STA-RITE Signature 2000 Owner's Manual

OWNER’s MANUAL

Signature 2000

High Pressure Booster Pump

60 Hz. 1/2 through 3 HP

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.STA-RITE.COM

PH: 888-782-7483

© 2012 Pentair, Inc. All Rights Reserved. S327 (11/01/12)

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see

this symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause serious personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious personal injury, death or major property damage if

ignored.

warns about hazards that will or can

cause minor personal injury or property damage if

ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in

this manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

California Proposition 65 Warning

This product and related accessories

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

ELECTRICAL SAFETY

Some models of

WARNING

Hazardous voltage. Can

shock, burn, or cause

death.

Ground pump before

connecting to power

supply.

type cord. Do not allow any part of cord or

receptacle ends to sit in water or damp locations.

pump are supplied

with 3-connector

grounding type cord.

Connect only to properly

grounded, GFCI protected

outlet. Do not lift pump by

electrical cord.

Pump is non-

submersible. Keep

motor dry at all times. Do

not wash motor. Do not

immerse. Protect motor

from wet weather.

If using extension

cord, use only

UL approved indoor/

outdoor, 3-wire, grounding

Follow local and/or national plumbing and electrical

codes when installing.

Hazardous Pressure. DO NOT run the

pump with discharge shutoff, as hose may burst or

pump may be damaged due to high temperatures.

GENERAL SAFETY

To avoid risk of serious bodily injury and property

damage, read safety instructions carefully before

installing pump.

Do not allow pump or any system component to freeze.

To do so may damage system and will void warranty.

Risk of electric shock. To avoid fatal

shocks, proceed as follows if pump needs servicing.

A. Disconnect power to pump outlet box before pul-

ling pump cord plug. After plug is pulled, let pump

cool for 20 minutes before attempting to work on it.

B. Take extreme care when changing fuses. To

re-duced chance of fatal electrical shocks, DO NOT

stand in water or put your finger in the fuse socket.

C. Ground electrical outlet box.

D. Use only Ground Fault Circuit Interrupter (GFCI)

protected grounded outlet for cord plug.

Never run pump dry. Running pump dry can damage

internal parts, overheat pump (which can cause burns

to people handling or servicing pump), and will void

warranty.

Do not pump chemicals or corrosive liquids with pump.

Hazardous Pressure.

A. Use high pressure reinforced type discharge

hose ONLY. See parts list for available hose,

nozzle and fittings. A high pressure relief valve is

recommended.

B. DO NOT use garden hose with High Pressure

Booster pump. Garden hose will not stand the

discharge pressure produced and will fail.

C. High pressure discharge stream is dangerous. To

avoid injury, DO NOT aim the discharge stream at

any person or animal.

D. BE SURE that the pump suction pipe pressure

plus the pump discharge pressure does not

exceed the pressure rating of hose and fittings.

See Table I for pump discharge pressure ratings.

Unplug pump before servicing.

Burn Hazard. Do not touch an

operating motor. Modern motors can operate at high

temperatures. To avoid burns when servicing pump,

allow it to cool for 20 minutes after shut-down before

handling.

2

INSPECT THE SHIPMENT

From pressurized

The high pressure booster pump has been carefully

inspected and packaged to assure safe delivery.

Inspect the pump and fittings and report to the carrier

any items which are damaged or missing.

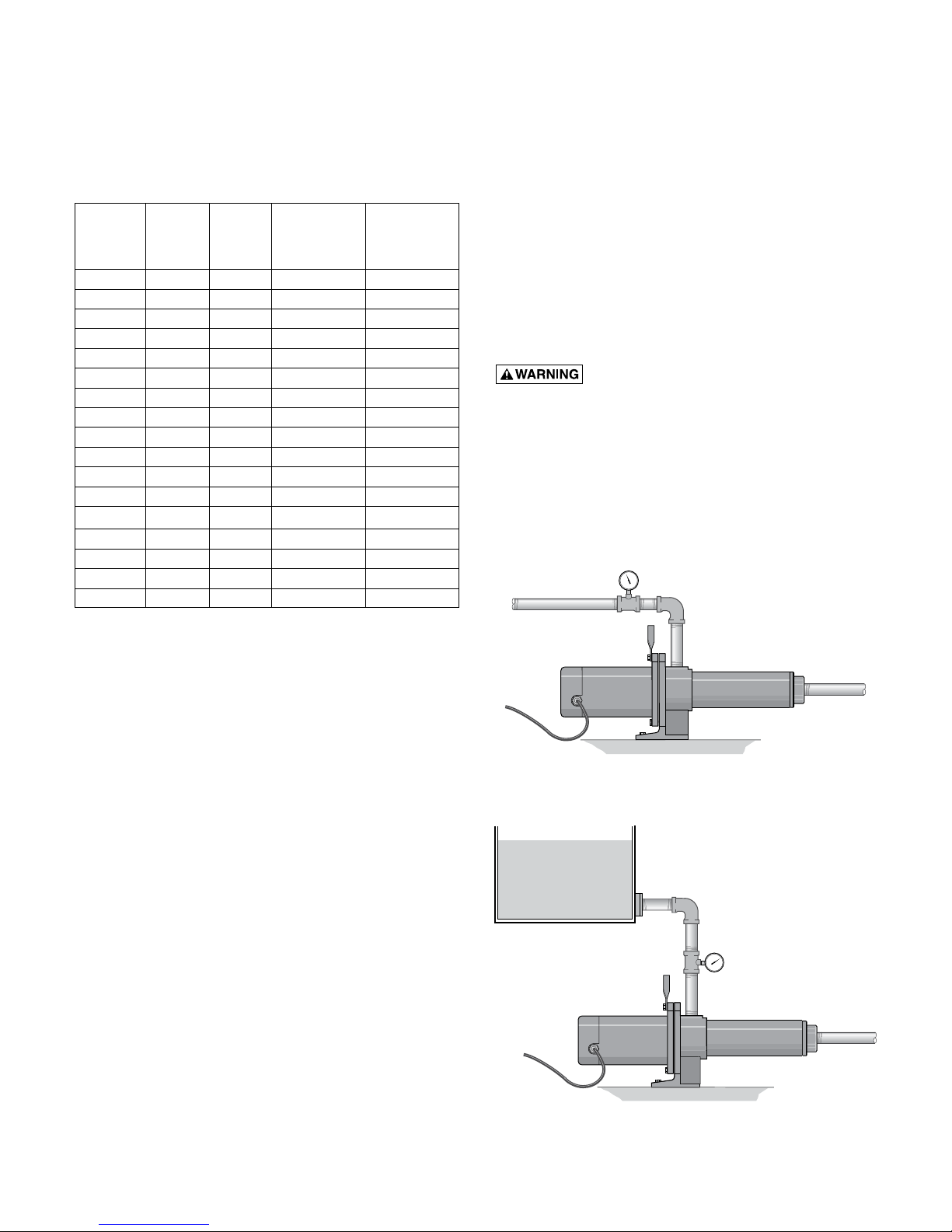

TABLE I - DISCHARGE PRESSURE

Discharge Discharge

Pressure Pressure

No. of PSI at PSI at

GPM HP Stages Rated Flow No Flow

7 1/2 9 90 130

7 3/4 12 123 173

7 1 16 162 229

10 1/2 6 74 113

10 3/4 8 97 147

10 1 10 134 188

10 1 11 146 202

10 1-1/2 14 173 206

10 2 16 197 260

20 1 7 75 110

20 1-1/2 9 97 143

20 2 11 123 175

20 3 15 195 250

30 1 5 59 75

30 1-1/2 6 71 91

30 2 7 81 106

30 3 11 129 167

INSTALLATION

The pump is designed to boost city water pressure or

water pressure from a private water system. Use this

high pressure stream to wash down milk parlors, barns,

garages and driveways, or for fire protection.

The pump is portable with a convenient carrying handle.

If an existing pressure water system is to be used as a

water supply, it can be connected with available fittings

and 3/4” or 1” high pressure hose to the pump inlet. A

special heavy duty 3/4” or 1” suction hose with fittings

is available as an accessory. If pump is permanently

mounted on wall, use a 3/4” or 1” pipe or heavy-duty

hose for suction line. 20 GPM models require one-inch

discharge hose to reduce friction losses and 30 GPM

models require 1-1/4”.

Hazardous pressure. Pump body may

explode if pressures exceed rated limits. Maximum

inlet pressure is 80 PSI. Maximum discharge pressure is

315 PSI. Warranty is void if these pressure limits are

exceeded.

HIGH PRESSURE BOOSTER PUMP

INSTALLATION INSTRUCTIONS

These instructions cover high pressure booster pump

installations as shown below:

house service

*For total discharge pressure, add this pressure to suction

pipe pressure. For example, an HP7C pump taking suction from

a 100 psi water service line will produce 130 + 100 = 230 psi total

discharge pressure at 0 GPM flow. If suction pressure drops to

50 psi, discharge pressure will drop to 180 psi.

NOTE: Model numbers that include an “S” (HPS7C, HPS10D, etc)

have a stainless steel suction, discharge assembly, and capscrews.

Model numbers ending in “3” (HP7C3, HPS10C3, etc) have 3-phase

motors. Models numbers ending in “T” have TEFC motors.

Suction

Figure 1 – Connection to house service.

Water tank

or reservoir

Suction

Discharge

Discharge

Figure 2 – Connection to water reservoir.

3

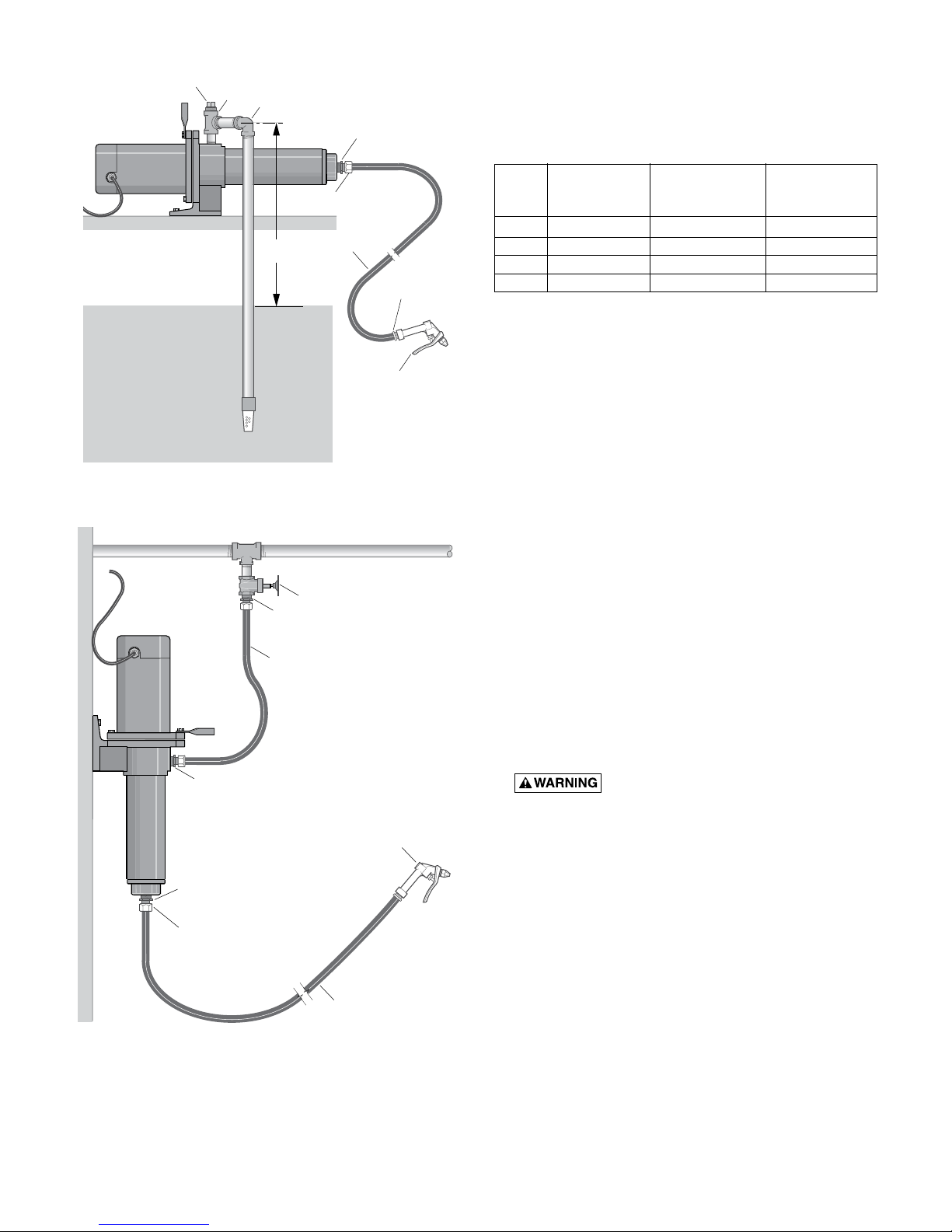

1209 0894

Priming Plug

Tee

90 Elbow

Male Pipe to Male Hose Adapter

Female Hose Connection

15 Feet

Maximum

High Pressure

Hose

Male Hose

Connection

To reduce friction losses to a minimum, inlet (suction)

line should be short and have as few elbows as

possible.

Size the inlet according to the chart below:

Recommended Recommended

Ave. Threaded Inlet Discharge

GPM Inlet Size Line Size Line Size

7 3/4” NPT 1” 1”

10 3/4” NPT 1” 1”

20 1” NPT 1-1/4” 1-1/4”

30 1-1/4” NPT 1-1/2” 1-1/2”

Water Supply

Gun Nozzle

Weeping Type ONLY

Foot Valve

Figure 3 – Cistern or shallow well installation.

To Power

Gate Valve or Hose Bibb

Male Pipe to Male Hose Adapter

High Pressure Hose with two

Female Connections

Male Pipe to Male Hose Adapter

Male Pipe to Male Hose Adapter

Female Hose Connection

(Suction)

(Discharge)

Gun Nozzle

Weeping Type ONLY

Service Line

High Pressure Hose

An inlet strainer will prevent suspended debris from

clogging pump.

The internal running surfaces of the pump and seals

require water lubrication for good, consistent operation.

Allowing pump to run dry will severely damage

pump and seals.

Install a pressure gauge in pump inlet line. Keep at

least two pounds per square inch pressure (2 PSI)

in inlet line whenever pump is operating. If this is not

possible, consult customer service representative.

LUBRICATION

It is not necessary to lubricate pump or motor. The

motor is equipped with sealed ball bearings, lubricated

for the life of the bearing. The mechanical shaft seal

in the pump is self-lubricating and requires no adjustment. Disassemble pump to replace seal (See “Maintenance”, Pages 8 to 9).

OPERATION

NOTICE: Observe the following precautions when

operating the pump:

1. Keep the motor dry! Do not direct stream from

pump discharge onto the motor!

2. Hazardous pressure. Do not run the

pump with discharge shutoff, as hose may burst or

pump may be damaged due to high temperatures.

3. Do not use a standard trigger gun with this pump.

Use only trigger guns with an automatic weeping

feature. These are available as accessories and are

provided with three nozzles. The smallest nozzle

restricts the flow, allowing use of a smaller water

source. The two larger nozzles are used if the water

source will supply the pump’s full capacity.

4. Do not run pump dry; to do so may damage the seal.

5. To avoid internal damage to pump, Do not operate

with water temperature above 175 degrees F.

Figure 4 – Wall mounted to pressurized service

line.

4

Disconnect power before working on pump, motor, pressure switch, or wiring.

Ground

Single Phase, ODP Motor

MOTOR SWITCH SETTINGS

Dual-voltage motors (motors that can operate at either

115 or 230 volts), are set at the factory to 230 volts. Do

not change motor voltage setting if line voltage is 230

volts, or if you have a single voltage motor.*

NOTICE: Never wire a 115 volt motor to a 230 volt line.

REMOVE MOTOR END COVER

If you have a dual-voltage motor, and will connect it to

115 volts, follow the procedure below.

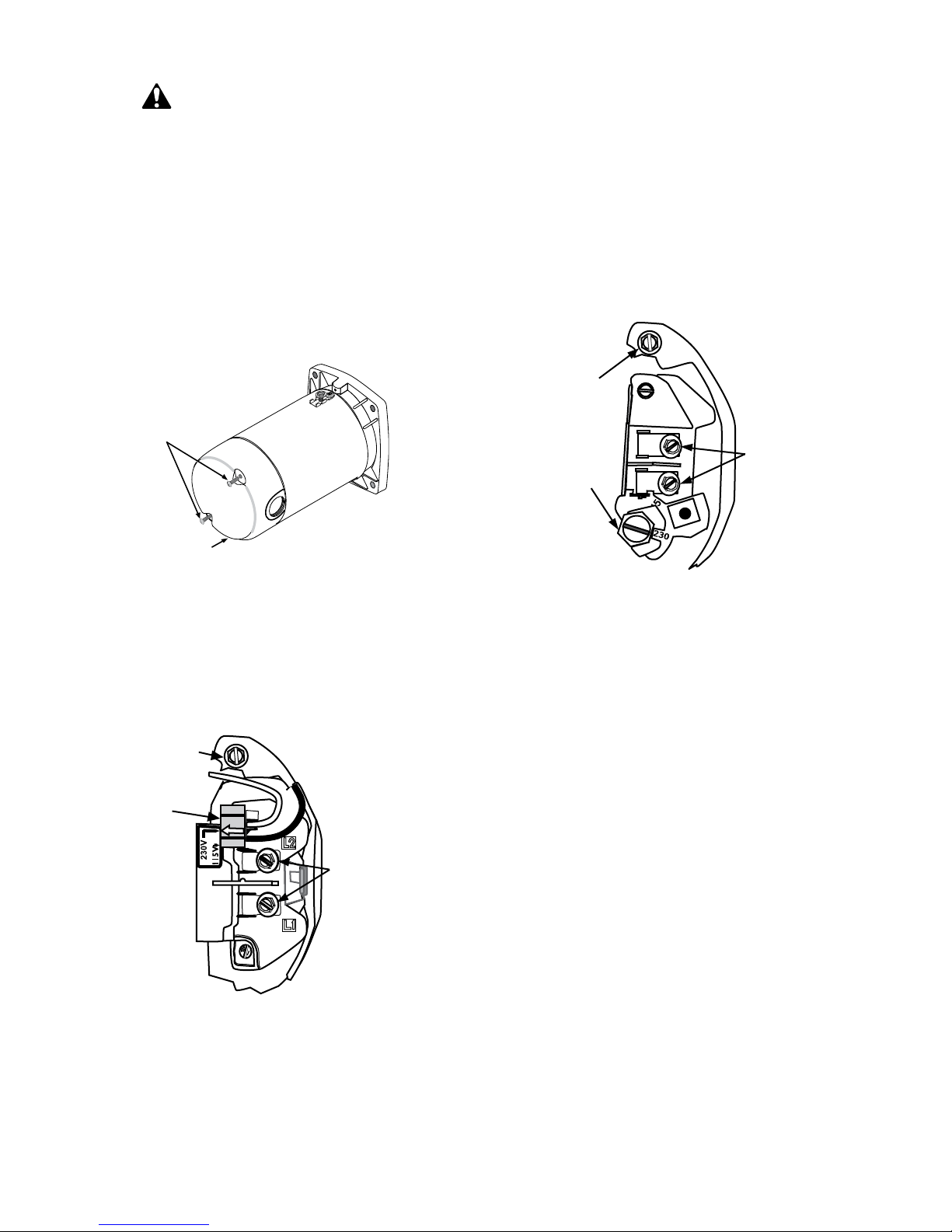

End Cover Screws

Motor

End Cover

Figure 5 – Removing Motor End Cover

You will need to remove the motor end cover to change

the voltage setting.

Your motor terminal board (located under the motor

end cover) should look like one of the following.

PLUG TYPE VOLTAGE SELECTOR

Screw

Voltage

Change

Plug

3. Move and attach the plug at the 115 volt position.

The plug will now cover 2 metal tabs. The arrow on

the plug will point to 115V.

4. Attach the power lead wires to the power lead

terminals. Make sure the wires are secure.

5. Attach the ground wire to the green ground screw

6. Reinstall the Motor end cover

Go to Wiring Connections, page 6.

DIAL TYPE VOLTAGE SELECTOR

Ground

Screw

Voltage

Change

Dial

Figure 7 – Voltage set to 230 volts, Dial Type

To change to 115 volts:

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in

the dial window.

3. Attach the power lead wires to the power lead

terminals. Make sure the wires are secure.

4. Attach the ground wire to the green ground screw

5. Reinstall the Motor end cover

Go to Wiring Connections, page 6.

Power

Lead

Terminals

Figure 6 – Voltage set to 230 volts, Plug Type

To change to 115 volts:

1. Make sure power is off.

2. Pull the plug straight up.

*Models with power cords are pre-wired for 115 volts.

This includes models HP7D-02 and HP7C-02.

Power

Lead

Terminals

5

Loading...

Loading...