STA-RITE System 2 PLD50, System 2 PLD70 Installation, Operation & Parts

TM

System 2

Modular DE Filter

O W N E R ’ S M A N U A L

RELEASE

RELEASE

OUTLET

OUTLET

2161 1295

E

N

G

L

I

S

H

F

R

A

N

Ç

A

I

S

INSTALLATION, OPERATION & PARTS

MODELS

PLD50 PLD70

Pentair Water Pool and Spa, Inc.

© 2010 Pentair Water Pool and Spa, Inc. All rights reserved. This document is subject to change without notice.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Customer Support: (800) 831-7133

System 2™, Posi_Lok™, Sta-Rite

Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/or other countries. Unless noted,

names and brands of others that may be used in this document are not used to indicate an affiliation or endorsement

between the proprietors of these names and brands and Pentair Water Pool and Spa, Inc. Those names and brands may be

the trademarks or registered trademarks of those parties or others. Printed in U.S.A.

03-17-10 S339 (Rev. B)

®

and Pentair Water Pool and Spa®are trademarks and/or registered trademarks of

This manual should be furnished to

the end user of this filter; its use will

reduce service calls and chance of

injury and will lengthen filter life.

E

S

P

A

Ñ

O

L

WARNING

Hazardous Pressure!

Can cause tank

explosion.

Do not connect filter to

compressed air under any

circumstances.

Table of Contents

Safety Instructions.............................................................................................2

General Information ..........................................................................................3

Specifications....................................................................................................4

Installation.........................................................................................................5

Initial Startup .....................................................................................................6

Filter Disassembly / Assembly .......................................................................6-7

Module Cleaning Procedure..............................................................................8

Special Cleaning Instruction...........................................................................8

System Inspection/Winterizing ..........................................................................9

Troubleshooting Guide....................................................................................10

Repair Parts List..............................................................................................11

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol on your filter or in

this manual, look for one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause death, serious personal injury,

or major property damage if ignored.

warns about hazards that can cause death, serious personal injury,

or major property damage if ignored.

warns about hazards that will or can cause minor personal injury or

property damage if ignored.

NOTICE indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this manual and on equipment.

Keep safety labels in good condition; replace if missing or damaged.

Incorrectly installed or tested equipment may fail, causing

severe injury or property damage. Read and follow instructions in

owner's manual when installing and operating equipment. Have a

trained pool professional perform all pressure tests.

1. Do not connect system to a city water system or other external source of

pressurized water.

2. Use equipment only in a pool or spa installation.

3. Trapped air in system can cause explosion. BE SURE all air is out of system

before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, lock rings and system accessories before testing.

• Release all air in system before testing.

• Tighten Sta-Rite pump trap lids to 30 ft. lbs. (4.1 kg-cm) torque for testing.

• Water pressure for test must be less than 25 PSI (172 kPa).

• Water Temperature for test must be less than 100

• Limit test to 24 hours. After test, visually check system to be sure it is ready for

operation. Remove pump trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only. For

non-Sta-Rite equipment, consult equipment manufacturer.

o

F. (38oC).

2

When to Clean the Filter

The filter module should normally be

cleaned when the pressure gauge reading increases 10 PSI over the start-up

pressure (record the start-up pressure

under “Owner’s Information”, below,

right).

In some pools, accessories such as

fountains or pool cleaners may be noticeably affected by the normal decrease

in flow as the filter becomes dirty. If so,

clean the filter more frequently (that is, at

a pressure increase of less than 10 PSI)

in order to maintain the required flow.

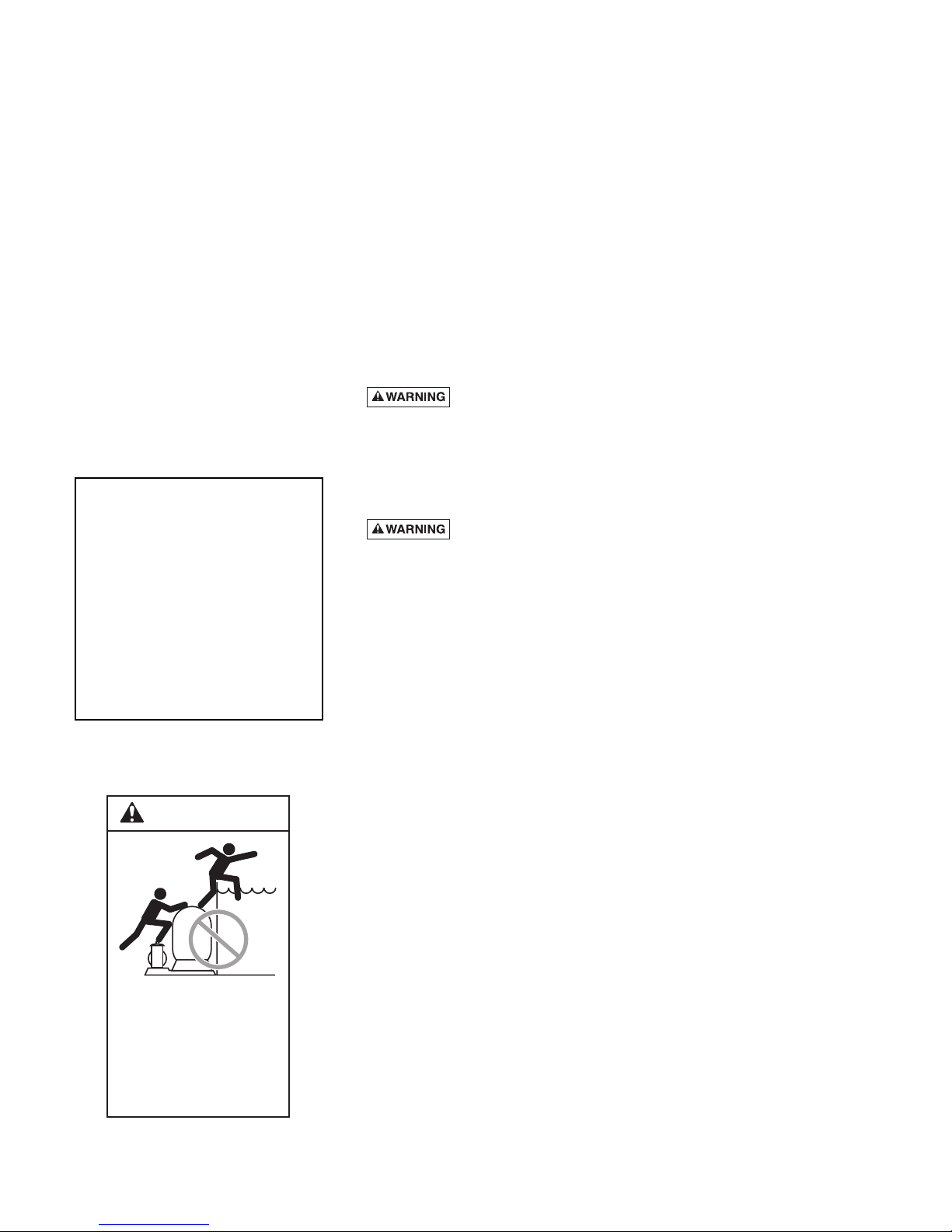

WARNING

Head

reArm

o

F

Arm

Upper

Body

Leg Joi

Head

Body

Risk of drowning and

falls. Place equipment

at least 4 feet from pool

so that children cannot

climb over it into pool.

sss

Do not allow children

to stand or play on filter

or pump.

nt

Leg Joint

Leg Joint

GENERAL INFORMATION

• Clean a new pool as well as possible before filling pool and operating filter. Excess dirt and large particles of foreign matter in the system can

cause serious damage to the filter and pump.

• With a modular Diatomaceous Earth (DE) filter in place and operating correctly, clean water is returned to the pool faster than pool water is being

contaminated. A typical pool installation will require approximately one

week to obtain and maintain the sparkle that your filter is capable of giving

you.

• Do not use more than the recommended amount of DE in your filter.

Excess DE can cause a buildup of DE and “bridging” between the pleats

which will plug the filter.

• Maximum pressure is 50 PSI (345 kPa). DO NOT connect the filter to a

city water system or to an individual water well system.

Hazardous pressure. Open air release valve to vent all air

from system before operating system. NEVER operate filter with air

trapped inside.

• The Sta-Rite modular DE filter is designed to filter water for swimming

pools. On a new pool installation, we recommend:

1.Disassemble the filter after the initial cleanup.

Hazardous pressure. To prevent severe injury or major property damage, exactly follow "Filter Disassembly/Assembly Procedure" on

Pages 6 and 7.

2.Remove and hose down the element assembly to remove spent DE and

contaminants.

• Maintain pool water pH between 7.2 and 7.6.

• Make sure that internal air bleed tube and filter are clean and installed

properly at top of module before operating filter.

• Make sure that Posi-Lok™ Ring is securely locked in place before operating filter.

• Maintain pressure gauge in good working order. Replace a damaged

gauge immediately.

• Cleaning interval is based on pressure rise, not on length of time filter is

operated. Different water conditions will have different normal cleaning intervals.

• Check local codes for restrictions on waste water and DE disposal requirements.

NOTICE: Some pool disinfectants may clog filter module. To maximize

module life and filter cycle time, closely follow disinfectant manufacturer’s

instructions when cleaning pool or filter (see Page 8).

Owner’s Information

Serial Number ______________________________________________

Dealer ____________________________________________________

Dealer’s Telephone # _________________________________________

Purchase Date ______________________________________________

Installation Date _____________________________________________

Pressure Gauge Reading at Startup _____________________________

3

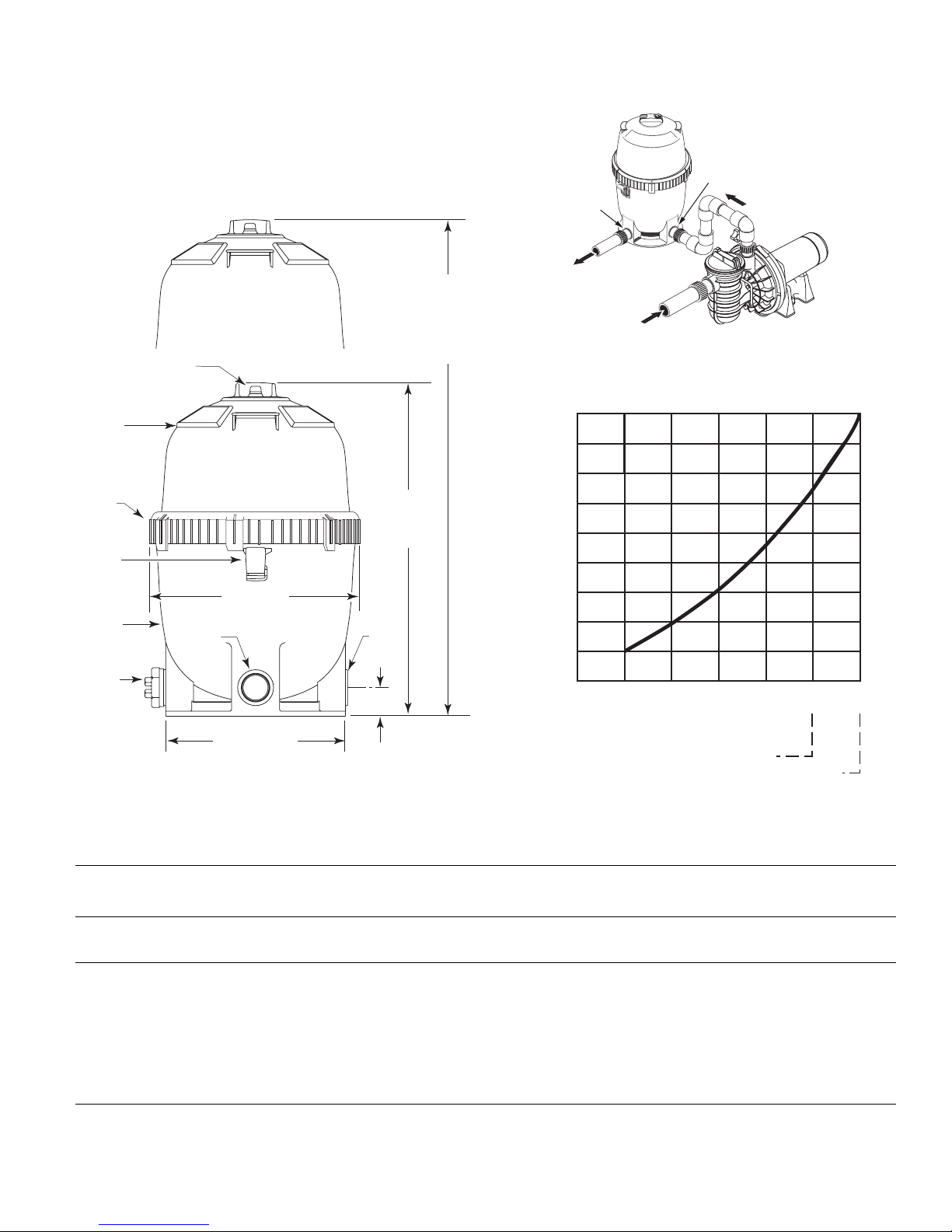

SPECIFICATIONS

Air Release Valve

(Pressure Gauge

Behind)

Upper

Tank

Shell

Posi-Lok™

Ring

Safety

Latch

Lower

Tank

Shell

Drain

Plug

Outlet

2" NPT

18.58" Dia.

(472 mm)

15" Dia.

(381 mm)

27.75"

(705 mm)

Inlet

2" NPT

2.25"

(57 mm)

38.5"

(978 mm)

Minimum

Service

Height

2148 1195

Filter

REL

R

EL

E

E

AS

A

SE

E

Inlet

Outlet

INLET

INLET

To Pool

From

Pool

FIGURE 1B – Piping Connections

9

(62.1)

8

(55.2)

6

(41.4)

4

(27.6)

Pressure Drop in

Pounds per Square Inch (kPa)

2

(13.8)

10

(38)

20

(76)

30

(114)

Flow in Gallons Per Minute (LPM)

40

(151)50(189)

2496 0796

PLD50

Pump

4085 1001

60

(227)70(265)

PLD70

FIGURE 1A – Dimensions in inches (mm)

Table 1 - Recommended DE Manufacturers

World Minerals, Inc. Celite®545

Eagle-Picher Minerals, Inc. Celtom

Table 2 - Filter Specifications

Filter Area sq. ft. (m2) 30(2.8) 36(3.3)

Lbs. (kg) of DE Used 6 lbs.(2.7 kg.) 4 lbs.(1.8 kg.)

Maximum Flow Rate gpm (L/m) 60(227) 70(265)

Max. Operating Pressure psi (kPa) 50(345) 50(345)

Max. Continuous Water Temperature F(C) 104°(40°) 104°(40°)

One half pound of DE will fill a one pound coffee can.

Celite®is a registered trademark of Celite Corporation, and Celtom®is a registered trademark of EP Minerals, LLC LTD.

FIGURE 2 – Pressure Drop Curve

®

PLD50 PLD70

4

Loading...

Loading...