STM32F105xx

FBGA

LQFP64 10 × 10 mm,

LQFP100 14 × 14 mm,

LFBGA100 10 × 10 mm

STM32F107xx

Connectivity line, ARM-based 32-bit MCU with 64/256 KB Flash, USB

OTG, Ethernet, 10 timers, 2 CANs, 2 ADCs, 14 communication interfaces

Preliminary Data

Features

■ Core: ARM 32-bit Cortex™-M3 CPU

– 72 MHz maximum frequency,

1.25 DMIPS/MHz (Dhrystone 2.1)

performance at 0 wait state memory

access

– Single-cycle multiplication and hardware

division

■ Memories

– 64 to 256 Kbytes of Flash memory

– up to 64 Kbytes of SRAM

■ Clock, reset and supply management

– 2.0 to 3.6 V application supply and I/Os

– POR, PDR, and programmable voltage

detector (PVD)

– 3-to-25 MHz crystal oscillator

– Internal 8 MHz factory-trimmed RC

– Internal 40 kHz RC with calibration

– 32 kHz oscillator for RTC with calibration

■ Low power

– Sleep, Stop and Standby modes

–V

■ 2 × 12-bit, 1 µs A/D converters (16 channels)

supply for RTC and backup registers

BAT

– Conversion range: 0 to 3.6 V

– Sample and hold capability

– Temperature sensor

– up to 2 MSps in interleaved mode

■ 2 × 12-bit D/A converters

■ DMA: 12-channel DMA controller

– Supported peripherals: timers, ADCs, DAC,

2

I

Ss, SPIs, I2Cs and USARTs

■ Debug mode

– Serial wire debug (SWD) & JTAG interfaces

– Cortex-M3 Embedded Trace Macrocell™

■ Up to 80 fast I/O ports

– 51/80 I/Os, all mappable on 16 external

interrupt vectors and almost all 5 V-tolerant

■ Up to 10 timers

– Up to four 16-bit timers, each with up to 4

IC/OC/PWM or pulse counter and

quadrature (incremental) encoder input

– 1 × 16-bit motor control PWM timer with

dead-time generation and emergency stop

– 2 × watchdog timers (Independent and

Window)

– SysTick timer: a 24-bit downcounter

– 2 × 16-bit basic timers to drive the DAC

■ Up to 14 communication interfaces

– Up to 2 × I

2

C interfaces (SMBus/PMBus)

– Up to 5 USARTs (ISO 7816 interface, LIN,

IrDA capability, modem control)

– Up to 3 SPIs (18 Mbit/s), 2 with a

multiplexed I

2

S interface that offers audio

class accuracy via advanced PLL schemes

– 2 × CAN interfaces (2.0B Active) with

512 bytes of dedicated SRAM

– USB 2.0 full-speed device/host/OTG

controller with on-chip PHY that supports

HNP/SRP/ID with 1.25 Kbytes of dedicated

SRAM

– 10/100 Ethernet MAC with dedicated DMA

and SRAM (4 Kbytes): IEEE1588 hardware

support, MII/RMII available on all packages

■ CRC calculation unit, 96-bit unique ID

Table 1. Device summary

Reference Part number

STM32F105R8, STM32F105V8

STM32F105xx

STM32F107xx

STM32F105RB, STM32F105VB

STM32F105RC, STM32F105VC

STM32F107RB, STM32F107VB

STM32F107RC, STM32F107VC

February 2009 Rev 2 1/90

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

www.st.com

1

Contents STM32F105xx, STM32F107xx

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Full compatibility throughout the family . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 ARM® CortexTM-M3 core with embedded Flash and SRAM . . . . . . . . 11

2.3.2 Embedded Flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.3 CRC (cyclic redundancy check) calculation unit . . . . . . . . . . . . . . . . . . 12

2.3.4 Embedded SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.5 Nested vectored interrupt controller (NVIC) . . . . . . . . . . . . . . . . . . . . . . 12

2.3.6 External interrupt/event controller (EXTI) . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.7 Clocks and startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.8 Boot modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.9 Power supply schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.10 Power supply supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3.11 Voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.12 Low-power modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.13 DMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.14 RTC (real-time clock) and backup registers . . . . . . . . . . . . . . . . . . . . . . 15

2.4 Timers and watchdogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4.1 Advanced-control timer (TIM1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4.2 General-purpose timers (TIMx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.3 Basic timers TIM6 and TIM7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.4 Independent watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.5 Window watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.6 SysTick timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.7 I²C bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.8 Universal synchronous/asynchronous receiver transmitters (USARTs) 17

2.4.9 Serial peripheral interface (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.10 Inter-integrated sound (I

2.4.11 Ethernet MAC interface with dedicated DMA and IEEE 1588 support . 17

2.4.12 Controller area network (CAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2

S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.13 Universal serial bus on-the-go full-speed (USB OTG FS) . . . . . . . . . . . 18

2/90

STM32F105xx, STM32F107xx Contents

2.4.14 GPIOs (general-purpose inputs/outputs) . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.15 ADCs (analog-to-digital converters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.16 DAC (digital-to-analog converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.17 Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.18 Serial wire JTAG debug port (SWJ-DP) . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.19 Embedded Trace Macrocell™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 Memory mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1 Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.1 Minimum and maximum values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.2 Typical values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.3 Typical curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.4 Loading capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.5 Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.6 Power supply scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.1.7 Current consumption measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.1 General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.2 Operating conditions at power-up / power-down . . . . . . . . . . . . . . . . . . 35

5.3.3 Embedded reset and power control block characteristics . . . . . . . . . . . 35

5.3.4 Embedded reference voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3.5 Supply current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3.6 External clock source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3.7 Internal clock source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3.8 PLL characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3.9 Memory characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3.10 EMC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3.11 Absolute maximum ratings (electrical sensitivity) . . . . . . . . . . . . . . . . . 53

5.3.12 I/O port characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.13 NRST pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3.14 TIM timer characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.3.15 Communications interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3/90

Contents STM32F105xx, STM32F107xx

5.3.16 12-bit ADC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.3.17 DAC electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.3.18 Temperature sensor characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6 Package characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.1 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Appendix A Applicative block diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1 USB OTG FS interface solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.2 Ethernet interface solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3 Complete audio player solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

A.4 USB OTG FS interface + Ethernet/I

2

S interface solutions . . . . . . . . . . . . 87

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4/90

STM32F105xx, STM32F107xx List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. STM32F105xx and STM32F107xx features and peripheral counts . . . . . . . . . . . . . . . . . . 10

Table 3. STM32F105xx and STM32F107xx family versus STM32F103xx family . . . . . . . . . . . . . . 11

Table 4. Timer feature comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

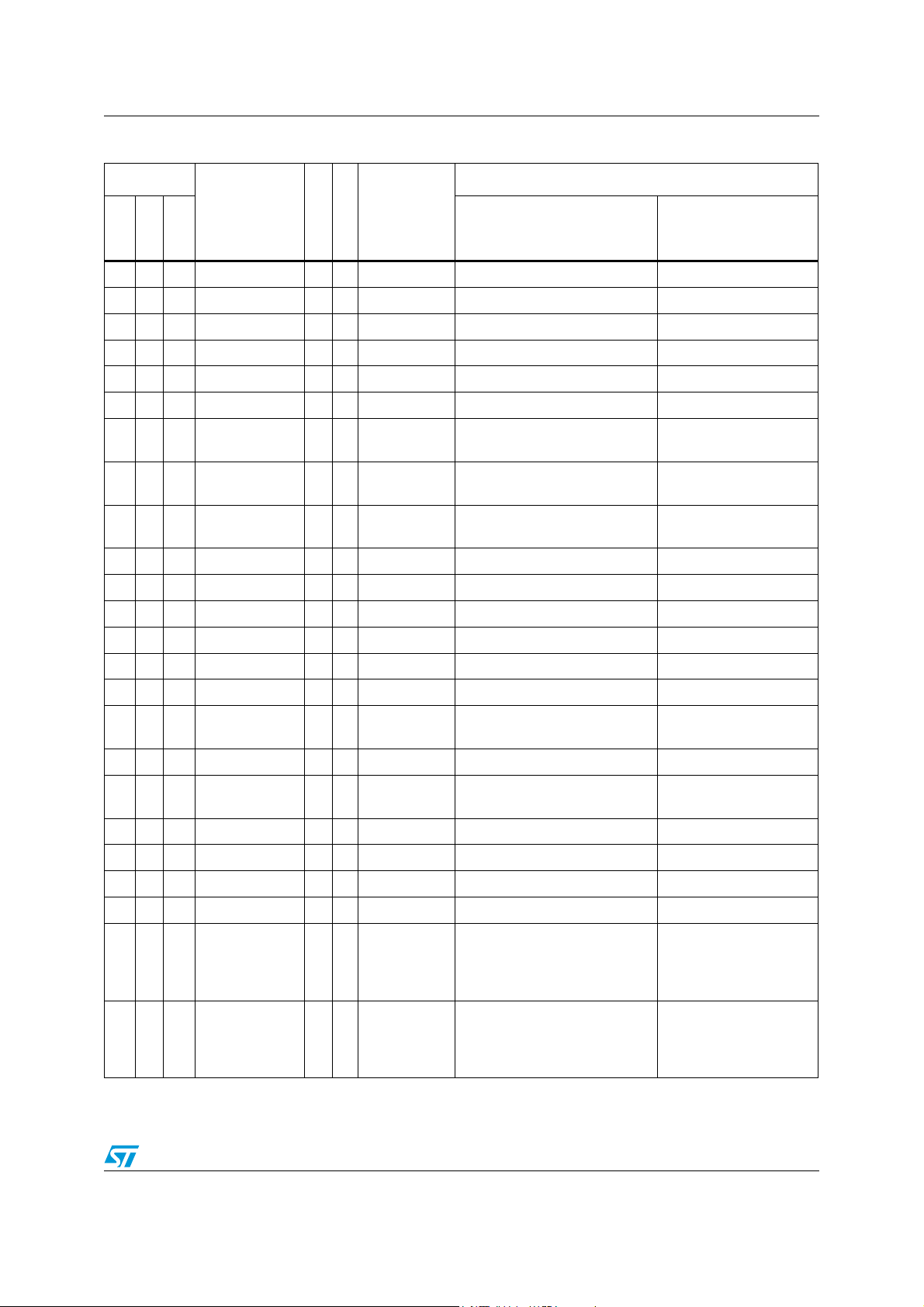

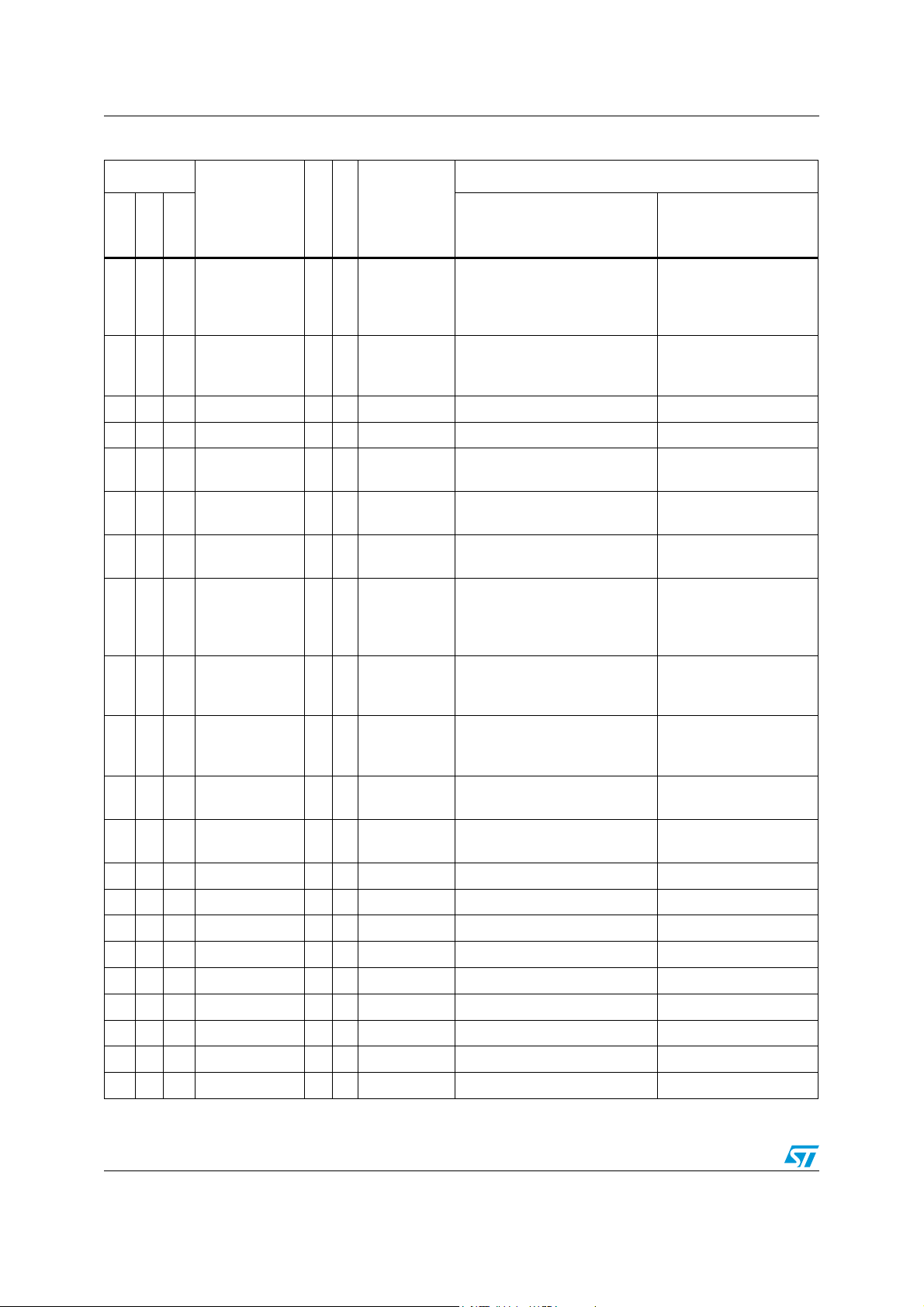

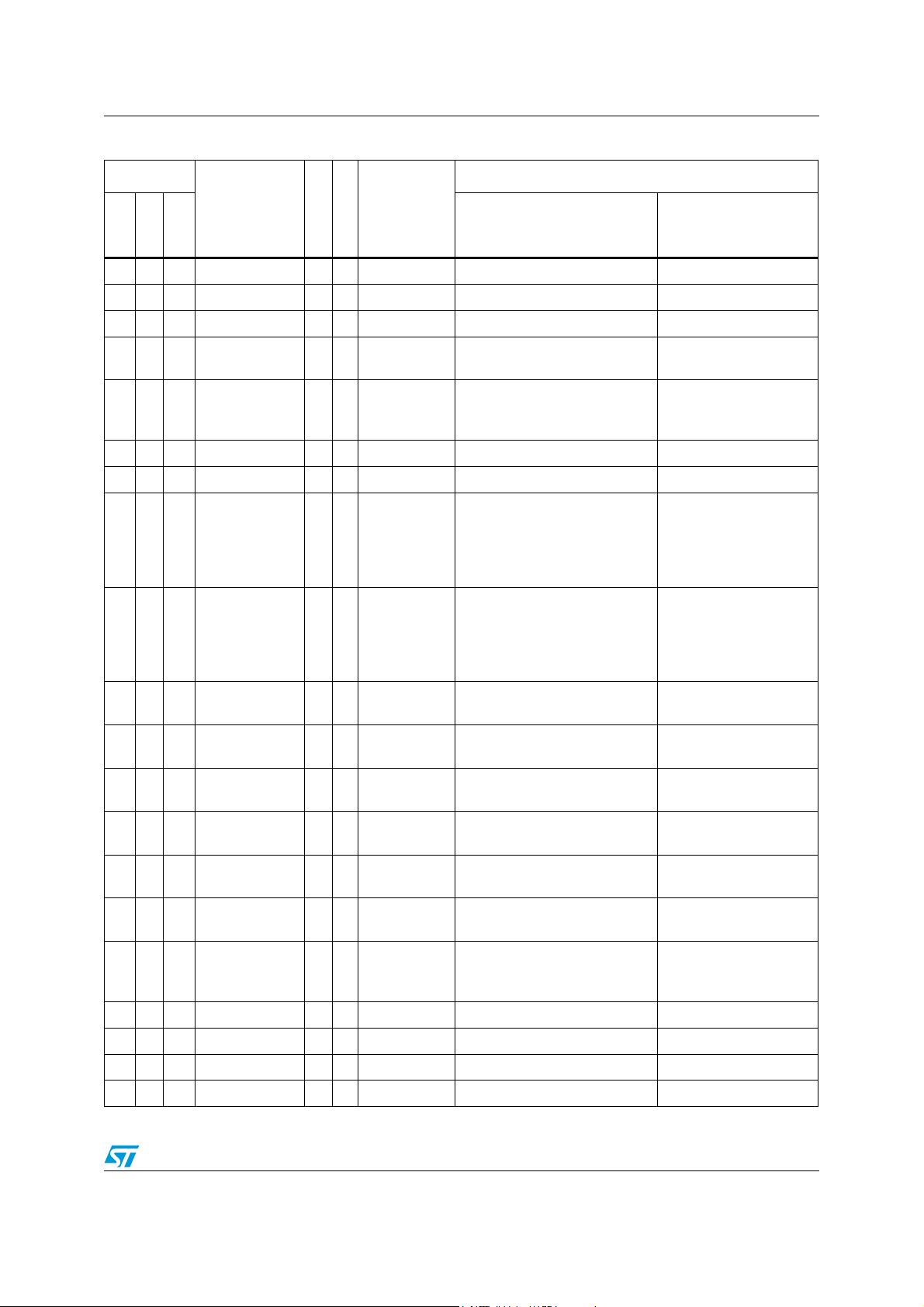

Table 5. Pin definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 6. Voltage characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 7. Current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 8. Thermal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 9. General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 10. Operating conditions at power-up / power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 11. Embedded reset and power control block characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 12. Embedded internal reference voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 13. Maximum current consumption in Run mode, code with data processing

running from Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 14. Maximum current consumption in Run mode, code with data processing

running from RAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 15. Maximum current consumption in Sleep mode, code running from Flash or RAM. . . . . . . 39

Table 16. Typical and maximum current consumptions in Stop and Standby modes . . . . . . . . . . . . 40

Table 17. Typical current consumption in Run mode, code with data processing

running from Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 18. Typical current consumption in Sleep mode, code with data processing

code running from Flash or RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 19. Peripheral current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 20. High-speed external user clock characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 21. Low-speed external user clock characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 22. HSE 3-25 MHz oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 23. LSE oscillator characteristics (f

Table 24. HSI oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 25. LSI oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 26. Low-power mode wakeup timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 27. PLL1 characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 28. PLL2 and PLL3 characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 29. Flash memory characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 30. Flash memory endurance and data retention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 31. EMS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 32. EMI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 33. ESD absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 34. Electrical sensitivities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 35. I/O static characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 36. Output voltage characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 37. I/O AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 38. NRST pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 39. TIMx characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 40. I

Table 41. SCL frequency (f

2

C characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

= 36 MHz.,VDD = 3.3 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

PCLK1

Table 42. SPI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 43. I

2

S characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 44. USB OTG FS startup time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

= 32.768 kHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

LSE

5/90

List of tables STM32F105xx, STM32F107xx

Table 45. USB OTG FS DC electrical characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 46. USB OTG FS electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 47. Dynamics characteristics: Ethernet MAC signals for SMI. . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 48. Dynamics characteristics: Ethernet MAC signals for RMII . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 49. Dynamics characteristics: Ethernet MAC signals for MII . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 50. ADC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 51. R

max for f

AIN

= 14 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

ADC

Table 52. ADC accuracy - limited test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 53. ADC accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 54. DAC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 55. TS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 56. LFBGA100 - low profile fine pitch ball grid array package mechanical data. . . . . . . . . . . . 76

Table 57. LQPF100 – 100-pin low-profile quad flat package mechanical data . . . . . . . . . . . . . . . . . 78

Table 58. LQFP64 – 64 pin low-profile quad flat package mechanical data. . . . . . . . . . . . . . . . . . . . 79

Table 59. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 60. PLL configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 61. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6/90

STM32F105xx, STM32F107xx List of figures

List of figures

Figure 1. STM32F105xx and STM32F107xx connectivity line block diagram . . . . . . . . . . . . . . . . . 21

Figure 2. STM32F105xxx and STM32F107xxx connectivity line LQFP100 pinout . . . . . . . . . . . . . . 22

Figure 3. STM32F105xxx and STM32F107xxx connectivity line LQFP64 pinout . . . . . . . . . . . . . . . 23

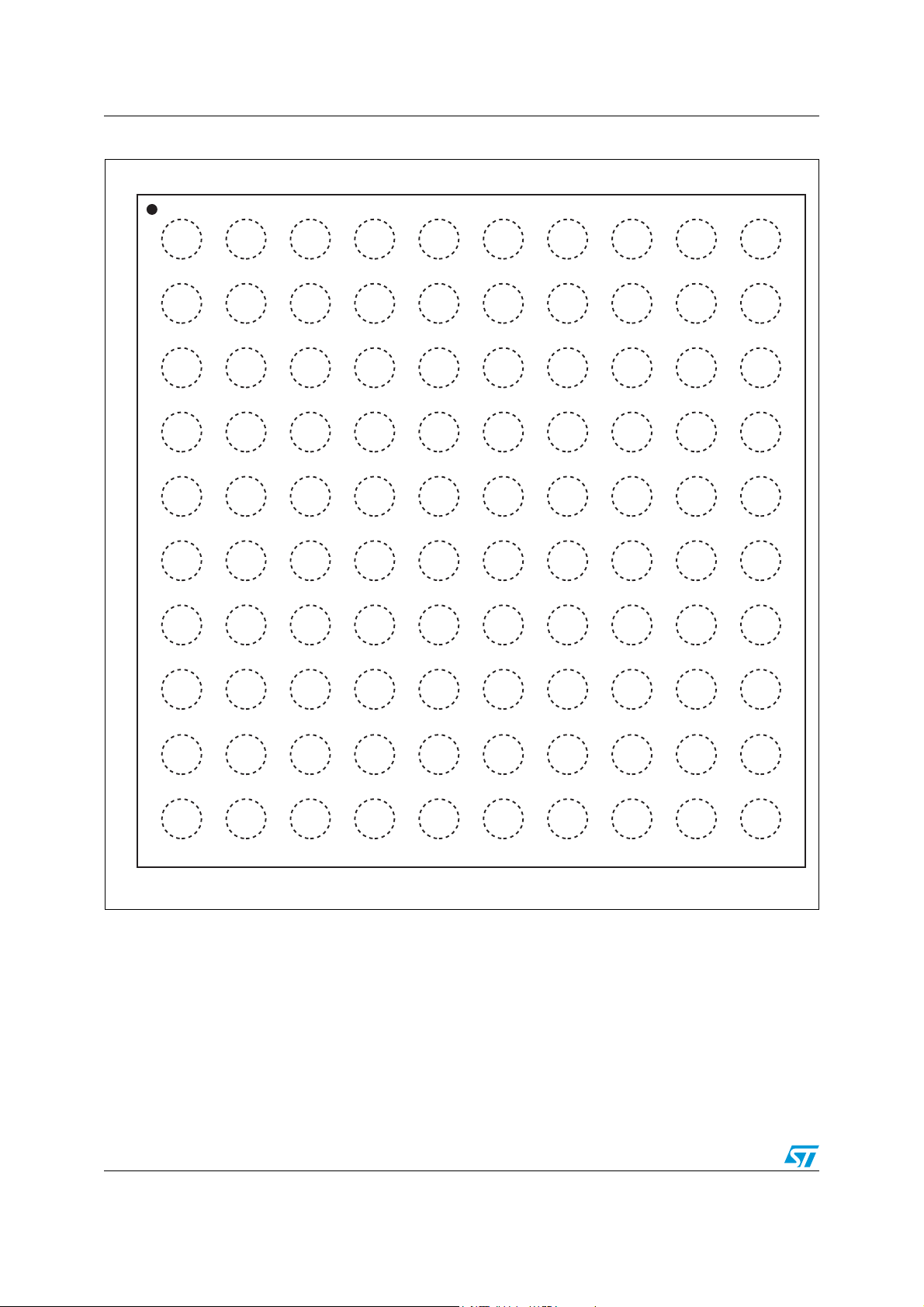

Figure 4. STM32F105xxx and STM32F107xxx connectivity line BGA100 ballout. . . . . . . . . . . . . . . 24

Figure 5. Memory map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 6. Pin loading conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 7. Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 8. Power supply scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 9. Current consumption measurement scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 10. Typical current consumption in Run mode versus frequency (at 3.6 V) -

code with data processing running from RAM, peripherals enabled. . . . . . . . . . . . . . . . . . 38

Figure 11. Typical current consumption in Run mode versus frequency (at 3.6 V) -

code with data processing running from RAM, peripherals disabled . . . . . . . . . . . . . . . . . 38

Figure 12. Typical current consumption in Stop mode with regulator in Run mode versus

temperature at different V

Figure 13. Current consumption in Stop mode with regulator in Low-power mode versus

temperature at different V

Figure 14. Current consumption in Standby mode versus temperature at different V

Figure 15. High-speed external clock source AC timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 16. Low-speed external clock source AC timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 17. Typical application with an 8 MHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 18. Typical application with a 32.768 kHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 19. I/O AC characteristics definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 20. Recommended NRST pin protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 21. I

2

C bus AC waveforms and measurement circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 22. SPI timing diagram - slave mode and CPHA = 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 23. SPI timing diagram - slave mode and CPHA = 1

Figure 24. SPI timing diagram - master mode

Figure 25. I

Figure 26. I

2

S slave timing diagram

2

S master timing diagram

Figure 27. USB OTG FS timings: definition of data signal rise and fall time . . . . . . . . . . . . . . . . . . . . 66

Figure 28. Ethernet SMI timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 29. Ethernet RMII timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 30. Ethernet MII timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 31. ADC accuracy characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 32. Typical connection diagram using the ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 33. Power supply and reference decoupling (V

Figure 34. Power supply and reference decoupling (V

Figure 35. LFBGA100 - low profile fine pitch ball grid array package outline . . . . . . . . . . . . . . . . . . . 76

Figure 36. Recommended PCB design rules (0.80/0.75 mm pitch BGA) . . . . . . . . . . . . . . . . . . . . . . 77

Figure 37. LQFP100, 100-pin low-profile quad flat package outline . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 38. Recommended footprint

Figure 39. LQFP64 – 64 pin low-profile quad flat package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 40. Recommended footprint

Figure 41. USB OTG FS device mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 42. Host connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 43. OTG connection (any protocol). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 44. MII mode using a 25 MHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DD

values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

DD

(1)

(1)

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

(1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

REF+

REF+

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

not connected to V

connected to V

DDA

). . . . . . . . . . . . . . . . . 72

DDA

values . . . . . 41

DD

). . . . . . . . . . . . . . 72

7/90

List of figures STM32F105xx, STM32F107xx

Figure 45. RMII with a 50 MHz oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 46. RMII with a 25 MHz crystal and PHY with PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 47. RMII with a 25 MHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 48. Complete audio player solution 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 49. Complete audio player solution 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 50. USB OTG FS + Ethernet solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 51. USB OTG FS + I

2

S (Audio) solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8/90

STM32F105xx, STM32F107xx Introduction

1 Introduction

This datasheet provides the description of the STM32F105xx and STM32F107xx

connectivity line microcontrollers. For more details on the whole STMicroelectronics

STM32F10xxx family, please refer to Section 2.2: Full compatibility throughout the family.

The STM32F105xx and STM32F107xx datasheet should be read in conjunction with the

STM32F10xxx reference manual.

For information on programming, erasing and protection of the internal Flash memory

please refer to the STM32F10xxx Flash programming manual.

The reference and Flash programming manuals are both available from the

STMicroelectronics website www.st.com.

For information on the Cortex™-M3 core please refer to the Cortex™-M3 Technical

Reference Manual, available from the www.arm.com website at the following address:

http://infocenter.arm.com/help/index.jsp?topic=/com.arm.doc.ddi0337e/.

2 Description

The STM32F105xx and STM32F107xx connectivity line family incorporates the highperformance ARM

speed embedded memories (Flash memory up to 256 Kbytes and SRAM up to 64 Kbytes),

and an extensive range of enhanced I/Os and peripherals connected to two APB buses. All

devices offer two 12-bit ADCs, four general-purpose 16-bit timers plus a PWM timer, as well

as standard and advanced communication interfaces: up to two I

five USARTs, an USB OTG FS and two CANs. Ethernet is available on the STM32F107xx

only.

The STM32F105xx and STM32F107xx connectivity line family operates in the –40 to +105

°C temperature range, from a 2.0 to 3.6 V power supply. A comprehensive set of powersaving mode allows the design of low-power applications.

The STM32F105xx and STM32F107xx connectivity line family offers devices in three

different package types: from 64 pins to 100 pins. Depending on the device chosen, different

sets of peripherals are included, the description below gives an overview of the complete

range of peripherals proposed in this family.

®

Cortex™-M3 32-bit RISC core operating at a 72 MHz frequency, high-

2

Cs, three SPIs, two I2Ss,

9/90

Description STM32F105xx, STM32F107xx

These features make the STM32F105xx and STM32F107xx connectivity line

microcontroller family suitable for a wide range of applications:

● Motor drive and application control

● Medical and handheld equipment

● Industrial applications: PLC, inverters, printers, and scanners

● Alarm systems, Video intercom, and HVAC

● Car audio, home audio equipment

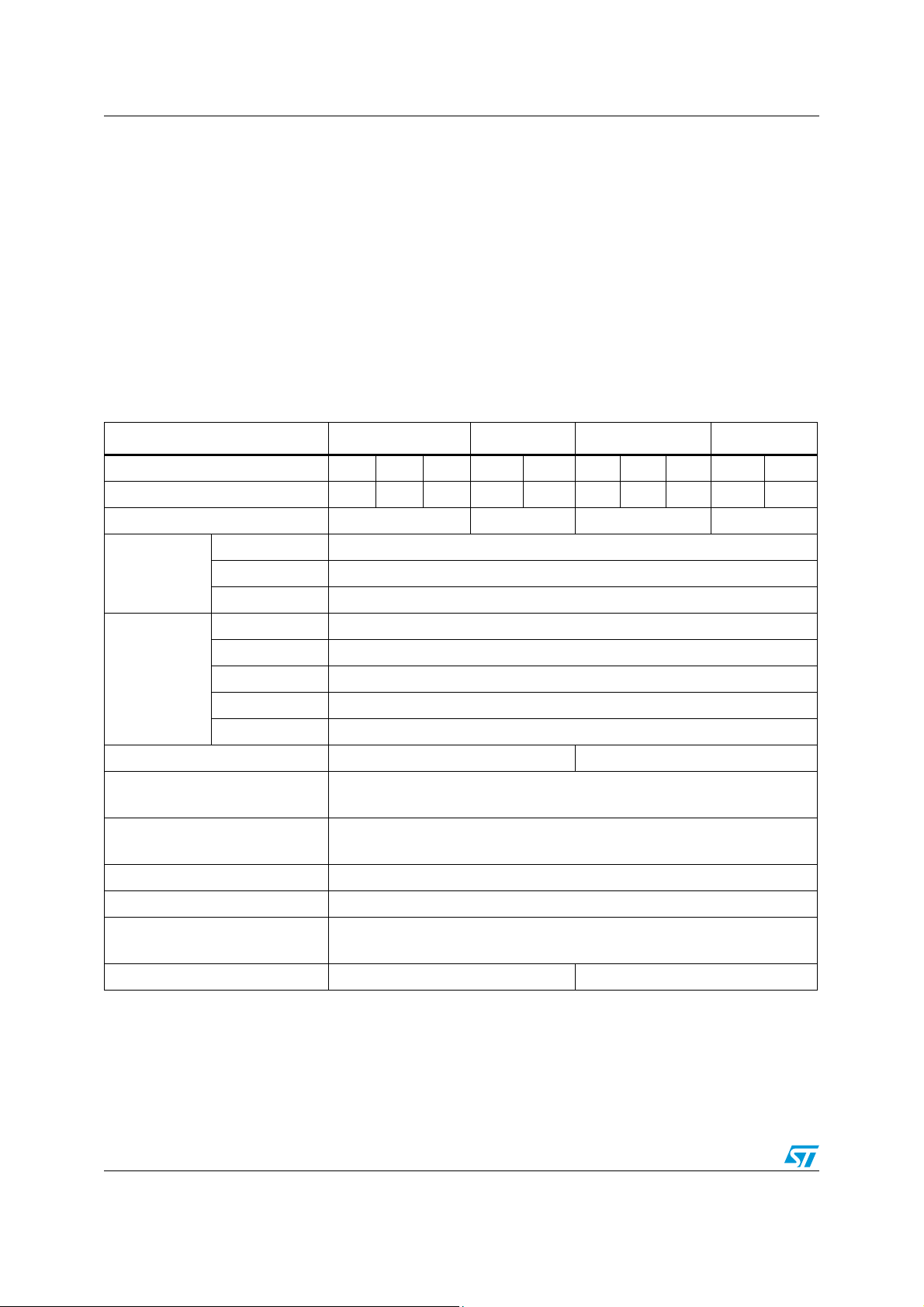

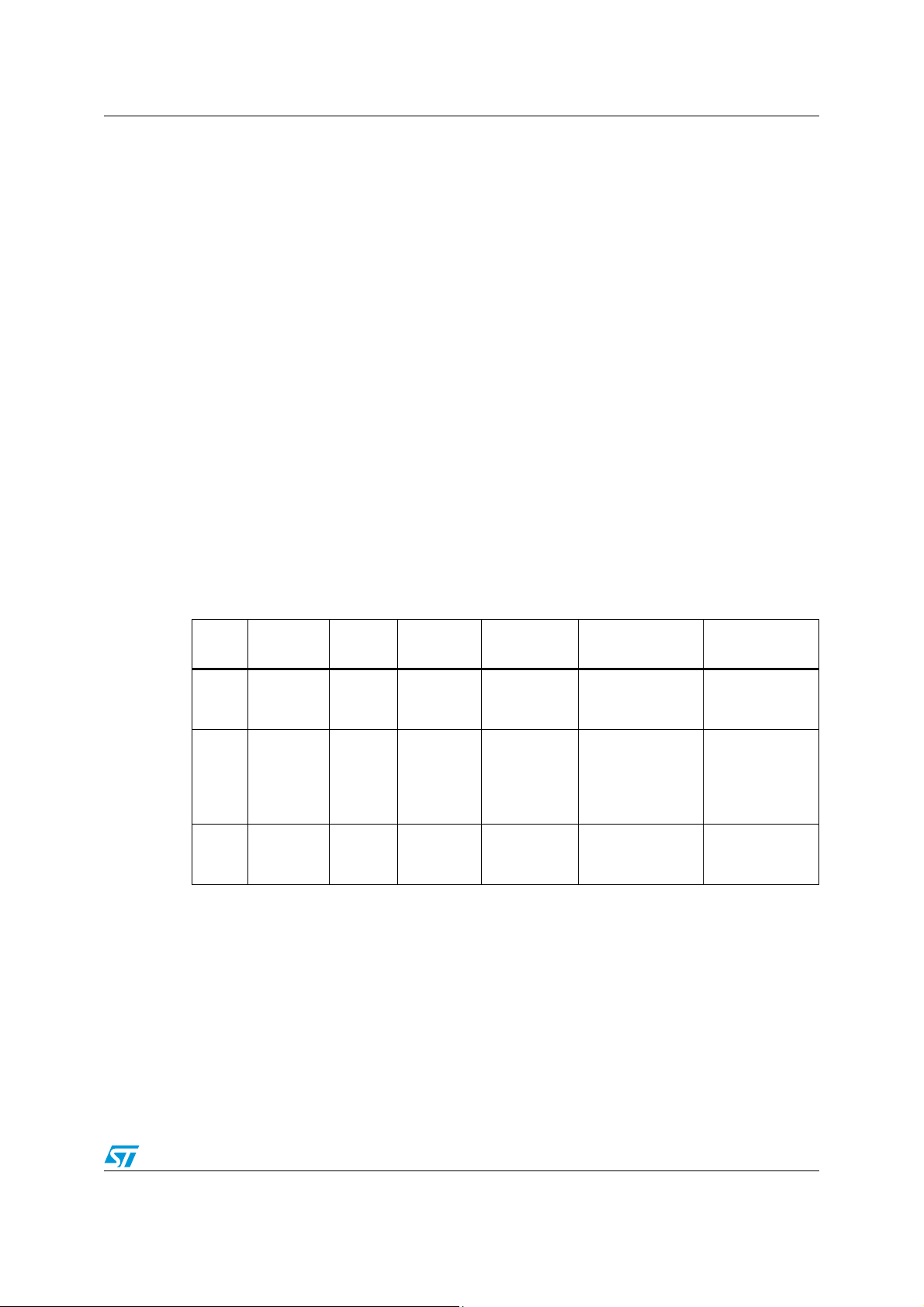

Figure 1 shows the general block diagram of the device family.

2.1 Device overview

Table 2. STM32F105xx and STM32F107xx features and peripheral counts

Peripherals STM32F105Rx STM32F107Rx STM32F105Vx STM32F107Vx

Flash memory in Kbytes 64 128 256 128 256 64 128 256 128 256

SRAM in Kbytes 20 32 64 48 64 20 32 64 48 64

Ethernet No Yes No Yes

General-purpose 4

Timers

Advanced-control 1

Basic 2

Communication

interfaces

2S)(1)

SPI(I

2

I

C2

USART 5

3(2)

USB OTG FS Yes

CAN 2

GPIOs 51 80

12-bit ADC

Number of channels

12-bit DAC

Number of channels

2

16

2

2

CPU frequency 72 MHz

Operating voltage 2.0 to 3.6 V

Operating temperatures

Ambient temperatures: –40 to +85 °C /–40 to +105 °C

Junction temperature: –40 to + 125 °C

Package LQFP64 LQFP100, BGA100

1. The SPI2 and SPI3 interfaces give the flexibility to work in either the SPI mode or the I2S audio mode.

10/90

STM32F105xx, STM32F107xx Description

2.2 Full compatibility throughout the family

The STM32F105xx and STM32F107xx constitute the connectivity line family whose

members are fully pin-to-pin, software and feature compatible.

The STM32F105xx and STM32F107xx are a drop-in replacement for the low-density

(STM32F103x4/6), medium-density (STM32F103x8/B) and high-density

(STM32F103xC/D/E) performance line devices, allowing the user to try different memory

densities and peripherals providing a greater degree of freedom during the development

cycle.

Table 3. STM32F105xx and STM32F107xx family versus STM32F103xx family

STM32

device

Low-density

STM32F103xx

devices

Medium-density

STM32F103xx devices

High-density

STM32F103xx devices

STM32F105xx STM32F107xx

Flash

size (KB)

RAM

size (KB)

144 pins

100 pins

64 pins

48 pins

36 pins

1. Ports F and G are not available in devices delivered in 100-pin packages.

16 32 32 64 128 256 384 512 64 128 256 128 256

610 10 202048646420326448 64

5 × USARTs

2 × USARTs

2 × 16-bit timers

1 × SPI, 1 × I

USB, CAN,

1 × PWM timer

2 × ADCs

2

C,

2 × USARTs

2 × 16-bit

timers

1 × SPI,

2

1 × I

C,

USB, CAN,

1 × PWM

timer

2 × ADCs

3 × USARTs

3 × 16-bit

timers

2 × SPIs,

2

2 × I

Cs, USB,

CAN,

1 × PWM timer

2 × ADCs

4 × 16-bit timers,

2 × basic timers, 3 × SPIs,

2

2 × I

Ss, 2 × I2Cs, USB,

CAN, 2 × PWM timers

3 × ADCs, 1 × DAC,

1 × SDIO, FSMC (100and 144-pin packages

5 × USARTs,

4 × 16-bit timers,

2 × basic timers, 3 × SPIs,

2

2 × I

Ss, 2 × I2Cs,

USB OTG FS,

2 × CANs, 1 × PWM timer,

(1)

)

2 × ADCs, 1 × DAC

2.3 Overview

2.3.1 ARM® CortexTM-M3 core with embedded Flash and SRAM

5 × USARTs,

4 × 16-bit timers,

2 × basic timers,

3 × SPIs, 2 × I

2 × I2Cs,

USB OTG FS,

2 × CANs,

1 × PWM timer,

2 × ADCs,

1 × DAC, Ethernet

2

Ss,

The ARM Cortex™-M3 processor is the latest generation of ARM processors for embedded

systems. It has been developed to provide a low-cost platform that meets the needs of MCU

implementation, with a reduced pin count and low-power consumption, while delivering

outstanding computational performance and an advanced system response to interrupts.

The ARM Cortex™-M3 32-bit RISC processor features exceptional code-efficiency,

delivering the high-performance expected from an ARM core in the memory size usually

associated with 8- and 16-bit devices.

With its embedded ARM core, STM32F105xx and STM32F107xx connectivity line family is

compatible with all ARM tools and software.

Figure 1 shows the general block diagram of the device family.

11/90

Description STM32F105xx, STM32F107xx

2.3.2 Embedded Flash memory

64 to 256 Kbytes of embedded Flash is available for storing programs and data.

2.3.3 CRC (cyclic redundancy check) calculation unit

The CRC (cyclic redundancy check) calculation unit is used to get a CRC code from a 32-bit

data word and a fixed generator polynomial.

Among other applications, CRC-based techniques are used to verify data transmission or

storage integrity. In the scope of the EN/IEC 60335-1 standard, they offer a means of

verifying the Flash memory integrity. The CRC calculation unit helps compute a signature of

the software during runtime, to be compared with a reference signature generated at linktime and stored at a given memory location.

2.3.4 Embedded SRAM

20 to 64 Kbytes of embedded SRAM accessed (read/write) at CPU clock speed with 0 wait

states.

2.3.5 Nested vectored interrupt controller (NVIC)

The STM32F105xx and STM32F107xx connectivity line embeds a nested vectored interrupt

controller able to handle up to 67 maskable interrupt channels (not including the 16 interrupt

lines of Cortex™-M3) and 16 priority levels.

● Closely coupled NVIC gives low latency interrupt processing

● Interrupt entry vector table address passed directly to the core

● Closely coupled NVIC core interface

● Allows early processing of interrupts

● Processing of late arriving higher priority interrupts

● Support for tail-chaining

● Processor state automatically saved

● Interrupt entry restored on interrupt exit with no instruction overhead

This hardware block provides flexible interrupt management features with minimal interrupt

latency.

2.3.6 External interrupt/event controller (EXTI)

The external interrupt/event controller consists of 20 edge detector lines used to generate

interrupt/event requests. Each line can be independently configured to select the trigger

event (rising edge, falling edge, both) and can be masked independently. A pending register

maintains the status of the interrupt requests. The EXTI can detect an external line with a

pulse width shorter than the Internal APB2 clock period. Up to 80 GPIOs can be connected

to the 16 external interrupt lines.

2.3.7 Clocks and startup

System clock selection is performed on startup, however, the internal RC 8 MHz oscillator is

selected as default CPU clock on reset. An external 3-25 MHz clock can be selected, in

which case it is monitored for failure. If failure is detected, the system automatically switches

back to the internal RC oscillator. A software interrupt is generated if enabled. Similarly, full

12/90

STM32F105xx, STM32F107xx Description

interrupt management of the PLL clock entry is available when necessary (for example with

failure of an indirectly used external oscillator).

A single 25 MHz crystal can clock the entire system including the ethernet and USB OTG

FS peripherals. Several prescalers and PLLs allow the configuration of the AHB frequency,

the high speed APB (APB2) and the low speed APB (APB1) domains. The maximum

frequency of the AHB and the high speed APB domains is 72 MHz. The maximum allowed

frequency of the low speed APB domain is 36 MHz. Refer to Figure 50: USB OTG FS +

Ethernet solution on page 87.

The advanced clock controller clocks the core and all peripherals using a single crystal or

oscillator. In order to achieve audio class performance, an audio crystal can be used. In this

case, the I

96 kHz with less than 0.5% accuracy error. Refer to Figure 51: USB OTG FS + I

2

S master clock can generate all standard sampling frequencies from 8 kHz to

2

S (Audio)

solution on page 87.

To configure the PLLs, please refer to Table 60 on page 88, which provides PLL

configurations according to the application type.

2.3.8 Boot modes

At startup, boot pins are used to select one of three boot options:

● Boot from User Flash

● Boot from System Memory

● Boot from embedded SRAM

The boot loader is located in System Memory. It is used to reprogram the Flash memory by

using USART1, USART2 (remapped), CAN2 (remapped), USB OTG FS in device mode

(DFU: device firmware upgrade) and Ethernet.

2.3.9 Power supply schemes

● V

● V

● V

= 2.0 to 3.6 V: external power supply for I/Os and the internal regulator.

DD

Provided externally through V

, V

SSA

= 2.0 to 3.6 V: external analog power supplies for ADC, Reset blocks, RCs

DDA

and PLL (minimum voltage to be applied to V

and V

BAT

must be connected to VDD and VSS, respectively.

SSA

= 1.8 to 3.6 V: power supply for RTC, external clock 32 kHz oscillator and backup

registers (through power switch) when V

2.3.10 Power supply supervisor

The device has an integrated power-on reset (POR)/power-down reset (PDR) circuitry. It is

always active, and ensures proper operation starting from/down to 2 V. The device remains

in reset mode when V

external reset circuit.

The device features an embedded programmable voltage detector (PVD) that monitors the

V

DD/VDDA

generated when V

than the V

power supply and compares it to the V

DD/VDDA

threshold. The interrupt service routine can then generate a warning

PVD

message and/or put the MCU into a safe state. The PVD is enabled by software.

is below a specified threshold, V

DD

drops below the V

DD

pins.

is 2.4 V when the ADC is used). V

DDA

is not present.

DD

POR/PDR

threshold. An interrupt can be

PVD

threshold and/or when VDD/V

PVD

, without the need for an

is higher

DDA

DDA

13/90

Description STM32F105xx, STM32F107xx

2.3.11 Voltage regulator

The regulator has three operation modes: main (MR), low power (LPR) and power down.

● MR is used in the nominal regulation mode (Run)

● LPR is used in the Stop modes.

● Power down is used in Standby mode: the regulator output is in high impedance: the

kernel circuitry is powered down, inducing zero consumption (but the contents of the

registers and SRAM are lost)

This regulator is always enabled after reset. It is disabled in Standby mode.

2.3.12 Low-power modes

The STM32F105xx and STM32F107xx connectivity line supports three low-power modes to

achieve the best compromise between low power consumption, short startup time and

available wakeup sources:

● Sleep mode

In Sleep mode, only the CPU is stopped. All peripherals continue to operate and can

wake up the CPU when an interrupt/event occurs.

● Stop mode

Stop mode achieves the lowest power consumption while retaining the content of

SRAM and registers. All clocks in the 1.8 V domain are stopped, the PLL, the HSI RC

and the HSE crystal oscillators are disabled. The voltage regulator can also be put

either in normal or in low-power mode.

The device can be woken up from Stop mode by any of the EXTI line. The EXTI line

source can be one of the 16 external lines, the PVD output, the RTC alarm or the USB

OTG FS wakeup.

● Standby mode

The Standby mode is used to achieve the lowest power consumption. The internal

voltage regulator is switched off so that the entire 1.8 V domain is powered off. The

PLL, the HSI RC and the HSE crystal oscillators are also switched off. After entering

Standby mode, SRAM and register contents are lost except for registers in the Backup

domain and Standby circuitry.

The device exits Standby mode when an external reset (NRST pin), an IWDG reset, a

rising edge on the WKUP pin, or an RTC alarm occurs.

Note: The RTC, the IWDG, and the corresponding clock sources are not stopped by entering Stop

or Standby mode.

2.3.13 DMA

The flexible 12-channel general-purpose DMAs (7 channels for DMA1 and 5 channels for

DMA2) are able to manage memory-to-memory, peripheral-to-memory and memory-toperipheral transfers. The two DMA controllers support circular buffer management,

removing the need for user code intervention when the controller reaches the end of the

buffer.

Each channel is connected to dedicated hardware DMA requests, with support for software

trigger on each channel. Configuration is made by software and transfer sizes between

source and destination are independent.

The DMA can be used with the main peripherals: SPI, I

and advanced control timers TIMx, DAC, I

14/90

2

S and ADC.

2

C, USART, general-purpose, basic

STM32F105xx, STM32F107xx Description

2.3.14 RTC (real-time clock) and backup registers

The RTC and the backup registers are supplied through a switch that takes power either on

V

supply when present or through the V

DD

registers used to store 84 bytes of user application data when V

pin. The backup registers are forty-two 16-bit

BAT

power is not present.

DD

They are not reset by a system or power reset, and they are not reset when the device

wakes up from the Standby mode.

The real-time clock provides a set of continuously running counters which can be used with

suitable software to provide a clock calendar function, and provides an alarm interrupt and a

periodic interrupt. It is clocked by a 32.768 kHz external crystal, resonator or oscillator, the

internal low power RC oscillator or the high-speed external clock divided by 128. The

internal low-speed RC has a typical frequency of 40 kHz. The RTC can be calibrated using

an external 512 Hz output to compensate for any natural quartz deviation. The RTC features

a 32-bit programmable counter for long term measurement using the Compare register to

generate an alarm. A 20-bit prescaler is used for the time base clock and is by default

configured to generate a time base of 1 second from a clock at 32.768 kHz.

2.4 Timers and watchdogs

The STM32F105xx and STM32F107xx devices include six general-purpose timers, two

basic timers and two watchdog timers.

Ta bl e 4 compares the features of the general-purpose and basic timers.

Table 4. Timer feature comparison

Timer

TIM1 16-bit

TIMx

(TIM2,

TIM3,

TIM4,

TIM5)

TIM6,

TIM7

Counter

resolution

16-bit

16-bit Up

Counter

type

Up,

down,

up/down

Up,

down,

up/down

Prescaler

factor

Any integer

between 1

and 65536

Any integer

between 1

and 65536

Any integer

between 1

and 65536

2.4.1 Advanced-control timer (TIM1)

The advanced control timer (TIM1) can be seen as a three-phase PWM multiplexed on 6

channels. It has complementary PWM outputs with programmable inserted dead-times. It

can also be seen as a complete general-purpose timer. The 4 independent channels can be

used for:

● Input capture

● Output compare

● PWM generation (edge or center-aligned modes)

● One-pulse mode output

DMA request

generation

Ye s 4 Ye s

Ye s 4 N o

Ye s 0 N o

Capture/compare

channels

Complementary

outputs

15/90

Description STM32F105xx, STM32F107xx

If configured as a standard 16-bit timer, it has the same features as the TIMx timer. If

configured as the 16-bit PWM generator, it has full modulation capability (0-100%).

The counter can be frozen in debug mode.

Many features are shared with those of the standard TIM timers which have the same

architecture. The advanced control timer can therefore work together with the TIM timers via

the Timer Link feature for synchronization or event chaining.

2.4.2 General-purpose timers (TIMx)

There are up to 4 synchronizable standard timers (TIM2, TIM3, TIM4 and TIM5) embedded

in the STM32F105xx and STM32F107xx connectivity line devices. These timers are based

on a 16-bit auto-reload up/down counter, a 16-bit prescaler and feature 4 independent

channels each for input capture/output compare, PWM or one pulse mode output. This

gives up to 16 input captures / output compares / PWMs on the largest packages. They can

work together with the Advanced Control timer via the Timer Link feature for synchronization

or event chaining.

The counter can be frozen in debug mode.

Any of the standard timers can be used to generate PWM outputs. Each of the timers has

independent DMA request generations.

2.4.3 Basic timers TIM6 and TIM7

These timers are mainly used for DAC trigger generation. They can also be used as a

generic 16-bit time base.

2.4.4 Independent watchdog

The independent watchdog is based on a 12-bit downcounter and 8-bit prescaler. It is

clocked from an independent 40 kHz internal RC and as it operates independently from the

main clock, it can operate in Stop and Standby modes. It can be used either as a watchdog

to reset the device when a problem occurs, or as a free running timer for application timeout

management. It is hardware or software configurable through the option bytes. The counter

can be frozen in debug mode.

2.4.5 Window watchdog

The window watchdog is based on a 7-bit downcounter that can be set as free running. It

can be used as a watchdog to reset the device when a problem occurs. It is clocked from the

main clock. It has an early warning interrupt capability and the counter can be frozen in

debug mode.

2.4.6 SysTick timer

This timer is dedicated to real-time operating systems, but could also be used as a standard

down counter. It features:

● A 24-bit down counter

● Autoreload capability

● Maskable system interrupt generation when the counter reaches 0.

● Programmable clock source

16/90

STM32F105xx, STM32F107xx Description

2.4.7 I²C bus

Up to two I²C bus interfaces can operate in multimaster and slave modes. They can support

standard and fast modes.

They support 7/10-bit addressing mode and 7-bit dual addressing mode (as slave). A

hardware CRC generation/verification is embedded.

They can be served by DMA and they support SMBus 2.0/PMBus.

2.4.8 Universal synchronous/asynchronous receiver transmitters (USARTs)

The STM32F105xx and STM32F107xx connectivity line embeds three universal

synchronous/asynchronous receiver transmitters (USART1, USART2 and USART3) and

two universal asynchronous receiver transmitters (UART4 and UART5).

These five interfaces provide asynchronous communication, IrDA SIR ENDEC support,

multiprocessor communication mode, single-wire half-duplex communication mode and

have LIN Master/Slave capability.

The USART1 interface is able to communicate at speeds of up to 4.5 Mbit/s. The other

available interfaces communicate at up to 2.25 Mbit/s.

USART1, USART2 and USART3 also provide hardware management of the CTS and RTS

signals, Smart Card mode (ISO 7816 compliant) and SPI-like communication capability. All

interfaces can be served by the DMA controller except for UART5.

2.4.9 Serial peripheral interface (SPI)

Up to three SPIs are able to communicate up to 18 Mbits/s in slave and master modes in

full-duplex and simplex communication modes. The 3-bit prescaler gives 8 master mode

frequencies and the frame is configurable to 8 bits or 16 bits. The hardware CRC

generation/verification supports basic SD Card/MMC modes.

All SPIs can be served by the DMA controller.

2.4.10 Inter-integrated sound (I2S)

Two standard I2S interfaces (multiplexed with SPI2 and SPI3) are available, that can be

operated in master or slave mode. These interfaces can be configured to operate with 16/32

bit resolution, as input or output channels. Audio sampling frequencies from 8 kHz up to

96 kHz are supported. When either or both of the I

mode, the master clock can be output to the external DAC/CODEC at 256 times the

sampling frequency with less than 0.5% accuracy error owing to the advanced clock

controller (see Section 2.3.7: Clocks and startup).

Please refer to the “Audio frequency precision” tables provided in the “Serial peripheral

interface (SPI)” section of the STM32F10xxx reference manual.

2

S interfaces is/are configured in master

2.4.11 Ethernet MAC interface with dedicated DMA and IEEE 1588 support

Peripheral not available on STM32F105xx devices.

The STM32F107xx devices provide an IEEE-802.3-2002-compliant media access controller

(MAC) for ethernet LAN communications through an industry-standard media-independent

interface (MII) or a reduced media-independent interface (RMII). The STM32F107xx

requires an external physical interface device (PHY) to connect to the physical LAN bus

17/90

Description STM32F105xx, STM32F107xx

(twisted-pair, fiber, etc.). the PHY is connected to the STM32F107xx MII port using as many

as 17 signals (MII) or 9 signals (RMII) and can be clocked using the 25 MHz (MII) or 50 MHz

(RMII) output from the STM32F107xx.

The STM32F107xx includes the following features:

● Supports 10 and 100 Mbit/s rates

● Dedicated DMA channel

● Tagged MAC frame support (VLAN support)

● Half-duplex (CSMA/CD) and full-duplex operation

● MAC control sublayer (control frames) support

● 32-bit CRC generation and removal

● Several address filtering modes for physical and multicast address (multicast and group

addresses)

● 32-bit status code for each transmitted or received frame

● Internal FIFOs to buffer transmit and receive frames. The transmit FIFO and the receive

FIFO are both 2 Kbytes (512 × 35 bits), that is 4 Kbytes in total

● Supports hardware PTP (precision time protocol) in accordance with IEEE 1588 1.0

with the timestamp comparator connected to the TIM2 trigger input

● Triggers interrupt when system time becomes greater than target time

2.4.12 Controller area network (CAN)

The two CANs are compliant with the 2.0A and B (active) specifications with a bitrate up to

1 Mbit/s. They can receive and transmit standard frames with 11-bit identifiers as well as

extended frames with 29-bit identifiers. Each CAN has three transmit mailboxes, two receive

FIFOS with 3 stages and 28 shared scalable filter banks (all of them can be used even if one

CAN is used). The 256 bytes of SRAM which are allocated for each CAN (512 bytes in total)

are not shared with any other peripheral.

2.4.13 Universal serial bus on-the-go full-speed (USB OTG FS)

The STM32F105xx and STM32F107xx connectivity line devices embed a USB OTG fullspeed (12 Mb/s) device/host/OTG peripheral with integrated transceivers. The USB OTG FS

peripheral is compliant with the USB 2.0 specification and with the OTG 1.0 specification. It

has software-configurable endpoint setting and supports suspend/resume. The USB OTG

full-speed controller requires a dedicated 48 MHz clock that is generated by a PLL

connected to the HSE oscillator. The major features are:

● 1.25 KB of SRAM used exclusively by the endpoints (not shared with any other

peripheral)

● 4 bidirectional endpoints

● HNP/SNP/IP inside (no need for any external resistor)

● for OTG/Host modes, a power switch is needed in case bus-powered devices are

connected

● the SOF output can be used to synchronize the external audio DAC clock in

isochronous mode

● in accordance with the USB 2.0 Specification, the supported transfer speeds are:

– in Host mode: full speed and low speed

– in Device mode: full speed

18/90

STM32F105xx, STM32F107xx Description

2.4.14 GPIOs (general-purpose inputs/outputs)

Each of the GPIO pins can be configured by software as output (push-pull or open-drain), as

input (with or without pull-up or pull-down) or as peripheral alternate function. Most of the

GPIO pins are shared with digital or analog alternate functions. All GPIOs are high currentcapable except for analog inputs.

The I/Os alternate function configuration can be locked if needed following a specific

sequence in order to avoid spurious writing to the I/Os registers.

I/Os on APB2 with up to 18 MHz toggling speed

2.4.15 ADCs (analog-to-digital converters)

Two 12-bit analog-to-digital converters are embedded into STM32F105xx and

STM32F107xx connectivity line devices and each ADC shares up to 16 external channels,

performing conversions in single-shot or scan modes. In scan mode, automatic conversion

is performed on a selected group of analog inputs.

Additional logic functions embedded in the ADC interface allow:

● Simultaneous sample and hold

● Interleaved sample and hold

● Single shunt

The ADC can be served by the DMA controller.

An analog watchdog feature allows very precise monitoring of the converted voltage of one,

some or all selected channels. An interrupt is generated when the converted voltage is

outside the programmed thresholds.

The events generated by the standard timers (TIMx) and the advanced-control timer (TIM1)

can be internally connected to the ADC start trigger and injection trigger, respectively, to

allow the application to synchronize A/D conversion and timers.

2.4.16 DAC (digital-to-analog converter)

The two 12-bit buffered DAC channels can be used to convert two digital signals into two

analog voltage signal outputs. The chosen design structure is composed of integrated

resistor strings and an amplifier in inverting configuration.

This dual digital Interface supports the following features:

● two DAC converters: one for each output channel

● 8-bit or 12-bit monotonic output

● left or right data alignment in 12-bit mode

● synchronized update capability

● noise-wave generation

● triangular-wave generation

● dual DAC channel independent or simultaneous conversions

● DMA capability for each channel

● external triggers for conversion

● input voltage reference V

REF+

19/90

Description STM32F105xx, STM32F107xx

Eight DAC trigger inputs are used in the STM32F105xx and STM32F107xx connectivity line

family. The DAC channels are triggered through the timer update outputs that are also

connected to different DMA channels.

2.4.17 Temperature sensor

The temperature sensor has to generate a voltage that varies linearly with temperature. The

conversion range is between 2 V < V

connected to the ADC1_IN16 input channel which is used to convert the sensor output

voltage into a digital value.

< 3.6 V. The temperature sensor is internally

DDA

2.4.18 Serial wire JTAG debug port (SWJ-DP)

The ARM SWJ-DP Interface is embedded, and is a combined JTAG and serial wire debug

port that enables either a serial wire debug or a JTAG probe to be connected to the target.

The JTAG TMS and TCK pins are shared respectively with SWDIO and SWCLK and a

specific sequence on the TMS pin is used to switch between JTAG-DP and SW-DP.

2.4.19 Embedded Trace Macrocell™

The ARM® Embedded Trace Macrocell provides a greater visibility of the instruction and

data flow inside the CPU core by streaming compressed data at a very high rate from the

STM32F10xxx through a small number of ETM pins to an external hardware trace port

analyzer (TPA) device. The TPA is connected to a host computer using USB OTG FS,

Ethernet, or any other high-speed channel. Real-time instruction and data flow activity can

be recorded and then formatted for display on the host computer running debugger

software. TPA hardware is commercially available from common development tool vendors.

It operates with third party debugger software tools.

20/90

PA[1 5:0]

EXT.IT

WWDG

12bit ADC1

16 ADC12_INs

common to

ADC1 & ADC2

JTDI

JTCK /SWCLK

JTMS/SWDIO

JNTRST

JTDO

NRST

VDD = 2 to 3.6 V

80 AF

PB[1 5:0]

PC[15:0 ]

AHB2

CAN1_RX as AF

2x(8x16bi t)

WKUP

GPIO port AP

GPIO port BP

F

max

: 48 / 72 MHz

V

SS

SCL,SDA,SM BAL

I2C2

GP DMA1

TIM2

TIM3

XT

AL osc

3-25 MHz

XTAL 32kH z

OSC_IN

OSC_OUTC_O

OSC32_OUT

OSC32_IN

APB1 : F

max

=24 / 36 MHz

HCLK

MANAGT

as AF

Flash 256 KB

Voltage reg.

3.3 V to 1.8 V

V

DD18

Power

Backup interface

as AF

TIM4

Bus Matrix

64 bit

Int erfa ce

RTC

RC HS

Cortex-M3 CPU

Ibus

Dbus

obl

Flashl

SRAM 512B

USART1

USART2

SPI2 / I2S2

bxCAN1 dev ice

7 ch ann els

Back up

register

4 Channels

TIM1

4 compl. Channels

SCL,SDA,SMBAL

I2C1

as AF

RX,TX, CTS, RTS,

USART3

Temp se nsor

PD[15:0 ]

PE[15:0 ]

BKIN, ETR input as AF

4 Channe ls , ETR

4 Channe ls , ETR

4 Channe ls , ETR

FCLK

RC LS

Standby

IWDG

@V

DD

@V

BAT

POR / PDR

Supply

supervision

@V

DDA

V

DDA

V

SSA

@VDDA

V

BAT

=1.8 V to 3.6 V

CK as A F

RX,TX, CTS, RTS,

CK as AF

RX,TX, CTS, RTS,

CK as AF

APB2 : F

max

=48 / 72 MHz

NVIC

SPI1

MOSI,MISO,

SCK,NSS as AF

12bit ADC2

IF

IF

interface

PVD

Reset

Int

@V

DD

AHB2

APB2

APB1

AWU

POR

TAMPER-RTC/

ALARM/SECOND OUT

System

2x(8x16bi t)

SPI3 / I2S3

UART4

RX,TX as AF

UART5

RX,TX as AF

TIM5

4 Channel s, ETR

Reset &

clock

control

12bit DAC1

IFIF

IF

12bit DAC 2

@VDDA

USB OTG FS

SOF

VBUS

ID

DM

DP

SRAM

64 KB

GP DMA2

5 ch ann els

TIM6

TIM7

CAN1_TX as AF

SW/JTAG

TPIU

ETM

Trac e/Tri g

TRACECLK

TRACED[ 0:3]

as AF

as AF

as AF

as AF

as AF

Ethernet MAC

10/100

SRAM 1.25KB

DPRAM 2KB DPRAM 2KB

MII_TXD[3:0]/RMII_TXD[1:0]

MII_TX_CLK/RMII_TX_CLK

MII_TX_EN/RMII_TX_EN

MII_RXD[3:0]/RMII_RXD[1:0]

MII_RX_ER/RMII_RX_ER

MII_RX_CLK/RMII_REF_CLK

MII_RX_DV/RMII_CRS_DV

MII_CRS

MII_COL/RMII_COL

MDC

MDIO

PPS_OUT

bxCA N2 device

CAN2_RX as AF

CAN2_TX as AF

ai15411

DAC_OUT1 as AF

DAC_OUT2 as AF

@V

DDA

PLL1

GPIO port C

GPIO port D

GPIO port E

V

REF+

V

REF–

V

REF+

MOSI/SD, MISO, MCK,

SCK/CK, NSS/WS as AF

MOSI/SD, MISO, MCK,

SCK/CK, NSS/WS as AF

PCLK1

PCLK2

PLL2

PLL3

STM32F105xx, STM32F107xx Description

Figure 1. STM32F105xx and STM32F107xx connectivity line block diagram

1. TA = –40 °C to +85 °C (suffix 6, see Table 59) or –40 °C to +105 °C (suffix 7, see Table 59), junction temperature up to

105 °C or 125 °C, respectively.

2. AF = alternate function on I/O port pin.

21/90

Pin descriptions STM32F105xx, STM32F107xx

100

9998979695949392919089888786858483828180797877

76

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

VDD_2

VSS_2

NC

PA 1 3

PA 1 2

PA 1 1

PA 1 0

PA 9

PA 8

PC9

PC8

PC7

PC6

PD15

PD14

PD13

PD12

PD11

PD10

PD9

PD8

PB15

PB14

PB13

PB12

PA 3

VSS_4

VDD_4

PA 4

PA 5

PA 6

PA 7

PC4

PC5

PB0

PB1

PB2

PE7

PE8

PE9

PE10

PE11

PE12

PE13

PE14

PE15

PB10

PB11

VSS_1

VDD_1

VDD_3

VSS_3

PE1

PE0

PB9

PB8

BOOT0

PB7

PB6

PB5

PB4

PB3

PD7

PD6

PD5

PD4

PD3

PD2

PD1

PD0

PC12

PC11

PC10

PA15

PA14

26272829303132333435363738394041424344454647484950

PE2

PE3

PE4

PE5

PE6

VBAT

PC13-TAMPER-RTC

PC14-OSC32_IN

PC15-OSC32_OUT

VSS_5

VDD_5

OSC_IN

OSC_OUT

NRST

PC0

PC1

PC2

PC3

VSSA

VREF-

VREF+

VDDA

PA 0- W K UP

PA 1

PA 2

ai14391

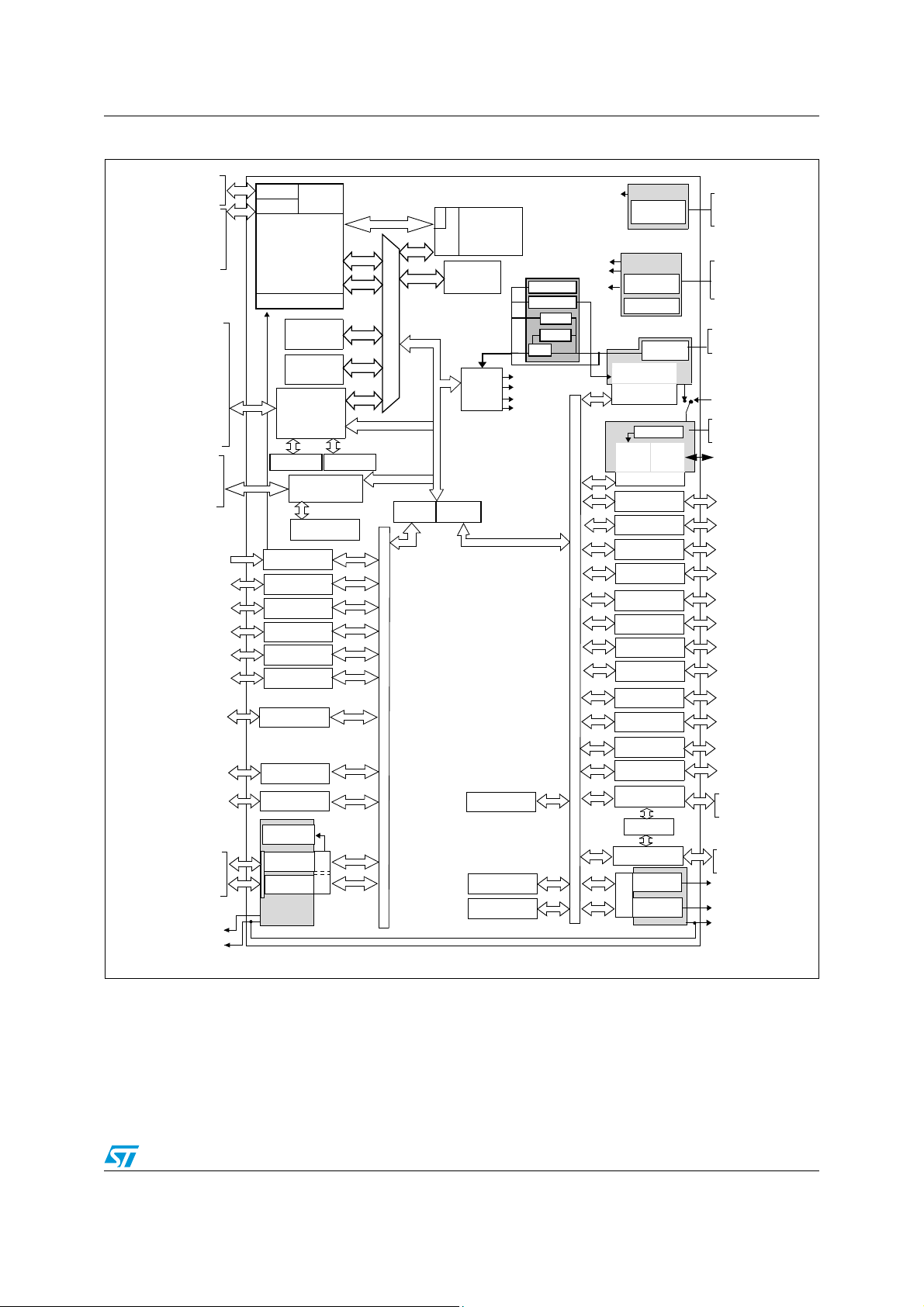

LQFP100

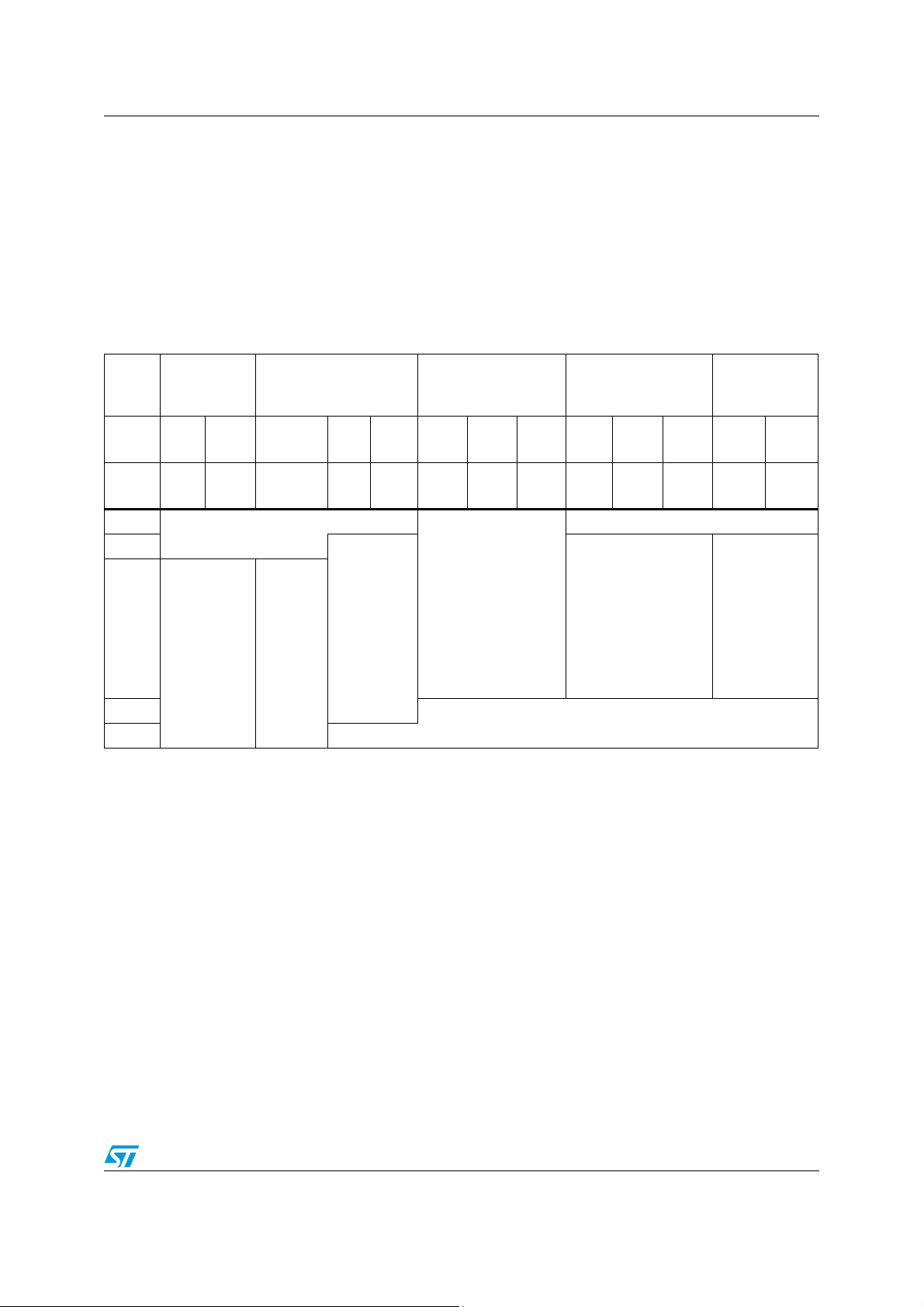

3 Pin descriptions

Figure 2. STM32F105xxx and STM32F107xxx connectivity line LQFP100 pinout

22/90

STM32F105xx, STM32F107xx Pin descriptions

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

17 18 19 20 21 22 23 24 29 30 31 3225 26 27 28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

V

BAT

PC13-TAMPER-RTC

PC14-OSC32_IN

PC15-OSC32_OUT

PD0 OSC_IN

PD1 OSC_OUT

NRST

PC0

PC1

PC2

PC3

V

SSA

V

DDA

PA 0- W K UP

PA 1

PA 2

V

DD_3

V

SS_3

PB9

PB8

BOOT0

PB7

PB6

PB5

PB4

PB3

PD2

PC12

PC11

PC10

PA 1 5

PA 14

V

DD_2

V

SS_2

PA 1 3

PA 1 2

PA 1 1

PA 1 0

PA 9

PA 8

PC9

PC8

PC7

PC6

PB15

PB14

PB13

PB12

PA 3

V

SS_4

V

DD_4

PA 4

PA 5

PA 6

PA 7

PC4

PC5

PB0

PB1

PB2

PB10

PB11

V

SS_1

V

DD_1

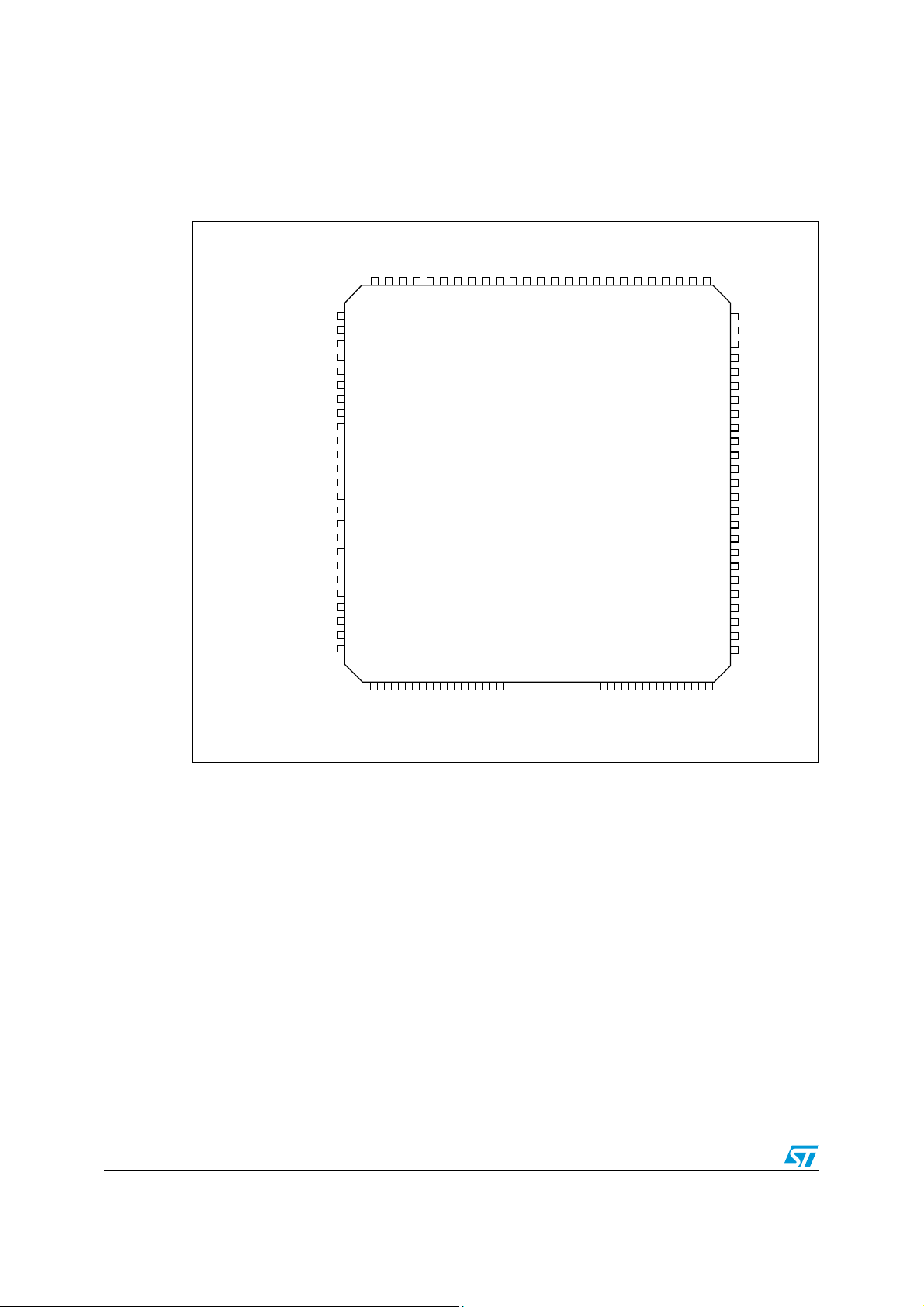

LQFP64

ai14392

Figure 3. STM32F105xxx and STM32F107xxx connectivity line LQFP64 pinout

23/90

Pin descriptions STM32F105xx, STM32F107xx

AI16001c

PE10

PC14-

OSC32_IN

PC5PA5

PC3

PB4

PE15

PB2

PC4PA4

H

PE14

PE11PE7

D PD4

PD3

PB8PE3

C

PD0

PC12

PE5

PB5

PC0

PE2

B PC11PD2

PC15-

OSC32_OUT

PB7

PB6

A

87654321

V

SS_5

OSC_IN

OSC_OUT V

DD_5

G

F

E

PC1

V

REF–

PC13-

TAMPER-RTC

PB9

PA15

PB3

PE4

PE1

PE0

V

SS_1

PD1PE6NRST

PC2

V

SS_3

V

SS_4

NCV

DD_3

V

DD_4

PB15

V

BAT

PD5

PD6

BOOT0 PD7

V

SS_2

V

SSA

PA1

V

DD_2

V

DD_1

PB14

PA0-WKUP

109

K

J

PD10

PD11

PA8

PA9

PA10

PA11

PA12

PC10

PA13

PA14

PC9

PC7

PC6

PD15

PC8

PD14

PE12

PB1PA7

PB11

PE8

PB0PA6

PB10

PE13PE9V

DDA

PB13

V

REF+

PA3

PB12

PA2

PD8

PD9 PD13

PD12

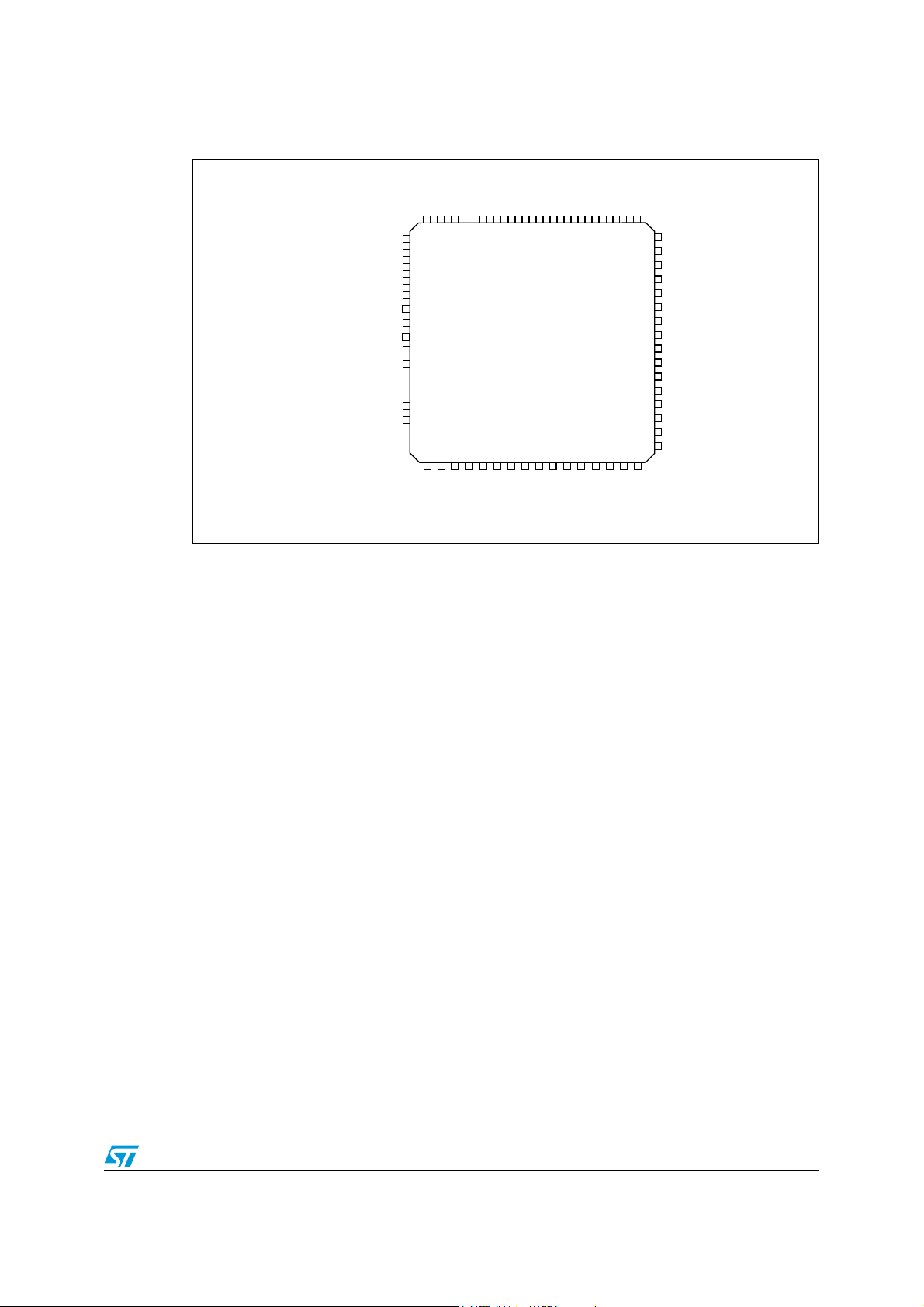

Figure 4. STM32F105xxx and STM32F107xxx connectivity line BGA100 ballout

24/90

STM32F105xx, STM32F107xx Pin descriptions

Table 5. Pin definitions

Pins

BGA100

A3 - 1 PE2 I/O

B3 - 2 PE3 I/O

C3 - 3 PE4 I/O

D3 - 4 PE5 I/O

E3 - 5 PE6 I/O

B2 1 6 V

A2 2 7

A1 3 8

B1 4 9

C2 - 10 V

D2 - 11 V

LQFP64

LQFP100

PC13-TAMPER-

OSC32_OUT

Pin name

BAT

(4)

RTC

PC14-

OSC32_IN

PC15-

SS_5

DD_5

(2)

(1)

Typ e

function

(after reset)

I / O Level

FT

FT

FT

FT

FT

SV

I/O PC13

I/O PC14

(4)

I/O PC15

(4)

SV

SV

Main

(3)

Default Remap

PE2 TRACECK

PE3 TRACED0

PE4 TRACED1

PE5 TRACED2

PE6 TRACED3

BAT

(5)

(5)

(5)

SS_5

DD_5

TAMPER-RTC

OSC32_IN

OSC32_OUT

Alternate functions

C1 5 12 OSC_IN I OSC_IN

D1 6 13 OSC_OUT O OSC_OUT

E1 7 14 NRST I/O NRST

F1 8 15 PC0 I/O PC0 ADC12_IN10

F2 9 16 PC1 I/O PC1

ADC12_IN11/ ETH_MII_MDC/

ETH_RMII_MDC

E2 10 17 PC2 I/O PC2 ADC12_IN12/ ETH_MII_TXD2

F3 11 18 PC3 I/O PC3

G1 12 19 V

H1 - 20 V

J1 - 21 V

K1 13 22 V

SSA

REF-

REF+

DDA

SV

SV

SV

SV

SSA

REF-

REF+

DDA

G2 14 23 PA0-WKUP I/O PA0

ADC12_IN0/TIM2_CH1_ETR

ADC12_IN13/

ETH_MII_TX_CLK

WKUP/USART2_CTS

TIM5_CH1/

(6)

ETH_MII_CRS_WKUP

(6)

/ ADC12_IN1/

(6)

H 2 15 2 4 PA 1 I / O PA 1

USART2_RTS

TIM5_CH2 /TIM2_CH2

ETH_MII_RX_CLK/

ETH_RMII_REF_CLK

/

25/90

Pin descriptions STM32F105xx, STM32F107xx

Table 5. Pin definitions (continued)

Pins

LQFP64

BGA100

Pin name

LQFP100

(2)

(1)

Typ e

Main

function

(after reset)

I / O Level

J 2 1 6 25 PA 2 I / O PA2

(3)

USART2_TX

TIM5_CH3/ADC12_IN2/

TIM2_CH3

Alternate functions

Default Remap

(6)

/

(6)

/ ETH_MII_MDIO/

ETH_RMII_MDIO

(6)

/

/ ETH_MII_COL

(6)

/DAC_OUT1

(6)

ADC12_IN4

(6)

(6)

/ADC12_IN6

(6)

(6)

/ADC12_IN7

(6)

/

TIM1_BKIN

TIM1_CH1N

K 2 1 7 2 6 PA 3 I / O PA 3

E4 18 27 V

F4 19 28 V

SS_4

DD_4

SV

SV

SS_4

DD_4

G 3 2 0 2 9 PA 4 I /O PA 4

H 3 2 1 3 0 PA 5 I / O PA5

J 3 2 2 31 PA 6 I / O PA6

K 3 2 3 32 PA 7 I /O PA 7

USART2_RX

TIM5_CH4/ADC12_IN3

TIM2_CH4

(6)

SPI1_NSS

USART2_CK

SPI1_SCK

DAC_OUT2 ADC12_IN5

SPI1_MISO

TIM3_CH1

SPI1_MOSI

TIM3_CH2

ETH_MII_RX_DV/

ETH_RMII_CRS_DV

ADC12_IN14/

G4 24 33 PC4 I/O PC4

ETH_MII_RXD0/

ETH_RMII_RXD0

ADC12_IN15/

H4 25 34 PC5 I/O PC5

ETH_MII_RXD1/

ETH_RMII_RXD1

J4 26 35 PB0 I/O PB0

K4 27 36 PB1 I/O PB1

G5 28 37

PB2 I/O FT PB2/BOOT1

ADC12_IN8/TIM3_CH3/

ETH_MII_RXD2

ADC12_IN9/TIM3_CH4

ETH_MII_RXD3

(6)

TIM1_CH2N

/

TIM1_CH3N

H5 - 38 PE7 I/O FT PE7 TIM1_ETR

J5 - 39 PE8 I/O FT PE8 TIM1_CH1N

K5 - 40 PE9 I/O FT PE9 TIM1_CH1

--- V

--- V

SS_7

DD_7

S

S

G6 - 41 PE10 I/O FT PE10 TIM1_CH2N

H6 - 42 PE11 I/O FT PE11 TIM1_CH2

J6 - 43 PE12 I/O FT PE12 TIM1_CH3N

26/90

STM32F105xx, STM32F107xx Pin descriptions

Table 5. Pin definitions (continued)

Pins

LQFP64

BGA100

LQFP100

Pin name

(2)

(1)

Typ e

Main

function

(3)

(after reset)

I / O Level

Alternate functions

Default Remap

K6 - 44 PE13 I/O FT PE13 TIM1_CH3

G7 - 45 PE14 I/O FT PE14 TIM1_CH4

H7 - 46 PE15 I/O FT PE15 TIM1_BKIN

J7 29 47 PB10 I/O FT PB10

K7 30 48 PB11 I/O FT PB11

I2C2_SCL/USART3_TX

ETH_MII_RX_ER

I2C2_SDA/USART3_RX

ETH_MII_TX_EN/

(6)

(6)

/

TIM2_CH3

/

TIM2_CH4

ETH_RMII_TX_EN

E7 31 49 V

F7 32 50 V

SS_1

DD_1

K8 33 51 PB12 I/O FT PB12

SV

SV

SS_1

DD_1

SPI2_NSS/I2S2_WS/

I2C2_SMBAL// USART3_CK

TIM1_BKIN

(6)

/CAN2_RX/

(6)

/

ETH_MII_TXD0/

ETH_RMII_TXD0

J8 34 52 PB13 I/O FT PB13

SPI2_SCK/I2S2_CK

USART3_CTS

TIM1_CH1N/CAN2_TX/

(6)

/

ETH_MII_TXD1/

ETH_RMII_TXD1

H8 35 53 PB14 I/O FT PB14

G8 36 54 PB15 I/O FT PB15

K9 - 55 PD8 I/O FT PD8

J9 - 56 PD9 I/O FT PD9

H9 - 57 PD10 I/O FT PD10

G9 - 58 PD11 I/O FT PD11

SPI2_MISO/TIM1_CH2N

USART3_RTS

SPI2_MOSI/I2S2_SD

TIM1_CH3N

(6)

(6)

USART3_TX/

ETH_MII_RX_DV

USART3_RX/

ETH_MII_RX_D0

USART3_CK/

ETH_MII_RX_D1

USART3_CTS/

ETH_MII_RX_D2

TIM4_CH1 /

K10 - 59 PD12 I/O FT PD12

USART3_RTS/

ETH_MII_RX_D3

J10 - 60 PD13 I/O FT PD13 TIM4_CH2

H10 - 61 PD14 I/O FT PD14 TIM4_CH3

G10 - 62 PD15 I/O FT PD15 TIM4_CH4

F10 37 63 PC6 I/O FT PC6 I2S2_MCK/ TIM3_CH1

27/90

Pin descriptions STM32F105xx, STM32F107xx

Table 5. Pin definitions (continued)

Pins

LQFP64

BGA100

LQFP100

Pin name

(2)

(1)

Typ e

Main

function

(3)

(after reset)

I / O Level

Alternate functions

Default Remap

E10 38 64 PC7 I/O FT PC7 I2S3_MCK/ TIM3_CH2

F9 39 65 PC8 I/O FT PC8 TIM3_CH3

E9 40 66 PC9 I/O FT PC9 TIM3_CH4

D 9 4 1 6 7 PA 8 I / O FT PA 8

C 9 4 2 6 8 PA 9 I / O FT PA 9

D10 43 69 PA10 I/O FT PA10

C10 44 70 PA11 I/O FT PA11

B10 45 71 PA12 I/O FT PA12

A10 46 72 PA13 I/O FT JTMS-SWDIO

USART1_CK/OTG_FS_SOF

TIM1_CH1

USART1_TX

(6)

/MCO

(6)

/ TIM1_CH2

OTG_FS_VBUS

USART1_RX

TIM1_CH3

USART1_CTS/CAN1_RX

TIM1_CH4

USART1_RTS/OTG_FS_DP

CAN1_TX

(6)

(6)

(6)

(6)

/

/OTG_FS_ID

/OTG_FS_DM

/TIM1_ETR

(6)

(6)

/

PA 1 3

F8 - 73 Not connected

E6 47 74

F6 48 75

A9 49 76

A8 50 77

B9 51 78

B8 52 79

C8 53 80

D8 5 81

E8 6 82

B7 54 83

C7 - 84

D7 - 85

B6 - 86

C6 - 87

D6 - 88

A7 55 89

V

V

SS_2

DD_2

SV

SV

SS_2

DD_2

PA14 I/O FT JTCK-SWCLK PA14

PA15 I/O FT JTDI SPI3_NSS/

PC10 I/O FT PC10 UART4_TX

PC11 I/O FT PC11 UART4_RX

PC12 I/O FT PC12 UART5_TX

PD0 I/O FT OSC_IN

PD1 I/O FT OSC_OUT

(7)

(7)

TIM2_CH1_ETR

SPI1_NSS

USART3_TX/ SPI3_SCK

USART3_RX/

SPI3_MISO

USART3_CK/

SPI3_MOSI

CAN1_RX

CAN1_TX

PD2 I/O FT PD2 TIM3_ETR/UART5_RX

PD3 I/O FT PD3

PD4 I/O FT PD4

PD5 I/O FT PD5

PD6 I/O FT PD6

PD7 I/O FT PD7

PB3 I/O FT JTDO SPI3_SCK

USART2_CTS

USART2_RTS

USART2_TX

USART2_RX

USART2_CK

PB3 / TRACESWO/

TIM2_CH2 / SPI1_SCK

/ PA15

28/90

STM32F105xx, STM32F107xx Pin descriptions

Table 5. Pin definitions (continued)

Pins

LQFP64

BGA100

A6 56 90

Pin name

LQFP100

PB4 I/O FT JNTRST SPI3_MISO

(2)

(1)

Typ e

Main

function

(3)

(after reset)

I / O Level

I2C1_SMBAl/ SPI3_MOSI/

C5 57 91 PB5 I/O PB5

ETH_MII_PPS_OUT/

ETH_RMII_PPS_OUT

B5 58 92 PB6 I/O FT PB6 I2C1_SCL

A5 59 93 PB7 I/O FT PB7 I2C1_SDA

Alternate functions

Default Remap

TIM3_CH1/

PB4 /

SPI1_MISO

TIM3_CH2/SPI1_MOSI/

CAN2_RX

(6)

/TIM4_CH1

(6)

/TIM4_CH2

(6)

USART1_TX/CAN2_TX

(6)

USART1_RX

D5 60 94 BOOT0 I BOOT0

B4 61 95 PB8 I/O FT PB8 TIM4_CH3

A4 62 96 PB9 I/O FT PB9 TIM4_CH4

(6)

/ ETH_MII_TXD3 I2C1_SCL/CAN1_RX

(6)

I2C1_SDA / CAN1_TX

D4 - 97 PE0 I/O FT PE0 TIM4_ETR

C4 - 98 PE1 I/O FT PE1

E5 63 99 V

F5 64 100 V

1. I = input, O = output, S = supply, HiZ = high impedance.

2. FT = 5 V tolerant.

3. Function availability depends on the chosen device.

4. PC13, PC14 and PC15 are supplied through the power switch, and so their use in output mode is limited: they can be used

only in output 2 MHz mode with a maximum load of 30 pF and only one pin can be put in output mode at a time.

5. Main function after the first backup domain power-up. Later on, it depends on the contents of the Backup registers even

after reset (because these registers are not reset by the main reset). For details on how to manage these IOs, refer to the

Battery backup domain and BKP register description sections in the STM32F10xxx reference manual, available from the

STMicroelectronics website: www.st.com.

6. This alternate function can be remapped by software to some other port pins (if available on the used package). For more

details, refer to the Alternate function I/O and debug configuration section in the STM32F10xxx reference manual,

available from the STMicroelectronics website: www.st.com.

7. For the LQFP64 package, the pins number 5 and 6 are configured as OSC_IN/OSC_OUT after reset, however the

functionality of PD0 and PD1 can be remapped by software on these pins. For the LQFP100 and BGA100 packages, PD0

and PD1 are available by default, so there is no need for remapping. For more details, refer to Alternate function I/O and

debug configuration section in the STM32F10xxx reference manual.

SS_3

DD_3

SV

SV

SS_3

DD_3

29/90

Memory mapping STM32F105xx, STM32F107xx