State GTS-710-NIEA Installation Manual

710 / 710 ASME (T-M32/ T-M32 ASME)

On-Demand Water Heater

Installation Manual and Owner’s Guide

Gas Tankless Water Heater

(T-M32 / T-M32 ASME )Models

Suitableforpotablewaterheatingandspace‐heating

*Pleaserefertolocalcodesforspace‐heatingcompliance.

710 / 710 ASME

ANSIZ21.10.3

andCSA4.3

HLW

WARNING

-Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electric switch, do not

use any phone in your building.

Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

If you cannot reach your gas supplier,

call the fire department.

-Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

*

If the information in these

instructions is not followed

exactly, a fire or explosion

may result causing property

damage, personal injury or

death.

For supplying potable

hot water

ASME model ONLY

FEATURING

ENDLESS HOT WATER

ON-DEMAND USAGE

COMPACT, SPACE SAVING

ENERGY CONSERVATION

COMPUTERIZED SAFETY

NO PILOT LIGHT

EASY-LINK SYSTEM

If you have any questions, please

call or write to:

500 Tennessee Waltz Parkway

Ashland City, TN 37015

Toll Free: 1-877-737-2840

CONTENTS

SPECIFICATIONS

SPECIFICATIONS……………………….

INTRODUCTION…………………………

SAFETY GUIDELINES………………....

INSTALLATION…………………………..

General…………………………………

Included Accessories….……………….

Warning for Installations………………

Outdoor Installation…………………...

Indoor Installation…………………...…

Direct Intake Vent System…………….

Venting Instructions………………......

Gas Supply / Gas Pipe Sizing………..

Water Connections……………………

Pressure Relief Valve…………………

Electrical Connections……………......

Remote Controller Connections………

Pump Control Connections……………

Pump Control Mode……………………

Easy-Link System ……………………..

Multi-Unit System………………………

Initial Operation………… ……………..

NORMAL OPERATION………………….

Normal Operation…………………......

Flow……………………………………..

Freeze Protection System…………...

Temperature Setting s………………….

Maintenance and Service…… …. .…… .

GENERAL TROUBLESHOOTING…… . .

OPERATING SAFETY……..……………..

APPLICATIONS………………………......

Re-Circulation…………………………..

Dual-Purpose Heating……………......

ADDITIONAL CLEARANCES……………

OPTIONAL ITEMS………...……………..

COMPONENTS DIAGRAM…………….

PARTS LIST………………………………

OUTPUT TEMPERATURE CHART……

LIMITED WARRANTY……………………

The manufacturer reserves the right to discontinue, or change at any time,

specifications or designs without notice and without incurring obligations.

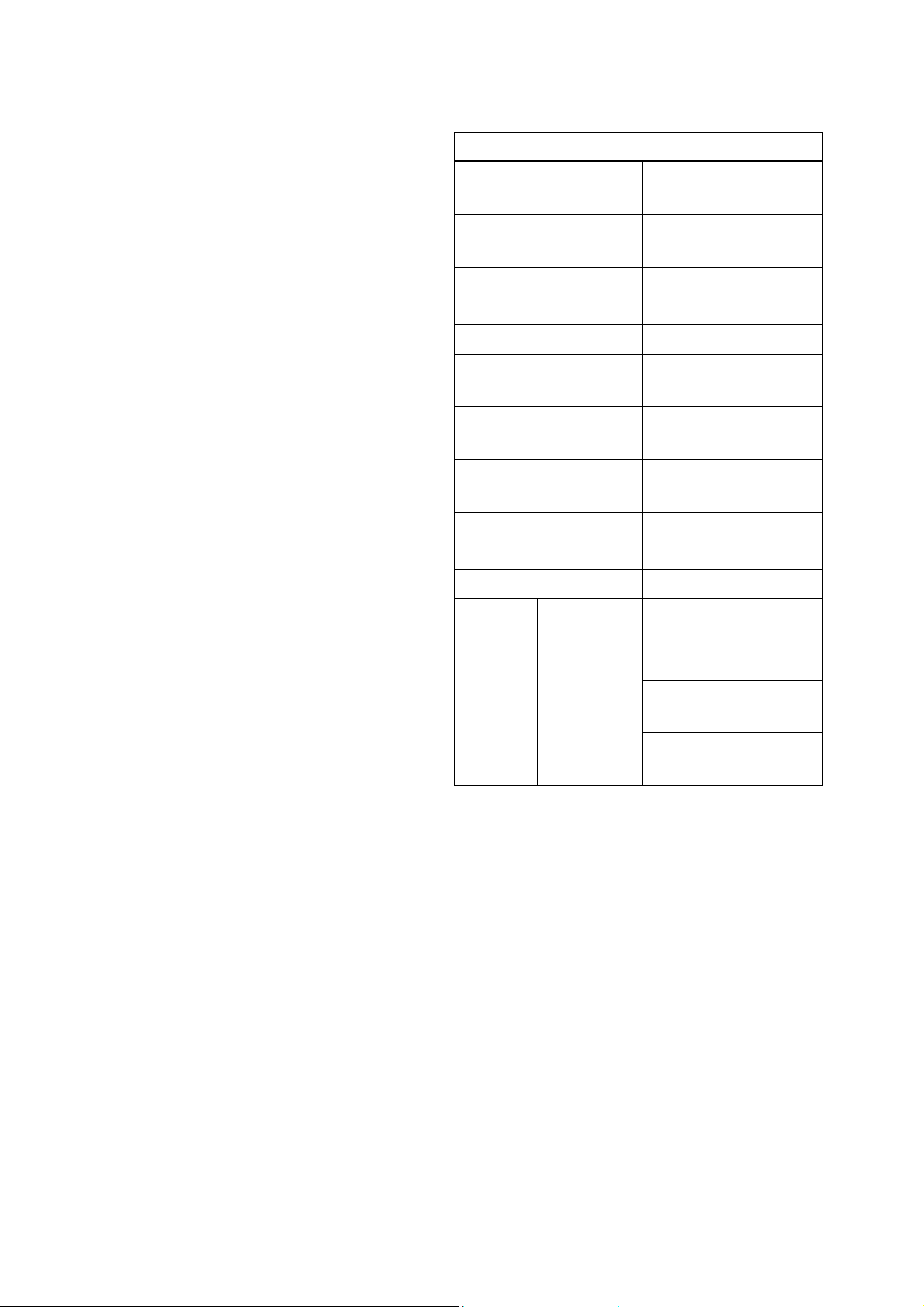

Natural Gas Input

2

(Operating Range)

3

4

Propane Input

5

(Operating Range)

6

Gas Connection 3/4” NPT

6

Water Connections

7

Water Pressure

8

9

Natural Gas

10

Inlet Pressure

11

Propane

15

Inlet Pressure

18

Manifold Pressure**

18

19

Weight

20

Dimensions

21

22

Ignition

24

28

30

31

Electric

31

33

33

34

35

*40 psi or above is recommended for maximum flow.

**The Manifold Pressure is the factory setting and

36

39

41

41

42

43

44

45

48

50

51

generally should not need adjustment.

NOTE

*All references to the 710 (T-M32) also refer to the

710 ASME (T-M32 ASME) model.

*Check the rating plate to ensure this product

matches your specifications.

*In accordance with ANSI Z21.10.3,

CO emission does not exceed 400 PPM for

normal input.

Supply

Consumption

Min: 24,000 Btu/h

Max: 240,000 Btu/h

Min: 24,000 Btu/h

Max: 240,000 Btu/h

3/4” NPT

15 - 150 psi *

Min. 5.0” WC

Max. 10.5” WC

Min. 8.0” WC

Max. 14.0” WC

Natural: 2.35” WC

Propane: 3.55” WC

59 lbs.

H23.6”×W18.5”×D8.9”

Electric Ignition

120 VAC / 60 Hz

Operation

Standby

FreezeProtection

112 W

(0.93 A)

8.9 W

(0.07 A)

187 W

(1.56 A)

- 2 -

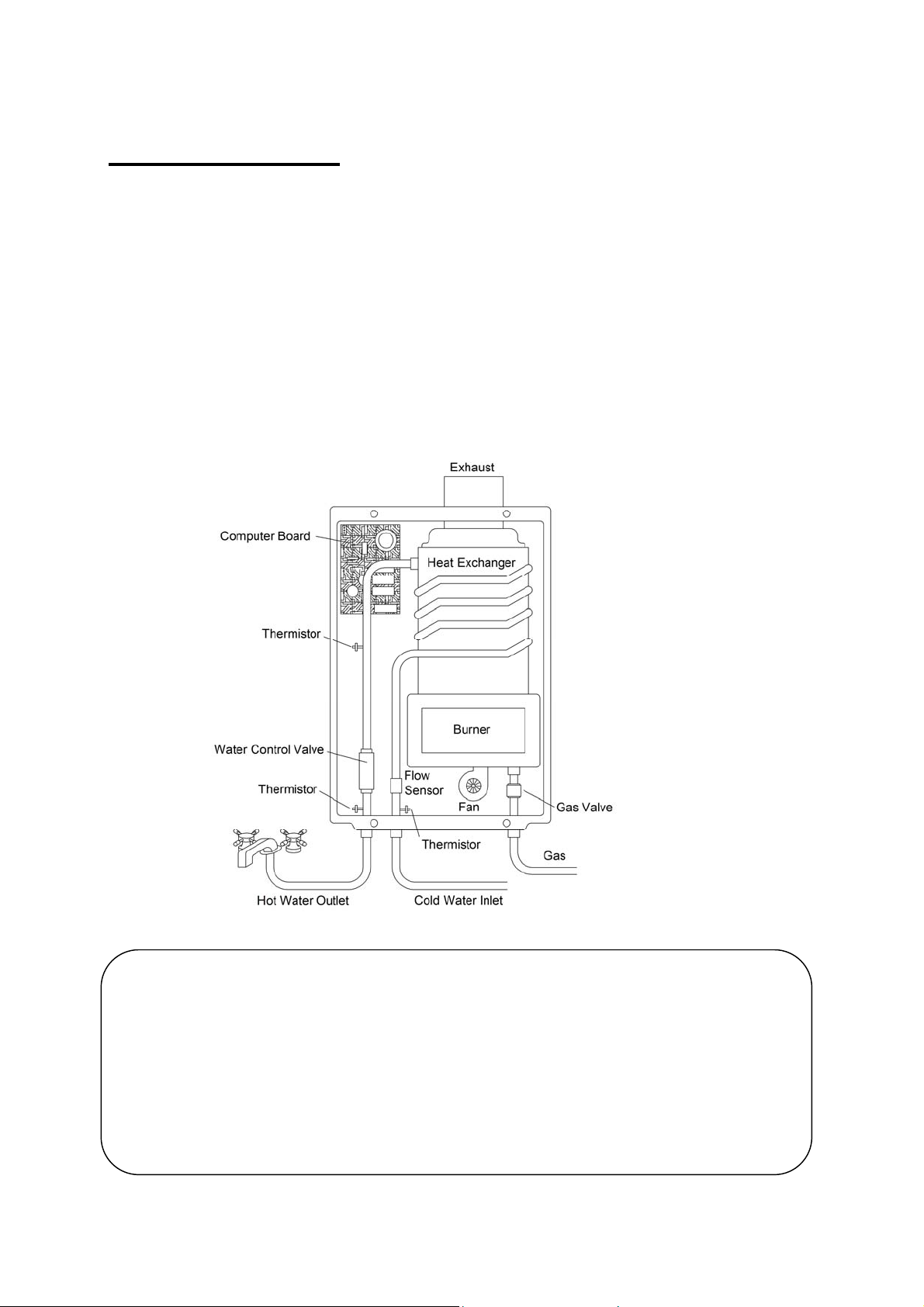

INTRODUCTION

p

y

This manual provides information necessary for the installation, operation, and

maintenance of the water heater.

The model description is listed on the rating plate which is a ttached to the front cover of

the water heater.

Please read all installation instructions completely before installing this product.

If you have any problems or questions regarding this equipment, consult with the

manufacturer or its local re

This equipment is an on-demand, tankless water heater designed to efficiently supply

endless hot water for

The principle behind the water heater is simple:

1. A hot water tap is turned on.

2. Water enters the heater.

3. The water flow sensor detects the water flow.

4. The computer automatically ignites the burner.

5. Water circulates through the heat exchanger and then gets hot.

6. The computer will modulate the gas supply valve and water flow to produce the right

amount of hot water at the correct temperature.

7. When the tap is turned off, the unit shuts down.

resentative.

our needs.

*This diagram illustrates

tankless water heater

design concepts only and is

not accurate to the water

heater’s physical

description.

- 3 -

SAFETY GUIDELINES

Installation and service must be performed by a qualified installer (for

example, a licensed plumber or gas fitter), otherwise the warranty will be

void.

The installer (licensed professional) is responsible for the correct

WARNING

PLEASE READ THIS MANUAL CAREFULLY AND FOLLOW ALL DIRECTIONS.

1. Follow all local codes, or in the absence of loca l codes, follow the most recent edition of

the National Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or CAN/CSA B149.1

Natural Gas, Propane Installation Code in Canada.

2. Properly ground the unit in accordance with all loc al code s or in the absence of local codes,

with the National Electrical Codes: ANSI/NFPA 70 in the USA or CSA standard C22.1

Canada Electrical Code Part 1 in Canada.

3. Carefully plan where you intend to install the water heater. Please ensure:

Your water heater will have enough combustible air and proper ventilation.

Locate your heater where water leakage will not damage surrounding areas (please

refer to p. 5).

4. Check the rating plate for the correct GAS TYPE, GAS PRESSURE, WATER PRESSURE

and ELECTRIC RATING.

*If this unit does not match your requirements, do not install and consult with the

manufacturer.

5. If any problem should occur, turn off all hot water taps and turn off th e gas. Then call a

trained technician or the Gas Company or the manufacturer.

installation of the water heater and for compliance with all national,

state/provincial, and local codes.

GENERAL

WARNING

Water temperatures over 125ºF (52ºC) can cause severe burns instantly or death from

scalding. The water temperature is set at 120ºF (49ºC) from the factory to minimize

any scalding risk. Before bathing or showering always check the water temperature.

Do not store or use gasoline or other flammables, vapors, or liquids in

the vicinity of this appliance.

Do not reverse the water and/or gas connections as this will

damage the gas valves and can cause severe injury or death.

Follow the diagram on p. 17 when installing your water heater:

Do not use this appliance if any part has been in contact with or

Prohibited

been immersed in water. Immediately call a licensed plumber, a

licensed gas fitter, or a professional service technician to inspect

and/or service the unit if necessary.

Do not disconnect the electrical supply if the ambient temperature will drop below

freezing. The Freeze Prevention System only works if t he unit has electrical power. The

warranty will not be covered if the heat exchanger is damaged due to freezing. Refer to

the section on the Freeze Prevention System on p. 33 for more information.

- 4 -

INSTALLATION

All gas water heaters require careful and correct installation to ensure safe and efficient

operation. This manual must be followed exac tly. Read the “Safety Guidelines” section at the

beginning of this manual.

The warranty will not cover damage caused by water quality. Water

hardness that leads to scale formation and/or corrosion may

affect/damage the water heater. Hard water scaling and/or corros ion must

be avoided or controlled by proper water treatment.

CAUTION

WARNING

The manufacturer recommends using the direct-vent kit, when the

water heater is installed in a beauty salon. Some chemicals used in a

beauty salon may affect the flame sensor. Water heater may not work

properly.

Although this water heater is designed to operate with minimal sound , the

manufacturer does not recommend installing the unit on a wall

adjacent to a bedroom, or a room that is intended for quiet study or

meditation, etc.

Locate your heater close to a drain where water leakage will not do da ma ge

to surrounding areas. As with any water hea ting applianc e, the potentia l for

leakage at some time in the life of the product does exist. The manufacturer

will not be responsible for any water damage that may occur. If you install a

drain pan under the unit, ensure that it will not restrict the combustion air

flow.

The manufacturer does not recommend installing unit in an attic due

to safety issues. If you install your water heater in an attic:

Make sure your unit will have enough combustion air and proper

ventilation.

Keep the area around your water heater clean. When dust collects on

the flame sensor, the water heater will shut down on errors.

If the above conditions cannot be met, use the direct-vent conversion kit

9007668005 (TM-DV32).

Locate unit for easy access for service and maintenance.

A drain pan is required to be installed under the water heater in cas e of

leaks.

- 5 -

GENERAL

1. The manifold gas pressure is preset at the factory. It is computer controlled and should

not need adjustment.

2. Maintain proper space for servicing. Install the unit so that it can be connected or

removed easily. Refer to p. 8 and p. 9 for proper clearances.

3. The electrical connection requires a means of disconnection, to terminate power to the

water heater for servicing and safety purposes.

4. If you will be installing the unit in a contaminated area with a high level of dust, sand,

flour, aerosols or other contaminants/chemicals, they can become airborne and enter

and build up within the fan and burner causing damage to the unit. In those

environments (e.g. residential or commercial laundry facilities, hair salons, pet salons,

chemical plants etc.), please purchase the optional direct-vent conversion kit and

convert the water heater to a s ealed combustion unit. Direct venting allows the water

heater to draw fresh intake air from the outside. The warranty will not cover damage

caused to the unit due to installation in a contaminated environment that has not been

converted using the direct-vent conversion kit.

5. Particles from flour, aerosols, and other contaminants may clog the air vent or reduce

the functions of the rotating fan and cause improper burning of the gas. Regularly ensure

that the area around the unit is dust- or debris-free; regular maintenance is

recommended for these types of environment.

6. Do not install the unit where the exhaust vent is pointing into any opening in a building or

where the noise may disturb your neighbors . Make sure the vent termination mee ts the

required distance by local code from any doorway or opening to prevent exhaust from

entering a building (refer to p. 14).

INCLUDED ACCESSORIES

Check that these items below are included with the water heater.

Items

Manual

Communication Cable

- 6 -

Qty: 1

Qty: 1

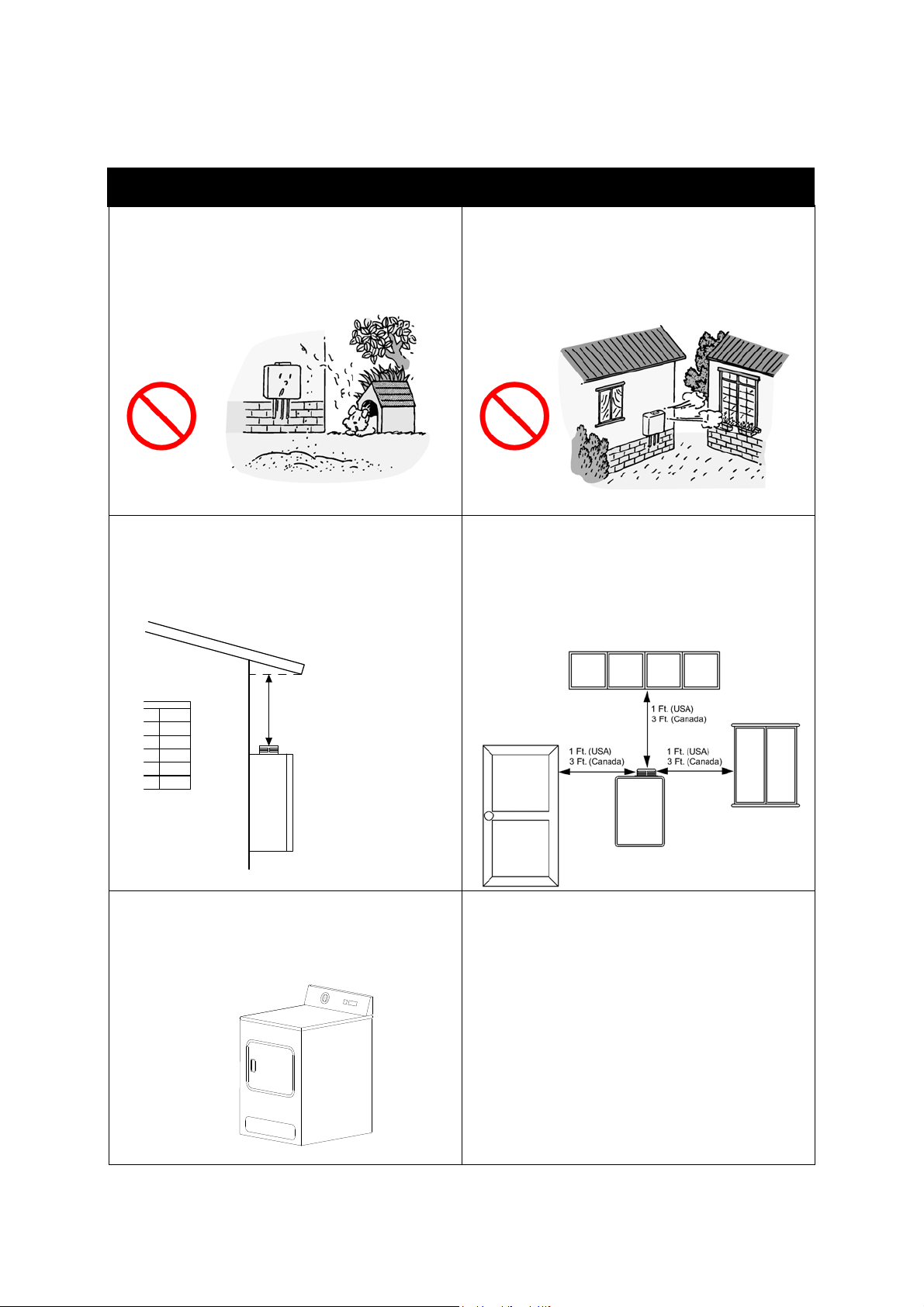

WARNING FOR INSTALLATIONS

FOR YOUR SAFETY, READ BEFORE INSTALLATION:

Do not install the heater where water, debris

or flammable vapors may get into the flue

terminal. This may cause damage to the

heater and void the warranty.

Prohibited Prohibited

Do not install this water heater under an

overhang less than 3 feet from its top or

eaves. The area under an overhang must be

open to three sides.

Do not have the vent terminal pointing toward

any opening into a building. Do not locate

your heater in a pit or location where gas a nd

water can accumulate.

Do not install the water heater vent terminator

within 1 ft. in the USA of any air intake or

building opening, and within 3 ft. in Canada of

any air intake or building opening. (Refer to

p.14)

3 Ft.

Do not install next to a dryer or any source of

airborne debris that can be trapped inside the

combustion chamber, unless the system is

direct vented.

- 7 -

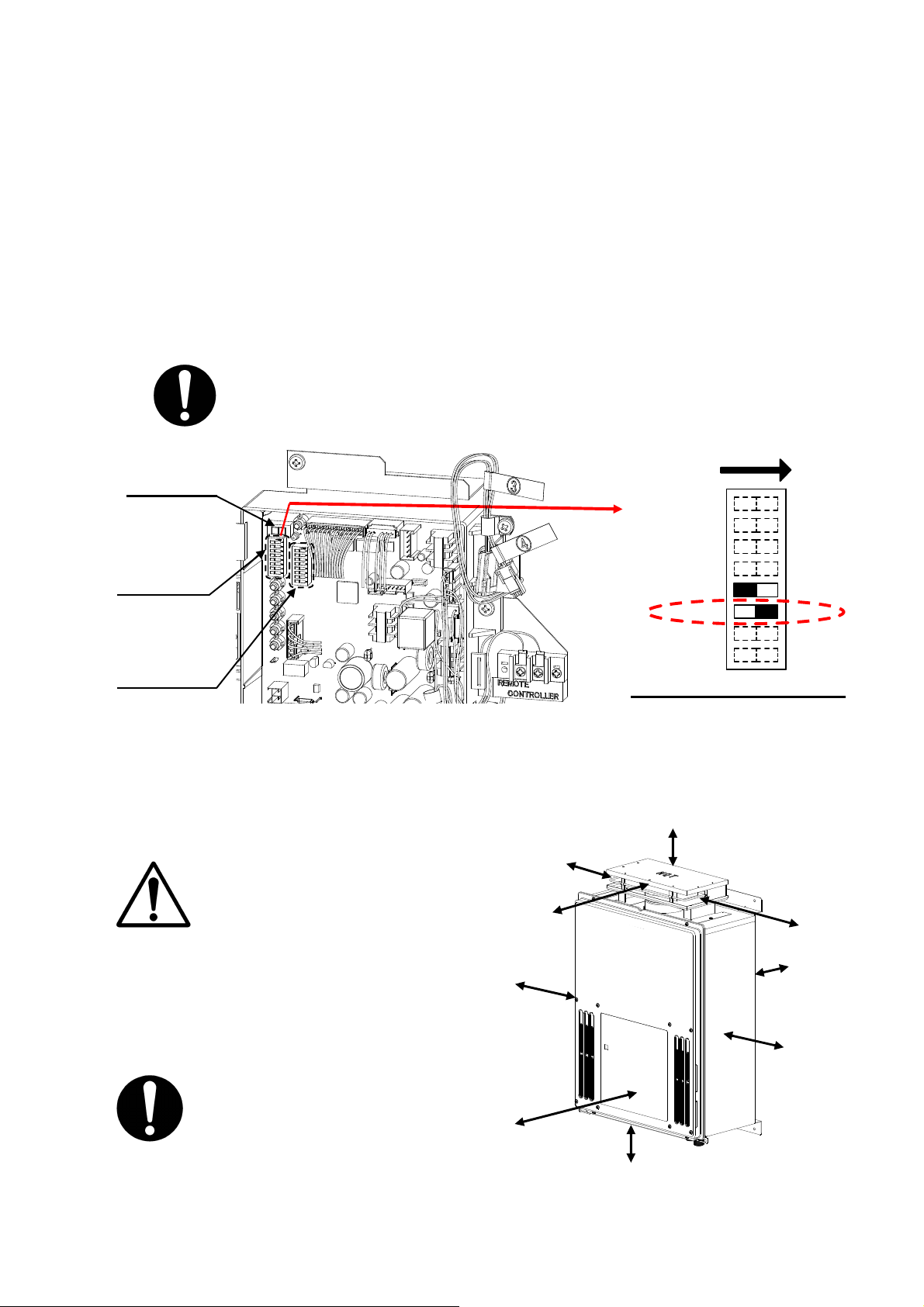

OUTDOOR INSTALLATION

1. Follow all local codes, or in the absence of local codes, follow the most recent edition of

the National Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or CAN/CSA B149.1

Natural Gas, Propane Installation Code in Canada.

2. Install outdoors only in areas with mild, temperate climates.

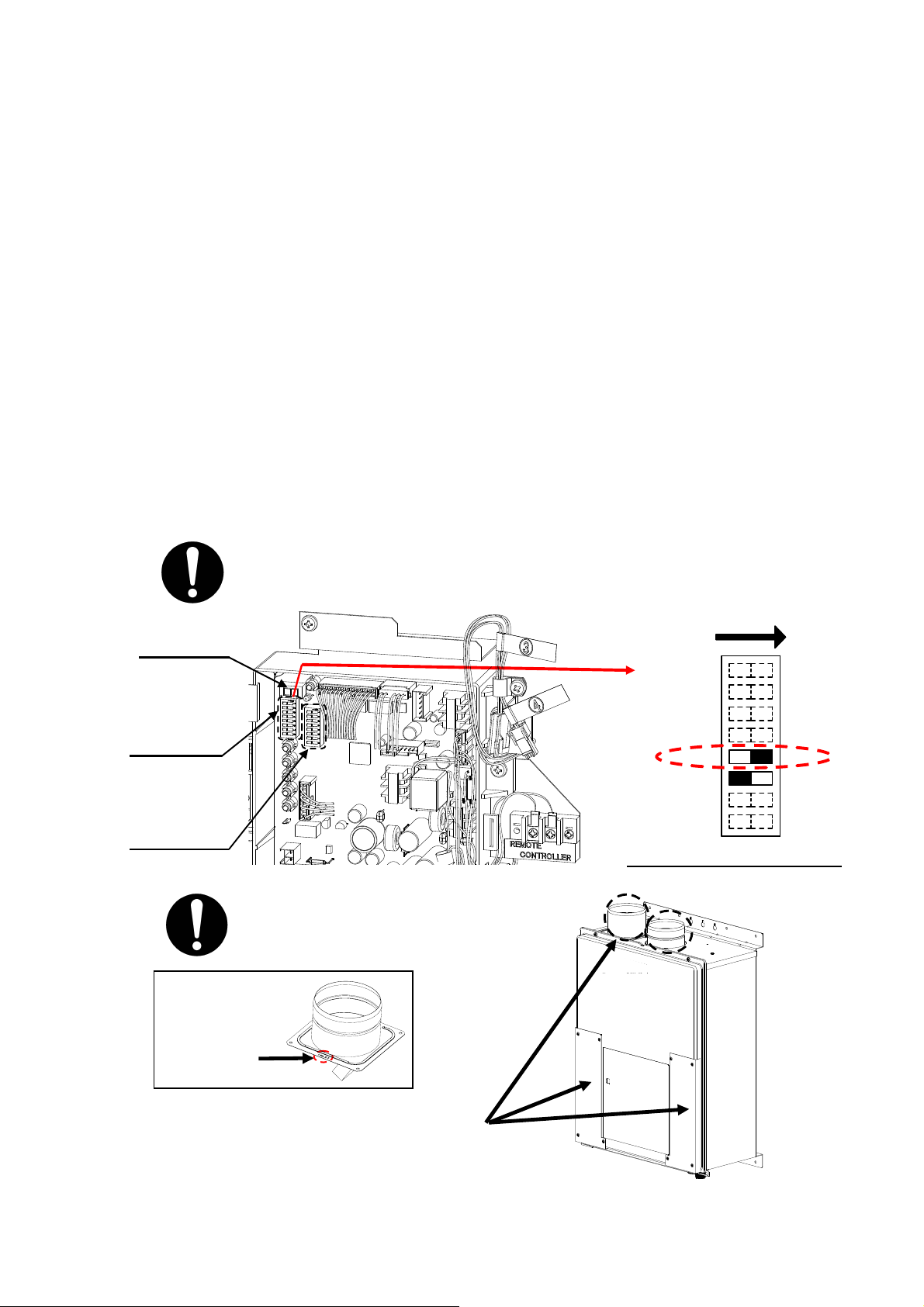

3. Ensure that the unit is set for outdoor installation. Locate the left bank of dipswitches to

the bottom of the 7-Seg. LED on the computer board. The ‘OUT’ dipswitch on that

bank should be switched to its ‘ON’ (right) position (Do not adjust the right bank of

dipswitches).

7-Seg LED

Left bank of

dipswitches

Right bank of

dipswitches

4. The outdoor vent cap must be used when unit is installed outdoor. The manufacturer

requires the use of its part No. 9007676005 (TM-VC32).

Make sure power to the unit is

turned OFF before changing

the dipswitch settings.

The dark square is the direction

the dipswitch should be set to.

ON

TMP1

TMP2

TMP3

MODE

DIRE

OUT

D-PRT

MST

Left Bank of Dipswitches

1

2

3

4

5

6

7

8

5. When installed outdoors, the water heater shall be wall-mounted or mounted on a stand.

Locate the water heater in an open, unroo fed area and maintain the followin g minimum

clearances:

There is a 2” clearance from the

left and right sides of the unit to

combustible and non-combustible

surfaces. Howeve r, if any portion

or area of the surface is exposed

*Side 24”

*Front 24”

Top 36”

to the exhaust fumes (i.e. directly

to the sides of the vent cap), that

surface must be at least 24”

away.

Side 2”

Keep the clearances.

Front 4”

(24” Recommended

for Maintenance)

- 8 -

Bottom 12”

*Side 24”

Back 1”

Side 2”

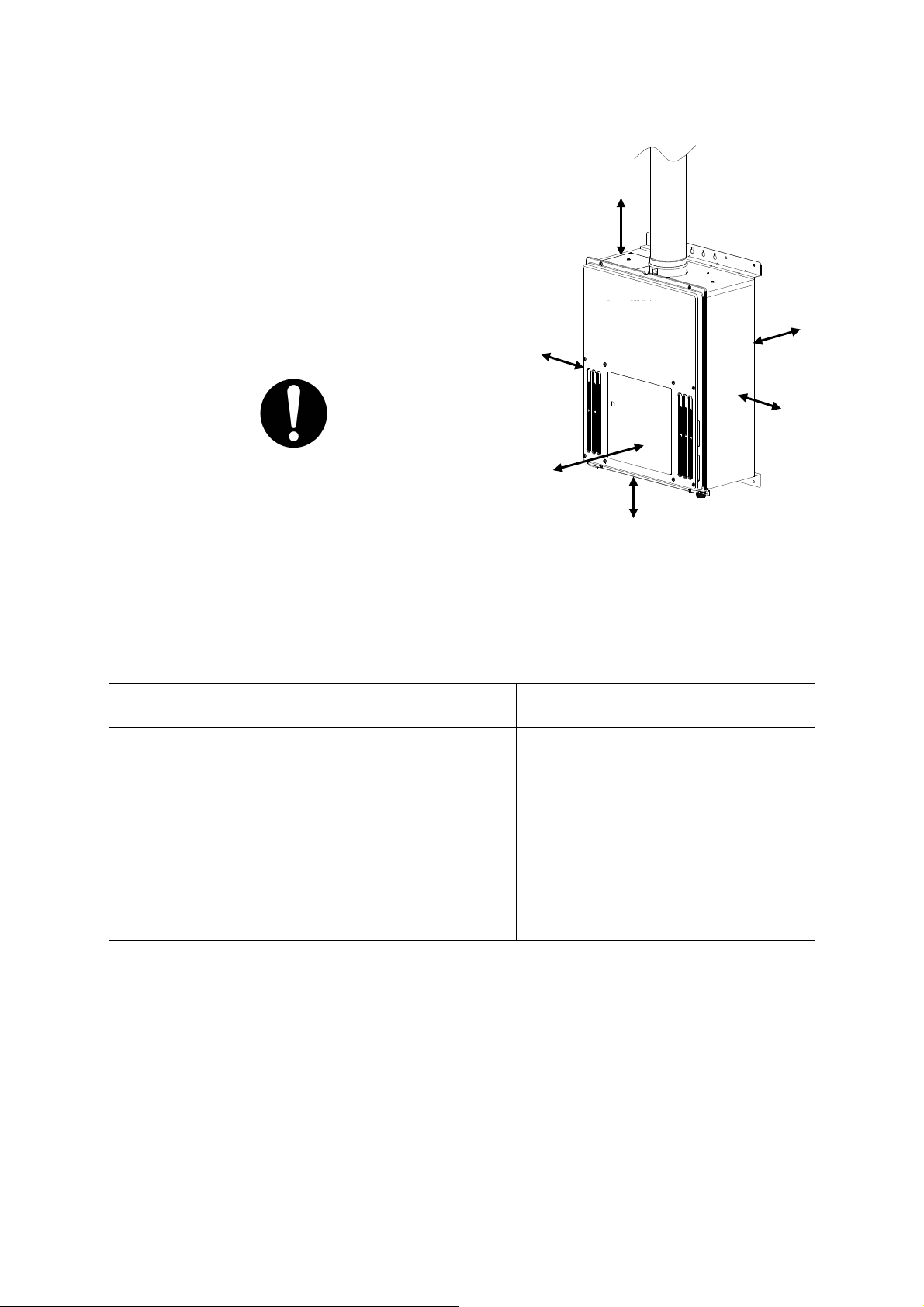

INDOOR INSTALLATION

1. Follow all local codes, or in the absence of local

codes, follow the most recent edition of the

National Fuel Gas Code: ANSI Z223.1/NFPA 54

in the USA or CAN/CSA B149.1 Natural Gas,

Propane Installation Code in Canada.

2. When installed indoors, the water heater shall be

located in an area to maintain the following

minimum clearances around the unit:

Keep the following

clearances.

(24” Recommended

for Maintenance)

Combustion Air Supply

The water heater location must provide enough air for proper combustion and ventilation of the

surrounding area. See the latest edi tion of ANSI Standard Z22 3.1 or an y a pplicable local codes .

In general, these requirements specify that if the unit is install ed in a confi ned space, there mu st

be a permanent air supply opening.

Minimum recommended air supply opening size for water heater:

Water heater size

When drawing

outside the building

make-up air from

Side 2”

Front 4”

When drawing make-up

the building (from other rooms within)

Top 12”

Back 1”

Side 2”

Bottom 12”

air from inside

240 Sq. IN

MAX

240,000 BTU

/h

16.0 Sq. IN

When combustion air is supplied

from outside the building, an

opening communicating directly

with the outside should have a

minimum free area of one

square inch per 15,000 BTUH

input of the total input rating of

water heater in the enclosed

area.

When combustion air is supplied from

inside the building, an opening

communicating with the rest of the

dwelling should have a minimum free

area of one square inch per 1,000

BTUH inpu t of the total input rating of

water heater in the enclosed area.

This opening should never be less

than 199 sq. in.

Combustible Air Supplied by Mechanical fan or Make up air device

The water heater is equipped with a combustible air sensor that will shut off the unit when

inadequate combustible air supply to unit is detected.

If a mechanical fan or make up air device is used to supply air to the water heater or

utility room, the installer should make sure it does not create drafts which could cause

nuisance shutdowns.

If a blower is necessary to provide adequate combustion air to the water heater, the

blower and water heater must be set up so that the water heater cannot fire unless the

blower is operating. Possible methods include the use of external flow

sensors/transmitters and relays.

- 9 -

DIRECT INTAKE VENT SYSTEM

This water heater may be converted to a direct-vent (sealed combustion) appliance by installing

an adapter (Part No. 9007668005 (TM-DV32)) which will bring all requir ed combustible air from

outside the building. When installing the direct-vent conversion kit, please follow all instructions

included with the kit.

The water heater must be installed in a location where the proper amount of combustible

air will be available to it at all times without obstructions.

If used as a direct-vent appliance, the water h eater requires a 4” combustible air supply

pipe. The intake pipe must be sealed airtight.

Air supply pipe can be made of ABS, PVC, galvanized steel, corrugated aluminum,

corrugated stainless steel or Category III stainless steel.

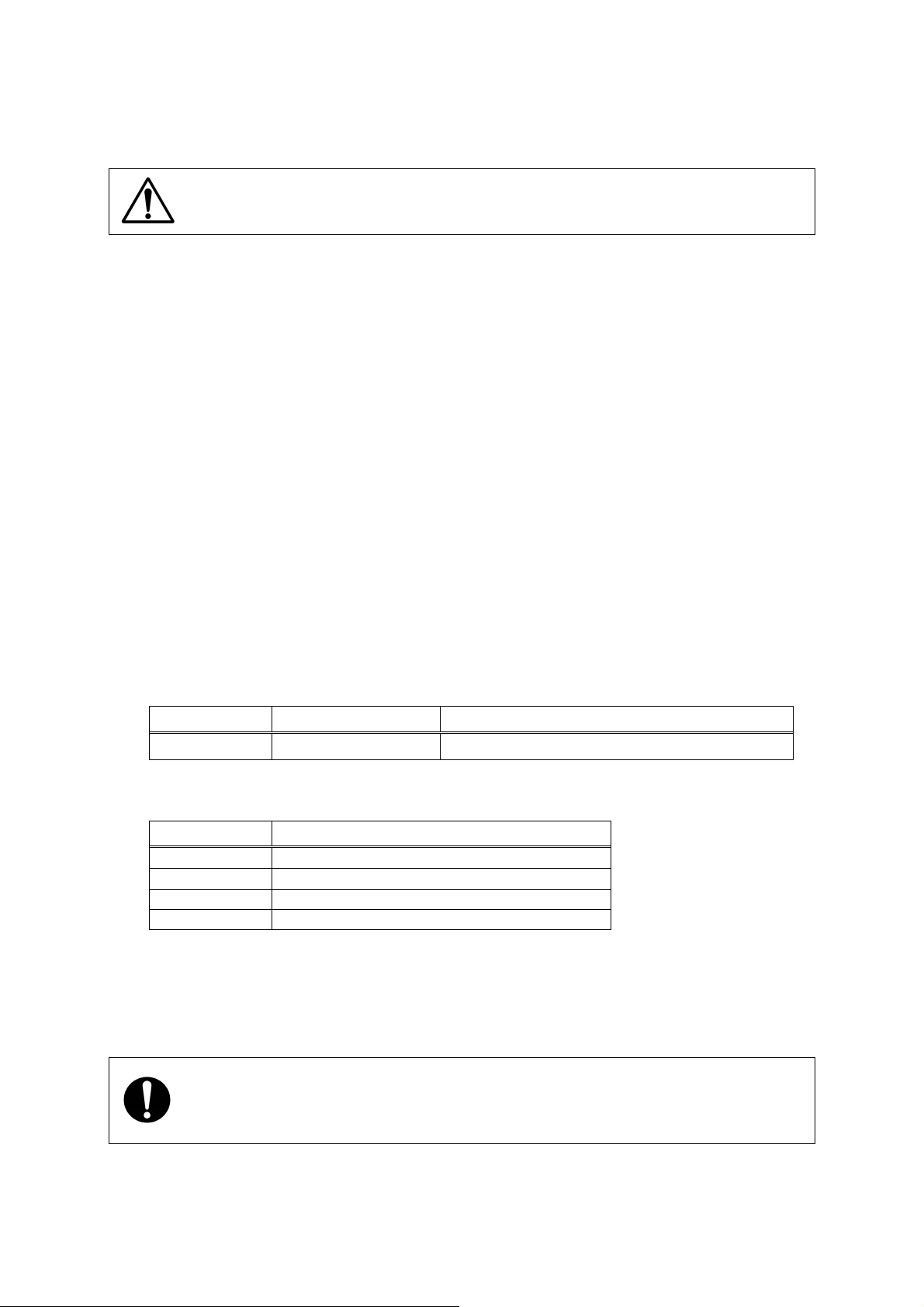

Change the dipswitch settings to the direct-vent system. (See diagram below)

Sidewall venting is recommended for the direct-vent system.

The manufacturer recommends running the exhaust vent and the intake pipe parallel.

The Direct-Vent Conversion Kit has an “INLET” mark as shown below. Do not

reverse the INLET and the EXHAUST connections when installing vent pipes.

7-Seg LED

Left bank of

dipswitches

Right bank of

dipswitches

Make sure power to the unit is

turned OFF before changing

the dipswitch settings.

The dark square is the direction

the dipswitch should be set to.

ON

TMP1

TMP2

TMP3

MODE

DIRE

OUT

D-PRT

MST

1

2

3

4

5

6

7

8

Left Bank of Dipswitches

INLET

Direct-Vent

Conversion Kit

EXHAUST

“INLET” mark

DIRECT-VENT

CONVERSION KIT

- 10 -

VENTING INSTRUCTIONS

This water heater must be vented in accordance with the sec tion “Venting of Equipment" o f the

latest edition of the Natural Fuel Gas Code: ANSI Z223.1, all applicable loc al building codes,

and Section 7 of CAN/CSA B149.1 Natural Gas in Canada, Propane Installation Code in

Canada.

WARNING: Improper venting of this appliance can result in excessive levels of

carbon monoxide which can result in severe personal injury or death.

EXHAUST VENT

This is a Category III appliance and must be vented accordingly. The vent system must be

sealed airtight. All seams and joints without gaskets must be sealed with high heat res istant

silicone sealant or UL listed aluminum adhesive tape ha ving a minimum temperature rating of

350 ºF. For best results, a vent system should be as short and straight as possible.

1. This water heater is a Category III appliance and must be vented accordingly with an y 4”

vent approved for use with Category III or Special BH type gas vent.

2. The manufacturer recommends the NovaVent line. However, the following are also UL

listed manufacturers: ProTech Systems Inc. (FasNSeal), Metal-Fab Inc., and Heat-Fab Inc.

(Saf-T Vent).

3. Follow the vent pipe manufacturer’s instructions when installing the vent pipe.

4. Do not common vent this appliance with any other vented appliance. (Do not

terminate vent into a chimney. If the vent must go through the chimney, the vent must run

all the way through the chimney with Category III approved or Special BH vent pipe.)

5. The maximum length of exhaust vent piping must not exceed 50 ft. deducting 5 ft. for each

elbow used in the venting system. Do not use more than 5 elbows.

Diameter Max. No. of Elbows Max. Vertical or Horizontal Length

4” 5 Ea. 50 ft

*For each elbow added, deduc t 5 ft. from max. vent le ngth.

No. of Elbows Max. Vertical or Horizontal Length

0 50 ft.

1 45 ft.

2 40 ft.

5 25 ft.

6. When the horizontal vent run exceeds 5 ft., support the vent run at 3 ft. intervals with

overhead hangars.

7. The manufacturer will not be responsible for any damage to the water heater caused by

condensation from the vent. Installing a condensate drain is recommended. Please refer

to p. 13 for the diagrams.

When installing the vent system, all applicable national and local codes must be

followed. If you install thimbles, fire stops or other protective devices and they

penetrate any combustible or noncombustible construction, be sure to follow all

applicable national and local codes.

- 11 -

VENT TERMINATION

WARNING: Improper installation can cause nausea or asphyxiation, severe injury

or death from carbon monoxide and flue gases poisoning. Improper installation

will void product warranty.

The vent termination provides a means of instal ling vent pipe through the building wall and

must be located in accordance with ANSI Z223.1/NFPA 54, or in Canada with CAN/CSAB149.1 and local applicable codes.

A proper sidewall vent termination is recommen ded when the w ater heat er is v ented through

a sidewall. If the water heater is converted to a direct-vent unit, a proper sidewall direct-vent

termination is to be used.

General rules for venting the water heater are:

1. Place the water heater as close as possible to the vent termination.

2. The vent collar of the water heater must be fastened directly to an unobstructed vent pipe.

3. Do not weld the vent pipe to the water heater collar.

4. Do not cut the vent collar of the unit.

5. The weight of the vent stack must not rest on the water heater.

6. The vent must be easily removable from the top of the water heater for normal service and

inspection of the unit.

7. The water heater vent must not be connected to any other gas appliance or vent stack.

8. Avoid locating the water heater vent termination near any air intake devices. These fans

can pick up the exhaust flue products from the water heater and return them to the building.

This can create a health hazard.

9. Avoid using an oversized vent pipe or using extremely long runs of the pipe.

10. Locate the vent termination so that it cannot be blocked by any debris, at any time. Most

codes require that the termination be at least 12 inches above grade, but the ins taller may

determine if it should be higher depending on the job site condition and applicable codes.

11. For rooftop venting, a rain cap must be installed.

12. The manufacturer recommends the NovaVent line. How ever, the following a re also UL

listed manufacturers: ProTech Systems Inc. (FasNSeal), Metal-Fab Inc., and Heat-Fab Inc.

(Saf-TVent).

- 12 -

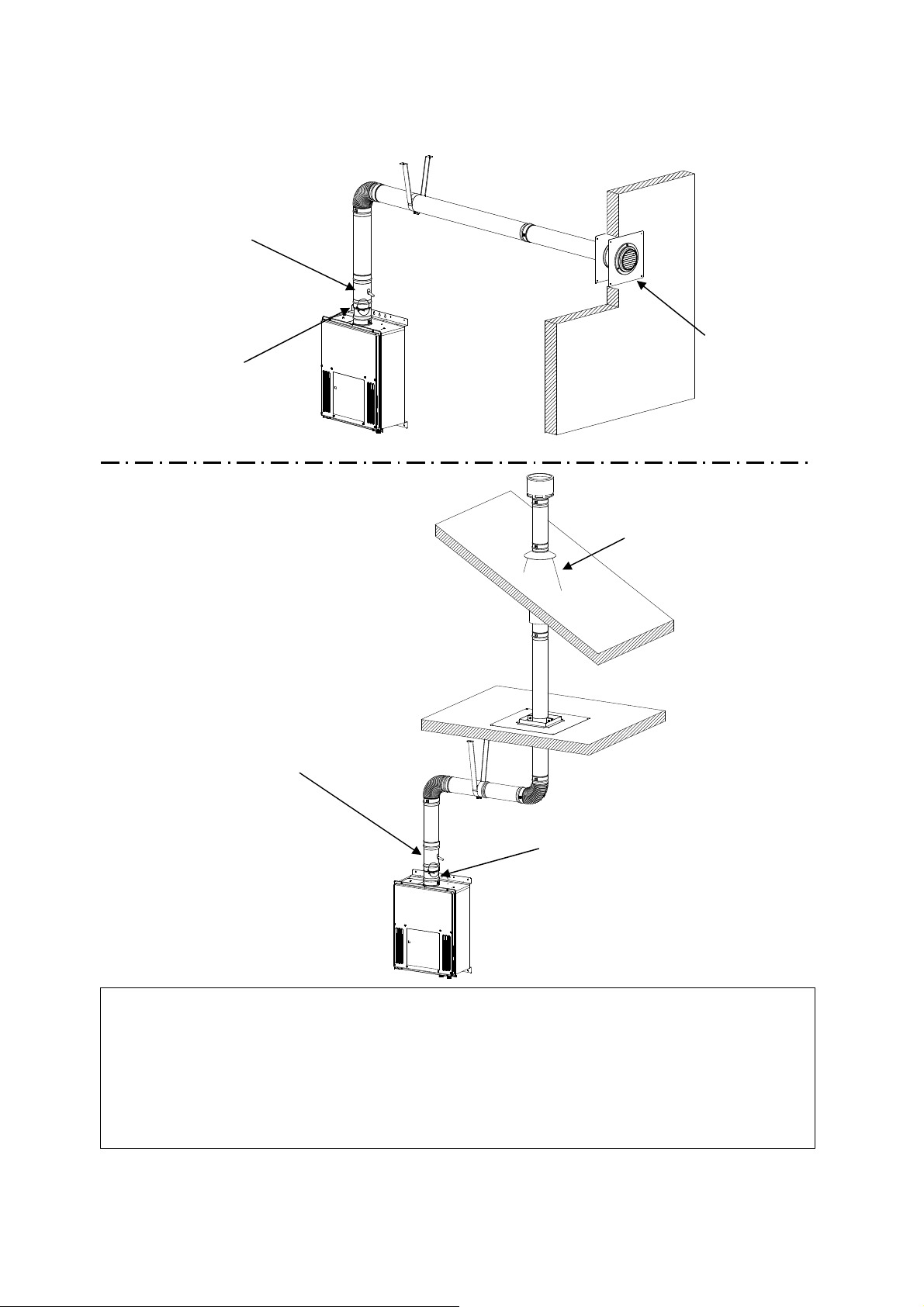

Horizontal Installation Diagram

Vertical condensation drain

(Install according to local codes)

Backflow preventer

(Recommended for freezing

weather conditions: 36 °F and

below)

Vertical Installation Diagram

Vertical condensation drain

(Install according to local codes)

Roof

Rain cap

Roof flashing

Backflow preventer

(Recommended for freezing

weather conditions: 36 °F and

below)

Wall

Sidewall vent

termination

Regarding the clearance from the terminal to the air inlet or opening, refer to the next page.

Install a condensation drain in the venting.

Follow the vent manufacturer’s instructions and local codes.

Do not common vent or connect any vent from other appliances to the water heater vent.

Use 4” category III approved or Special BH, single or double wall stainless steel vent pipe.

- 13 -

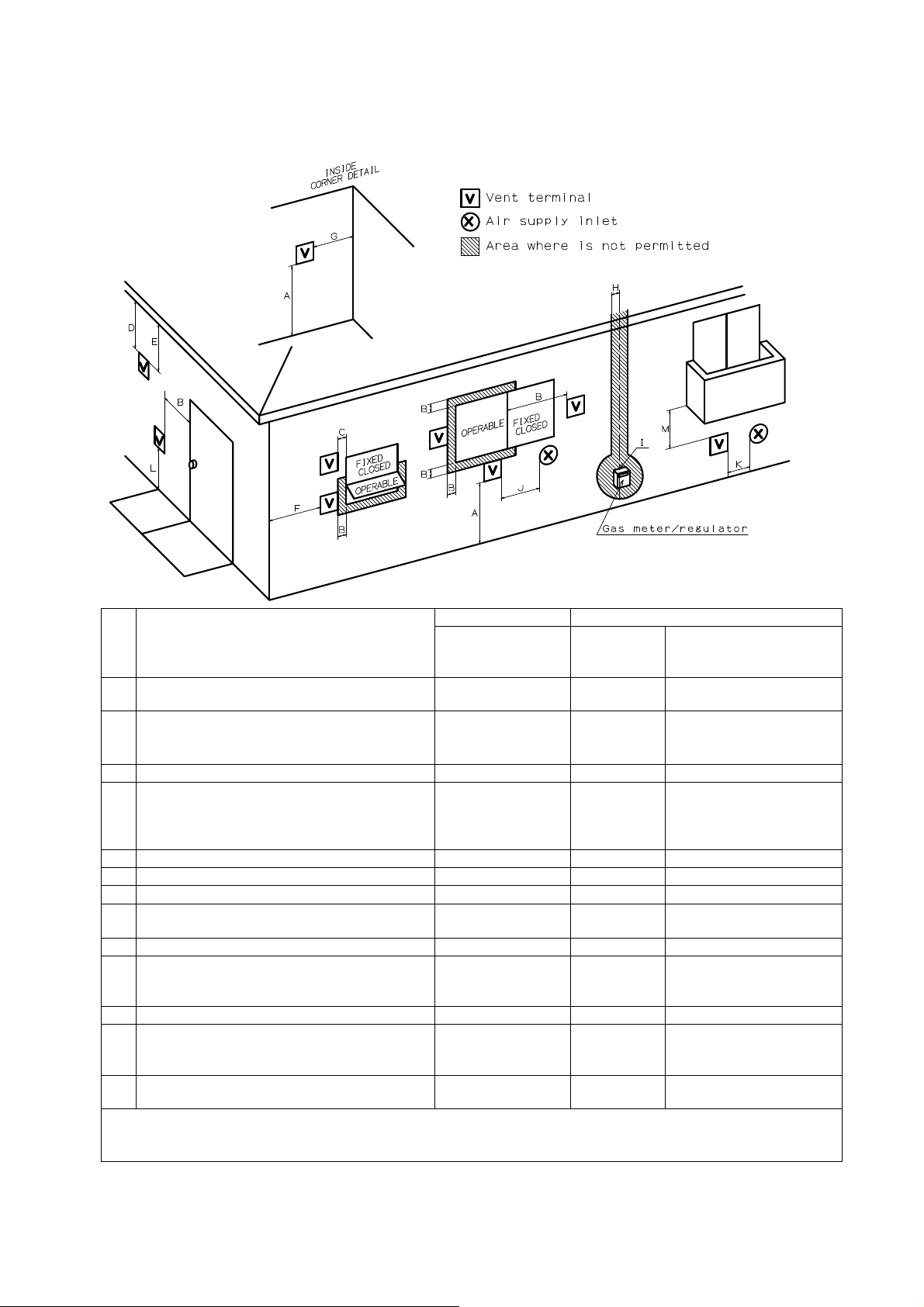

VENT CLEARANCES

Canada U.S.A

Clearance above gra d e, v era nd a, porch,

A

deck, or balcony.

Clearance to window or door that may be

B

opened.

Clearance to permanently closed window * * *

C

Vertical clearance to ventilated soffit

located above the vent terminator within a

D

horizontal distance of 2 feet (61cm) from

the center line of the terminator.

Clearance to unventilated soffit * * *

E

Clearance to outside corner * * *

F

Clearance to inside corn e r * * *

G

Clearance to each side of center line

H

extended above meter/regulator assembly

Clearance to service regu l ator vent outlet. 3 feet * *

I

Clearance to non-mechanical air supply

inlet to building or the combustion air inlet

J

to any other application.

Clearance to mechanical air supply inlet. 6 feet 3 feet 3 feet

K

Clearance above paved sidewalk or

paved driveway located on public

L

property.

Clearance under v er a nda, porch deck, or

M

balcony.

*For clearances not specified in ANSI Z223.1 / NFPA 54 or CAN/CSA-B149.1, please use clearances in

accordance with local ins tallation codes and the requirement of the gas supplier.

Direct vent and

other than Direct

Vent

1 foot 1 foot 1 foot

3 feet 1 foot

* * *

3 feet * *

3 feet 1 foot

7 feet * 7 feet

1 foot * *

Direct vent Other than Direct Vent

4 feet from below or

side opening. 1 foot

from above opening.

4 feet from below or

side opening. 1 foot

from above opening.

- 14 -

GAS SUPPLY AND GAS PIPE SIZING

1. Turn off all electric power to the water heater if service is to be performed.

2. Turn the manual gas valve located on the outside of the unit clockwise to the off position.

WARNING: Conversion of this unit from natural gas to propane or vice versa will

void all warranty. Contact your local distributor to get the correct unit for your gas

type. The manufacturer is not liable for any property and/or personal

damage resulting from gas conversions.

*Check that the type of gas matches the rating plate first.

The minimum and maximum inlet gas pressures are:

Gas type Inlet gas pressure

Natural Gas Min. 5.0” W.C. – Max. 10.5” W.C.

Propane Min. 8.0” W.C. – Max. 14.0” W.C.

Inlet gas pressures that fall outside the range of values listed above may adversely affect the

performance of the water heater. These pressures are measured when the water heater is in full

operation.

TO TURN OFF GAS TO APPLIANCE

Inlet gas pressure must not exceed the above maximum values; gas pressure above the specified

range will cause dangerous operating conditions and da mage to the unit. Ensure that any and all

gas regulators used are operating properly and are providing gas pressures within the specified

range shown above.

Until testing of the main gas line supply pressure is completed, ensure the gas line to the water

heater is disconnected to avoid any damage to the water heater.

-Gas connections-

1. Install a manual gas shutoff valve between the water heater and the gas supply line.

2. When the gas connections are completed, it is necessary to perform a gas leak test either by

applying soapy water to all gas fittings and observing for bubb les or by using a gas leak detection

device.

The water heater and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pr essures in excess of 1/2 psi

(3.5 kPa).

The water heater must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5kPa).

3. Always purge the gas line of any debris and/or water before connecting to the gas inlet.

NOTICE

Size the gas pipe appropriately to supply the necessary volume of gas required for the

water heater using ANSI Z223.1/NFPA 54 in the USA or CAN/CSA B149.1 in Canada

or local codes. Otherwise, flow capabilities and output temperatures will be limited.

- 15 -

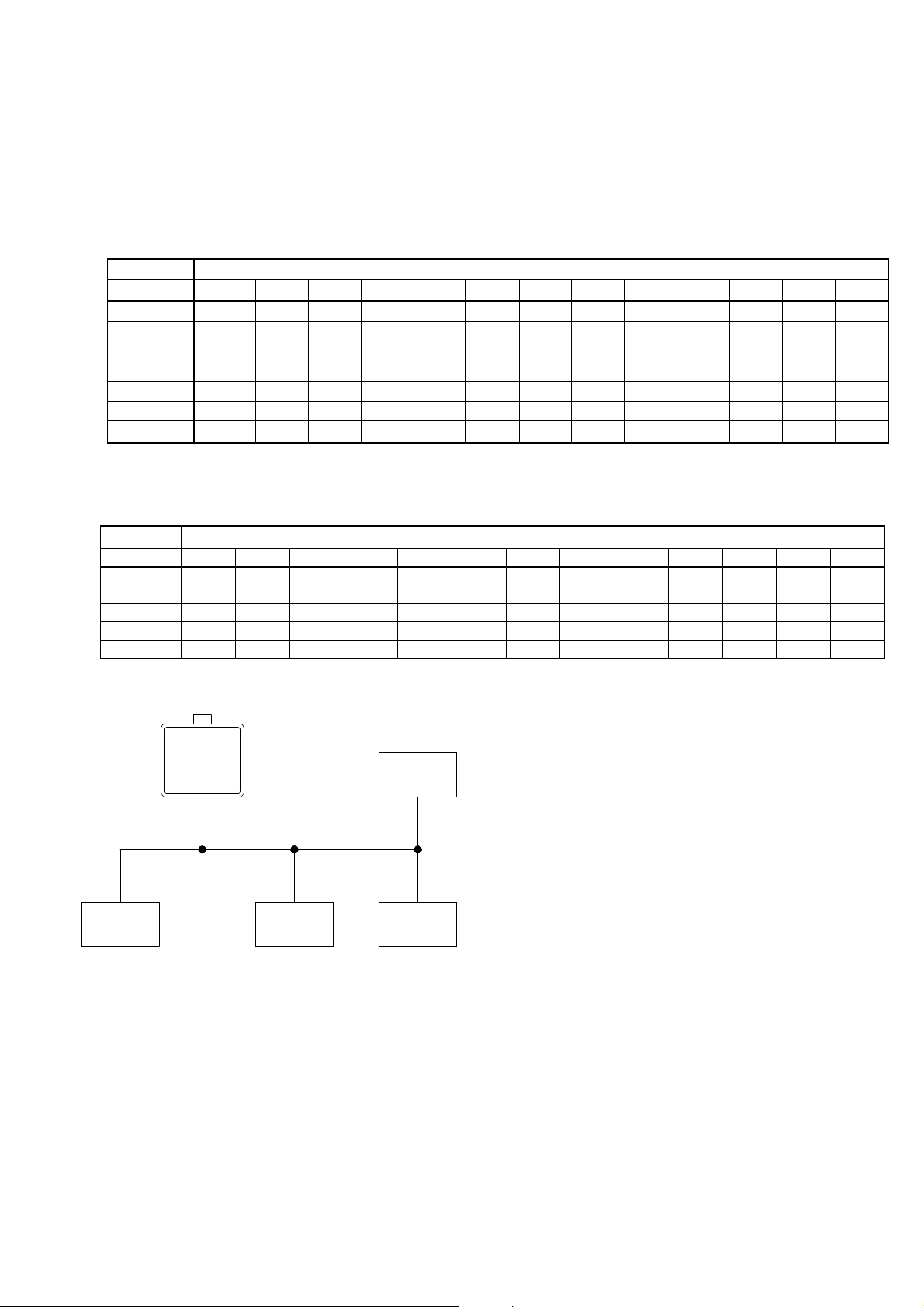

Natural Gas Supply Piping

Maximum Delivery Capacity of Cubic Feet of Gas per Hour of IPS Pipe Carrying Natural Gas of 0.60 Specific Gravity

Based on Pressu re Drop of 0.5” WC

Based on Energy Content of 1,000 BTU/Cubic Ft.: 710 (T-M32) requires 240 Cubic Ft./hr. Unit: Cubic Feet per Hour

Pipe Size Length

Diameter 10' 20' 30' 40' 50' 60' 70' 80' 90' 100' 125' 150' 200'

¾”

1”

1 ¼”

1 ½”

2”

2 ½”

3”

363 249 200 171 152 138 127 118 111 104 93 84 72

684 470 377 323 286 259 239 222 208 197 174 158 135

1,404 965 775 663 588 532 490 456 428 404 358 324 278

2,103 1,445 1,161 993 880 798 734 683 641 605 536 486 416

4,050 2,784 2,235 1,913 1,696 1,536 1,413 1,315 1,234 1,165 1,033 936 801

6,455 4,437 3,563 3,049 2,703 2,449 2,253 2,096 1,966 1,857 1,646 1,492 1,277

11,412 7,843 6,299 5,391 4,778 4,329 3,983 3,705 3,476 3,284 2,910 2,637 2,257

Propane (LP) Gas Supply Piping

Maximum Capacity of Propane (LP) Gas Based on 11” WC supply pressure at a 1.0” WC pressure drop

Unit: kBTU per Hour

Pipe Size

Diameter 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ 100’ 125’ 150’ 200’

¾”

1”

1 ¼”

1 ½”

2”

567 393 315 267 237 217 196 185 173 162 146 132 112

1,071 732 590 504 448 409 378 346 322 307 275 252 213

2,205 1,496 1,212 1,039 913 834 771 724 677 630 567 511 440

3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787 675

6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496 1,260

Water

Heater

240,000BTU

5’ Length

1-1/4” Pipe Size

A

5’ Length

1-1/4” Pipe Size

Gas Meter

Gas Sizing Example

(Natural Gas)

10’ Length

3/4” Pipe Size

10’ Length

1” Pipe Size

B

10’ Length

3/4” Pipe Size

Furnace

120,000BTU

15’ Length

3/4” Pipe Size

Dryer

35,000BTU

10’ Length

1/2” Pipe Size

15’ Length

1/2” Pipe Size

Range

65,000BTU

Length

Based on Energy Content of 1,000BTU/Cubic Ft:

Divide each appliance’s BTU requirement by 1,000BTU to get

the appliances Cubic Ft. requirement.

Take into account the distance the appliance is from the gas

meter, look in the above gas chart to properly size the line.

For sections of the gas line supplying gas to more than one

appliance (Ex: Point A to Point B), add up the cubic ft.

requirements of the appliances that are being supplied by that

section, and size to the farthest appliance.

For Example: The section from A to B supplies gas to the

furnace, range, and dryer. Adding up the BTU requirements and

dividing by 1,000 yields a cubic ft. requirement of 220 cubic ft. of

gas. The farthest appliance is the range, which is 50 ft. away

from the meter. Looking at the above chart, and under the

column of 50ft., Section A to B needs to be 1” in order to supply

220 cubic ft.

- 16 -

Loading...

Loading...