Sta-Rite SG12200325MB Installation Manual

SG12B/SGC12B, SG13B/SGC13B

and SGC20B Series

Grinder Pumps

INSTALLATION, OPERATION, & PARTS MANUAL

SAFETY INFORMATION

Carefully read and follow all safety instructions in this

manual or on pump.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury!

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns bout hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

1. Read these rules and instructions carefully. Failure to

follow them could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing. You must comply with their rules.

3. Vent sewage or septic tank according to local codes.

4. Disconnect electrical power and keep hands away from

pump inlet opening when working on or handling pump

for any reason. Do not use automatic reset controls with

this pump. Accidental rotation of the cutter with hands in

the cutter area can cause severe injury.

5. Always keep pump properly serviced and maintained.

6. Use pump for designed task – that is, pumping domestic

sewage and waste water containing solids. Do not pump

metal particles, rocks, or other hard objects.

7. Do not pump corrosive or flammable liquids with this

pump.

DESCRIPTION

These submersible wastewater pumps are designed for

sewage, effluent and wastewater removal or transfer, sump

drainage, dewatering, flood control and for circulation.

SGC12B, SGC13B and SGC20B Series Models include

internal circuitry that detects seal leakage and overheating

of windings. This circuitry is also available on the SG12B

and SG13B Series Models. Other options available include

lift-out system components, control panels, switches and

alarms.

SPECIFICATIONS

Power Supply Required: . . . . . . . . . . . . . .208/230-230/460

Motor Duty: . . . . . . . . . . . . . . . . . . . . . . . . . . . .Intermittent

Maximum Liquid Temperature: . . . .1 Phase - 40° C (104° F)

3 Phase - 60° C (140° F)

Discharge Adapter:

SG12B/SGC12B/SG13B/SGC13B Series . . . . . . . .1-1/4”

SG20B/SGC20B Series . . . . . . . . . . . . . . . . . . . . . . . .2”

Power Cable: . . . . . . . . . . . . . . . . . . . . . . . . . . . .Type STO

Volute, Impeller and Pump Body: . . . . . .Class 30 Cast Iron

O-Rings and Elastomer Part of Shaft Seal: . . . . . . .Buna-N

Shaft Seal Faces: . . . . . . . . . . . . .Carbon and Ceramic with

Stainless Steel Trim

Fasteners in contact with liquid

being pumped: . . . . . . . . . . . . . . . . . . . . . . .Stainless Steel

Grinder Assembly: . . . . . . . . . . . . . .17-4ph Stainless Steel

© 2002 Printed in U.S.A. BE500 (7/26/02)

293 Wright Street • Delavan, WI 53115

New Model Number Original Model Number

SG12200225MB 12SG1-1012

SG12200325MB 12SG3-1012

SG13200225MB 12SG1-1011

SG13200325MB 12SG3-1011

SGC12200225MB 12SGC1-1012

SGC12200325MB 12SGC3-1012

SGC13200225MB 12SGC1-1011

SGC13200325MB 12SGC3-1011

SGC20300225MB 20SG1-2013

SGC20300325MB 20SG3-2013

SGC20500225MB 20SG1-2012

SGC20500325MB 20SG3-2012

SGC20750325MB 20SG3-2011

MODEL NUMBER CROSS

REFERENCE CHART

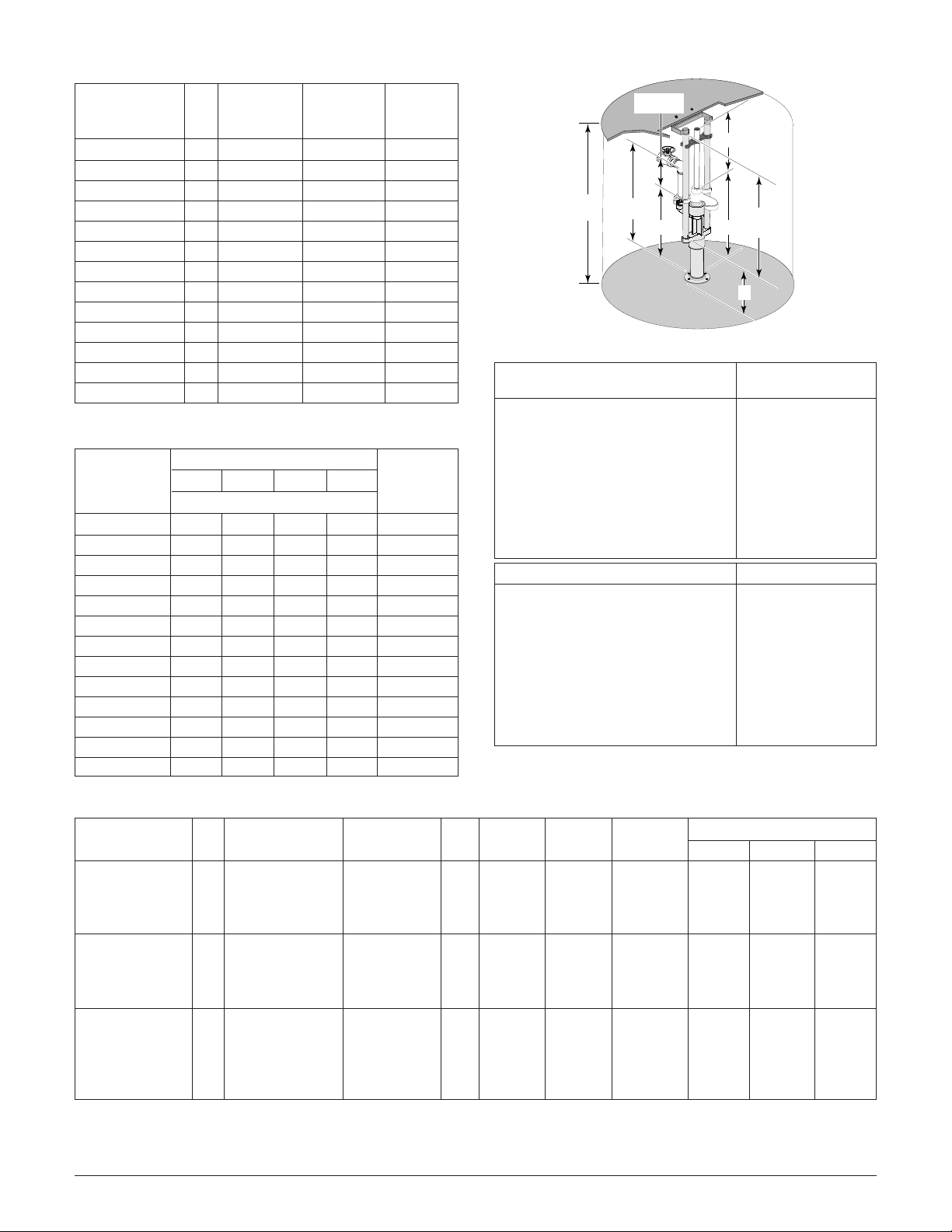

PIPING DIMENSIONAL GUIDE

2

Thermal Leak Insulation

Winding Resistance in Ohms*

Model HP Volts/Hz/Ph Amps KW Sensor Sensor Class B-W B-R R-W

SG12200225MB 2 230/60/1 12.0 1.5 No No B .90 5.3 6.2

SG12200325MB 2 208-230/460/60/3 6.6-6.0/3.0 1.5 No No F 2.2/8.8 2.2/8.8 2.2/8.8

SG13200225MB 2 230/60/1 14.0 1.5 No No B .90 5.3 6.2

SG13200325MB 2 208-230/460/60/3 7.1-6.4/3.2 1.5 No No F 2.2/8.8 2.2/8.8 2.2/8.8

SGC12200225MB 2 230/60/1 12.0 1.5 Yes Yes B .90 5.3 6.2

SGC12200325MB 2 208-230/460/3 6.6-6.0/3.0 1.5 Yes Yes F 2.2/8.8 2.2/8.8 2.2/8.8

SGC13200225MB 2 230/60/1 14.0 1.5 Yes Yes B .90 5.3 6.2

SGC13200325MB 2 208-230/460/60/3 7.1-6.4/3.2 1.5 Yes Yes F 2.2/8.8 2.2/8.8 2.2/8.8

SGC20300225MB 3 230/60/1 28.0 2.2 Yes Yes B .36 1.9 2.26

SGC20300325MB 3 208-230/460/60/3 15.5-14.0/7.0 2.2 Yes Yes F .74/2.96 .74/2.96 .74/2.96

SGC20500225MB 5 230/60/1 34.0 3.0 Yes Yes B .36 1.9 2.26

SGC20500325MB 5 208-230/460/60/3 20.0-18.0/9.0 3.0 Yes Yes F .74/2.96 .74/2.96 .74/2.96

SGC20750325MB 7.5 208-230/460/60/3 24.3-22.0/11.0 5.6 Yes Yes F .54/2.16 .54/2.16 .54/2.16

Table I: Electrical Nameplate Data

* Motor RPM is 3450.

NOTICE: Motors rated at 230V/60Hz/1ø may overload if operated on 208 volts. Consult factory before attempting to operate

single phase motors on 208 volts.

Figure 1: Basin Dimensions

SG12B/SGC12B

Dimension SG13B/SGC13B

Vertical Discharge Pipe Length

(= Disch. Pipe Height – X) X = 22-3/4” (58 cm)

Locking Rail Length

( = Basin Depth – Y) Y =29-1/4” (74 cm)

Guide Rail Length

(= Basin Depth – Z) Z = 19-3/8” (49 cm)

Cut Length of Base Pipe: 14” (36 cm)

Minimum Basin Diameter (Simplex): 24” (61 cm)

Minimum Basin Diameter (Duplex): 36” (91 cm)

Dimension SGC20B

Vertical Discharge Pipe Length

(= Disch. Pipe Height – X) X = 25-7/16”(64.5cm)

Locking Rail Length

( = Basin Depth – Y) Y = 26-3/4”(68 cm)

Guide Rail Length

(= Basin Depth – Z) Z = 21-5/8”(55 cm)

Cut Length of Base Pipe: 16” (41 cm)

Minimum Basin Diameter (Simplex): 30” (76 cm)

Minimum Basin Diameter (Duplex): 42”(107 cm)

Dimensional guide to be used only if upper bracket is

attached to cover as shown.

Motor Minimum

Model Voltage/ Max. Load Circuit

Number HP Phase Amps Req.(Amp)

SG12200225MB 2 208-230/1 12.0 20

SG12200325MB 2 208-230/460/1 6.6-6.0/3.0 10/10

SG13200225MB 2 208-230/1 14.0 30

SG13200325MB 2 208-230/460/3 7.1-6.4/3.2 10/10

SGC12200225MB 2 208-230/1 12.0 20

SGC12200325MB 2 208-230/460/3 6.6-6.0/3.0 10/10

SGC13200225MB 2 208-230/1 14.0 30

SGC13200325MB 2 208-230/460/3 7.1-6.4/3.2 10/10

SGC20300225MB 3 208-230/1 28.0 50

SGC20300325MB 3 208-230/460/3 15.5-14.0/7.0 20/10

SGC20500225MB 5 208-230/1 34.0 60

SGC20500325MB 5 208-230/460/3 20.0-18.0/9.0 30/20

SGC20750325MB 7.5 208-230/460/3 24.3-22.0/11.0 30/20

MOTOR SPECIFICATIONS

GPM at Total Feet (M) No Flow at

Model 20(6) 50(15) 80(24) 110(34) Height Shown

Number Capacity Gallons/Minute(LPM) Below Ft. (M)

SG12200225MB 44(167) 36(136) 12(45) – 85(26)

SG12200325MB 44(167) 36(136) 12(45) – 85(26)

SG13200225MB 55(208) 45(170) 28(106) 8(30) 116(35)

SG13200325MB 55(208) 45(170) 28(106) 8(30) 116(35)

SGC12200225MB 44(167) 36(136) 12(45) – 85(26)

SGC12200325MB 44(167) 36(136) 12(45) – 85(26)

SGC13200225MB 55(208) 45(170) 28(106) 8(30) 116(35)

SGC13200325MB 55(208) 45(170) 28(106) 8(30) 116(35)

SGC20300225MB 104(394) 76(288) 15(57) – 84(25.6)

SGC20300325MB 104(394) 76(288) 15(57) – 84(25.6)

SGC20500225MB 116(439) 108(409) 80(303) 18(68) 116(35)

SGC20500325MB 116(439) 108(409) 80(303) 18(68) 116(35)

SGC20750325MB 168(636) 150(568) 120(454) 86(326) 150(46)

PERFORMANCE CHART

Vert. Disch.

Pipe Length

Locking Rail Length

Basin

Discharge

Depth

Height

X

Guide

Rail

Y

Length

Z

2014 0995

PIPING DIMENSIONAL

GUIDE FOR GUIDE-RAIL

LIFT-OUT SYSTEM

3

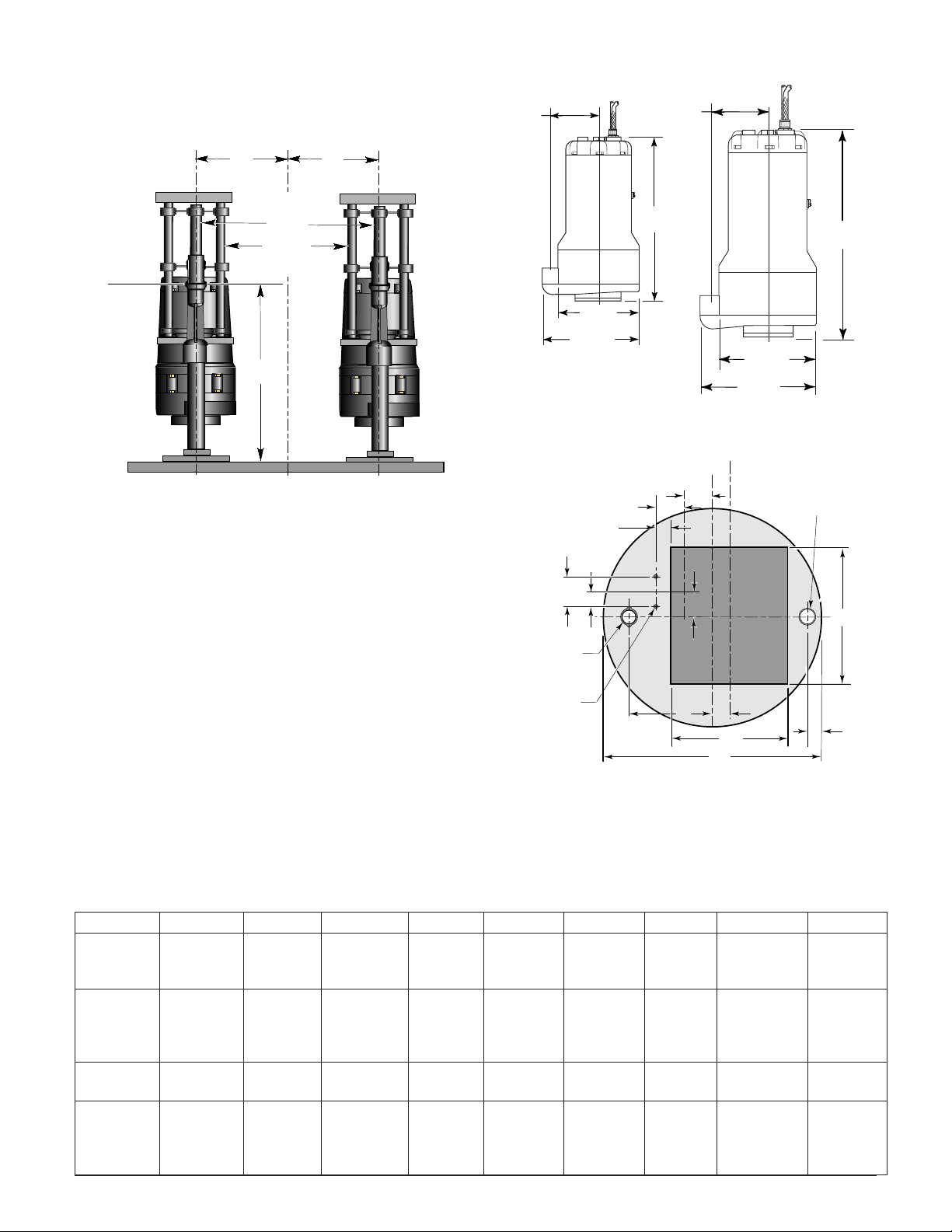

Figure 2: Duplex Dimensions

Figure 3A: Pump Dimensions

Figure 3B: Basin Dimensions

Model Basin Size A B C D E F G H

SG12B/SGC12B

42(1066.8) 46(1168.4) .58(14.7) 17(431.8) 18(457.2) 28(711.2) 7(177.8) 6.17(156.7) 22.88(581)

SG13B/SGC13B

48(1219.2) 54(1371.6) –2.58(–65.5) 17(431.8) 21(533.4) 28(711.2) 7(177.8) 9.3(3236.9) 22.88(581)

Duplex

60(1524) 66(1676.4) –2.75(–69.8) 17(431.8) 27(685.8) 28(711.2) 7(77.8) 9.5(241.3) 22.88(581)

SG12B/SGC12B

36(914.4) 40(1016) 2.38(60.4) 17(431.8) 15(381) 16(406.4) – 4.37(110.9) 22.88(581)

SG13B/SGC13B

42(1066.8) 46(1168.4) –.62(–15.7) 17(431.8) 18(457.2) 16(406.4 – 7.37(187.1) 22.88(581)

Simplex

48(1219.2) 54(1371.6) –2.92(–74.1) 17(431.8) 21(533.4) 16(406.4 – 9.67(245.6) 22.88(581)

60(1524) 66(1676.4) –2.92(–74.1) 17(431.8) 27(685.8) 32(812.8) – 9.67(245.6) 22.88(581)

SGC20B

48(1219.2) 54(1371.6) 2.69(68.3) 22(558.8) 21(533.4) 32(812.8) 9(228.6) 6.56(166.6) 24.88(632)

Duplex

60(1524) 66(1676.4) –2.70(–68) 22(558.8) 27(685.8) 20(508) 9(228.6) 11.95(303.5) 24.88(632)

SGC20B

36(914.4) 42(1066.8) 6.94(176.2) 22(558.8) NA 20(508) – 2.31(58.6) 24.88(632)

Simplex

42(1066.8) 46(1168.4) 3.94(100.0) 22(558.8) 18(457.2) 20(508) – 5.31(134.8) 24.88(632)

48(1219.2) 54(1371.6) .94(23.8) 22(558.8) 21(533.4) 20(508) – 6.31(160.2) 24.88(632)

60(1524) 66(1676.4) –3.13(–79.5) 22(558.8) 27(685.8) 20(508) – 12.38(314.4) 24.88(632)

Table II: Dimensioning Guide (See Figures 2 and 3)

Dimensions in Inches (mm)

All basin information listed below is for basin and cover combinations with covers having a separate access opening. Smaller basins

without a separate access opening are listed above.

Notice: A Negative “B” dim denotes that the centerline of the lift-out opening is to the left of the centerline of the basin cover.

SG12B/SGC12B

SG13B/SGC13B

SGC20B

5-1/8''

(130mm)

7-15/16''

(202mm)

G

Connection

Height of

Stationary

Flange

H

Locking

Rail

Guide

Rails

G

17-5/8''

8-1/4"

(210mm)

10-5/8

(270mm)

(448mm)

10-9/16"

(268mm)

13-1/4"

(337mm)

23-1/2"

(597mm)

1930 0895

1931 0895

4-1/2"

2-1/4"

2-1/4"

Lift-Out Opening

Basin Cover

Base Flange

C

4"

C

L

C

L

L

F

G

2" Galvanized

Pipe Coupler

E

2" Mounting

Flange (Vent)

1/2" Dia. Hole

2 Required

BD

C

A

1932 0895

6"

4

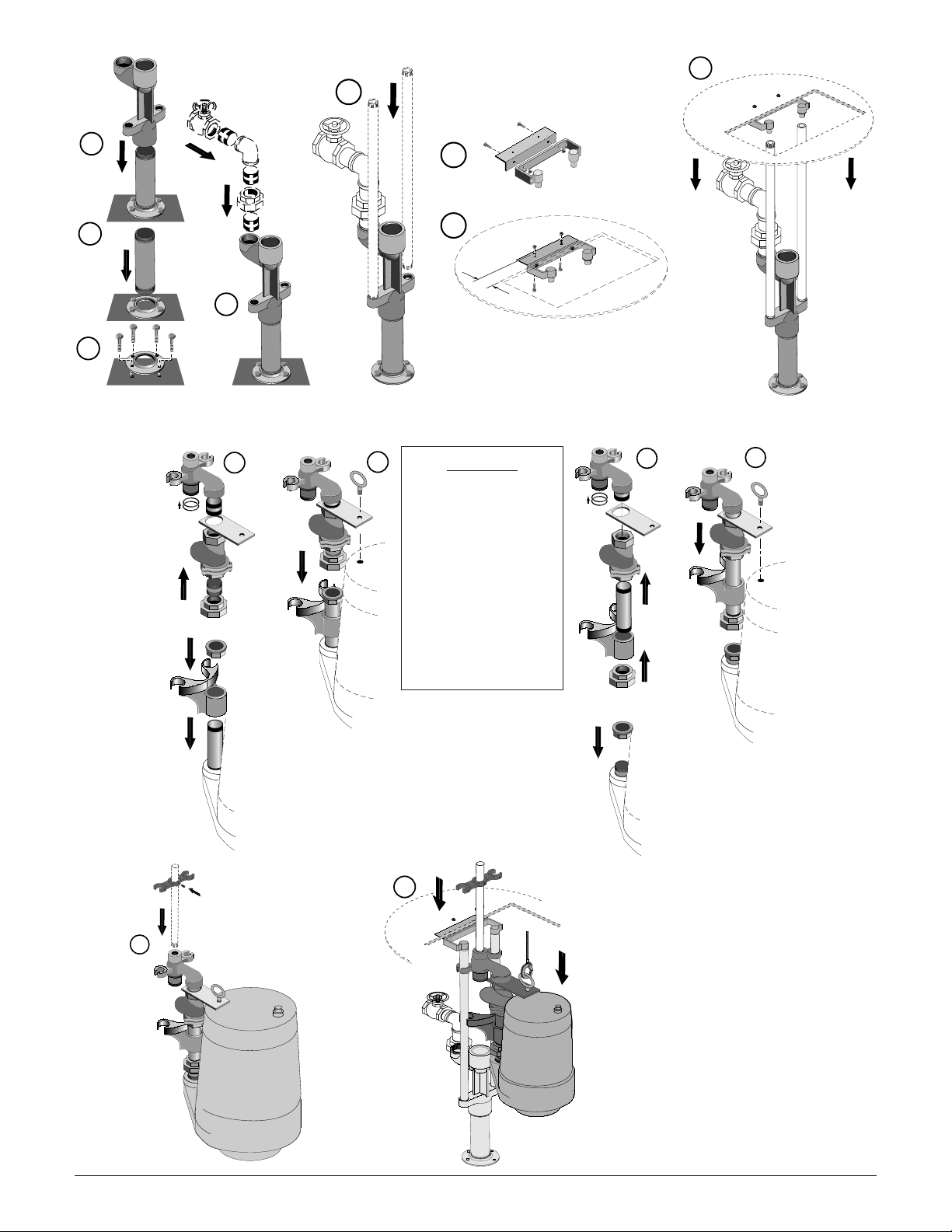

Figure 4: Assembly sequence for

Guide Rail Lift-out System, Models

SG12B/SGC12B, SG13B/SGC13B and

SGC20B. Follow the numbered steps

to assemble and install your Lift-Out

system.

Notice that, for the SGC20B, the

assembly sequence for the Guide Rail

Bracket, the Ball Check Valve, the

Movable Flange, and associated parts

differs from the SG12B/SGC12B and

SG13B/SGC13B. This difference is

required by the difference in size

between the two pumps.

Make sure that you use the correct

sequence for your pump or the piping

assembly will not mount on the pump

or on the guide rails.

8

SG12B/SGC12B/SG13B/SGC13B SGC20B

NOTICE

The assembly

sequence for the

moveable parts

(Steps 9 and 10)

differs from

SG12B/SGC12B/

SG13B/SGC13B to

SGC20B models.

Follow the sequence

that is correct for

your pump.

5

3

2

4

6

7

2-1/4"

1938 0895

1

1939 0895

9

10

9

1937 0895

10

11

1935 0895

1936 0895

12

1933 0895

1934 0895

INSTALLATION

Install the pump as a free standing unit or with a guide rail

lift-out system.

Free-Standing Unit:

Install the pump on the floor of an open top basin. Install a

pipe union in the discharge piping, so that the pump can be

lifted out of the basin without interference.

Lift-out System (see Assembly Steps, Page 4):

(See Figures 4 and 5 before assembling)

1. Mount the base flange (See Step 1, Page 4) to the

basin floor.

2. Thread the 2-1/2” (64 mm) dia. pipe section (Step 2) into

the base flange and tighten it.

3. Install the stationary flange (Step 3) on the base pipe

and tighten the set screw to hold it.

4. Install the connecting plumbing in the stationary flange

(Step 4).

5. Thread the user supplied 1” (25 mm) dia. guide rails

(Step 5) into the stationary flange and tighten them.

6. Mount the upper rail bracket on the angle bracket

(Step 6).

7. Install the angle bracket and upper rail bracket assembly

in the tank or attach it to the basin lid as desired

(Step 7).

8. Install the basin lid now if the guide rail bracket is

mounted on it (Step 8).

The stationary parts (all those parts mounted in the basin) of

the guide-rail lift-out system are now complete. Go on to

Step 9 to assemble the movable parts of the system. These

will mount on the pump discharge assembly. Follow the

sequence below that applies to your pump model.

SG12 / SG13 Series:

9A. SG12B/SGC12B/SG13B/SGC13B Thread the 1-1/4x8-1/2”

nipple into the pump discharge and tighten it.

9B. SG12B/SGC12B/SG13B/SGC13B Install the movable

guide rail bracket over the 8-1/4” nipple, then install one

half of the pipe union on top of the nipple and tighten it.

Do not tighten the set screws in the guide rail bracket yet.

9C. SG12B/SGC12B/SG13B/SGC13B Clamp the ball check

valve upside down (that is, flange up) in a vise so that it

cannot turn (or fall) and thread one of the short nipples

into it. Install the unused union half on the short nipple

and tighten the assembly.

9D. SG12B/SGC12B/SG13B/SGC13B Turn the check valve

assembly over in the vise; clamp it so that the ball

chamber points to your right or your left. Install the other

short nipple in the discharge (hex) end of the check

valve. Add the discharge pipe bracket over the nipple

and then thread the movable flange onto the nipple.

When tight, the movable flange should point directly

away from you (that is, the check valve and the flange

should be at right angles to each other). Install two

O-Rings on the movable flange (see Step 9, Page 4).

10. SG12B/SGC12B/SG13B/SGC13B Remove the check

valve assembly from the vise and turn it over; connect

the union and tighten it with the movable flange pointing

directly away from the pump. The ball check should

point to one side or the other while the movable bracket

points away from the pump. Thread the eyebolt through

the discharge pipe bracket into the tapped hole provided

in the top of the pump.

11. SG12B/SGC12B/SG13B/SGC13B Thread the locking

rail into the movable flange; mount the locking bracket

and tighten.

The movable parts of the SG12B/SGC12B/SG13B/SGC13B

system are now complete. You are ready to rig lifting gear

and lower the pump into the basin. Skip to Step 12.

SG20 Series:

9A. SGC20B Thread one of the short nipples into the pump

discharge; add a union half and tighten the assembly.

9B. SGC20B Clamp the ball check valve in a vise; thread the

2x6” nipple into the inlet side. Slide the guide rail bracket

(also upside down) on to the nipple and thread the other

union half over the free end of the nipple. Tighten.

9C. SGC20B Turn the assembly over in the vise and thread

the other short nipple onto the discharge side of the ball

check valve. Add the discharge pipe bracket and the

movable flange to this nipple and tighten the assembly.

When tight, the ball check should point to one side or

the other and the movable flange should point directly

away from you (that is, the check valve and the flange

should be at right angles to each other). Install two

O-Rings on the movable flange (see Step 9, Page 4).

10. SGC20B Mount the ball check valve/discharge flange

assembly on the pump with the movable flange pointing

directly away from the pump. Tighten the union and

thread the eyebolt through the discharge pipe bracket

into the the threaded hole provided in the top of the

pump.

11. SGC20B Thread the locking rail into the movable flange;

mount the locking bracket and tighten.

The movable parts of the SGC20B system are now complete. You are ready to rig lifting gear and lower the pump

into the basin.

12. Lift the pump assembly; slide the guide rail bracket and

the movable flange over the guide rails at the top and

lower the pump into the basin until it bottoms on the stationary flange. Raise the pump 1/8” and tighten the

guide rail bracket set screws.

13. Slide the locking bracket over the guide rails and locking

rail, then tighten all three set screws.

14. To remove the pump, loosen the guide rail set screws

in the locking bracket and hoist the pump out of the

basin.

CONTROLS

Risk of electric shock. Ground pump and

motor before connecting controls or power supply.

Adhere to local electrical codes governing pump and control

installations.

Install simplex or duplex control panel for proper pump operation. A full range of controls and switches is listed in our

catalog.

If a Berkeley control panel is not used, install a control panel

with circuit breaker or fused disconnect as required by local

code. Use magnetic starters with ambient compensated

overload protection. Three phase units require three line

protection; single phase units require only one line protection. Inadequate protection voids warranty.

SGC12B/SGC13B Series pumps are equipped with an onwinding thermostat (to protect the pump from overheating)

and seal leak detection probe (to monitor seal plate and

motor housing for the presence of water).

5

Loading...

Loading...