Star Micronics TSP700 Installation Manual

Attaching the Wall Mounting Bracket of TSP700

1. Unpacking : Confirm that all accessories are included.

φ 4mm screws(8)

Not Supplied Users must prepare φ 4mm screws for bracket.

2. Attaching procedure :

Precautions when mounting

Shaft(C) |

Brand seal |

Holder plate |

|

||

|

|

|

Shafts(D) |

|

Bracket |

|

|

M3 × 12 screws (2)

(for attaching the holder plate)

M3 × 12 screw with flat washer (2) (for attaching the holder plate)

Roll stoppers

Ensure that power that is supplied to the printer and that all devices connected to the printer have been switched OFF and that the cables have been unplugged before starting the modification. If the AC adapter is connected to the printer, unplug it from the main socket.

Select a location where the unit will not be exposed to moisture or physical shocks. Make sure that the wall is wide enough to mount the brackets.

Carefully select screws for mounting the bracket to the wall. These screws must be strong enough to hold the printer and must be long enough to completely enter the wall to provide a secure mounting. Remember that Star accepts no responsibility for damage resulting from the printer falling due to improper mounting.

The weight of the printer, including a roll of paper with the largest diameter, is approximately 2.9 kg.

The screws for mounting the bracket must have both a shear and tensile strength capable of withstanding a load of 12 kgf (118 N) or more. It is recommended that anchor nuts be used.

A screw diameter of 4 mm is recommended.

Always use all eight (8) screw holes in the mounting bracket when securing the mounting bracket to the wall.

Mount the bracket to the wall so that its mounting accuracy is within a range of ±2 ° to the vertical direction.

The wall used for mounting should be 90°±2° in reference to the horizontal direction.

2-1. Specifications of the wall mounting bracket

Main unit outer dimensions |

121 × 168 × 14.5 mm (Width × Height × Depth) |

|

|

Main unit weight |

Approx. 0.27 kg. |

|

|

|

|

|

|

Screws for wall mounting |

Wood structure wall |

The eight (8) screws used must have both a |

Use commercially avail- |

bracket |

|

shear and tensile strength capable of withstand- |

able screws that have suf- |

|

|

ing a load of 12 kgf (118 N) or more |

ficient strength to with- |

|

|

|

stand the weight of the |

|

Concrete wall |

The anchor nuts used must have both a shear |

|

|

main unit. |

||

|

|

and tensile strength capable of withstanding a |

|

|

|

|

|

|

|

load of 12 kgf (118 N) or more |

|

|

|

|

|

2-2. Mounting the bracket for the wall mount model

1 Make sure there is enough room for the printer, particularly in the front of the printer when its cover is opened.

2As shown in the illustration to the right, place the mounting bracket against the wall where the printer is to be mounted and mark the positions of the screw holes.

3 Drill holes at the locations marked.

4Secure the bracket in place using screws with a diameter of 4 mm.

Note : Screws are not included in the package. Prepare the screws that can be used on the type of wall for mounting.

Wall material

Bracket

fig.1 Attaching the bracket

|

|

|

|

|

|

Wood structure wall |

Concrete structure wall |

|

|

|

|

|

|

|

|

• Locate the beams in the wall and |

• Drive the anchor nuts into the wall and |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

mount using them. |

tighten the screws. |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

• Do not tighten the screws or anchors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

to locations with one wall sheet. |

Anchor nuts |

|

|

|

|

|

|

|||

|

|

|

|

|

|

Always make sure that the screws |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Beam |

penetrate the beams. (This is so the |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

weight of the printer can be supported.) |

Concrete wall |

|

|

|

|

|

|

|

Wall |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

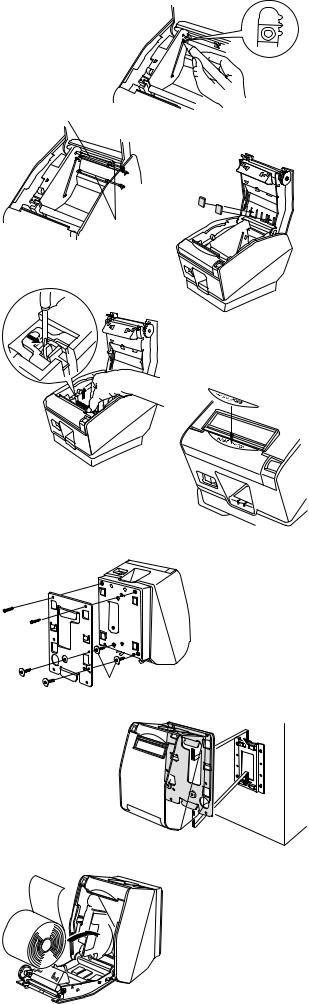

2-3. Changing the position of the near end sensor

Press the sensor hole with the tip of a pen or any other pointed-tip object and slide the Near End Sensor to the position shown in the figure. Check that the protrusion is securely fit into the groove.

2-4. Attaching the shafts

Attach the three shafts to the printer.

2-5. Attaching the roll stoppers

Attach the two roll stoppers in the positions shown in the figure. Ensure that any dirt has been completely wiped away before attaching the stoppers.

2-6. Removing the tension bar unit

Use a regular screwdriver to remove the clips at both ends of the bar to remove the tension bar unit.

2-7. Attaching the brand seal

Place the brand seal that was supplied over the existing brand seal. (The characters on the operation panel will be inverted when the printer is attached to a wall or onto a stand.)

2-8. Attaching the holder plate

1Remove the two screws from the printer as shown in the illustration.

2Attach the holding plate to the printer. Then tighten the four M3 screws that were supplied to secure it in place. The screws fitted with flat washers are used where the screws were previously removed.

2-9. Setting the printer onto the bracket

Position the printer over the wall bracket and then slide it downward to set it in place.

The printer is fixed in place by interlocking the hook on the plate attached to the bottom of the printer with the hook connector on the bracket. It is not necessary to secure it further with screws.

Shaft(C) |

fig.2 Changing the position of the |

|

near end sensor |

Shafts(D)

fig.3 Attaching the shafts

fig.4 Attaching the roll stoppers

fig.5 Removing the tension bar unit

fig.6 Attaching the brand seal

Remove the screws

fig.7 Attaching the holder plate

fig.8 Setting the printer onto the bracket

2-10. Setting the roll paper

1 Push the cover open lever, and open the printer cover. 2 Insert the roll paper as shown.

fig.9 Setting the roll paper

80871180 WB-T700

Loading...

Loading...