STA-RITE SilentFlo SF550100, SilentFlo SF1100100, SilentFlo SF1500100, SilentFlo SF750103 Owner's Manual

OWNER’S MANUAL

Should the installer or owner be unfamiliar with the correct

installation or operation of this type of equipment you should contact

the distributor/manufacturer for the correct advice before proceeding

with the installation or operation of this product.

For the Installation, Operation and Service of

SilentFlo

Pool Pump

The pump must be supplied from a circuit

protected by a residual current device (RCD) with

a maximum rated residual current of 30mA

Table of Contents

Page

Model Data 2

Installation 3

Pressure Testing 4

Pump Mount 5

Tefl on Taping Instructions 6

Fittings 6

Pool Outlets 6

Entrapment Protection 7

Testing and Certifi cation 7

Outlets per Pump 7

Water Velocity 7

Electrical 8

Operation 9

Priming Pump 10

Service and Maintenance 11

Troubleshooting 12

Parts Breakdown 14

Warranty 15

1

2

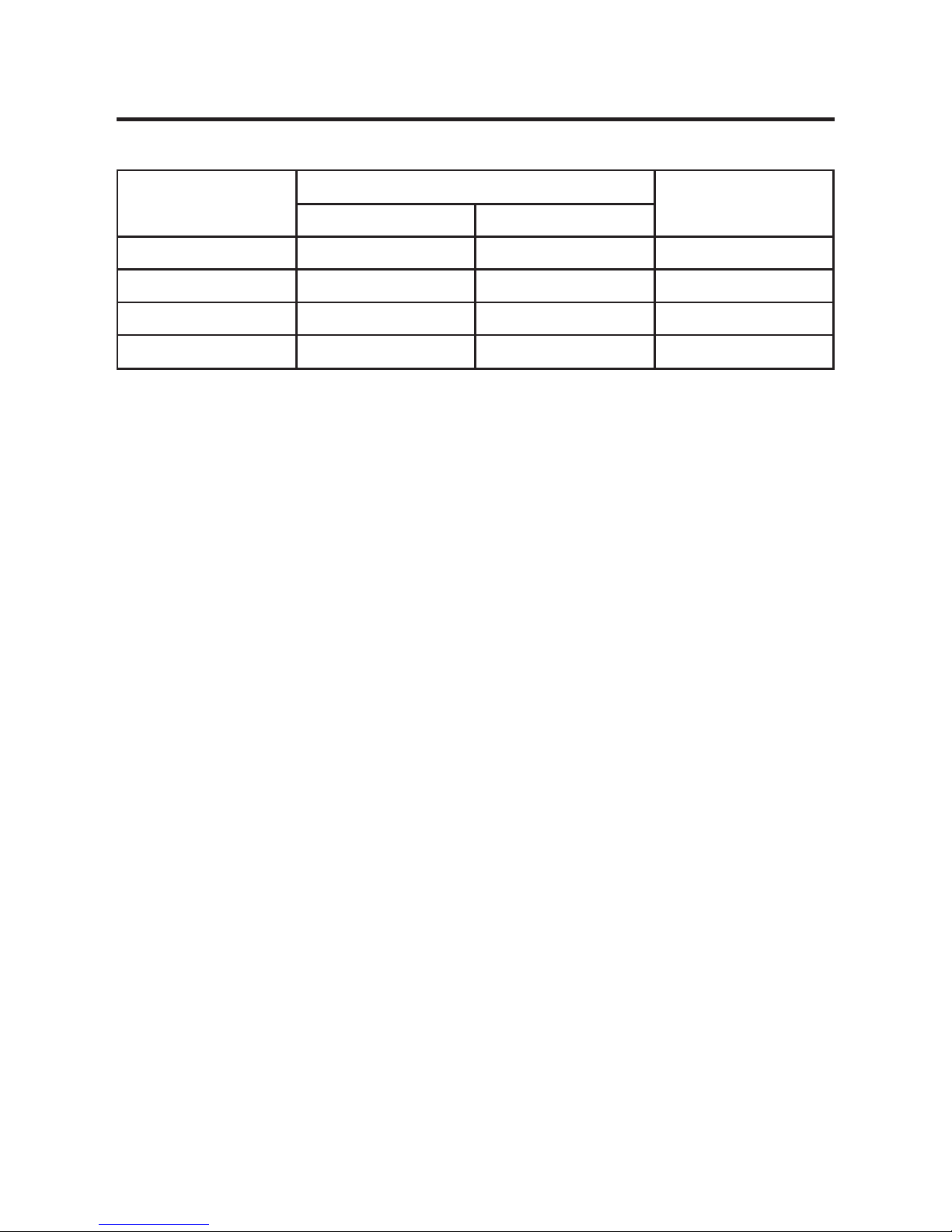

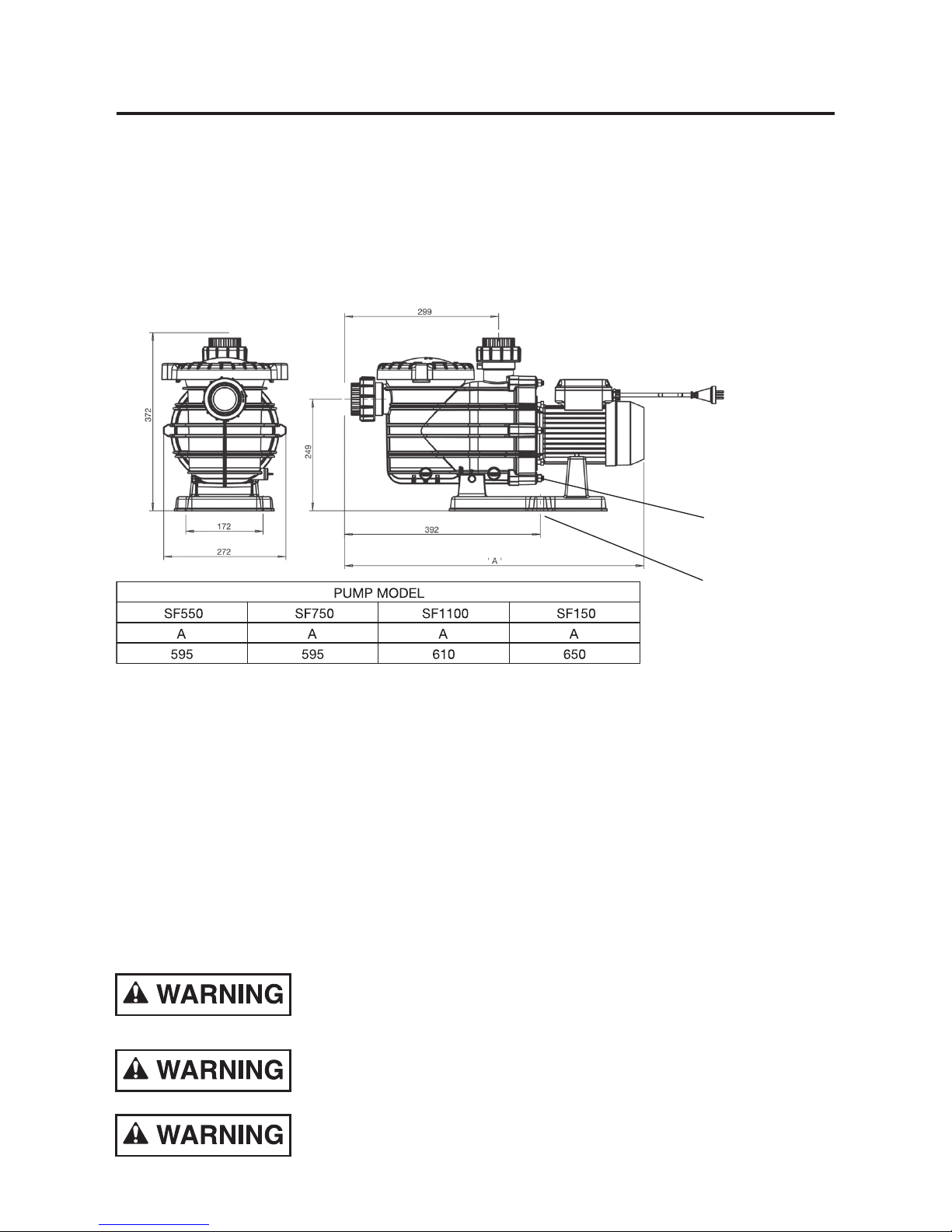

Model Data

Part

Number

Output Power

Max Total Head

(m)

(W) (hp)

SF550100 550 3/4 18

SF750103 750 1 17

SF1100100 1100 1.5 15

SF1500100 1500 2 12

Technical Information

Inlet (Suction): ABS Barrel Union to suit 50mm I.D PVC pipe

to AS/NZS 1477

Outlet (Discharge): ABS Barrel Union to suit 50mm I.D PVC pipe

to AS/NZS 1477

Max Working Pressure: 260 kPa

Water Temperature Range: 5°C – 38°C

IP Rating: IPX5

Electrical Rating: 230-240V 50Hz single phase

Motor: Built in auto reset overload protection.

Flexible power supply cord 10Amp.

Recommended pH Range: 7.2 - 7.8 (Guide Only)

Maximum Ambient temperature: 55°C

3

Incorrectly installed or tested equipment may fail, causing severe injury

or property damage.

Read the following instructions in this owner’s manual

when installing and operating equipment. Have a trained

pool professional perform all pressure tests.

1. Do not connect system to high pressure or mains

water system.

2. Use equipment only in a swimming pool or spa pool

installation.

3. Install pump with at least 2 hydraulically balanced

main drains equipped with correctly installed, screw fastened, antientrapment certifi ed covers according

to local regulations.

4. Trapped air in system can cause explosion.

Ensure all air is out of the system before operating or

testing equipment.

Silentfl o is electrically connected. Ensure that it is isolated

from electrical supply during installation and any subsequent

service work.

The pump should be installed and serviced by a suitably

qualifi ed person in order to avoid hazard.

These instructions are a guide only. Should you the installer or

owner of the product be unfamiliar with the correct installation

or operation of this product you should contact a suitably

qualifed person for advice.

Freezing conditions will damage the unit, as water expands as

it freezes. Ensure that Silentfl o is located so that it is not prone

to freezing, or ensure that the product is disconnected and

dried of water during cold conditions.

Installation

4

(Have a trained pool professional perform all pressure tests).

Before pressure testing, make the following safety checks:

1. Check all clamps, bolts, lids, and system accessories prior to testing.

2. Release all air in system before testing.

3. Tighten trap lid to 4.1kg-m torque for testing.

4. Water pressure for test must be less than 170kPa (25 PSI)

5. Water tempertaure for test must be less than 38°C

6. Limit test to 24 hours. After test, visually check system to be sure it is ready

for operation. Remove trap lid and retighten hand tight only.

Fire and burn hazard. Modern motors run at high temperatures. To reduce

risk of fi re, do not allow leaves, debris, or foreign matter to collect around the

pump motor. To avoid burns when handling the motor, let it cool for at least

20 minutes before trying to work on it. A thermal overload switch protects the

motor from heat damage during operation.

Only qualifi ed, licensed personnel should install pump. The electrical

installation shall be in accordance with the national wiring rules (AS/NZS 3000)

for class I, IP55 rated products. Refer to page 10 for Electrical Installation.

Pressure Testing

Pump mount must:

1. Be located away from corrosive or fl ammable chemicals. Have enough ventilation to

maintain air tempertaure at less than the maximum ambient temperture rating. If this

pump is installed in an enclosure/pump house, the enclosure must have adequate

ventilation (200sq.cm min, inlet & outlet) and air circulation to keep the temperature

in the enclosure at or below the motor’s rated ambient temperature whenever the

pump is running. Keep rear of motor clear (150mm).

2. Be solid, level, rigid and ribration free. (To reduce vibration and pipe stress, bolt pump

to mount). Fixing holes accept 12mm fasteners.

3. Allow pump suction inlet height to be as far below water level as possible.

4. Allow use of short, direct suction pipe (to reduce friction losses).

5. Allow for shut-off valves in suction and discharge piping.

6. Have adequate fl oor drainage to prevent fl ooding.

7. Be protected from excess moisture

8. Allow adequate access for servicing pump and piping.

We recommend mounting the pump on a concrete platform for quietest performance.

Use Tefl on tape for making all threaded connections to the

pump. DO NOT use pipe dope (glue) as this will cause stress

fractures in the pump.

Pump suction and discharge connections have moulded in

thread stops. DO NOT screw pipe in beyond these stops.

DO NOT use sealants which are incompatible with pipe fi ttings.

5

Pump Mount

Equipotential

Bonding Terminal

Fixing Holes

Loading...

Loading...