Page 1

DOT MATRIX PRINTER MECHANISM

MP111MP-24G-A

MP115MP-24G-A

SPECIFICATION

AND

OPERATION MANUAL

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without STAR’s

express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time of going to

press. However, should any errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

Copyright 1999 Star Micronics Co., LTD.

Page 3

Contents

1. GENERAL DESCRIPTION ................................................................................................................ 1

2. CONSTRUCTION ................................................................................................................................ 2

2.1 Configuration ........................................................................................................................... 2

2.2 Principle of Operation.............................................................................................................. 2

3. GENERAL SPECIFICATIONS .......................................................................................................... 5

3.1 Printing Specifications ............................................................................................................. 5

3.2 Paper Specifications................................................................................................................. 6

3.3 Ink Ribbon Specifications........................................................................................................ 7

3.4 Connector Specifications ......................................................................................................... 9

3.5 Print Timing ........................................................................................................................... 11

3.6 Timing Chart.......................................................................................................................... 12

3.7 Print Head Specifications....................................................................................................... 14

3.8 CR Motor Specifications........................................................................................................ 18

3.9 Paper Feed Motor Specifications ........................................................................................... 20

3.10 Ribbon Shift Solenoid (RS-SOL) Specifications................................................................... 21

3.11 Timing Signal Detector Specifications .................................................................................. 22

3.12 Home Position Detector (HP-sig) Specifications .................................................................. 23

3.13 Paper-out Detector (PE-sig) Specifications ........................................................................... 23

3.14 Ribbon Position Detector (RS-sig) Specifications (MP115MP only) ................................... 24

3.15 Dimension and Weight .......................................................................................................... 24

4. RELIABILITY SPECIFICATIONS ................................................................................................. 27

5. SETTING THE RIBBON CARTRIDGE ......................................................................................... 28

6. SETTING THE PAPER ..................................................................................................................... 29

6.1 Setting the Paper .................................................................................................................... 29

6.2 Removing the Paper............................................................................................................... 29

7. INSTALLATION ................................................................................................................................ 30

8. OPERATIONAL NOTES .................................................................................................................. 35

8.1 Power ON/OFF Note ............................................................................................................. 35

8.2 Carriage Motor Protection Method (Against Mechanical Errors) ......................................... 36

8.3 Other Notes ............................................................................................................................ 36

9. POWER SUPPLY CAPACITY .........................................................................................................37

9.1 24 V Line ............................................................................................................................... 37

9.2 5 V Line ................................................................................................................................. 37

10.OPTIONS............................................................................................................................................. 38

Page 4

1. GENERAL DESCRIPTION

MP111MP-24G-A and MP115MP-24G-A are serial impact dot matrix printer mechanisms used to record

data and as electrical equipment such as for ECR.

Model Name Notation

MP1 1 1 M P - 24 G - A

G: FG compatible

Voltage

24 : 24 VDC

Paper-out detector

P : Includes the paper-out detector

Paper feed method

M : Friction method and stepping motor

Mechanism type

1 : Monochromatic, 16.9 CPI, 32 columns per line

5 : 2 colors, 16.9 CPI, 32 columns per line

Printer type

1 : Type 1

MP100 Series printer mechanism

– 1 –

Page 5

2. CONSTRUCTION

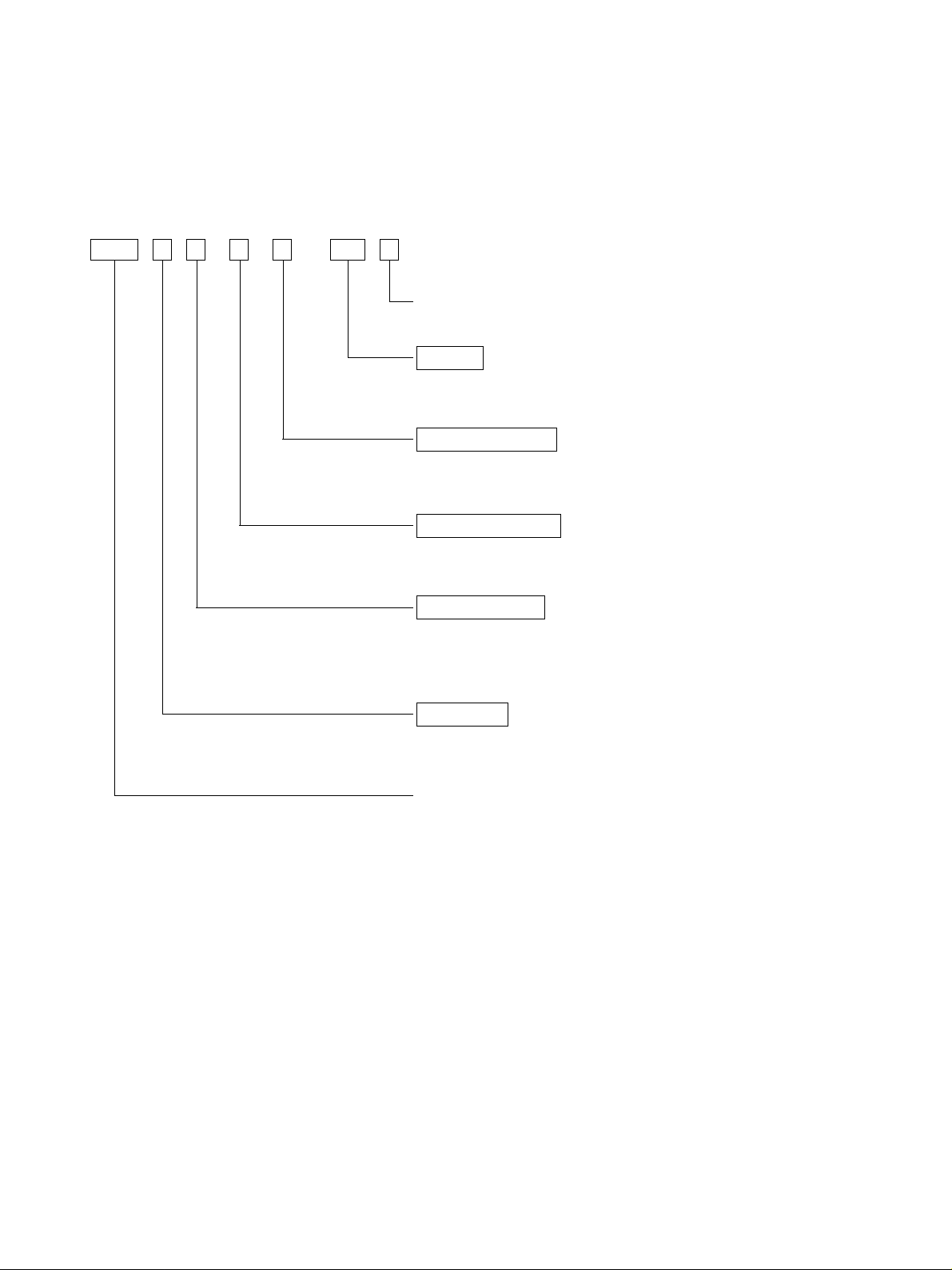

2.1 Configuration

This printer mechanism is composed of the following components.

Printer mechanism Drive unit, gears, and carriage unit

Detectors Timing detector

Home position detector

Paper out detector

Paper feed mechanism

Ink ribbon wind mechanism

Print head unit

Frame unit

Other

You can also use 1.75 inch (45 mm) width roll paper by removing the paper guide B and attaching the optional

guide.

2.2 Principle of Operation

2.2.1 Drive

This printer mechanism moves the print head, feeds paper and feed ribbon with the motor.

2.2.2 Print head movement

The rotation of the motor is transmitted to drive shaft through the reduction gears. The carriage makes lateral

reciprocal movements along a groove that is carved on this drive shaft, consequently moving the print head.

2.2.3 Print timing

Printing is done when the timing signal is generated synchronized with the rotation of the motor, based on the

home position signal.

2.2.4 Ribbon feed

The ink ribbon is housed inside a ribbon cartridge in endless fashion. A ribbon feed roller is turned by the

rotation of the motor whereby the ink ribbon is wound up.

2.2.5 Paper feed

Paper feeding is done by the rotation of the stepping motor.

– 2 –

Page 6

PF Motor

Drive Shaft

Carriage

Timing Detector

Motor

Home Position Detector

Paper Guide B

Paper Guide A

Paper-out

Detector

Platen

Ink Ribbon

Cassette

Print Head

Connector

Fig. 2-1 MP111MP External view

– 3 –

Page 7

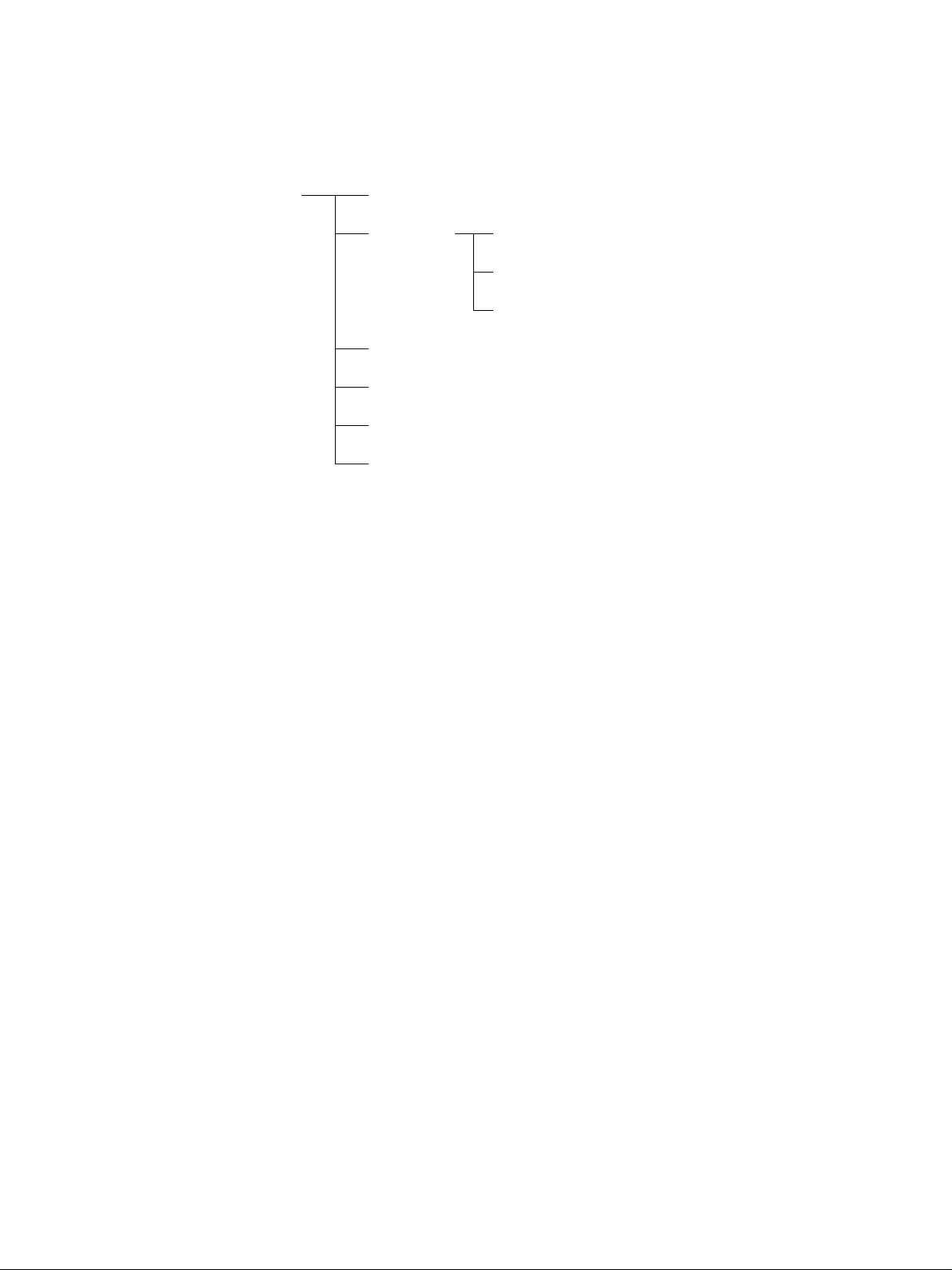

PF

Motor

Drive Shaft

Carriage

Timing Detector

Motor

Ribbon Position

Detector

Home Position Detector

Ribbon Solenoid

Paper Guide A

Paper-out

Paper Guide B

Detector

Print Head

Ink Ribbon Cassette

Platen

Connector

Fig. 2-2 MP115MP External view

– 4 –

Page 8

3. GENERAL SPECIFICATIONS

3.1 Printing Specifications

Item Specifications

Printing method Impact Dot Matrix

Printing configuration 7 x 9 (half dot) or 5 x 9

Printing direction Bidirectional (See note 1)

Printing speed Approximately 3.85 lines/second

Printing lines 32 lines (when using 7 x 9 half dots)

Character dimension Width 1.2 mm (when using 7 x 9 half dots) Height 2.42 mm

Dot spacing Horizontal 0.3 mm (with full dots) Vertical 0.353 mm

Printing area 48 mm

Paper feed speed Approximately 3.77 in./sec. (continuous feeding)

Wire diameter ø 0.3 mm

Line space 1/6, 1/8, 1/12, 1/72, 1/144 inches

Feed paper more than one line before printing graphics or vertically

expanded characters.

Note 1: When performing bidirectional printing, horizontal drift is likely to occur in unidirectional printing.

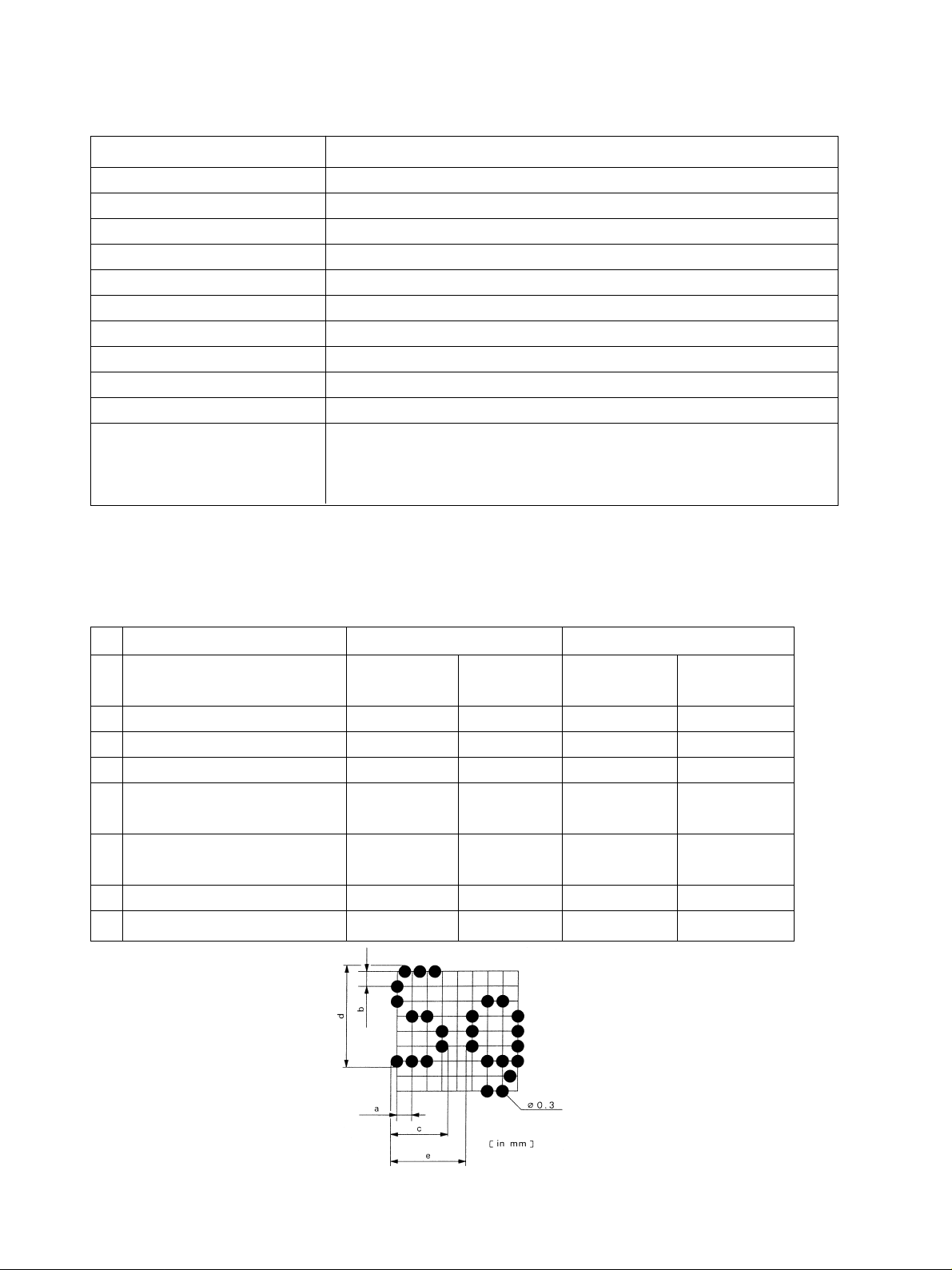

Details of Character Dimentions

1 Paper width 2.25 inches (57.5 mm) 1.75 inches (44.5 mm) Optional

2 Fonts configuration (H x V) 7 x 9 5 x 9 7 x 9 5 x 9

(half) (half)

3 CPI 16.9 14.1 16.9 14.1

4 Printing column count 32 26 24 20

5 Spacing e mm 1.5 1.8 1.5 1.8

6 Character dimensions c mm 1.2 1.5 1.2 1.5

d mm 2.42 2.42 2.42 2.42

7 Dot space a mm 0.3 0.3 0.3 0.3

b mm 0.353 0.353 0.353 0.353

8 Total no. of dots 160 156 120 120

9 Printing area mm 48 46.8 36 36

Fig. 3-1 Character Size (7x 9 font)

– 5 –

Page 9

3.2 Paper Specifications

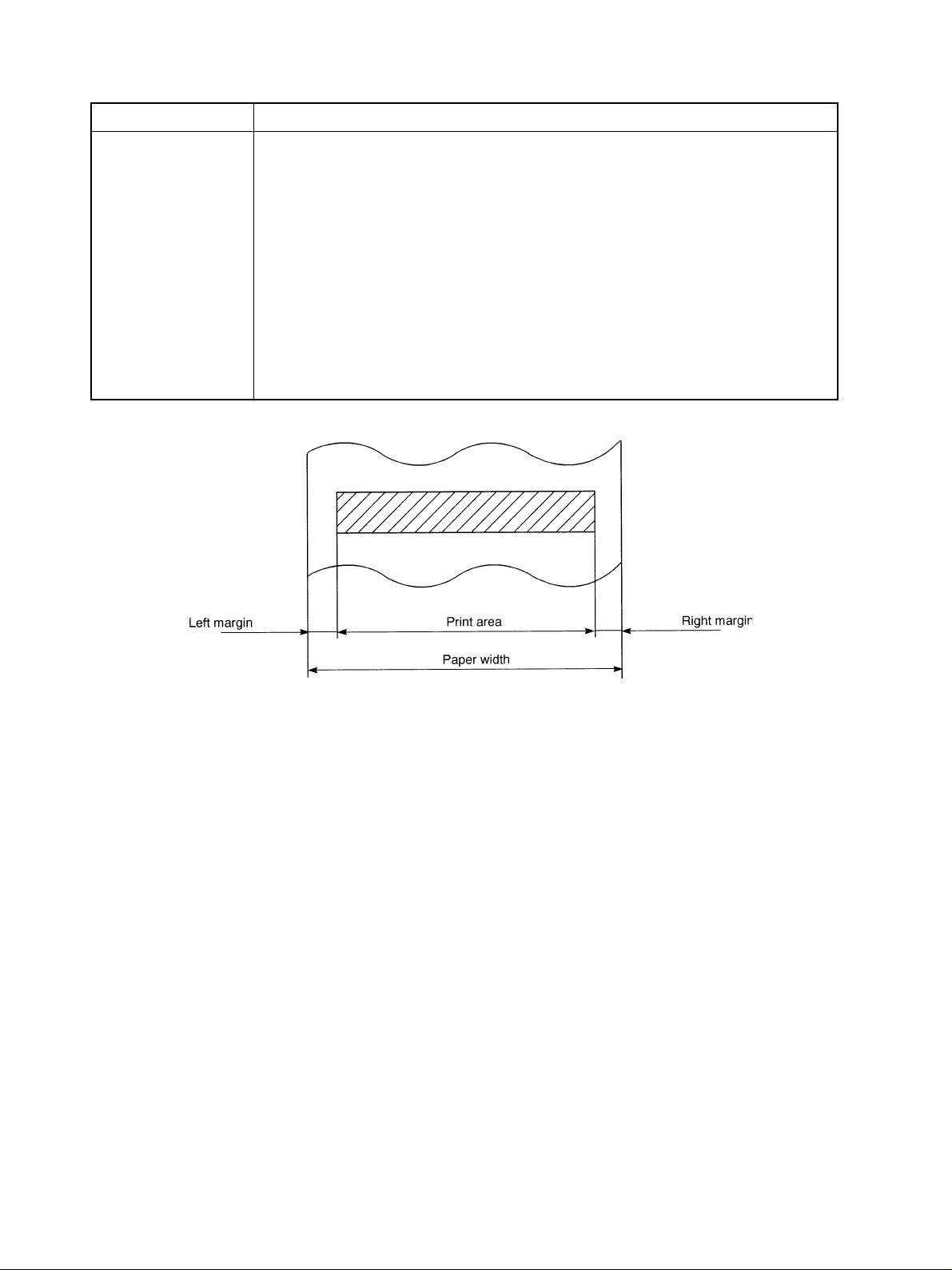

Item Specifications

Paper type Ordinary roll paper (1P) and carbonless roll paper (2P or 3P)

Paper width 57.5 ± 0.5 mm (2.25 inch). With options, 44.5 ±0.5 mm(1.75 inch) possible

Roll diameter Max. 85 mm (3.35 inch)

Thickness Single : 0.07 mm to 0.10 mm

Copies : Original + 1 copy

Total thickness max. 0.14 mm, with each sheet 0.05 to 0.08 mm thick

Original + 2 copies

Total thickness max. 0.2 mm, with each sheet 0.05 to 0.08 mm thick

Core diameter 12 ± 1 mm

Other No glue between the paper and the core diameter

Fig. 3-2 Paper spec. & Print area

– 6 –

Page 10

3.3 Ink Ribbon Specifications

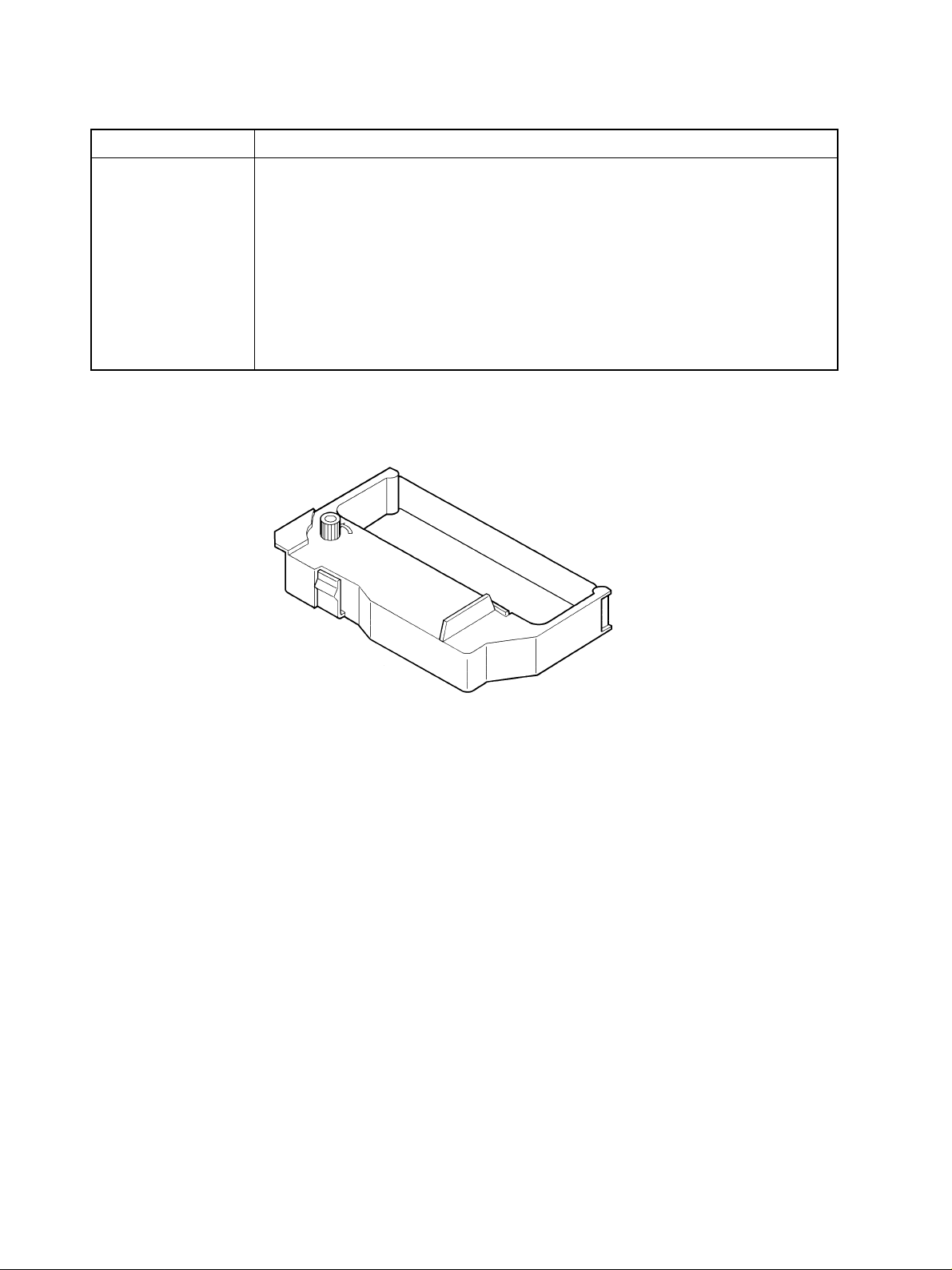

1) MP111

Item Specifications

Type Dedicated cartridge

Color Purple (standard)

Ribbon material Nylon 66

Ribbon size Width: 13 mm

Model name Purple (standard): Ribbon cassette RC100 P

Black (optional): Ribbon cassette RC100 B

Ribbon life Purple: Approx. 1,500,000 characters

Black: Approx. 800,000 characters

Note: There is the possibility of damaging the printer by using ribbon cassettes that have not been speci-

fied. We do not offer warrantee for problems that occur from using the wrong ribbon cassette.

Fig. 3-3 Ink ribbon cartridge (RC100 P.B.)

– 7 –

Page 11

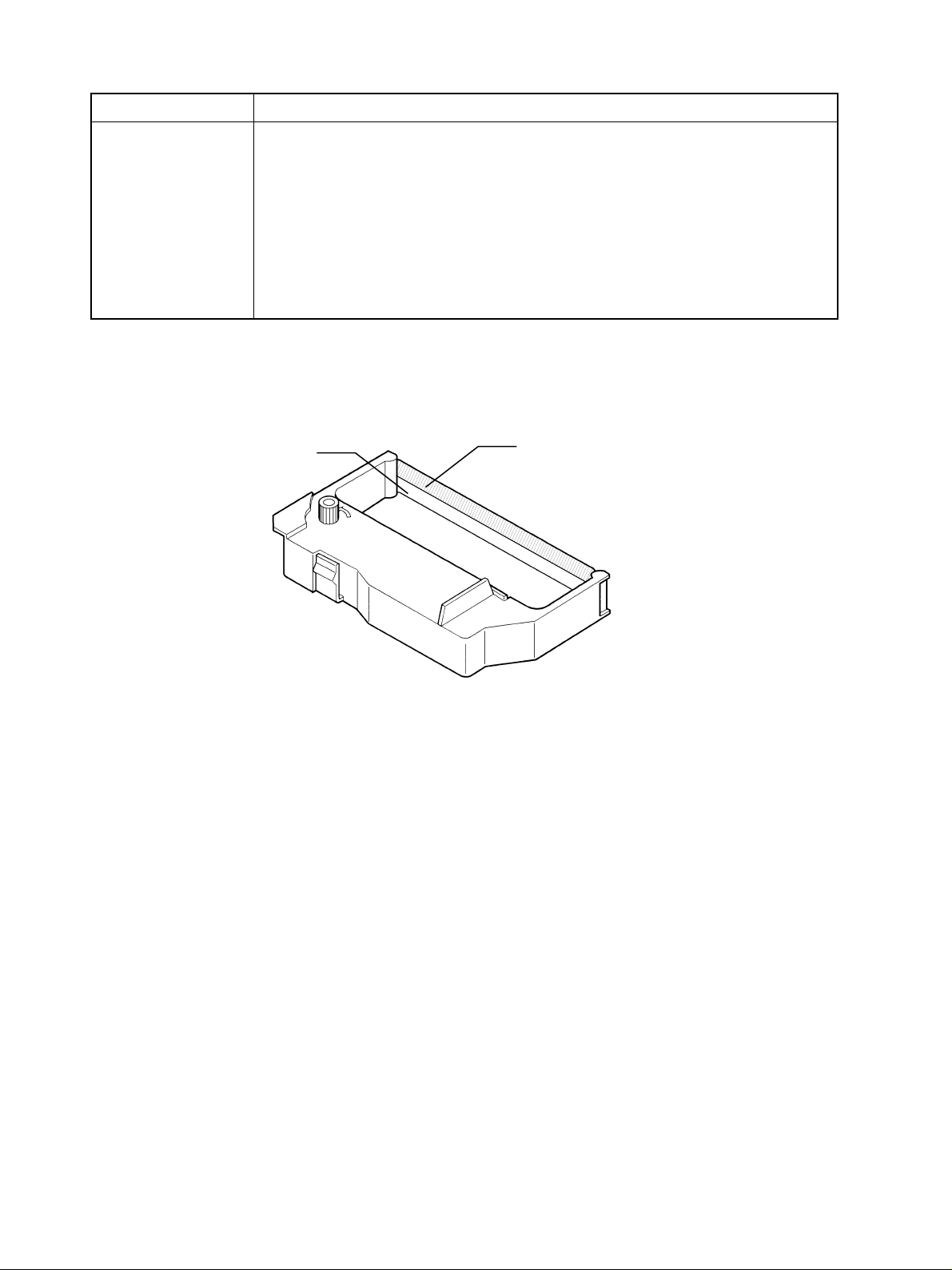

2) MP115

Item Specifications

Type Dedicated cartridge

Color Black and red

Ribbon material Nylon 66, (#40 denier)

Ribbon size Width: 13 mm

Model No. Black and red: Ribbon cassette RC100BR

Ribbon life Black: Approx. 400,000 characters

Red: Approx. 250,000 characters

Note: There is the possibility of damaging the printer by using ribbon cassettes that have not been speci-

fied. We do not offer warrantee for problems that occur from using the wrong ribbon cassette.

Red

Black

Fig. 3-4 Ink ribbon cartridge (RC100BR)

– 8 –

Page 12

3.4 Connector Specifications

Connector Type

NIPPON FCI

HLEM28R-1

Connection Drawing See next page

1 HD #6

2 HD CMN

3 HD #4

4 HD #5

5 HD #1

6 HD CMN

7 HD #2

8 HD #3

9 HD CMN

10 HD #7

11 HD #8

12 HD #9

13 LF-ø4

14 LF-CMN A, B

15 LF-ø2

16 LF-ø1

17 LF-ø3

18 RS-Sig (Ribbon shift) MP115M only

19 S-GND

20 PE-Sig

21 CR MOTOR (–)

22 HP-Sig

23 RS-SOL (Ribbon shift) MP115M only

24 T2-Sig

25 T1-Sig

26 +5V

27 NC

28 CR MOTOR (+) (CMN VH)

– 9 –

Page 13

LF-ø1

16

LF-CMN A,B

LF-ø3

LF-ø2

LF-ø4

+5V 26

T1-sig 25

T2-sig 24

HP-sig 22

PE-sig 20

(RS-sig) *1 18

S-GND 19

14

17

15

13

M

(

RS-SOL) *1 23

)

CR MOTOR(+

(

CMN(VH

NC 27

CR MOTOR(-

))

28

)

21

M

*1 MP115MP only

Fig. 3-5 Connector connections

– 10 –

Page 14

3.5 Print Timing

This printer uses a timing signal of 1 as the total number of pulses to control the solenoid and motor. The

numbering of Tn of the timing signal 1 is found as shown below. The first timing signal 2 after the rise of the

home position signal is detected and the fall of the first timing signal 1 after the rise of timing signal 2 is set

as T-1. The subsequent timing signal falls are set as T0, T1 and T2.

You should be careful of the following points concerning this print timing.

There is a minimum of 2 pulses for the timing signal 1 for electrical cycles for the same pin. Therefore, you

cannot energize Tn, Tn+1 using the same pin.

7✕9 (half) font

Forward printing

Normal character

Rotated character

Backward printing

5✕9 font

T2

T4 T6 T8 T10 T12 T14 T16 T18 T20 T22 T312T314T316T318T320T322

T1 T3 T5 T7 T9

1st chara

135

T11

7

246

7531 7531 7311

642 642 642

32th chara

T754T752T750T748T746T744

T753T751T749T747T745T743

Note ) The electric cycles for identical 1 pins has 2 pulses or more.

There Tn, Tn+1 electricity is impossible

T13 T15 T17 T19 T21 T311T313T315T317T319T321

2nd chara

1357

32th chara

1357

246 246

31th chara

T742T740T738T736T734

T741T739T737T735T733

T444T442T440T438T436T434

1st chara

T443T441T439T437T435T433

Forward printing

Normal character

Rotated character

Backward printing

T2

T4 T6 T8 T10 T12 T14 T16 T18 T20 T22 T312T314

T1

T3 T5 T7 T9

1st chara

12345 12345

T754T752T750T748T746T744

T753T751T749T747T745T743

T11

T13 T15 T17 T19 T21 T311T313T315T317T319T321

2nd chara

1234

5

432

26th chara

T742T740T738T736T734

T741T739T737T735T733

T310 T316T318T320T322

T309

26th chara

5

4321

1st chara

T444T442T440T438T436T434

T446

T443T441

T445 T439T437T435T433

Fig. 3-6 Print Timing

– 11 –

Page 15

3.6 Timing Chart

(1) Printing Action

– 12 –

MOTOR

OFF

HIGH

HP-sig

LOW

HIGH

Fig. 3-7 Printing action

T2-sig

LOW

HIGH

T1-sig

LOW

PRINT

PF MOTOR

ON

T0 T2

T-1

T4

T1

T3 T322 T323 T754

Carriage reversal

area

(110 pulses)

TYP. 66.3 ms

Forward print area (322 pulses)

MIN. 64.3 ms

T433 T490

ON

1/6 Inch = 24 Steps

T1-sig: Type 1660 Hz, Max. 1710 Hz (Software and CPU should be designed at Max. 2000 Hz.)

Printing speed: T1-sig 1600 Hz = Approximately 3.84 lines/sec. 1710 Hz = 3.96 lines/sec.

Paper feed action must be carried out within the carriage reversal area.

After print

Motor OFF Timing

Backward print area

(322 pulses)

T755

Carriage reversal

area

(110 pulses)

TYP. 66.3 ms

MIN. 64.3 ms

T-1

T0 (T863)

T1

Forward print area

Page 16

(2) Ribbon Shift Operation (Only with 2 color printing on the MP115)

Release Action

MOTOR

TIMING SIG-1

RIBBON SHIFT

RIBBON SHIFT GEAR

ON

OFF

HIGH

LOW

ON

OFF

ROTATE

STOP

T1 T2T3

T30

18 Pulses

288 Pulses

Ribbon shift gear rotation:

18 x 6 x 32/12 = 288 pulses

Fig. 3-8 Release action

T336

– 13 –

Page 17

3.7 Print Head Specifications

(1) Basic Specifications

Item Specifications

Supply voltage 24 VDC ± 2.4 V

Response frequency Max. 900 Hz

Energized time See below

Coil resistance 14.7 ± 0.4 Ω (includes cable resistance)

Peak current 1.0 A/solenoid (for 24 VDC, 375 µs)

Timing Energizing is begun at the fall of the output signal of timing signal 1.

Energizing cycle shall be 2 pulses or more of timing signal 1.

Peak current 1.0 A 1.1 A

Condition 24 V 26.4 V

Typ. Max.

375 µs 340 µs

Transistor’s turn off delay time (td): 2 µs

Fig. 3-9 Current waveform

(µs)

415

395

375

Energizing Time

355

340

21.6 24 25.222.8 26.4 (V)

Voltage

Fig. 3-10 Head Energizing Time - Head Power Supply Voltage

– 14 –

Page 18

We employ a zener diode to control spike voltages that occur when the transistor is turned OFF. The following figure

shows and example of the drive circuit. With this circuit, we use a transistor equipped with a zener diode (zener voltage

60 + 10/-5V) between the base and collector.

TR1 2SD2041 (ROHM)

R1 1K Ω

R2 330Ω

HV (24 V)

VH 23V + TR1 for VCE (sat) = 24 V

Fig. 3-11 Example of Print Solenoid Drive Circuit

– 15 –

Page 19

(2) Pre-fire

This operation applies minute vibrations to the needle wire to allow for its smooth movement as printer warmup.

Pre-fire is performed under the following conditions. The energizing time is too short to allow for the printing

action to occur.

Operating time When power is turned ON. Number of times 32 Times

Frequency 900 Hz Power supply voltage DC24V ±2.4 V

Energizing time 175 ± 5 µs

(3) Print Duty

This print head is not equipped with a head temperature detector. Therefore, use the printer within the maximum printing ratio shown below. If you print exceeding this printing ratio, you can damage the printer.

Ambient Temperature 25°C

1140

Print Ratio N

(dot /sec)

Ambient Temperature 50°C

830

21.6 V 24.0 V 26.4 V

Fig. 3-12 Print duty

The figure above shows the print duty that is possible with continuous printing when each wire is used an

equivalent number of times. In this case, you can calculate the possible dot count for D per character using the

following numerical formula.

N (Print Ratio) x T (Print time per line includes the time of the paper feed [sec])

L (number of character per line)

[dot/chara]

– 16 –

Page 20

When you use the specific wires many times, make sure the maximum print ratio is not over the print duty shown in Fig.

3-13. Fig. 3-13 shows operation at 24.0V.

1200

1100

1000

900

800

700

Print Ratio N (dot/sec)

600

500

400

Temperature 25°C

500

380

12345678

Ambient

(1155)

1100

(1030)

950

(850)

750

(785)

(730)

680

(615)

550

Number of the specific wires

Fig. 3-13 Print duty (specific wires)

(1200)

890

(840)

Ambient

Temperature 50°C

– 17 –

Page 21

3.8 CR Motor Specifications

Item Specifications

Type DC motor

Supply voltage 24 VDC + 1.2 V

Start current Max. 1.6 A

Average current Approx. 0.15 A

Fig. 3-14 Current waveform of the motor

– 18 –

Page 22

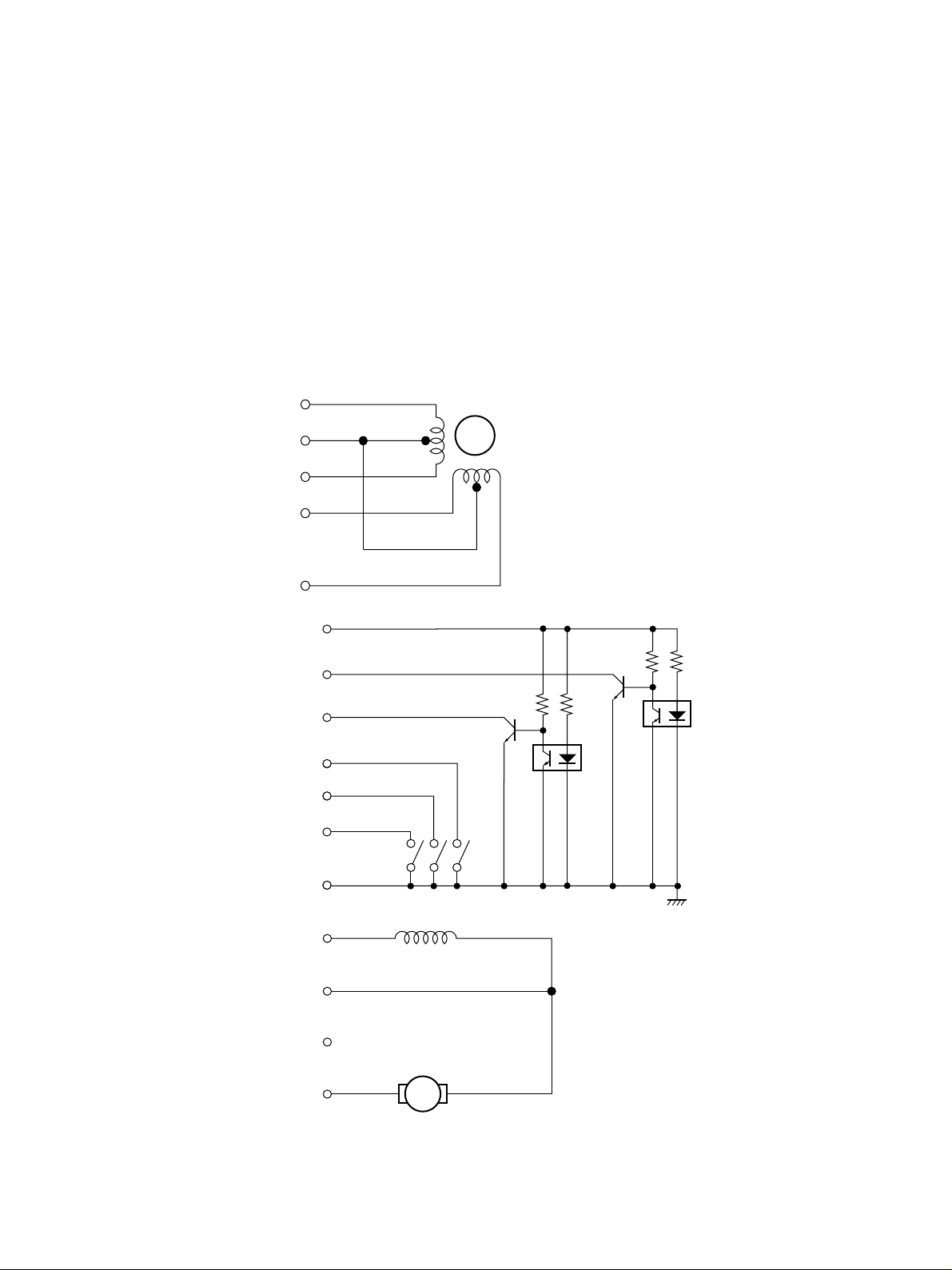

Fig. 3-15 Motor drive circuit (example)

R1 10 KΩ TR1 2SA950

R2 3.3 KΩ TR2 2SC1740

R3 6.8 KΩ 1/6 W TR3 2SA1175

Notes: Adjust motor speed with VR

adjustment and T1 signal to

1660 Hz ± 30 Hz.

R4 2.2 KΩ TR4 2SD882

R5 1.2 KΩ TR5 2SB1359

R6 10 KΩ TR6 2SD1637

R7 20 KΩ IC1 SN74LS05

C1 0.47 µF (Film) IC2 M51971L (MITSUBISHI)

C2 0.033 µF (Film) VR 6.8 KΩ

C3 0.022 µF (Film)

3.8.1 FG Circuit

The motor control circuit with a Frequency Governor circuit maintains the printing speed at the settings. It is

mainly constructed of a Speed Control IC (IC2) and a Power Transistor TR6 shown in Fig. 3-15. It measures

the number of rotations of the Carriage Motor from the Timing Signal 1. This signal is then compared to the

standard signal to control the speed by controlling the voltage energizing the Carriage Motor.

3.8.2 Merits of the FG Circuit

The FG circuit maintains a stable output regardless of the environment where it is being used.

It maintains stability even at high speeds.

It protects the head because the speed is stable.

– 19 –

Page 23

3.9 Paper Feed Motor Specifications

Item Specifications

Type PM type stepping motor

Drive method 2-Phase excitation unipolar method

Terminal voltage 24 VDC ± 1.2 V (for drive), 4.2 VDC (when holding)

Peak current Max. 0.7 A

Average current About 0.28 A

Holding current About 0.08 A

Amount of paper feed

1/144 inch per 1 step

Feed method Forward feed only

Excitation signal a. When paper feed amount is less that 4 steps.

Set to 350 pps drive.

b. When paper feed amount is over 5 steps and less than 8 steps. Set the slow-

down area so that the final 2 steps become 300 pps and 200 pps. The other

areas are set to 350 pps drive.

c. When paper feed amount is over 9 steps and less than 18 steps. Set the inital

4 steps so that they become 350 pps (slow-up area). Set the slow-down area

so that the final 4 steps become 500 pps, 400 pps, 300 pps, and 200 pps.

The other areas are set to 550 pps drive.

d. When paper feed amount is over 19 steps.

Set the initial and final 4 steps so that they become 350 pps. The other areas

are set to 550 pps drive.

VH 24 V D1 DSM1D1 (HITACHI)

TA1 µPA1428AH (NEC)

R2 to R3

10 kΩ

TR1 2SB1359 Compatible D1 DSM1D1 (Hitachi)

TR2 2SC1740 Compatible IC SN74L04

15

13

Fig. 3-16 Drive circuit of paper feed motor (example)

– 20 –

Page 24

3.10 Ribbon Shift Solenoid (RS-SOL) Specifications

MP115MP only

Item Specifications

Supply voltage 24 VDC ± 1.2 V

Pulse width T1-sig 18 pulses (Approx. 12 ms)

Coil resistance Approx. 57.0 Ω

Average current Approx. 400 mA

Fig. 3-17 Current waveform of RS-SOL

TR1 2SD2010 (ROHM)

D1 DSM1D1

R1 1 kΩ

R2 330 Ω

VH 23 V + TR1 V

CE (sat.) = 24 V

Fig. 3-18 RS-SOL drive circuit (example)

– 21 –

Page 25

3.11 Timing Signal Detector Specifications

The timing signal detector is composed of a detection slit mounted on the motor shaft, a photo interruptor,

and waveform shaping circuit.

Timing signal 1 is generated 18 pulses and timing signal 2 is generated 1 pulse every time the motor rotates

by 1 turn.

PS Photo interruptor

ON1004R

(MATSUSHITA)

TR1 2SC1740

R1 4.7 kΩ

R2 56 kΩ

R3 150 Ω

C1 2200 PF

Fig. 3-19 Circuit of timing signal 1 (example)

PS Photo interruptor

ON1004R

(MATSUSHITA)

TR1 2SC1740

R1 4.7 kΩ

R2 56 kΩ

R3 150 Ω

C1 2200 PF

Fig. 3-20 Circuit of timing signal 2 (example)

– 22 –

Page 26

3.12 Home Position Detector (HP-sig) Specifications

The home position detector is composed of the mechanical switch. While the carriage is located at the left

end, the switch remains ON.

R1 10 kΩ

R2 15 kΩ

C1 0.022 µF

Fig. 3-21 Home position detector circuit (example)

In order to improve reliability, we recommend that the HP-sig is detected as described below.

(1) When the T1-sig is unstable when turning on the power, etc.

Detect the L level after having detected the H level of the HP-sig, and then, after having carried out 81

pulse counts for the T1-sig, detect the H level.

(2) When the T1-sig is decided during continuous operation of the motor

Detect the L level of the HP-sig, and then, after having counted 847 pulses of the T1-sig, detect the H

level.

3.13 Paper-out Detector (PE-sig) Specifications

The Paper-out Detector is composed of a mechanical switch. While the paper is set in the paper tray, the

switch remains ON.

R1 10 kΩ

R2 15 kΩ

C1 0.022 µF

Fig. 3-22 Paper-out detector circuit (example)

– 23 –

Page 27

3.14 Ribbon Position Detector (RS-sig) Specifications (MP115MP only)

The ribbon position is made up by a mechanical switch.

When the ribbon is at the position for printing of black characters, the switch is ON.

R1 10 kΩ

R2 15 kΩ

C1 0.022 µF

Fig. 3-23 Example of ribbon position detection circuit

In order to improve the reliability, we recommend that the RS-sig is detected while the motor is off.

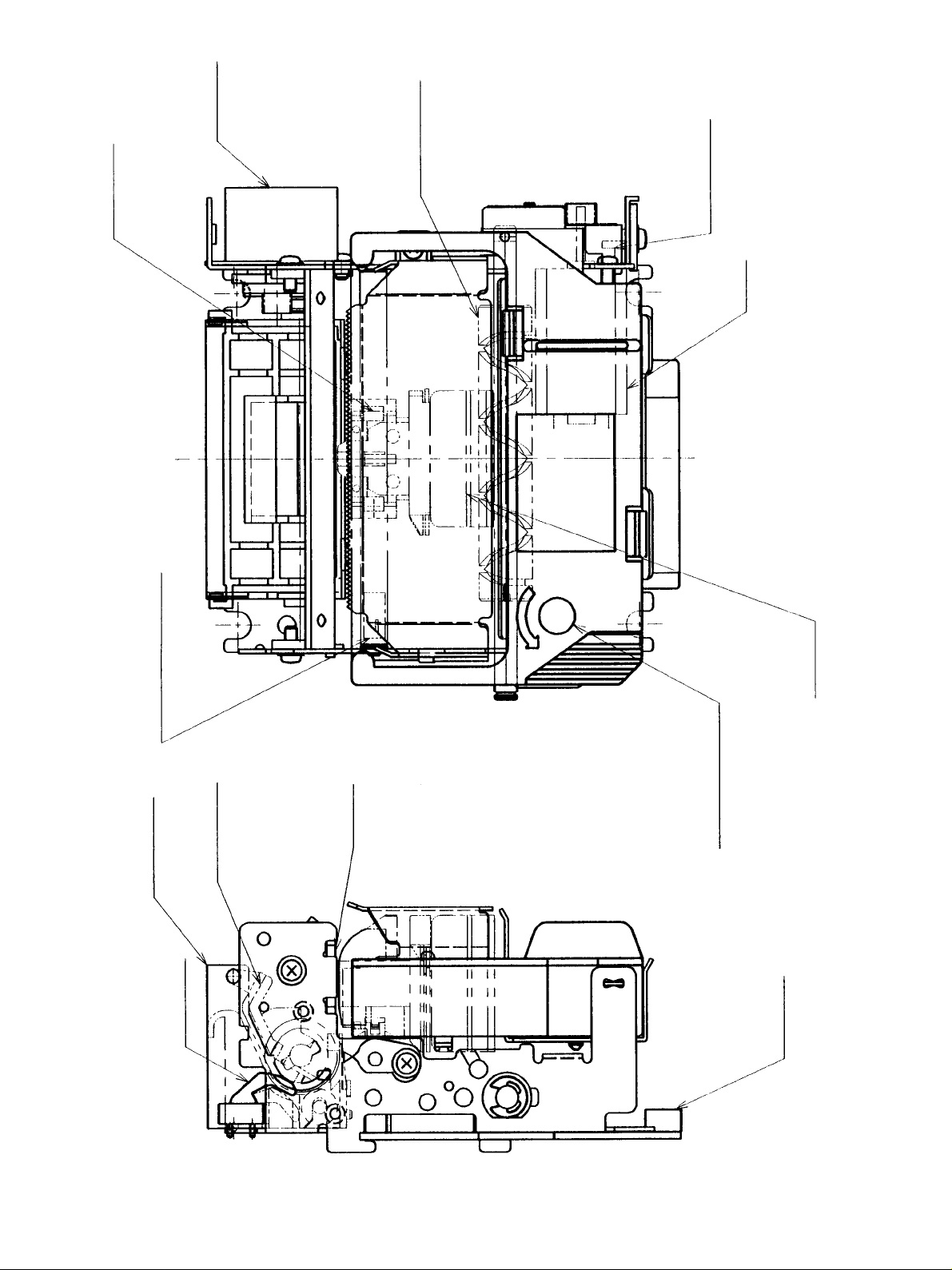

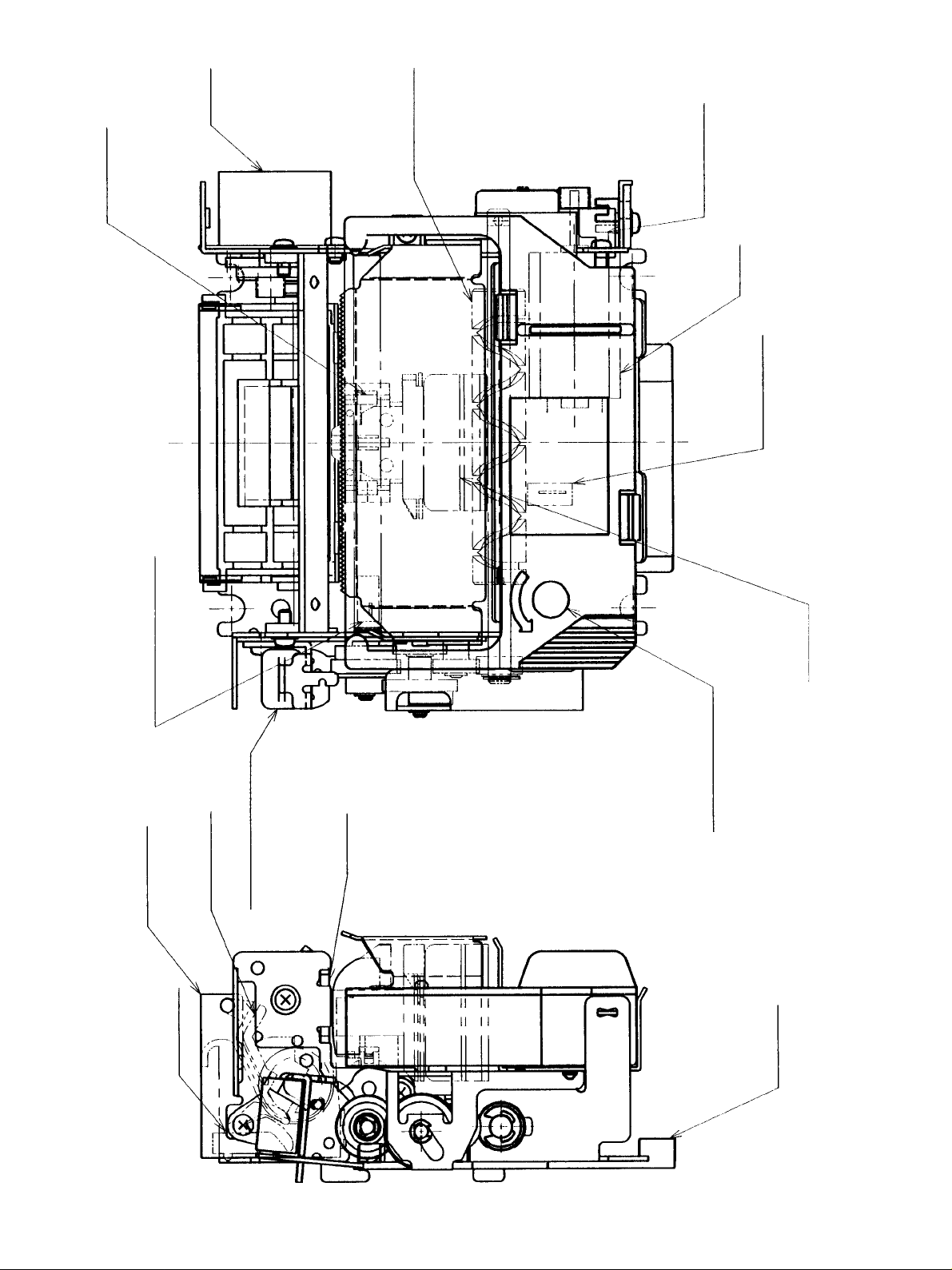

3.15 Dimension and Weight

See Fig on the next page for external dimension of the printer mechanism.

Weight of printer mechanism: MP111MP, approx. 410 g (excludes the ribbon cartridge)

MP115MP, approx. 450 g (excludes the ribbon cartridge)

Weight of ink ribbon cartridge: approx. 24 g

– 24 –

Page 28

Paper Entrance

Paper Entrance

Connector

Position

Paper Entrance

Paper Entrance

Paper Entrance

Print Center

Print Area

Paper Guide Wdith

Paper Entrance

Figure 3-24 MP111MP External dimension (unit: mm)

– 25 –

Print Center

Page 29

Connector

Position

Paper Entrance

Paper Entrance

Paper Entrance

Paper Entrance

Paper Entrance

Print Center

Paper Guide Wdith

Paper Entrance

Print Area

Print Center

Figure 3-25 MP115MP External dimension (unit: mm)

– 26 –

Page 30

4. RELIABILITY SPECIFICATIONS

Item Specification Remarks

Printer reliability

4 million lines MCBF

Except print head life

Life

Operating

environment

Storage

environment

Vibration test

Shock test

Print head life

Temperature

Relative

humidity

Temperature

Relative

humidity

Approx. 70 million characters

0°C to 50°C

10 to 80% RH (at 40°C)

(no condensation)

-20°C to +70°C

5 to 95% RH (at 40°C)

(no condensation)

Vibration : 10 ~ 55 ~ 10 Hz

Amplitude : 1.54 mm (at regular range)

Sweep : one minute

Gravity : 0.3 ~ 9.3 G

Direction : X,Y and Z directions

Test time : Two hours in each direction

(Six hours in three directions)

Packing : With the least packing unit

Height : 85 cm

Order : 1 corner, 3 edges, and 6 sur-

faces

Packing : With the least packing unit

14 dots per character

Recommended ribbon:

Purple color ink ribbon cartridge (RC100 P)

After being left under this

environment for two hours,

the printer mechanism must

satisfy general specification.

After being left under this

environment 96 hours, and

under normal temperature

and humidity for two hours,

the printer mechanism must

satisfy general specification.

The printer must satisfy general specification after testing.

The printer must satisfy general specification after testing.

Insulation resistance

1 MΩ (100 VDC)

When you put the printer

mechanism to the quality

control test, use the printer

under the environment as

shown at the left.

– 27 –

Page 31

5. SETTING THE RIBBON CARTRIDGE

1. Turn the ribbon feed knob of ribbon cartridge in the direction of the arrow to remove slack in the ribbon.

2. Place the ribbon cartridge and press it to set in the Unit. When the ribbon cartridge is hard to set to the

proper position, turn the ribbon feed knob in the direction of the arrow.

Insert the ink ribbon between the print head and the platen.

3. Turn the ribbon feed knob of ribbon cartridge in the direction of the arrow to remove slack in the ribbon.

– 28 –

Page 32

6. SETTING THE PAPER

6.1 Setting the Paper

1. Cut straight the leading edge of the paper.

2. Insert the paper squarely into the paper guide.

3. Turn the paper feed motor to feed the paper.

4. When the paper comes out of the paper outlet, turn the feed motor off, and stop the paper feed.

6.2 Removing the Paper

1. Cut the paper behind the paper guide.

2. Turn the paper feed motor to remove the paper.

– 29 –

Page 33

7. INSTALLATION

1. At the time of mounting the printer mechanism into its housing cabinet, put cushion material, such as,

rubber foot, on the printer mechanism legs. If installed directly, reverberations occur producing noise.

We recommend that you use the following rubber foot.

Parts name : DAMPER RUBBER

SP2

Parts No. : 30290010

Fig. 7-1 Recommended Rubber foot

Parts name : SCREW 3.0

Parts No. : 30250010

Fig. 7-2 Recommended Set screw (unit: mm)

2. Set the play between the roll paper holder and paper thrust direction to within 2 mm, and ensure that the

roll paper holder doesn’t hold back the edge of paper.

3. Set the paper inserting angle to within 65°.

4. Edges around the paper insertion area should be rounded at R2 mm or more.

5. Set the paper feed load, at the printer’s paper inlet, to 30 g or less.

6. Take into account prevention of paper rewinding, when designing the case.

7. Allow needed space surrounding the printer. Fig. 7-3 shows an example of installation space.

8. Fig. 7-4 shows an example of installation.

9. Since this printer mechanism employs galvanized steel panels, the end surface doesn’t come plated.

– 30 –

Page 34

Mechanism Attachment

Position (4 Places)

Paper Entrance

Paper Exit

(Paper Tube

Inner Diameter

Roll Diameter

Paper Entrance

Paper Entrance

Sectional View of Paper Holder AA

Frame

Screw 3.0

Vibration Isolation

Rubber SP2

Chassis

Fig. 7-3 Installation space (example) (unit: mm)

– 31 –

Page 35

Mechanism Attachment

Position (4 Places)

Paper Entrance

Paper Exit

Roll Diameter

Paper Entrance

Paper Entrance

Roll Diameter

Frame

Screw 3.0

Vibration Isolation

Rubber SP2

Chassis

Sectional View of Paper Holder

Fig. 7-4 Printer installation (example) (unit: mm)

– 32 –

Page 36

Mechanism Attachment

Position (4 Places)

Roll Diameter

Paper Entrance

Paper Entrance

Paper Entrance

(Rib Height)

Paper Exit

Frame

Screw 3.0

Vibration Isolation

Rubber SP2

Chassis

Sectional View of Paper Holder

Fig. 7-5 Printer installation (Placing the roll paper without using the roller.)

– 33 –

Page 37

Be careful of the

soldered

side of the PCB.

(MP111MP)

(MP115MP)

Fig. 7-6 Printer installation

– 34 –

Page 38

8. OPERATIONAL NOTES

8.1 Power ON/OFF Note

If the 5 V power supply line for logic has not fully risen or fallen immediately after the power supply is

turned ON or OFF, the CPU or TTL in the logic circuit may misoperate. At such times, power is supplied to

the motor or solenoid, causing, in the worst case, burnt out solenoid or running of motor (misoperation),

unless the 24 V power supply line for motor drive is completely OFF. To avoid such misoperation, take into

account the following points.

8.1.1 Power supply ON/OFF timing rule

Supply 24 V line after the 5 V line has fully risen. Similarly, cut off the 5 V line after the 24 V line has fully

fallen.

Fig. 8-1 Power supply ON/OFF timing rule

8.1.2 Method of controlling the drive circuit

Fig. 8-2 Drive circuit controlling method

If the power supply ON/OFF timing rule cannot be followed, reset the print solenoid or motor drive circuit

with control signal. An example of this type of circuit is shown in Fig. 8-3. Turn OFF transistor TR1, while

the 5 V line has not completely risen, in order to inhibit power to the print solenoid. Then as soon as the 5 V

line has completely risen, turn ON TR1, permitting power to the print solenoid.

– 35 –

Page 39

TR1 2SD2041 (ROHM)

HRT Type

R1 1 kΩ

R2 330 Ω

VH 23 V+V

CE (Sat.) of

TR1=24 V

Fig. 8-3 Circuit to control drive circuit (example)

8.2 Carriage Motor Protection Method (Against Mechanical Errors)

If the carriage motor gets locked as a result of trapping foreign matter, etc. in the printer mechanism, a risk

of damaging the motor due to flow of excess current to it is generated. Therefore, it becomes necessary to

monitor the excess load status of printer mechanism, by detecting the cycle of timing signal 1 with timer,

etc. Once the cycle of timing signal 1 becomes as given below, stop power being supplied to the motor.

a. Print interval: 2.57 ms or more/450 µms or less

b. Outside print interval: 257 ms or more

8.3 Other Notes

1. Do not attempt to print when the paper or ribbon cartridge are not loaded in the printer mechanism as

this could damage the print head.

2. Do not store or use the printer mechanism at places of substantial dust, iron content, etc., or in oily

atmosphere.

3. Wipe off dust, dirt, etc. from the printer mechanism, using a soft brush. Or, wipe with a piece of cloth

dampened in alcohol.

4. Never inflict strong force on the printer mechanism. Otherwise, the frame or other parts may be distorted, rendering normal functioning impossible.

5. Avoid sudden changes in the ambient conditions like temperature, humidity, etc. even while they are

hold in prescribed limits. If sudden change occurs, allow about 30 minutes for acclimatizing, before

using the printer mechanism.

6. Never use the printer mechanism with condensation deposited onto it.

– 36 –

Page 40

9. POWER SUPPLY CAPACITY

9.1 24 V Line

Arrange for the following power supply, taking into account the voltage drop (about 1 V) of V

power transistor for driving print solenoid.

Power supply voltage 23V+1V = 24V ± 10 %

Similarly, arrange for 2.0 A or larger power supply capacity; and connect an electrolytic condenser of 4700

µF to 6800 µF/35 V to the power source.

9.2 5 V Line

Arrange for 5 V power supply for the detector (photo interruptor).

Voltage 5 V ± 5 %

Current consumption Approx. 60 mA

CE (sat) of the

– 37 –

Page 41

10. OPTIONS

You can also use 1.75 inch (44.5 mm) width roll paper by removing the paper guide B and attaching the

optional guide C.

(1) Removing the Paper Guide B

Spread the boss unit on both sides of the paper guide B and remove the the boss from the paper guide

A side. Rotate the paper guide B and remove it.

(2) Setting the Paper Guide C

When you remove the paper guide B, you can see the groove at the right side of the paper guide A.

Insert the paper guide C into that groove.

Fig. 10-1 Paper Guide Option

– 38 –

Page 42

HEAD OFFICE

ELECTRONIC PRODUCTS DIVISION

STAR MICRONICS CO., LTD.

536 Nanatsushinya, Shimizu,

Shizuoka, 424-0066 JAPAN

Tel : 0543-47-0112

Fax: 0543-48-5271

Please access the following URL

http://www.star-micronics.co.jp/service/sp_sup_e.htm

for the lastest revision of the manual.

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

70-D Ethel Road West,

Piscataway, NJ 08854 U.S.A.

Tel : 732-572-9512

Fax: 732-572-5095

Distributed by

STAR MICRONICS U.K. LTD

Star House, Peregrine Business

Park, Gomm Road, High Wycombe,

Bucks, HP13 7DL, U.K.

Tel : 01494-471111

Fax: 01494-473333

Printed in Japan, 80874315

Loading...

Loading...