Page 1

STM32G4A1xE

LQFP48 (7 x 7 mm)

LQFP64 (10 x 10 mm)

LQFP80 (12 x 12 mm)

UFBGA64

(5 x 5 mm)

UFQFPN32 (5 x 5 mm)

UFQFPN48 (7 x 7 mm)

WLCSP64

(Pitch 0.4)

FBGA

LQFP80 (14 x 14 mm)

LQFP100 (14 x 14 mm)

Arm® Cortex®-M4 32-bit MCU+FPU, 170 MHz / 213 DMIPS, up to

512 KB Flash, 112 KB SRAM, rich analog, math accelerator, AES

Datasheet - production data

Features

• Core: Arm® 32-bit Cortex®-M4 CPU with FPU,

Adaptive real-time accelerator (ART

Accelerator) allowing 0-wait-state execution

from Flash memory, frequency up to 170 MHz

with 213 DMIPS, MPU, DSP instructions

• Operating conditions:

–V

• Mathematical hardware accelerators

– CORDIC for trigonometric functions

– FMAC: filter mathematical accelerator

• Memories

– 512 Kbytes of Flash memory with ECC

– 96 Kbytes of SRAM, with hardware parity

– Routine booster: 16 Kbytes of SRAM on

– Quad-SPI memory interface

• Reset and supply management

– Power-on/power-down reset

– Programmable voltage detector (PVD)

– Low-power modes: sleep, stop, standby

–V

• Clock management

–4

– 32 kHz oscillator with calibration

– Internal 16 MHz RC with PLL option (± 1%)

–

• Up to 86 fast I/Os

– All mappable on external interrupt vectors

, V

DD

voltage range:

DDA

1.71 V to 3.6 V

acceleration

support, proprietary code readout

protection (PCROP), securable memory

area, 1 Kbyte OTP

check implemented on the first 32 Kbytes

instruction and data bus, with hardware

parity check (CCM SRAM)

(POR/PDR/BOR)

and shutdown

supply for RTC and backup registers

BAT

to 48 MHz crystal oscillator

Internal 32 kHz RC oscillator (± 5%)

– Several I/Os with 5 V tolerant capability

• Interconnect matrix

• 16-channel DMA controller

• 3 x ADCs 0.25 µs (up to 36 channels).

Resolution up to 16-bit with hardware

oversampling, 0 to 3.6 V conversion range

• 4 x 12-bit DAC channels

– 2 x buffered external channels 1 MSPS

– 2 x unbuffered internal channels 15 MSPS

• 4 x ultra-fast rail-to-rail analog comparators

• 4 x operational amplifiers that can be used in

PGA mode, all terminals accessible

• Internal voltage reference buffer (VREFBUF)

supporting three output voltages (2.048 V,

2.5 V, 2.9 V)

• 15 timers:

– 1 x 32-bit timer and 2 x 16-bit timers with up

to four IC/OC/PWM or pulse counter and

quadrature (incremental) encoder input

– 3 x 16-bit 8-channel advanced motor

control timers, with up to 8 x PWM

channels, dead time generation and

emergency stop

– 1 x 16-bit timer with 2 x IC/OCs, one

OCN/PWM, dead time generation and

emergency stop

– 2 x 16-bit timers with IC/OC/OCN/PWM,

dead time generation and emergency stop

– 2 x watchdog timers (independent, window)

– 1 x SysTick timer: 24-bit downcounter

– 2 x 16-bit basic timers

November 2020 DS13268 Rev 2 1/200

This is information on a product in full production.

www.st.com

Page 2

STM32G4A1xE

– 1 x low-power timer

• Calendar RTC with alarm, periodic wakeup

from stop/standby

• Communication interfaces

– 2 x FDCAN controller supporting flexible

data rate

– 3 x I

2

C Fast mode plus (1 Mbit/s) with

20 mA current sink, SMBus/PMBus,

wakeup from stop

– 5 x USART/UARTs (ISO 7816 interface,

LIN, IrDA, modem control)

–1 x LPUART

– 3 x SPIs, 4 to 16 programmable bit frames,

2 x with multiplexed half duplex I

2

S

– 1 x SAI (serial audio interface)

– USB 2.0 full-speed interface with LPM and

BCD support

– IRTIM (infrared interface)

– USB Type-C™ /USB power delivery

controller (UCPD)

• True random number generator (RNG)

• CRC calculation unit, 96-bit unique ID

• AES: 128/256-bit key encryption hardware

accelerator

• Development support: serial wire debug

(SWD), JTAG, Embedded Trace Macrocell™

interface

Table 1. Device summary

Reference Part number

STM32G4A1xE STM32G4A1CE, STM32G4A1KE, STM32G4A1ME, STM32G4A1RE, STM32G4A1VE

2/200 DS13268 Rev 2

Page 3

STM32G4A1xE Contents

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Functional overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Arm® Cortex®-M4 core with FPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Adaptive real-time memory accelerator (ART accelerator) . . . . . . . . . . . 17

3.3 Memory protection unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Embedded Flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Embedded SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Multi-AHB bus matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.7 Boot modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.8 CORDIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.9 Filter mathematical accelerator (FMAC) . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.10 Cyclic redundancy check calculation unit (CRC) . . . . . . . . . . . . . . . . . . . 21

3.11 Power supply management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.11.1 Power supply schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.11.2 Power supply supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.11.3 Voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.11.4 Low-power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.11.5 Reset mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.11.6 VBAT operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.12 Interconnect matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.13 Clocks and startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.14 General-purpose inputs/outputs (GPIOs) . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.15 Direct memory access controller (DMA) . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.16 DMA request router (DMAMux) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.17 Interrupts and events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.17.1 Nested vectored interrupt controller (NVIC) . . . . . . . . . . . . . . . . . . . . . . 28

3.17.2 Extended interrupt/event controller (EXTI) . . . . . . . . . . . . . . . . . . . . . . 28

3.18 Analog-to-digital converter (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.18.1 Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DS13268 Rev 2 3/200

6

Page 4

Contents STM32G4A1xE

3.18.2 Internal voltage reference (VREFINT) . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.18.3 VBAT battery voltage monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.18.4 Operational amplifier internal output (OPAMPxINT): . . . . . . . . . . . . . . . 30

3.19 Digital to analog converter (DAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.20 Voltage reference buffer (VREFBUF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.21 Comparators (COMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.22 Operational amplifier (OPAMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.23 Random number generator (RNG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.24 Advanced encryption standard hardware accelerator (AES) . . . . . . . . . . 32

3.25 Timers and watchdogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.25.1 Advanced motor control timer (TIM1, TIM8, TIM20) . . . . . . . . . . . . . . . 34

3.25.2 General-purpose timers (TIM2, TIM3, TIM4, TIM15, TIM16,

TIM17) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.25.3 Basic timers (TIM6 and TIM7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.25.4 Low-power timer (LPTIM1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.25.5 Independent watchdog (IWDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.25.6 System window watchdog (WWDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.25.7 SysTick timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.26 Real-time clock (RTC) and backup registers . . . . . . . . . . . . . . . . . . . . . . 37

3.27 Tamper and backup registers (TAMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.28 Infrared transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.29 Inter-integrated circuit interface (I

2

C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.30 Universal synchronous/asynchronous receiver transmitter (USART) . . . 40

3.31 Low-power universal asynchronous receiver transmitter (LPUART) . . . . 41

3.32 Serial peripheral interface (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.33 Serial audio interfaces (SAI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.33.1 SAI peripheral supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.34 Controller area network (FDCAN1, FDCAN2) . . . . . . . . . . . . . . . . . . . . . 43

3.35 Universal serial bus (USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.36 USB Type-C™ / USB Power Delivery controller (UCPD) . . . . . . . . . . . . . 43

3.37 Clock recovery system (CRS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.38 Quad SPI memory interface (QUADSPI) . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.39 Development support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.39.1 Serial wire JTAG debug port (SWJ-DP) . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.39.2 Embedded trace macrocell™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4/200 DS13268 Rev 2

Page 5

STM32G4A1xE Contents

4 Pinouts and pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1 UFQFPN32 pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2 UFQFPN48 pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3 LQFP48 pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.4 WLCSP64 ballout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.5 LQFP64 pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.6 UFBGA64 ballout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.7 LQFP80 pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.8 LQFP100 pinout description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.9 Pin definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.10 Alternate functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1 Parameter conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1.1 Minimum and maximum values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1.2 Typical values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1.3 Typical curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1.4 Loading capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1.5 Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.1.6 Power supply scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.1.7 Current consumption measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.3.1 General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.3.2 Operating conditions at power-up / power-down . . . . . . . . . . . . . . . . . . 75

5.3.3 Embedded reset and power control block characteristics . . . . . . . . . . . 75

5.3.4 Embedded voltage reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.3.5 Supply current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.3.6 Wakeup time from low-power modes and voltage scaling

transition times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.3.7 External clock source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.3.8 Internal clock source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.3.9 PLL characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.3.10 Flash memory characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.3.11 EMC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.3.12 Electrical sensitivity characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

DS13268 Rev 2 5/200

6

Page 6

Contents STM32G4A1xE

5.3.13 I/O current injection characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.3.14 I/O port characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

5.3.15 NRST pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

5.3.16 Extended interrupt and event controller input (EXTI) characteristics . . 120

5.3.17 Analog switches booster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

5.3.18 Analog-to-digital converter characteristics . . . . . . . . . . . . . . . . . . . . . . 121

5.3.19 Digital-to-Analog converter characteristics . . . . . . . . . . . . . . . . . . . . . 136

5.3.20 Voltage reference buffer characteristics . . . . . . . . . . . . . . . . . . . . . . . 143

5.3.21 Comparator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

5.3.22 Operational amplifiers characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 147

5.3.23 Temperature sensor characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

5.3.24 V

5.3.25 Timer characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

5.3.26 Communication interfaces characteristics . . . . . . . . . . . . . . . . . . . . . . 153

5.3.27 QUADSPI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

5.3.28 UCPD characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

monitoring characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

BAT

6 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

6.1 UFQFPN32 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

6.2 UFQFPN48 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

6.3 LQFP48 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

6.4 WLCSP64 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

6.5 LQFP64 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

6.6 UFBGA64 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

6.7 LQFP80 12 x 12 mm package information . . . . . . . . . . . . . . . . . . . . . . . 185

6.8 LQFP80 14 x 14 mm package information . . . . . . . . . . . . . . . . . . . . . . . 188

6.9 LQFP100 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

6.10 Thermal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

6.10.1 Reference document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

6.10.2 Selecting the product temperature range . . . . . . . . . . . . . . . . . . . . . . 196

7 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

6/200 DS13268 Rev 2

Page 7

STM32G4A1xE List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2. STM32G4A1xE features and peripheral counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3. STM32G4A1xE peripherals interconnect matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 4. DMA implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 5. Temperature sensor calibration values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 6. Internal voltage reference calibration values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 7. Timer feature comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 8. I2C implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 9. USART/UART/LPUART features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 10. SAI implementation for the features implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 11. Legend/abbreviations used in the pinout table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 12. STM32G4A1xE pin definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 13. Alternate function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 14. Voltage characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 15. Current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 16. Thermal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 17. General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 18. Operating conditions at power-up / power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 19. Embedded reset and power control block characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 20. Embedded internal voltage reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 21. Current consumption in Run and Low-power run modes, code with data

processing running from Flash in single Bank, ART enable (Cache ON Prefetch OFF) . . 79

Table 22. Current consumption in Run and Low-power run modes,

code with data processing running from SRAM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 23. Typical current consumption in Run and Low-power run modes, with different codes

running from Flash, ART enable (Cache ON Prefetch OFF) . . . . . . . . . . . . . . . . . . . . . . . 83

Table 24. Typical current consumption in Run and Low-power run modes, with different codes

running from SRAM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 25. Typical current consumption in Run and Low-power run modes, with different codes

running from SRAM2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table 26. Typical current consumption in Run and Low-power run modes, with different codes

running from CCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 27. Current consumption in Sleep and Low-power sleep mode Flash ON . . . . . . . . . . . . . . . . 87

Table 28. Current consumption in low-power sleep modes, Flash in power-down . . . . . . . . . . . . . . . 88

Table 29. Current consumption in Stop 1 mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 30. Current consumption in Stop 0 mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 31. Current consumption in Standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 32. Current consumption in Shutdown mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 33. Current consumption in VBAT mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 34. Peripheral current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 35. Low-power mode wakeup timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 36. Regulator modes transition times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 37. Wakeup time using USART/LPUART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 38. High-speed external user clock characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 39. Low-speed external user clock characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Table 40. HSE oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 41. LSE oscillator characteristics (f

Table 42. HSI16 oscillator characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

= 32.768 kHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

LSE

DS13268 Rev 2 7/200

9

Page 8

List of tables STM32G4A1xE

Table 43. HSI48 oscillator characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 44. LSI oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 45. PLL characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 46. Flash memory characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 47. Flash memory endurance and data retention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 48. EMS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 49. EMI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 50. ESD absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 51. Electrical sensitivities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 52. I/O current injection susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 53. I/O static characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 54. Output voltage characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 55. I/O (except FT_c) AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 56. I/O FT_c AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 57. NRST pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 58. EXTI input characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Table 59. Analog switches booster characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Table 60. ADC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table 61. Maximum ADC RAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Table 62. ADC accuracy - limited test conditions 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Table 63. ADC accuracy - limited test conditions 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Table 64. ADC accuracy - limited test conditions 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Table 65. ADC accuracy (Multiple ADCs operation) - limited test conditions 1 . . . . . . . . . . . . . . . . 132

Table 66. ADC accuracy (Multiple ADCs operation) - limited test conditions 2 . . . . . . . . . . . . . . . . 133

Table 67. ADC accuracy (Multiple ADCs operation) - limited test conditions 3 . . . . . . . . . . . . . . . . 134

Table 68. DAC 1MSPS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Table 69. DAC 1MSPS accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Table 70. DAC 15MSPS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Table 71. DAC 15MSPS accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Table 72. VREFBUF characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Table 73. COMP characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Table 74. OPAMP characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Table 75. TS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Table 76. V

Table 77. V

monitoring characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

BAT

charging characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

BAT

Table 78. TIMx characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Table 79. IWDG min/max timeout period at 32 kHz (LSI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Table 80. WWDG min/max timeout value at 170 MHz (PCLK). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Table 81. Minimum I2CCLK frequency in all I2C modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Table 82. I2C analog filter characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Table 83. SPI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Table 84. I2S characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Table 85. SAI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Table 86. USB electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Table 87. USART electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Table 88. Quad SPI characteristics in SDR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Table 89. QUADSPI characteristics in DDR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Table 90. UCPD characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Table 91. UFQFPN32 - mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Table 92. UFQFPN48 - mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Table 93. LQFP48 - mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Table 94. WLCSP64 - Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

8/200 DS13268 Rev 2

Page 9

STM32G4A1xE List of tables

Table 95. WLCSP64 - Recommended PCB design rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Table 96. LQFP64 - mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Table 97. UFBGA64 – Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Table 98. UFBGA64 recommended PCB design rules (0.5 mm pitch BGA) . . . . . . . . . . . . . . . . . . 183

Table 99. LQFP80 12 x 12 mm - mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Table 100. LQFP80 14 x 14 mm mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Table 101. LQPF100 - mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Table 102. Package thermal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Table 103. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Table 104. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

DS13268 Rev 2 9/200

9

Page 10

List of figures STM32G4A1xE

List of figures

Figure 1. STM32G4A1xE block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2. Multi-AHB bus matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3. Voltage reference buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 4. Infrared transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 5. STM32G4A1xE UFQFPN32 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 6. STM32G4A1xE UFQFPN48 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 7. STM32G4A1xE LQFP48 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 8. STM32G4A1xE WLCSP64 ballout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 9. STM32G4A1xE LQFP64 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 10. STM32G4A1xE UFBGA64 ballout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 11. STM32G4A1xE LQFP80 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 12. STM32G4A1xE LQFP100 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 13. Pin loading conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 14. Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 15. Power supply scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 16. Current consumption measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 17. VREFINT versus temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 18. High-speed external clock source AC timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 19. Low-speed external clock source AC timing diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 20. Typical application with an 8 MHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 21. Typical application with a 32.768 kHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 22. HSI16 frequency versus temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 23. HSI48 frequency versus temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 24. I/O input characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 25. I/O AC characteristics definition

Figure 26. Recommended NRST pin protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 27. ADC accuracy characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 28. Typical connection diagram using the ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 29. 12-bit buffered / non-buffered DAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 30. VREFOUT_TEMP in case VRS = 00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 31. VREFOUT_TEMP in case VRS = 01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 32. VREFOUT_TEMP in case VRS = 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 33. OPAMP noise density @ 25°C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Figure 34. SPI timing diagram - slave mode and CPHA = 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 35. SPI timing diagram - slave mode and CPHA = 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Figure 36. SPI timing diagram - master mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Figure 37. SAI master timing waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 38. SAI slave timing waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 39. Quad SPI timing diagram - SDR mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 40. Quad SPI timing diagram - DDR mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 41. UFQFPN32 - outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 42. UFQFPN32 - recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 43. UFQFPN32 top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 44. UFQFPN48 - outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 45. UFQFPN48 - recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 46. UFQFPN48 top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Figure 47. LQFP48 - outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Figure 48. LQFP48 - recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10/200 DS13268 Rev 2

Page 11

STM32G4A1xE List of figures

Figure 49. LQFP48 top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Figure 50. WLCSP64 - outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Figure 51. WLCSP64 - recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Figure 52. WLCSP64 top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Figure 53. LQFP64 - outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Figure 54. LQFP64 - recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Figure 55. LQFP64 top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Figure 56. UFBGA64 outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Figure 57. UFBGA64 recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Figure 58. UFBGA64 top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Figure 59. LQFP80 12 x 12 mm - outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Figure 60. LQFP80 12 x 12 mm - recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Figure 61. LQFP80 12 x 12 mm top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 62. LQFP80 14 x 14 mm - outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Figure 63. LQFP80 14 x 14 mm- recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 64. LQFP80 14 x 14 mm - top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 65. LQFP100 - outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Figure 66. LQFP100 - recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Figure 67. LQFP100 top view example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

DS13268 Rev 2 11/200

11

Page 12

Introduction STM32G4A1xE

1 Introduction

This datasheet provides the ordering information and mechanical device characteristics of

the STM32G4A1xE microcontrollers.

This document should be read in conjunction with the reference manual RM0440

“STM32G4 Series advanced Arm

®

32-bit MCUs”. The reference manual is available from

the STMicroelectronics website www.st.com.

For information on the Arm

®(a)

Cortex®-M4 core, refer to the Cortex®-M4 technical

reference manual, available from the www.arm.com website.

a. Arm is a registered trademark of Arm Limited (or its subsidiaries) in the US and/or elsewhere.

12/200 DS13268 Rev 2

Page 13

STM32G4A1xE Description

2 Description

The STM32G4A1xE devices are based on the high-performance Arm® Cortex®-M4 32-bit

RISC core. They operate at a frequency of up to 170 MHz.

The Cortex-M4 core features a single-precision floating-point unit (FPU), which supports all

the Arm single-precision data-processing instructions and all the data types. It also

implements a full set of DSP (digital signal processing) instructions and a memory protection

unit (MPU) which enhances the application’s security.

These devices embed high-speed memories (512 Kbytes of Flash memory, and 112 Kbytes

of SRAM), a Quad SPI Flash memory interface, an extensive range of enhanced I/Os and

peripherals connected to two APB buses, two AHB buses and a 32-bit multi-AHB bus

matrix.

The devices also embed several protection mechanisms for embedded Flash memory and

SRAM: readout protection, write protection, securable memory area and proprietary code

readout protection.

The devices embed peripherals allowing mathematical/arithmetic function acceleration

(CORDIC for trigonometric functions and FMAC unit for filter functions).

They offer three fast 12-bit ADCs (5 Msps), four comparators, four operational amplifiers,

four DAC channels (2 external and 2 internal), an internal voltage reference buffer, a low-

power RTC, one general-purpose 32-bit timers, three 16-bit PWM timers dedicated to motor

control, seven general-purpose 16-bit timers, and one 16-bit low-power timer.

They also feature standard and advanced communication interfaces such as:

- Three I2Cs

- Three SPIs multiplexed with two half duplex I2Ss

- Three USARTs, two UARTs and one low-power UART.

- Two FDCANs

- One SAI

- USB device

- UCPD

The STM32G4A1xE devices embed an AES.

The devices operate in the -40 to +85 °C (+105 °C junction) and -40 to +125 °C (+130 °C

junction) temperature ranges from a 1.71 to 3.6 V power supply. A comprehensive set of

power-saving modes allows the design of low-power applications.

Some independent power supplies are supported including an analog independent supply

input for ADC, DAC, OPAMPs and comparators. A V

the registers.

The STM32G4A1xE family offers 9 packages from 32-pin to 100-pin.

input allows backup of the RTC and

BAT

DS13268 Rev 2 13/200

45

Page 14

Description STM32G4A1xE

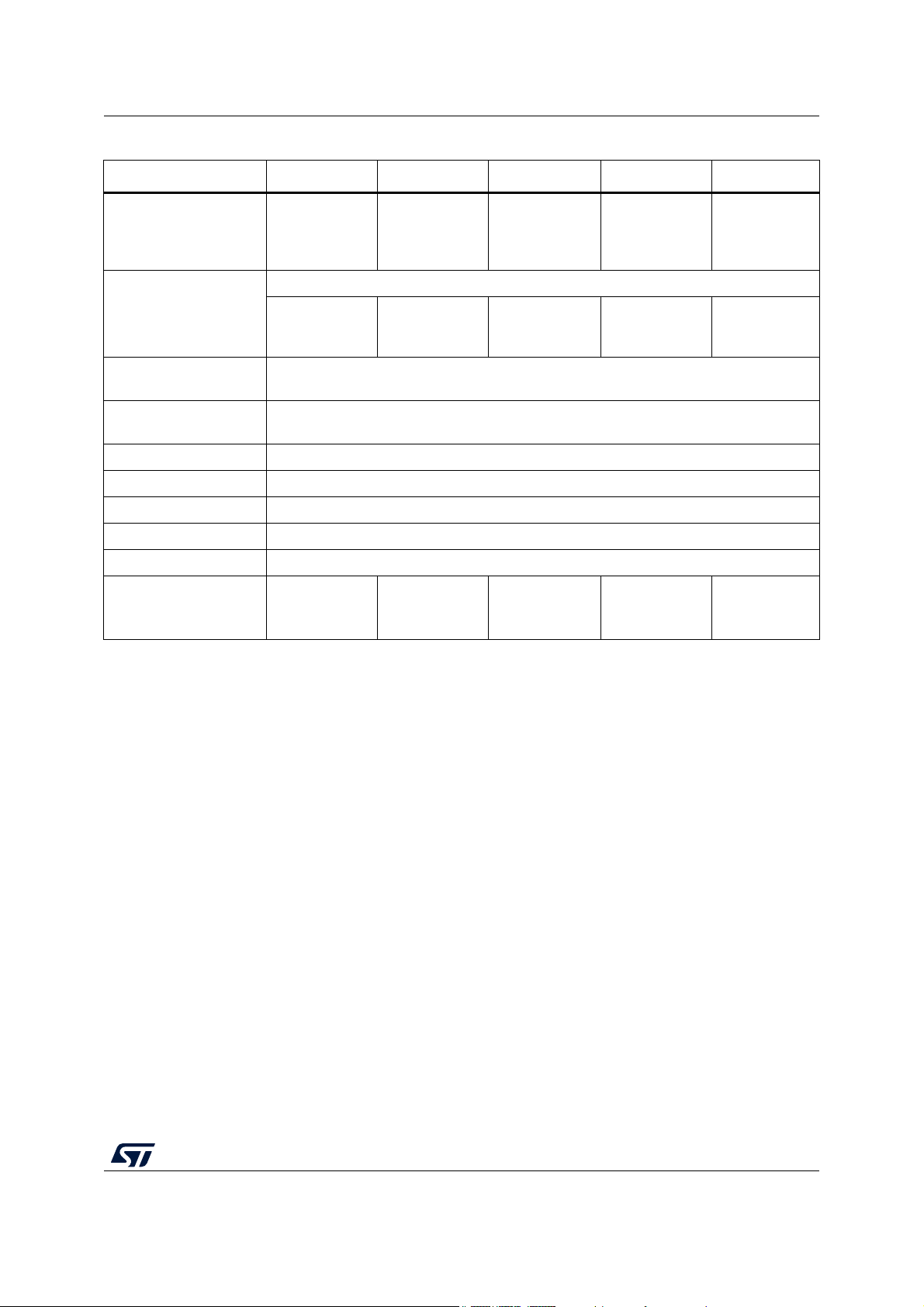

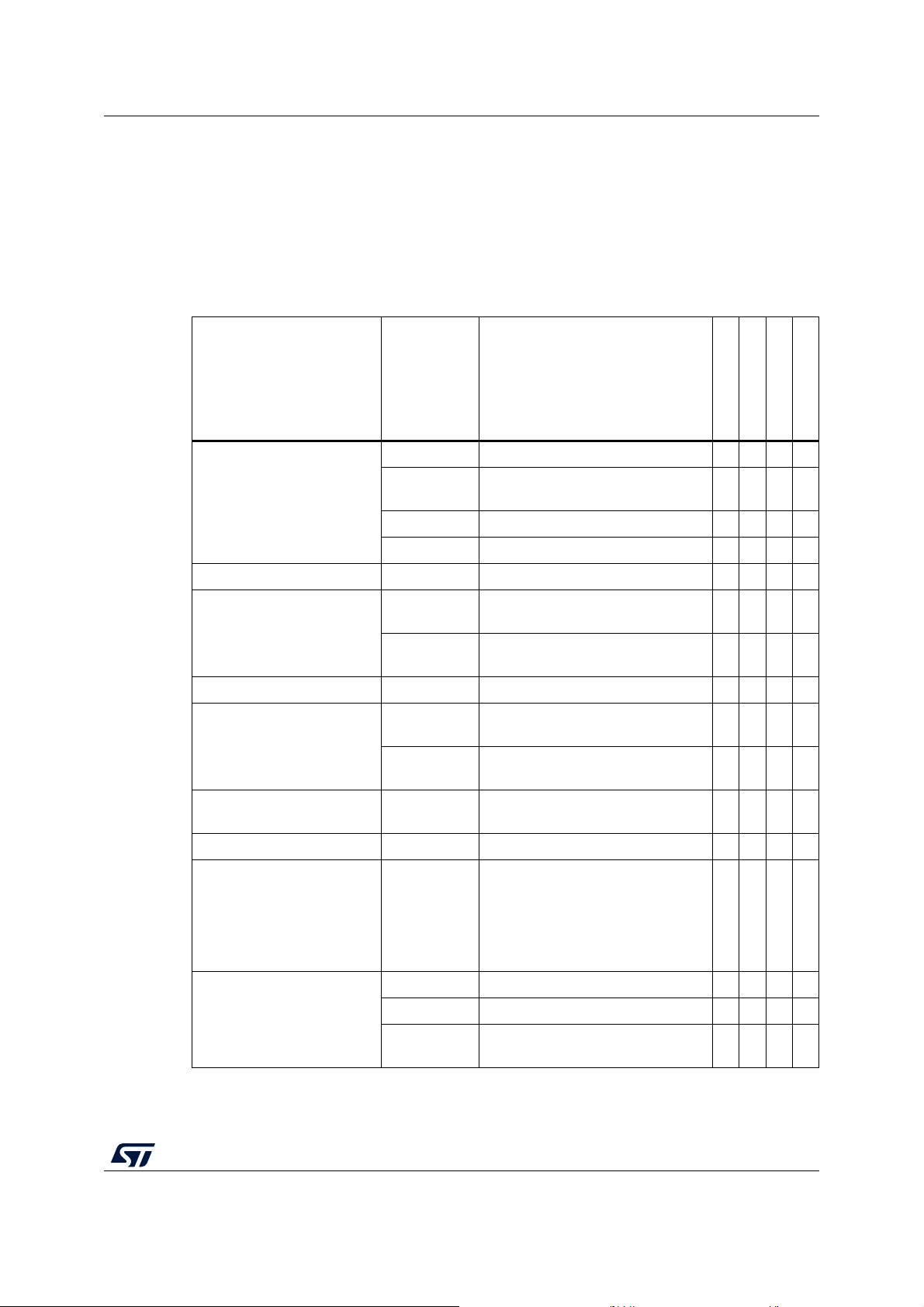

Peripheral STM32G4A1KE STM32G4A1CE STM32G4A1RE STM32G4A1ME STM32G4A1VE

Table 2. STM32G4A1xE features and peripheral counts

Flash memory 512 KB 512 KB 512 KB 512 KB 512 KB

SRAM1 80 KB

SRAM2 16 KB

CCM SRAM 16 KB

QUADSPI 1

Advanced

motor control

General

purpose

3 (16-bit)

5 (16-bit)

1 (32-bit)

Basic 2 (16-bit)

Low power 1 (16-bit)

SysTick timer 1

Timers

Watchdog

timers

(independent,

2

window)

PWM channels

(all)

23 32 38 38 44

PWM channels

(except compl

23 26 28 28 29

ementary)

SPI(I2S)

2

I

(1)

C3

3 (2)

USART 2 3

Comm.

interfac

es

UART 0 2

LPUART 1

FDCANs 2

USB device Yes

UCPD Yes

SAI Yes

RTC Yes

Tamper pins 1 2 2 3

Random number

generator

Yes

AES Yes

CORDIC Yes

FMAC Yes

14/200 DS13268 Rev 2

Page 15

STM32G4A1xE Description

Table 2. STM32G4A1xE features and peripheral counts (continued)

Peripheral

GPIOs

Wakeup pins

STM32G4A1KE STM32G4A1CE STM32G4A1RE STM32G4A1ME STM32G4A1VE

26

2

38 in LQFP48

42 in

UFQFPN48

3

52

66

4

4

3

12-bit ADCs

Number of channels

11

18 in LQFP48

19 in

24 32 36

UFQFPN48

12-bit DAC

Number of channels

Internal voltage

reference buffer

4 (2 external + 2 internal)

2

Yes

Analog comparator 4

Operational amplifiers 4

Max. CPU frequency 170 MHz

Operating voltage 1.71 V to 3.6 V

Operating temperature Ambient operating temperature: -40 to 85 °C / -40 to 125 °C

Packages UFQFPN32

1. The SPI2/3 interfaces can work in an exclusive way in either the SPI mode or the I2S audio mode.

LQFP48/

UFQFPN48

LQFP64/

UFBGA4

WLCSP64

LQFP80 LQFP100

86

5

DS13268 Rev 2 15/200

45

Page 16

GPIO PORT A

AHB/APB2

USART 2MBps

EXT IT. WKUP

86 AFP

USART 2MBps

GPIO PORT B

PB(15:0)

USART 2MBps

GPIO PORT C

PC(15:0)

USART 2MBps

RX, TX, SCK,CTS,

RTS as AF

USART 2MBps

GPIO PORT D

PD(15:0)

USART 2MBps

GPIO PORT E

PE(15:0)

USART 2MBps

SPI 1

MOSI, MISO

SCK, NSS as AF

APB2 60MHzAPB1

4 CH, ETR as AF

TIMER2

4 CH, ETR as AF

TIMER3&4

RX, TX, SCK,

CTS, RTS as AF

USART2&3

UART4&5

MOSI, MISO, SCK

SPI2&3

NSS, as AF

OUT1/OUT2

DAC1

TIMER6

RTC_OUT

RTC_TS

RTC_TAMPx

OSC_IN

OSC_OUT

VDD, VSS,

VDDA, VSSA,

RESET

VBAT = 1.55 to 3.6V

AHB/APB1

JTAG & SW

Arm

®

Cortex-M4

170 MHz

S-BUS

ETM

MPU

TRACECK

TRACED(3:0)

JTRST, JTDI,

JTCK/SWCLK

JTDO/SWD, JTDO

GP-DMA2

GP-DMA1

8 Chan

FLASH 512 KB

ACCEL/

CACHE

AHB1

@VDDA

POR / BOR

SUPPLY

@VDD

SUPERVISION

Reset

Int

POR

XTAL OSC

4-48MHz

XTAL 32kHz

RTC

AWU

BKPREG

LSI

Standby Interface

IWDG

@VBAT

@VDD

RESET&

CLOCKCTRL

PLL

VDD = 1.71 to 3.6V

VSS

VOLT. REG.

3.3V TO 1.2V

VDD12

POWER MNGT

AHB BUS-MATRIX 5M / 8S

APB2

peripheralclocks

RTC Interface

FPU

WinWATCHDOG

and system

LP timer1

AHB2

SAR ADC2

Ain ADC

SysCfg

CRC

LP_UART1

I2C1&2&3

SCL, SDA, SMBAL as AF

RNG

RNB1

analog

COMP

1,2,3,4

SRAM2 16 KB

PWRCTRL

CAN1&2

FIFO

RX,TX as AF

Vref_Buf

CRS

8 Chan

SRAM1 80 KB

CCM SRAM 16 KB

DMAMUX

HSI

SAR ADC1

IF

@VDDA

16b trigg

TIMER7

16b trigg

USBPD

PHY

CC1

CC2

HSI48

CH2

USB

Device

PHY

D+

D-

FIFO

I2S half

duplex

CH1

OPAMP

1,2,3,6

USART 2MBps

GPIO PORT F

PF(10:9,2:0)

DAC3

CH2

CH1

USART 2MBps

GPIO PORT G

PG(10:10)

CORDIC

FMAC

SAI1

FS, SCK, SD,

MCLK as AF

MSv63469V1

irDA

Smcard

irDA

RX, TX, CTS,

RTS as AF

RX, TX as AF

OSC32_IN

OSC_OUT

@VDDA

NVIC

I-BUS

D-BUS

PVD, PWM

PA(15:0)

TIMER1

16b PWM

TIMER8

16b PWM

USART 2MBps

CH as AF

TIMER15

16b

USART 2MBps

CH as AF

TIMER16

16b

USART 2MBps

TIMER17

CH as AF16b

16b

4 PWM,4PWM,

ETR,BKIN as F

4 PWM,4PWM,

ETR,BKIN as F

USART1

Smcard

irDA

QUADSPI

CLK, NCS, BK1_IO[3:0]

SAR ADC3

IF

TIMER20

16b PWM

4 PWM,4PWM,

ETR,BKIN as F

TinyAES

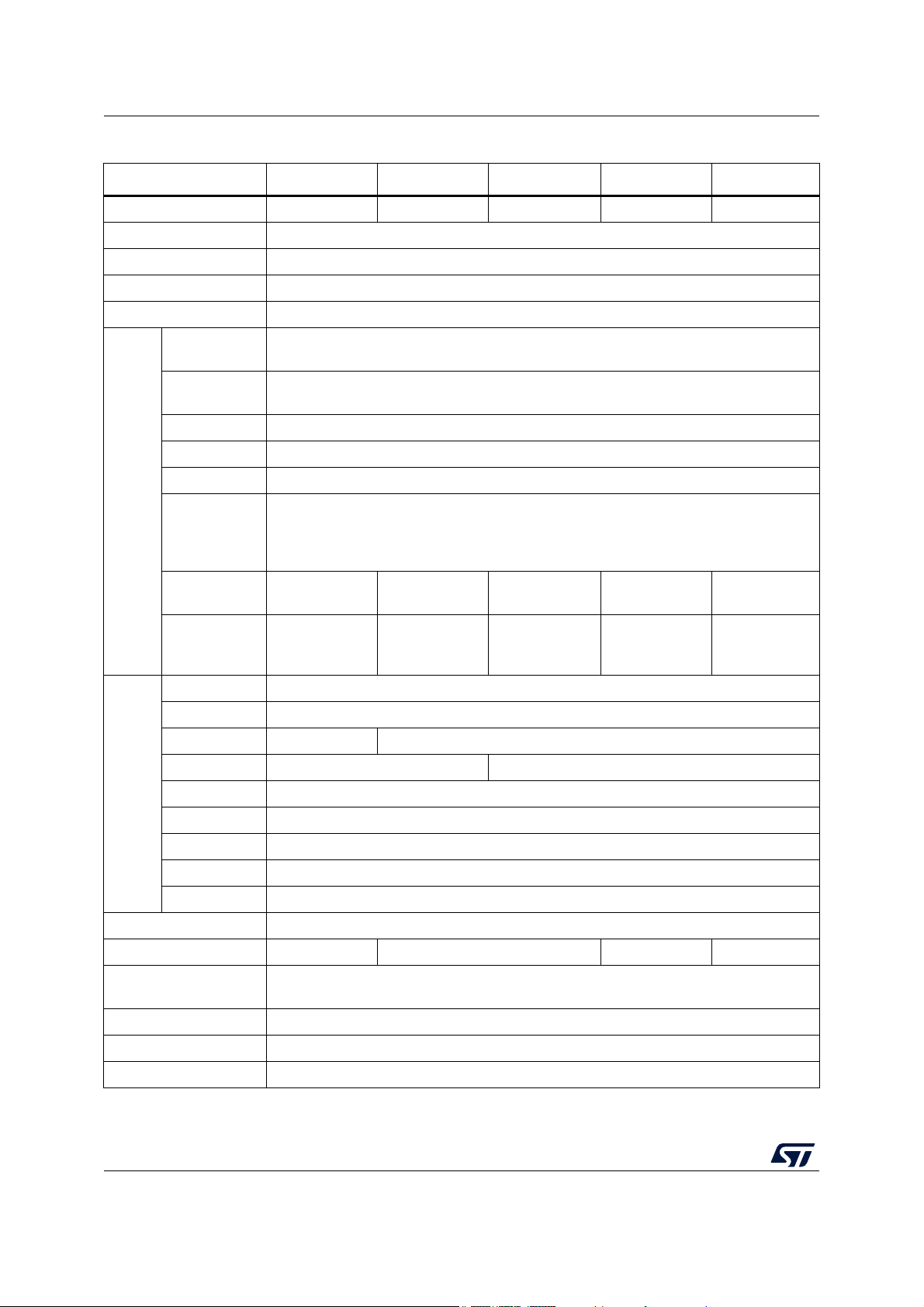

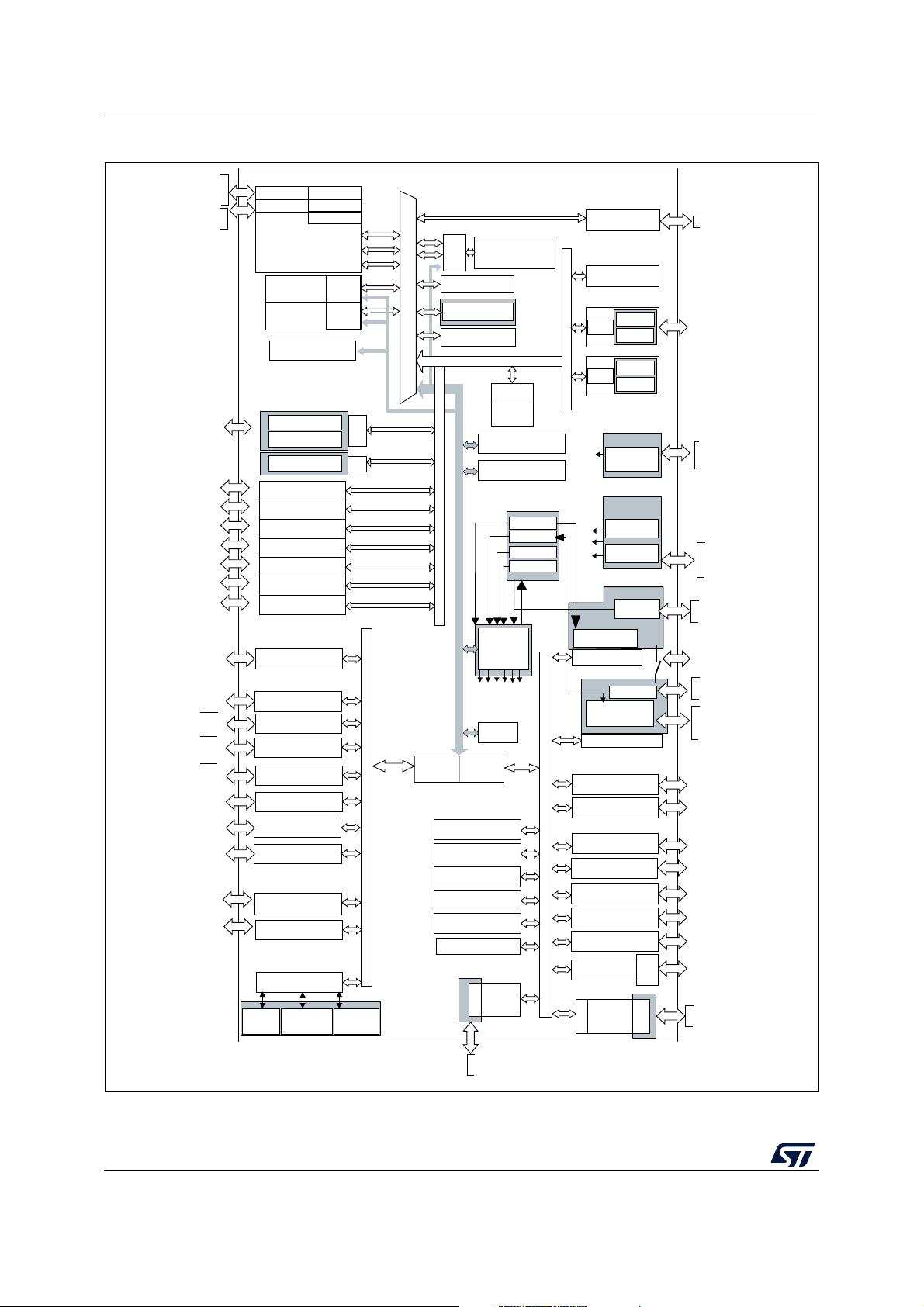

Description STM32G4A1xE

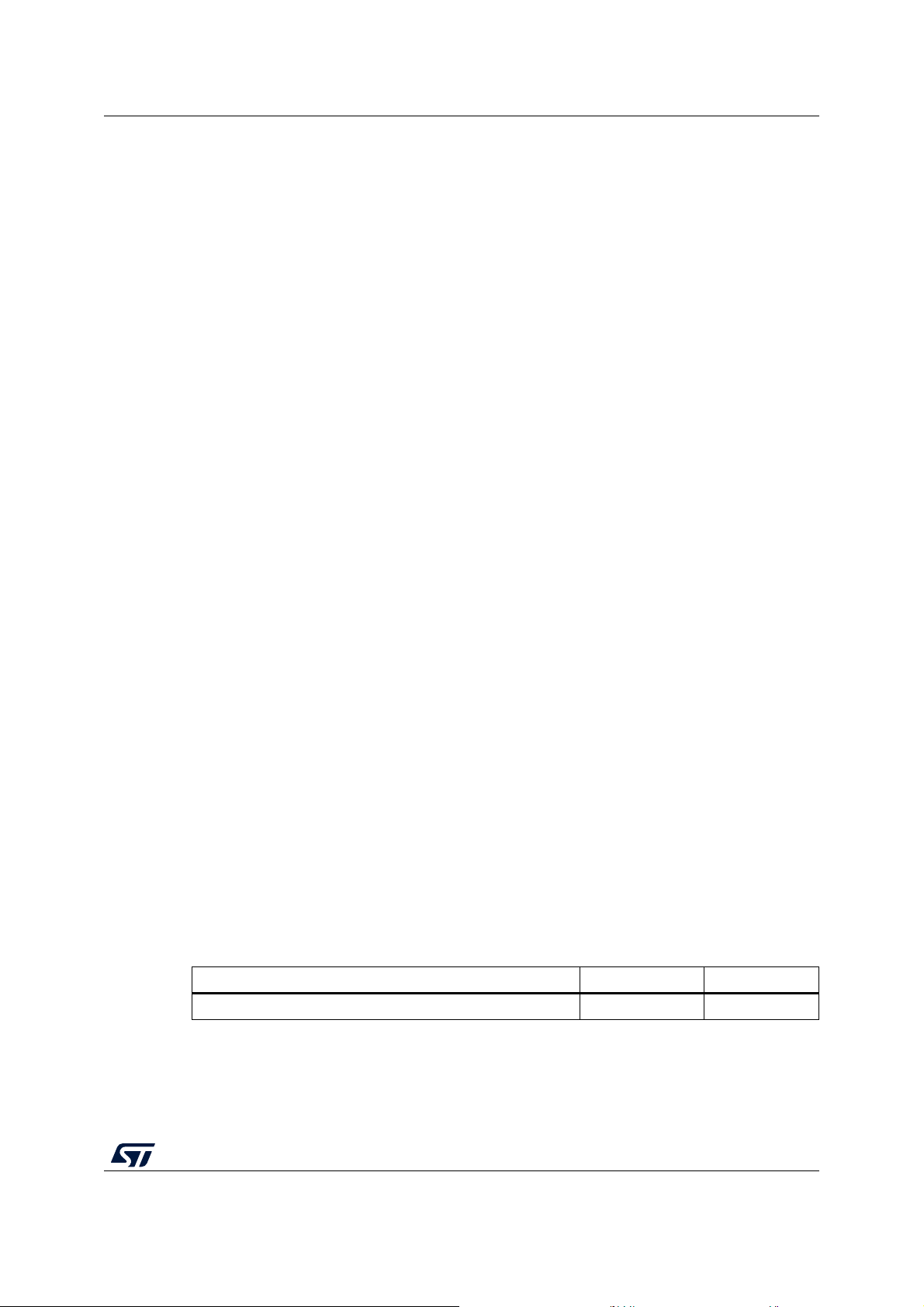

Figure 1. STM32G4A1xE block diagram

1. AF: alternate function on I/O pins.

16/200 DS13268 Rev 2

Page 17

STM32G4A1xE Functional overview

3 Functional overview

3.1 Arm® Cortex®-M4 core with FPU

The Arm® Cortex®-M4 with FPU processor is the latest generation of Arm processors for

embedded systems. It was developed to provide a low-cost platform that meets the needs of

the MCU implementation, with a reduced pin count and with low-power consumption, while

delivering outstanding computational performance and an advanced response to interrupts.

The Arm

efficiency, delivering the expected high-performance from an Arm core in a memory size

usually associated with 8-bit and 16-bit devices.

The processor supports a set of DSP instructions which allows an efficient signal processing

and a complex algorithm execution. Its single precision FPU speeds up the software

development by using metalanguage development tools to avoid saturation.

With its embedded Arm core, the STM32G4A1xE family is compatible with all Arm tools and

software.

Figure 1 shows the general block diagram of the STM32G4A1xE devices.

®

Cortex®-M4 with FPU 32-bit RISC processor features an exceptional code-

3.2 Adaptive real-time memory accelerator (ART accelerator)

The ART accelerator is a memory accelerator that is optimized for the STM32 industry-

standard Arm

the Arm

processor to wait for the Flash memory at higher frequencies.

®

®

Cortex®-M4 processors. It balances the inherent performance advantage of

Cortex®-M4 over Flash memory technologies, which normally requires the

3.3 Memory protection unit

The memory protection unit (MPU) is used to manage the CPU accesses to the memory

and to prevent one task to accidentally corrupt the memory or the resources used by any

other active task. This memory area is organized into up to 8 protected areas, which can be

divided in up into 8 subareas each. The protection area sizes range between 32 bytes and

the whole 4 gigabytes of addressable memory.

The MPU is especially helpful for applications where some critical or certified code has to be

protected against the misbehavior of other tasks. It is usually managed by an RTOS (real-

time operating system). If a program accesses a memory location that is prohibited by the

MPU, the RTOS can detect it and take action. In an RTOS environment, the kernel can

dynamically update the MPU area setting based on the process to be executed.

The MPU is optional and can be bypassed for applications that do not need it.

3.4 Embedded Flash memory

The STM32G4A1xE devices feature 512 kbytes of embedded Flash memory which is

available for storing programs and data.

Flexible protections can be configured thanks to the option bytes:

DS13268 Rev 2 17/200

45

Page 18

Functional overview STM32G4A1xE

• Readout protection (RDP) to protect the whole memory. Three levels of protection are

available:

– Level 0: no readout protection

– Level 1: memory readout protection; the Flash memory cannot be read from or written

to if either the debug features are connected or the boot in RAM or bootloader are

selected

– Level 2: chip readout protection; the debug features (Cortex-M4 JTAG and serial

wire), the boot in RAM and the bootloader selection are disabled (JTAG fuse). This

selection is irreversible.

• Write protection (WRP): the protected area is protected against erasing and

programming.

• Proprietary code readout protection (PCROP): a part of the Flash memory can be

protected against read and write from third parties. The protected area is execute-only

and it can only be reached by the STM32 CPU as an instruction code, while all other

accesses (DMA, debug and CPU data read, write and erase) are strictly prohibited. An

additional option bit (PCROP_RDP) allows to select if the PCROP area is erased or not

when the RDP protection is changed from Level 1 to Level 0.

• Securable memory area: a part of Flash memory can be configured by option bytes to

be securable. After reset this securable memory area is not secured and it behaves like

the remainder of main Flash memory (execute, read, write access). When secured, any

access to this securable memory area generates corresponding read/write error.

Purpose of the Securable memory area is to protect sensitive code and data (secure

keys storage) which can be executed only once at boot, and never again unless a new

reset occurs.

The Flash memory embeds the error correction code (ECC) feature supporting:

• Single error detection and correction

• Double error detection

• The address of the ECC fail can be read in the ECC register

• 1 Kbyte (128 double word) OTP (one-time programmable) bytes for user data. The

OTP area is available in Bank 1 only. The OTP data cannot be erased and can be

written only once.

3.5 Embedded SRAM

STM32G4A1xE devices feature 112 Kbytes of embedded SRAM. This SRAM is split into

three blocks:

• 80 Kbytes mapped at address 0x2000 0000 (SRAM1). The CM4 can access the

SRAM1 through the System Bus (or through the I-Code/D-Code buses when boot from

SRAM1 is selected or when physical remap is selected by SYSCFG_MEMRMP

register). The first 32 Kbytes of SRAM1 support hardware parity check.

• 16 Kbytes mapped at address 0x2001 4000 (SRAM2). The CM4 can access the

SRAM2 through the System bus. SRAM2 can be kept in stop and standby modes.

• 16 Kbytes mapped at address 0x1000 0000 (CCM SRAM). It is accessed by the CPU

through I-Code/D-Code bus for maximum performance.

It is also aliased at 0x2001 8000 address to be accessed by all masters (CPU, DMA1,

DMA2) through SBUS contiguously to SRAM1 and SRAM2.The CCM SRAM supports

hardware parity check and can be write-protected with 1-Kbyte granularity.

• The memory can be accessed in read/write at max CPU clock speed with 0 wait states.

18/200 DS13268 Rev 2

Page 19

STM32G4A1xE Functional overview

MS52814V1

Cortex

®

-M4

with FPU

DMA1 DMA2

AHB2

peripherals

AHB1

peripherals

CCM

SRAM

SRAM1

FLASH

512 KB

ACCEL

S-bus

D-bus

ICode

DCode

I-bus

BusMatrix-S

SRAM2

QUADSPI

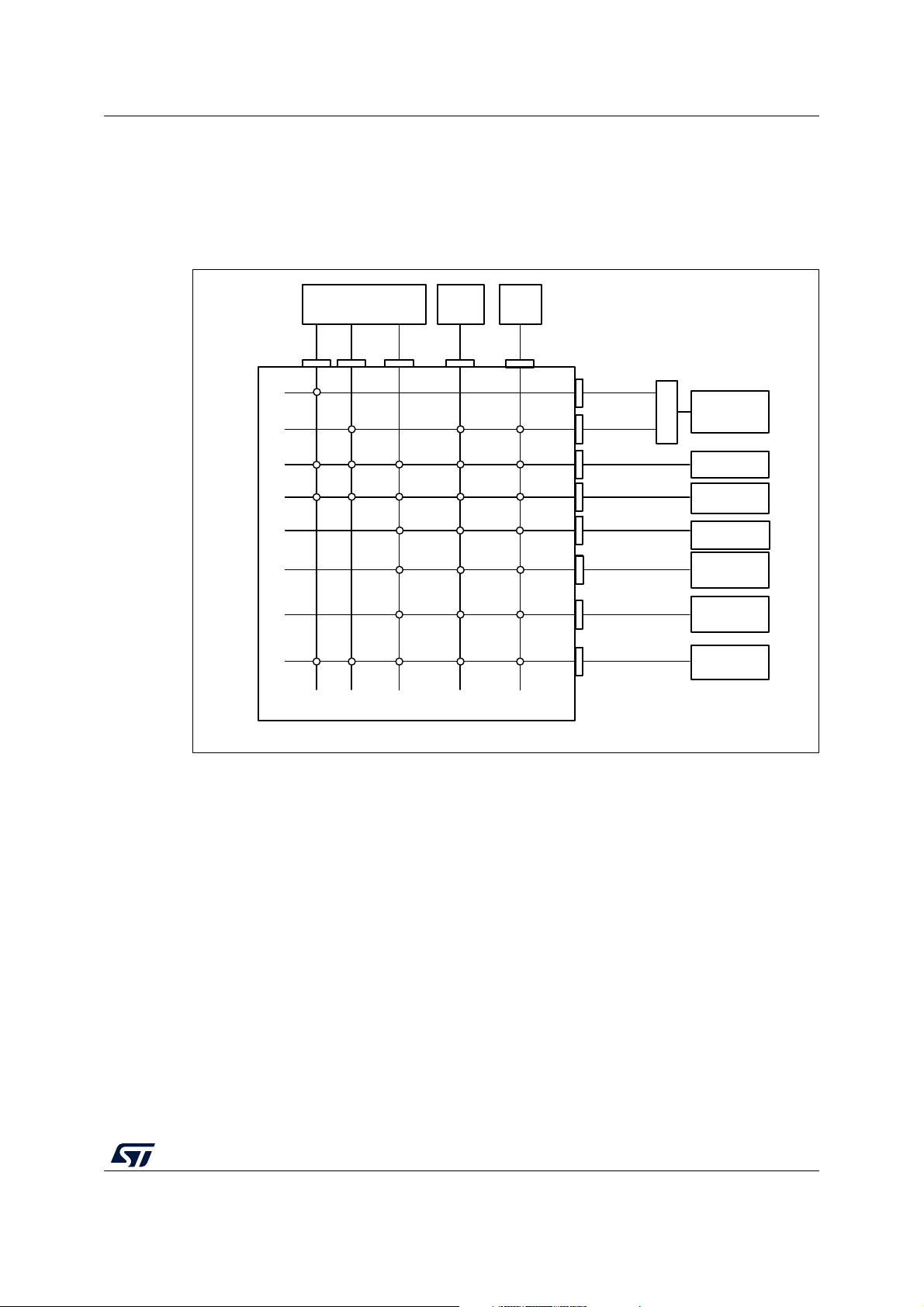

3.6 Multi-AHB bus matrix

The 32-bit multi-AHB bus matrix interconnects all the masters (CPU, DMAs) and the slaves

(Flash memory, RAM, QUADSPI, AHB and APB peripherals). It also ensures a seamless

and efficient operation even when several high-speed peripherals work simultaneously.

Figure 2. Multi-AHB bus matrix

3.7 Boot modes

At startup, a BOOT0 pin (or nBOOT0 option bit)and an nBOOT1 option bit are used to select

one of three boot options:

• Boot from user Flash

• Boot from system memory

• Boot from embedded SRAM

The BOOT0 value may come from the PB8-BOOT0 pin or from an nBOOT0 option bit

depending on the value of a user nBOOT_SEL option bit to free the GPIO pad if needed.

The boot loader is located in the system memory. It is used to reprogram the Flash memory

by using USART, I2C, SPI, and USB through the DFU (device firmware upgrade).

DS13268 Rev 2 19/200

45

Page 20

Functional overview STM32G4A1xE

3.8 CORDIC

The CORDIC provides hardware acceleration of certain mathematical functions, notably

trigonometric, commonly used in motor control, metering, signal processing and many other

applications.

It speeds up the calculation of these functions compared to a software implementation,

allowing a lower operating frequency, or freeing up processor cycles in order to perform

other tasks.

Cordic features

• 24-bit CORDIC rotation engine

• Circular and Hyperbolic modes

• Rotation and Vectoring modes

• Functions: Sine, Cosine, Sinh, Cosh, Atan, Atan2, Atanh, Modulus, Square root,

Natural logarithm

• Programmable precision up to 20-bit

• Fast convergence: 4 bits per clock cycle

• Supports 16-bit and 32-bit fixed point input and output formats

• Low latency AHB slave interface

• Results can be read as soon as ready without polling or interrupt

• DMA read and write channels

3.9 Filter mathematical accelerator (FMAC)

The filter mathematical accelerator unit performs arithmetic operations on vectors. It

comprises a multiplier/accumulator (MAC) unit, together with address generation logic,

which allows it to index vector elements held in local memory.

The unit includes support for circular buffers on input and output, which allows digital filters

to be implemented. Both finite and infinite impulse response filters can be realized.

The unit allows frequent or lengthy filtering operations to be offloaded from the CPU, freeing

up the processor for other tasks. In many cases it can accelerate such calculations

compared to a software implementation, resulting in a speed-up of time critical tasks.

20/200 DS13268 Rev 2

Page 21

STM32G4A1xE Functional overview

FMAC features

• 16 x 16-bit multiplier

• 24+2-bit accumulator with addition and subtraction

• 16-bit input and output data

• 256 x 16-bit local memory

• Up to three areas can be defined in memory for data buffers (two input, one output),

defined by programmable base address pointers and associated size registers

• Input and output sample buffers can be circular

• Buffer “watermark” feature reduces overhead in interrupt mode

• Filter functions: FIR, IIR (direct form 1)

• AHB slave interface

• DMA read and write data channels

3.10 Cyclic redundancy check calculation unit (CRC)

The CRC (cyclic redundancy check) calculation unit is used to get a CRC code using a

configurable generator with polynomial value and size.

Among other applications, the CRC-based techniques are used to verify data transmission

or storage integrity. In the scope of the EN/IEC 60335-1 standard, they offer a mean to verify

the Flash memory integrity.

The CRC calculation unit helps to compute a signature of the software during runtime, which

can be ulteriorly compared with a reference signature generated at link-time and which can

be stored at a given memory location.

3.11 Power supply management

3.11.1 Power supply schemes

The STM32G4A1xE devices require a 1.71 V to 3.6 V V

Several independent supplies, can be provided for specific peripherals:

• V

• V

• V

= 1.71 V to 3.6 V

DD

V

is the external power supply for the I/Os, the internal regulator and the system

DD

analog such as reset, power management and internal clocks. It is provided externally

through the VDD pins.

= 1.62 V to 3.6 V (see Section 5: Electrical characteristics for the minimum V

DDA

voltage required for ADC, DAC, COMP, OPAMP, VREFBUF operation).

V

is the external analog power supply for A/D converters, D/A converters, voltage

DDA

reference buffer, operational amplifiers and comparators. The V

independent from the V

voltage and should preferably be connected to VDD when

DD

these peripherals are not used.

= 1.55 V to 3.6 V

BAT

V

is the power supply for RTC, external clock 32 kHz oscillator and backup registers

BAT

(through power switch) when V

is not present.

DD

operating voltage supply.

DD

voltage level is

DDA

DDA

DS13268 Rev 2 21/200

45

Page 22

Functional overview STM32G4A1xE

• VREF-, VREF+

V

is the input reference voltage for ADCs and DACs. It is also the output of the

REF+

internal voltage reference buffer when enabled.

When V

When V

DDA

DDA

< 2 V V

2 V V

must be equal to V

REF+

must be between 2 V and V

REF+

DDA

.

.

DDA

The internal voltage reference buffer supports three output voltages, which are

configured with VRS bits in the VREFBUF_CSR register:

–V

–V

–V

V

REF-

= 2.048 V

REF+

= 2.5 V

REF+

= 2.9 V

REF+

is double bonded with V

SSA

.

3.11.2 Power supply supervisor

The device has an integrated ultra-low-power brown-out reset (BOR) active in all modes

(except for Shutdown mode). The BOR ensures proper operation of the device after poweron and during power down. The device remains in reset mode when the monitored supply

voltage V

The lowest BOR level is 1.71 V at power on, and other higher thresholds can be selected

through option bytes.The device features an embedded programmable voltage detector

(PVD) that monitors the V

interrupt can be generated when V

higher than the VPVD threshold. The interrupt service routine can then generate a warning

message and/or put the MCU into a safe state. The PVD is enabled by software.

is below a specified threshold, without the need for an external reset circuit.

DD

power supply and compares it to the VPVD threshold. An

DD

drops below the VPVD threshold and/or when VDD is

DD

In addition, the device embeds a peripheral voltage monitor which compares the

independent supply voltages V

peripheral is in its functional supply range.

3.11.3 Voltage regulator

Two embedded linear voltage regulators, main regulator (MR) and low-power regulator

(LPR), supply most of digital circuitry in the device. The MR is used in Run and Sleep

modes. The LPR is used in Low-power run, Low-power sleep and Stop modes. In Standby

and Shutdown modes, both regulators are powered down and their outputs set in highimpedance state, such as to bring their current consumption close to zero.

The device supports dynamic voltage scaling to optimize its power consumption in Run

mode. the voltage from the main regulator that supplies the logic (VCORE) can be adjusted

according to the system’s maximum operating frequency.

The main regulator (MR) operates in the following ranges:

• Range 1 boost mode with the CPU running at up to 170 MHz.

• Range 1 normal mode with CPU running at up to 150 MHz.

• Range 2 with a maximum CPU frequency of 26 MHz.

, with a fixed threshold in order to ensure that the

DDA

22/200 DS13268 Rev 2

Page 23

STM32G4A1xE Functional overview

3.11.4 Low-power modes

By default, the microcontroller is in Run mode after system or power Reset. It is up to the

user to select one of the low-power modes described below:

• Sleep mode: In Sleep mode, only the CPU is stopped. All peripherals continue to

operate and can wake up the CPU when an interrupt/event occurs.

• Low-power run mode: This mode is achieved with VCORE supplied by the low-power

regulator to minimize the regulator's operating current. The code can be executed from

SRAM or from Flash, and the CPU frequency is limited to 2 MHz. The peripherals with

independent clock can be clocked by HSI16.

• Stop mode: In Stop mode, the device achieves the lowest power consumption while

retaining the SRAM and register contents. All clocks in the VCORE domain are

stopped. The PLL, as well as the HSI16 RC oscillator and the HSE crystal oscillator are

disabled. The LSE or LSI keep running. The RTC can remain active (Stop mode with

RTC, Stop mode without RTC). Some peripherals with wakeup capability can enable

the HSI16 RC during Stop mode, so as to get clock for processing the wakeup event.

• Standby mode: The Standby mode is used to achieve the lowest power consumption

with brown-out reset, BOR. The internal regulator is switched off to power down the

VCORE domain. The PLL, as well as the HSI16 RC oscillator and the HSE crystal

oscillator are also powered down. The RTC can remain active (Standby mode with

RTC, Standby mode without RTC). The BOR always remains active in Standby mode.

For each I/O, the software can determine whether a pull-up, a pull-down or no resistor

shall be applied to that I/O during Standby mode. Upon entering Standby mode, SRAM

and register contents are lost except for registers in the RTC domain and standby

circuitry. The device exits Standby mode upon external reset event (NRST pin), IWDG

reset event, wakeup event (WKUP pin, configurable rising or falling edge) or RTC

event (alarm, periodic wakeup, timestamp, tamper), or when a failure is detected on

LSE (CSS on LSE).

• Shutdown mode: The Shutdown mode allows to achieve the lowest power

consumption. The internal regulator is switched off to power down the VCORE domain.

The PLL, as well as the HSI16 and LSI RC-oscillators and HSE crystal oscillator are

also powered down. The RTC can remain active (Shutdown mode with RTC, Shutdown

mode without RTC). The BOR is not available in Shutdown mode. No power voltage

monitoring is possible in this mode. Therefore, switching to RTC domain is not

supported. SRAM and register contents are lost except for registers in the RTC

domain. The device exits Shutdown mode upon external reset event (NRST pin),

IWDG reset event, wakeup event (WKUP pin, configurable rising or falling edge) or

RTC event (alarm, periodic wakeup, timestamp, tamper).

3.11.5 Reset mode

In order to improve the consumption under reset, the I/Os state under and after reset is

“analog state” (the I/O schmitt trigger is disabled). In addition, the internal reset pull-up is

deactivated when the reset source is internal.

3.11.6 V

operation

BAT

The V

pin allows to power the device V

BAT

supercapacitor, or from V

supercapacitor is present. The V

registers. Three anti-tamper detection pins are available in V

domain from an external battery, an external

when there is no external battery and when an external

DD

BAT

DS13268 Rev 2 23/200

BAT

pin supplies the RTC with LSE and the backup

mode.

BAT

45

Page 24

Functional overview STM32G4A1xE

The V

operation is automatically activated when VDD is not present. An internal V

BAT

battery charging circuit is embedded and can be activated when V

Note: When the microcontroller is supplied from V

alarm/events exit the microcontroller from the V

is present.

DD

, neither external interrupts nor RTC

BAT

operation.

BAT

BAT

24/200 DS13268 Rev 2

Page 25

STM32G4A1xE Functional overview

3.12 Interconnect matrix

Several peripherals have direct connections between them. This allows autonomous

communication between peripherals, saving CPU resources thus power supply

consumption. In addition, these hardware connections allow fast and predictable latency.

Depending on peripherals, these interconnections can operate in Run, Sleep and Stop

modes.

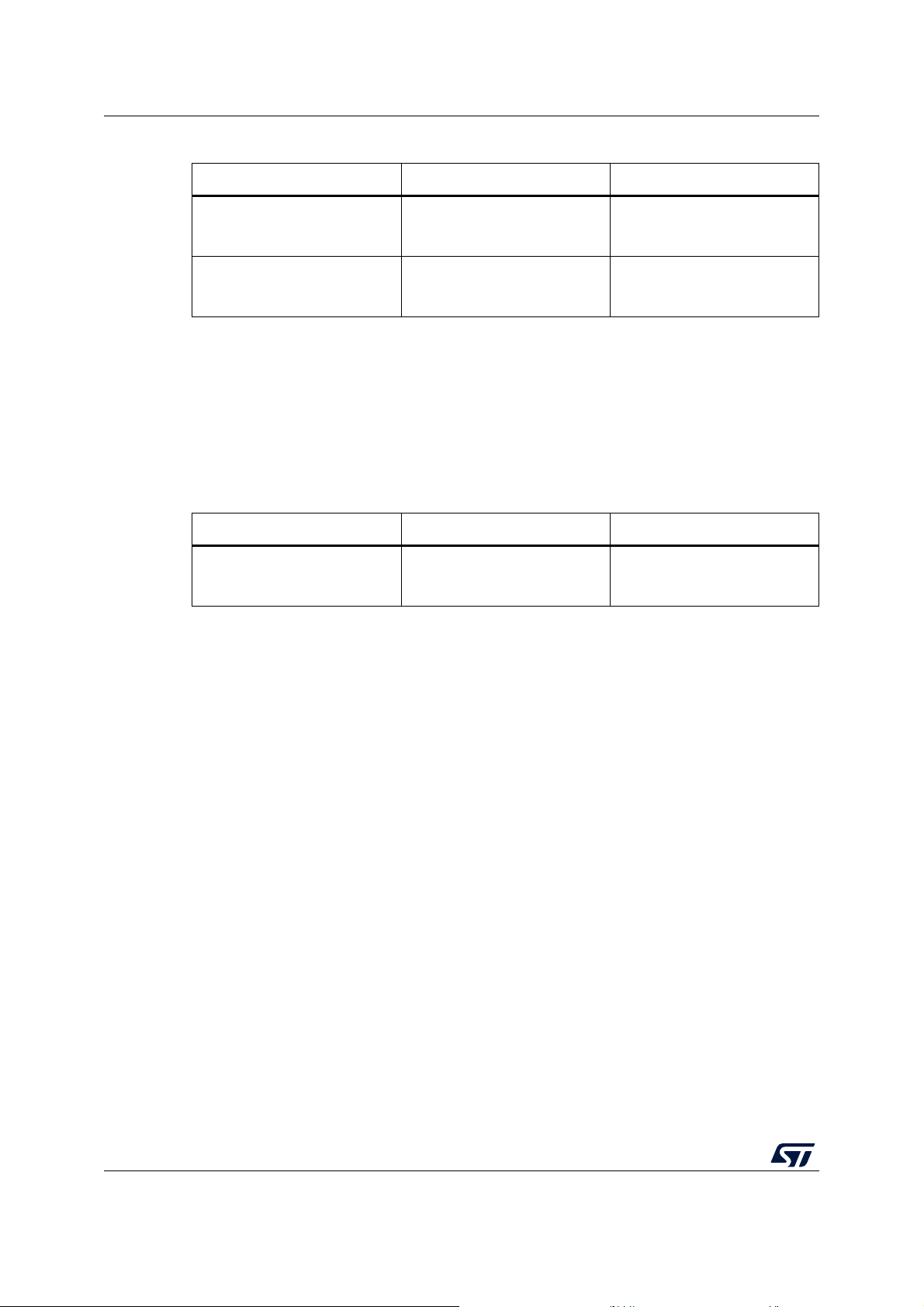

Table 3. STM32G4A1xE peripherals interconnect matrix

Interconnect source

TIMx

TIM16/TIM17 IRTIM Infrared interface output generation Y Y Y -

COMPx

ADCx TIM1, 8, 20 Timer triggered by analog watchdog Y Y Y -

RTC

All clocks sources (internal

and external)

USB TIM2 Timer triggered by USB SOF Y Y - -

CSS

CPU (hard fault)

RAM (parity error)

Flash memory (ECC error)

COMPx

PVD

Interconnect

destination

TIMx Timers synchronization or chaining Y Y Y -

ADCx

DACx

DMA Memory to memory transfer trigger Y Y Y -

COMPx Comparator output blanking Y Y Y -

TIM1, 8, 20

TIM2, 3, 4

LPTIMER1

TIM16

LPTIMER1

TIM15, 16, 17

TIM1, 8, 20

TIM15, 16, 17

TIMx External trigger Y Y Y -

Conversion triggers Y Y Y -

Timer input channel, trigger, break

from analog signals comparison

Low-power timer triggered by

analog signals comparison

Timer input channel from RTC

events

Low-power timer triggered by RTC

alarms or tampers

Clock source used as input channel

for RC measurement and trimming

Timer break Y Y Y -

Interconnect action

Run

Sleep

Low-power run

YYY -

YYYY

YYY -

YYYY

YYY -

Stop

GPIO

LPTIMER1 External trigger Y Y Y -

ADCx

DACx

DS13268 Rev 2 25/200

Conversion external trigger Y Y Y -

45

Page 26

Functional overview STM32G4A1xE

3.13 Clocks and startup

The clock controller distributes the clocks coming from different oscillators to the core and

the peripherals. It also manages clock gating for low-power modes and ensures clock

robustness. It features:

• Clock prescaler: to get the best trade-off between speed and current consumption,

the clock frequency to the CPU and peripherals can be adjusted by a programmable

prescaler

• Safe clock switching: clock sources can be changed safely on the fly in run mode

through a configuration register.

• Clock management: to reduce power consumption, the clock controller can stop the

clock to the core, individual peripherals or memory.

• System clock source: three different sources can deliver SYSCLK system clock:

– 4 - 48 MHz high-speed oscillator with external crystal or ceramic resonator (HSE).

It can supply clock to system PLL. The HSE can also be configured in bypass

mode for an external clock.

– 16 MHz high-speed internal RC oscillator (HSI16), trimmable by software. It can

supply clock to system PLL.

– System PLL with maximum output frequency of 170 MHz. It can be fed with HSE

or HSI16 clocks.

• RC48 with clock recovery system (HSI48): internal HSIRC48 MHz clock source can

be used to drive the USB or the RNG peripherals.

• Auxiliary clock source: two ultra-low-power clock sources for the real-time clock

(RTC):

– 32.768 kHz low-speed oscillator with external crystal (LSE), supporting four drive

capability modes. The LSE can also be configured in bypass mode for using an

external clock.

– 32 kHz low-speed internal RC oscillator (LSI) with ±5% accuracy, also used to

clock an independent watchdog.

• Peripheral clock sources: several peripherals (I2S, USART, I2C, LPTimer, ADC, SAI,

RNG) have their own clock independent of the system clock.

• Clock security system (CSS): in the event of HSE clock failure, the system clock is

automatically switched to HSI16 and, if enabled, a software interrupt is generated. LSE

clock failure can also be detected and generate an interrupt.

• Clock-out capability:

– MCO: microcontroller clock output: it outputs one of the internal clocks for external

use by the application

– LSCO: low speed clock output: it outputs LSI or LSE in all low-power modes.

Several prescalers allow to configure the AHB frequency, the High-speed APB (APB2) and

the low speed APB (APB1) domains. The maximum frequency of the AHB and the APB

domains is 170 MHz.

26/200 DS13268 Rev 2

Page 27

STM32G4A1xE Functional overview

3.14 General-purpose inputs/outputs (GPIOs)

Each of the GPIO pins can be configured by software as output (push-pull or open-drain), as

input (with or without pull-up or pull-down) or as peripheral alternate function. Most of the

GPIO pins are shared with digital or analog alternate functions. Fast I/O toggling can be

achieved thanks to their mapping on the AHB2 bus.

The I/Os alternate function configuration can be locked if needed following a specific

sequence in order to avoid spurious writing to the I/Os registers.

3.15 Direct memory access controller (DMA)

The device embeds 2 DMAs. Refer to Table 4: DMA implementation for the features

implementation.

Direct memory access (DMA) is used in order to provide a high-speed data transfer

between peripherals and memory as well as from memory to memory. Data can be quickly

moved by DMA without any CPU actions. This keeps the CPU resources free for other

operations.

The two DMA controllers have 16 channels in total, each one dedicated to manage memory

access requests from one or more peripherals. Each controller has an arbiter for handling

the priority between DMA requests.

The DMA supports:

• 16 independently configurable channels (requests)

– Each channel is connected to a dedicated hardware DMA request, a software

trigger is also supported on each channel. This configuration is done by software.

• Priorities between requests from channels of one DMA are both software

programmable (4 levels: very high, high, medium, low) or hardware programmable in

case of equality (request 1 has priority over request 2, etc.)

• Independent source and destination transfer size (byte, half word, word), emulating

packing and unpacking. Source/destination addresses must be aligned on the data

size.

• Support for circular buffer management

• 3 event flags (DMA half transfer, DMA transfer complete and DMA transfer error)

logically ORed together in a single interrupt request for each channel

• Memory-to-memory transfer

• Peripheral-to-memory, memory-to-peripheral, and peripheral-to-peripheral transfers

• Access to Flash, SRAM, APB and AHB peripherals as source and destination

• Programmable number of data to be transferred: up to 65536.

DMA features DMA1 DMA2

Number of regular channels 8 8

Table 4. DMA implementation

DS13268 Rev 2 27/200

45

Page 28

Functional overview STM32G4A1xE

3.16 DMA request router (DMAMux)

When a peripheral indicates a request for DMA transfer by setting its DMA request line, the

DMA request is pending until it is served and the corresponding DMA request line is reset.

The DMA request router allows to route the DMA control lines between the peripherals and

the DMA controllers of the product.

An embedded multi-channel DMA request generator can be considered as one of such

peripherals. The routing function is ensured by a multi-channel DMA request line

multiplexer. Each channel selects a unique set of DMA control lines, unconditionally or

synchronously with events on synchronization inputs.

For simplicity, the functional description is limited to DMA request lines. The other DMA