Stanley SDH600, SDH700 User manual

ENGLISH (Original instructions)

SDH600

SDH700

English |

Page |

3 |

||

Русский |

Page |

18 |

|

|

Українська |

Page |

15 |

|

|

Türkçe |

Page |

21 |

||

ENGLISH (Original instructions)

7

10 |

8 |

9 |

5 |

5 |

4 |

|

|

|

|

6 |

3 |

|

7 |

11 |

1 |

|

|

2 |

2

ENGLISH (Original instructions)

Intended use

Your STANLEY SDH600-SDH700 impact drill has been designed for drilling in wood, metal, plastics, and masonry as well as for screw driving purposes. This tool is intended for professional use.

Safety instructions

General power tool safety warnings

Warning! Read all safety warnings and all instructions. Failure to follow the warnings and instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in all of the warnings listed below refers to your mains operated (corded) power tool or battery

1. Work area safety

a.Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b.Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c.Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2. Electrical safety

a.Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b.Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c.Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d.Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e.When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f.If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3. Personal safety

a.Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

b.Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c.Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

d.Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e.Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f.Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g.If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

4. Power tool use and care

a.Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

b.Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c.Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

3

ENGLISH (Original instructions)

d. |

Store idle power tools out of the reach of children |

Residual risks. |

|

|

and do not allow persons unfamiliar with the power |

Even with the application of the relevant safety regulations |

|

|

tool or these instructions to operate the power tool. |

and the implementation of safety devices, certain residual |

|

|

Power tools are dangerous in the hands of untrained |

risks can not be avoided. These include: |

|

e. |

users. |

♦♦ Injuries caused by touching any rotating/moving parts. |

|

Maintain power tools. Check for misalignment or |

♦♦ Impairment of hearing. |

||

|

binding of moving parts, breakage of parts and |

♦♦ Risk of injury when changing any parts, or accessories. |

|

|

any other condition that may affect the power tools |

♦♦ Health hazards caused by breathing dust developed |

|

|

operation. If damaged, have the power tool repaired |

when sawing wood, especially oak, beech and MDF. |

|

|

before use. Many accidents are caused by poorly |

♦♦ Injuries caused by prolonged use of a tool. When using |

|

f. |

maintained power tools. |

any tool for prolonged periods ensure you take regular |

|

Keep cutting tools sharp and clean. Properly |

breaks. |

||

|

maintained cutting tools with sharp cutting edges are |

Safety of others |

|

g. |

less likely to bind and are easier to control. |

||

Use the power tool, accessories and tool bits etc. |

This appliance is not intended for use by persons (including |

||

|

In accordance with these instructions, taking into |

children) with reduced physical, sensory or mental |

|

|

account the working conditions and the work to |

capabilities, or lack of experience and knowledge, unless |

|

|

be performed. Use of the power tool for operations |

they have been given supervision or instruction concerning |

|

|

different from those intended could result in a |

use of the appliance by a person responsible for their |

|

|

hazardous situation. |

safety. |

|

5. |

Service |

Children should be supervised to ensure that they do not |

|

a. |

Have your power tool serviced by a qualified repair |

play with the appliance. |

|

|

person using only identical replacement parts. |

Labels on tool |

|

|

This will ensure that the safety of the power tool is |

||

|

|

||

|

maintained. |

The label on your tool may include the following symbols: |

|

Additional power tool safety warnings |

|||

Warning! To reduce the risk of injury, the user must |

|||

|

Warning! Additional safety warnings for drills and |

read the instruction manual. |

|

|

impact drills |

Always wear safety goggles |

|

♦♦ Wear ear protectors when impact drilling. Exposure |

|||

|

|||

|

to noise can cause hearing loss. |

Always wear safety hearing protection |

|

♦♦ Use auxiliary handle(s) if supplied with the tool. |

Position of date barcode |

||

|

Loss of control can cause personal injury. |

||

♦♦ Hold power tool by insulated gripping surfaces |

The Date Code, which also includes the year of |

||

|

when performing an operation where the cutting |

manufacture, is printed into the housing. |

|

|

accessory may contact hidden wiring or its own |

Example: |

|

|

cord. Cutting accessory contacting a “live” wire may |

||

|

2015 XX ZY |

||

|

make exposed metal parts of the power tool “live” and |

||

|

Year of manufacturing |

||

|

could give the operator an electric shock. |

||

|

|

||

♦♦ Use clamps or another practical way to secure |

Electrical safety |

||

|

and support the workpiece to a stable platform. |

This tool is double insulated; therefore no earth |

|

|

Holding the work by hand or against your body leaves it |

||

|

unstable and may lead to loss of control. |

wire is required. Always check that the power |

|

♦♦ Before drilling into walls, floors or ceilings, check for the |

supply corresponds to the voltage on the rating |

||

|

location of wiring and pipes. |

plate. |

|

♦♦ Avoid touching the tip of a drill bit just after drilling, as it |

♦♦ If the supply cord is damaged, it must be replaced by |

||

|

may be hot. |

the manufacturer or an authorised STANLEY Service |

|

♦♦ The intended use is described in this instruction |

Centre in order to avoid a hazard. |

||

manual. The use of any accessory or attachment or performance of any operation with this tool other than those recommended in this instruction manual may present a risk of personal injury and/or damage to property.

4

ENGLISH (Original instructions)

Using an extension cable

♦♦ Always use an approved extension cable suitable for the power input of this tool (see technical data). Before use, inspect the extension cable for signs of damage, wear and ageing. Replace the extension cable if damaged or defective. When using a cable reel, always unwind the cable completely. Use of an extension cable not suitable for the power input of the tool or which is damaged or defective may result in a risk of fire and electric shock.

Features

This tool includes some or all of the following features.

1.Variable speed switch

2.Lock-on button

3.Forward/reverse button

4.Drilling mode selector

5.Chuck

6.Depth stop

7.Side handle

Assembly.

Warning! Before assembly, make sure that the tool is switched off and unplugged.

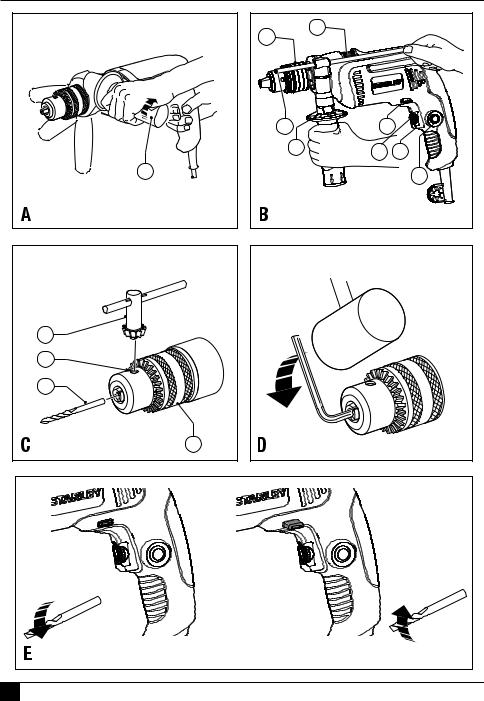

Fitting the side handle and depth stop (fig.A,B)

♦♦ Turn the grip counter clockwise until you can slide the side handle (7) onto the front of the tool as shown (fig.A).

♦♦ Rotate the side handle into the desired position. ♦♦ Insert the depth stop(6) into the mounting hole as

shown (fig.B).

♦♦ Set the drilling depth as described below.

♦♦ Tighten the side handle by turning the grip clockwise.

Fitting a drill bit (fig.C)

♦♦ Open the chuck by turning the sleeve (5) counter clockwise.

♦♦ Insert the bit shaft (9) into the chuck (drill bit not included).

♦♦ Insert the chuck key(10) into each hole (8) in the side of the chuck and turn clockwise until it is tight.

Removing and refitting the chuck (fig.D)

♦♦ Open the chuck as far as possible.

♦♦ Remove the chuck retaining screw, located in the chuck, by turning it clockwise using a screwdriver.

♦♦ Tighten an Allen key into the chuck and strike it with a Impact as shown.

♦♦ Remove the Allen key. Remove the chuck by turning it counter clockwise.

♦♦ To refit the chuck, screw it onto the spindle and secure it with the chuck retaining screw.

Use

Warning! Let the tool work at its own pace.Do not overload.

Warning! Before drilling into walls, floors or ceilings, check for the location of wiring and pipes.

Selecting the direction of rotation (fig.E)

For drilling and for tightening screws, use forward (clockwise) rotation For loosening screws or removing a jammed drill bit, use reverse (counter clockwise) rotation. ♦♦ To select forward rotation, push the forward/reverse

button (3) to the left position.

♦♦ To select reverse rotation, push the forward/reverse button (3) to the right. Warning! Never change the direction of rotation while the motor is running.

Selecting the drilling mode

♦♦ |

For drilling in masonry, set the drilling mode selector (4) |

|

to the position. |

♦♦ |

For drilling in other materials and for screwdriving, set |

|

the drilling mode selector to the position. |

Setting the drilling depth (fig.B)

♦♦ Slacken the side handle (7) by turning the grip counter clockwise.

♦♦ Set the depth stop(6) to the desired position. The maximum drilling depth is equal to the distance between the tip of the drill bit and the front end of the depth stop.

♦♦ Tighten the side handle by turning the grip clockwise.

Switching on and off

♦♦ To switch the tool on, press the variable speed switch(1). The tool speed depends on how far you press the switch. As a general rule, use low speeds for large diameter drill bits and high speeds for smaller diameter drill bits.

♦♦ For continuous operation, press the lock-on button (2) and release the variable speed switch. This option is available only at full speed in both forward and reverse modes.

♦♦ To switch the tllo off, release the variable speed switch. To switch the tool off when in continuous operation, press the variable speed switch again and release it.

♦♦ Based on the different applications, turn around the speed dial(11) to control the maximum speed.

Drilling in metal

Start drilling with slow speed and increase to full power while applying firm pressure on the tool. A smooth even flow of metal chips indicates the proper drilling rate. Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which should be drilled dry.

5

ENGLISH (Original instructions)

NOTE: Large [5/16” (8 mm) to 1/2” (13 mm)] holes in steel can be made easier if a pilot hole [5/32” (4 mm) to 3/16” (5 mm)] is drilled first.

Drilling in wood

Start drilling with slow speed and increase to full power while applying firm pressure on the tool. Holes in wood can be made with the same twist drills used for metal. These bits may overheat unless pulled out frequently to clear chips from the flutes. Work that is apt to splinter should be backed up with a block of wood.

Drilling in masonry

When drilling in masonry, use carbide-tipped bits rated for Impact drilling and be certain that the bits are sharp. Use a constant and firm force on the tool to drill most effectively. A smooth, even flow of dust indicates the proper drilling rate.

Screwdriving

Select forward or reverse rotation.

Accessories

The performance of your tool depends on the accessory used. STANLEY accessories are engineered to high quality standards and designed to enhance the performance of your tool. By using these accessories you will get the very best from your tool.

Maintenance

Your tool has been designed to operate over a long period of time with a minimum of maintenance. Continuous satisfactory operation depends upon proper tool care and regular cleaning.

Warning! Before performing any maintenance, switch off and unplug the tool.

♦♦ Regularly clean the ventilation slots in your tool using a soft brush or dry cloth.

♦♦ Regularly clean the motor housing using a damp cloth. Do not use any abrasive or solvent-based cleaner.

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your STANLEY product needs replacement, or if it is of no further use to you, do not dispose of it with household waste. Make this product available for separate collection.

Should you find one day that your STANLEY product needs replacement, or if it is of no further use to you, do not dispose of it with household waste. Make this product available for separate collection.

Separate collection of used products and packag ing allows materials to be recycled and used again. Re-use of recycled materials helps prevent environmental pollution and reduces the demand for raw materials.

Local regulations may provide for separate collection of electrical products from the household, at municipal waste sites or by the retailer when you purchase a new product.

STANLEY provides a facility for the collection and recycling of STANLEY products once they have reached the end of their working life. To take advantage of this service please return your product to any authorised repair agent who will collect them on our behalf.

You can check the location of your nearest authorised repair agent by contacting your local STANLEY office at the address indicated in this manual. Alternatively, a list of authorised STANLEY repair agents and full details of our after-sales service and contacts are available on the Internet at: www.2helpU.com

Notes

♦♦ STANLEY’s policy is one of continuous improvement to our products and as such, we reserve the right to change product specifications without prior notice.

♦♦ Standard equipment and accessories may vary by country.

♦♦ Product specifications may differ by country.

♦♦ Complete product range may not be available in all countries. Contact your local STANLEY dealers for range availability.

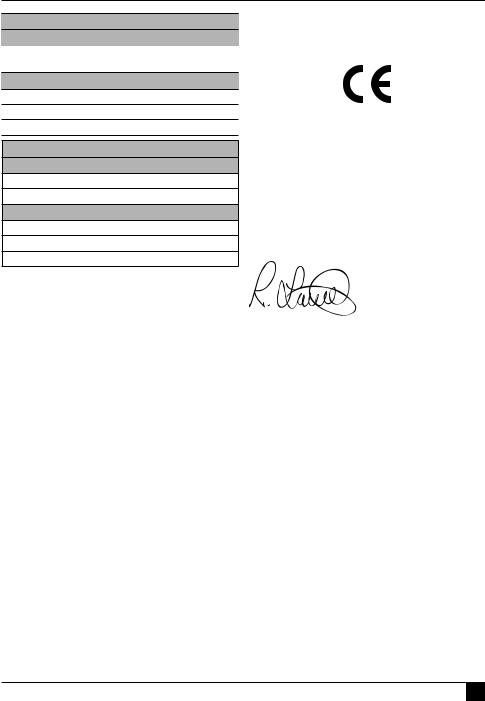

Technical data |

|

|

|

|

|

SDH600 |

SDH700 |

Input voltage |

VAC |

220-240 |

220-240 |

Power input |

W |

600 |

700 |

Frequency |

Hz |

50/60 |

50/60 |

No-load speed |

min-1 |

0-2900 |

0-2900 |

Impact rate |

ipm |

49300 |

49300 |

Chuck capacity |

mm |

1.5-13 |

1.5-13 |

Max.Drilling Capacity |

|

|

|

Concrete/Metal/ |

mm |

13/13/25 |

13/13/30 |

Wood |

|

|

|

Weight |

kg |

1.75 |

1.87 |

6

ENGLISH (Original instructions)

SDH600

Level of sound pressure according to EN 60745:

Sound pressure (LpA) 97.0 dB(A), uncertainty (K) 3 dB(A) Sound power (LWA) 108.0 dB(A), uncertainty (K) 3 dB(A)

Vibration emission value ah: ah,ID = m/s² 8.2

ah,D = m/s² 3.7 Uncertainty K = m/s² 1.5

SDH700

Level of sound pressure according to EN 60745:

Sound pressure (LpA) 100.0 dB(A), uncertainty (K) 3 dB(A) Sound power (LWA) 110.0 dB(A), uncertainty (K) 3 dB(A)

Vibration emission value ah: ah,ID = m/s² 8.7

ah,D = m/s² 3.8 Uncertainty K = m/s² 1.5

Vibration

The declared vibration emission values stated in the technical data and the declaration of conformity have been measured in accordance with a standard test method provided by EN 60745 and may be used for comparing one tool with another. The declared vibration emission value may also be used in a preliminary assessment of exposure.

Warning! The vibration emission value during actual use of the power tool can differ from the declared value depending on the ways in which the tool is used. The vibration level may increase above the level stated.

When assessing vibration exposure to determine safety measures required by 2002/44/EC to protect persons regularly using power tools in employment, an estimation of vibration exposure should consider, the actual conditions of use and the way the tool is used, including taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time.

Service Information

STANLEY offers a full network of company-owned and/ or authorized service agents throughout your country. All STANLEY Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool service. Whether you need technical advice, repair, or genuine factory replacement parts, contact the STANLEY location nearest to you.

EC declaration of conformity

MACHINERY DIRECTIVE

SDH600-SDH700 - Impact Drills

Stanley Europe declares that these products described under “technical data” are in compliance with:

2006/42/EC, EN 60745-1:2009 + A11:2010, EN 60745-2-1: 2010

These products also comply with Directive 2004/108/EC (until 19/04/2016) 2014/30/EU (from 20/04/2016) and 2011/65/EU.

For more information, please contact Stanley Europe at the following address or refer to the back of the manual.

The undersigned is responsible for compilation of the technical file and makes this declaration on behalf of Stanley Europe.

Ray Laverick Engineering Manager Stanley Europe, Egide Walschaertsstraat 14-18, 2800 Mechelen, Belgium 08/2015

TWO YEAR WARRANTY

If your STANLEY product becomes defective due to faulty materials or workmanship within 24 months from the date of purchase, STANLEY guarantees to replace all defective parts free of charge or – at our discretion – replace the unit free of charge provided that:

♦♦ The product has not been misused and has been used in accordance with the instruction manual;

♦♦ The product has been subject to fair wear and tear; ♦♦ Repairs have not been attempted by unauthorized

persons;

♦♦ Proof of purchase is produced;

♦♦ The STANLEY product is returned complete with all original components;

♦♦ The product hasn’t been used for hire purposes.

If you wish to make a claim, contact your seller or check the location of your nearest authorised STANLEY repair agent in the STANLEY catalogue or contact your local STANLEY office at the address indicated in this manual. A list of authorised STANLEY repair agents and full details of our after sales service is available on the internet at: www.2helpU.com

7

Русский язык (Перевод с оригинала инструкции)

Назначение

Ваша ударная электрическая дрель STANLEY SDH600SDH700 предназначена для сверления отверстий в древесине, металле, пластмассе и кирпичной кладке, а также для заворачивания саморезов. Данный инструмент предназначен для профессионального использования.

Инструкции по технике безопасности

Общие правила безопасности при работе с электроинструментами

Внимание! Внимательно прочтите все инструкции по безопасности и руководство по эксплуатации. Несоблюдение всех перечисленных ниже правил безопасности

иинструкций может привести к поражению электрическим током, возникновению пожара и/или получению тяжелой травмы.

Сохраните все инструкции по безопасности и руководство по эксплуатации для их дальнейшего использования. Термин «Электроинструмент» во всех приведенных ниже указаниях относится к Вашему сетевому (с кабелем) или аккумуляторному (беспроводному) электроинструменту.

1. Безопасность рабочего места

a.Содержите рабочее место в чистоте и обеспечьте хорошее освещение. Плохое освещение или беспорядок на рабочем месте может привести к несчастному случаю.

b.Не используйте электроинструменты, если есть опасность возгорания или взрыва, например, вблизи легко воспламеняющихся жидкостей, газов или пыли. В процессе работы электроинструмент создает искровые разряды, которые могут воспламенить пыль или горючие пары.

c.Во время работы с электроинструментом не подпускайте близко детей или посторонних лиц.

Отвлечение внимания может вызвать у Вас потерю контроля над рабочим процессом.

2. Электробезопасность

a.Вилка кабеля электроинструмента должна соответствовать штепсельной розетке. Ни в коем случае не видоизменяйте вилку электрического кабеля. Не используйте

соединительные штепселипереходники, если в силовом кабеле электроинструмента есть провод заземления. Использование оригинальной

вилки кабеля и соответствующей ей штепсельной розетки уменьшает риск поражения электрическим током.

b.Во время работы с электроинструментом избегайте физического контакта с заземленными объектами, такими как трубопроводы, радиаторы отопления, электроплиты и холодильники. Риск поражения электрическим током увеличивается, если Ваше тело заземлено.

c.Не используйте электроинструмент под дождем или во влажной среде. Попадание воды в электроинструмент увеличивает риск поражения электрическим током.

d.Бережно обращайтесь с электрическим кабелем. Ни в коем случае не используйте кабель для переноски электроинструмента или для вытягивания его вилки из штепсельной розетки. Не подвергайте электрический кабель воздействию высоких температур и смазочных веществ; держите его в стороне от острых кромок и движущихся частей инструмента.

Поврежденный или запутанный кабель увеличивает риск поражения электрическим током.

e.При работе с электроинструментом на открытом воздухе используйте удлинительный кабель, предназначенный для наружных работ.

Использование кабеля, пригодного для работы на открытом воздухе, снижает риск поражения электрическим током.

f.При необходимости работы с электроинструментом во влажной среде используйте источник питания, оборудованный устройством защитного отключения (УЗО).

Использование УЗО снижает риск поражения электрическим током.

3. Личная безопасность

a.При работе с электроинструментами будьте внимательны, следите за тем, что Вы делаете, и руководствуйтесь здравым смыслом. Не используйте электроинструмент, если Вы устали, а также находясь под действием алкоголя или понижающих реакцию лекарственных препаратов и других средств.

Малейшая неосторожность при работе с электроинструментами может привести к серьезной травме.

b.При работе используйте средства индивидуальной защиты. Всегда надевайте защитные очки. Своевременное использование защитного снаряжения, а именно: пылезащитной маски, ботинок на нескользящей подошве, защитного шлема или противошумовых наушников, значительно снизит риск получения травмы.

c.Не допускайте непреднамеренного запуска. Перед тем, как подключить электроинструмент к сети и/или аккумулятору, поднять или

8

Loading...

Loading...