Features

SPIMD20

■ Advanced brushless motor control in a single

module easy to piggyback to the motor

■ Extremely compact dimensions: 165x60x26

mm, <0.5 kg weight

■ Up to 2 kW power with 800 Vdc supply, on

100°C motor surface, can withstand peak of

current up to 40 A

■ Can operate on a motor surface temperature

up to 100°C

■ Integrated drive with real time connectivity via

Ethernet-based fieldbus (i.e. EtherCAT

CANopen

■ Safe torque off to disable IGBT drivers via

®

DS402

hardware

■ CAN bus hand-shaking channel

■ RS232 interface for programming

■ 2 Mb Flash memory aboard; also support

removable Flash memory card.

■ Supports position feedback both with resolver

or digital encoder EnDat 2.2

■ Motor current sensing with shunt sensors (2

phases)

■ Vibration analysis and thermal sensing

■ IP65 compliant

■ Safe architecture to apply to most popular

safety standards IEC61800-5-1

■ EMI: IEC61800 - 3 / A11 and UL508C

■ Up to 800 V

V

DC

RoHS compliant

■

supply, auxiliary supply 18-48

DC

®

) and

SPIMD20

Integrated motor drive

Datasheet — production data

This Shuttle version of the IMD is suitable for

direct integration to the permanent magnet

synchronous motor (i.e. 6 Nm torque) thanks to

the reduced dimensions 165x60x26 mm. The

Shuttle Drive™ is designed to operate on a motor

with a surface temperature up to 100 °C. The IMD

performs all motor driving required functions

including speed, position and current loop

execution, plus connectivity. Connection to the

master is performed via real time ethernet

fieldbus, including but not limited to EtherCAT

per IEC61158. However, the IMD is an open and

flexible platform to execute any other

communication standard with the aboard FPGA

(Altera Cyclone III type) and the two

microprocessors STM32F103 series. A basic

software package is available with SPIMD20. This

software package includes PWM driving, current

loop and speed loop execution; all the above

being synchronized to the fieldbus.

Table 1. Device summary

Order code

SPIMD20

®

as

Description

SPIMD20 is an integrated motor drive with real

time connectivity enabling brushless motor

manufacturers to create a proprietary motion

control system based on a general purpose brick.

July 2012 Doc ID 17527 Rev 3 1/20

This is information on a product in full production.

www.st.com

20

Contents SPIMD20

Contents

1 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

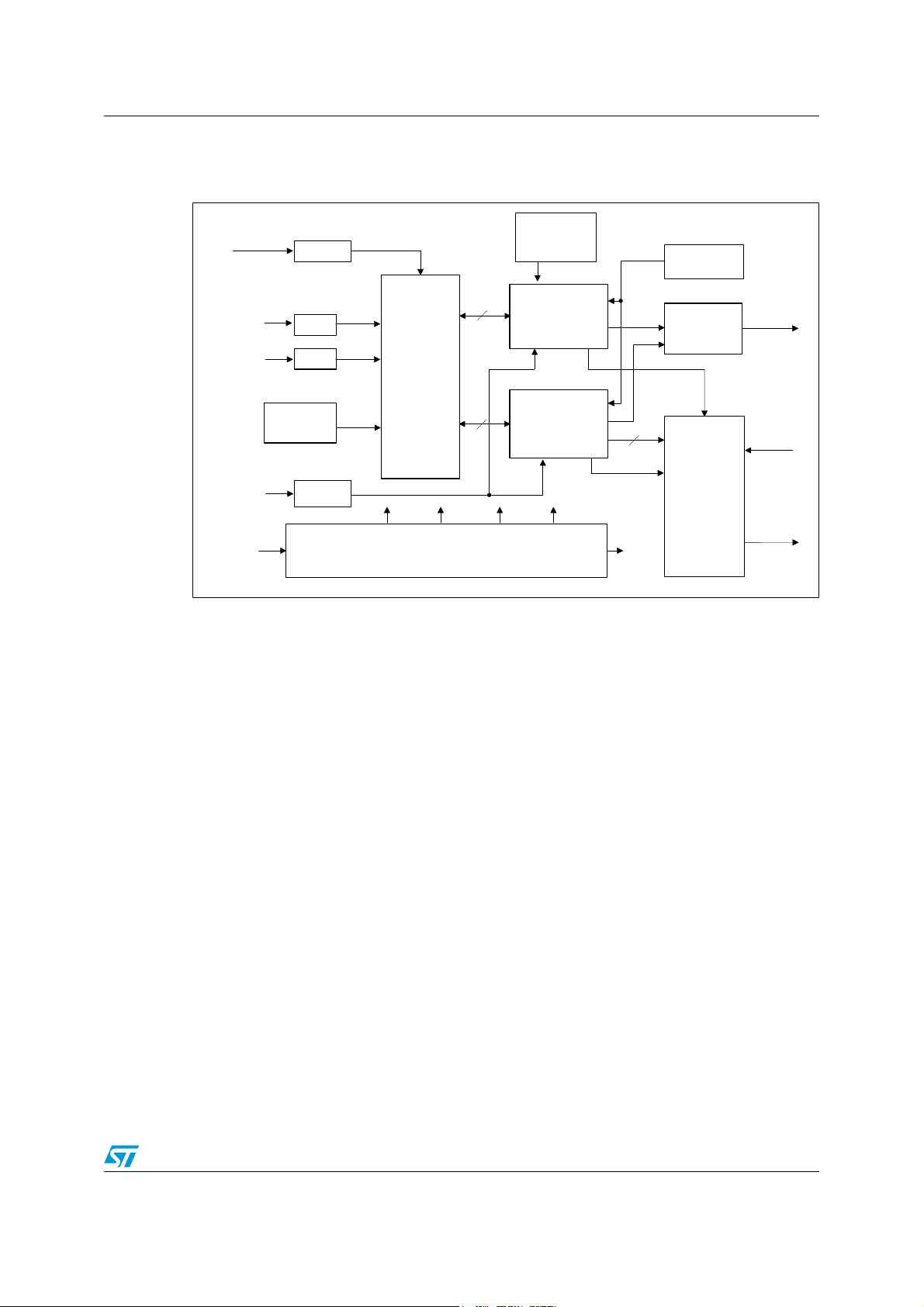

1.1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

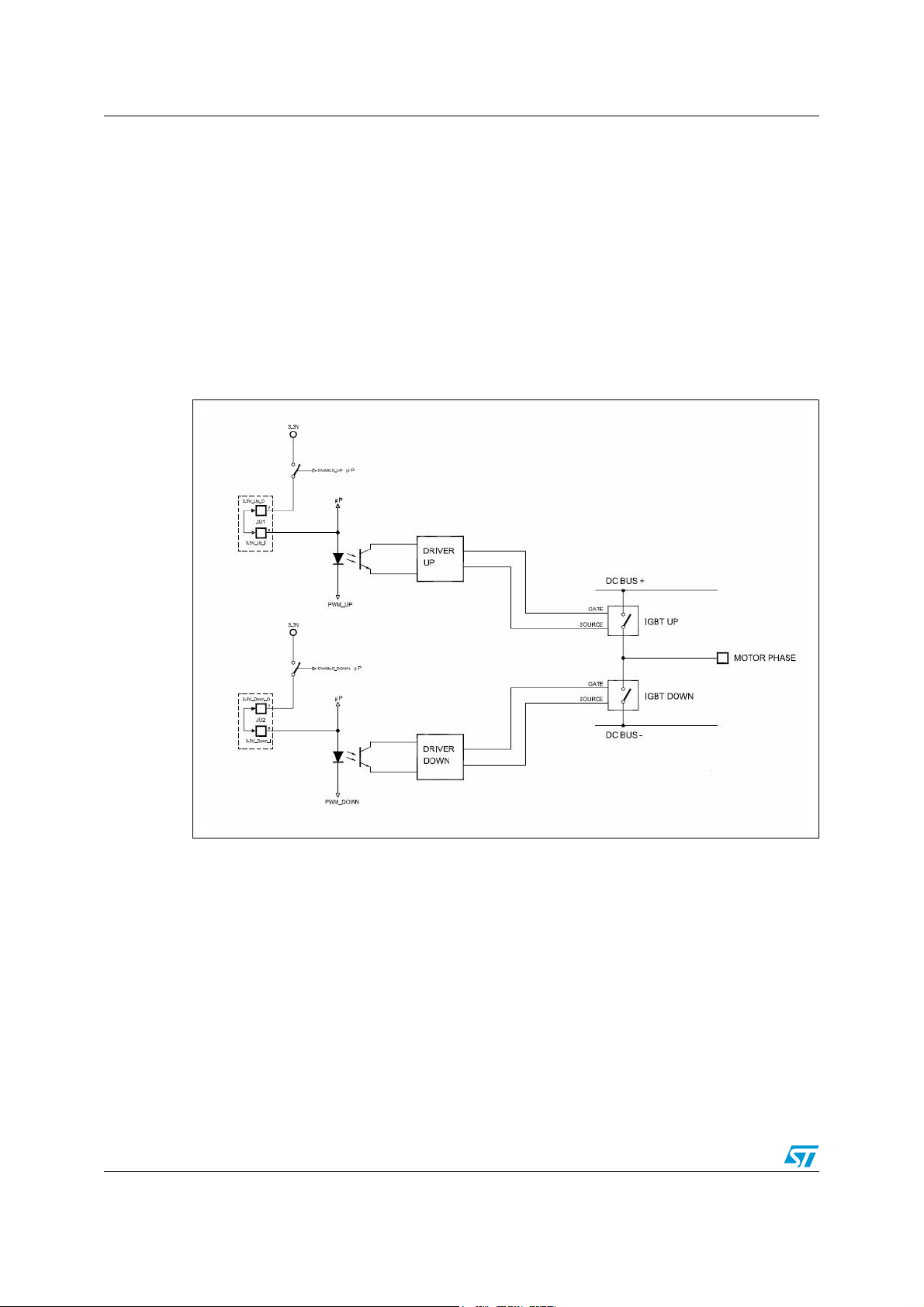

1.2 Safe torque off diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Vibrations and shocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Pin out description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Power stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Mechanical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Mechanical data (dimensions in mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Technical specifications for surface coupling . . . . . . . . . . . . . . . . . . . . . 17

5.2 The basic software package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.3 Safety characteristics and connection requirements . . . . . . . . . . . . . . . . 18

5.4 Installation and user's manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2/20 Doc ID 17527 Rev 3

SPIMD20 Main features

1 Main features

The SPIMD20 is the top level performing power drive system designed by

STMicroelectronics in cooperation with ROBOX S.p.A. Coming in a very compact size and

operating at very high temperature, the SPIMD20 is ideal for direct installation on a

permanent magnet synchronous motor or nearby the motor.

The advantages of this system architecture are many, among them:

● SPIMD20 directly assembled to the motor permits a strong wiring reduction. The

SPIMD20 just needs a DC power supply, a DC auxiliary supply, a fieldbus. All these

connections can jump from one device to the other. The electrical cabinet will therefore

result very compact.

● The distributed architecture allows faster designing and faster commissioning.

● The DC power supply shared between many SPIMD20s permits to realize sensible

energy saving in a lot of applications.

● The fieldbus, Ethernet real-time, permits to make profit of all the advantages of flexible

automation such as: recipes, fast switching among different previously saved menus,

in-line behaviour optimization, centralized diagnostic and data logging. CANopen is

optionally available in the development roadmap.

● A high performance FPGA Altera Cyclon III is available in the SPIMD20 to configure,

among others, the Ethernet real-time bus according to your needs or preferences. The

basic pack includes EtherCAT.

● Position read-out can be realized using the very popular resolver or other more

performing devices such as EnDat 2.2 which are interfaced through the high

performance FPGA. Different position transducers can be connected using their IP’s.

● PWM driving is organized for operation at 4-8-16-32 kHz. All the devices connected to

the same master are synchronized to the driving fieldbus. The synchronization involves

position, speed, current loops and the PWM.

● A MEMS accelerometer permits to analyze the vibrations: abnormal behavior can be

detected before a fatal crash occur

● An SPI channel is available to support a compact flash or similar device in order to

store parameters, programs or other tools depending on the application.

Doc ID 17527 Rev 3 3/20

Main features SPIMD20

● A basic software package is available with the SPIMD20. This software package

includes:

– torque speed position control

– PWM driving 4-8-16-32 kHz

– current loop closure 4-8-16 kHz (PI)

– speed loop closure 1-2 kHz (PI)

– position loop closure 1-2 kHz (P)

– torque, speed, feed forward inputs provided

– low pass or/and notch filters provided

– All the above are synchronized to the fieldbus

– Position transducers: resolver or encoder EnDat 2.2

– EtherCat connectivity (CoE DSP402)

– CANopen (DS301, DSP402) is also in the development roadmap

● Two powerful development environments are available:

– IAR’s Embedded WorkBench to work at source code level (C, C++)

– Robox’s RDE to work at system level, permitting debugging and performance

optimization under real operating conditions.

A third one, QUARTUS II Altera development environment, should be used to implement

other real time Ethernet standards or other digital transducers into the FPGA.

4/20 Doc ID 17527 Rev 3

SPIMD20 Main features

)3*$

3RZHU6XSSO\

3RZHU

6WDJH

'5,9(

SURFHVVRU

),(/'%86

SURFHVVRU

)ODVK

0HPRU\

5HVROYHU

+ROGLQJ

%UDNH

(1&2'(5

(Q'DW

&$1%XV

3+<

3+<

&$1%XV

0,,

0,,

)LHOGEXV

&$1%XV

ELW

ELW

(QDEOH8SSHU

%UXVKOHVV

0RWRU

9'&

+ROGLQJ

%UDNH

)LHOGEXV

(WKHUQHW

+DQG

6KDNLQJ

%XV

9'&

1.1 Block diagram

Figure 1. Block diagram

Doc ID 17527 Rev 3 5/20

Main features SPIMD20

1.2 Safe torque off diagram

The module is equipped with four pins, available at JU1 and JU2 connectors, aimed to

disable the IGBT drivers via hardware.

The schematic architecture is showed in Figure 2.

Once the pins 7 of JU1 and JU2 are respectively let opened versus the pins 8 of JU1 and

JU2, the IGBT drivers are disabled.

If the pin 7 is shorted with the pin 8 on both the connectors JU1 and JU2, the module is

properly working.

The current flowing on those connections is less than 5 mA.

Figure 2. Safe torque off diagram

6/20 Doc ID 17527 Rev 3

SPIMD20 General specifications

2 General specifications

2.1 Ambient conditions

Table 2. Ambient conditions

operation (Ambient) 0 … +40°C

operation (Motor) 0 … +100°C

Temperature

Relative humidity

Altitude 4000mt

Protection degree IP 65 & IP 67

1. Without ice and condensation

operation (Bottom Heatsink) 0 … +100°C

operation (Top Heatsink) 0 … +70°C

storage -30 … +70°C

transportation -25 … +70°C

operation

storage

transportation

2.2 Vibrations and shocks

Table 3. Vibrations and shocks

Description Test conditions Value Unit

Vibration sine: amplitude

peak-peak

10…57Hz conforming to EN/IEC 60068-2-36 0.15 +/-15% mm

5 … 95%

5 … 95%

5 … 95%

(1)

(1)

(1)

Vibration sine: acceleration 57…150Hz conforming to EN/IEC 60068-2-6 1 +/-15% g

Vibration noise (random)

IEC 68-2-36

Vibration sine according to

EN 60068-2-6 and

EN 60068-2-37

Frequency 20 … 150 Hz

Spectral acceleration density, amplitude 0,005 ±3dB g2/Hz

10 … 2000Hz amplitude peak-peak 0.75 mm

Acceleration at 10 … 2000Hz 5 g

Doc ID 17527 Rev 3 7/20

Pin out description SPIMD20

3 Pin out description

Table 4. Pin description JU1/JU2

Name JU1 JU2 Type Description

PS_AUX+

PS_AUX-

POW_OK - 2 INP-48V Input power OK, PS_AUX- referred

IO_24V 5 -

IO_GND 6 -

INP1 - 5 INP-24V

INP2 - 6 INP-24V

3.3V_UP_O 7 -

3.3V_UP_I 8 -

3.3V_DOWN_O - 7

3.3V_DOWN_I - 8

ETH1_TXD+ 9 -

ETH1_TXD- 10 -

ETH1_RXD+ 11 -

11

2-

33

44

Power in

Power out 24Vdc digital inputs feeding

Safe torque off

Ethernet CH1 ethernet 10/100 IEEE 802.3

Auxiliary input voltage

18 to 48Vdc

Dig. inputs, 24Vdc, IO_GND referred

Disable the IGBT drivers via hardware. If the pin 7 is shorted with the

pin 8 on both the connectors JU1 and JU2, the module is properly

working

ETH1_RXD- 12 -

ETH2_TXD+ 13 -

ETH2_TXD- 14 -

ETH2_RXD+ 15 -

ETH2_RXD- 16 -

CANH - 9

CAN_GND - 11

SB_GND - 12

SB- - 14

HBR_RLS# - 15 INP-OD-3V3 Holding brake release

PB# - 16 INP-OD-3V3 User push-button

EXT_FLASH# - 17 INP-OD-3V3

Ethernet CH2 ethernet 10/100 IEEE 802.3

CanBus Fieldbus CANCANL - 10

CanBus Service busSB+ - 13

Connect to GND to enable boot from external flash memory (type

M25P16). External flash have to be connected to CRD_pins. (see

next page) leave pin EXT_FLASH floating to enable boot from

internal flash memory.

8/20 Doc ID 17527 Rev 3

SPIMD20 Pin out description

Table 4. Pin description JU1/JU2 (continued)

Name JU1 JU2 Type Description

LED1# 17 - OUT-LO-3V3

LED2# 18 - OUT-LO-3V3

WS_SDA - 18 BIDIR-3V3

WS_SCL 19 - OUT-3V3

JTMS 20 - INP-3V3

JTCK 21 - INP-3V3

JTDI 22 - INP-3V3

JTDO 23 - OUT-3V3

JTRST# 24 - INP-LO-3V3

JRESET# 25 - INP-OD-3V3

IO3# - 19 BIDIR-OD-3V3

IO4# - 20 BIDIR-OD-3V3

3V3 - 21

Power out 3.3V power supply for outputs, LED and I

GND - 22

CRD_CS# - 23 OUT-LO-3V3

CRD_CLK - 24 OUT-3V3

CRD_DI - 25 OUT-3V3

CRD_DO - 26 INP-3V3

User Led

2

C line for WorkStation connection

I

JTAG software debug port

TTL digital I/O, GND referred

External decoupling required

3.3V external flash.

SPI Interface 50mA max.

2

C - 100mA max

CRD_VCC - 27

CRD_GND - 28

RS232_GND 26 -

RS232_TXD 28 -

● INP-48 V: 48 V digital input, active high

● INP-24 V: 24 V digital input, active high

● INP-3V3: 3.3 V digital input, active high

● INP-LO-3V3: 3.3 V digital input, active low

● INP-OD-3V3: 3.3 V dig. input (Internal pull-up) to be connected to open-drain output

● OUT-3V3: 3.3 V digital output, push-pull active high

● OUT-LO-3V3: 3.3 V digital output, push-pull active low

● BIDIR-3V3: 3.3 V digital input/output

● BIDIR-OD-3V3: 3.3 V digital input/output (Internal Pull-up) to be connected to open-

drain output

Power out

RS232 RS232 full duplex connectionRS232_RXD 27 -

Doc ID 17527 Rev 3 9/20

Pin out description SPIMD20

Table 5. Pin description JU3

Name Pin Type Description

DC_BUS-

Power in 800VDC BusBar-

2

- 3 - Position not loaded

4

1

DC_BUS+

Power in 800VDC BusBar+

5

- 6 - Position not loaded

FE

7

8

Table 6. Pin description JM3

Functional

Earth

Connected to chassis and shield/FE pins of

JU1, JU2, JM3,JM7, JM9, JM10 and JM11 connectors

Name Pin Type Description

TMOT- 1 Analog

TMOT+ 2 Analog

Connection to PTC motor thermal probe

(KTY84-130)

-3 -N.C.

SHIELD 4 - Connected to PE pins on JU3

Table 7. Pin description JM7

Name Pin Type Description

PE 1 - Connected to PE pins on JU3

DC_BUS- 2 Power 800VDC BusBar capacitor connection

PE 3 - Connected to PE pins on JU3

DC_BUS+ 4 Power 800VDC BusBar capacitor connection

Table 8. Pin description JM9

Name Pin Type Description

1-

PE

Connected to PE pins on JU32

3

MOTOR_U 4 Motor Motor U phase

MOTOR_V 5 Motor Motor V phase

MOTOR_W 6 Motor Motor W phase

10/20 Doc ID 17527 Rev 3

SPIMD20 Pin out description

Table 9. Pin description JM10

Name Pin Type Description

SHIELD 1 - Connected to PE pins on JU3

-2 --

HBR+ 3 Brake

HBR- 4 Brake

24VDC holding brake connection

Current max 500mA

Table 10. Pin description JM11

Name Pin Type Description

SHIELD

ENC_GND 2

ENC_5V 9

ENC_CLK- 3

ENC_CLK+ 10

ENC_DAT- 4

ENC_DAT+ 11

RES_EXC- 5

RES_EXC+ 12

RES_SIN- 6

RES_SIN+ 13

RES_COS- 7

RES_COS+ 14

1

8

- Connected to PE pins on JU3

Power out

RS422

RS485

Analog

Analog

Analog

5V, 200mA max Encoder EnDat 2.2

Resolver

Doc ID 17527 Rev 3 11/20

Electrical characteristics SPIMD20

4 Electrical characteristics

4.1 Absolute maximum ratings

Table 11. Absolute maximum ratings

Symbol Parameter Value Unit

DC_BUS_MAX MAX DC BusBar supply voltage (JU3 pin 1, 2, 4, 5) 850 V

DC_BUS_MIN MIN DC BusBar supply voltage (JU3 pin 1, 2, 4, 5) 40 V

Pw_MAX Max continuous power (Output current = 6A rms MAX) 2000 W

I_OUT_MAX Max output current (RMS) 6 A

I_OUT Max output current peak (200ms on 1.5s period) 17 A

PS_AUX DC auxiliary supply voltage (JU1 pin 1-4 JU2 pin 1, 3, 4) 50 V

IO_24V DC logic supply voltage (JU1 pin 5, 6) 28 V

Tstg Storage temperature range -30 … +70 °C

4.2 Electrical data

4.2.1 Power supply

Table 12. Power supply

Val u e

Symbol Parameter Test conditions

Min Typ Max

DC_AUX DC auxiliary supply voltage Power In ( JU1/JU2 pin 1-2 ) 18 24 48 V

Vin ( JU1/JU2 pin 1-2 ) = 18V, BRAKE

DC auxiliary current BRAKE

DC_AUX_

MAX_CUR

DC_Brake 24 V DC Brake connection Current max 500mA ( JM10 pin 3-4 ) 21.6 24 26.4 V

CRD_VCC

3V3 I

connected

DC auxiliary current without

BRAKE

Analogue supply for

external Flash

2

C power supply

connected

Vin ( JU1/JU2 pin 1-2 ) = 48V, BRAKE

connected

Vin ( JU1/JU2 pin 1-2 ) = 18V, without BRAKE 0.6 A

Vin ( JU1/JU2 pin 1-2 ) = 48V, without BRAKE 0.3 A

SPI max current 50mA ( JU2 pin 27 ) 3.2 3.3 3.4 V

DC for Outputs, I2C & LEDs 100mA max JU2

pin 21

3.2 3.3 3.4 V

1.6 A

0.8 A

Unit

IO_24V 24 Vdc digital inputs feeding 100mA max JU1 pin 5-6 21.6 24 26.4 V

12/20 Doc ID 17527 Rev 3

SPIMD20 Electrical characteristics

!-V

4.2.2 Power stage

Figure 3. Equivalent circuit Figure 4. Test circuit for inductive load

Table 13. IGBT

switching

Symbol Parameter Test conditions

= 15V, IC= 30A

V

V

CE(sat)

I

CES

I

GES

t

d(on)

t

d(off)

E

on

E

C

C

C

1. Eon is the turn-on losses when a typical diode is used in the test circuit in Figure 6.

Collector-emitter saturation voltage

Collector cut-off current (VGE = 0)

Gate-emitter leakage current (VCE = 0) VGE =± 20V - ± 100 nA

Tu r n- on d el a y t i me

Current rise time - 38 ns

t

r

Turn-off delay time - 420 ns

t

Current fall time - 360 ns

f

(1)

Turn-on switching losses - 4.7 mJ

Turn-off switching losses - 9.3 mJ

off

Input capacitance VCE = 25V, f = 1MHz, VGE=0 - 2577 pF

ies

Output capacitance - 196 pF

oes

Reverse transfer capacitance - 39.5 pF

res

Q

Total gate charge VCE = 960V, IC= 20A,VGE=15V - 126 nC

g

GE

V

= 15V, IC= 30A,

GE

=125 °C

T

j

=1200V

V

CE

=1200V, Tj=125 °C

V

CE

V

= 960V, IC = 30A

CC

= 10Ω, VGE= 15V,

R

G

T

= 125°C see Figure 6

j

Val ue

Min Typ Max

2.8

3.85

2.7

-

-

50010µA

- 45 ns

Unit

V

mA

Doc ID 17527 Rev 3 13/20

Electrical characteristics SPIMD20

Table 14. Diodes

Val ue

Symbol Parameter Test conditions

Unit

Min Typ Max

I

= 8A Tj = 25°C - 2.2

(1)

V

Forward voltage drop

F

I

1. Pulse test: tp = 380 µs, δ < 2 %

To evaluate the conduction losses use the following equation: P = 1.5 x I

Reverse recovery current

RM

Reverse recovery time

t

rr

F

= 8A Tj = 125°C - 1.3 2.0

I

F

= 8A, dIF/dt = -200A/μs,

I

F

= 600V, Tj = 125°C

V

R

IF = 1A, dIF/dt = -100A/µs,

V

= 30V, Tj = 25°C

R

+ 0.05 IF ² (RMS)

F(AV)

-1421A

-5070ns

V

Table 15. Thermal resistance

Value

Symbol Parameter Test conditions

Min TypMax

Unit

R

R

R

th(CH)

th(j-c)

th(j-c)

Thermal resistance

IGBT - - 0.42 °C/W

Diode - - 0.52 °C/W

Module with heatsink compound - - TBD °C/W

14/20 Doc ID 17527 Rev 3

SPIMD20 Mechanical dimensions

AM02500v1

5 Mechanical dimensions

5.1 Mechanical data (dimensions in mm)

Figure 5. Mechanical data (dimensions in mm)

Doc ID 17527 Rev 3 15/20

Mechanical dimensions SPIMD20

Figure 6. Mechanical data (dimensions in mm) continued

16/20 Doc ID 17527 Rev 3

SPIMD20 Mechanical dimensions

5.1.1 Technical specifications for surface coupling

IMD module can be coupled with a plane surface finished with characteristics detailed

below:

Table 16. Technical specifications for surface coupling

Parameter Value

Roughness 3.2 Ra

Planarity 0.1 mm

Max coupling torque on fixing screws 3 N/m

5.2 The basic software package

A basic software package is available on request, at source level. This software package is

written in C language (not C++) by Robox and is supplied AS IS.

The comments are in English. It was developed using the IAR’s Embedded WorkBench

development tool.

In the design workspace each processor, the fieldbus processor and the drive processor,

has its own project. The interface between them is defined in some common files.

The fieldbus processor main tasks are:

● building up of the whole system at power on

● communication handling with the external master fieldbus according to the EtherCat

CoE profile (Ecat sync mode or Distributed clock mode)

● information exchange with the drive processor through the dual port ram implemented

into the FPGA

● handling of the I

● holding brake management

2

C port to get application parameters

The drive processor main tasks are:

● PWM driving performed at the same frequency of the current loop or at double

frequency (4-8-16-32 kHz).

● current loop closure (4-8-16 kHz). The control algorithm is PI

● speed loop closure (1-2 kHz). The control algorithm is PI

● position loop closure (1-2 kHz). The control algorithm is P

The system is able to work in torque control or in speed control or in position control.

The feed forward inputs are provided for the two inner loops. The PWM driving, and the

loops closure, are synchronized to the external master fieldbus sync event.

● DC bus reading

An optically coupled reading of the DC bus voltage allows its monitoring. Moreover the

gains of the current loop are independent from the DC bus level.

● Filtering:

3 optional 2nd order filter stages (LowPass/Notch) can be activated on

SpeedReference

Doc ID 17527 Rev 3 17/20

Mechanical dimensions SPIMD20

3 optional 2nd order filter stages (LowPass/Notch) can be activated on

TorqueReference.

Triple sampling on the resolver reading is provided

● Position or time capture on the two digital inputs

● Self tuning

a complete self tuning procedure is available. It includes:

– motor characteristics (correct wiring, number of motor and transducer poles)

– current loop gains

– speed loop gains

– EnDat offset position read-out and storage in the e2prom

– resolver adjustment (amplitude, sample phase, position offset and alarm

threshold)

● Self test

built-in self test allowing to generate square or synusoidal waveforms on the speed or

torque reference with adjustable frequency, amplitude, offset and TT cycle.

A complete library to access all the involved peripherals is included.

The EtherCAT

request.

®

entries manual of the basic software package is available at Robox on

5.3 Safety characteristics and connection requirements

The IMD module is designed to comply with the IEC61800-5-1 norms, applicable to the D.C.

drive systems connected to the line voltage up to 800 V D.C.

The earthing connections are intended as TN or TT having the voltage between phase and

Earth 300 V r.m.s. maximum.

In case this voltage is higher than 300 V r.m.s. the user shall provide the system with

protective device (varistor, voltage discharger, etc.) in order to reduce the impulse voltage to

2500 V max.

The P.E. connections, available at JU3 pins 7, 8 and/or JM9 pins 1, 2, 3 shall be connected

to the protective bonding before supplying the system.

Please note that Earth leakage current is > 3.5 mA. Automatic disconnection of thesupply in

case of discontinuity of the protective conductor must be provided.

5.4 Installation and user's manual

For installation on a system or motor please ask end user.

Specifications for surface coupling can be find in this document section Section 5.1.1.

5.5 Maintenance

The IMD module doesn't require maintenance. In case of failure module is not repairable

and have to be replaced.

18/20 Doc ID 17527 Rev 3

SPIMD20 Revision history

6 Revision history

Table 17. Document revision history

Date Revision Changes

31-May-2010 1 First release

26-Jan-2011 2

25-Jul-2012 3 Updated Table 5 on page 10 and Table 11 on page 12.

Updated coverpage, Table 4 on page 8

Added Section 1.2 on page 6

Doc ID 17527 Rev 3 19/20

SPIMD20

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

20/20 Doc ID 17527 Rev 3

Loading...

Loading...