched

accidentally , or is accessible to small children, installation of a

protective vent cover is recommended. See Figure 9.

9

Page 10

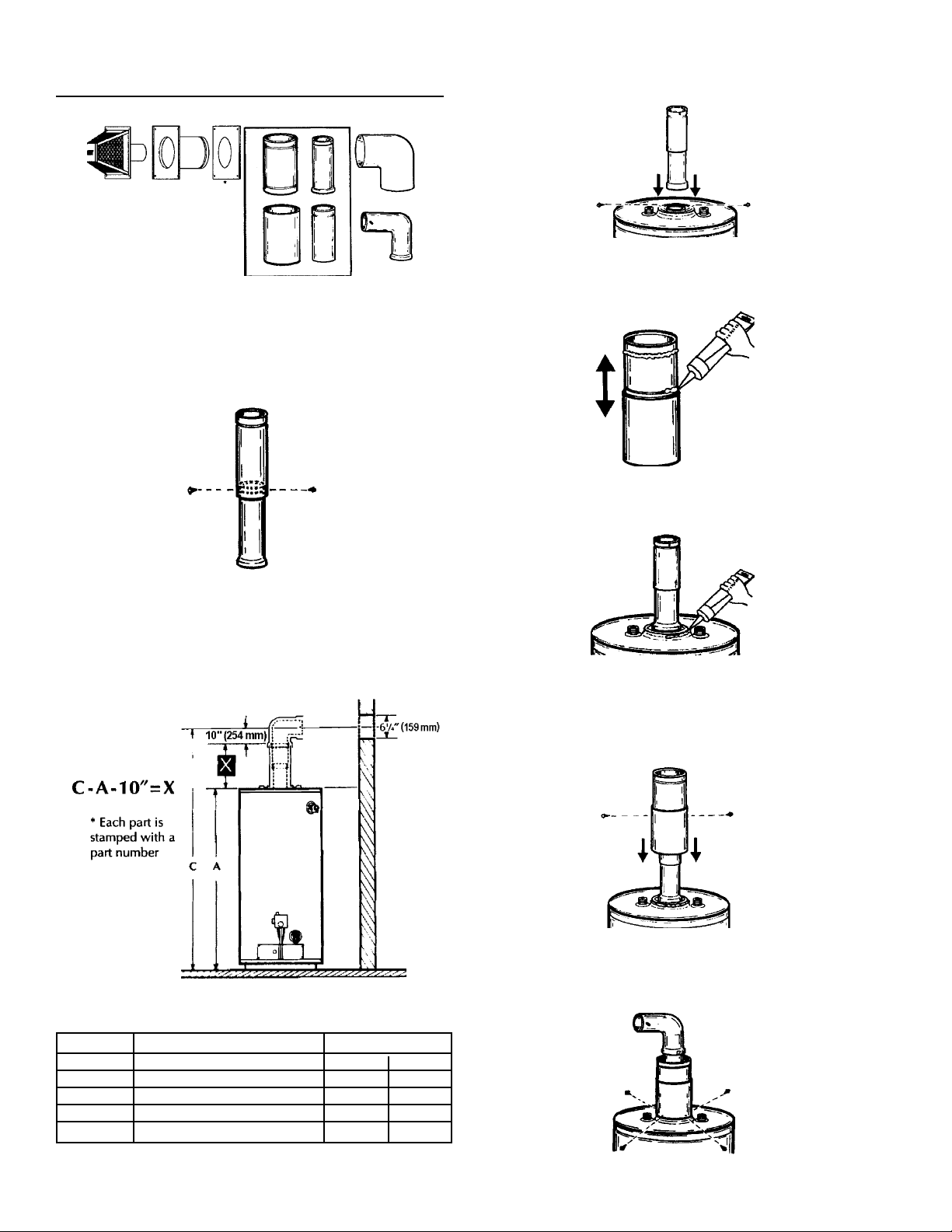

V ertical Height (Extension Kit)

It is simple to determine which kit is needed for vertical height. T ake the

total height (to the top of the flue) required and comparing that to “F

dimension” in the chart #1, it can be determined which kit needs to be

used vertically.

BTU’s DIMENSION “F” (IN CENTIMETERS)

*Gal. in 1000’s 9000687 9001246 9001247 9001248

Cap. Nat/L.P STD. MIN. MAX. MIN. MAX. MIN. MAX.

40 36/36 162 183 196 196 224 224 279

50 38/38 183 205 218 219 247 247 302

40 40/40 162 183 196 196 224 224 279

50 48/44 193 214 228 228 256 256 312

75 55 NAT. 194 21 5 2 2 7 227 255 255 311

*Check the model and rating plate attached to the water heater for

specific model number and other detailed information.

Horizontal (Extension Kit)

T o determine the horizontal length and extension kit needed, simply

plug the dimensions “D” and “G” into the equation below. The answer

“E” should then be located in Chart #2. The size range in which “E”

dimension falls indicates the kit that should be used horizontally to

obtain the desired length.

“D” = The wall thickness

“G” = The distance wanted between the edge of the water heater

and the inside edge of the wall

“E” = The distance the extension kit must be able to extend

The Equation: D + G = E

FIGURE 11.

FIGURE 12.

CHART #1 .

BTU’s DIMENSION “F” (IN INCHES)

*Gal. in 1000’s 9000687 9001246 9001247 9001248

Cap. Nat/L.P STD. MIN. MAX. MIN. MAX. MIN. MAX.

40 36/36 63 3/4 72 77 77 88 88 110

50 38/38 72 80 3/4 86 86 1/4 97 1/4 97 1/4 1 18 3/4

40 40/40 63 3/4 72 77 77 88 88 110

50 48/44 76 84 1/4 89 3/4 89 3/4 100 3/4 100 3/4 122 3/4

75 55 NAT. 76 1/4 84 1/2 89 1/2 89 1/2 100 1/2 100 1/2 122 1/2

FIGURE 13 .

CHART #2.

DIMENSION “E” (IN INCHES)

40-50 GAL. 75 GAL.

VENT KITS MIN MAX MIN MAX

9000687-Std. 3 1/2 10 7/8 7 3/8

9001246 10 15 1/2 7 3/8 12 7/8

9001247 15 1/2 26 1/2 12 7/8 23 7/8

9001248 26 1/2 48 23 7/8 45 3/8

DIMENSION “E” (I N CENTIMETERS )

40-50 GAL. 75 GAL.

VENT KITS MIN MAX MIN MAX

9000687-Std. 8.9 cm 25.4 cm 2.2 cm 18.7 cm

9001246 25.4 cm 29.4 cm 18.7 cm 32.7 cm

9001247 39.4 cm 67.3 cm 32.7 cm 60.6 cm

9001248 67.3 cm 121.9 cm 60.6 cm 115.3 cm

BTU’s DIMENSION “A, B, C” (INCHES/CENTIMETERS)

*Gal. in 1000’s

Cap. Nat.

40 36/36 48 3/4” 124 cm 41 3/4” 106 cm 21” 53 cm

50 38/38 57 1/2” 146 cm 50 1/2” 128 cm 21” 53 cm

40 40/40 48 3/4” 124 cm 41 3/4” 106 cm 21” 53 cm

50 48/44 61” 155 cm 54” 137 cm 21” 53 cm

75 55 NAT. 63” 160 cm 54 3/4” 139 cm 26 1/4” 67 cm

10

ABC

Page 11

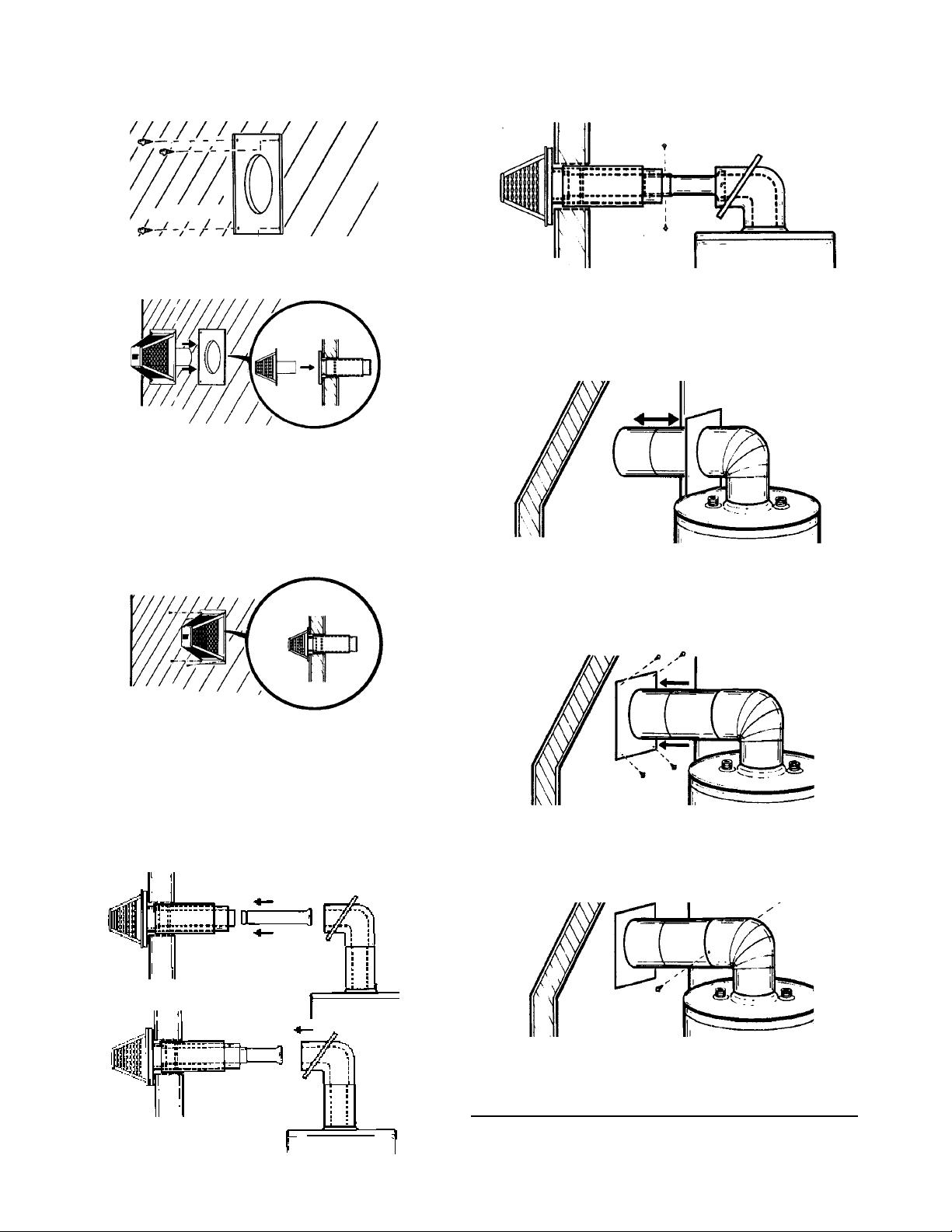

ALL INST ALLA TIONS

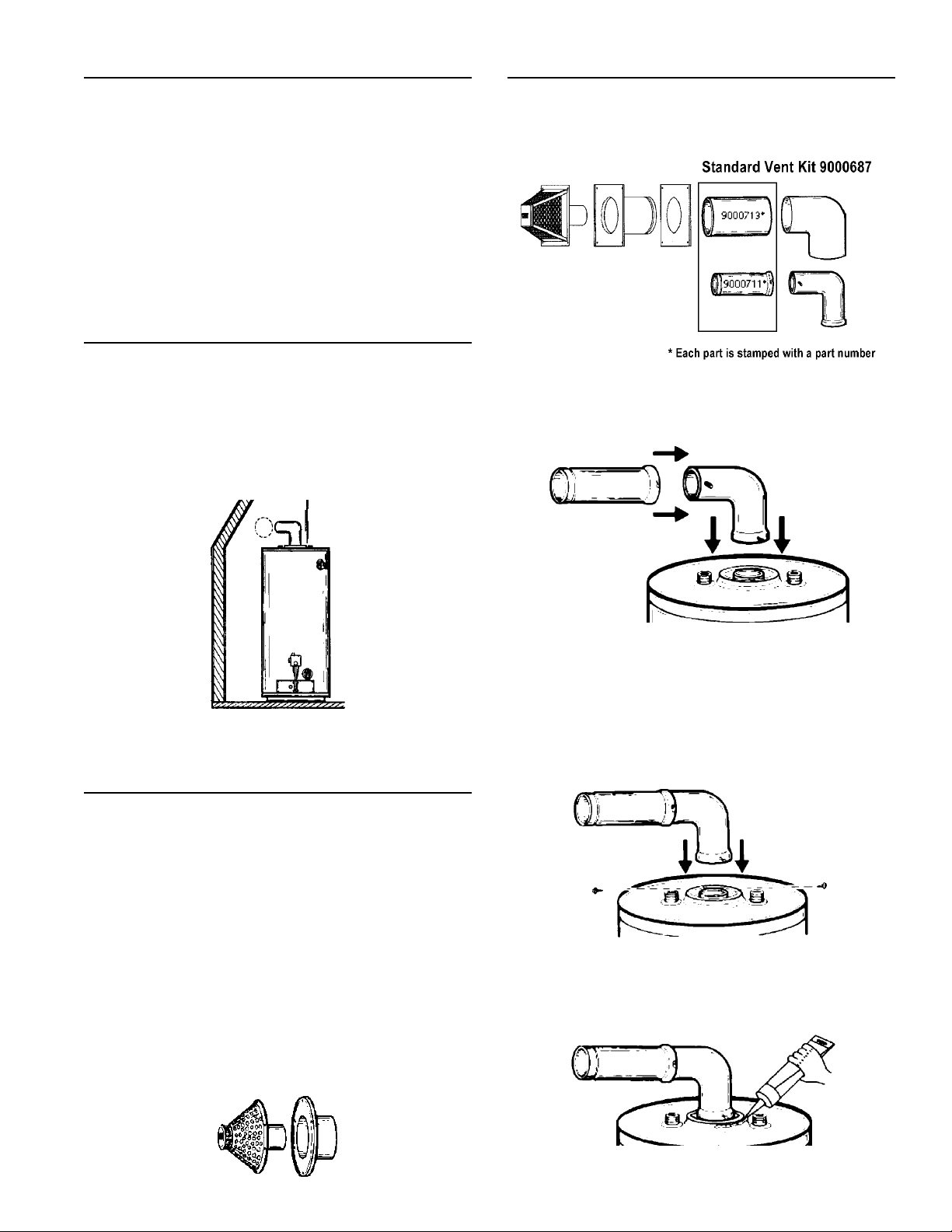

Standard Vent Kit - Installation #1

For ease of assembly the installation of the various kit combinations

has been broken into individual sections. The two steps below are

common to all installations. Once these have been performed, you

need only to refer to the type installation that pertains to you.

Installation Using Vent Kit s:

1. St andard Vent Kit 9000687 ............................................. Page 1 1

2. Optional Vertical V ent Kit................................................. Page 14

with Standard V ent Kit

3. Optional Horizontal Vent Kit............................................. Page 17

4. Optional Horizontal.......................................................... Page 19

and Vertical V ent Kits

Cutting The Opening Through The Outside Wall

After thoroughly reading the “Locating the New Water Heater”

section of this manual and you have chosen a suitable water

heater installation site, use Chart #1 to determine dimensions for

the wall opening.

Cut a 6 1/4” (159 mm) diameter hole completely through the outside

wall.

The opening through the wall should be cut at this time. If this has not

been done, refer to “Cutting The Opening Through The Outside Wall ”

section.

1. Lock the elbow to the straight 3” (76 mm) flue pipe. Set this assembly

in place on the end of the water heater’s flue collar.

FIGURE 14.

Water Heater Attitude

There is a certain amount of variance with regard to the direction the

water heater faces.

Standing in front of the water heater (gas control facing you), set the

3” (76 mm) diameter elbow (slotted end) on the flue. This will give you

a better understanding of the relation of the vent assembly to the

opening in the wall and more importantly any possibility of interference

of venting and water piping.

The direction of the water heater can now be made. Also consider the

gas control valve to insure installation, lighting and maintenance

accessibility are retained.

NOTE: Supplementary installation instructions are applicable only if

this direct vent water heater is provided with the alternate brown

porcelain-enameled vent cap and the 6” (152 mm) vent wall assembly

show below, See pages 22 thru 24.

FIGURE 15.

2. Mark the flue collar at the slots in the elbow . Using a #22 drill bit, drill

holes into the flue collar at the two slots and secure the elbow to the

flue collar using the screws provided.

NOTE: Make sure elbow is properly aligned to opening in the

outside wall.

FIGURE 16 .

3. Using the tube of sealant supplied, run an ample amount around the

oval flare of the jacket.

11

FIGURE 17.

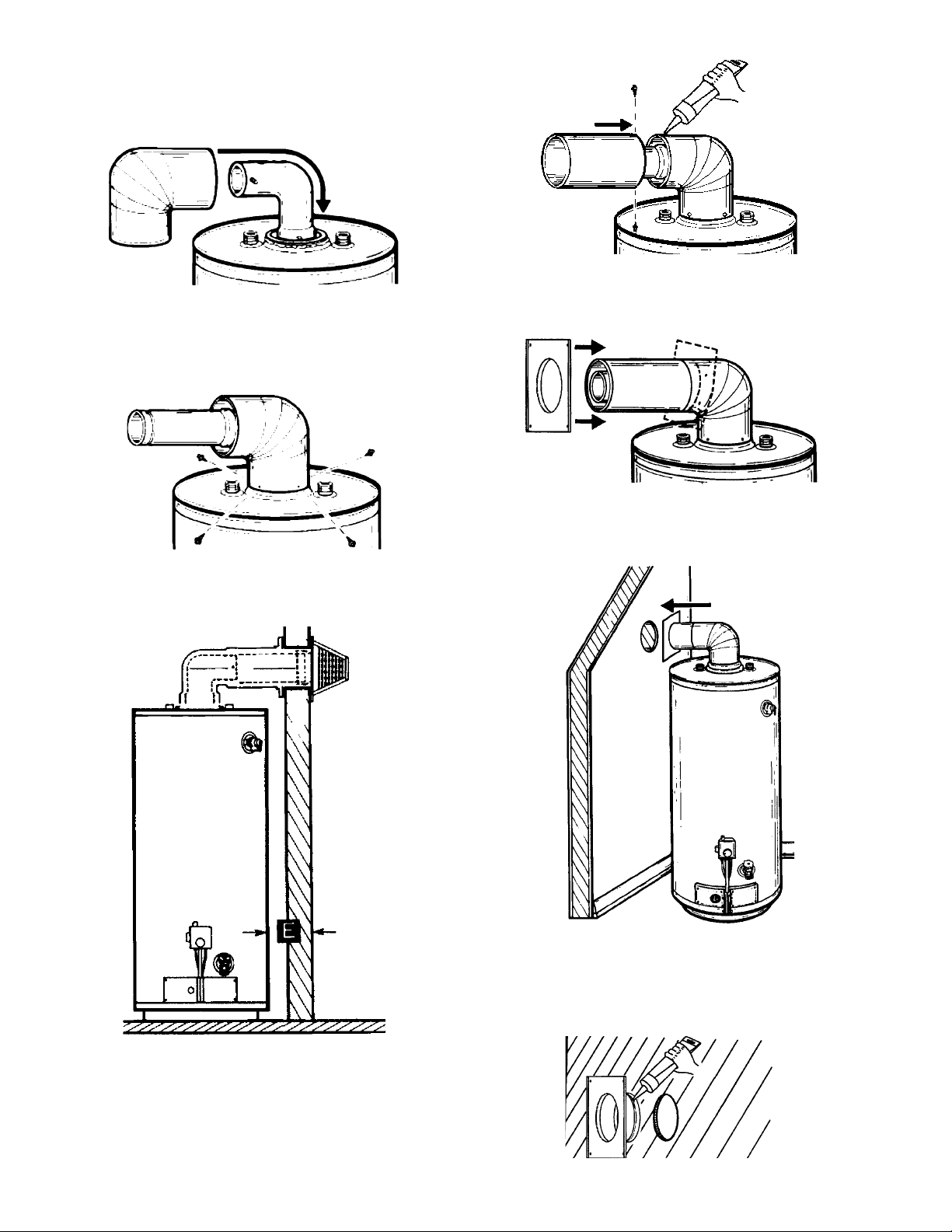

Page 12

4. First remove the 3” (76 mm) horizontal extension from the elbow. Starting with the long end (with four securing holes), place the 6” (152 mm)

diameter vent elbow over the 3” (76 mm) diameter elbow . Bend the

round end “oval” to fit the flared oval end of the jacket top.

FIGURE 18.

5. Making sure the 6” (152 mm) diameter elbow is centered around the 3”

(76 mm) diameter flue, secure the 6” (152 mm) diameter vent pipe

using four sheet metal screws at the connection of the jacket top.

FIGURE 21.

8. Slide the vent collar (to be installed later) over the 6” (152 mm) vent

elbow.

FIGURE 22.

9. Place the water heater at the opening in the wall, at the predetermined

clearance.

FIGURE 19 .

6. The standard vent kit includes a 6” (152 mm) diameter extension pipe

which is used when “E” dimension is over 6 1/2” ( 165 mm).

FIGURE 23.

10. Move outdoors with all the remaining vent parts. Using the tube of

sealant supplied, run an ample amount on the inside surface of the

collar assembly that will contact the exterior wall and also fill the

bead on the end of the 6” ((152 mm) diameter vent collar.

FIGURE 20.

7. If “E” dimension is less than 6 1/2” (165 mm) move to next step.

If “E” dimension is over 6 1/2” (165 mm), assemble the 6” (152 mm)

diameter extension pipe (crimped end) to the 6” (152 mm) diameter vent

elbow and secure using two sheet metal screws. Apply an ample amount

of sealant around the joint to ensure a good seal.

FIGURE 24.

12

Page 13

11. Inst all the vent collar assembly through the wall, connecting it to the

extension and/or elbow (depending on which one was used).

FIGURE 25.

12. We have supplied four wood screws to temporarily attach the collar

to the exterior wall of the building. However , other types of screws

may have to be substituted depending on the material used in the

construction of the exterior wall.

15. The vent cap has four holes around the outer edge. Remove the four

screws used to temporarily attach the collar to the exterior wall.

Then secure the vent cap assembly with the vent collar assembly to

the exterior wall using the same four screws.

NOTE: Screws are supplied: However, substitution may be

necessary depending on the exterior wall material.

FIGURE 26.

13. Insert the 3” (76 mm) diameter flue extension pipe into the vent collar

assembly (flared & notched end first) and lock (turn clockwise to

lock studs to slots) the flue extension pipe to the flue elbow .

14. Connect the vent cap by sliding its end over the 3” (76 mm) diameter

extension pipe and O-ring.

NOTE: T o facilitate ease of assembly of the vent cap to the 3” (76 mm )

pipe, a soap solution can be applied to the O-ring gasket.

FIGURE28.

16. Go back indoors to a ttach inside collar to the inside wall. Place the collar

against the wall. Secure to wall by using four long sheet metal screws.

NOTE: Screws are supplied: However, substitution may be

necessary depending on the interior wall material.

FIGURE 29.

17. Using the tube of sealant supplied, run an ample amount of sealant

around the edge of the vent pipe where it is inserted through the

inside collar to seal air drafts from wall.

FIGURE 27.

FIGURE 30.

13

Page 14

Optional Vertical Vent Kit with Standard Horizontal

V ent Kit - Installation #2

Any Optional Vent Kit

2. Set the vertical 3” (76 mm) diameter telescoping flue section in place

on the flue collar. Using a # 22 drill bit, drill two holes (180° apart) and

secure the vertical assembly to the flue collar.

FIGURE 33.

*Each part is stamped with a part number.

The opening through the wall should be cut at this time. If this has not been

done, refer to “Cutting The Opening Through The Out side Wall,” on page 1 1.

1. First it must be determined how far the vertical 3” (76 mm) diameter

telescoping flue sections are set and locked together using the two

screws supplied.

FIGURE 31 .

Use chart #3, drawing and simple equation below, to find the length of

expansion of the telescoping flue sections. Because of manufacturing

tolerances, place the telescoping extension on the water heater and

adjust the height (“X” Dimension) and mark the point. Once the length has

been determined, lock the two sections together by drilling two holes

(180° apart) in the pipe and securing with the screws supplied.

3. Slide the 6” (152 mm) vent telescoping section apart to reveal the

beads. Using the caulking supplied, fill the beads.

FIGURE34.

4. Apply an ample amount of sealant around the oval flare of the jacket.

FIGURE 35.

5. Place the 6” (152 mm) vent section over the 3” (76 mm) flue section.

Subtract 3/4” (19 mm) from the predetermined “X” dimension. This

determines the length of the 6” (152 mm) vent extension. Slide the 6”

(152 mm) vent extension apart to this dimension and secure with the

two screws supplied.

FIGURE 32.

CHART #3

*GAL CAP . *BTU’s in 1000’ s - NAT./L.P . A

40 36/36 48 3/4” 124 cm

50 38/38 57 1/2” 146 cm

40 40/40 48 3/4” 124 cm

50 48/4 4 61” 155 cm

75 55 NAT . 63” 160 cm

*Check the model and rating plate attached to the water heater for

specific model number and other detailed information.

FIGURE 36.

6. Form the round end of the 6” (152 mm) vent extension to the top of the

jacket and secure with four sheet metal screws.

FIGURE 37.

14

Page 15

7. Place the 3” (76 mm) elbow on the flue extension.

NOTE: Make sure elbow is properly aligned to opening in

the outside wall.

Mark the 3” (76 mm) diameter end of the flue extension at the slots

in the elbow. Using a #22 drill bit, drill holes into the flue extension

at the two slots and secure the elbow to the flue extension using

the screws provided.

10. If “E” dimension is less than 6 1/2” (165 m m) move to next step. If “E”

dimension is over 6 1/2” (165 mm), assemble the 6” (152 mm) diameter

extension pipe to the 6” (152 mm) diameter vent elbow and secure

using two sheet metal screws. Using the tube of sealant supplied,

run an ample amount around the joint to insure a good seal.

FIGURE 41.

FIGURE 38.

8. Be sure the 6” ( 1 52 mm) diameter elbow is centered around the 3”

(76 mm) diameter flue. Secure the 6” (152 mm) diameter vent pipe

using two sheet metal screws at the cnnection of the elbow and

6” (152 mm) vertical extension.

FIGURE 39.

9. The standard vent kit includes a 6” (152 mm) diameter extension

pipe which is used when dimension “E” (refer to Chart 2) is over

6 1/2” (165 mm).

11. Slide the vent collar (to be installed later ) over the 6” ( 152 mm) vent elbow.

FIGURE 42.

12. Move the water heater into position at the vent opening.

FIGURE 40.

FIGURE43.

13. T ake the remaining vent parts outside to complete the inst allation.

Using the tube of sealant supplied, apply an ample amount of sealant

to the inside surface of the collar assembly that will contact the

exterior wall. Also, apply sealant to the bead around the outside

edge at the end of the 6” ( 152 mm) diameter vent collar.

FIGURE 44.

15

Page 16

14. Install the vent collar assembly through the wall, connecting it to the

extension and/or elbow depending on which one was used.

FIGURE 45.

15. Four wood screws are supplied to temporarily attach the collar to the

exterior wall of the building. However, other types of screws may

have to be substituted depending on the construction material of the

exterior wall.

18. The vent cap has four holes around the outer edge. Remove the four

screws used to temporarily attach the collar to the exterior wall. Then

secure the vent cap to the exterior wall using the same four screws.

NOTE: Screws are supplied. However, substitution may be

necessary depending on the exterior wall material.

FIGURE 49.

FIGURE46.

16. Insert the 3” (76 mm) diameter flue extension pipe into the vent collar

assembly (flared and notched end first) and rotate clockwise to lock

the studs to the slots in the extension pipe.

FIGURE 47.

17. Connect the vent cap by sliding it’s end over the 3” (7.6 cm) diameter extension pipe an O-ring.

NOTE: to facilitate ease of assembly of the vent cap to the 3”

(7.6 cm) pipe a soap solution can be applied to the O-ring

gasket.

19. Go back in do or s to att ach ins id e collar to the inside wall. Place the collar

against the wall. Secure to wall by using four long sheet metal screws.

NOTE: Screws are supplied. However, substitution may be

necessary depending on the exterior wall material.

FIGURE 50.

20. Using the tube of sealant supplied, apply an ample amount of sealant

around the edge of the vent pipe where it is inserted through the

inside collar. This will seal air draft from the walls.

FIGURE 48.

FIGURE 51.

16

Page 17

Optional Horizontal V ent Kit - Installation #3

If the vent hole has not been cut, refer to “Cutting The Opening

Through The Outside W all.” See page 11.

1. Lock the elbow to the straight 3” (76 mm) flue pipe. Set this assembly

in place on the end of the water heater’s flue collar.

FIGURE 54.

4. First remove the 3” (7.6 cm) horizontal extension from the elbow.

Starting with the long end, which has four mounting holes, place the 6”

(152 mm) diameter vent elbow over the 3” (76 mm) elbow. Bend the

round end to fit the flared oval end of the jacket top.

FIGURE 55.

FIGURE 52.

2. Mark the flue collar at the slots in the elbow. Using a # 22 drill bit, drill

holes into the collar at the two slots and secure the elbow to the collar

with the screws provided.

NOTE: make sure elbow is properly aligned to the opening in

the outside wall.

5 . Be sure the 6” (152 mm ) diam eter e lbow is cen tered aro und the

3” (76 mm ) diameter flue. Secure the vent pipe with four sheet metal

screws at the connection at the jacket top.

FIGURE 56.

NOTE: the standard kit includes a 3” (76 mm) flue extension

and a 6” (152 mm) elbow extension. These parts will not

be used with the horizontal kit.

6. Slide the vent collar (to be installed later) over the 6” (152 mm)

vent elbow.

FIGURE 53.

3. Using the tube of sealant supplied run an ample amount around the

oval flare of the jacket.

FIGURE 57.

17

Page 18

7. Place the waterheater at the opening in the wall at the

predetermined clearance.

FIGURE 58.

8. Slide the 6” (152 mm) telescoping vent section apart to expose the

beads. Use the supplied tube of sealant and fill the exposed beads.

11. Insert the vent collar assembly through the wall opening, connecting to the 6” (1 52 mm) telescoping extension. Remember, the vent

extension has not been connected so it may be necessary to go

back outdoors and push it back up into the wall opening for a tight

fit to the collar.

FIGURE 62.

12. Four wood screws were supplied to temporarily attach the collar to

the exterior wall of the building. However, you may have to substitute other types of screws depending on the construction material of

the exterior wall.

FIGURE 59.

9. Insert the 6” (152 mm) telescoping vent section into the opening in

the wall.

FIGURE 60.

10. The remaining vent parts will be installed from the outside. Apply ample

amount of sealant to the inside surface of the collar assembly that will

contact the exterior wall. Also, apply sealant to the bead around the

outside edge at the end of the 6” (152 mm) diameter vent collar .

FIGURE 63.

13. Insert the vent cap into the vent collar assembly .

FIGURE 64.

14. The vent cap has four holes around the outer edge. Remove the four

screws used to temporarily attach the collar to the exterior wall.

Then secure the vent cap assembly with the vent collar assembly to

the exterior wall using the same screws.

Note: Screws are supplied; however, substitution may be

necessary depending on the exterior wall material.

FIGURE 61.

FIGURE 65.

15. The remainder of the installation will be indoors to complete the

assembly process.

18

Page 19

16. Collapse the 6” flue extension assembly as shown below. Install

the O-ring end of the 3” (7.6 cm) extension approximately 1 1/4”

(3.2 cm) into the end of the vent cap. If necessary, apply a soap

solution to the O-ring to ease the assembly. Rot ate the 3” extension

clockwise until the other end is locked to the studs on the elbow.

FIGURE 66.

17. Using a # 22 drill bit, drill holes 180° apart at the connection point of

the two 3” (7.6 cm) flue extensions. Secure with the two screws

provided.

20. Secure the 6” (15.2 cm) vent extension to the vent elbow with the

two provided screws spacing them 180° apart.

FIGURE 70.

Optional Vertical and Horizontal Vent Kit Installation #4

FIGURE 67.

18. Expand the 6” (15.2 cm) telescoping extension to connect at the

vent elbow.

FIGURE 68.

19. Push the vent collar from the elbow against the wall and secure with

the four provided screws.

FIGURE 69.

If the vent hole has not been cut, refer to section, “Cutting The Opening

Through The Outside Wall.” See page 11.

1. First determine how far the vertical 3” (7.6 cm) diameter telescoping

flue sections are to be set and locked together with two screws

supplied.

FIGURE 71.

Use the Chart #4, and figure 72 to determine the length of expansion of

the telescoping flue sections. Because of manufacturing tolerances, put

the telescoping extension on the water heater, adjust the height (dimension “X”) and mark the point. Once the length has been determined, lock

the two sections together by drilling two holes (180° apart) in the pipe

and secure with the supplied screws.

19

Page 20

CHART #4.

5. Place the 6” (15.2 cm) vent section over the 3” (7.6 cm) flue section.

Subtract 3/4” ( 1.9 cm) from the predetermined “X” dimension. This

determines the length of the 6” (15.2 cm) vent extension. Slide the 6”

(15.2 cm) vent extension apart to this dimension and secure with the

two screws supplied.

FIGURE 72.

*GAL CAP *BTU’s in 1000’s - NA T . /L.P. A

40 36/36 48 3/4” 124 cm

50 38/38 57 1/2” 146 cm

40 40/40 48 3/4” 124 cm

50 48/44 61” 155 cm

75 55 NAT . 63” 160 cm

*Check the model and rating plate attached to the water heater for

specific model number and other detailed information.

2. Set the vertical 3” (7. 6 c m ) diameter telescoping flue s ect io n i n place on

the flue collar . Using a #22 drill bit, drill two holes ( 180° apart) and secure

the vertical assembly to the flue collar with the two supplied screws.

FIGURE 73.

3. Slide the 6” (15.2 cm) vent telescoping section apart to reveal the

beads. Fill the beads using the supplied caulking.

FIGURE 76.

6. Form the round end of the 6” (15.2 cm) vent extension to the top of the

jacket and secure with four sheet metal screws.

FIGURE 77 .

7. Place the 3” (7.6 cm) elbow on the flue extension. Align the elbow to

the hole previously made in the outside wall. Using the slots in the

elbow, mark the 3” (7.6 cm) diameter end of the flue extension. Using

a #22 drill bit, drill two holes into the flue extension and secure with

the two provided sheet metal screws.

FIGURE 74.

4. Apply an ample amount of sealant around the oval flare of the jacket.

FIGURE 75.

FIGURE 78.

NOTE: the standard kit includes a 3” (7.6 cm) flue extension

and a 6” (15.2 cm) elbow extension. These parts will not

be used with the horizontal kit.

20

Page 21

8. Be sure the 6” (15.2 cm) diameter elbow is centered around the 3”

(7.6 cm) diameter flue, secure using two sheet metal screws at the

connection of the elbow and the 6” (1 5.2 cm) vertical extension.

FIGURE 79.

9. Slide the vent collar ( to be installed later) over the 6” (15.2 cm ) vent elbow.

11. Slide the 6” (15.2 cm) telescoping vent section apart to expose the

beads. Use the supplied tube of caulking and fill the exposed beads.

FIGURE 82.

12. Insert the 6” (15.2 cm) telescoping vent section into the wall.

FIGURE 80.

10. Move the water heater into position at the vent opening.

FIGURE 83.

13. The remaining vent parts will be installed from the outside. Apply

ample amount of sealant to the inside surface of the collar assembly

that will contact the exterior wall. Also, apply sealant to the bead

around the outside edge at the end of the 6” (15.2 cm) diameter vent

collar.

FIGURE 84.

14. Install the vent collar assembly through the wall, connecting to the

6” (15.2 cm) telescoping extension. R emember, the extension is not

connected and may be necessary to return indoors to push the

extension back against the interior wall for a tight fit to the collar.

FIGURE 81.

FIGURE 85.

21

Page 22

15. Four wood screws were supplied to temporarily attach the collar to

the exterior wall of the building. However, you may have to substitute

other types of screws depending on the construction material of the

exterior wall.

FIGURE 86.

20. Using a #22 drill bit, drill holes 180° apart at the connection point of

the two 3” (76 mm) flue extensions. Secure with the two screws

provided.

16. Insert the vent cap into the vent collar assembly.

FIGURE 87.

17. The vent cap has four holes around the outer edge. Remove the four

screws used to temporarily attach the collar to the exterior wall.

Then secure the vent cap assembly with the vent collar assembly to

the exterior wall using the same screws.

Note: Screws are supplied; however, substitution may be

necessary depending on the exterior wall material.

FIGURE 88.

FIGURE 90.

21. Expand the 6” (152 mm) telescoping extension pipes to connect at

the vent elbow.

FIGURE 91.

22. Push the vent collar from the elbow against the wall and secure with

the four provided screws.

18. The remainder of the installation will be conducted indoors to

complete the assembly process.

19. Collapse the 6” extension assembly as shown below. Inst all the O-

ring end of the 3” (7.6 cm) extension approximately 1 1/4” (3.2 cm) into the

end of the vent cap. If necessary , apply a soap solution to the O-ring

to ease the assembly. Rotate the extension clockwise until the other

end is locked to the studs on the elbow.

FIGURE 89.

FIGURE 92.

23. Secure the 6” (152 mm) vent extension to the vent elbow with the

two provided screws spacing them 180° apart.

FIGURE 93.

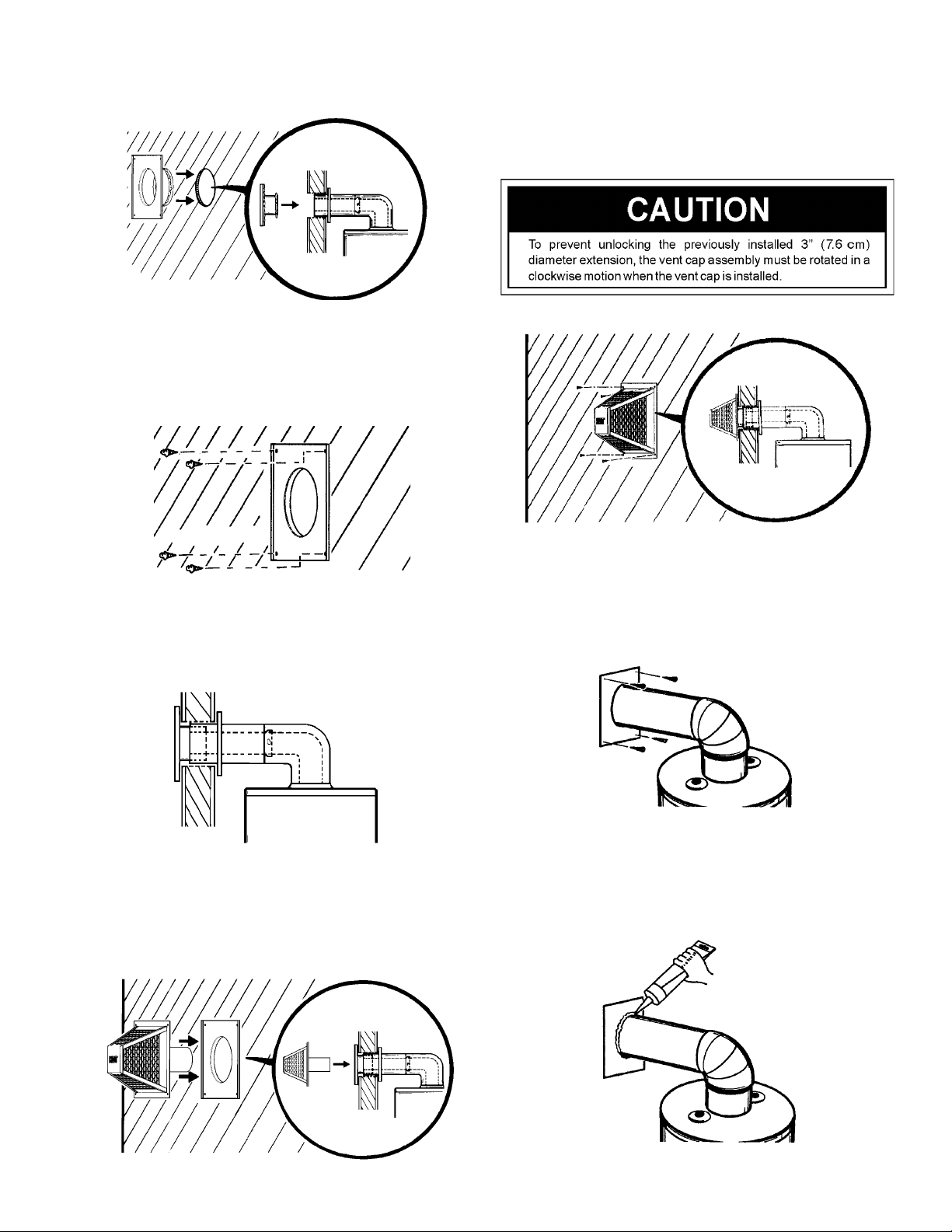

Optional Vent Cap - Porcelain-Enameled

These supplementary installation instructions are applicable only

if this direct vent water heater is provided with the alternate brown

22

Page 23

porcelain-enameled ven t cap assembly and the 6” ( 15 .2 cm) vent

wall assembly shown by Figure 94.

FIGURE 94.

The water heater model designation on the rating plate will have a suffix

“P” to indicate this alternate vent cap assembly.

The alternate installation instructions below will replace the itemized

instructions in the manual as follows: Items 11 thru 15 on page 13 and

items 14 thru 18 on page 16.

1. Making sure the arrow points “UP”, install the vent collar assembly

through the wall, connecting it to the extension and/or elbow

depending on which one was used.

16. Insert the 3” (7.6 cm) diameter flue extension pipe into the vent collar

assembly (flared and notched end first). Lock the flue extension pipe

to the flue elbow by rotating clockwise to lock studs to slots.

FIGURE 97.

4. Connect the vent cap by sliding it over the 3” (7.6 cm) diameter

extension pipe and O-ring.

NOTE: for ease of assembly of the vent cap to the 3” (7.6 cm) pipe a

soap solution can be applied to the O-ring gasket.

FIGURE 95.

2. Three wood screws are supplied to attach the collar to the

exterior wall of the building. However, other types of screws

may have to be substituted depending on the construction of the

exterior wall.

NOTE: alternate screws used must not have a head larger than 3/8”

(.95 cm).

The three screws must be placed at every other hole (120° apart) to

secure the vent collar assembly to the outside wall.

FIGURE 98.

5. The vent cap has six holes around the outer edge. The three larger

ones are to fit over the three screws securing the vent collar assembly to the exterior wall. The three smaller ones will now be used to

attach the vent cap assembly .

NOTE: screws are supplied. However, substitution may be necessary

depending on the exterior wall material.

FIGURE 96.

FIGURE 99.

23

Page 24

The following alternate illustrated instructions will replace the

itemized instructions in the manual as follows: Items 11 through

14 on page 18 and Items 14 through 17 on pages 21 and 22.

1. Making sure the arrow points “up”, install the vent collar assembly

through the wall, connecting it to the 6” (15.2 cm) telescoping

extension. Remember, the extension is not connected, and it may be

necessary to return indoors to push the extension back against the

interior wall for a tight fit to the collar.

FIGURE 100.

2. Three wood screws are supplied to attach the collar to the exterior

wall of the building. However, other types of screws may be substituted

depending on the construction of the exterior wall.

NO TE: alternate screws used must not have heads larger than 3/8” (.9 5 cm).

The three screws must be placed at every other hole 120° apart to

secure the vent collar assembly to the outside wall.

3. Insert the vent cap in the vent collar assembly.

FIGURE 102.

4.The vent cap has six holes around its outer edge. The three larger

ones are to fit over the three screws securing the vent collar assembly

to the exterior wall. The three smaller ones will now be used to attach

the vent cap assembly.

NOTE: screws are supplied. However , substitution may be necessary ,

depending on the exterior wall material.

FIGURE 101.

FIGURE 103.

24

Page 25

INSTALLING THE NEW WATER HEATER

WATER PIPING

HOTTER WA TER CAN SCALD:

Water heaters are intended to produce hot water. Water heated to a

temperature which will satisfy space heating, clothes washing, dish

washing, cleaning and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to be permanently

injured by hot water than others. These include the elderly , children, the

infirm, or physically/mentally handicapped. If anyone using hot water in

your home fits into one of these groups or if there is a local code or state

law requiring a certain temperature water at the hot water tap, then you

must take special precautions. In addition to using the lowest possible

temperature setting that satisfies your hot water needs, a means such

as a *mixing valve, shall be used at the hot water taps used by these

people or at the water heater, see Figure. V alves for reducing point of

use temperature by mixing cold and hot water are also available. Consult

a Qualified Installer or Service Agency. Follow manufacturer’s instructions

for installation of the valves. Before changing the factory setting on the

thermostat, read the “T emperature Regulation” section in this manual.

As water is heated, it expands (thermal expansion) and closed systems

do not allow for the expansion of heated water.

The water within the water heater tank expands as it is heated and

increases the pressure of the water system. If the relieving point of the

water heater’s temperature-pressure relief valve is reached, the valve

will relieve the excess pressure. The temperature-pressure relief

valve is not intended for the constant relief of thermal

expansion. This is an unacceptable condition and must be corrected.

It is recommended that any devices installed which could create a closed

system have a by-pass and/or the system have an expansion tank to

relieve the pressure built by thermal expansion in the water system.

Expansion tanks are available for ordering through a local plumbing

contractor. Contact the local water supplier and/or a service agency for

assistance in controlling these situations.

NOTE: To protect against untimely corrosion of hot and cold

water fittings, it is strongly recommended that di-electric unions

or couplings be installed on this water heater when connected

to copper pipe.

This water heater shall not be connected to any heating systems or

component(s) used with a non-potable water heating appliance.

All piping components connected to this unit for space heating applications

shall be suitable for use with potable water.

T oxic chemicals, such as those used for boiler treatment shall not be

introduced into this system.

When the system requires water for space heating at temperatures

higher than required for domestic water purposes, a tempering valve

must be installed. Please refer to Figure 2 for suggested piping

arrangement.

Water supply systems may, because of such events as high line

pressure, frequent cut-offs, the effects of water hammer among others,

have installed devices such as pressure reducing valves, check valves,

back flow preventers, etc. to control these types of problems. When

these devices are not equipped with an internal by-pass, and no other

measures are taken, the devices cause the water system to be closed.

FIGURE 104.

25

Page 26

Figure 104 shows the typical attachment of the water piping to the

water heater. The water heater is equipped with 3/4 inch NPT water

connections.

NOTE: If using copper tubing, solder tubing to an adapter before

attaching the adapter to the cold water inlet connection. Do

not solder the cold water supply line directly to the cold water

inlet. It will harm the dip tube and damage the tank.

T & P Valve and Pipe Insulation

Remove insulation for T & P valve and pipe connections from carton.

FIGURE 105.

The valve must be marked with a maximum set pressure not to exceed

the marked hydrostatic working pressure of the water heater

(150 psi = 1,035 kPa) and a discharge capacity not less than the water

heater input rate as shown on the model rating plate.

For safe operation of the water heater, the relief valve must not be

removed from its designated opening nor plugged.

The temperature-pressure relief valve must be installed directly into the

fitting of the water heater designed for the relief valve. Position the

valve downward and provide tubing so that any discharge will exit only

within 6 inches (153 mm) above, or at any distance below the structural

floor. Be cert ain that no contact is made with any live electrical part. The

discharge opening must not be blocked or reduced in size under any

circumstances. Excessive length, over 30 feet (9.14 m), or use of more

than four elbows can cause restriction and reduce the discharge

capacity of the valve, see Figure 106.

No valve or other obstruction is to be placed between the relief valve

and the tank. Do not connect tubing directly to discharge drain unless a 6

inch air gap is provided. T o prevent bodily injury, hazard to life , or property

damage, the relief valve must be allowed to discharge water in quantities

should circumstances demand. If the discharge pipe is not connected to a

drain or other suitable means, the water flow may cause property damage.

Fit pipe insulation over the incoming cold water line and the hot water

line. Make sure that the insulation is against the top cover of the heater.

Fit T & P valve insulation over valve. Make sure that the insulation does

not interfere with the lever of the T & P valve.

Secure all insulation using tape.

TEMPERA TURE-PRESSURE RELIEF VALVE

The Discharge Pipe:

•Shall not be smaller in size than the outlet pipe size of the valve, or

have any reducing couplings or other restrictions.

•Shall not be plugged or blocked.

•Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both the

temperature-pressure relief valve, and the discharge pipe.

•Shall terminate at an adequate drain.

•Shall not have any valve between the relief valve and tank.

This heater is provided with a properly certified combination

temperature - pressure relief valve by the manufacturer.

The valve is certified by a nationally recognized testing laboratory that

maintains periodic inspection of production of listed equipment of

materials as meeting the requirements for Relief V alves and Automatic

Gas Shut-off Devices for Hot Water Supply Systems, ANSI Z21.22 •

CSA 4.4, and the code requirements of ASME.

If replaced, the valve must meet the requirements of local codes, but

not less than a combination temperature and pressure relief valve

certified as indicated in the above paragraph.

The temperature-pressure relief valve must be manually operated at least

once a year. Caution should be t aken to ensure that (1) no one is in front

of or around the outlet of the temperature-pressure relief valve discharge

line, and (2) the water manually discharged will not cause any bodily

injury or property damage because the water may be extremely hot.

26

Page 27

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet to the

water heater, follow the draining instructions, and replace the

temperature-pressure relief valve with a new one.

GAS PIPING

Make sure the gas supplied is the same type listed on the model rating

plate. The inlet gas pressure must not exceed 14 inch water column (2.6 kPa)

for natural and propane gas (L.P.). The minimum inlet gas pressure

shown on the rating plate is that which will permit firing at rated input.

If the gas control valve is subjected to pressures exceeding 1/2 pound

per square inch (3.5 kPa), the damage to the gas control valve could

result in a fire or explosion from leaking gas.

FIGURE 106.

FILLING THE WATER HEA TER

Never use this water heater unless it is completely full of water. To

prevent damage to the tank, the tank must be filled with water. W ater

must flow from the hot water faucet before turning “ON” gas to the

water heater.

To fill the water heater with water:

1. Close the water heater drain valve by turning the handle to the

right (clockwise). The drain valve is on the lower front of the

water heater.

If the main gas line Shut-off serving all gas appliances is used, also turn

“off” the gas at each appliance. Leave all gas appliances shut “off” until

the water heater installation is complete.

A gas line of suf ficient size must be run to the water heater. Consult the

current edition of National Fuel Gas Code ANSI Z223.1/NFP A 54 and your

gas supplier concerning pipe size.

There must be:

• A readily accessible manual shut off valve in the gas supply line serving

the water heater , and

• A drip leg (sediment trap) ahead of the gas control valve to help prevent

dirt and foreign materials from entering the gas control valve.

• A flexible gas connector or a ground joint union between the shut off

valve and control valve to permit servicing of the unit.

Be sure to check all the gas piping for leaks before lighting the water

heater. Use a soapy water solution, not a match or open flame. Rinse

off soapy solution and wipe dry.

2. Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open when

the water heater is in use.

3. T o insure complete filling of the tank, allow air to exit by opening the

nearest hot water faucet. Allow water to run until a constant flow

is obtained. This will let air out of the water heater and the piping.

4. Check all water piping and connections for leaks. Repair as needed.

27

Page 28

When installed at elevations above 2,000 feet (610 meters), input rating

should be reduced at the rate of 4 percent for each 1,000 feet

(305 meters) above sea level which requires replacement of the

burner orifice in accordance with National Fuel Gas Code ANSI Z223.1/

NFPA 54. Contact your local gas supplier for further information.

Failure to replace the standard orifice with a high altitude orifice when

installed could result in improper and inefficient operation of the appliance,

producing carbon monoxide gas in excess of safe limits, which could

result in serious injury or death. Contact your gas supplier for any

specific changes which may be required in your area.

Use pipe joint compound or teflon tape marked as being resistant to the

action of petroleum [Propane (L.P.)] gases.

The appliance and its gas connection must be leak tested before placing

the appliance in operation.

GAS PIPING WITH ALL BLACK IRON PIPE TO GAS CONTROL

FIGURE 108.

SEDIMENT TRAPS

The appliance and its individual Shut-off valve shall be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 pound per square inch

(3.5 kPa). It shall be isolated from the gas supply piping system by

closing its individual manual Shut-off valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

1/2 pound per square inch (3.5 kPa).

Conn ecting the gas piping to the gas control valve of the water heater can be

accomplished by either of the two methods shown in Figures 107 and 108.

GAS PIPING WITH FLEXIBLE CONNECTOR

FIGURE 107.

A sediment trap shall be installed as close to the inlet of the water

heater as practical at the time of water heater installation. The sediment

trap shall be either a tee fitting with a capped nipple in the bottom outlet

or other device recognized as an effective sediment trap. If a tee fitting

is used, it shall be installed in conformance with one of the methods of

installation shown in Figures 1 07 a nd 10 8 .

Contaminants in the gas lines may cause improper operation of the gas

control valve that may result in fire or explosion. Before attaching the

gas line be sure that all gas pipe is clean on the inside. T o trap any dirt

or foreign material in the gas supply line, a drip leg (sometimes called a

sediment trap) must be incorporated in the piping. The drip leg must be

readily accessible. Install in accordance with the “Gas Piping” section.

Refer to the current edition of the National Fuel Gas Code,

ANSI Z223.1/NFP A 54.

28

Page 29

INSTALLING THE NEW WATER HEATER (cont’d.)

INSTALLATION CHECKLIST

BEFORE LIGHTING THE PILOT:

1. Check the gas line for leaks.

a. Use a soapy water solution. DO NOT test for gas leaks using

a match or open flame.

b. Brush the soapy water solution on all gas pipes, joints and fittings.

c. Check for bubbling soap. This means you have a leak. Turn

“OFF” gas and make the necessary repairs.

d. Recheck for leaks.

e. Rinse off soapy solution and wipe dry .

2. Is this new temperature-pressure relief valve properly installed

and piped to an adequate drain? See “T emperature-Pressure Relief

V alve” section.

3. Are the cold and hot water lines connected to the water heater

correctly? See “Water Piping” instructions in the “Installing the New

Water Heater” section.

4. Is the water heater completely filled with water? See “Filing the Water

Heater” instructions in the “Installing the New Water Heater” section.

5. Will a water leak damage anything? See the “Locating the New

Water Heater” section.

6. Is there proper clearance between the water heater and anything

that might catch fire? See the “Locating the New Water Heater”

section.

7. Do you have adequate ventilation so that the water heater will

operate properly? See “Combustion Air and V entilation” in the “Locating

the New Water Heater” section.

8. Is the vent piping properly secured? See “Venting” instructions in

the “Installing the New Water Heater section.

9. Is there proper clearance between the vent pipe and anything that

might catch fire? See “Venting” instructions in the “Installing the New

Water Heater” section.

10. Is the vent pipe properly sloped and does the vent terminate outdoors?

See “Venting” instructions in the “Installing the New W ater Heater”

section.

1 1. Do you need to call your gas company to check the gas pipe and its

hookup?

29

Page 30

30

Page 31

TEMPERATURE REGULATION

NOTE: A water temperature range of 120°F-140°F (49°C-60°C) is

recommended by most dishwasher manufacturers.

The thermostat of this water heater has been factory set at its lowest

position (PILOT LIGHTING). It is adjustable and must be reset to the

desired temperature setting to reduce the risk of scald injury. The mark

) indicative of approximately 120°F (49°C) is preferred starting

(

point. Some States have a requirement for a lower setting.

HOT WA TER CAN SCALD: W ater heaters are intended to produce hot

water. Water heated to a temperature that will satisfy space heating,

clothes washing, dish washing, and other sanitizing needs can scald

and permanently injure you upon contact. Some people are more likely to

be permanently injured by hot water than others. These include the

elderly, children, the infirm, or physically/ment ally handicapped. If anyone

using hot water in your home fits into one of these groups or if there is

a local code or state law requiring a specific hot water temperature at

the tap, then you must take special precautions. Never allow small

children to use a hot water tap, or to draw their own bath water. Never

leave a child or handicapped person unattended in a bathtub or shower.

It is recommended that lower water temperatures be used to avoid the

risk of scalding. It is further recommended, in all cases, that the water

temperature be set for the lowest temperature that satisfies your hot

water needs. This will also provide the most energy efficient operation

of the water heater.

Figure 110 shows the approximate water temperatures produced at

various thermostat settings. Short repeated heating cycles caused by

small hot water uses can cause temperatures at the point of use to

exceed the thermostat setting by up to 30°F (17°C). If you experience

this type of use you should consider using lower temperature settings to

reduce scald hazards.

Turn the water temperature dial clockwise (

temperature, or counterclockwise (

temperature.

Should overheating occur or the gas supply fail to shut off, turn off the

manual gas control valve to the appliance.

FIGURE 109.

) to decrease the

) to increase the

V alves for reducing the point-of-use temperature by mixing cold and hot

water are available. See Figure 2. Also available are inexpensive devices

that attach to faucets to limit hot water temperatures. Contact a licensed

plumber or the local plumbing authority .

FOR YOUR INFORMATION

ST ART UP CONDITIONS

CONDENSA TE

Whenever the water heater is filled with cold water, some condensate

will form while the burner is on. A water heater may appear to be

leaking when in fact the water is condensation. This usually

happens when:

a. A new water heater is filled with cold water for the first time.

b. Burning gas produces water vapor in water heaters, particularly

high efficiency models where flue temperatures are lower.

c. Large amounts of hot water are used in a short time and the

refill water in the tank is very cold.

FIGURE 110.

Moisture from the products of combustion condense on the cooler tank

surfaces and form drops of water which may fall onto the burner or

other hot surfaces to produce a “sizzling” or “frying” noise.

Excessive condensation can cause pilot outage due to water running

down the flue tube onto the main burner and putting out the pilot.

Because of the suddenness and amount of water, condensation water

may be diagnosed as a “tank leak”. After the water in the tank warms

up (about 1-2 hours), the condition should disappear.

Do not assume the water heater is leaking until there has been enough

time for the water in the tank to warm up.

An undersized water heater will cause more condensation. The water

heater must be sized properly to meet the family’s demands for hot water

including dishwashers, washing machines and shower heads.

31

Page 32

Excessive condensation may be noticed during the winter and early spring

months when incoming water temperatures are at their lowest.

Good venting is essential for a gas fired water heater to operate properly

as well as to carry away products of combustion and water vapor.

will cause a reaction between this rod and the water. The most common

complaint associated with the anode rod is one of a “rotten egg smell” in

the hot water. This odor is derived from hydrogen sulfide gas dissolved

in the water. The smell is the result of four factors which must all be

present for the odor to develop:

SMOKE / ODOR

It is not uncommon to experience a small amount of smoke and odor during

the initial start-up. This is due to burning off of oil from metal parts, and will

disappear in a short while.

THERMAL EXP ANSION

Water supply systems may, because of such events as high line

pressure, frequent cut-offs, the effects of water hammer among others,

have installed devices such as pressure reducing valves, check valves,

back flow preventers, etc. to control these types of problems. When

these devices are not equipped with an internal by-pass, and no other

measures are taken, the devices cause the water system to be closed.

As water is heated, it expands (thermal expansion) and closed systems

do not allow for the expansion of heated water.

a. A concentration of sulfate in the supply water.

b. Little or no dissolved oxygen in the water.

c. A sulfate reducing bacteria which has accumulated within the water

heater (this harmless bacteria is nontoxic to humans).

d. An excess of active hydrogen in the tank. This is caused by the

corrosion protective action of the anode.

Smelly water may be eliminated or reduced in some water heater models

by replacing the anode(s) with one of less active material, and then

chlorinating the water heater tank and all hot water lines. Contact the

local water heater supplier or service agency for further information

concerning an Anode Replacement Kit and this chlorination treatment.

If the smelly water persists after the anode replacement and chlorination

treatment, we can only suggest that chlorination or aeration of the water

supply be considered to eliminate the water problem.

Do not remove the anode leaving the tank unprotected. By

doing so, all warranty on the water heater tank is voided.

“AIR” IN HOT WA TER F AUCETS

The water within the water heater tank expands as it is heated and

increases the pressure of the water system. If the relieving point of the

water heater’s temperature-pressure relief valve is reached, the valve

will relieve the excess pressure. The temperature-pressure relief

valve is not intended for the constant relief of thermal

expansion. This is an unacceptable condition and must be corrected.

It is recommended that any devices installed which could create a closed

system have a by-pass and/or the system have an expansion tank or

device to relieve the pressure built by thermal expansion in the water

system. Expansion tanks are available for ordering through a local

plumbing contractor. Contact the local water heater supplier or service

agency for assistance in controlling these situations.

STRANGE SOUNDS

Possible noises due to expansion and contraction of some metal parts

during periods of heat-up and cool-down do not necessarily represent

harmful or dangerous conditions.

Condensation causes sizzling and popping within the burner area during

heating and cooling periods and should be considered normal. See

“Condensation” in this section.

OPERA TIONAL CONDITIONS

SMELL Y WA TER

In each water heater there is installed at least one anode rod (see parts

sections) for corrosion protection of the tank. Certain water conditions

HYDROGEN GAS: Hydrogen gas can be produced in a hot water system

that has not been used for a long period of time (generally two weeks or

more). Hydrogen gas is extremely flammable and explosive. T o prevent

the possibility of injury under these conditions, we recommend the hot

water faucet, located farthest away, be opened for several minutes

before any electrical appliances which are connected to the hot water

system are used (such as a dishwasher or washing machine). If hydrogen

gas is present, there will probably be an unusual sound similar to air

escaping through the pipe as the hot water faucet is opened. There

must be no smoking or open flame near the faucet at the time it is open.

HIGH WA TER TEMPERA TURE SHUT OFF SYSTEM

This water heater is equipped with an automatic gas Shut-off system.

This system works when high water temperatures are present. Turn

“OFF” the entire gas supply to the water heater . The high temperature

Shut-off is built into the gas control valve. It is non-resettable. If the high

temperature Shut-off activates, the gas control valve must be replaced.

Contact your gas supplier or service agency .

32

Page 33

PERIODIC MAINTENANCE

VENTING SYSTEM INSPECTION

At least once a year a visual inspection should be made of the venting

system. Y ou should look for:

1. Obstructions which could cause improper venting. The combustion

and ventilation air flow must not be obstructed.

2. Damage or deterioration which could cause improper venting or

leakage of combustion products.

3. Rusted flakes around top of water heater.

Be sure the vent piping is properly connected to prevent escape of

dangerous flue gasses which could cause deadly asphyxiation.

Y ou should check for sooting. Soot is not normal and will impair proper

combustion.

Soot build-up indicates a problem that requires correction before further

use. Turn “OFF” gas to water heater and leave off until repairs are

made, because failure to correct the cause of the sooting can result in a

fire causing death, serious injury, or property damage.

FIGURE 11 1.

BURNER CLEANING

In the event your burner needs cleaning, follow these instructions:

If inspection of the burner shows that cleaning is required, turn the gas

control knob clockwise (

NOTE: The knob cannot be turned from “PILOT” to “OFF” unless

knob is depressed slightly. DO NOT FORCE.

Loose deposits on or around the burner can be removed by carefully

using the hose of a vacuum cleaner inserted through the access doors

of the water heater. If the burner needs to be removed for additional

cleaning, call the local gas utility to remove and clean the burner and

correct the problem that required the burner to be cleaned.

) to the “OFF” position, depressing slightly.

Obstructions and deteriorated vent systems may present serious health

risk or asphyxiation.

Chemical vapor corrosion of the flue and vent system may occur if air for

combustion contains certain chemical vapors. Spray can propellants,

cleaning solvents, refrigerator and air conditioner refrigerants, swimming

pool chemicals, calcium and sodium chloride, waxes, bleach and process

chemicals are typical compounds which are potentially corrosive.

If after inspection of the vent system you found sooting or deterioration,

something is wrong. Call the local gas utility to correct the problem and

clean or replace the flue and venting before resuming operation of the

water heater.

BURNER INSPECTION

Flood damage to a water heater may not be readily visible or immediately

detectable. However , over a period of time a flooded water heater will

create dangerous conditions which can cause DEATH, SERIOUS BODIL Y