Page 1

System 3

™

Modular Media Filter System

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

For Model Numbers and Descriptions See Page 5.

Sta-Rite Pool/Spa Group U.S. PATENT NO. 5190651 (Other patents pending)

293 Wright Street, Delavan, WI 53115

North America: 800-752-0183, FAX 800-582-2217

International: 262-728-5551, FAX: 262-728-4461, TELEX: ITT 4970245

Union City, TN • Delavan, WI • Mississauga, Ont. • Murrieta, CA

© 2000, Sta-Rite Industries, Inc. Printed in U.S.A. S340 (Rev. 1/25/00)

This manual should be furnished to

the end user of this filter; its use will

reduce service calls and chance of injury and will lengthen filter life.

RELEASE

RELEASE

OUTLET

OUTLET

INLET

INLET

2160 1295

Page 2

2

SYSTEM 3™ MODULAR MEDIA

FILTER SYSTEM

To avoid unneeded service calls, prevent possible injuries, and get the most

out of your filter system, READ THIS MANUAL CAREFULLY!

The System 3™ Modular Media Filter System Pool Pumps:

• Without a cord or with a 3’ cord or no cord are for use with permanently

installed pools ONLY

(see CAUTION #7, below)

.

• With a 25’ cord are for use with storable pools ONLY

(see CAUTION #8,

below)

.

Table of Contents

Safety Instructions......................................................................................2-3

General Information......................................................................................4

Specifications / Model Numbers and Descriptions.........................................5

Installation ....................................................................................................6

Electrical .......................................................................................................7

Initial Startup / Operation..............................................................................8

Filter Disassembly / Assembly..................................................................9-10

Module Cleaning Procedure........................................................................10

Special Cleaning Instruction.....................................................................10

System Inspection / Winterizing...................................................................11

Pump Service .........................................................................................11-12

Troubleshooting Guide - Pump....................................................................13

Troubleshooting Guide - Filter.....................................................................14

Repair Parts List......................................................................................15-18

Warranty.....................................................................................................19

IMPORTANT SAFETY INSTRUCTIONS

When installing and using electrical equipment, basic safety precautions should always be followed,

including the following:

SAVE THESE INSTRUCTIONS

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

2. To reduce the risk of injury, do not permit

children to use this product unless they are closely supervised at all times.

3. Risk of electrical shock. Connect only to a

grounding type receptacle protected by a ground-fault circuit-interrupter (GFCI). Contact a qualified electrician if you

cannot verify that the receptacle is protected by a GFCI.

4. Do not bury cord. Locate cord to minimize abuse from

lawn mowers, hedge trimmers, and other equipment.

5. To reduce the risk of electrical shock,

replace a damaged cord immediately.

6.

To reduce the risk of electrical shock, do

not use an extension cord to connect unit to electrical supply; provide a properly located outlet.

7. Permanent pool pumps are for use with permanently installed pools and may also be used with hot

tubs and spas if so marked. Do not use with storable pools.

A permanently installed pool is constructed in or on the

ground or in a building such that it cannot be readily disassembled for storage. A storable pool is constructed so that

it may be readily disassembled for storage and reassembled

to its original integrity.

8. Storable pool pumps are for use with

storable pools only. Do not use with permanently installed

pools. A storable pool is constructed so that it is capable

of being readily disassembled for storage and reassembled

to its original integrity. A permanently installed pool is

constructed in or on the ground, or in a building, such that

it cannot be readily disassembled for storage.

Page 3

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol on your filter or in

this manual, look for one of the following signal words and be alert to the

potential for personal injury.

warns about hazards that will cause death, serious personal injury, or

major property damage if ignored.

warns about hazards that can cause death, serious personal injury, or

major property damage if ignored.

warns about hazards that will or can cause minor personal injury or

property damage if ignored.

NOTICE indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this manual and on equipment.

Keep safety labels in good condition; replace if missing or damaged.

Incorrectly installed or tested equipment may fail, causing

severe injury or property damage. Read and follow instructions in

owner's manual when installing and operating equipment. Have a

trained pool professional perform all pressure tests.

1. Do not connect system to a city water system or other external source of

pressurized water.

2. Use equipment only in a pool or spa installation.

3. Trapped air in system can cause explosion. BE SURE all air is out of system before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, lock rings and system accessories before testing.

• Release all air in system before testing.

• Tighten Sta-Rite trap lids to 30 ft. lbs. (4.1 kg-cm) torque for testing.

• Water pressure for test must be less than 25 PSI (172 kPa).

• Water Temperature for test must be less than 100oF. (38oC).

• Limit test to 24 hours. After test, visually check system to be sure it is ready for

operation. Remove trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only. For

non-Sta-Rite equipment, consult equipment manufacturer.

3

WARNING

Hazardous Pressure!

Can cause tank

explosion.

Do not connect filter to

compressed air under any

circumstances.

Page 4

4

GENERAL INFORMATION

• Clean a new pool as well as possible before filling pool and operating filter.

Excess dirt and large particles of foreign matter in the system can cause serious damage to the filter and pump.

• With a modular media filter system in place and operating correctly, clean

water is returned to the pool faster than pool water is being contaminated. A

typical pool installation will require approximately one week to obtain and

maintain the sparkle that your filter is capable of giving you.

• Maximum pressure is 50 PSI (345 kPa). DO NOT connect the filter to a city

water system.

Hazardous pressure. Open air release valve to vent all air

from system before operating system. NEVER operate filter with air

trapped inside.

• The Sta-Rite modular media filter system is designed to filter water for swimming pools and spas. On a new installation, we recommend:

1. Disassemble the filter after the initial cleanup.

Hazardous pressure. To prevent severe injury or major property damage, exactly follow "Filter Disassembly/Assembly Procedure" on

Pages 8 and 9.

2. Remove and hose down the filter module to remove contaminants.

• Maintain pool water pH between 7.2 and 7.6.

• Make sure that internal air bleed tube and filter are clean and installed properly at top of module before operating filter.

• Make sure that Posi-Lok™ Ring is securely locked in place before operating

filter.

• Maintain pressure gauge in good working order. Replace a damaged gauge

immediately.

• Cleaning interval is based on pressure rise, not on length of time filter is operated. Different water conditions will have different normal cleaning intervals.

• Check local codes for restrictions on waste water disposal requirements.

NOTICE: Some pool disinfectants may clog filter module. To maximize

module life and filter cycle time, closely follow disinfectant manufacturer’s

instructions when cleaning pool or filter. Failure to follow these instructions

may affect warranty coverage of the module.

Owner’s Information

Serial Number ____________________________________________________

Dealer ___________________________________________________________

Dealer’s Telephone #_______________________________________________

Purchase Date ____________________________________________________

Installation Date___________________________________________________

Pressure Gauge Reading at Startup ___________________________________

When to Clean the Filter

The filter module should normally be

cleaned when the pressure gauge reading

increases 10 PSI over the start-up pressure

(record the start-up pressure under

“Owner’s Information”, below, right).

In some pools, accessories such as fountains or pool cleaners may be noticeably

affected by the normal decrease in flow as

the filter becomes dirty. If so, clean the filter more frequently (that is, at a pressure

increase of less than 10 PSI) in order to

maintain the required flow.

WARNING

Risk of falls and injury.

Filter surface is

slippery.

Do not allow children to

stand or play on filter.

ForeArm

Arm

Upper

Head

Upper

Arm

ForeArm

Body

Leg Joint

Leg Joint

Leg Joint

Leg Joint

Page 5

PLM100JWAE-06 PLM100JWAF-06

PLM150JWAE-06 PLM150JWAF-06

Adapters, Clamps, and Canadian Spec. Motor

(Includes 25’ Cord w/Straight Plug)

PLM100JWAE-12 PLM100JWAF-12

PLM150JWAE-12 PLM150JWAF-12

Adapters, Clamps, and U.S.A. Spec. Motor

(Includes 3’ Cord w/Twist-Lok Plug)

PLM100JWAE-03 PLM100JWAF-03

PLM150JWAE-03 PLM150JWAF-03

Hoses, Adapters, Clamps, and U.S.A. Spec. Motor

(Includes 3’ Cord w/Straight Plug)

PLM100JWAE-04 PLM100JWAF-04

PLM150JWAE-04 PLM150JWAF-04

Adapters, Clamps, and U.S.A. Spec. Motor

(Includes 3’ Cord w/Straight Plug)

5

SPECIFICATIONS / MODEL DESCRIPTIONS

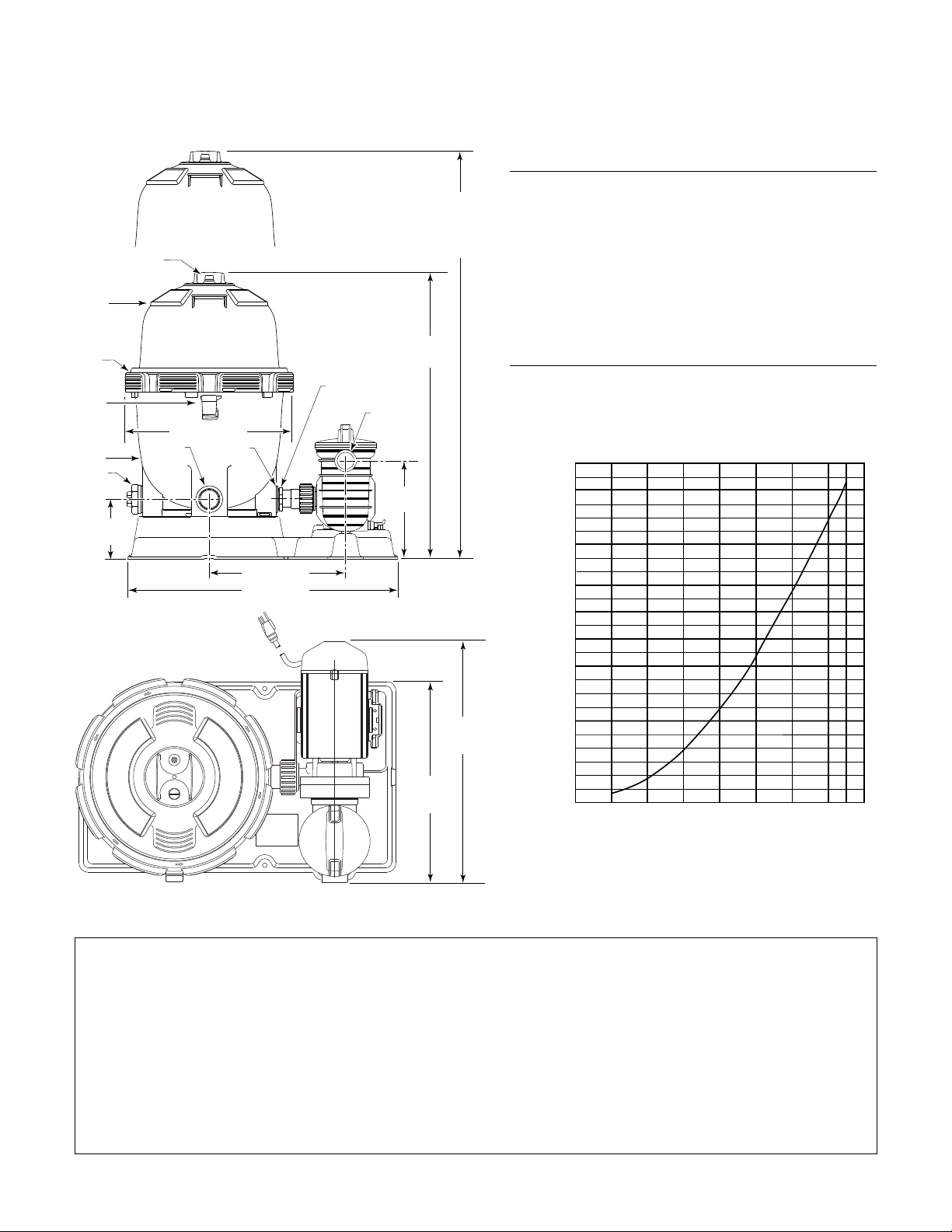

FIGURE 1 – Dimensions in inches (mm)

Table 1 - Filter Specifications

Model No.

PLM100 PLM150

Filter Area sq. ft. (m2) 100(9.3) 150(14)

Max. Rated Flow GPM (LPM)*

Residential 100(379) 150(568)

Commercial 37(140) 56(212)

Max. Operating Pressure PSI (kPa) 50(345) 50(345)

Max. Continuous Water

Temperature F(C) 104°(40°) 104°(40°)

* For best water clarity and filter cycle length, restrict

water flow to 50 GPM (189 LPM).

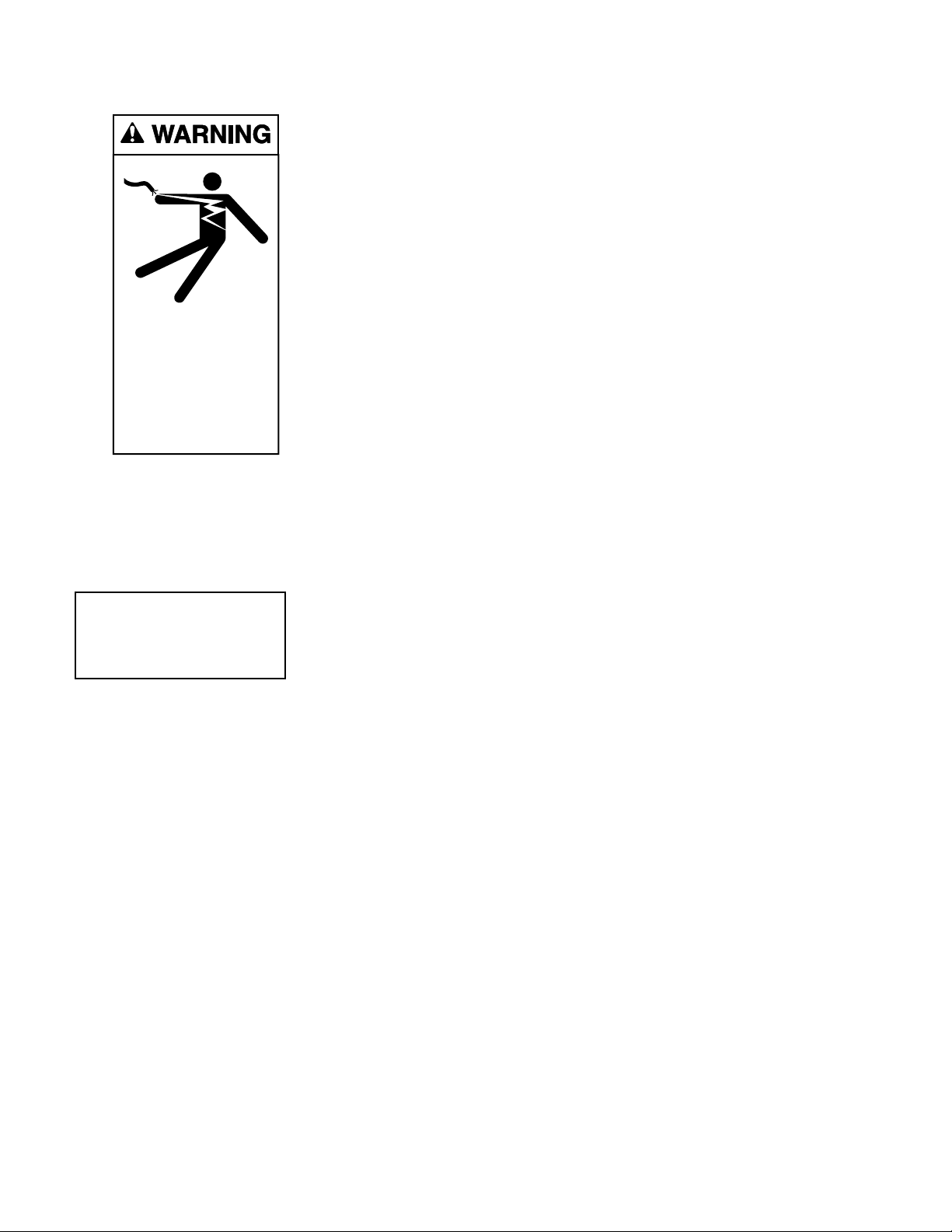

FIGURE 2 – Pressure Drop Curve

Model Descriptions

Air Release Valve

(Pressure Gauge

Behind)

Upper

Tank

Shell

Posi-Lok™

Ring

Safety

Latch

Lower

Tank

Shell

Drain

Plug

7.4"

(188 mm)

19.5" (495 mm)

Outlet

2" NPT

Inlet

2" NPT

15" (381 mm)

30" (762 mm)

2" NPT x 1-1/2" NPT

Reducer Bushing

Pump

Suction

1-1/2" NPT

11"

(279 mm)

(1105 mm)

32.75"

(832 mm)

2157 1295

43.5"

Minimum

Service

Height

24 (165)

22 (152)

20 (138)

18 (124)

16 (110)

14 (97)

LL

OO

CC

KK

RR

EE

MM

OO

VV

EE

EE

RR

GG

UU

SS

AA

UU

SS

GG

EE

EE

RR

PP

AA

EE

II

SS

RR

AA

RR

EE

LL

EE

LL

OO

CC

KK

RR

EE

MM

OO

VV

EE

EE

VV

OO

MM

EE

RR

KK

CC

OO

LL

12 (88)

10 (69)

8 (55)

Pressure Drop in

Pounds per Square Inch (kPa)

RELEASERELEASE

23"

(584 mm)

6 (41)

4 (28)

2 (14)

19"

(483 mm)

(38)

2158 1295

20

10

(76)

40

(151)

Flow in Gallons Per Minute (LPM)

60

(227)80(303)

100

(378)

2497 0796

120

(454)

140

(529)

150

(568)

160

(606)

Page 6

6

INSTALLATION

Installation of filter should only be done by qualified, licensed personnel.

Assembly:

• Unpack filter system and check it for transit damage.

• Open the accessory package and install the pressure gauge (with the filter

screen under it; see exploded view, Page 15) in the open port on top of the filter

tank. Do not overtighten.

• Install hoses with adapters and clamps provided in the accessory package. Run

one line from the skimmer to the pump suction port. Run the other line from the

filter outlet to the pool inlet fitting.

Filter mount must:

• Provide weather and freezing protection.

• Provide adequate ventilation and drainage for pump.

• Provide space and lighting for easy access for routine maintenance. (See Figure

1 for space requirements.)

• Be installed with the trap suction inlet below the pool water level at all times (to

allow the pump to prime).

• Be on a reasonably level surface and provide adequate drainage.

Piping:

• Piping must conform to local/state plumbing and sanitary codes.

• Use teflon tape, Plasto-Joint Stik®1, or Silastic RTV #732®on all male connections of plastic pipe and fittings. DO NOT use pipe compounds on plastic pipe;

it will cause the pipe to crack. Do not use sealant on unions – assemble them

dry and hand tight.

• Support pipe independently to prevent strains on filter or pump.

• Fittings restrict flow; for best efficiency use fewest possible fittings.

• For ease of maintenance, use Sta-Rite union couplings to connect the piping to

the filter inlet and outlet ports.

• Keep piping tight and free of leaks: pump suction line leaks may cause trapped

air in filter tank or loss of prime at pump; pump discharge line leaks may show

up as dampness or jets of water.

• NOTICE: Overtightening can crack filter ports.

Valves:

• Install valves on both sides of the filter to isolate filter for easy servicing.

NOTICE: Install heater downstream of filter. If heater does not incorporate a

check valve, install one at the heater inlet to prevent hot water from backing up

into the filter. Filter modules damaged by excessive heat will void the warranty.

• A check valve installed ahead of filter inlet will prevent contaminants from

draining back into pool.

1

Lake Chemical Co., Chicago, IL

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

NOTICE

Make sure that the filter and all piping can be drained for winterizing.

See “Winterizing”, Page 10.

Page 7

7

ELECTRICAL

Risk of electrical shock. Plug pump into a grounded, GFCI-protected 115

Volt circuit only. Incorrect voltage can cause fire or seriously damage

motor and voids warranty. Protect cord from water and physical damage.

GFCI tripping indicates an electrical problem. If GFCI trips and will not

reset, have a qualified electrician inspect and repair electrical system.

Risk of electrical shock. Unplug motor before servicing or re-

pairing pump or motor.

Wiring:

Install a Ground Fault Circuit Interrupter (GFCI) in circuit; it will sense a short

circuit to ground and disconnect power before it becomes dangerous to pool or

spa users. For size of GFCI required and test procedures for GFCI, see manufacturer’s instructions.

In case of power outage, check GFCI for tripping (which will prevent normal

water circulation); reset if necessary.

Do not connect any other lights or appliances to the same circuit.

Match circuit breaker size to Table II below.

• Do not modify cord, plug, or receptacle. If an existing circuit must be used

and the receptacle and plug do not match exactly, consult a licensed electrician.

• Do not use an extension or drop cord with this system; it could cause a fire

hazard or low voltage problems. Wet cords cause shock hazards. Extension

cords can easily become cut or frayed and dangerous when placed across

yard areas or walkways.

Voltage:

Voltage at motor must be not more than 10% above or below motor nameplate rated voltage or motor may overheat, causing overload tripping and reduced component life. If voltage is less than 90% or more than 110% of rated

voltage when motor is running at full load, consult power company.

Table II–Recommended Fusing Data, 115 Volt 60 Hz Motors.

Model Motor Max Load Branch Circuit Breaker

No. H.P. Amps Rating (Amps)

JWPA5E7L-2A1, -2A2 1 12.0 15

JWPA5E7C-2A3, 2A3U 1 11.9 15

JWPA5F7L-2A1, -2A2, -A1 1-1/2 16.0 20

JWPS5F7C-2A3, 2A3U 1-1/2SPL 11.9 15

NOTICE Values given are for pump motor only. Do not put any other accessories on

this circuit.

Hazardous voltage.

Can shock, burn,

or cause death.

Disconnect power

before working

on pump or motor.

FIGURE 3 - Plug configurations

1 HP Pumps with -2A2

suffix and Canadian Spec

Pumps use 15-amp straight

outlet, above.

1-1/2 HP Pumps with

-2A2 suffix use 20 amp

straight outlet, above.

All Pumps with

-2A1 suffix use 20-amp

twist-lock outlet, above.

1 HP Filter system with

Model No. suffix:

-03, -04, or -06

1-1/2 HP Filter system

with Model No. suffix:

-03, -04, or -06

All

Filter systems with

Model No. suffix:

-12 or -15

Page 8

8

Hazardous pressure.

Can cause severe

injury or major

property damage

from tank blow up.

Release all pressure

and read instructions

before working on filter.

INITIAL START-UP

Hazardous suction. Pump suction can trap or tear body parts,

especially with children. Do not block suction. Small children using pool must

ALWAYS have close adult supervison!

Do not operate system with water temperature above 104° F (40° C).

NEVER run pump dry. Running pump dry may damage seals,

causing leakage and flooding. Fill pump with water through the hair and lint

strainer lid before starting the pump.

Do not add chemicals to pool directly in the pool skimmer.

Adding undiluted chemicals may damage pump and void warranty.

Be sure pump is OFF before starting procedure.

Do not operate these filters at more than 50 PSI (345 kPa) under any

circumstances!

1. Securely lock Posi-Lok™ ring in place by rotating ring CLOCKWISE until it

“clicks” past the safety latch (see Figure 4). Stop turning as soon as the ring

clicks past the latch. The ring may feel slightly loose, but it will tighten up

when pump is on and filter is under pressure.

2. Fill trap on pump with water.

3. Open air release valve on top of filter.

4. Open isolation valves.

5. Start pump to purge air from system.

6. When steady stream of water comes from air release valve, close the

valve.

NOTICE: Leaking around the Posi-Lok™ ring may indicate that the ring is

not fully locked. In this case, proceed as follows:

A. Stop the pump, close the isolation valves, and open the air release valve

to release any pressure within the filter.

B. Remove the drain plug and drain all water from the filter.

C. Push down on the top of the filter to fully seat the upper tank shell.

D.Rotate the Posi-Lok™ clockwise until it locks behind the safety latch

(see Figure 4).

E. If the ring was already locked, remove it and the upper tank shell.

Inspect and clean the O-ring and all sealing surfaces. Relubricate the

O-ring.

NOTICE: Lubricate O-ring only with the silicone grease provided or equivalent, as other lubricants may cause the ring to swell. DO NOT lubricate

Posi-Lok™ ring or threads on lower tank shell as this may collect grit and

make removal difficult.

After filter is operating, record filter pressure gauge reading in owner's manual

for future use.

NOTICE: When installed on a new pool, after approximately 48 hours of operation disassemble filter and clean out plaster dust, construction debris, etc.

(see “Module Cleaning Procedure", Page 9).

OPERATION

Priming Pump:

Fill pump with water through hair and lint strainer lid opening.

Open suction and discharge valves before starting system.

Make sure that pool water is 2” - 3” (51mm - 76mm) above bottom of skimmer

opening and/or other suction outlets.

Water Maintenance:

Keep water level at least two inches (51mm) above bottom of skimmer opening

when system is not in use. Failure to do so can allow air to enter system, causing pump to lose prime and filter to entrap air.

Maintain pH at 7.2 to 7.6 in pool.

Figure 4 – Rotate Posi-Lok™

Ring until tab locks behind the

safety latch.

Tab

RELEASE

RELEASE

Latch

2149 1195

Page 9

9

FILTER DISASSEMBLY/

ASSEMBLY PROCEDURE

Hazardous pressure. Before disassembling filter:

1. STOP PUMP.

2. CLOSE isolation valves.

3. OPEN air release valve and drain fitting.

4. WAIT until all pressure is released and water drained from filter tank and

system before loosening Posi-Lok™ Ring.

Disassembly:

1. Stop the pump.

2. Close isolation valves to prevent flooding.

3. Open air release valve on top of filter tank to release all pressure from inside

of tank.

NOTICE: Make sure that waste water disposal complies with local codes

and ordinances.

4. Remove drain plug and drain all water from tank.

5. Remove Posi-Lok™ ring as follows:

a. Press safety latch (below the ring) toward the tank to release it (see Figure

5).

b. Hold latch in the release position and rotate ring COUNTERCLOCKWISE

to remove. If ring is difficult to turn, tap gently with a rubber mallet to

overcome initial resistance.

NOTICE: DO NOT use screwdriver or bladed instrument that may damage

shell surfaces to pry tank shells apart.

6. Separate upper and lower tank shell halves using tabs on bottom of

Posi-Lok™ ring. Insert tab into slot located at tank joint and twist ring to pry

shell halves apart. See Figures 6 and 7.

7. Remove O-ring from upper tank shell. Inspect for cuts, cracking, deformation or signs of wear; replace if necessary.

NOTICE: To avoid strain or damage, allow filter module to drain before lifting it out of the tank.

SAFETY LATCH (See Figure 8)

The purpose of the safety latch is to hold the Posi-Lok™ ring in the locked position. If the latch is damaged, replace it as follows:

1. Press down on the small catch behind the safety latch and press or tap the

latch out of the “Tee” slot in the tank (see Figure 8).

2. Snap the new latch into position.

NOTICE: DO NOT operate the filter if the safety latch is damaged or will

not hold the Posi-Lok™ ring in the locked position.

Assembly:

1. Inspect and clean the tank, ring threads and O-ring groove. Replace damaged parts as necessary.

2. Install the filter by placing the port in the bottom of the filter cartridge over

the tank outlet port. Push down firmly to seal.

3. Ensure that the air bleed assembly on top of the module is clean and properly mounted.

NOTICE: Lubricate O-ring only with the silicone grease provided or equivalent, as other lubricants may cause the ring to swell. DO NOT lubricate

Posi-Lok™ ring or threads on lower tank shell as this may collect grit and

make removal difficult.

Figure 6 – Insert ring tab in slot in

filter body.

Figure 7 – Roll ring to one side to

loosen upper tank half.

Figure 8 – Safety Latch

Figure 5 – Depress safety latch to

unscrew Posi-Lok™ Ring.

RELEASE

RELEASE

Depress Safety Latch

to unscrew Posi-Lok™

RELEASE

RELEASE

Small

Catch

Page 10

4. Install the O-ring in the upper tank shell O-ring groove. Be sure that the

O-ring is clean and not twisted.

5. Push the upper tank shell into the lower tank shell to compress the O-ring.

6. Place the Posi-Lok™ ring squarely over the tank shell threads and rotate

COUNTERCLOCKWISE until the ring falls into the slots; then rotate

CLOCKWISE until securely latched.

7. Follow instructions in the “Initial Startup” section of this manual.

MODULE CLEANING PROCEDURE

Follow all steps in the “Disassembly” section of this manual.

The filter module should be removed and cleaned when pressure rises more

than 10 psi (69 kPa) above startup pressure. See also “When to Clean the

Filter,” at left.

Risk of chemical burns. Do not attempt to acid clean the filter or

module. If the filter requires acid cleaning, have a trained pool professional do

the job.

NOTICE: When sanitizing your pool using PHMB (polyhexamethylene biquanide based) cleaners, use

only

PHMB cleaners to clean the module. When

using PHMB sanitizers, the filter module MUST be cleaned more thoroughly

and frequently than for a pool using chlorine. Follow manufacturer’s instructions carefully. Use of any other type of cleansers with PHMB pool sanitizers

will void the filter’s warranty.

NOTICE: Avoid washing filter debris into the outlet port. Remove drain plug

and flush foreign material from inside of tank before removing filter module.

1. With a hose equipped with a soft flow nozzle, wash as much dirt as possible

off of the filter module while it is still inside the tank. Allow tank to drain

completely.

2. Make sure that the inside of the tank is clean. Lift out the module and hose it

down thoroughly. Spray the entire module surface. Allow module to drain.

3. Inspect the module. If necessary, repeat the washing operation. If the mod-

ule is damaged, replace it.

NOTICE: If this cleaning method does not remove all deposits, see “Special

Cleaning Instructions” section in this manual.

4. Inspect and clean air bleed filter at top of module.

5. Follow all steps in the “Assembly” and “Initial Startup” sections of this manual.

Special Cleaning Instructions:

Use this procedure to clean scale or oils which are not removed by hosing

down module. Be sure to dispose of spent chemicals according to all applicable codes and waste disposal ordinances. Use a soft stream nozzle to minimize

flying water and spray.

Risk of fire or explosion. Isolate filter from system before chemi-

cal cleaning; rinse filter and elements completely before returning to service.

If filter cannot be isolated, remove media and clean at another location. Follow

chemical manufacturer’s instructions for use. Do not mix chemicals except as

directed by manufacturer. Do not allow cleaning chemicals to mix with or to

come in contact with chlorine, bromines, other chemicals, or chemical feed

devices.

1. Sponge or spray the module according to chemical manufacturer’s direc-

tions.

2. If soaking is required, remove the module from the filter tank and submerge

it in a separate tank. Follow cleaner manufacturer’s instructions carefully.

3. After completing chemical manufacturer’s instructions, drain and rinse the

module completely. Dispose of cleaners in accordance with local codes and

disposal ordinances.

4. Rinse the inside of the filter tank. Drain it completely.

5. Follow instructions in the “Assembly” and “Initial Startup” sections of this

manual.

10

Recommended Specialty

Filter Cleaners

Filter Cleanse™,

Great Lakes Biochemical

BIOGUARD Strip Kwik™,

BIOGUARD KleenIt™,

Softswim®Filter Cleaner,**

BIOLABS, Inc.

Filter Kleen™,

Haviland Products Co.

BAQUA CLEAN™, **

Zeneca, Inc.

** MUST be used when

using any PHMB based

sanitizer.

When to Clean the Filter

The filter module should normally be

cleaned when the pressure gauge reading

increases 10 PSI over the start-up pressure

(record the start-up pressure under

“Owner’s Information”, Page 3).

In some pools, accessories such as fountains or pool cleaners may be noticeably

affected by the normal decrease in flow as

the filter becomes dirty. If so, clean the filter more frequently (that is, at a pressure

increase of less than 10 PSI) in order to

maintain the required flow.

Page 11

11

SYSTEM INSPECTION

General:

Wash the outside of the filter with a mild detergent and water. Rinse off with a

hose.

NOTICE: DO NOT use solvents to clean the filter; solvents may damage plastic components in the system.

NOTICE: Open the air bleed valve and bleed all air from the filter each time

the pump is stopped and restarted.

Weekly Inspection:

1. Remove debris from the pool skimmer basket.

2.

Stop the pump; open the air release valve to release all pressure.

3. Remove the trap cover and basket; remove debris.

4. Check the pump for leaks. If found, see the pump owner's manual.

5. Replace the trap basket and the cover. Tighten the cover securely hand

tight. DO NOT use a lid wrench to tighten it.

6. Start the pump. When the filter air release valve runs a solid stream of

water, close the valve.

7. When the system has returned to normal operation, check the filter pres-

sure. If the filter pressure is 10 PSI (69kPa) or more higher than the initial

startup pressure, the filter needs cleaning. See “Module Cleaning

Procedure”, Page 9.

WINTERIZING

Explosion hazard. Purging the system with compressed air can

cause components to explode, with risk of severe injury or death to anyone

nearby. Use only a low pressure (below 5 PSI), high volume blower when air

purging the pump, filter, or piping.

NOTICE: Protect the filter from freezing. Allowing the filter to freeze will damage it and will void the warranty.

1. Clean the filter according to instructions (Page 9) before winterizing.

2. Stop the pump.

3. Open the air release valve; open all the system valves.

4. Remove the drain plugs from the trap, pump, and filter.

5. Drain the system piping.

A. Gravity drain system as far as possible.

B. Protect areas which retain water with non-toxic propylene glycol

antifreeze (“RV antifreeze”).

6. Loosen the union nuts (if used) to drain all water from the filter interior.

Leave these nuts loose until the system is restarted.

7. Disassemble the filter (follow instructions under “Filter Disassembly”, Pages

8 and 9). Remove the filter module and store it in a warm, dry area.

8. If the filter is equipped with an optional internal spring check valve (in the

tank outlet), manually open the check valve to allow any water trapped in

the tank to drain.

9. Cover the filter with plastic or tarpaulin to prevent water entrance and

freezing.

PUMP SERVICE

Pump should only be serviced by qualified personnel.

For continued protection against possible electric shock, use only identical replacement parts when servicing.

Before removing trap cover:

1. STOP PUMP before proceeding.

NOTICE

The filter outlet piping will not empty

through the filter drain. Make sure that

the outlet piping has a separate drain for

winterizing.

Page 12

12

2. CLOSE GATE VALVES in suction and discharge pipes.

3. RELEASE ALL PRESSURE from pump and piping system.

To avoid dangerous or fatal electrical shock hazard, turn OFF power to

motor before working on pump or motor.

No lubrication or regular maintenance is needed beyond reasonable care and periodic cleaning of strainer basket. Trap cover O-Ring is internally lubricated and

needs no additional lubrication.

If shaft seal is worn or damaged, repair as follows:

Pump Disassembly:

1. Unplug motor before servicing or repairing pump or motor.

2. Close all valves in suction and discharge piping.

3. Remove drain plugs from the bottom of pump and trap; drain pump com-

pletely.

4. Disconnect pipe unions (or clamps) on suction and discharge piping. Re-

move hold down bolts and withdraw complete pump/motor/trap assembly.

5. Remove cap screws (Key No. 16, Pages 16 and 17) from front plate (Key

No. 13). Remove front plate with trap (Key No. 20) attached. Remove and

inspect O-Ring (Key No. 12).

6. Remove end cap (Key No. 2) from motor.

7. Hold motor shaft with 7/16” wrench on flats on motor shaft; unscrew im-

peller (Key No. 11).

8. Carefully remove rotating half of seal (Key No. 10) from impeller sleeve.

Twist as you pull; make sure you do not damage surface of sleeve where

seal both seats and seals. See Figure 9.

9. Remove motor throughbolts (see Figure 10). Remove seal plate (Key No.

9). Tap stationary half of seal out of seal plate (see Figure 11).

10.If necessary, disconnect electrical wiring from motor terminal board and

remove motor (Key No. 6) from motor cover (Key No. 8; -06 models only).

Pump Assembly:

1. Examine seal cup and O-Rings. Replace anything that shows signs of wear

or damage.

2. Check the shaft seal (Key No. 10) for scoring, scratches, chips, etc., and for

any signs of damage to spring or retainer. Replace if any wear or damage is

visible.

3. Press stationary half of seal into seal plate (Key No. 9) using finger pressure

only (see Figure 12). Make sure seal is firmly and evenly seated.

4. Install rotating half of seal on impeller sleeve. Push it onto sleeve until it

butts against back of impeller.

5. Insert impeller sleeve through center hole in seal plate (Key No. 9). Thread

flinger (Key No. 7) over the end of the impeller sleeve.

6. If motor has been removed from motor cover, reinstall it now. Set up seal

plate (Key No. 9) in front of motor cover; hold motor shaft with 7/16”

wrench on shaft flats (under cap) and thread impeller through center hole

in seal plate onto shaft. Make sure that flinger is in place on impeller

sleeve – not loose on shaft.

7. Install motor throughbolts; make sure seal plate butts firmly against motor

endbell.

8. Install front plate (Key No. 13). Tighten cap screws in sequence as shown

in Figure 13; tighten to 30 inch-lbs. (34.5 cm-kg.) torque.

9. Reinstall drain plugs; reinstall pump and motor on base and tighten hold-

down bolts.

10.Reconnect unions; tighten hand tight only.

Figure 13 - Torque Sequence

Figure 11

Figure 9

Figure 10

Figure 12

START HERE

1

3

5

2

4

6

604 0993

Page 13

13

Read and understand safety and operating instructions in this manual before doing any work on

pump.

A. Pump does not operate:

1. Check GFCI (Ground Fault Circuit Interrupter) for

proper operation according to GFCI manufacturer’s instructions.

2. Check for blown fuses, circuit breakers, or disconnected electrical wiring.

3. Check for sand locked impeller. Disconnect power

to motor; follow pump disassembly instructions,

Pages 10 and 11. Clean out sand from impeller

and from wear ring in front plate. Reassemble according to instructions, Page 11.

4. Consult dealer/installer or service representative.

B. Motor runs, but does not pump water or pressurize

system:

1. Check to make sure all valves are open.

2. Check skimmer, trap basket, and piping for debris

or obstructions.

3. Check pump impeller for obstructions such as

hair, leaves, grass, or stones. Follow “Pump

Disassembly” instructions, under “Pump Service”

on Pages 10 and 11.

4. Consult with dealer/installer or service representative.

C. Excessive air in system – pump loses prime:

1. Make sure water level in skimmer is at least 2”

above bottom of skimmer throat with system not

operating.

2. Make sure that there are no leaves in suction piping and skimmer basket.

3. Make sure there is no vortex (whirlpool) at the

skimmer suction; add water to pool if necessary.

4. Consult dealer/installer or service representative.

D. Circuit breaker in home panel trips repeatedly:

1. Breaker must be of correct rating (see Page 6).

2. If breaker is a GFCI breaker, test according to

GFCI manufacturer’s instructions.

3. Be sure no other lights and appliances are on circuit.

4. Check wiring size leading to pump. Undersize

wire will cause overheating and excessive amp

draw, leading to the circuit breaker tripping.

Circuit wiring to the receptacle serving the pump

must meet code for the load on the circuit. If in

doubt, consult a licensed electrician.

5. Consult dealer/installer or service representative.

TROUBLESHOOTING GUIDE – PUMP

Page 14

14

1. Short Cycle Time:

NOTICE: Cycle Time will vary with each installation

and between different areas of the country. The following causes and remedies are for cycle times shorter

than normal for your area.

A. Chlorine residual too low; maintain proper resid-

ual (consult pool professional for recommendation).

B. Flow rate too high; restrict flow to rated capacity

of filter (see instruction plate on filter or specifica-

tions on Page 4).

C. Filter is too small; install an additional filter.

D.Filter module is dirty or plugged; thoroughly clean

the filter (see No. 4, “Plugged Module Cloth”, and

“Module Cleaning Procedure", Page 9).

E. Water is chemically out of balance; consult pool

professional.

F. Algae in the pool. Apply heavy dose of chlorine or

algicide as recommended by the pool manufac-

turer.

2. Low Flow/High Pressure:

A. Elements plugged; clean filter thoroughly (see

Page 9).

B. Pipe blocked downstream from filter; remove ob-

struction.

C. Piping too small; use larger pipe (consult dealer

for sizing).

D.Filter area too small; install an auxiliary filter (con-

sult dealer for recommendation).

E. Outlet port check valve obstructed (if applicable);

remove obstruction to allow valve to open.

3. Low Flow/Low Pressure:

A. Pump too small; consult dealer for recommenda-

tions.

B. Plugged pump or plugged hair and lint trap; clean

thoroughly.

4. Plugged Module Cloth:

A. Insufficient cleaning; follow cleaning instructions

closely and clean thoroughly (see Page 9).

B. Water is chemically out of balance; consult pool

professional.

C. Excessive air in filter. Vent air from tank and check

for pump suction pipe leaks. Clean air bleed filter

in module assembly with a hose and soft flow

nozzle.

D. Filter is too small. Install an additional filter.

E. Pool water contains iron. See “Special Cleaning

Instructions”, Page 9.

F. Heavy or improper application of powdered chlo-

rine tablets using a binder. See “Special Cleaning

Instructions”, Page 9.

G. Algae in the pool. Apply heavy dose of chlorine

or algicide as recommended by the pool manufac-

turer.

H.Use of incorrect chemicals with PHMB sanitizers.

Replace filter module.

5. Pool Water Not Clean:

A. Chlorine residual too low; maintain adequate

chlorine residual (consult pool service technician

for recommendation).

B. Filter module cloth torn, plugged, or punctured;

replace module.

C. Inadequate turnover rate; consult dealer to verify

that equipment is properly sized for your pool.

D.Pump is too large and is overpumping. Reduce the

flow rate.

E. The filter is installed backwards. Reinstall it cor-

rectly.

F. Pool water contains iron. See “Special Cleaning

Instructions”, Page 9.

G.Heavy or improper application of powdered chlo-

rine tablets using a binder. See “Special Cleaning

Instructions”, Page 9.

H.Algae in the pool. Apply heavy dose of chlorine or

algicide as recommended by the pool manufac-

turer.

6. Pool Accessories Stop Working:

A. Clean filter and observe performance of acces-

sories.

B. If accessories perform better after filter has been

cleaned, use a shorter cleaning cycle for the filter

(that is, clean the filter after a pressure rise of less

than 10 PSI).

TROUBLESHOOTING GUIDE – FILTER

Page 15

15

Model No.

PLM100JWAE-03 PLM100JWAF-03 PLM150JWAE-03 PLM150JWAF-03

PLM100JWAE-04 PLM100JWAF-04 PLM150JWAE-04 PLM150JWAF-04

PLM100JWAE-06 PLM100JWAF-06 PLM150JWAE-06 PLM150JWAF-06

Key Part PLM100JWAE-12 PLM100JWAF-12 PLM150JWAE-12 PLM150JWAF-12

No. Description Qty. 1 HP 1-1/2 HP 1 HP 1-1/2 HP

1 Filter Tank Assembly 1 PLM100 PLM100 PLM150 PLM150

2 Union Half Assembly 1 27001-0120 27001-0120 27001-0120 27001-0120

3 O-Ring 1 U9-226 U9-226 U9-226 U9-226

4 Pump Assembly (-03, -04 Models) 1 JWPA5E7L-2A2 JWPA5F7L-2A2 JWPA5E7L-A2 JWPA5F7L-2A2

4 Pump Assembly (-06 Models) 1 JWPA5E7C-2A3U JWPS5F7C-2A3U JWPA5E7C-2A3U JWPS5F7C-2A3U

4 Pump Assembly (-12 Models) 1 JWPA5E7L-2A1 JWPA5F7L-2A1 JWPA5E7L-2A1 JWPA5F7L-2A1

4 Pump Assembly (-15 Models) 1 – JWPA5YF7L-A1 – –

• Adapter Kit (includes Key No. 6, 7) 1 27001-0141 27001-0141 27001-0141 27001-0141

5 Hose Adapter 1-1/2” MPT Male 2 11201-0002 11201-0002 11201-0002 11201-0002

6 Hose Clamp 4 P19-30 P19-30 P19-30 P19-30

7 Platform Base 1 27001-0031 27001-0031 27001-0031 27001-0031

8 2” NPT x 1-1/2” NPT Reducer Bushing 1 U78-820P U78-820P U78-820P U78-820P

• System Nameplate 1 27002-0045 27002-0045 27002-0045 27002-0045

•

Hose Assembly 1-1/2” X 77” (-03 Models only

) 2 34055-7038 34055-7038 34055-7038 34055-7038

• Platform Extension (Optional) 1 27001-0032 27001-0032 27001-0032 27001-0032

REPAIR PARTS LIST – Modular Media System

REPAIR PARTS LIST

Modular Media Filter Systems

See Page 15 for Filter Tank Assembly Parts

See Pages 16 and 17 for Pump Parts

• Not illustrated.

1

RELEASE

RELEASE

2

8

OUTLET

5

OUTLET

INLET

INLET

3

4

6

7

5

6

2159 1295

Page 16

16

Key Part

No. Description Qty. Number

1 Posi-Lok™ ring* 1 27001-0050B

2 Air release valve assembly 1 25010-0200

3 Tank shell upper half* 1 27001-0020S

4 Tank O-ring 1 27001-0061S

5 Tank shell lower half 1 27001-0009S

6 Safety latch for ring 1 27001-0051

7A 1-1/2” NPT plug 1 11201-0005B

7B Adapter fitting 1 24900-0509

8 O-ring 1 35505-1424

9 2” x 1-1/2” Pipe reducer*** 2 U78-820P

10 Pressure gauge*** 1 15060-0000T

10A Pressure gauge screen*** 1 WC8-72D

11 Air bleed assembly 1 24800-0121

12 Filter module (PLM100) 1 27002-0100S

12 Filter module (PLM150) 1 27002-0150S

13 Spring check valve** 1 27001-0130S

• Accessory package 1 27001-0140

• Decal, logo 1 27001-0041

• Decal, warning 1 27001-0042

• Decal, operating instr. 1 27002-0043

• Decal, nameplate (PLM100) 1 27002-0042

• Decal, nameplate (PLM150) 1 27002-0045

• Owner’s manual 1 S340

• Teflon tape*** 1 U97-58

• O-ring grease*** 1 34725-0013

• Not illustrated.

* Includes all decals and labels.

** Optional equipment.

*** Shipped in accessory package.

REPAIR PARTS

Filter Tank Assembly

11

1

12

2

10

10A

3

4

13

5

RELEASE

RELEASE

6

7A

7B

OUTLET

OUTLET

8

9

Base rotated 90° to show

check valve installed.

DRAIN

DRAIN

Page 17

17

1

REPAIR PARTS LIST — 17290 SERIES PUMPS

See Pump nameplate for Pump Model Number

for Filter System with Suffix -06

Parts are common to all models listed except as noted;

Key Nos. 6, Motor; and 11, Impeller, are listed below.

Motor No. Impeller No.

Model No.HP (Key No. 6) (Key No. 11)

115V/60/1

JWPA5E7C-2A3 1 AS901EL C105-228PWS

JWPS5F7C-2A3 1-1⁄2SPL AS901SFL C105-228PWS

Model No. HP Cord & Cap Assembly

115V/60/1

JWPA5E7C-2A3 1 17190-0026-S

JWPS5F7C-2A3 1-1/2SPL 17190-0026-S

Key Part

No. Description Qty. Number

1 End Cap Screw 3 37337-0085

2 Cap and Cord Ass’y 1 Chart at Right

3 Toggle Switch 1 16920-0511

4 Toggle Switch Boot 1 32800-0107

5 Baffle Ring 1 17290-0004

6 Motor 1 Chart at Right

7 Flinger 1 C69-2

8 Motor Cover 1 17190-0021

9 Seal Plate 1 17301-0150

10 Shaft Seal 1 U9-358SS

11 Impeller 1 Chart at Right

12 O-Ring 1 U9-357

13 Front Plate 1 C101-272P

14 Plain Washer 4 U43-60SS

15 Lock Washer 4 U43-10SS

16 Cap Screw 4 U30-873SS

17 Trap Lid 1 C3-139P1

18 Trap Lid O-Ring 1 U9-229

19 Trap Basket 1 C108-33P

20 Trap Body 1 C153-53P

21 Drain Plug w/O-Ring 2 U178-920P

22 Cap Screw 4 U30-64SS

23 Lock Washer 4 U43-11SS

24 Plain Washer 4 U43-41SS

25 Trap Outlet Gasket 1 C20-123

26 Mounting Foot 1 17190-0023

• Nameplate 1 32155-4073

• Decal – GFCI Required 1 U27-558

• Tag – Do Not Use Pipe Dope 1 61002-0002

• Tag – Electrical, priming 1 61002-0004

Trap Cover/O-Ring Kit (5” Trap)

Kit includes C3-139P1 Trap Cover and U9-229 O-Ring.

Parts-Pak No. PP2075.

2

4

3

5

6

7

8

9

10

11

12

13

21

25

14

24

15

16

23

806 0394

22

17

18

19

20

21

Page 18

18

2A

REPAIR PARTS LIST — JWA Series PUMPS

See Pump nameplate for Pump Model Number

for Filter System with Suffix -03, -04, -12, or -15

• Not illustrated.

* Model JWPA5YF7L-A1 uses Part No. 62003-2032.

-A1 and -2A1 Models -2A2 Models

HP Cord Ass’y with Cord Ass’y with

Twist-lock Plug Straight Plug

1 31953-0101 U117-1117

1-1/2 31953-0101 U117-1118

Cord and Plug Part Numbers

Trap Cover/O-Ring Kit (5” Trap)

Kit includes C3-139P1 Trap Cover and

U9-229 O-Ring.

Parts-Pak No. PP2075.

Model Number

JWPA5YF7L-A1

JWPA5E7L-2A1 JWPA5F7L-2A1

Key JWPA5E7L-2A2 JWPA5F7L-2A2

No. Description Qty. 1 HP 1-1/2 HP

2 Motor End Cap 1 Not Available separately

2A Cord Assembly 1 See Chart See Chart

6 Motor 115/60H/1Ph (Without Cord)* 1 AS920ELL AS920FLL

7 Slinger 1 C69-23 C69-23

9 Seal Plate 1 C1-260P C1-260P

10 Seal 1 U109-358SS U109-358SS

11 Impeller 1 C105-228PG 17301-0101

12 O-Ring 1 U9-357 U9-357

13 Front Plate 1 C101-272P C101-272P

13A Pipe Plug 2 WC78-40T WC78-40T

14 Washer, 1/4 Flat 6 U43-117SS U43-117SS

15 Washer, 1/4 Lock 6 U43-10SS U43-10SS

16 Screw, 1/4-20x1-3/4 6 U30-873SS U30-873SS

17 Trap Cover 1 C3-139P1 C3-139P1

18 O-Ring - Cover 1 U9-229 U9-229

19 Strainer Basket 1 C108-33P C108-33P

20 Trap Body 1 C153-53P1 C153-53P1

21 Drain Plug - 1/4” NPT (w/O-Ring) 2 U178-920P U178-920P

22 Capscrew 5/16-18x1-1/4” 4 U30-64SS U30-64SS

23 Washer, Lock 5/16” 4 U43-11SS U43-11SS

24 Washer, Flat 5/16” 4 U43-41SS U43-41SS

25 Gasket 1 C20-123 C20-123

• Nameplate 1 U33-155 U33-155

• Decal “Tested for Pools & Spas” 1 U27-635 U27-635

• Decal - GFCI required 1 U27-558 U27-558

• Decal - Caution 1 32165-4038 32165-4038

• Tag - bonding instructions 1 C63-12 C63-12

• Tag - CAUTION Securely 1 61002-0002 61002-0002

Tighten…Warning…

2

6

7

9

10

11

12

13A

21

13

14

15

16

25

24

23

22

2248 0196

21

17

18

19

20

Page 19

▲ Retain Warranty Certificate (upper portion) in a safe and convenient location for your records.

DETACH HERE: Fill out bottom portion completely and mail within 10 days of purchase/installation to:

▼ Sta-Rite, Attn: Warranty Dept., 293 Wright St., Delavan, WI 53115

Pumps, filters, skimmers, underwater lights (except bulbs),

accessories and fittings manufactured by Sta-Rite are warranted to be free of defects in material and wor kmanship f or

one (1) year from date of installation.

Product specific warranties:

Year from date

of installation

HRPB, DEPB and System 3 – Tanks . . . . . . . . . . . .10 years

Internal filter components and valves . . . . . . . . . 1 year

Max-E-Therm – Pool/Spa Heaters . . . . . . . . . . . . . 2 years

Heater Enclosure only (Upper RH & LH;

lower enclosure; and control board enclosure)… 10 years

Automatic Pool Cleaners including Hose . . . . . . . 2 years

Cristal-Flo filters – Tanks . . . . . . . . . . . .10 years pro-rated*

Valve and internal components. . . . . . . . . . . . . . . . 1 year

Posi-Flo II – Tanks . . . . . . . . . . . . . . . . . . . . . . . . . .10 year s

Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year

Waterford Sand – Tanks . . . . . . . . . . . . .10 years pro-rated*

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year

Valve and Internals . . . . . . . . . . . . . . . . . . . . . . . . . 1 year

Waterford Cartridge – Filter Tank . . . . . . . . . . . . .10 years

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year

System 3 Above Ground Systems – Tanks . . . . . . .10 years

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year

Platform and Internals . . . . . . . . . . . . . . . . . . . . . . 1 year

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 year

When equipped with A.O. Smith

2-compartment motors (Does not include

pumps sold as part of a systems package) . . . . . . 2 years

* Full warranty coverage is in effect for one year after installation. The pro-rated warranty covers the tank only during

the 2nd through 10th year after installation. The amount covered decreases by 10% each year. (ie., 2nd year 90% covered,

3rd year 80% covered, etc.).

The foregoing warranties relate to the original consumer purchaser (“Purchaser”) only. Sta-Rite shall have the option to repair or replace the defective product, at its sole discretion. Purchasers must pay all labor and shipping charges necessary to replace the product covered by this warranty.

Requests for warranty service must be made through the installing dealer. This warranty shall not apply to any product

that has been subject to negligence, misapplication, improper installation or maintenance, or other circumstances

which are not in Sta-Rite’s direct control.

This warranty sets forth Sta-Rite’s sole obligation and

Purchaser’s exclusive remedy for defective products.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED

W ARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

P ARTICULAR PURPOSE, SHALL NOT EXTEND BEY OND THE

DURATION OF THE APPLICABLE EXPRESS WARRANTIES

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long

an implied warranty lasts, so the above limitations or exclusion may not apply to you. This warranty gives you specific

legal rights and you may also have other rights which vary

from state to state.

Supersedes all previous publications.

Sta-Rite Industries, Inc.

293 Wright Street

Delavan, WI 53115

Warranty Registration Card

Name

Address

City State Zip

Purchase Date

Product Purchased

■■ New installation ■■ Replacement

Type of Pool ■■ Inground ■■ Vinyl ■■ Fiberglass ■■ Gunite

Size of Pool

Years pool has been in service ■■ less than 1 ■■ 1-3 ■■ 3-5 ■■ 5-10

Purchased from:

Company name

Address

City State Zip

Please send me more information on these

other products from Sta-Rite.

■■ Pumps ■■ Filters ■■ Automatic Pool Cleaners

■■ Maintenance Equipment ■■ Test Strips

■■ Heaters

S4877PS (2/20/98)

STA-RITE LIMITED WARRANTY

Page 20

20

Loading...

Loading...