STODD01

Monolithic power management for high definition ODD with true

shut-down, reset, and programmable step-up voltage

Features

■ 1.2 MHz DC-DC current mode PWM converter

■ Dual step-down of up to 800 mA

■ Single step-up of up to 700 mA

■ 2 % DC output voltage tolerance for step-down

■ 3 % DC output voltage tolerance for step-up

■ Programmable step-up output voltage by S-

WIRE

■

Synchronous rectification

■ Power save mode at light load for step-down

■ Typical efficiency: > 90 %

■ Internal soft start with controlled inrush current

■ Reset function

■ Enable function for step-up

■ True cut-off function for step-up

■ Low switching quiescent current: max 2.2 mA

overtemperature range

■ Uses tiny capacitors and inductors

■ Available in QFN16 (4 x 4 mm.)

Description

The STODD01 is a complete power management

for Blu-Ray, based on high density optical storage

devices. It integrates two step-down converters

and one step-up. The step-down converters are

optimized for powering low-voltage digital core, up

to 0.8 A, in ODD applications and, generally, to

replace the high current linear solution when

power dissipation may cause a high heating of the

application environment. The step-up provides

the necessary voltage to supply the blue laser in

mobile applications where only 5 V is available.

The output voltage is programmable by using the

Table 1. Device summary

S-Wire protocol, in the range of 6.5 V to 14 V, with

a current capability of 0.7 A. The integrated low

R

for N-channel and P-channel MOSFET

DSon

switches contribute to obtaining high efficiency.

The enable function for the step-up section, and

reset function for monitoring the input voltage,

make the device particularly suitable for optical

storage applications. The high switching

frequency (1.2 MHz typ.) allows the use of tiny

surface mounted components. Furthermore, a low

output ripple is achieved by the current mode

PWM topology and by the use of X7R or X5R low

ESR SMD ceramic capacitors. The device

includes soft-start control, thermal shutdown, and

peak current limit, to prevent damage due to

accidental overload. The STODD01 is packaged

in QFN16 (4 x 4 mm.).

QFN16L (4 x 4 mm.)

Part number Order code Marking Package

STODD01 STODD01PQR ODD01 QFN16 (4 x 4 mm.)

February 2011 Doc ID 17789 Rev 2 1/31

www.st.com

31

Contents STODD01

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Typical application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 S-wire protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.1 Brief overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.2 Enable pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.3 TX pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.4 Reset function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.5 Overtemperature protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.6 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.2 Programming the output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.3 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.4 Input and output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.5 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10 Recommended PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2/31 Doc ID 17789 Rev 2

STODD01 Block diagram

1 Block diagram

Figure 1. STODD01 block diagram

SW1

SW1

EN

EN

V

V

IN_A

IN_A

V

V

IN_P

IN_P

Reset

Reset

TX

TX

S-Wire

S-Wire

Reset

Reset

Step-Up 700mA

Step-Up 700mA

ch1

ch1

Step-Down

Step-Down

800mA

800mA

ch2

ch2

Step-Down

Step-Down

800mA

800mA

ch3

ch3

Out1

Out1

FB1

FB1

SW2

SW2

FB2

FB2

SW3

SW3

FB3

FB3

GND GND

GND GND

GND GND

GND GND

Doc ID 17789 Rev 2 3/31

Absolute maximum ratings STODD01

2 Absolute maximum ratings

Table 2. Absolute maximum ratings

Symbol Parameter Value Unit

V

V

IN_A

IN_P

Analog input voltage - 0.3 to 7 V

Power input voltage - 0.3 to 7 V

EN Enable voltage - 0.3 to 7 V

SW1 Switch pin for ch1 - 0.3 to 16 V

SW2,SW3 Switch pin for ch2 and ch3 - 0.3 to 7 V

OUT1 Output voltage for ch1 - 0.3 to 16 V

FB1 Feedback pin for ch1 - 0.3 to 2.5 V

FB2 Feedback pin for ch2 - 0.3 to 5 V

FB3 Feedback pin for ch3 - 0.3 to 2.5 V

Reset Reset pin - 0.3 to V

+ 0.3 V

IN

TX S-wire pin - 0.3 to 7 V

T

T

T

J

STG

JOP

Maximum junction temperature 150 °C

Storage temperature range - 65 to + 150 °C

Operating junction temperature range - 25 to + 125 °C

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these conditions is not implied.

Table 3. Thermal data

Symbol Parameter Value Unit

R

R

thJC

thJA

Thermal resistance junction-case 2.5 °C/W

Thermal resistance junction-ambient 46 °C/W

Table 4. ESD

Symbol Parameter Value Unit

HBM Human body model 2 kV

MM Machine model 200 V

4/31 Doc ID 17789 Rev 2

STODD01 Pin configuration

3 Pin configuration

Figure 2. Pin connection (top through view)

Table 5. Pin description

Pin n° Symbol Name and function

1 GND_P Power Ground pin (ch1)

2 FB1 Step-up feedback pin (ch1)

3V

IN_A

Power Supply for internal analog circuits

4 FB2 Step-down feedback pin (ch2)

5 GND_P Power Ground pin (ch2)

6 SW2 Step-down switching pin (ch2)

7V

IN_P

Power input voltage pin

8 SW3 Step-down switching pin (ch3)

9 GND_P Power Ground pin (ch3)

10 FB3 Step-down feedback pin (ch3)

11 GND_A Analog Ground pin

12 OUT1 Step-up output voltage

13 TX S-Wire pin. If connected to GND, V

FB1

=0.8V

(1)

14 SW1 Step-up switching pin (ch1)

Enable pin. Connecting the pin to a voltage higher than 1.2 V the step-up is

15 EN

ON.Connecting the pin to a voltage lower than 0.4 V the step-up is OFF,

resulting in no current flow to the load

16 Reset Reset pin. It is an open drain output

Exposed pad Ground and thermal dissipation pad

1. If this function is not used, the TX pin must be connected to GND

Doc ID 17789 Rev 2 5/31

Typical application STODD01

4 Typical application

Figure 3. Application circuit

L1

L1

C1

V

V

IN

IN

C3

C3

C2

C2

Reset

Reset

EN

EN

TX

TX

C1

R5

R5

V

V

IN_A

IN_A

V

V

IN_P

IN_P

Reset

Reset

EN

EN

TX

TX

GND

GND

SW1

SW1

STODD01

STODD01

GNDGND

GNDGND

Out1

Out1

FB1

FB1

SW2

SW2

FB2

FB2

SW3

SW3

FB3

FB3

GND

GND

R1

R1

R2

R2

L2

L2

L3

L3

R3

R3

R4

R4

C4

C4

C5

C5

C6

C6

V

V

V

V

V

V

OUT1

OUT1

OUT2

OUT2

OUT3

OUT3

Note: If the S-wire function is not used, the TX pin must be connected to GND.

Table 6. List of external components

Component Manufacturer Part number Value Size

C1, C2, C3 Murata GRM21BR61A106KE19L 10 µF 0805

C4, C5, C6 Murata GRM32ER61C226KE20L 22 µF 1210

L1 Coilcraft LPS6225-472MLB 4.7 µH 6 x 6 x 2.5

L2, L3 Coilcraft LPS4018-332MLB 3.3 µH 4.1 x 4.1 x 1.8

R1 33 kΩ (V

R2 3.3 kΩ 0603

R3 27 kΩ (V

R4 47 kΩ 0603

R5 100 kΩ

1. The components listed above refer to typical applications. Operation of the STODD01 is not limited to the choice of these

external components.

2. R1 and R2 are calculated according to the following formula:

R1 = R2 x (V

OUT1/VFB1

3. R3 and R4 are calculated according to the following formula:

R3 = R4 x (V

OUT3/VFB3

4. It is recommended to use resistors with values in the range of 100kΩ to 1MΩ.

- 1). It is recommended to use resistors with values in the range of 1 kΩ to 50 kΩ.

- 1). It is recommended to use resistors with values in the range of 1 kΩ to 50 kΩ.

(1)

OUT1

OUT3

= 8.8 V)

= 1.2 V)

(2)

(3)

(4)

0603

0603

0603

6/31 Doc ID 17789 Rev 2

STODD01 Electrical characteristics

5 Electrical characteristics

V

= V

IN_P

C

= 22 µF, L1 = 4.7 µH, L2 = L3 = 3.3 µH, TJ = - 25 to 125 °C (unless otherwise

4,5,6

specified; typical values are referred to T

Table 7. Electrical characteristics

Symbol Parameter Test conditions Min. Typ. Max. Unit

= VEN = 5 V, V

IN_A

OUT1

= 9 V, V

= 3.3 V, V

OUT2

= 25 °C).

J

OUT3

= 1.2 V, C

1,2,3

= 10 µF,

V

IN

I

SUPPLY

Step-up section

V

OUT

V

FB1

I

FB1

I

OUT1_OFF

(leak)

V

OVP Overvoltage protection

OUT1

R

DSon_N

R

DSon_P

I

SW1 (leak)

I

SW1 (LIM)

PWM f

s

D

MAX

ν Efficiency

V

EN_H

V

EN_L

I

EN

ΔV

/ΔVINLine transient response

OUT1

ΔV

/ΔI

OUT1

OUT

ΔV

/ΔVINStartup transient

OUT1

Input voltage range 4 6 V

V

> 1.2 V, No Switching 1.6 2.2 mA

Supply current

EN

V

< 0.4 V, No Switching 1.2 2.0 mA

EN

Output voltage range 6.5 14 V

Prog. feedback voltage

range

I

= 50 mA (prog. by S-Wire

OUT1

see Figure 9 and Ta b le 9 )

0.776 0.8 0.824 V

Feedback voltage accuracy -3 3 %

Feedback current V

= 0 V, VEN= 2 V 600 nA

FB1

Output leakage current VEN= 0 V, TJ = -25 to 80 °C 20 µA

(1)

V

= 0 V 14.8 15.3 15.8 V

FB1

Internal N-channel R

Internal P-channel R

DSon

DSon

Internal leakage current V

SW Current limitation V

Oscillator frequency to be measured on t

Max duty cycle on SW1 pin, V

Enable threshold high V

Enable threshold low V

Enable pin current V

Load transient response

(2)

I

=400 mA 300

SW1

I

=400 mA 300

SW1

SW1

OUT1

I

OUT1

I

OUT1

I

OUT1

I

OUT1

=4 to 6 V, I

IN

= 4 to 6 V, I

IN

= VIN = 5 V 2 µA

EN

VIN from 4 to 6 V, I

(2)

mA, t

V

(2)

= 5 V, I

IN

= 4 V, V

= 9.2 V 2.6 A

=50 mA, V

=700 mA, V

=100 mA, V

=700 mA, V

= tF => 30 µs, TJ=25 °C

R

= 2 V, VEN= 0 V 2 µA

FB1

= 0.7 V 70 90 %

FB1

OUT1

OUT1

OUT1

OUT1

OUT1

OUT1

OUT1

from 100 mA to

OUT1

500 mA, tR = tF => 5µs, TJ=25 °C

V

from 0 to 5 V, I

IN

OUT1

pin 0.75 1.2 1.5 MHz

SW1

=7 V 80 %

=7 V 90 %

=9 V 75 %

=9 V 90 %

= 50 mA 1.2

= 50 mA 0.4

= 500

-5 5

-5 5

= 500 mA -10 10

V

V

V

mΩ

V

%

OUT

%

OUT

%

OUT

Doc ID 17789 Rev 2 7/31

Electrical characteristics STODD01

Table 7. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

t

START

Startup time VEN from 0 to 5 V, I

Inrush current V

Step-down section

%V

%V

ΔV

I

ΔV

OUT2,3

FB

2

I

FB2

FB

3

I

FB3

I

OUT2,3

OUT_MIN

OUT2,3

PWM f

OUT2

OUT3

D

MAX

I

SWL

I

LKP2,3

I

LKN2,3

R

DSon-N

R

DSon-P

T2,3

Feedback voltage 3.23 3.3 3.37 V

FB2 Pin bias current V

Feedback voltage 0.784 0.8 0.816 mV

FB3 Pin bias current V

Output current

Minimum output current 0 mA

Reference load regulation 10 mA < I

PWM Switching frequency I

S

/ΔVINLine regulation 4 V < V

/ΔVINLine regulation 4 V < V

Maximum duty cycle V

Switching current limitation 1.5 A

PMOS Leakage current

NMOS Leakage current

NMOS Switch on resistance ISW = 250 mA 0.2 0.4 W

PMOS Switch on resistance ISW = 250 mA 0.3 0.5 W

/ΔI

OU

Load transient response

ν Efficiency V

ν Efficiency V

Reset section

OUT3

OUT2

(3)

= 1.2 V

= 3.3 V

=100 mA 500 µs

OUT1

=9.25 V, I

OUT

= 3.5 V 15 20 µA

FB2

= 1 V 600 nA

FB3

=100 mA 1.3 A

OUT

VIN = 4 to 6 V 700 800 mA

< 0.8 A 5.5 15 mV

OUT2,3

= 0.3 A 1.2 MHz

OUT2,3

< 6 V 0.032

IN

< 6 V 0.15

IN

(2)

= 3.0 V, V

FB2

= 3.5 V, V

V

FB2

= GND, TJ=- 25 to 80 °C

V

SW2,3

= 3.5 V, V

V

FB2

V

= 5 V, TJ =- 25 to 80 °C

SW2,3

100 mA < I

=> 100 ns, TJ = 25 °C

t

F

I

OUT3

I

OUT3

I

OUT2

I

OUT2

OUT2,3

= 100 mA 65

= 800 mA 80

= 100 mA 75

= 800 mA 90

= 0.7 V

FB3

= 0.9 V,

FB3

= 0.9 V,

FB3

< 500 mA, tR =

85 94 %

0.1 µA

0.1 µA

-5 +5

V

V

V

%

OUT

/V

%

OUT

/V

%

OUT

%

%

IN

IN

t

V

DEL

R_TH

Delay time TJ = 25 °C 100 ms

V

Rising (see Figure 12 and

IN

Figure 29) (measured on input

voltage pin)

Reset threshold

V

Falling (see Figure 12 and

IN

V

R_TL

Figure 29) (measured on input

voltage pin)

8/31 Doc ID 17789 Rev 2

4.3 4.4

V

4.1 4.2

STODD01 Electrical characteristics

Table 7. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

V

RL

I

RH

Reset output voltage low

Reset leakage current

V

output

V

°C

Thermal section

T

SHDN

T

HYS

1. If V

OUT1

2. Guaranteed by design, but not tested in production.

3. V

= 90 % of nominal value

OUT

Thermal shutdown

Thermal shutdown

hysteresis

> OVP voltage the device stops to switch.

(2)

(2)

=4 V, I

IN

=5 V, V

IN

=6 mA open drain

SINK

=5 V, TJ=-25 to 80

RES

0.4 V

5 200 nA

130 150 °C

15 °C

Doc ID 17789 Rev 2 9/31

S-wire protocol STODD01

6 S-wire protocol

Table 8. Timing

Parameter Symbol Min. Typ. Max. Unit

S-Wire signal start (see Figure 5, 6, 7, 8)t

S-Wire signal stop (see Figure 5, 6, 7, 8)t

S-Wire signal off (see Figure 5, 6, 7, 8)t

S-Wire high (see Figure 5, 6, 7, 8)t

S-Wire low (see Figure 5, 6, 7, 8)t

S-Wire rising time (see Figure 4)t

S-Wire falling time (see Figure 4)t

FB Voltage delay t

S-Wire threshold high (see Figure 4)V

S-Wire threshold low (see Figure 4)V

SW_START

SW_STOP

SW_OFF

SW_H

SW_L

SW_R

SW_F

SW_DELAY

SW_TH

SW_TL

300 500 µs

300 500 µs

270 µs

25 50 µs

25 50 µs

200 ns

200 ns

20 µs

1.6 V

00.4V

IN

Note: These are recommended values for proper operation of the S-wire interface.

The S-wire input pin is able to detect pulses also outside these ranges. Consequently, care

must be taken to avoid noise injected into the S-wire pin.

Figure 4. S-wire pulse thresholds

AM07818v1

AM07818v1

V

V

V

SW_TH

SW_TH

V

V

SW_TL

SW_TL

90%

90%

10%

10%

T

T

SW_R

SW_R

10/31 Doc ID 17789 Rev 2

T

T

SW_F

SW_F

STODD01 S-wire protocol

Figure 5. S-wire protocol timing diagrams (case a)

5 V

5 V

V

V

V

V

IN

IN

IN

IN

GND

GND

5 V

5 V

EN

EN

EN

EN

GND

GND

-

-

S-Wire

S-Wire

S-Wire

GND

GND

GND

GND

GND

GND

S-Wire

V

V

V

V

FB1

FB1

FB1

FB1

V

V

V

V

OUT1

OUT1

OUT1

OUT1

t

t

SW_START

SW_START

0.8 V

0.8 V

9 V

9 V

SET BY RESISTOR DIVIDER

SET BY RESISTOR DIVIDER

t

t

t

t

SW_H

SW_H

2 3 41

2 3 41

2 3 41

2 3 41

t

t

t

t

SW_L

SW_L

t

t

SW_STOP

SW_STOP

0.86 V

0.86 V

9.675 V

9.675 V

0.86 V

0.86 V

9.675 V

9.675 V

t

t

SW_START

SW_START

Figure 6. S-wire protocol timing diagrams (case b)

5V

5V

5V

V

V

V

IN

IN

IN

GND

GND

GND

EN

EN

EN

GND

GND

GND

S-Wire

S-Wire

GND

GND

GND

GND

GND

GND

GND

GND

GND

S-Wire

V

V

V

FB1

FB1

FB1

V

V

V

OUT1

OUT1

OUT1

t

t

t

SW_START

SW_START

SW_START

t

t

t

SW_H

SW_H

SW_H

2 3 41

2 3 41

22 33 4411

t

t

t

SW_L

SW_L

SW_L

t

t

t

SW_STOP

SW_STOP

SW_STOP

t

t

SW_DELAY

SW_DELAY

5V

5V

5V

0.86V

0.86V

0.86V

9.675V

9.675V

9.675V

t

t

SW_START

SW_START

0.86V

0.86V

0.86V

9.675V

9.675V

9.675V

t

t

t

SW_START

SW_START

SW_START

Doc ID 17789 Rev 2 11/31

S-wire protocol STODD01

Figure 7. S-wire protocol timing diagrams (case c)

5V

5V

5V

5V

t

t

SW_START

SW_START

t

t

SW_H

0.8V

0.8V

9V

9V

SET BY RESISTOR DIVIDER

SET BY RESISTOR DIVIDER

SW_H

2 3 41

22 33 4411

t

t

SW_L

SW_L

t

t

SW_STOP

SW_STOP

0.86V

0.86V

9.675V

9.675V

21

2211

t

t

SW_STOP

SW_STOP

0.83V

0.83V

9.338V

9.338V

t

t

SW_OFF

SW_OFF

0.8V

0.8V

9V

9V

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

V

V

IN

IN

EN

EN

S-Wire

S-Wire

V

V

FB1

FB1

V

V

OUT1

OUT1

t

t

t

SW_START

SW_START

Figure 8. S-wire protocol timing diagrams (case d)

5V

5V

V

V

IN

IN

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

EN

EN

S-Wire

S-Wire

V

V

FB1

FB1

V

V

OUT1

OUT1

5V

5V

t

t

SW_START

SW_START

t

t

SW_H

0.8V

0.8V

9V

9V

SET BY RESISTOR DIVIDER

SET BY RESISTOR DIVIDER

SW_H

2 3 41

22 33 4411

t

t

SW_L

SW_L

t

t

t

SW_STOP

SW_STOP

SW_DELAY

SW_DELAY

0.86V

0.86V

9.675V

9.675V

t

t

SW_OFF

SW_OFF

0.8V

0.8V

0.9V

0.9V

t

t

SW_START

SW_START

1

11

2

22

t

t

SW_STOP

SW_STOP

0.83V

0.83V

9.338V

9.338V

t

t

Sw_START

Sw_START

t

t

SW_DELAY

SW_DELAY

12/31 Doc ID 17789 Rev 2

STODD01 S-wire protocol

Table 9. Feedback one voltage level

S-Wire pulses V

(V) S-Wire pulses V

FB1

(V) S-Wire pulses V

FB1

FB1

0 (Default value) 0.800 11 0.965 22 1.130

1 0.815 12 0.980 23 1.145

2 0.830 13 0.995 24 1.160

3 0.845 14 1.010 25 1.175

4 0.860 15 1.025 26 1.190

5 0.875 16 1.040 27 1.205

6 0.890 17 1.055 28 1.220

7 0.905 18 1.070 29 1.235

8 0.920 19 1.085 30 1.250

9 0.935 20 1.100

10 0.950 21 1.115

Figure 9. Single wire programming

S-Wire

S-Wire

V

=0.8V (default value)

V

=0.8V (default value)

FB1

FB1

(V)

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

S-Wire

V

=0.8V

V

=0.8V

FB1

FB1

V

=0.815V

V

1

1

12

12

1

1

1234

1234

12345

12345

12345

12345

12345

12345

12345 26 28 29 3027

12345 26 28 29 3027

=0.815V

FB1

FB1

V

=0.830V

V

=0.830V

FB1

FB1

V

=0.845V

V

3

3

2

2

=0.845V

FB1

FB1

V

V

FB1

FB1

=0.860V

=0.860V

V

=0.875V

V

=0.875V

FB1

FB1

26 2827

26 2827

26 28 2927

26 28 2927

V

V

FB1

FB1

V

V

=1.22V

=1.22V

=1.235V

=1.235V

FB1

FB1

V

V

FB1

FB1

=1.25V

=1.25V

Doc ID 17789 Rev 2 13/31

Detailed description STODD01

7 Detailed description

7.1 Brief overview

The STODD01 is a complete high efficiency switching power management. Inside it has a

step-up converter with a current capability up to 0.7 A and two step-down converters with a

current capability up to 0.8 A.

The controller uses an average current mode technique in order to obtain good stability in all

application conditions.

The step-up converter, in order to guarantee the lowest switching ripple, operates in PWM

(pulse width modulation) in all load conditions.

Both step-down converters, in order to maintain good efficiency, operate in power-save

mode at light load. When the load increases, they automatically switch to PWM (pulse width

modulation) mode and the output voltage ripple is minimized.

The STODD01 is self protected against overtemperature and accidental short circuit in the

step down channel.

The soft-start function guarantees proper operation during startup.

7.2 Enable pin

The step-up section operates when the EN pin is set high. If the EN pin is set low the stepup turns OFF. In this condition the supply current is lower than 2 mA in the whole

temperature range, and it represents the consumption of the step-down section.

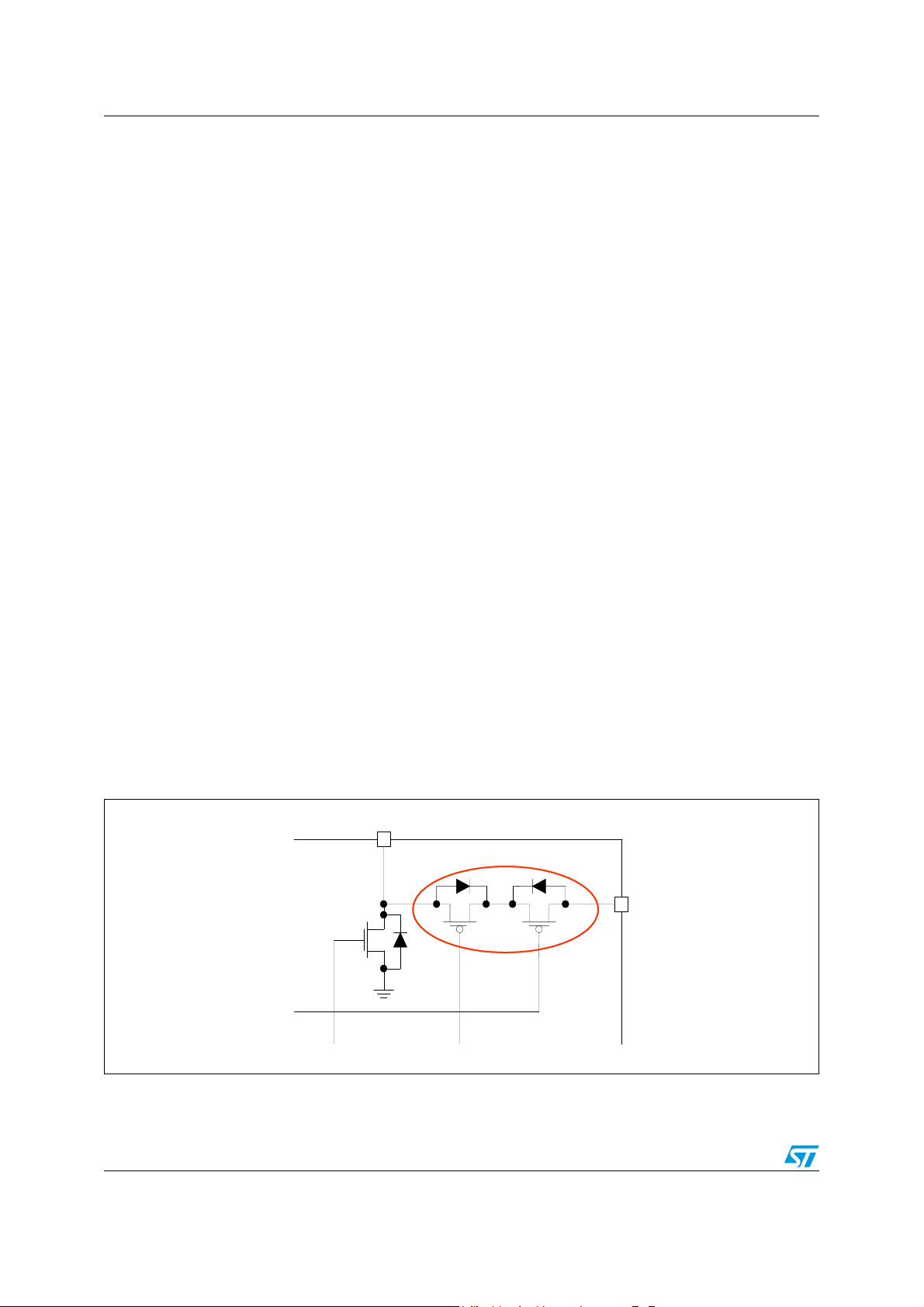

When the EN pin is low, thanks to at the true cut-off function, implemented using two Pchannel MOSFETs in a back-to-back configuration, as shown in Figure 10, the output

current is stopped. In order to control and reduce the in-rush current, the true cut-off Pchannel (P

Figure 10. True cut-off block

) manages the current during startup.

O

Ns

Ns

SW1

SW1

PGND

PGND

Ps

Ps

Po

Po

OUT1

OUT1

14/31 Doc ID 17789 Rev 2

STODD01 Detailed description

Figure 32 shows the in-rush current at enable transient. Initially, the C4 capacitor is

completely discharged and the current limitation is due only to the equivalent series resistor

of the inductor, the power MOSFET parasitic diode, and the cut-off MOSFETs’ R

DSon

. As

soon as the output voltage reaches the input voltage level, the device begins to switch and

the current is limited cycle by cycle.

The EN pin does not have an internal pull-up, which means that the enable pin cannot be

left floating.

If the enable function is not used, the EN pin must be connected to V

7.3 TX pin

The device implements an S-wire bus communication, which uses one control signal coming

from the microprocessor to program the step-up STODD01 output voltage (see Figure 11).

S-wire protocol allows the feedback voltage of the step-up section to be changed from 0.8 to

1.25 V, with steps of 15 mV (see Ta b le 9 ).

Figure 11. S-Wire connection

µP

GND

GND

Reset

EN

TX

Reset

EN

STODD01

TX

GND

GND

.

IN

This feature allows complete and easy control of the laser diode power during read and

write operation.

If this function is not used, the TX pin must be connected to GND.

7.4 Reset function

This flag shows that input voltage is in the correct range.

A comparator senses the input voltage. When it is higher than V

high impedance, with a delay of 100 ms (typ.). If it is below V

impedance (see Figure 12).

, the reset pin goes to

R_TH

, the reset pin goes to low

R_TL

Doc ID 17789 Rev 2 15/31

Detailed description STODD01

Figure 12. Reset function

V

V

R_TH

V

V

IN

IN

Reset

Reset

R_TH

t

t

DEL

DEL

V

V

R_TL

R_TL

The use of the reset function requires an external pull-up resistor which must be connected

between the reset pin and V

or any V

IN

voltage lower than 5 V. A pull-up resistor for reset

OUT

in the range of 100 kΩ to 1 MΩ is recommended.

If the reset function is not used, the reset pin may remain floating on the board.

7.5 Overtemperature protection

An internal temperature sensor continuously monitors the IC junction temperature. If the IC

temperature exceeds 150 °C (typ.) the device stops operating. As soon as the temperature

falls below 135 °C (typ.) normal operation is restored.

7.6 Overvoltage protection

The device provides overvoltage protection for monitoring the step-up output voltage.

If the sensed voltage on ch1 output exceeds 15.3 V (typ.) the step-up channel stops

switching. As soon as the output capacitor is discharged and the sensed voltage is below

14.8 V, it re-starts to switch (see Figure 13).

Figure 13. OVP function

OUTPU T Voltage

15.3V

14.8V

OVP sign al

Switching Switching

No Switching

16/31 Doc ID 17789 Rev 2

STODD01 Typical performance characteristics

8 Typical performance characteristics

C

= 10 µF, C

1,2,3

Figure 14. Supply current vs. temperature Figure 15. Feedback voltage vs. temperature

= 22 µF, L1 = 4.7 µH, L2 = L3 = 3.3 µH.

4,5,6

2.5

2

1.5

1

Supply Current [mA]

0.5

0

-40 -20 0 20 40 60 80 100 120 140

V

=5V, VEN<=0.4V, No Switching

IN_A=VIN_P

TEMPERATURE [°C]

Figure 16. Feedback voltage vs. temperature Figure 17. Feedback voltage vs. temperature

3.32

3.31

3.3

[V]

FB2

V

3.29

3.28

3.27

-40 -20 0 20 4 0 60 80 100 120 140

V

= V

= 5V, V

= 5V, I

IN_A

IN_P

EN

OUT2

= no load

TEMPERATURE [°C]

0.83

0.82

0.81

[V]

0.8

FB1

V

0.79

V

= V

= 5V, V

= 5V, I

IN_A

IN_P

0.78

0.77

-40 -20 0 20 40 60 80 100 120 140

EN

OUT1

= 50mA

TEMPERATURE [°C]

0.83

0.82

0.81

[V]

0.8

FB3

V

0.79

0.78

0.77

-40 -20 0 20 40 60 80 100 120 140

V

= V

= 5V, V

= 5V, I

IN_A

IN_P

EN

OUT3

= no load

TEMPERATURE [°C]

Figure 18. OVP vs. temperature Figure 19. True shutdown voltage vs.

15.5

15.3

15.1

OVP [V ]

14.9

14.7

14.5

-40 -20 0 20 40 60 80 100 120 140

V

= V

= 5V, V

= 5V, V

IN_A

IN_P

EN

FB1

= GND

TEMPERATURE [°C]

Doc ID 17789 Rev 2 17/31

[V]

V

OUT1_O FF

0.01

0.008

0.006

0.004

0.002

0

-0.002

temperature

V

= V

= 5V, V

IN_A

IN_P

-40-20 0 20 406080100

EN

= 0V, I

TEMPERATURE [°C]

OUT1

= no load

Typical performance characteristics STODD01

Figure 20. Output leakage current vs.

0.6

0.5

0.4

[µA]

0.3

0.2

LEAK_VOUT

I

0.1

0

-0.1

-40 -20 0 20 40 60 80 100

temperature

V

= V

IN_A

IN_P

= 5V, V

= 0V, V

EN

TEMPERATURE [°C]

OUT1

= GND

Figure 22. SW current limitation vs.

1.8

1.6

1.4

1.2

1

0.8

ISWL2 [A]

0.6

0.4

0.2

0

-40 -20 0 20 40 60 80 100 12 0 140

temperature

V

= V

= 6V, V

IN_A

IN_P

V

= 3.25V (measured @V

OUT2

= 6V,

EN

OUT2

= V

TEMPERATURE [°C]

OUT2_nom

- 10%)

Figure 21. SW current limitation vs.

temperature

3

2.9

2.8

2.7

[A]

2.6

SWL1

I

2.5

2.4

2.3

2.2

V

= V

= 5V, V

IN_A

IN_P

V

= 9.25V (measured @V

OUT1

-40-20 0 20406080100120140

EN

= 5V,

OUT1

= V

OUT1_nom

- 10%)

TEMPERATURE [°C]

Figure 23. SW current limitation vs.

temperature

1.8

1.6

1.4

1.2

1

0.8

ISWL3 [A]

0.6

0.4

0.2

V

= V

= 6V, V

IN_A

IN_P

= 1.2V (measured @V

V

OUT3

0

-40 -20 0 20 40 60 8 0 100 120 140

EN

= 6V,

OUT3

= V

OUT3_nom

- 10%)

TEMPERATURE [°C]

Figure 24. Oscillator frequency vs.

1.5

1.4

1.3

1.2

1.1

Frequency [MHz]

1

0.9

0.8

-40 -20 0 20 40 60 80 100 120 140

temperature

V

= V

IN_A

IN_P

= 5V, V

EN

= 1.2V

Figure 25. Enable vs. temperature

2

1.8

1.6

1.4

1.2

1

0.8

0.6

Enable Threshold (V)

0.4

0.2

0

-40 -20 0 20 40 60 80 100 120 140

TEMPERATURE [°C]

18/31 Doc ID 17789 Rev 2

V

= V

IN_A

IN_P

= 6V, V

OUT1

= 7V, I

TEMPERATURE [°C]

OUT1

= 50mA

VEN_H

VEN_TH

STODD01 Typical performance characteristics

Figure 26. Enable vs. temperature Figure 27. Efficiency step-up vs. output

current

2

1.8

1.6

1.4

1.2

1

0.8

0.6

Enable Threshold (V)

0.4

0.2

0

-40 -20 0 20 40 60 80 100 120 140

V

= V

IN_A

IN_P

= 4V, V

OUT1

= 7V, I

OUT1

= 50mA

VEN_H

VEN_TH

TEMPERATURE [°C]

Figure 28. Efficiency step-down vs. output

100

90

80

70

60

50

40

Efficiency [%]

30

20

10

0

10 100 1000

current

V

IN_A

= V

IN_P

Iout [mA]

= 5V, V

Vout=3. 3V

Vout=1. 2V

= 5V

EN

100

90

80

70

60

50

40

Effici ency [%]

30

20

10

0

10 100 1000

V

= V

= 5V, V

IN_A

IN_P

Iout [mA]

EN

= 1.2V

Vout=7V

Vout=9. 2V

Figure 29. Reset threshold vs. temperature

4.42

4.37

4.32

4.27

4.22

Reset Threshold (V)

4.17

4.12

-40 -20 0 20 40 60 80 100 120 140

TEMPERATURE [°C]

VR_TH

VR_TL

All efficiencies are relative to one channel, the other channel

is at no-load.

Figure 30. Startup transient Figure 31. Enable transient

V

V

= V

OUT1

OUT2

OUT3

IN_A

= V

EN

V

IN_A

I

OUT1

= V

= V

IN_P

= 500mA, t

from 0 to 5V, V

EN

= 100µs

RISE

OUT1

= 9.2V,

IN_P

V

V

V

EN

V

OUT1

V

OUT2

V

= V

= 5V, V

IN_A

V

OUT3

V

OUT1

IN_P

= 9.2V, I

OUT1

= 100mA

Doc ID 17789 Rev 2 19/31

from 0 to 5V ,

EN

Typical performance characteristics STODD01

Figure 32. Inrush current Figure 33. S-Wire protocol

V

EN

V

EN

5PULSESSEQUE NCE

DEFAULTVALU E

V

IN_A

V

OUT1

V

= V

= 5V, V

OUT1

from 0 to 5V,

EN

= 100mA

IN_A

V

IN

I

IN

V

OUT1

IN_P

= 9.2V, I

= V

IN_P

= 5V, V

30PULSESSEQUE NCE

from 0 to 5V

EN

20/31 Doc ID 17789 Rev 2

STODD01 Application information

9 Application information

9.1 Introduction

The following is some technical information for estimating the typical external components

characteristics using standard literature equations. Nevertheless, it is strongly

recommended to validate the external components suitability to the application

requirements, thoroughly testing any solution at bench level on a real evaluation circuit.

9.2 Programming the output voltage

The output voltage for the step-up (ch1) can be adjusted from 6.5 V up to 14 V by

connecting a resistor divider between the V

divider must be connected to the FB1 pin, as shown in Figure 3.

The resistor divider should be chosen in accordance with the following equation:

Equation 1

and the GND, the middle point of the

OUT1

1R

⎛

1VV

⎜

1FB1OUT

⎝

It is recommended to use a resistor with a value in the range of 1 kΩ to 50 kΩ. Lower values

can also be suitable, but increase current consumption.

For ch2 the device integrates the resistor divider needed to set the correct output voltage.

This allows 2 external components to be saved. The FB2 pin must be connected directly to

V

.

OUT2

The output voltage for Ch3 can be adjusted from 0.8 V up to 85 % of the input voltage value

by connecting a resistor divider between V

must be connected to FB3 pin, as shown in Figure 3.

The resistor divider must be chosen according to the following equation:

Equation 2

⎛

⎜

3FB3OUT

⎝

Using a resistor with a value in the range of 1 kΩ to 50 kΩ is recommended. Lower values

are also suitable, but increase current consumption.

⎞

+×=

⎟

2R

⎠

and GND, the middle point of the divider

OUT3

3R

1VV

⎞

+×=

⎟

4R

⎠

9.3 Inductor selection

The inductor is the key passive component for switching converters.

The inductor selection must take the boundary conditions in which the converter works into

consideration, the maximum input voltage for the buck and the minimum input voltage for the

boost.

Doc ID 17789 Rev 2 21/31

Application information STODD01

The critical inductance values can then be obtained according to the following formulas:

for the step-down

Equation 3

−×

=

L

MIN

)VV(V

OUTMAX_INOUT

Δ××

IFV

LSWMAX_IN

and for the step-up

Equation 4

L

=

MIN

−×

Δ××

)VV(V

MIN_INOUTMIN_IN

IFV

LSWOUT

where:

F

: switching frequency

SW

ΔI

= the peak-to-peak inductor ripple current. As a rule of thumb, the peak-to-peak ripple

L

can be set at 20 % - 40 % of the output current for the step-down and can be set at 20 % 40 % of the input current for the step-up.

The peak current of the inductor can be calculated as:

Equation 5

)VV(V

−×

)8.0/I(I

−

OUTDOWN_STEPPEAK

+=

OUTMAX_INOUT

LFV2

×××

SWMAX_IN

Equation 6

IV

×

I

−

=

UP_STEPPEAK

OUTOUT

V

×η

+

MIN_IN

−×

MIN_INOUTMIN_IN

LFV2

×××

SWOUT

In addition to the inductance value, in order to avoid saturation, the maximum saturation

current of the inductor must be higher than that of the I

9.4 Input and output capacitor selection

It is recommended to use ceramic capacitors with X5R or X7R dielectric and low ESR as

input and output capacitors, in order to filter any disturbance present in the input line and to

obtain stable operation. The output capacitor is very important for satisfying the output

voltage ripple requirement.

The output voltage ripple (V

OUT_RIPPLE

can be calculated:

22/31 Doc ID 17789 Rev 2

), in continuous mode, for the step-down channel,

)VV(V

PEAK

.

STODD01 Application information

(

Equation 7

⎡

+×Δ=

ESRIV

⎢

LRIPPLE_OUT

⎣

where Δ I

is the ripple current and FSW is the switching frequency.

L

The output voltage ripple (V

1

××

OUT_RIPPLE

Equation 8

⎡

+×=

ESRIV

⎢

OUTRIPPLE_OUT

⎣

where F

is the switching frequency.

SW

The use of ceramic capacitors with voltage ratings in the range higher than 1.5 times the

maximum input or output voltage is recommended.

9.5 Layout considerations

Due to the high switching frequency and peak current, the layout is an important design step

for all switching power supplies. Important parameters (efficiency, output voltage ripple,

switching noise immunity, etc.) can be affected if the PCB layout is not designed with close

attention to the following DC-DC general layout rules, such as:

● Short, wide traces must be implemented for mains current and for power ground paths.

The input capacitor must be placed as close as possible to the IC pins as well as the

inductor and output capacitor.

● The feedback pin (FB) connection to the external resistor divider is a high impedance

node, so interference can be minimized by placing the routing of the feedback node as

far as possible from the high current paths. To reduce pick up noise the resistor divider

must be placed very close to the device.

● A common ground node minimizes ground noise.

● The exposed pad of the package must be connected to the common ground node.

⎤

⎥

FC8

SWOUT

⎦

), in continuous mode, for the step-up channel, is:

⎤

)

−

VV

INOUT

⎥

××

FCV

SWOUTOUT

⎦

Moreover, the exposed pad ground connection must be properly designed in order to

facilitate the heat dissipation from the exposed pad to the ground layer using PCB vias, as

shown in the recommended PCB layout of Figure 34, 35, and 36.

Doc ID 17789 Rev 2 23/31

Recommended PCB layout STODD01

10 Recommended PCB layout

Figure 34. Component placement

Figure 35. Top layer routing

24/31 Doc ID 17789 Rev 2

STODD01 Recommended PCB layout

Figure 36. Bottom layer routing

Doc ID 17789 Rev 2 25/31

Package mechanical data STODD01

11 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK

specifications, grade definitions, and product status, are available at www.st.com.

ECOPACK is an ST trademark.

Table 10. QFN16 (4 x 4 mm.) mechanical data

Dim.

Min. Typ. Max.

A 0.80 0.90 1.00

A1 0.00 0.02 0.05

A3 0.20

b 0.25 0.30 0.35

D 3.90 4.00 4.10

D2 2.50 2.80

E 3.90 4.00 4.10

E2 2.50 2.80

e0.65

mm.

L 0.30 0.40 0.50

26/31 Doc ID 17789 Rev 2

STODD01 Package mechanical data

Figure 37. QFN16 (4 x 4 mm.) drawing

7571203_A

Doc ID 17789 Rev 2 27/31

Package mechanical data STODD01

Tape & reel QFNxx/DFNxx (4x4) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A 330 12.992

C 12.8 13.2 0.504 0.519

D 20.2 0.795

N 99 101 3.898 3.976

T 14.4 0.567

Ao 4.35 0.171

Bo 4.35 0.171

Ko 1.1 0.043

Po 4 0.157

P 8 0.315

28/31 Doc ID 17789 Rev 2

STODD01 Package mechanical data

Figure 38. QFN16 (4 x 4) footprint recommended data (dimension in mm.)

Doc ID 17789 Rev 2 29/31

Revision history STODD01

12 Revision history

Table 11. Document revision history

Date Revision Changes

03-Aug-2010 1 First release.

28-Feb-2011 2 Updated QFN16 mechanical data Table 10 on page 26, Figure 37 on page 27.

30/31 Doc ID 17789 Rev 2

STODD01

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 17789 Rev 2 31/31

Loading...

Loading...