Features

3

Type R

DS(on)

VNN7NV04

VNS7NV04

VND7NV04

60 mΩ 6A 40V

VND7NV04-1

■ Linear current limitation

■ Thermal shutdown

■ Short circuit protection

■ Integrated clamp

■ Low current drawn from input pin

■ Diagnostic feedback through input pin

■ ESD protection

■ Direct access to the gate of the Power

MOSFET (analog driving)

■ Compatible with standard Power MOSFET in

compliance with the 2002/95/EC European

Directive

I

lim

V

clamp

VNN7NV04, VNS7NV04

VND7NV04, VND7NV04-1

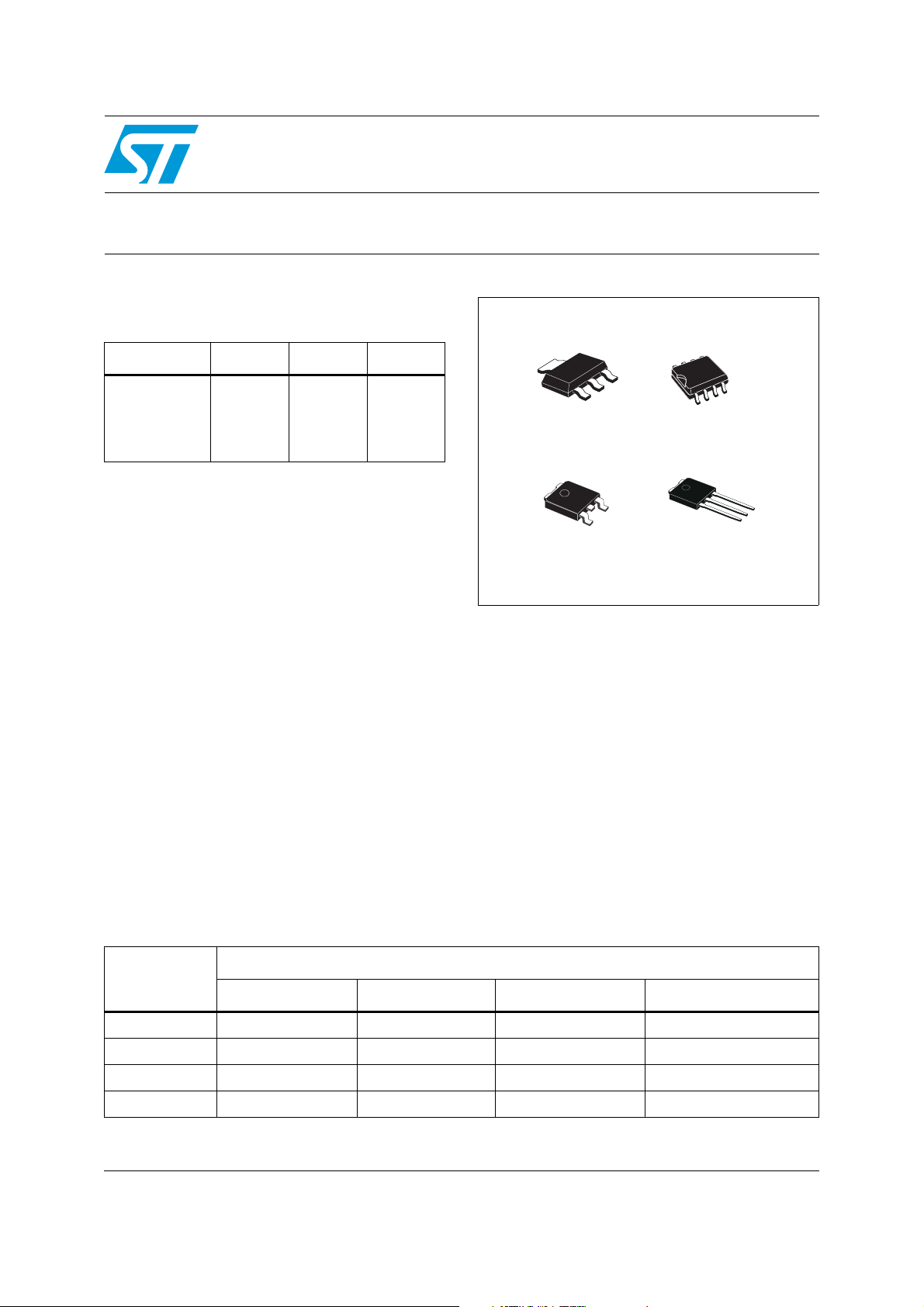

OMNIFET II

fully autoprotected Power MOSFET

2

3

2

1

SOT-223

3

1

TO252 (DPAK)

Description

The VNN7NV04, VNS7NV04, VND7NV04

VND7NV04-1, are monolithic devices designed in

STMicroelectronics VIPower M0-3 Technology,

intended for replacement of standard Power

MOSFETs from DC up to 50 kHz applications.

Built in thermal shutdown, linear current limitation

and overvoltage clamp protect the chip in harsh

environments.

SO-8

TO251 (IPAK)

2

1

Fault feedback can be detected by monitoring the

voltage at the input pin.

Table 1. Device summary

Package

Tube Tube (lead-free) Tape and reel Tape and reel (lead-free)

SOT-223 VNN7NV04 - VNN7NV0413TR -

SO-8 VNS7NV04 - VNS7NV0413TR -

TO-252 VND7NV04 VND7NV04-E VND7NV0413TR VND7NV04TR-E

TO-251 VND7NV04-1 VND7NV04-1-E - -

September 2010 Doc ID 7383 Rev 3 1/37

Order codes

www.st.com

1

Contents VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Contents

1 Block diagram and pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Protection features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Electrical characteristics curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 SO-8 maximum demagnetization energy . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 DPAK maximum demagnetization energy . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 SOT-223 maximum demagnetization energy . . . . . . . . . . . . . . . . . . . . . . 19

4 Package and PCB thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 SO-8 thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 SOT-223 thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 DPAK thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Package and packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 TO-251 (IPAK) mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 TO-252 (DPAK) mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3 SOT-223 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 SO-8 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5 SOT-223 packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.6 SO-8 packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.7 DPAK packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.8 IPAK packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5. SO-8 thermal parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 6. SOT-223 thermal parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 7. DPAK thermal parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 8. TO-251 (IPAK) mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 9. TO-252 (DPAK) mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 10. SOT-223 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 11. SO-8 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 12. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Doc ID 7383 Rev 3 3/37

List of figures VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

List of figures

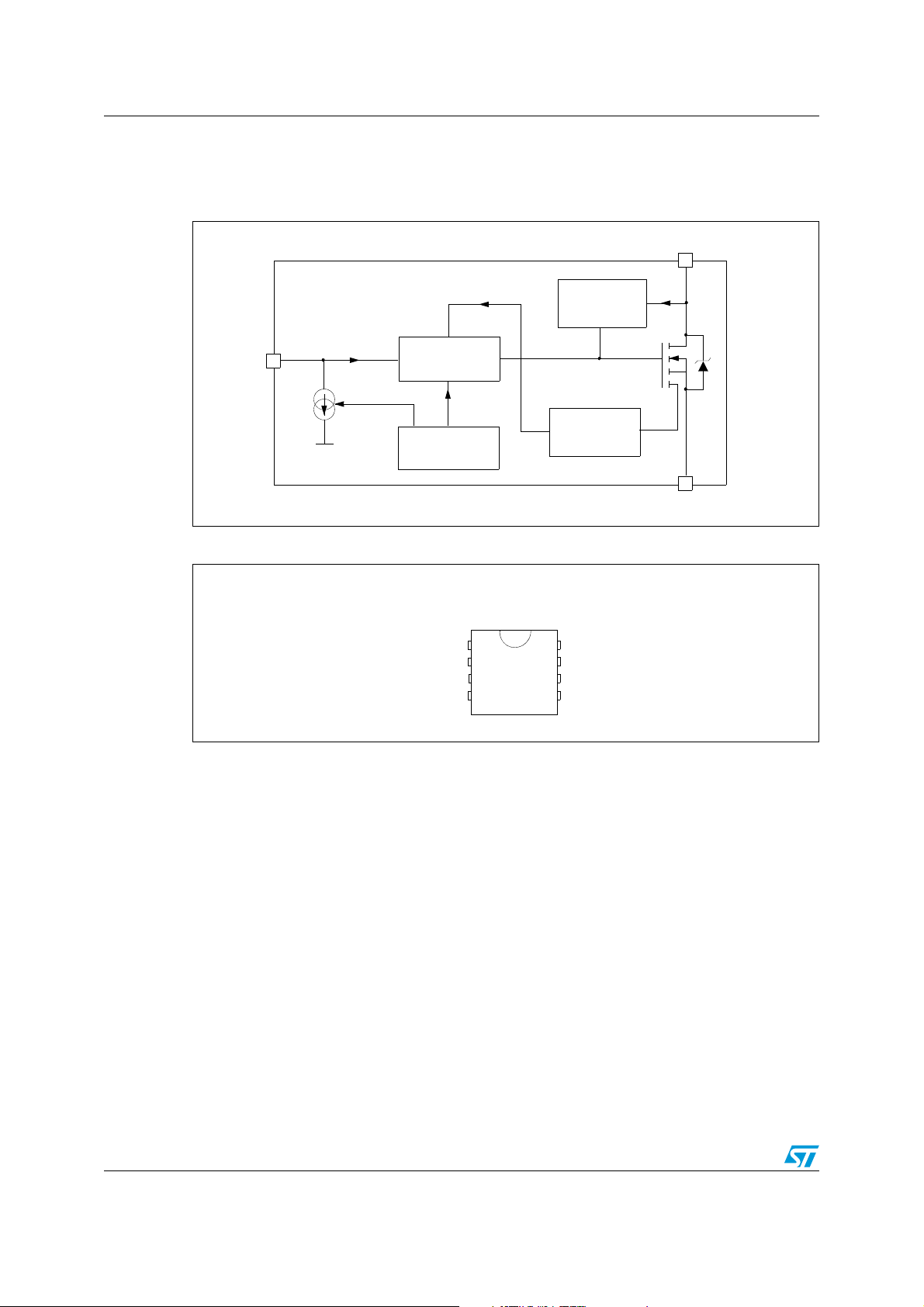

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Configuration diagram (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

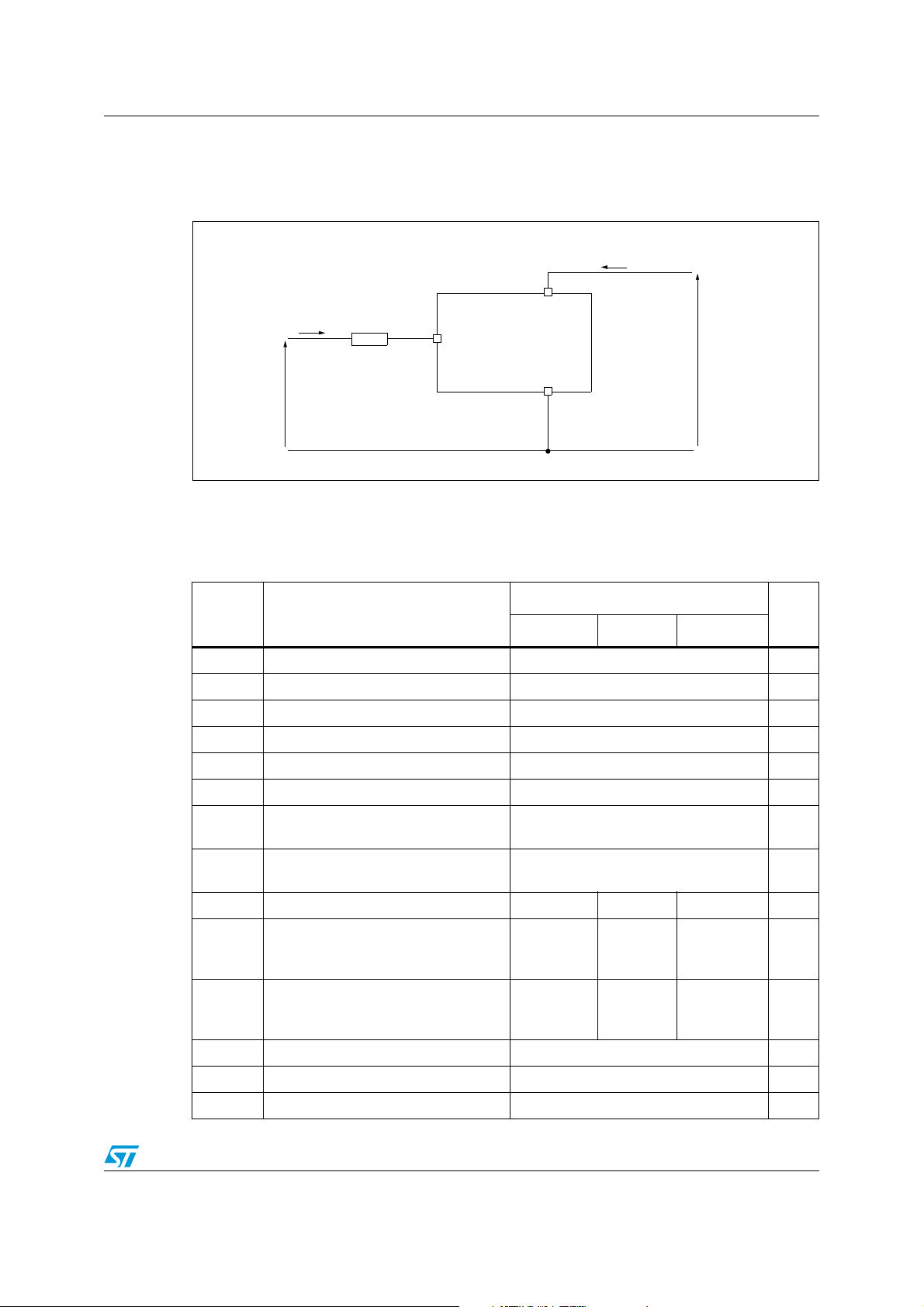

Figure 3. Current and voltage conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. Switching time test circuit for resistive load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. Test circuit for diode recovery times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Unclamped inductive load test circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. Input charge test circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Unclamped inductive waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. Derating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 10. Transconductance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 11. Static drain-source on resistance vs input voltage (part 1/2) . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 12. Static drain-source on resistance vs input voltage (part 2/2) . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 13. Source-drain diode forward characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 14. Static drain source on resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 15. Turn-on current slope (part 1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 16. Turn-on current slope (part 2/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 17. Transfer characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 18. Static drain-source on resistance vs Id . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 19. Input voltage vs input charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 20. Turn-off drain source voltage slope (part 1/2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 21. Turn-off drain source voltage slope (part 2/2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 22. Capacitance variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 23. Output characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 24. Normalized on resistance vs temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 25. Switching time resistive load (part 1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 26. Switching time resistive load (part 2/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 27. Normalized input threshold voltage vs temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 28. Normalized current limit vs junction temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 29. Step response current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 30. SO-8 maximum turn-off current versus load inductance. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 31. SO-8 demagnetization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 32. DPAK maximum turn-off current versus load inductance . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 33. DPAK demagnetization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 34. SOT-223 maximum turn-off current versus load inductance . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 35. SOT-223 demagnetization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 36. SO-8 PC board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 37. Rthj-amb vs PCB copper area in open box free air condition . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 38. SO-8 thermal impedance junction ambient single pulse. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 39. Thermal fitting model of an OMNIFET II in SO-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 40. SOT-223 PC board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 41. Rthj-amb vs PCB copper area in open box free air condition . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 42. SOT-223 thermal impedance junction ambient single pulse. . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 43. Thermal fitting model of an OMNIFET II in SOT-223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 44. DPAK PC board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 45. Rthj-amb vs PCB copper area in open box free air condition . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 46. DPAK thermal impedance junction ambient single pulse . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 47. Thermal fitting model of an OMNIFET II in DPAK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 48. TO-251 (IPAK) package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 List of figures

Figure 49. TO-252 (DPAK) package dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 50. SOT-223 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 51. SO-8 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 52. SOT-223 tape and reel shipment (suffix “TR”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 53. SO-8 tube shipment (no suffix) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 54. SO-8 tape and reel shipment (suffix “TR”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 55. DPAK footprint and tube shipment (no suffix). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 56. DPAK tape and reel shipment (suffix “TR”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 57. IPAK tube shipment (no suffix) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Doc ID 7383 Rev 3 5/37

Block diagram and pin description VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

1 Block diagram and pin description

Figure 1. Block diagram

DRAIN

2

Overvoltage

Clamp

INPUT

1

Gate

Control

Over

Temperature

Linear

Current

Limiter

Figure 2. Configuration diagram (top view)

SO-8 Package

SOURCE

SOURCE

SOURCE

INPUT

1

4

1. For the pins configuration related to SOT-223, DPAK, IPAK see outlines at page 1.

(1)

DRAIN

8

DRAIN

DRAIN

5

DRAIN

3

SOURCE

FC01000

6/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Electrical specifications

2 Electrical specifications

Figure 3. Current and voltage conventions

I

D

V

DS

R

I

IN

IN

INPUT

V

IN

2.1 Absolute maximum ratings

DRAIN

SOURCE

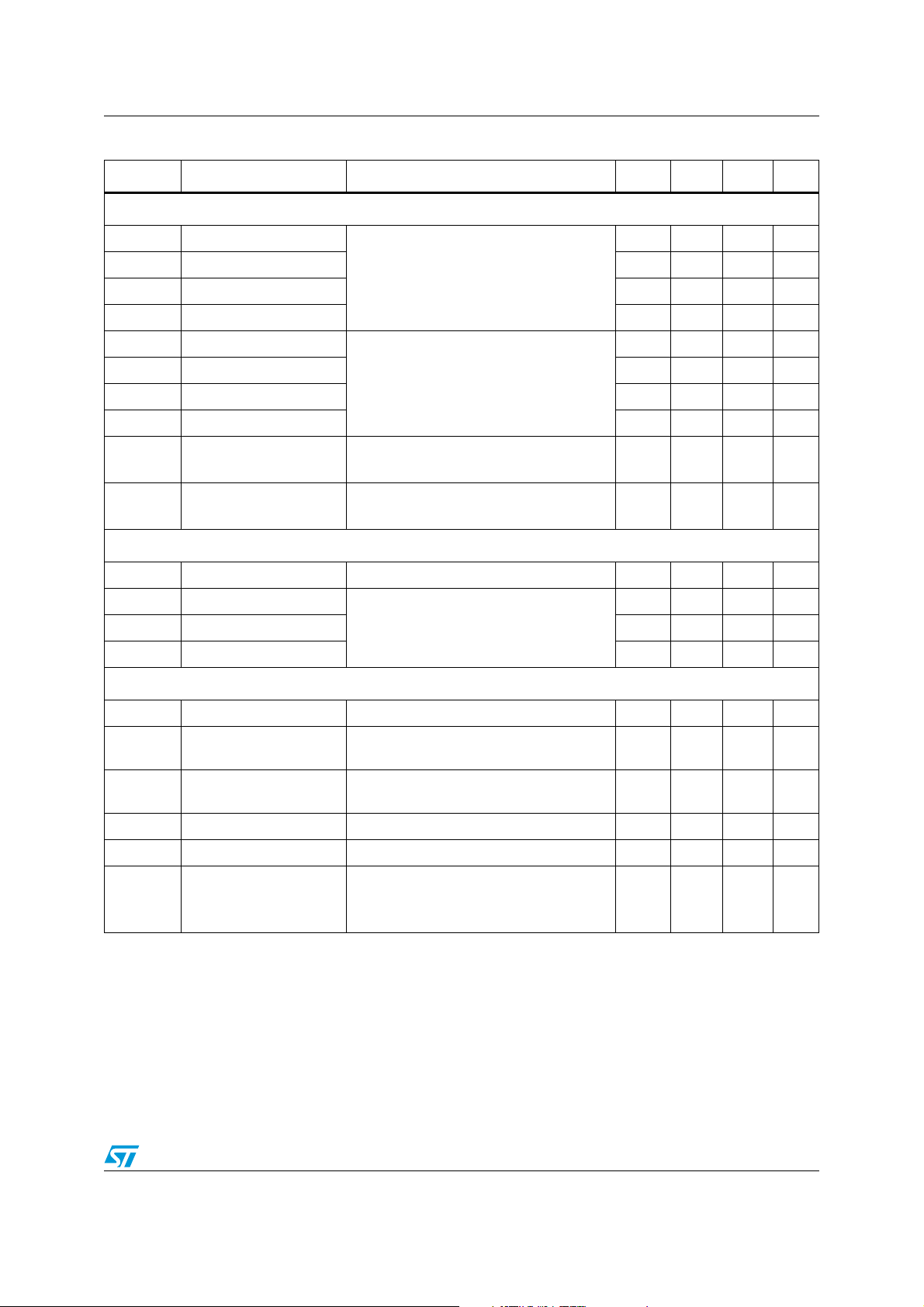

Table 2. Absolute maximum ratings

Val ue

Symbol Parameter

Unit

SOT-223 SO-8 DPAK/IPAK

V

R

IN MIN

V

V

V

I

ESD1

ESD2

P

Drain-source voltage (VIN=0 V) Internally clamped V

DS

Input voltage Internally clamped V

IN

Input current +/-20 mA

IN

Minimum input series impedance 150 Ω

Drain current Internally limited A

I

D

Reverse DC output current -10.5 A

I

R

Electrostatic discharge (R=1.5 KΩ,

C=100 pF)

Electrostatic discharge on output pin

only (R=330 Ω, C=150 pF)

Total dissipation at Tc=25 °C 7 4.6 60 W

tot

4000 V

16500 V

Maximum switching energy

E

MAX

(L=0.7 mH; R

T

=150 ºC; IL=9 A)

jstart

=0 Ω; V

L

=13.5 V;

bat

40 40 mJ

Maximum switching energy

E

MAX

T

T

(L=0.6 mH; R

T

=150 ºC; IL=9 A)

jstart

Operating junction temperature Internally limited °C

T

j

Case operating temperature Internally limited °C

c

Storage temperature -55 to 150 °C

stg

=0 Ω; V

L

=13.5 V;

bat

37 mJ

Doc ID 7383 Rev 3 7/37

Electrical specifications VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

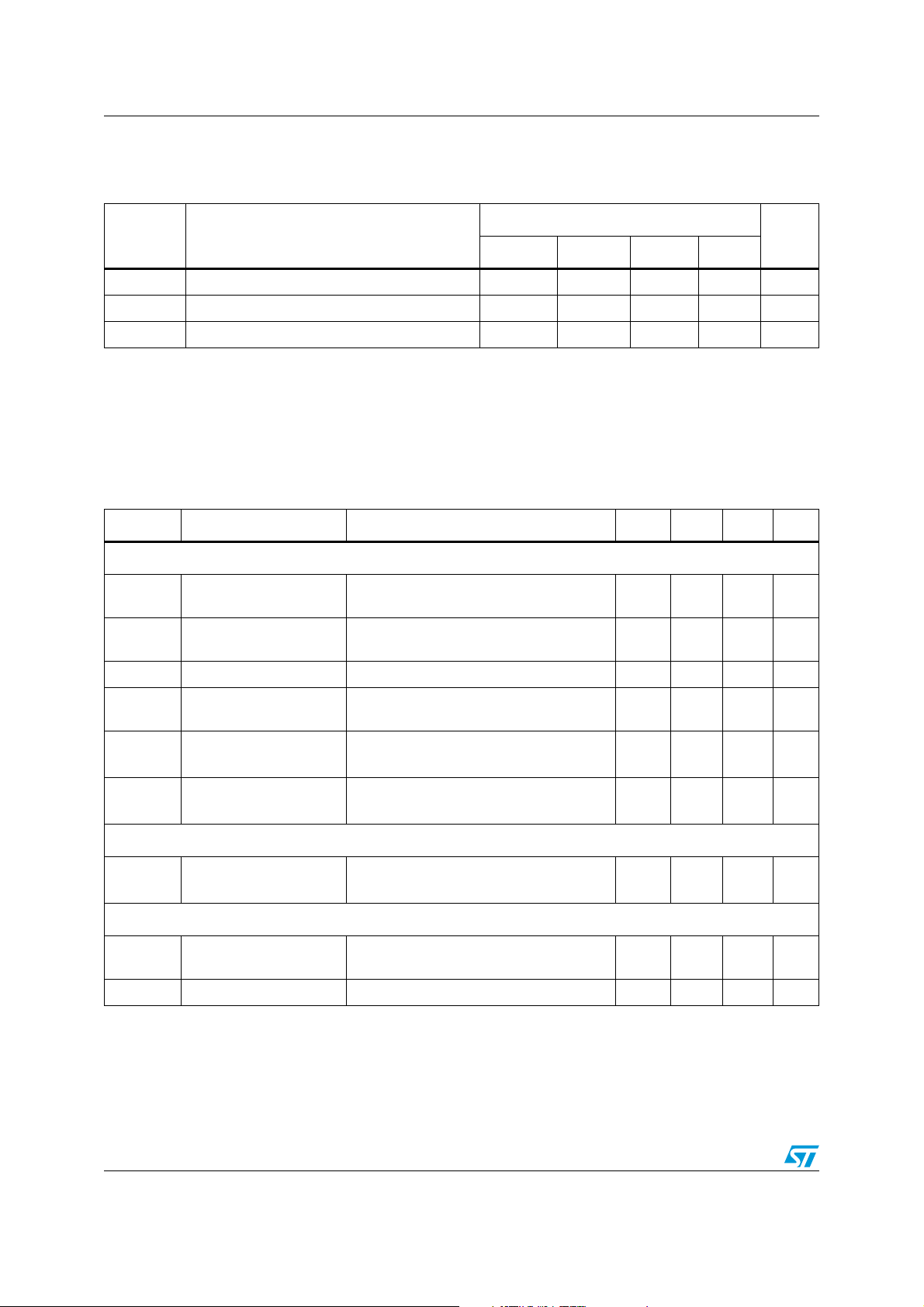

2.2 Thermal data

Table 3. Thermal data

Value

Symbol Parameter

SOT-223 SO-8 DPAK IPAK

R

thj-case

R

thj-lead

R

thj-amb

1. When mounted on a standard single-sided FR4 board with 0.5 mm2 of Cu (at least 35 µm thick) connected to all DRAIN

pins.

Thermal resistance junction-case max 18 2.1 2.1 °C/W

Thermal resistance junction-lead max 27 °C/W

Thermal resistance junction-ambient max 96

(1)

90

(1)

65

(1)

102 °C/W

2.3 Electrical characteristics

-40 °C < Tj < 150 °C, unless otherwise specified.

Table 4. Electrical characteristics

Symbol Parameter Test conditions Min Typ Max Unit

Off

V

CLAMP

V

CLTH

V

INTH

I

ISS

V

INCL

I

DSS

On

Drain-source clamp

voltage

Drain-source clamp

threshold voltage

V

=0 V; ID=3.5 A 40 45 55 V

IN

=0 V; ID=2 mA 36 V

V

IN

Input threshold voltage VDS=VIN; ID=1 mA 0.5 2.5 V

Supply current from input

pin

Input-source clamp

voltage

Zero input voltage drain

current (VIN=0 V)

=0 V; VIN=5 V 100 150 µA

V

DS

=1 mA

I

IN

=-1 mA

I

IN

=13 V; VIN=0 V; Tj=25 °C

V

DS

=25 V; VIN=0 V

V

DS

6

-1.0

6.8 8

-0.3

30

75

Unit

V

µA

=5 V; ID=3.5 A; Tj=25 °C

V

IN

=5 V; ID=3.5 A

V

IN

=13 V; ID=3.5 A 9 S

V

DD

R

DS(on)

Dynamic (T

(1)

g

fs

C

OSS

Static drain-source on

resistance

=25 °C, unless otherwise specified)

j

Forward

transconductance

Output capacitance VDS=13V; f=1MHz; VIN=0 V 220 pF

8/37 Doc ID 7383 Rev 3

60

120

mΩ

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Electrical specifications

Table 4. Electrical characteristics (continued)

Symbol Parameter Test conditions Min Typ Max Unit

Switching (Tj=25 °C, unless otherwise specified)

t

d(on)

t

t

d(off)

t

t

d(on)

t

t

d(off)

t

(dI/dt)

Q

Source drain diode (T

V

SD

t

Q

I

RRM

Protections (-40 °C < T

I

lim

t

dlim

Turn-on delay time

V

=15 V; ID=3.5 A

Rise time 470 1500 ns

r

Turn-off delay time 500 1500 ns

Fall time 350 1000 ns

f

DD

V

=5 V; R

gen

gen=RIN MIN

(see figure Figure 4.)

=150 Ω

Turn-on delay time

=15 V; ID=3.5 A

V

Rise time 4.6 14.0 µs

r

Turn-off delay time 5.4 16.0 µs

Fall time 3.6 11.0 µs

f

Turn-on current slope

on

Total input charge

i

=25 °C, unless otherwise specified)

j

(1)

Forward on voltage ISD=3.5 A; VIN=0 V 0.8 V

Reverse recovery time

rr

Reverse recovery charge 0.28 µC

rr

Reverse recovery current 2.5 A

< 150 °C, unless otherwise specified)

j

DD

V

gen

=5 V; R

=2.2 KΩ

gen

(see figure Figure 4.)

VDD=15 V; ID=3.5 A

=5 V; R

V

gen

V

=12 V; ID=3.5 A; VIN=5 V

DD

=2.13 mA (see figure Figure 7.)

I

gen

gen=RIN MIN

=150 Ω

ISD=3.5 A; dI/dt=20 A/µs

=30 V; L=200 µH

V

DD

(see test circuit, figure Figure 5.)

100 300 ns

0.75 2.3 µs

6.5 A/µs

18 nC

220 ns

Drain current limit VIN=5 V; VDS=13 V 6 9 12 A

Step response current

limit

VIN=5 V; VDS=13 V 4.0 µs

jsh

T

I

E

1. Pulsed: Pulse duration = 300 µs, duty cycle 1.5 %

shutdown

Over temperature reset 135 °C

jrs

Fault sink current VIN=5 V; VDS=13 V; Tj=T

gf

Single pulse avalanche

as

energy

Over temperature

T

jsh

starting T

V

IN

=25 °C; VDD=24 V

j

=5 V R

gen=RIN MIN

=150 Ω; L=24 mH

(see figures Figure 6. & Figure 8.)

Doc ID 7383 Rev 3 9/37

150 175 200 °C

15 mA

200 mJ

Protection features VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

3 Protection features

During normal operation, the input pin is electrically connected to the gate of the internal

Power MOSFET through a low impedance path.

The device then behaves like a standard Power MOSFET and can be used as a switch from

DC up to 50 kHz. The only difference from the user’s standpoint is that a small DC current

I

(typ. 100µA) flows into the input pin in order to supply the internal circuitry.

ISS

The device integrates:

● Overvoltage clamp protection: internally set at 45 V, along with the rugged avalanche

characteristics of the Power MOSFET stage give this device unrivalled ruggedness and

energy handling capability. This feature is mainly important when driving inductive

loads.

● Linear current limiter circuit: limits the drain current I

voltages. When the current limiter is active, the device operates in the linear region, so

power dissipation may exceed the capability of the heatsink. Both case and junction

temperatures increase, and if this phase lasts long enough, junction temperature may

reach the over temperature threshold T

● Over temperature and short circuit protection: these are based on sensing the chip

jsh

.

temperature and are not dependent on the input voltage. The location of the sensing

element on the chip in the power stage area ensures fast, accurate detection of the

junction temperature. Over temperature cutout occurs in the range 150 to 190 °C, a

typical value being 170 °C. The device is automatically restarted when the chip

temperature falls of about 15 °C below shutdown temperature.

● Status feedback: in the case of an over temperature fault condition (T

device tries to sink a diagnostic current I

through the input pin in order to indicate fault

gf

condition. If driven from a low impedance source, this current may be used in order to

warn the control circuit of a device shutdown. If the drive impedance is high enough so

that the input pin driver is not able to supply the current I

This will not however affect the device operation: no requirement is put on the current

capability of the input pin driver except to be able to supply the normal operation drive

current I

ISS

.

Additional features of this device are ESD protection according to the Human Body model

and the ability to be driven from a TTL logic circuit.

to I

D

whatever the input pin

lim

> T

j

, the input pin will fall to 0 V.

gf

jsh

), the

10/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Protection features

Figure 4. Switching time test circuit for resistive load

I

D

90%

t

r

t

V

gen

d(on)

10%

Figure 5. Test circuit for diode recovery times

A

FAST

DIODE

B

R

gen

I

V

gen

150

I

OMNIFET

Ω

D

S

t

d(off)

A

B

OMNIFET

t

f

D

S

L=100uH

t

t

V

DD

8.5

Ω

Doc ID 7383 Rev 3 11/37

Protection features VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

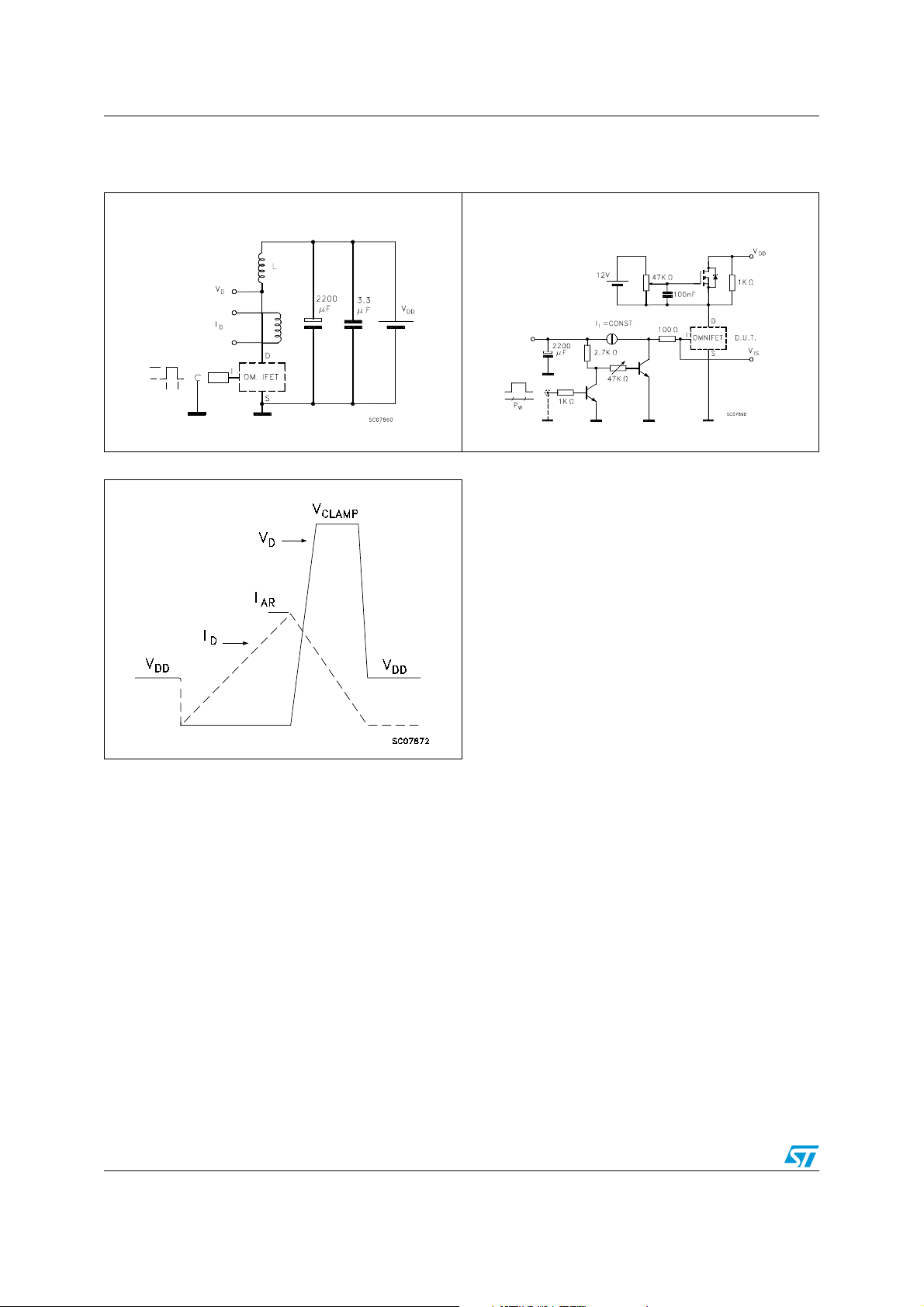

Figure 6. Unclamped inductive load test

Figure 7. Input charge test circuit

circuits

V

IN

R

V

IN

P

GEN

W

Figure 8. Unclamped inductive waveforms

12/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Protection features

3.1 Electrical characteristics curves

Figure 9. Derating curve Figure 10. Transconductance

Gfs (S)

20

18

16

14

12

10

8

6

4

2

0

Vds=13V

Tj=-40ºC

Tj=25ºC

Tj=150ºC

01234567 8

Id(A)

Figure 11. Static drain-source on resistance

vs input voltage (part 1/2)

Rds(on) (mOhm)

120

110

100

90

80

70

60

50

40

30

20

10

0

33.544.555.566.5 7

Id=3.5A

Tj=150ºC

Tj=25ºC

Tj= - 40ºC

Vin(V)

Figure 13. Source-drain diode forward

characteristics

Vsd (mV)

1000

950

900

850

800

750

700

650

600

550

500

Vin=0V

0 2 4 6 8 101214

Id(A)

Figure 12. Static drain-source on resistance

vs input voltage (part 2/2)

Rds(on) (m Ohm)

140

120

Tj=150ºC

100

80

Tj=25ºC

60

Tj=-40ºC

40

20

0

33.544.5 55.5 6 6.5

Id=6A

Id=1A

Id=6A

Id=1A

Id=6A

Id=1A

Vin(V)

Figure 14. Static drain source on resistance

Rds(on) (mohms)

150

125

Vin=5V

100

75

50

25

0

0123456

Id(A)

Tj=150ºC

Tj=25ºC

Tj=-40ºC

Doc ID 7383 Rev 3 13/37

)

dv/dt(V/us)

Protection features VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Figure 15. Turn-on current slope (part 1/2) Figure 16. Turn-on current slope (part 2/2)

di/dt(A/us)

2.25

2

1.75

1.5

1.25

1

0.75

0.5

0.25

100

200

300

400

500

Rg(ohm)

600

700

Vin=3.5V

Vdd=15V

Id=3.5A

800

900

1000

1100

di/dt(A/us)

8

7

6

5

4

3

2

1

0

100

200

300

400

500

Rg(ohm)

600

Vin=5V

Vdd=15V

Id=3.5A

700

800

900

1000

Figure 17. Transfer characteristics Figure 18. Static drain-source on resistance

vs Id

Idon(A)

10

9

8

7

6

Vds=13.5V

Tj=25ºC

Tj=-40ºC

Tj=150ºC

Rds(on) (mOhm)

140

120

100

80

Vin=3.5V

Tj=150ºC

5

4

3

2

1

0

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

Vin(V

60

Tj=25ºC

40

Tj=-40ºC

20

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

Id(A)

Figure 19. Input voltage vs input charge Figure 20. Turn-off drain source voltage slope

(part 1/2)

Vin(V)

8

7

6

Vds=12V

Id=3.5A

5

4

3

2

1

0

0 5 10 15 20 25

300

250

200

150

100

Vin=5V

Vdd=15V

Id=3.5A

50

0

100

200

300

400

500

600

700

800

900

Rg(ohm)

Vin=5V

Vin=3.5V

Vin=5V

Vin=3.5V

Vin=5V

1000

1100

1100

14/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Protection features

Figure 21. Turn-off drain source voltage slope

Figure 22. Capacitance variations

(part 2/2)

dv/dt(v/us)

300

250

700

Vin=3.5V

Vdd=15V

Id=3.5A

800

900

1000

1100

200

150

100

50

0

200

400

100

300

500

600

Rg(ohm)

C(pF)

600

500

400

300

200

100

0 5 10 15 20 25 30 35

f=1MHz

Vin=0V

Vds(V)

Figure 23. Output characteristics Figure 24. Normalized on resistance vs

temperature

v

ID(A)

12

11

10

9

8

7

6

5

4

3

2

1

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Vin=5V

Vin=4.5V

Vin=4V

Vin=3V

Vin=2.5V

Vin=2V

VDS(V)

Rds(on)

2.25

2

1.75

1.5

1.25

0.75

0.5

Vin=5V

Id=3.5A

1

-50 -25 0 25 50 75 100 125 150 175

T(ºC)

Figure 25. Switching time resistive load (part

1/2)

t(us)

5.5

5

4.5

3.5

2.5

1.5

0.5

Vdd=15V

Id=3.5A

Vin=5V

4

3

2

1

0

250

0

500

750

1000

1250

td(off)

td(on)

1500

1750

Rg(ohm)

2000

tr

tf

2250

Figure 26. Switching time resistive load (part

2/2)

t(ns)

1600

tr

1400

1200

1000

800

2500

600

400

200

0

3.25 3.5 3.75 4 4.25 4.5 4.75 5 5.25

td(off)

td(on)

Vin(V)

Doc ID 7383 Rev 3 15/37

Vdd=15V

Id=3.5A

Rg=150ohm

tf

Protection features VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Figure 27. Normalized input threshold voltage

vs temperature

Vin(th)

1.15

1.1

1.05

Vds=Vin

Id=1mA

1

0.95

0.9

0.85

0.8

0.75

0.7

-50 -25 0 25 50 75 100 125 150 175

T(ºC)

Figure 29. Step response current limit

Tdlim(us)

7

6.5

6

Vin=5V

Rg=150ohm

Figure 28. Normalized current limit vs junction

temperature

Ilim (A)

15

14

13

12

11

10

9

8

7

6

5

Vds=13V

Vin=5V

-50 -25 0 25 50 75 100 125 150 175

Tj (ºC)

5.5

5

4.5

4

3.5

5 101520253035

Vdd(V)

16/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Protection features

3.2 SO-8 maximum demagnetization energy

Figure 30. SO-8 maximum turn-off current versus load inductance

LMAX (A)

I

100

10

A

B

C

1

0.1 1 10 100

L(mH)

Legend

A = Single Pulse at T

B = Repetitive pulse at T

C = Repetitive Pulse at T

Conditions:

V

=13.5 V

CC

Values are generated with R

demagnetization) of every pulse must not exceed the temperature specified above for

curves B and C.

Figure 31. SO-8 demagnetization

VIN, I

L

Jstart

=150 °C

=100 °C

Jstart

=125 °C

Jstart

=0 Ω. In case of repetitive pulses, T

L

Demagnetization

Demagnetization

(at beginning of each

jstart

Demagnetization

t

Doc ID 7383 Rev 3 17/37

Protection features VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

3.3 DPAK maximum demagnetization energy

Figure 32. DPAK maximum turn-off current versus load inductance

LMAX (A)

I

100

10

1

0.01 0.1 1 10 100

L(mH)

Legend

A = Single Pulse at T

B = Repetitive pulse at T

C = Repetitive Pulse at T

Jstart

=150 °C

=100 °C

Jstart

=125 °C

Jstart

Conditions:

V

=13.5 V

CC

Values are generated with R

=0 Ω. In case of repetitive pulses, T

L

(at beginning of each

jstart

demagnetization) of every pulse must not exceed the temperature specified above for

curves B and C.

Figure 33. DPAK demagnetization

VIN, I

L

Demagnetization

Demagnetization

Demagnetization

t

18/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Protection features

3.4 SOT-223 maximum demagnetization energy

Figure 34. SOT-223 maximum turn-off current versus load inductance

LMAX (A)

I

100

10

1

0.01 0.1 1 10

L(mH)

Legend

A = Single Pulse at T

B = Repetitive pulse at T

C = Repetitive Pulse at T

Conditions:

V

=13.5 V

CC

Values are generated with R

demagnetization) of every pulse must not exceed the temperature specified above for

curves B and C.

Figure 35. SOT-223 demagnetization

VIN, I

L

Jstart

=150 °C

=100 °C

Jstart

=125 °C

Jstart

=0 Ω. In case of repetitive pulses, T

L

Demagnetization

Demagnetization

(at beginning of each

jstart

Demagnetization

t

Doc ID 7383 Rev 3 19/37

Package and PCB thermal data VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

4 Package and PCB thermal data

4.1 SO-8 thermal data

Figure 36. SO-8 PC board

Note: Layout condition of R

thickness=2 mm, Cu thickness=35 µm, Copper areas: 0.14 cm

Figure 37. R

thj-amb

RT Hj _am b ( º C / W)

and Zth measurements (PCB FR4 area=58 mm x 58 mm, PCB

th

2

, 0.8 cm2, 2 cm2).

vs PCB copper area in open box free air condition

SO-8 at 2 pins connecte d to TAB

110

105

100

95

90

85

80

75

70

00.511.522.5

20/37 Doc ID 7383 Rev 3

PCB Cu heatsink area (cm^2)

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and PCB thermal data

Figure 38. SO-8 thermal impedance junction ambient single pulse

ZTH (°C/W)

1000

100

10

1

0.1

0.0001 0.001 0.01 0.1 1 10 100 1000

Time (s)

Figure 39. Thermal fitting model of an OMNIFET II in SO-8

Tj

C1

R1 R2

Pd

C2

C3

R3

T_amb

C4

R4

C5

R5

C6

R6

Equation 1 Pulse calculation formula

Z

THδ

where

Table 5. SO-8 thermal parameter

R

δ t

TH

p

δ Z

T⁄=

THtp

1 δ–()+⋅=

Area/island (cm2) Footprint 2

R1 (°C/W) 0.2

R2 (°C/W) 0.9

R3 (°C/W) 3.5

R4 (°C/W) 21

R5 (°C/W) 16

R6 (°C/W) 58 28

C1 (W.s/°C) 3.00E-04

Doc ID 7383 Rev 3 21/37

Package and PCB thermal data VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Table 5. SO-8 thermal parameter (continued)

Area/island (cm2) Footprint 2

C2 (W.s/°C) 9.00E-04

C3 (W.s/°C) 7.50E-03

C4 (W.s/°C) 0.045

C5 (W.s/°C) 0.35

C6 (W.s/°C) 1.05 2

4.2 SOT-223 thermal data

Figure 40. SOT-223 PC board

Note: Layout condition of R

thickness=2 mm, Cu thickness=35 µm, Copper areas: 0.11 cm

Figure 41. R

th

vs PCB copper area in open box free air condition

thj-amb

RTH j-am b (°C/ W )

140

130

120

110

100

90

80

70

60

0 0.5 1 1.5 2 2.5

and Z

measurements (PCB FR4 area=58 mm x 58 mm, PCB

th

Cu area (cm^2)

2

, 1 cm2, 2 cm2).

22/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and PCB thermal data

Figure 42. SOT-223 thermal impedance junction ambient single pulse

ZTH (°C/W)

1000

100

10

1

0.1

0.0001 0.001 0.01 0.1 1 10 100 1000

Time (s)

Figure 43. Thermal fitting model of an OMNIFET II in SOT-223

Tj

C1

R1 R2

Pd

C2

C3

R3

T_amb

C4

R4

C5

R5

C6

R6

Equation 2 Pulse calculation formula

Z

THδ

where

Table 6. SOT-223 thermal parameter

R

δ t

TH

p

δ Z

T⁄=

THtp

1 δ–()+⋅=

Area/island (cm2) Footprint 2

R1 (°C/W) 0.2

R2 (°C/W) 1.1

R3 (°C/W) 4.5

R4 (°C/W) 24

R5 (°C/W) 0.1

R6 (°C/W) 100 45

C1 (W.s/°C) 3.00E-04

Doc ID 7383 Rev 3 23/37

Package and PCB thermal data VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Table 6. SOT-223 thermal parameter (continued)

Area/island (cm2) Footprint 2

C2 (W.s/°C) 9.00E-04

C3 (W.s/°C) 3.00E-02

C4 (W.s/°C) 0.16

C5 (W.s/°C) 1000

C6 (W.s/°C) 0.5 2

4.3 DPAK thermal data

Figure 44. DPAK PC board

Note: Layout condition of R

thickness=2 mm, Cu thickness=35µm, Copper areas: from minimum pad lay-out to 8 cm2).

Figure 45. R

vs PCB copper area in open box free air condition

thj-amb

RTH j_amb (ºC/W)

90

80

70

60

50

40

30

0246810

and Zth measurements (PCB FR4 area=60 mm x 60 mm, PCB

th

PCB CU he atsink area (cm^2)

24/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and PCB thermal data

Figure 46. DPAK thermal impedance junction ambient single pulse

ZTH (°C/W)

1000

100

10

1

0.1

0.0001 0.001 0.01 0.1 1 10 100 1000

Time (s)

Figure 47. Thermal fitting model of an OMNIFET II in DPAK

Tj

C1

R1 R2

Pd

C2

C3

R3

C4

R4

T_amb

C5

R5

C6

R6

Equation 3 Pulse calculation formula

Z

THδ

where

Table 7. DPAK thermal parameter

R

δ t

TH

p

δ Z

T⁄=

THtp

1 δ–()+⋅=

Area/island (cm2) Footprint 6

R1 (°C/W) 0.1

R2 (°C/W) 0.35

R3 (°C/W) 1.20

R4 (°C/W) 2

R5 (°C/W) 15

R6 (°C/W) 61 24

Doc ID 7383 Rev 3 25/37

Package and PCB thermal data VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Table 7. DPAK thermal parameter (continued)

Area/island (cm2) Footprint 6

C1 (W.s/°C) 0.0006

C2 (W.s/°C) 0.0021

C3 (W.s/°C) 0.05

C4 (W.s/°C) 0.3

C5 (W.s/°C) 0.45

C6 (W.s/°C) 0.8 5

26/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and packing information

5 Package and packing information

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com

ECOPACK® is an ST trademark.

5.1 TO-251 (IPAK) mechanical data

Table 8. TO-251 (IPAK) mechanical data

Symbol

Min. Typ. Max.

A2.2 2.4

A1 0.9 1.1

A3 0.7 1.3

B 0.64 0.9

B2 5.2 5.4

millimeters

.

B3 0.85

B5 0.3

B6 0.95

C 0.45 0.6

C2 0.48 0.6

D6 6.2

E6.4 6.6

G4.4 4.6

H 15.9 16.3

L9 9.4

L1 0.8 1.2

L2 0.8 1

Doc ID 7383 Rev 3 27/37

Package and packing information VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Figure 48. TO-251 (IPAK) package dimensions

5.2 TO-252 (DPAK) mechanical data

Table 9. TO-252 (DPAK) mechanical data

Symbol

Min. Typ. Max.

A 2.20 2.40

A1 0.90 1.10

A2 0.03 0.23

B 0.64 0.90

B2 5.20 5.40

C 0.45 0.60

C2 0.48 0.60

D 6.00 6.20

D1 5.1

E 6.40 6.60

E1 4.7

e2.28

G 4.40 4.60

H 9.35 10.10

millimeters

28/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and packing information

Table 9. TO-252 (DPAK) mechanical data (continued)

millimeters

Symbol

Min. Typ. Max.

L2 0.8

L4 0.60 1.00

R0.2

V2 0° 8°

Package Weight Gr. 0.29

Figure 49. TO-252 (DPAK) package dimensions

5.3 SOT-223 mechanical data

Table 10. SOT-223 mechanical data

Symbol

A 1.8

B0.60.70.85

B1 2.9 3 3.15

c 0.24 0.26 0.35

D6.36.56.7

e2.3

P032P

millimeters

Min. Typ. Max.

Doc ID 7383 Rev 3 29/37

Package and packing information VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Table 10. SOT-223 mechanical data (continued)

millimeters

Symbol

Min. Typ. Max.

e1 4.6

E3.33.53.7

H6.7 7 7.3

V 10 (max)

A1 0.02 0.1

Figure 50. SOT-223 package dimensions

5.4 SO-8 mechanical data

Table 11. SO-8 mechanical data

Symbol

Min Typ Max

A 1.75

a1 0.1 0.25

a2 1.65

30/37 Doc ID 7383 Rev 3

a3 0.65 0.85

b 0.35 0.48

A 1.75

A1 0.10 0.25

0046067

millimeters

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and packing information

Table 11. SO-8 mechanical data (continued)

millimeters

Symbol

Min Typ Max

A2 1.25

b 0.28 0.48

c 0.17 0.23

(1)

4.80 4.90 5.00

D

E 5.80 6.00 6.20

(2)

E1

3.80 3.90 4.00

e 1.27

h 0.25 0.50

L 0.40 1.27

L1 1.04

k 0° 8°

ccc 0.10

1. Dimension “D” does not include mold flash, protrusions or gate burrs. Mold flash, protrusions or gate burrs

shall not exceed 0.15 mm in total (both side).

2. Dimension “E1” does not include interlead flash or protrusions. Interlead flash or protrusions shall not

exceed 0.25 mm per side.

Figure 51. SO-8 package dimensions

0016023 D

Doc ID 7383 Rev 3 31/37

Package and packing information VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

5.5 SOT-223 packing information

Figure 52. SOT-223 tape and reel shipment (suffix “TR”)

REEL DIMENSIONS

Base Q.ty 1000

Bulk Q.ty 1000

A (max) 330

B (min) 1.5

C (± 0.2) 13

F 20.2

G (+ 2 / -0) 12.4

N (min) 60

T (max) 18.4

TAPE DIMENSIONS

According to Electronic Industries Association

(EIA) Standard 481 rev. A, Feb. 1986

Tape width W 12

Tape Hole Spacing P0 (± 0.1) 4

Component Spacing P 8

Hole Diameter D (± 0.1/-0) 1.5

Hole Diameter D1 (min) 1.5

Hole Position F (± 0.05) 5.5

Compartment Depth K (max) 4.5

Hole Spacing P1 (± 0.1) 2

All dimensions are in mm.

32/37 Doc ID 7383 Rev 3

Top

cover

tape

End

500mm min

Empty components pockets

saled with cover tape.

User direction of feed

Start

No componentsNo components Components

500mm min

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and packing information

5.6 SO-8 packing information

Figure 53. SO-8 tube shipment (no suffix)

B

C

Base Q.ty 100

Bulk Q.ty 2000

A

Tube length (± 0.5) 532

A 3.2

B 6

C (± 0.1) 0.6

Figure 54. SO-8 tape and reel shipment (suffix “TR”)

REEL DIMENSIONS

Base Q.ty 2500

Bulk Q.ty 2500

A (max) 330

B (min) 1.5

C (± 0.2) 13

F 20.2

G (+ 2 / -0) 12.4

N (min) 60

T (max) 18.4

All dimensions are in mm.

TAPE DIMENSIONS

According to Electronic Industries Association

(EIA) Standard 481 rev. A, Feb 1986

Tape width W 12

Tape Hole Spacing P0 (± 0.1) 4

Component Spacing P 8

Hole Diameter D (± 0.1/-0) 1.5

Hole Diameter D1 (min) 1.5

Hole Position F (± 0.05) 5.5

Compartment Depth K (max) 4.5

Hole Spacing P1 (± 0.1) 2

Top

cover

tape

End

500mm min

Empty components pockets

saled with cover tape.

User direction of feed

Start

No componentsNo components Components

500mm min

All dimensions are in mm.

Doc ID 7383 Rev 3 33/37

Package and packing information VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

5.7 DPAK packing information

Figure 55. DPAK footprint and tube shipment (no suffix)

A

B

6.7

6.7 3.01.8 1.6

2.3

2.3

Figure 56. DPAK tape and reel shipment (suffix “TR”)

C

Base Q.ty 75

Bulk Q.ty 3000

Tube length (± 0.5) 532

A 6

B 21.3

C (± 0.1) 0.6

REEL DIMENSIONS

Base Q.ty 2500

Bulk Q.ty 2500

A (max) 330

B (min) 1.5

C (± 0.2) 13

F 20.2

G (+ 2 / -0) 16.4

N (min) 60

T (max) 22.4

TAPE DIMENSIONS

According to Electronic Industries Association

(EIA) Standard 481 rev. A, Feb 1986

Tape width W 16

Tape Hole Spacing P0 (± 0.1) 4

Component Spacing P 8

Hole Diameter D (± 0.1/-0) 1.5

Hole Diameter D1 (min) 1.5

Hole Position F (± 0.05) 7.5

Compartment Depth K (max) 6.5

Hole Spacing P1 (± 0.1) 2

All dimensions are in mm.

End

Start

Top

cover

tape

500mm min

Empty components pockets

saled with cover tape.

User direction of feed

No componentsNo components Components

500mm min

34/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1 Package and packing information

5.8 IPAK packing information

Figure 57. IPAK tube shipment (no suffix)

A

C

Base Q.ty 75

Bulk Q.ty 3000

Tube length (± 0.5) 532

B

A 6

B 21.3

C (± 0.1) 0.6

All dimensions are in mm.

Doc ID 7383 Rev 3 35/37

Revision history VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

6 Revision history

Table 12. Document revision history

Date Revision Changes

01-Feb-2003 1 Initial Release

Added Table 1: Device summary on page 1 and Section 4:

28-Apr-2009 2

10-Sep-2010 3 Updated Table 4: Electrical characteristics

Package and PCB thermal data on page 20.

Updated Section 5: Package and packing information on

page 27.

36/37 Doc ID 7383 Rev 3

VNN7NV04, VNS7NV04, VND7NV04, VND7NV04-1

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 7383 Rev 3 37/37

Loading...

Loading...