Standard horizon P79 Owner Manual

OWNER’S GUIDE & INSTALLATION INSTRUCTIONS

Removable In-hull Depth Transducer

Model P79

U.S. Patent No. 6,201,767 B1

EP 1 118 074 B1

IMPORTANT : Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

CAUTION : NEVER USE SOLVENTS

17-217-01 rev. 07 03/04

Cleaners, fuel, paint, sealants, and other products may

contain strong solvents, such as acetone, which attack

many plastics greatly reducing their strength.

Applications

• Fiberglass hulls only

• Recommended for high speed powerboats and racing sailboats

• Accommodates a deadrise angle up to 22°

Tools and Materials Needed

Adhesive tape

Pole

Detergent

Weak solvent (such as alcohol)

Safety goggles (some installations)

Dust mask (some installations)

Disk sander (some installations)

Thin sealable plastic bag (optional)

Twist-tie

Water based lubricant (K-Y® jelly) (optional)

Digital level

Carpenter’s square

Pencil

Silicone sealant (such as GE Silicone I or Silicone II )

Screwdriver

Mineral oil (available at pharmacies) 71ml (2.4 fl. oz.)

For a cored fiberglass hull installation:

Drill

Hole saw 100mm

Miniature disk sander

Casting epoxy (Polypoxy #7035/7040)

Paper cup

Stirrer

or

bubble level and protractor

or

4"

or

resin

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

Mounting Location

Fiberglass Hull

Since the hull absorbs acoustic energy, transmitting through the

hull reduces the sensor’s performance. Fiberglass hulls are often

reinforced in places for added strength. These cored areas

contain balsa wood or structural foam which are poor sound

conductors.

Caution : Find an area of the boat where the fiberglass is solid:

• There are no air bubbles trapped in the fiberglass resin.

• There is no coring, flotation material, or dead air space

sandwiched between the inside skin and outer skin of the hull.

Acoustic Noise

Acoustic noise is always present and these sound waves can

interfere with the operation of the transducer. Background noise

from sources such as: waves, fish, and other vessels cannot be

controlled. However, carefully selecting the transducer mounting

location can minimize the affect of vessel generated noise from

the propeller(s) and shaft(s), other machinery, and other

echosounders. The lower the noise level, the higher the

echosounder gain setting that can be used.

Placement

Choose a location where:

• The water flowing across the hull is smoothest with a minimum

of bubbles and turbulence (especially at high speeds).

• The hull below the transducer will be in contact with the water.

• The transducer beam will be unobstructed by the keel or

propeller shaft(s).

• The deadrise angle does not exceed 22•.

• There is adequate headroom inside the vessel for the height of

the housing, tightening the locking ring, and removing the

transducer.

Caution : Do not mount the sensor:

Near water intake or discharge openings

Behind strakes, fittings, or hull irregularities

Behind eroding paint (an indication of turbulence)

Do not locate the sensor over coring

.

•

pressure waves

AIRMAR

• Fin keel sailboat —Mount to the side of the centerline and

®

forward of the fin keel 300–600mm (1–2').

• Full keel sailboat —Locate amidships and away from the keel

at the point of minimum deadrise angle.

1/3 aft

LWL

(Load Waterline Length)

step-hull

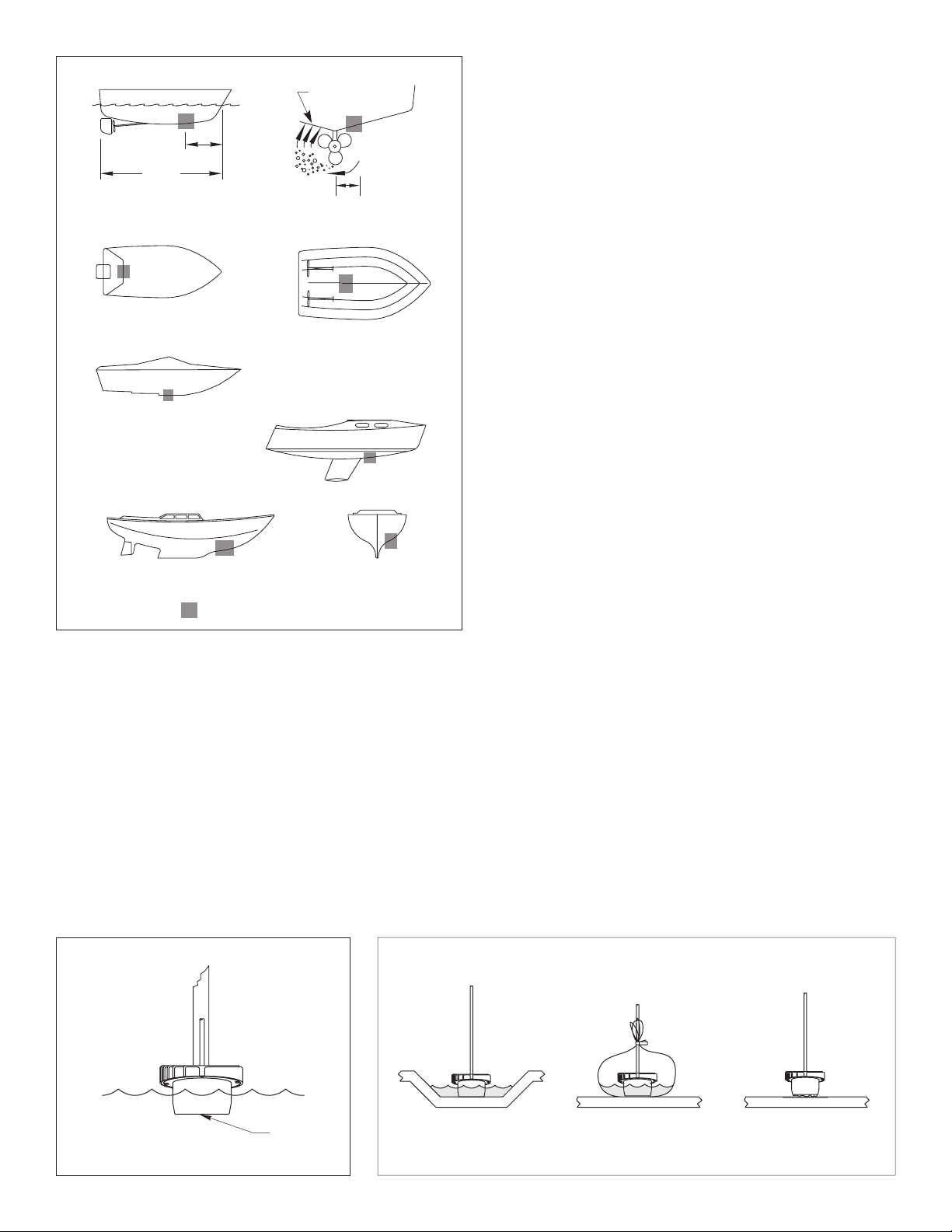

Figure 1.

Best location for the transducer

displacement hull

planing hulls

fin keel sailboat

full keel sailboat

150- 300 mm

(6-12")

inboard

Boat Types (see Figure 1)

Displacement hull powerboat —Locate 1/3 aft LWL and

150–300mm (6–12") off the centerline on the side of the hull

where the propeller is moving downward.

• Planing hull powerboat —Mount well aft, on or near the

centerline, and

insure that the transducer is in contact with the water at high

speeds. Mount on the side of the hull where the propeller is

moving downward.

Outboard and I/O —Mount just forward of the engine(s).

Inboard —Mount well ahead of the propeller(s) and shaft(s).

Step-hull —Mount just ahead of the first step.

well inboard of the first set of lifting strakes

to

Test the Selected Mounting Location

Establishing a Performance Baseline

The results of this test are used as a basis of comparison to

determine the best in-hull location for the sensor.

1. Take the boat to the maximum depth for which your instrument

is rated [up to 150m (500')] or the maximum depth in which you

will be operating the echosounder. If deep water is not available,

find a location with at least 30m (100').

2. Connect the transducer to the echosounder.

3. Tape the transducer to a pole with the cable side up. Hold it over

the side of the boat with the active face submerged in the water

(see Figure 2).

parallel to the surface of the water and fully submerged

4. Observe the echosounder’s performance and the depth

reading.

Testing the Mounting Location

While the boat is at the same site (depth of water), test the

transducer inside the hull at the mounting location. Use one of the

methods below:

A.This method is recommended if the sensor will be located near

the stern and the boat has a minimum deadrise angle. Clean

away any large build-up of dirt and/or grease using detergent or

a weak solvent such as alcohol. Place the transducer against

the hull and allow bilge water to cover the surface where they

touch (see Figure 3-A).

B.

Warning : Always wear safety goggles and a dust mask.

This method can be used at any location. If the hull surface is not

smooth, grind it with a disc sander. Partially fill a thin plastic bag with

water, place the transducer inside the bag and close it tightly with a

twist-tie. Wet the surface of the hull and press the transducer’s

active face against it through the bag (see Figure 3-B).

C. Warning : Always wear safety goggles and a dust mask.

This method can be used at any location. If the hull surface is not

smooth, grind it with a disc sander. Coat the active face of the

transducer with a water-based lubricant (such as K-Y

Press the active face against the hull with a twisting motion (see

Figure 3-C). After testing, wipe all traces of the lubricant from the

transducer’s face.

Be sure to keep the active face of the transducer

.

®

jelly).

AIRMAR

active face

Figure 2. Establishing a performance baseline

2

®

AIRMAR

®

AB C

Figure 3. Testing the transducer at the selected location

Loading...

Loading...