Page 1

ENGINE

SERVICE MANUAL

PYUNGTAEK, KOREA

Page 2

SECTION INDEX

SERVICE

MANUAL

(vol. 1 of 2)

REXTON

FOREWORD

This manual includes procedure for maintenance,

adjustment, service operation and removal and

installation of components.

VOLUME 1 OF 2

GENERAL INFORMATION

ENGINE ASSEMBLY

ENGINE HOUSING

INTAKE SYSTEM

EXHAUST SYSTEM

DI0A

DI01

DI02

DI03

DI04

All information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of manual

approval.

The right is reserved to make changes at any time

without notice.

SSANGYONG MOTOR CO., LTD.

PYUNGTAEK, KOREA

LUBRICATION SYSTEM

COOLING SYSTEM

FUEL SYSTEM

ENGINE CONTROL SYSTEM

ELECTRIC DEVICES AND

SENSORS

DIAGNOSIS

DI05

DI06

DI07

DI08

DI09

DI10

Page 3

DI ENGINE

CONTENTS

GENERAL INFORMATION....................DI0A

ENGINE ASSEMBLY ............................. DI01

ENGINE HOUSING ................................ DI02

INTAKE SYSTEM................................... DI03

EXHAUST SYSTEM............................... DI04

LUBRICATION SYSTEM ....................... DI05

COOLING SYSTEM ............................... DI06

FUEL SYSTEM ...................................... DI07

ENGINE CONTROL SYSTEM ............... DI08

ELECTRIC DEVICES AND SENSORS . DI09

DIAGNOSIS ........................................... DI10

Page 4

SECTION DI0A

GENERAL INFORMATION

Page 5

DI0A-1

00SECTION DI0A

GENERAL INFORMATION

Table of Contents

CLEANNESS ....................................... DI0A-3

STRUCTURE ...................................... DI0A-8

ENGINE CONTROLS ....................... DI0A-11

ECU related components ..............DI0A-11

Engine and sensors ..................... DI0A-12

Electrical components and

pre heating system ...................... DI0A-13

INTAKE SYSTEM ............................. DI0A-14

Intake air flow chart ...................... DI0A-15

INTAKE SYSTEM ............................. DI0A-16

Exhaust air flow chart ................... DI0A-17

LUBRICATION SYSTEM .................. DI0A-18

COOLING SYSTEM ......................... DI0A-19

Coolant flow chart ........................ DI0A-20

FUEL SYSTEM ................................. DI0A-21

Fuel supply system ...................... DI0A-22

GENERAL SPECIFICATIONS........... DI0A-23

Vehicle specifications................... DI0A-23

Maintenance ................................ DI0A-26

VEHICLE IDENTIFICATION .............. DI0A-28

HOW TO USE AND MAINTAIN WORKSHOP

MANUAL ........................................... DI0A-30

Consists of workshop manual ...... DI0A-30

Manual description ...................... DI0A-30

Guidelines for service work

safety ........................................... DI0A-31

Lifting points................................. DI0A-36

Tightening torque of standard

bolts.............................................. DI0A-37

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 6

Page 7

DI0A-3

CLEANNESS

Cleanness of DI Engine Fuel System and Service Procedures

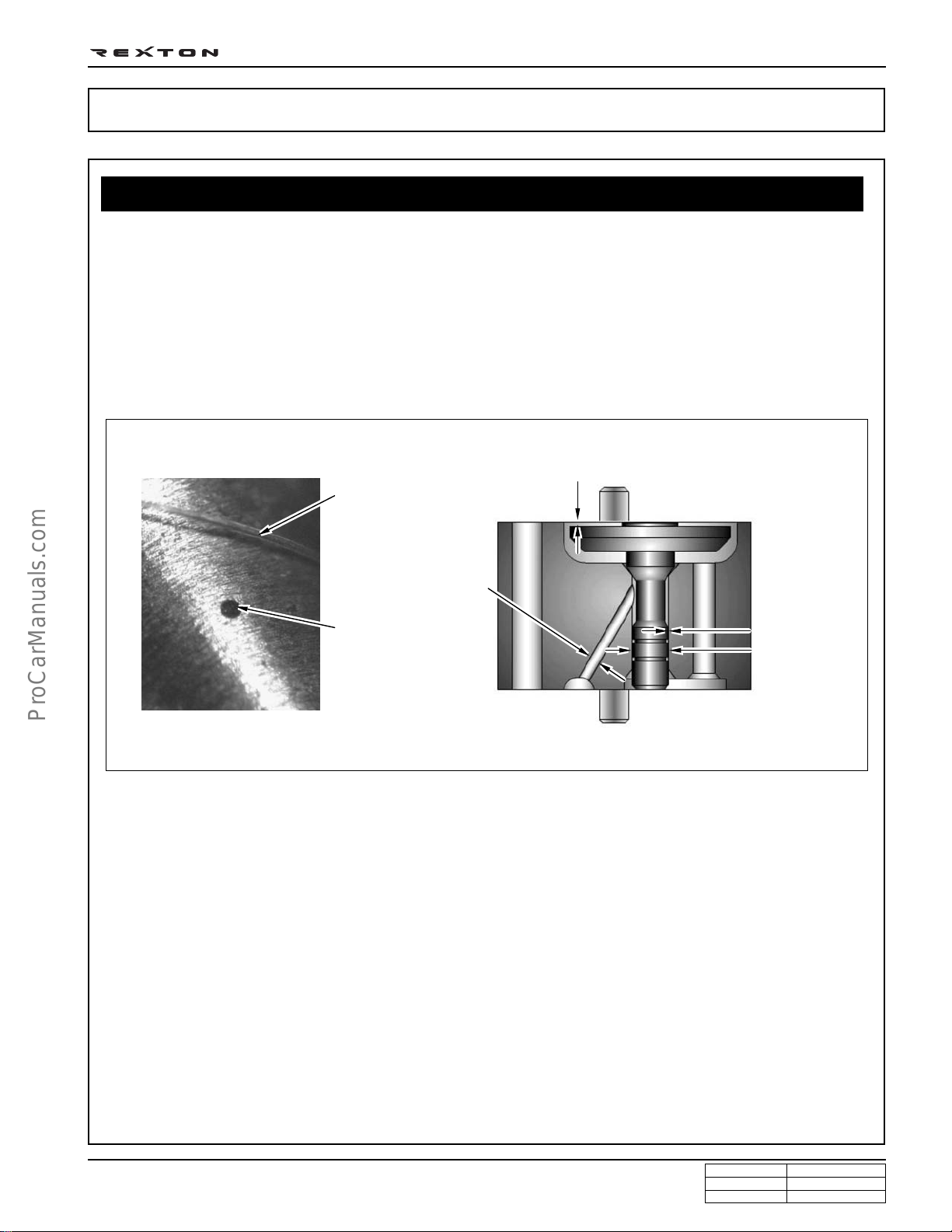

The fuel system for DI engine consists of transfer (low pressure) line and high pressure line. Its highest pressure

reaches over 1600 bar. Some components in injector and HP pump are machined at the micrometer 100 µm of

preciseness. The pressure regulation and injector operation are done by electric source from engine ECU.

Accordingly, if the internal valve is stucked due to foreign materials, injector remains open. Even in this case, the

HP pump still operates to supply high pressurized fuel. This increases the pressure to combustion chamber (over

250 bar) and may cause fatal damage to engine.

You can compare the thickness of injector nozzle hole and hair as shown in below figure (left side). The right side

figure shows the clearance between internal operating elements.

Valve actuator lift: 0.028 mm

Hair

The core elements of fuel system has very high preciseness that is easily affected by dust or very small foreign

material. Therefore, make sure to keep the preliminary works and job procedures in next pages. If not, lots of

system problems and claims may arise.

Diameter: 0.40 mm

Nozzle hole

Operating

clearance:

0.002 mm

Diameter:

2.0 mm

Y220_0A035

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 8

DI0A-4

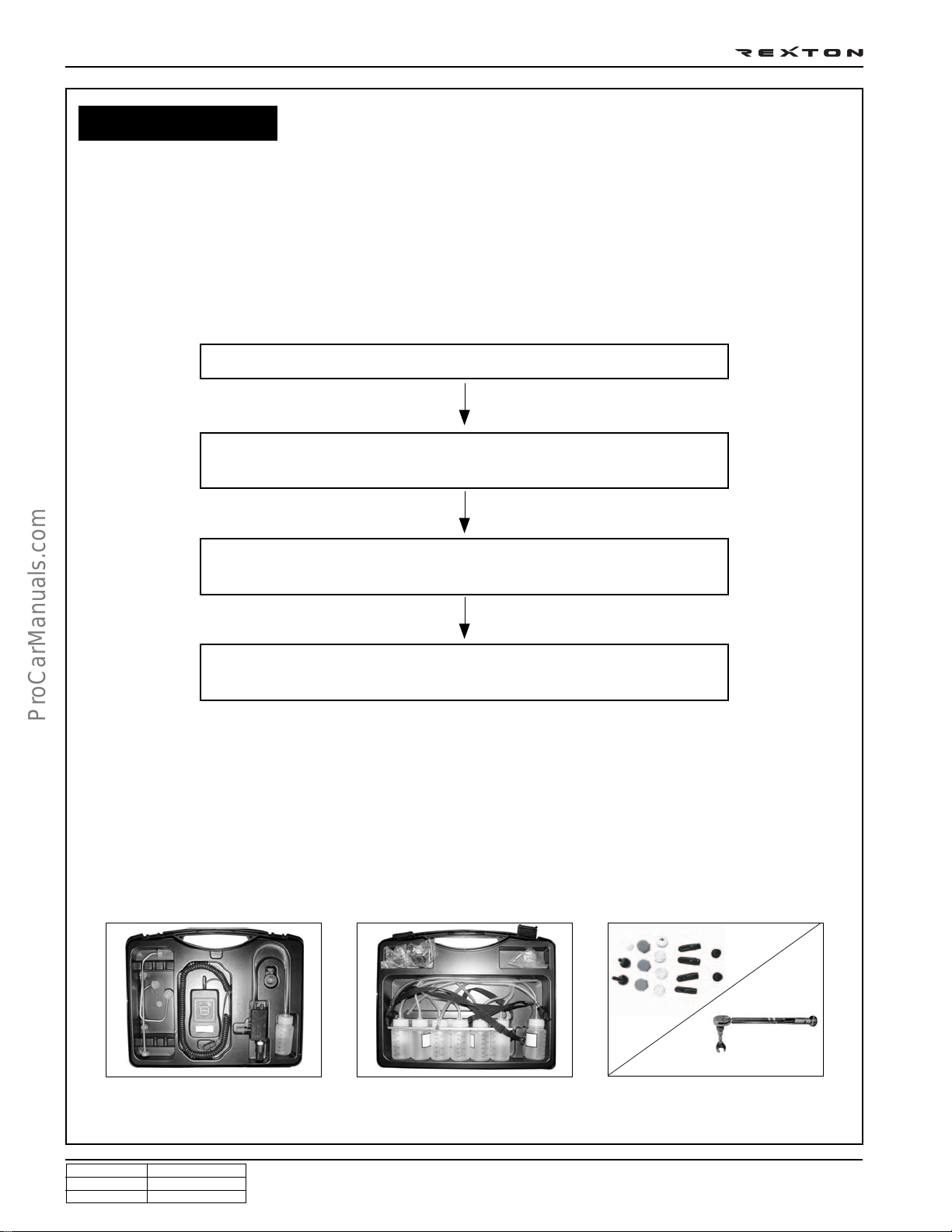

Job procedures

1. Always keep the workshop and lift clean (especially, from dust).

2. Always keep the tools clean (from oil or foreign materials).

3. Wear a clean vinyl apron to prevent the fuzz, dust and foreign materials from getting into fuel system. Wash

your hands and do not wear working gloves.

4. Follow the below procedures before starting service works for fuel system.

Carefully listen the symptoms and problems from customer.

Visually check the leaks and vehicle appearance on the wiring harnesses

and connectors in engine compartment.

Locate the fault. If the cause is from fuel system (from priming pump to

injector, including return line), follow the step 1 through step 3 above.

5. If the problem is from HP pump, fuel supply line or injector, prepare the clean special tools and sealing caps

to perform the diagnosis for DI engine fuel system in “DIAGNOSIS” section in this manual. At this point,

thoroughly clean the related area in engine compartment.

Notice

Clean the engine compartment before starting service works.

Perform the diagnosis proceee with Scan-i

(refer to “DIAGNOSIS” section in this manual).

Tool kit for high pressure line Took kit for low pressure line Removal tool box and cap kits

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 9

6. Follow the job procedures. If you find a defective component, replace it with new one.

Disconnect the negative battery cable.

For safety reasons: check pressure is low before opening the HP systems (pipes)

Use special tools and torque wrench to perform the correct works.

Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail

and each injector should be replaced with new ones. The pipes should be tightened to

specified tightening torques during installation. Over or under torques out of specified

range may cause damages and leaks at connections. Once installed, the pipes have been

deformed according to the force during installtion, therefore they are not reusable.

The copper washer on injector should be replaced with new one. The injector holder bolt

should be tightened to specified tightening torque as well. If not, the injection point may be

deviated from correct position, and it may cause engine disorder.

DI0A-5

Plug the disconnected parts with sealing caps, and remove the caps immediately

High pressure pump

IMV valve

Transfer pump and high

pressure pump

Fuel temperature sensor

Water separator

Water detection sensor

Fuel filter

before replacing the components.

Priming

pump

Fuel pressure sensor

Injection

pipe

Common rail

GENERAL INFORMATION

DI ENG SM - 2004.4

Fuel tank

Injector

Cap position

Supply line

Return line

Y220_0A039

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

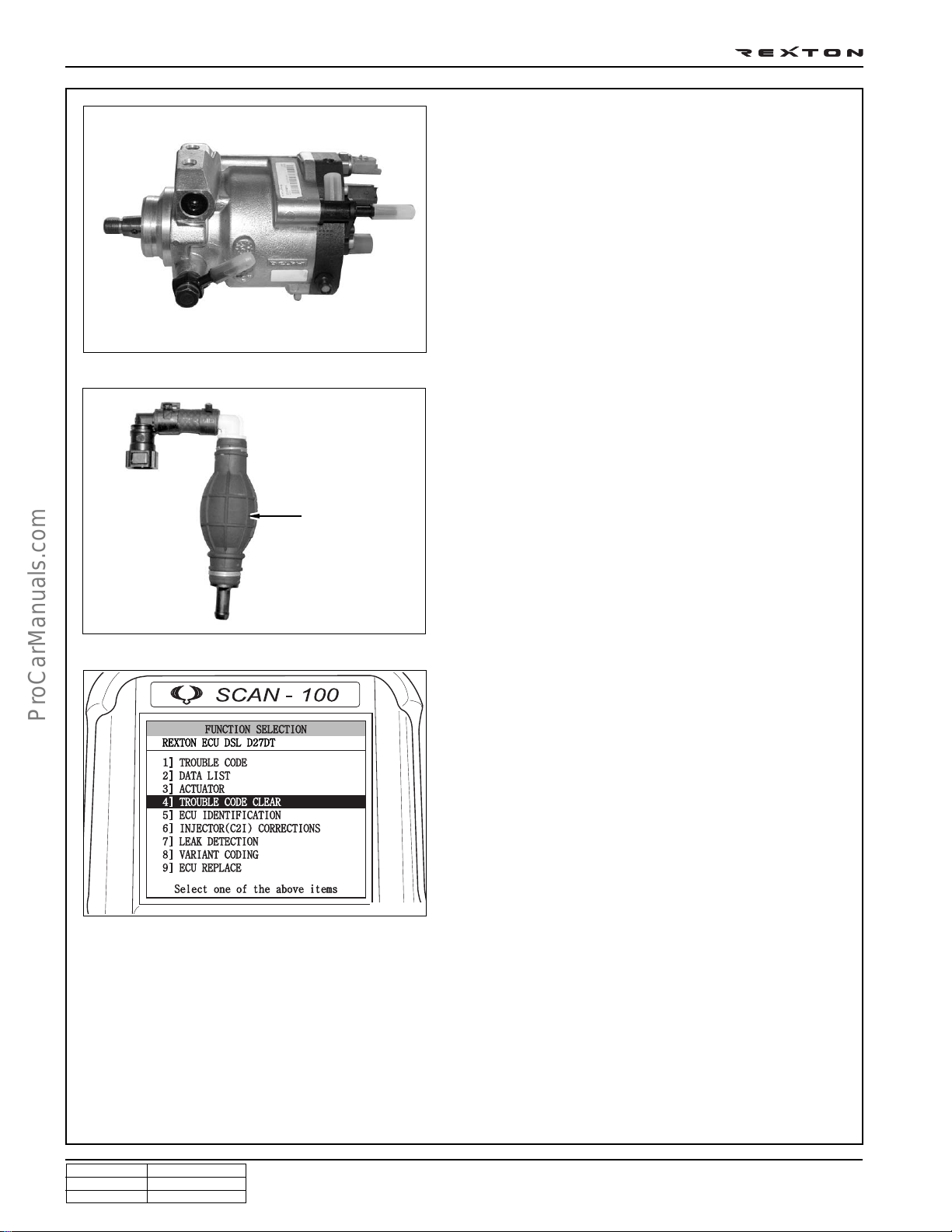

Page 10

DI0A-6

7. Plug the removed components with clean and

undamaged sealing caps and store it into the box to

keep the conditions when it was installed.

8. Clear the high pressure offset value by Scan-100 after

replacing the high pressure pump.

Y220_0A040

9. To supply the fuel to transfer line of HP pump press

the priming pump until it becomes hard.

Warning

Do not crank engine before having filled pump.

Priming pump

Y220_0A041

10. Check the installed components again and connect

the negative battery cable. Start the engine and check

the operating status.

11. With Scan-i, check if there are current faults and erase

the history faults.

Note

For details, refer to “DI10 Diagnosis teable”.

Y220_0A042

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 11

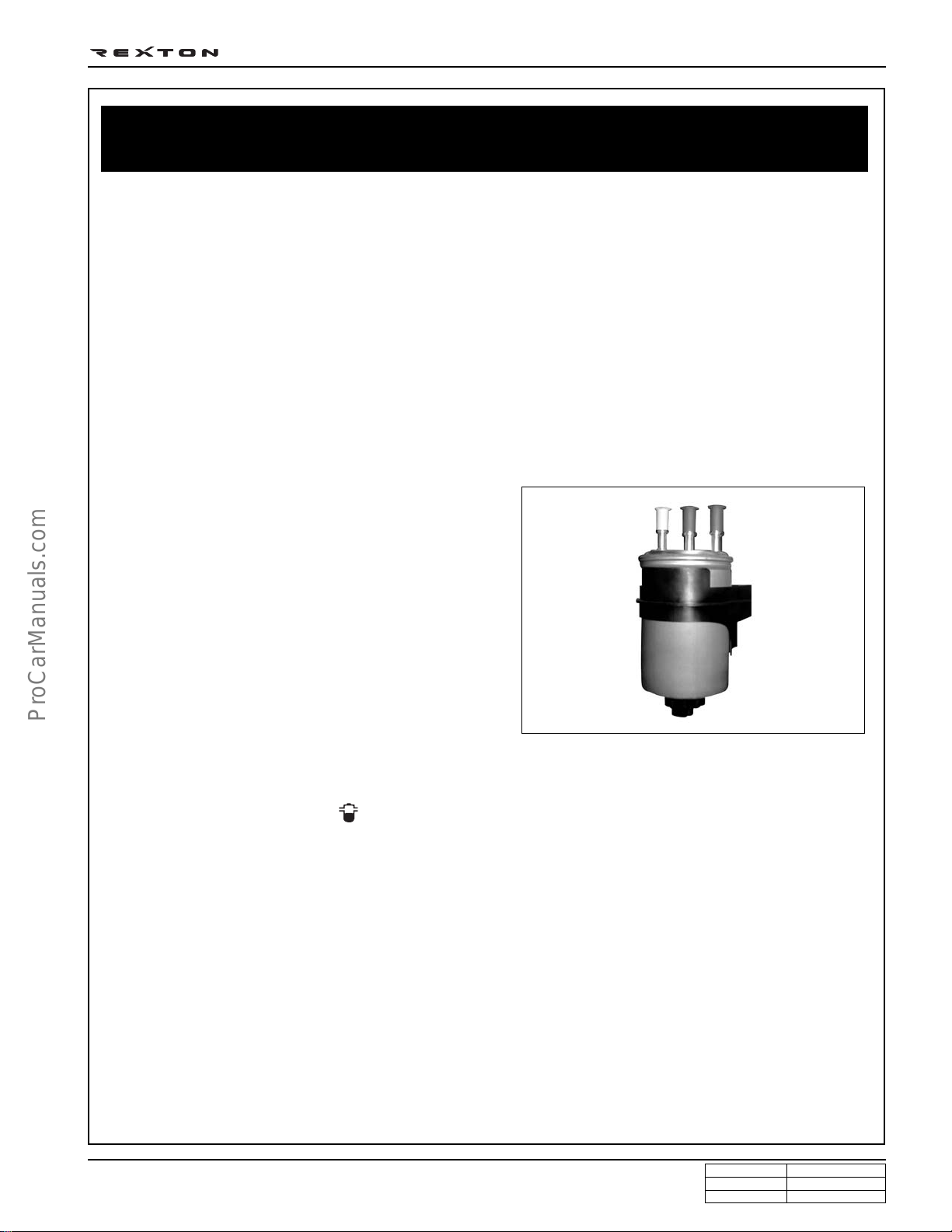

DI Engine and Its Expected Problems and Remedies Can be Caused

by Water in Fuel

SYSTEM SUPPLEMENT AGAINST PARAFFIN SEPARATION.

In case of Diesel fuel, paraffin, one of the elements, can be separated from fuel during winter and then can stick on

the fuel filter blocking fuel flow and causing difficult starting finally. Oil companies supply summer fuel and winter

fuel by differentiating mixing ratio of kerosene and other elements by region and season. However, above phenomenon

can be happened if stations have poor facilities or sell improper fuel for the season.

In case of DI engine, purity of fuel is very important factor to keep internal preciseness of HP pump and injector.

Accordingly, more dense mesh than conventional fuel filter is used. To prevent fuel filter internal clogging due to

paraffin separation, SYMC is using fuel line that high pressure and temperature fuel injected by injector returns

through fuel filter to have an effect of built-in heater (see fuel system).

SYSTEM SUPPLEMENT AND REMEDY AGAINST WATER IN FUEL

As mentioned above, some gas stations supply fuel with

excessive than specified water. In the conventional IDI

engine, excessive water in the fuel only causes dropping

engine power or engine hunting. However, fuel system in

the DI engine consists of precise components so water in

the fuel can cause malfunctions of HP pump due to poor

lubrication of pump caused by poor coating film during high

speed pumping and bacterization (under long period parking).

To prevent problems can be caused by excessive water in

fuel, water separator is installed inside of fuel filter. When

fuel is passing filter, water that has relatively bigger specific

gravity is accumulated on the bottom of the filter.

DI0A-7

Y220_0A041

If water in the separator on the fuel filter exceeds a certain level, it will be supplied to HP pump with fuel, so the

engine ECU turns on warning light ( ) on the meter cluster and buzzer if water level is higher than a certain level.

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a customer checks in to

change engine oil, be sure to perform water drain from fuel filter. (See fuel system for details.)

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 12

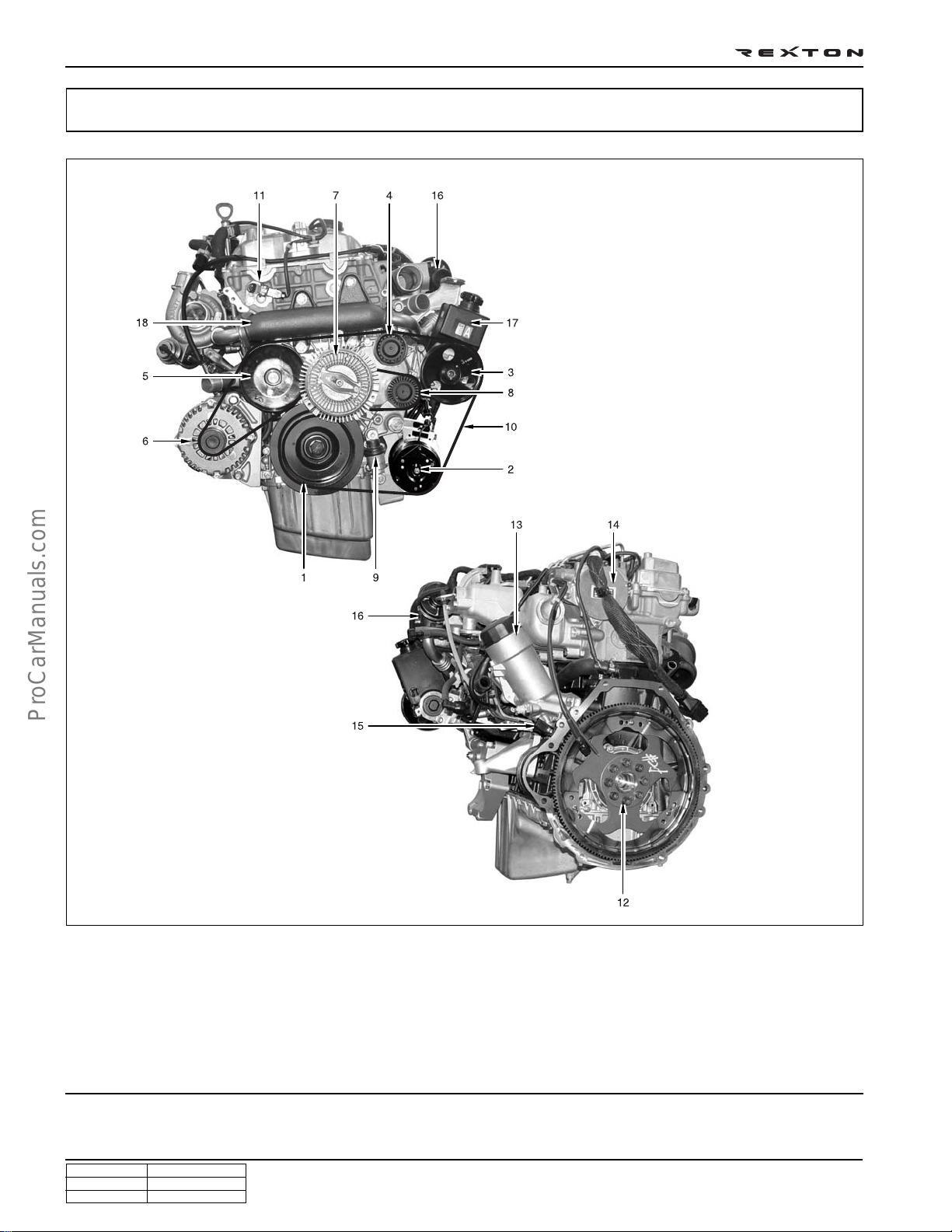

DI0A-8

STRUCTURE

Front view

Rear view

1. TVD (Torsional Vibration Damper)

2. Air conditioner compressor

3. Power steering pump pulley

4. Idle pulley

5. Water pump pulley

6. Alternator

7. Cooling fan pulley & viscos clutch

8. Aut tensioner pulley

9. Auto tensioner

10. Poly-groove belt

11. Cam position sensor

12. Drive plate (M/T: DMF)

Y220_0A001

13. Oil filter housing

14. Vacuum pump

15. Crank position sensor

16. EGR valve

17. Power steering pump

18. EGR center pipe

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 13

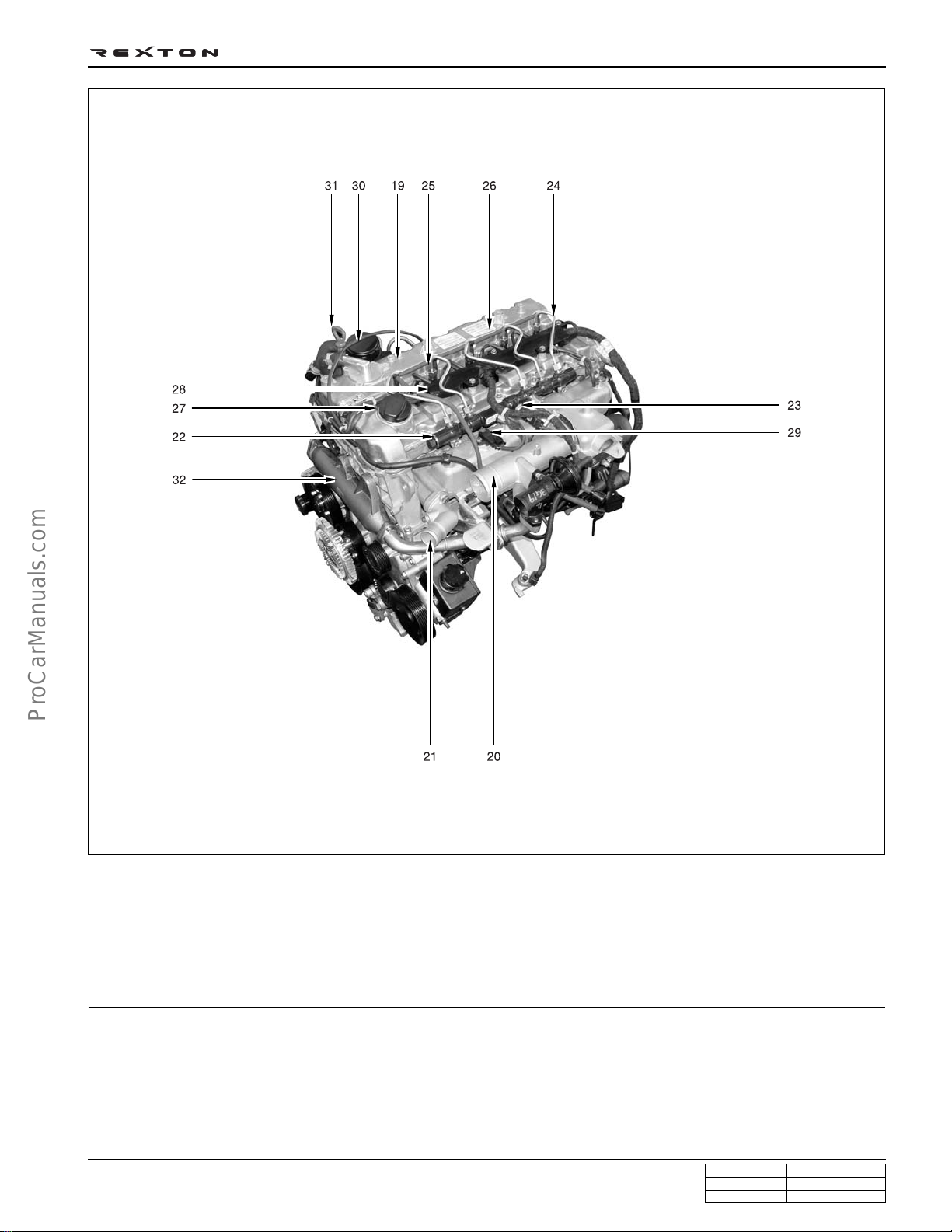

Top view

DI0A-9

19. Cylinder head cover

20. Intake manifold

21. Water outlet port

22. Common rail

23. Fuel pressure sensor

24. Fuel pipe

25. Injector

26. Fuel return line

27. Oil filler cap

28. Glow plug

Y220_0A002

29. Booster pressure sensor

30. Oil separator

31. Oil dipstic

32. EGR center pipe

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 14

DI0A-10

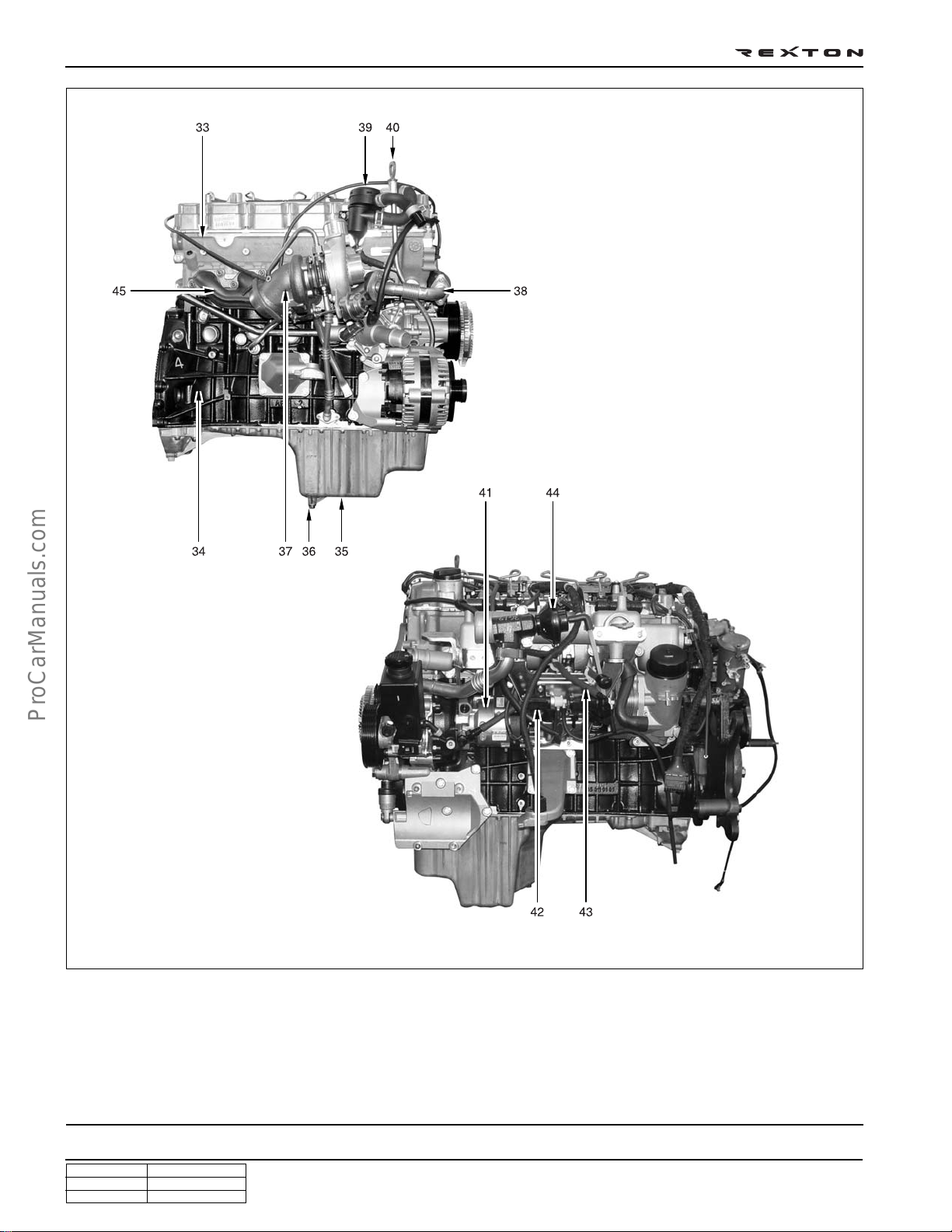

Left side view

33. Cylinder head

34. Cylinder block

35. Oil pan

36. Drain plug

37. Turbocharger

Right side view

38. EGR - RH pipe

39. Oil separator

40. Oil dipstic

41. HP pump

Y220_0A003

42. Turbocharger vacuum modulator

43. EGR valve vacuum modulator

44. EGR valve

45. Exhaust manifold

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 15

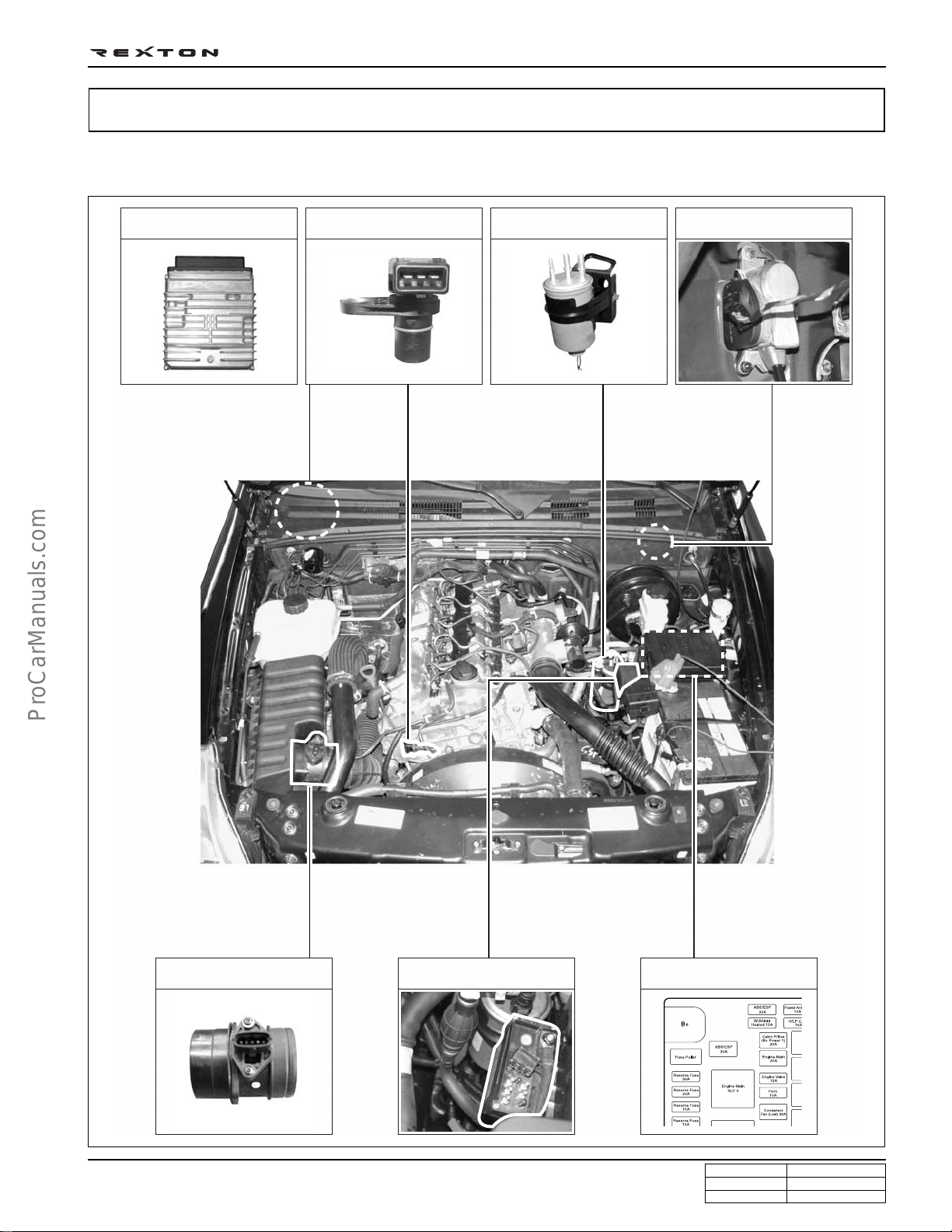

ENGINE CONTROLS

ECU RELATED COMPONENTS

DI0A-11

ECU/barometric sensor Cam position sensor

(water detection sensor)

Fuel filter

Accelerator pedal sensor

HFM sensor/intake air

temperature sensor

Pre heating time relay Main relay

Y220_0A004

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 16

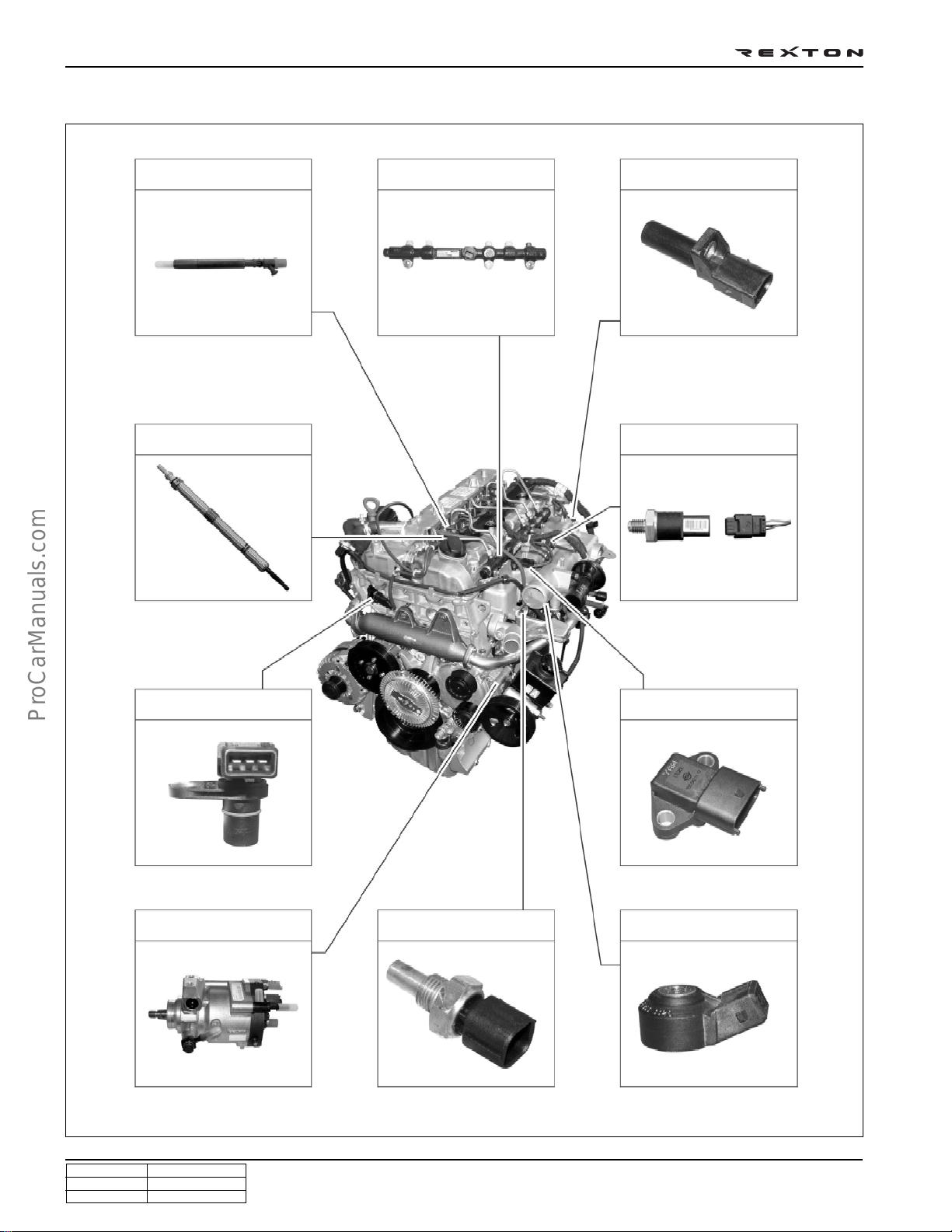

DI0A-12

ENGINE AND SENSORS

Injector

Glow plug

Common rail

Crankshaft position

sensor

Fuel pressure sensor

Camshaft position

sensor

HP pump

Coolant temperature

sensor

Booster pressure sensor

Knock sensor (2)

Y220_0A005

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 17

ELECTRICAL COMPONENTS AND PRE HEATING SYSTEM

Glow plug Pre heating time relay

DI0A-13

Starter motor

BatteryFuse box

Alternator

Y220_0A006

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 18

DI0A-14

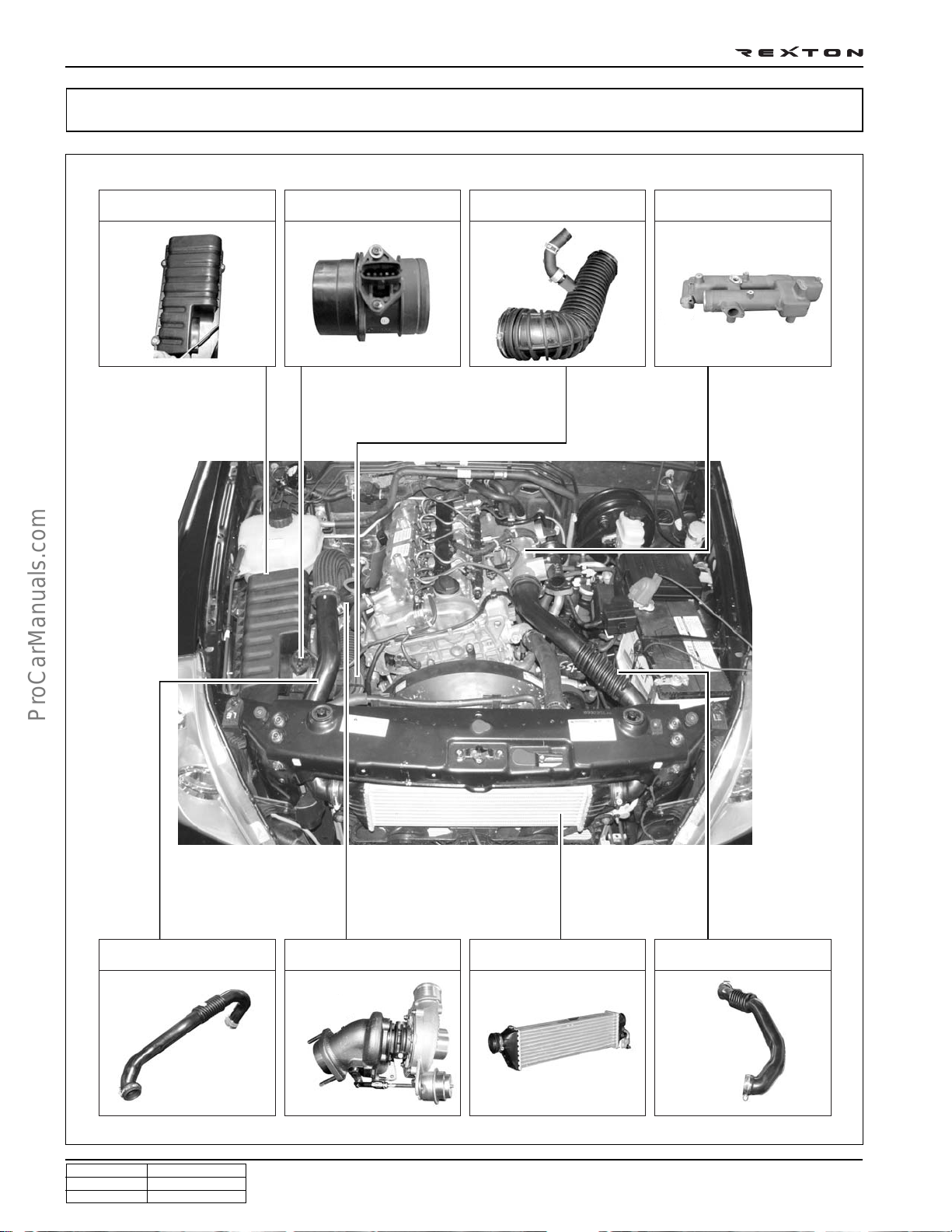

INTAKE SYSTEM

Air cleaner assembly Intake duct hoseHFM sensor Intake manifold

Intake outlet hose Turbocharger Intercooler Inlet hose

Y220_0A007

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 19

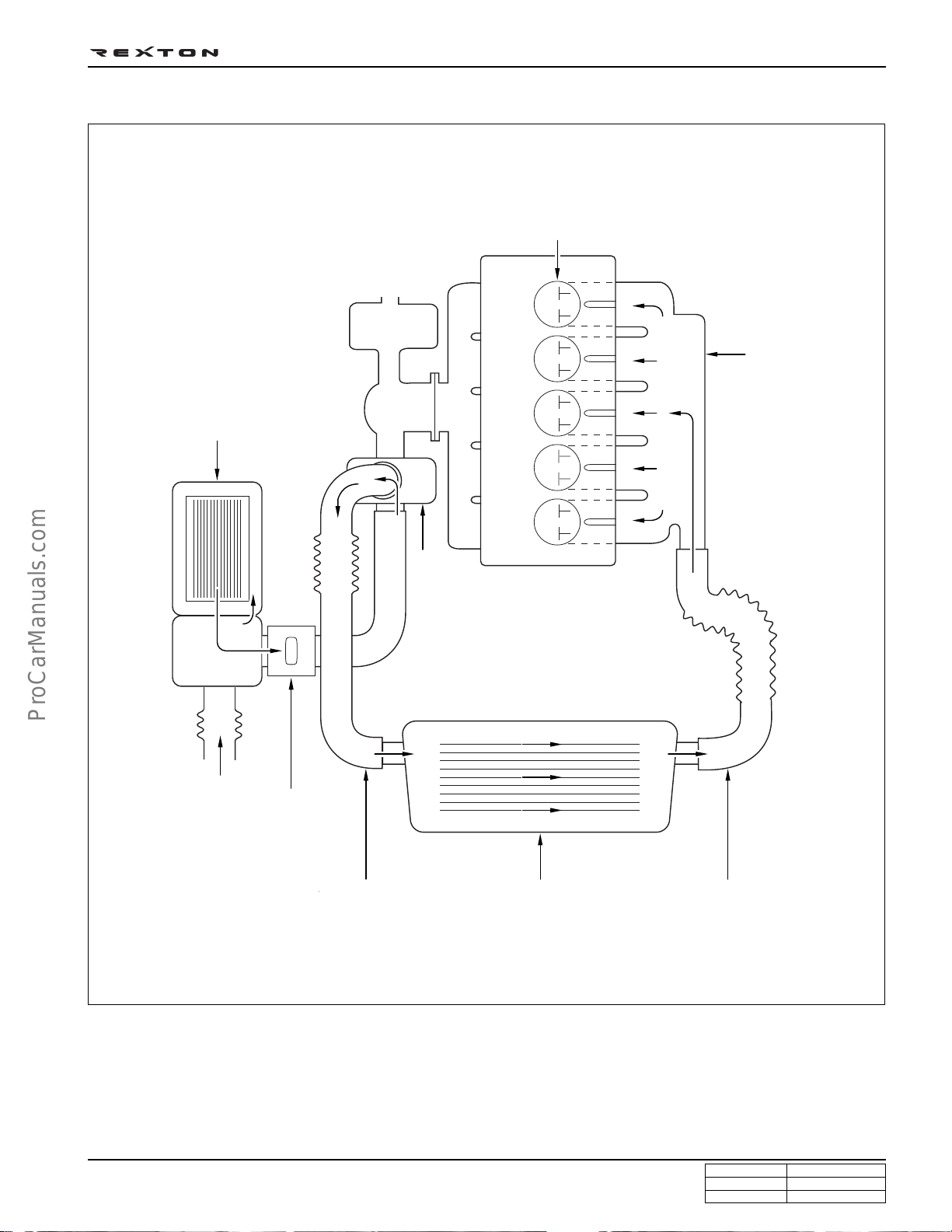

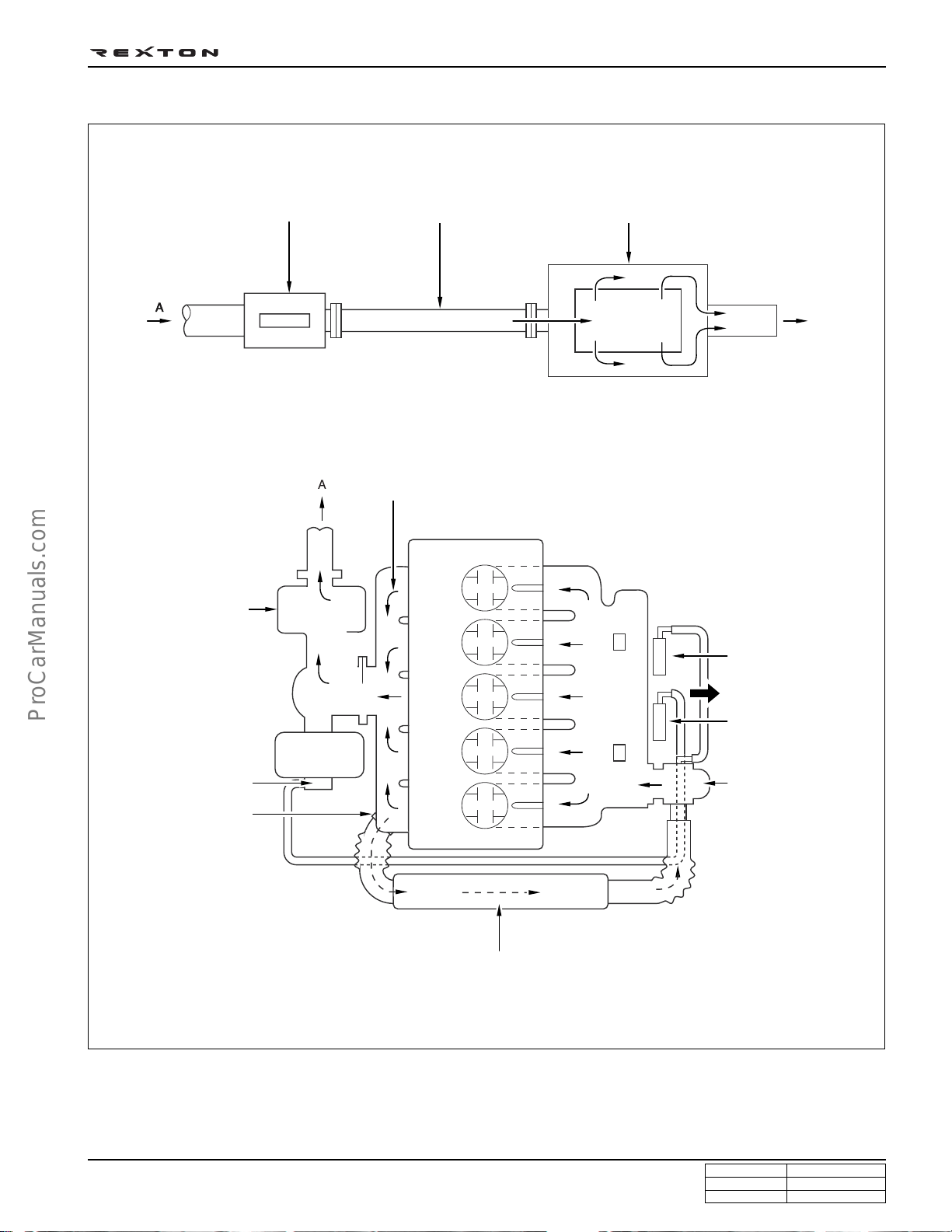

INTAKE AIR FLOW CHART

Air cleaner side

DI0A-15

Intake valve (in combustion chamber)

Intake manifold

HFM sensor

Turbocharger

(compressor)

Engine

Intake hose (inner)Intake hose (outlet) Intercooler

Y220_0A008

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 20

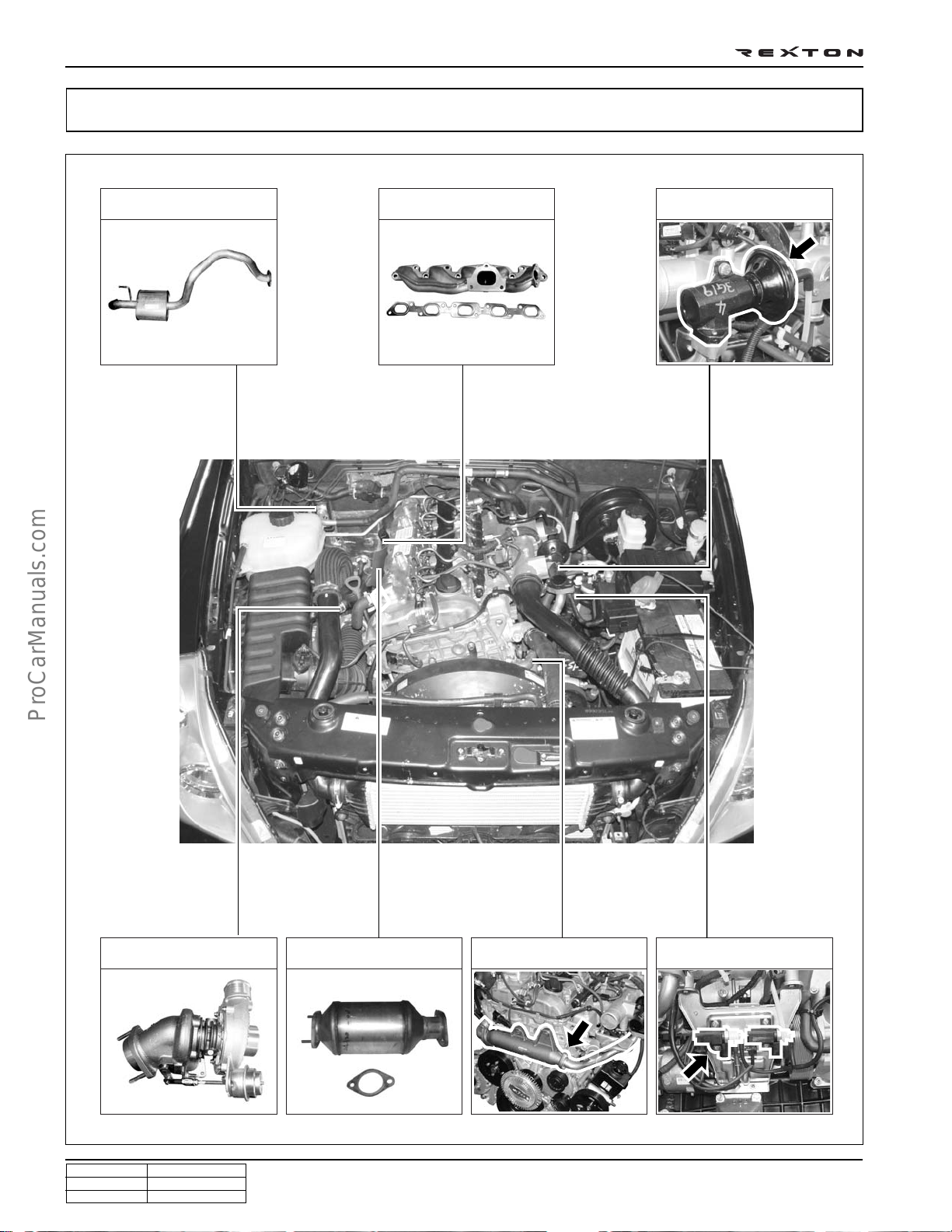

DI0A-16

INTAKE SYSTEM

Muffler Exhaust manifold EGR valve

Vacuum modulatorTurbocharger Catalytic converter EGR pipe

Y220_0A009

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 21

EXHAUST AIR FLOW CHART

Exhaust gas

DI0A-17

Exhaust pipeCatalytic converter Muffler

Ambient

air

Turbocharger

(turbine side)

Turbocharger booster

Exhaust manifold

EGR vacuum

modulator

To turbocharger

booster

Turbocharger

booster vacuum

modulator

EGR valve

EGR pipe

Y220_0A010

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 22

DI0A-18

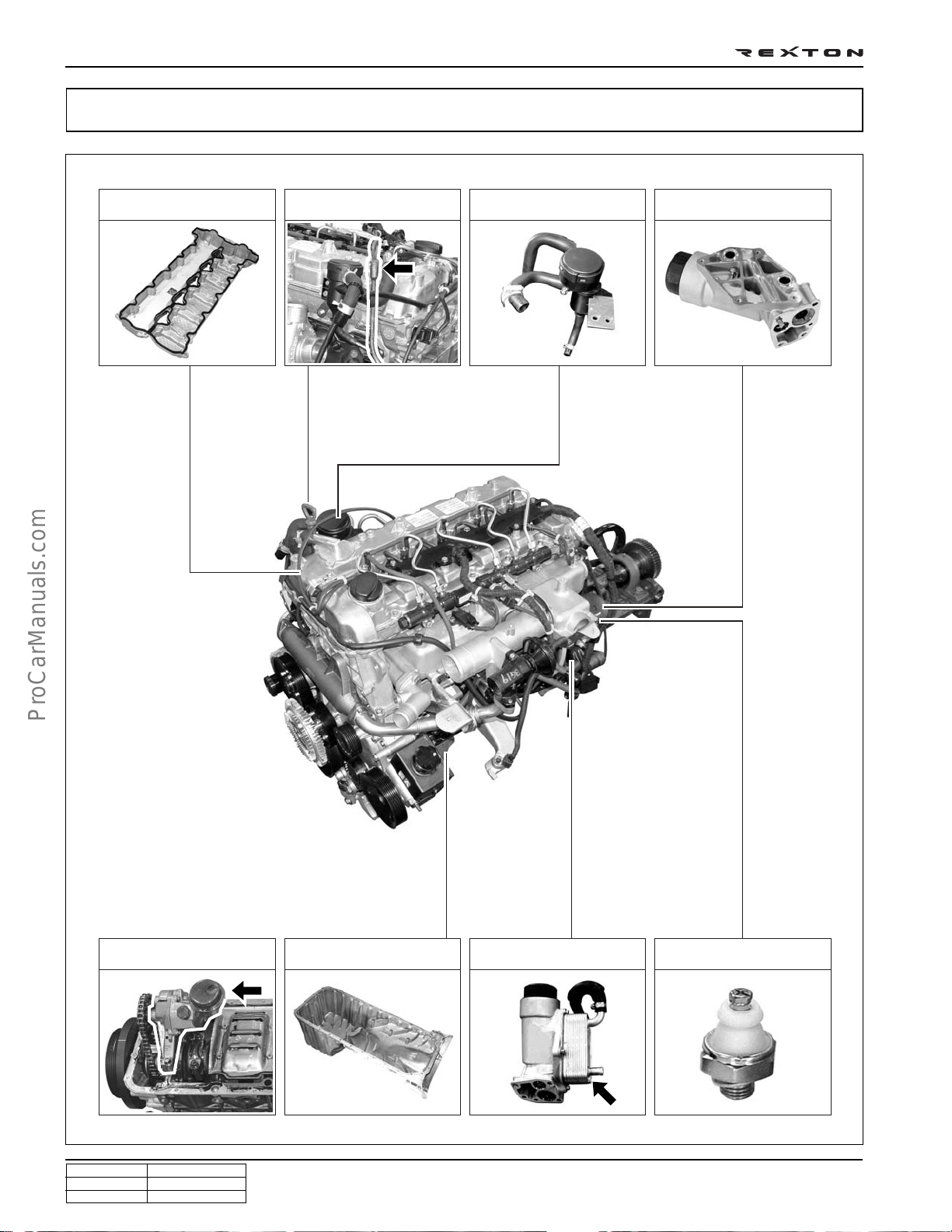

LUBRICATION SYSTEM

Cylinder head cover

Oil dipstic PCV valve

Engine oil filter

housing

Engine oil pump Oil pan Engine oil cooler

Engine oil pressure

switch

Y220_0A011

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 23

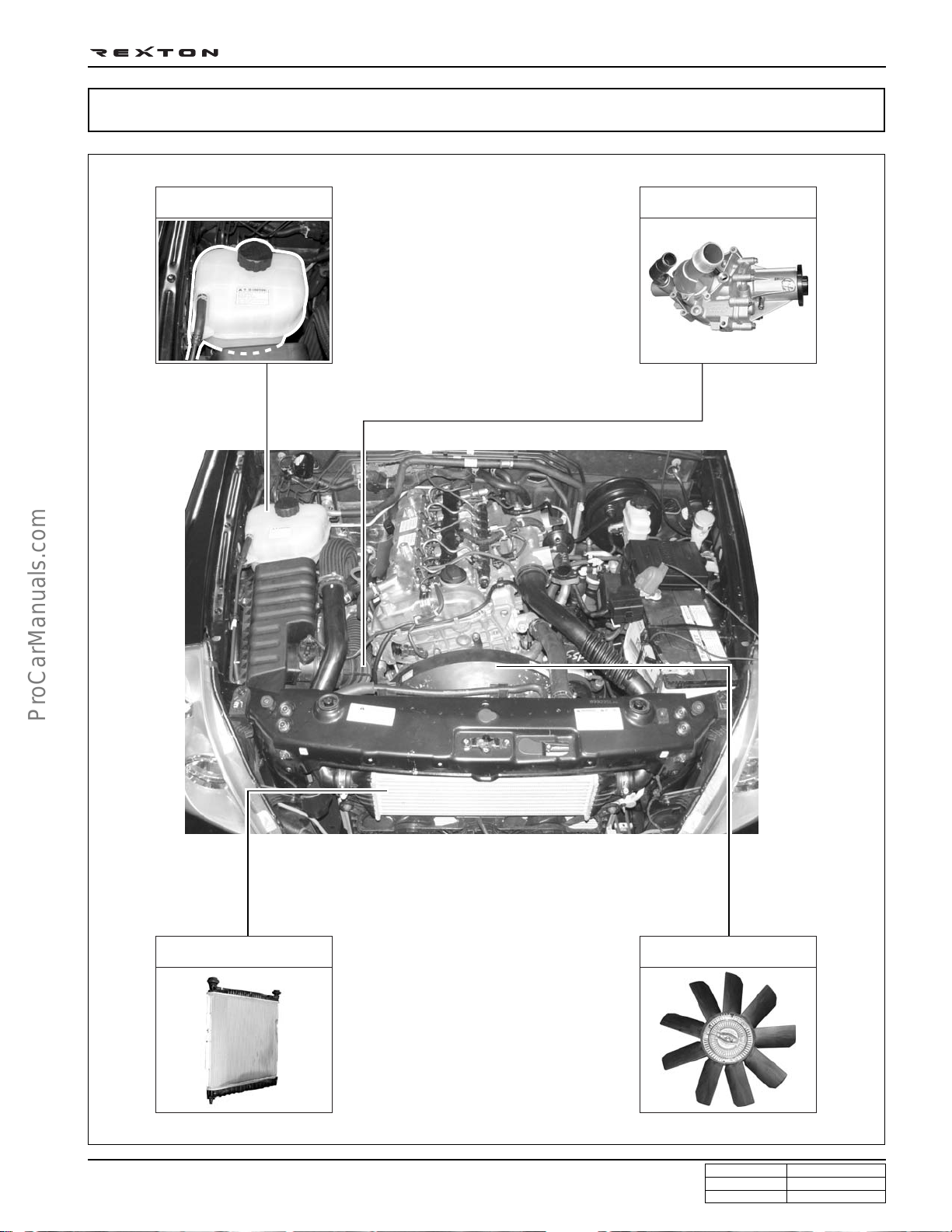

COOLING SYSTEM

DI0A-19

Coolant reservoir

Water pump

Radiator assembly

Cooling fan and fan

clutch

Y220_0A013

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 24

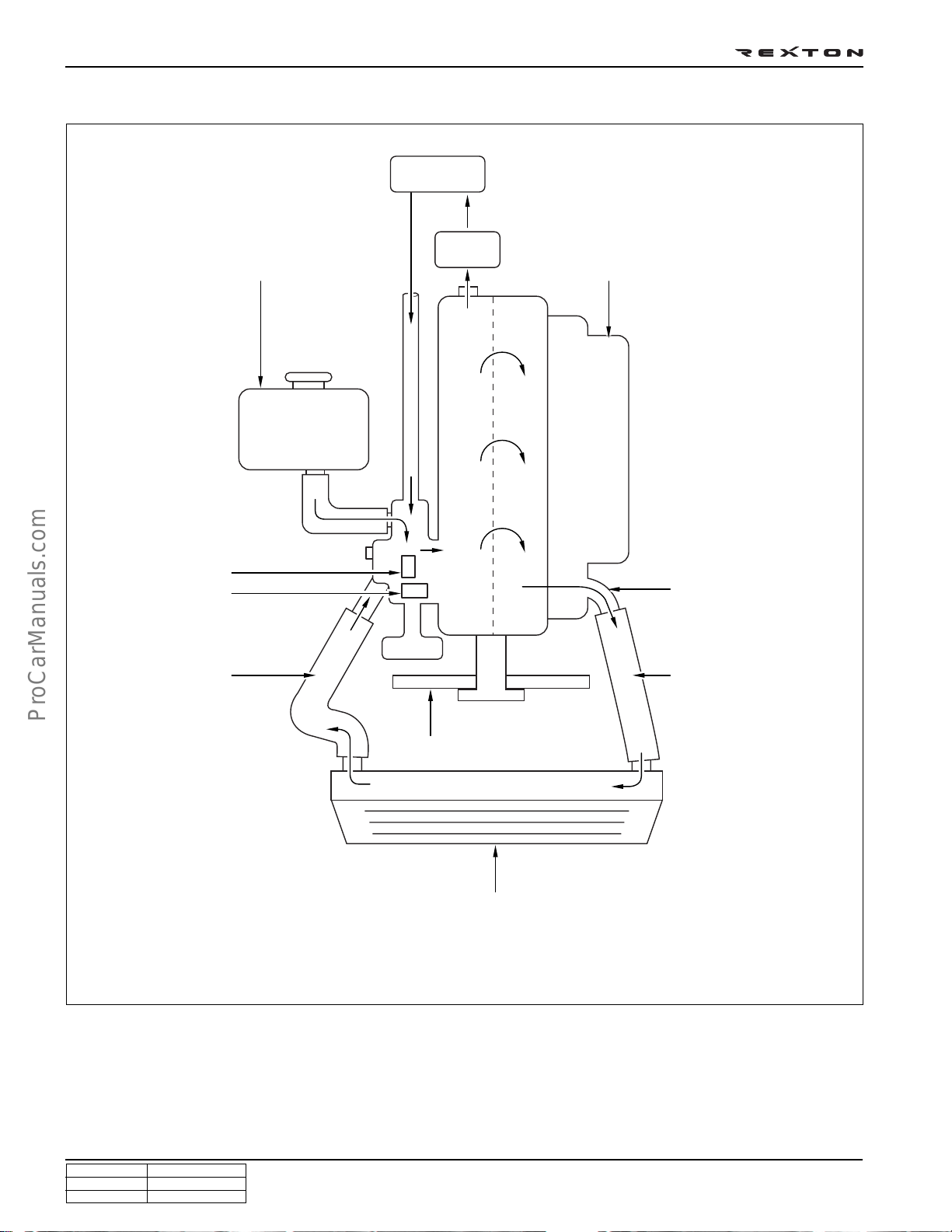

DI0A-20

COOLANT FLOW CHART

Coolant reservoir

Heater

Oil cooler

Intake manifold

Thermostat

Water pump

Inner hose

Coolant outlet port

Outlet hose

Cooling fan

Radiator

Y220_0A014

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 25

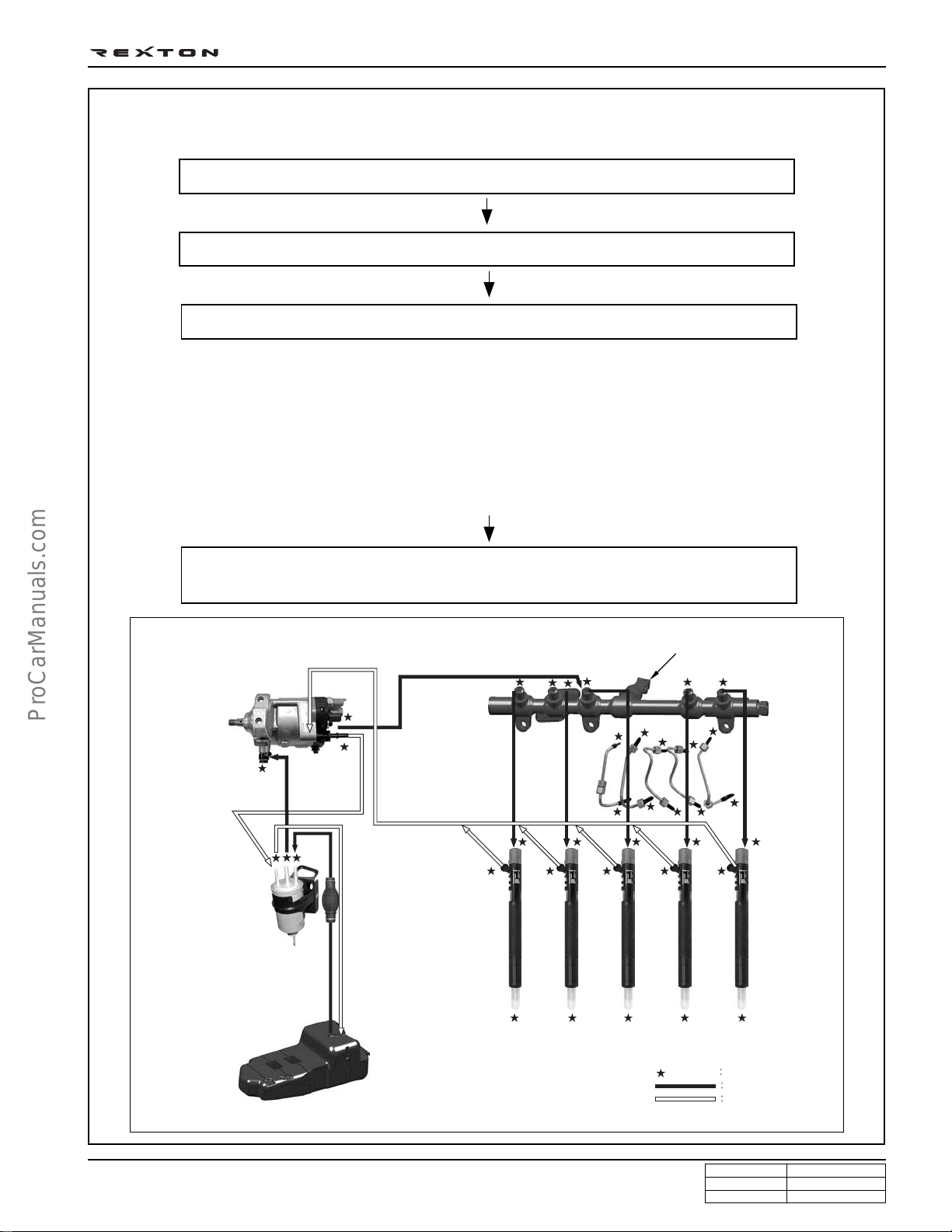

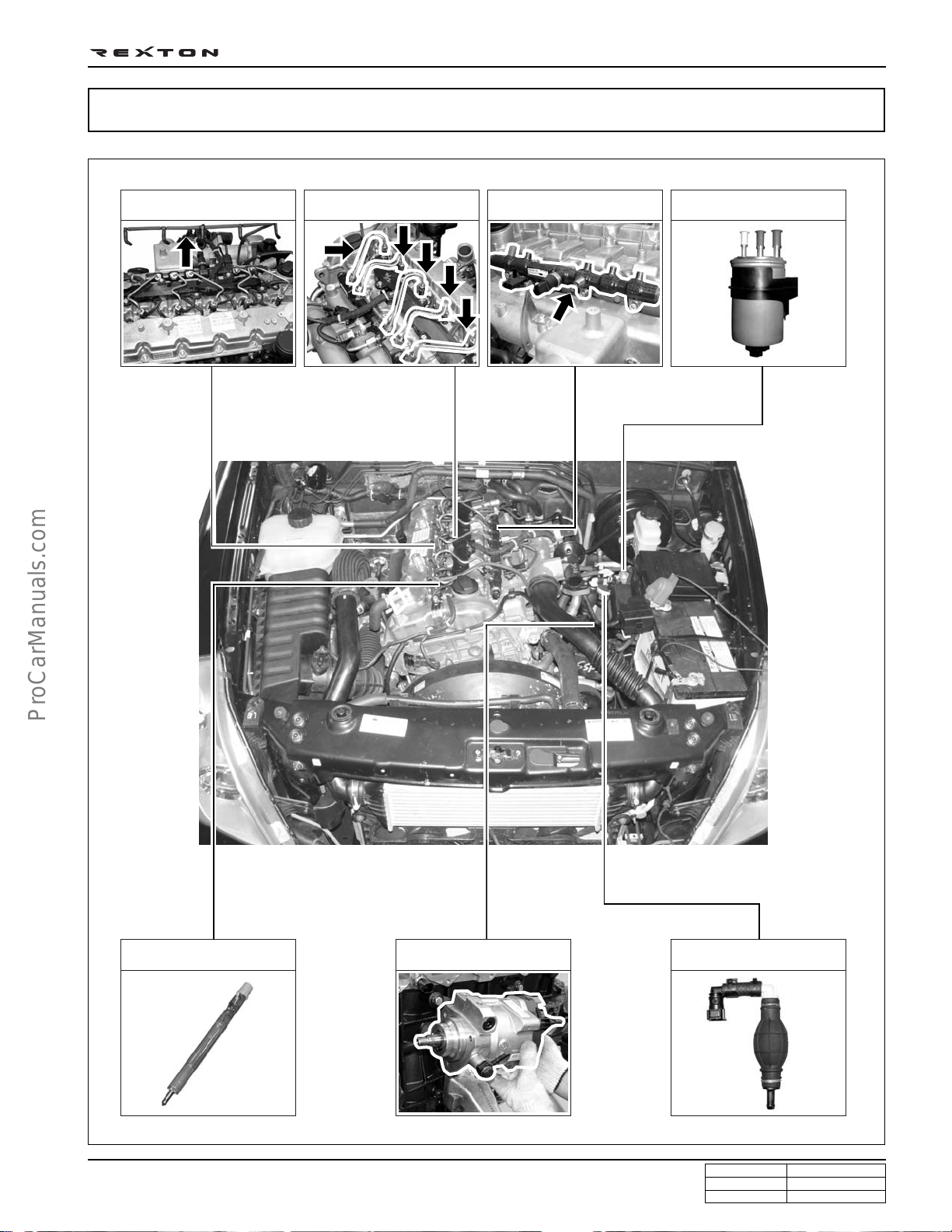

FUEL SYSTEM

Fuel return hose Fuel pressure pipe Common rail Fuel filter

DI0A-21

Injector HP pump Priming pump

Y220_0A015

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 26

DI0A-22

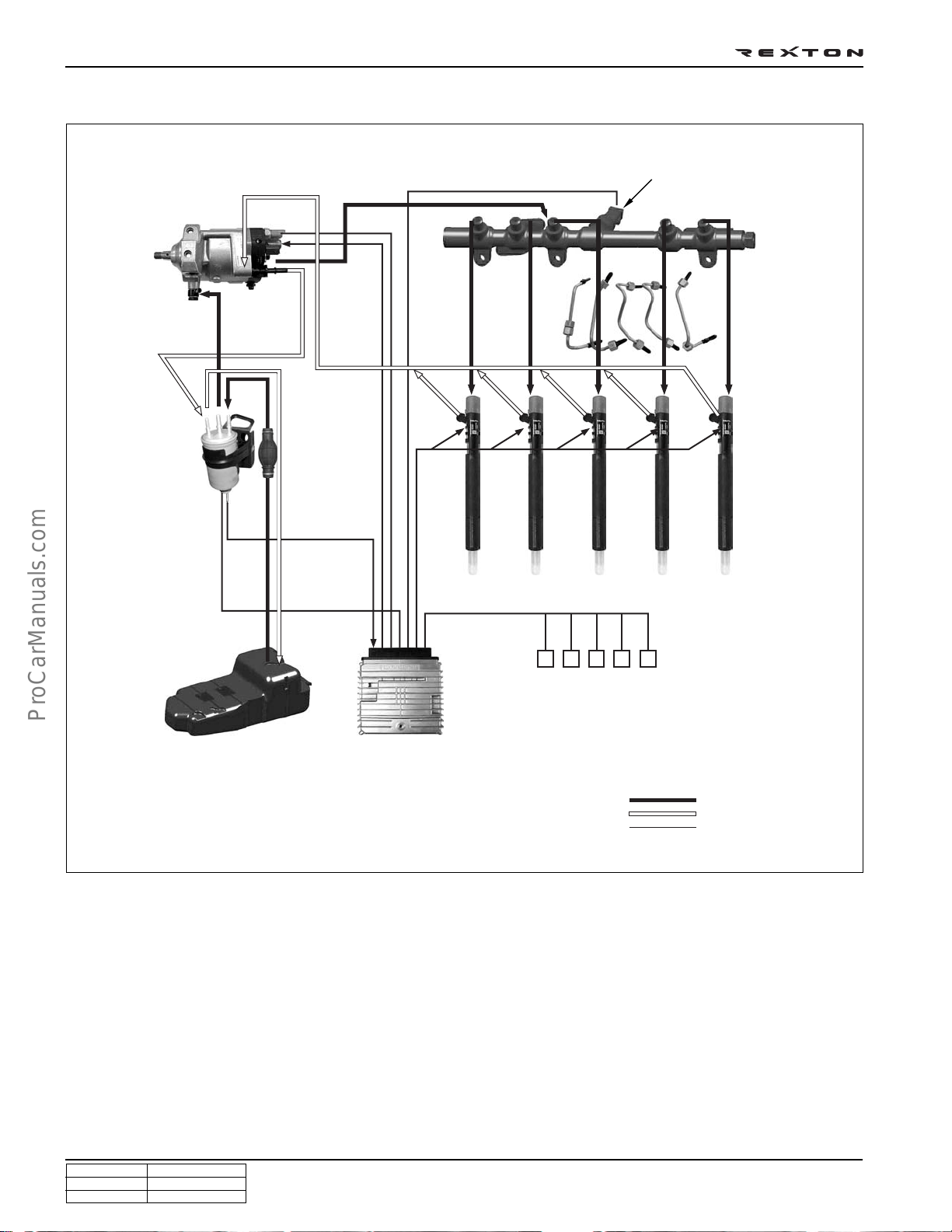

FUEL SUPPLY SYSTEM

Fuel pressure sensor

High pressure pump

IMV valve

Low and high

pressure pump

Fuel temperature

sensor

Water separator

Fuel filter

Water detection

sensor

Prining pump

Common rail

High

pressure

pipe

Label

(C21)

Injector

Sensors

Fuel tank

Components:

- High pressure fuel pump

- Fuel injectors

ECU

- Fuel rails

- Electroc control unit (ECU)

- Fuel pressure sensor

- Various sensors and actuators

HFM sensor

Cam position sensor

Crank position sensor

Knock sensor etc.

Supply line

Return line

ECU communication line

Y220_0A016

According to input signals from various sensors, engine ECU calculates driver’s demand (position of the accelerator

pedal) and then controls overall operating performance of engine and vehicle on that time.

ECU receives signals from sensors via data line and then performs effective engine air-fuel ratio controls based on those

signals. Engine speed is measured by crankshaft speed (position) sensor and camshaft speed (position) sensor determines injection order and ECU detects driver’s pedal position (driver’s demand) through electrical signal that is generated by variable resistance changes in accelerator pedal sensor. Air flow (hot film) sensor detects intake air volume and

sends the signals to ECU. Especially, the engine ECU controls the air-fuel ratio by recognizing instant air volume

changes from air flow sensor to decrease the emissions (EGR valve control). Furthermore, ECU uses signals from

coolant temperature sensor and air temperature sensor, booster pressure sensor and barometric sensor as compensation signal to respond to injection starting, pilot injection set values, various operations and variables.

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 27

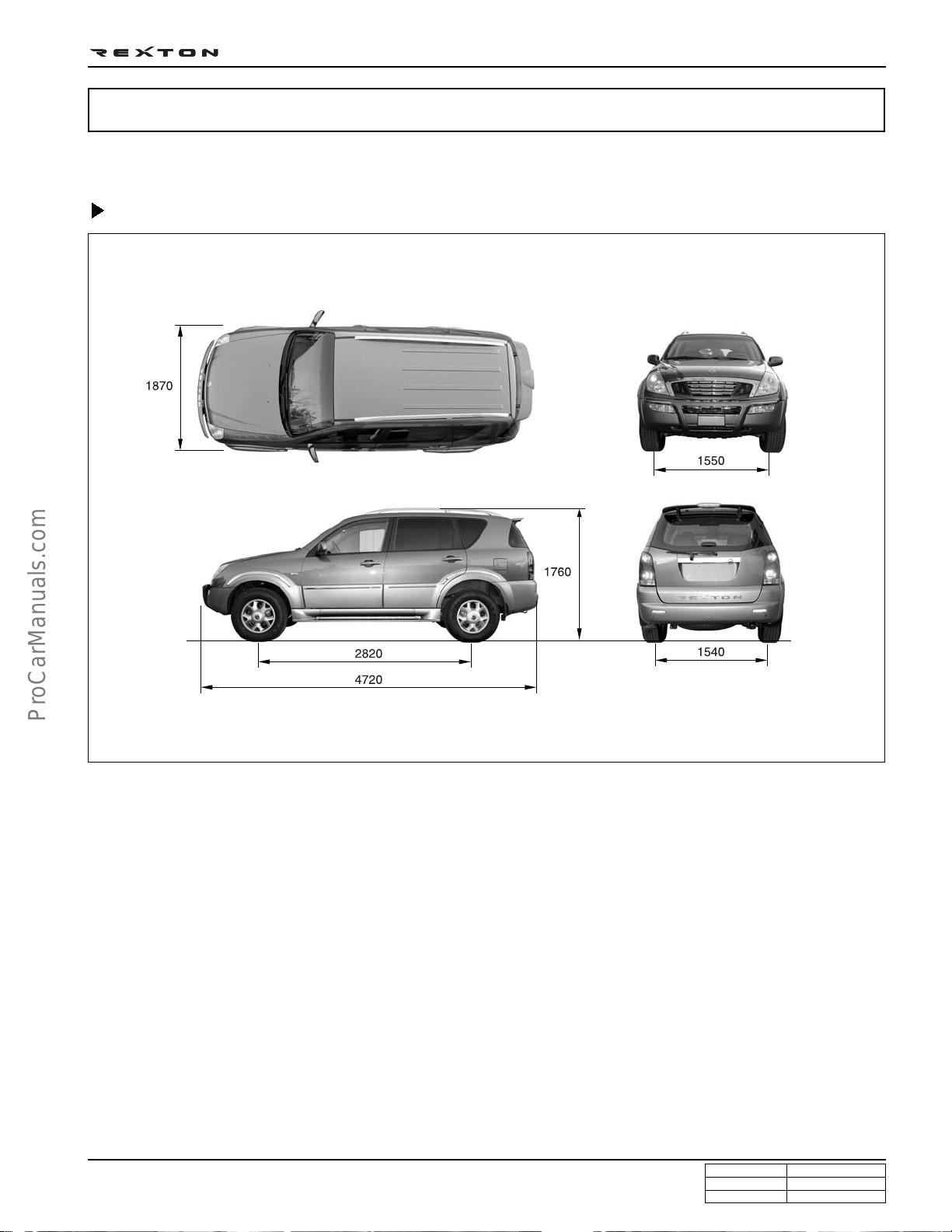

GENERAL SPECIFICATIONS

VEHICLE SPECIFICATIONS

DI0A-23

Vehicle Dimension

(mm)

Y220_0A017

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 28

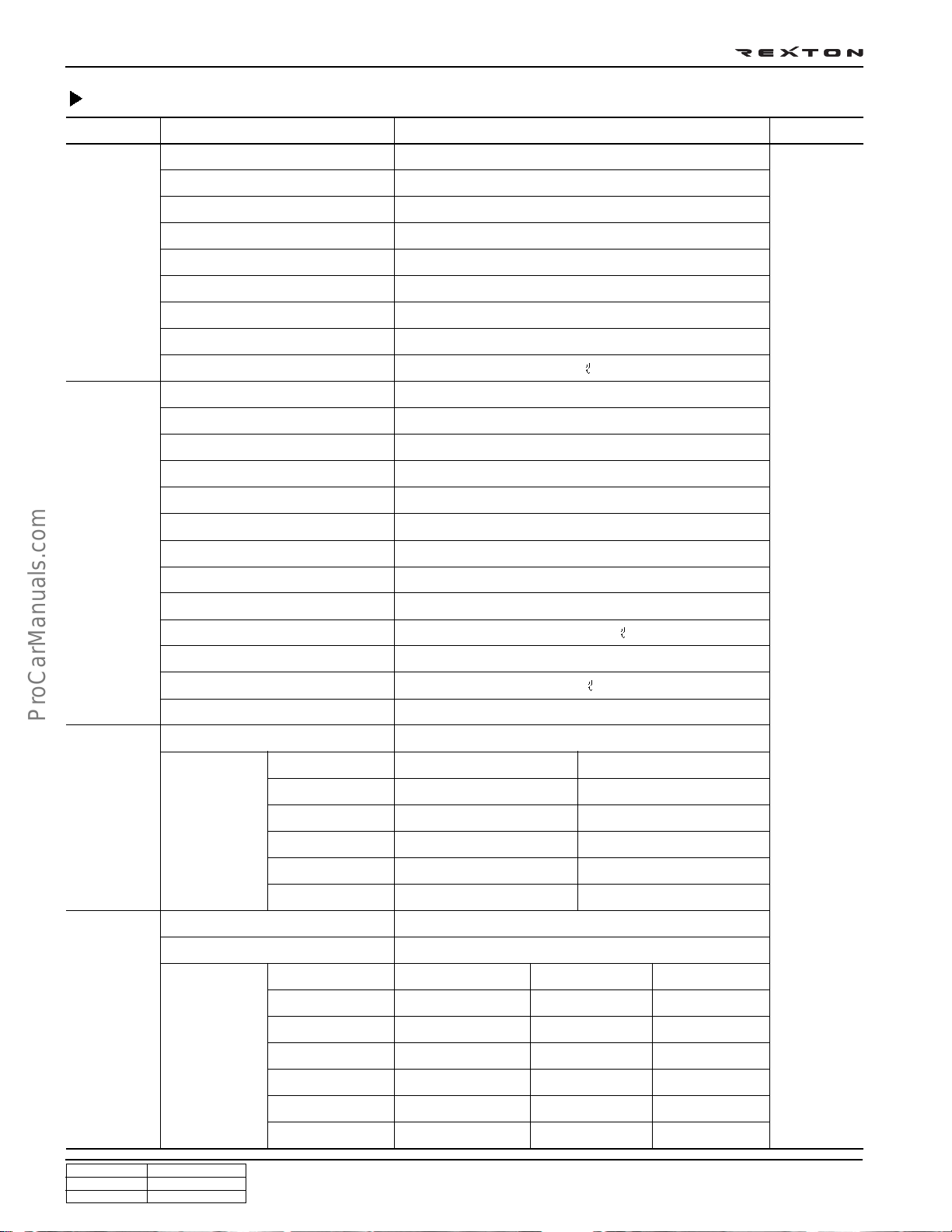

DI0A-24

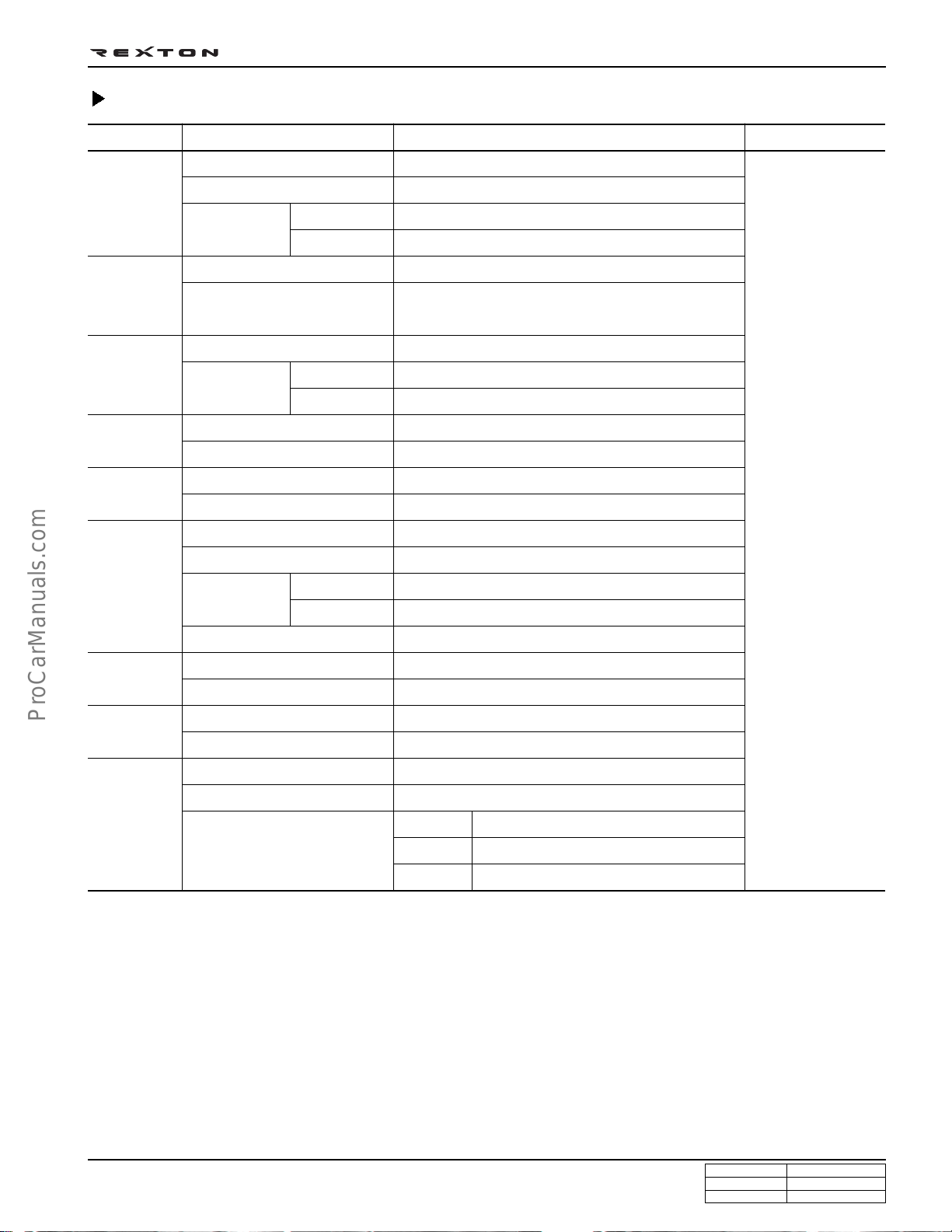

Specifications

Systems Items Diesel Remark

General Overall length (mm)

Overall width (mm)

Overall height (mm)

4,720 (4,785)

1,870

1,760 (1,830)

( ): optional

item

Engine

Gross vehicle weight (kg)

Curb weight (kg)

Min. turning radius (m)

Ground clearance (mm)

Fuel

Fuel tank capacity

Model

No. of cyl./Compression ratio

Total displacement

Camshaft arrangement

Max. power

Max. torque

Injection timing

Idle speed

Cooling system

Coolant capacity

Lubrication

Max. oil capacity

AT: 2450 (2510), MT: 2405 (2465)

AT: 1995 (2055), MT: 1950 (2010)

5.6

200

Diesel

80

D27DT

5/18:1

2,696 cc

DOHC

170 ps/4,000 rpm

34.7 kg•m/1,800 rpm

ATDC 4° ± 1°(at idle)

760 ± 50 rpm

Water-cooled/forced circulation

Approx. 11.5

Gear pump, forced circulation

9.3

Manual

Turbo charger and cooling type

Type

transmission

Automatic

transmission

Model

Type

st

1

nd

2

rd

3

th

4

th

5

Rev.

st

1

nd

2

rd

3

th

4

th

5

Rev. 1

Rev. 2

Turbo charger, air-cooled

Remote control, floor change type

IDI Engine 4.007

2.367

1.473

1.000

0.872

3.700

DI Engine 4.315

2.475

1.536

1.000

0.807

3.591

Electronic

Floor change type

2.742

1.508

1.000

0.708

-

st

nd

2.429

-

3.595

2.186

1.405

1.000

0.831

3.162

1.926

2.742

1.508

1.000

0.708

-

2.429

-

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 29

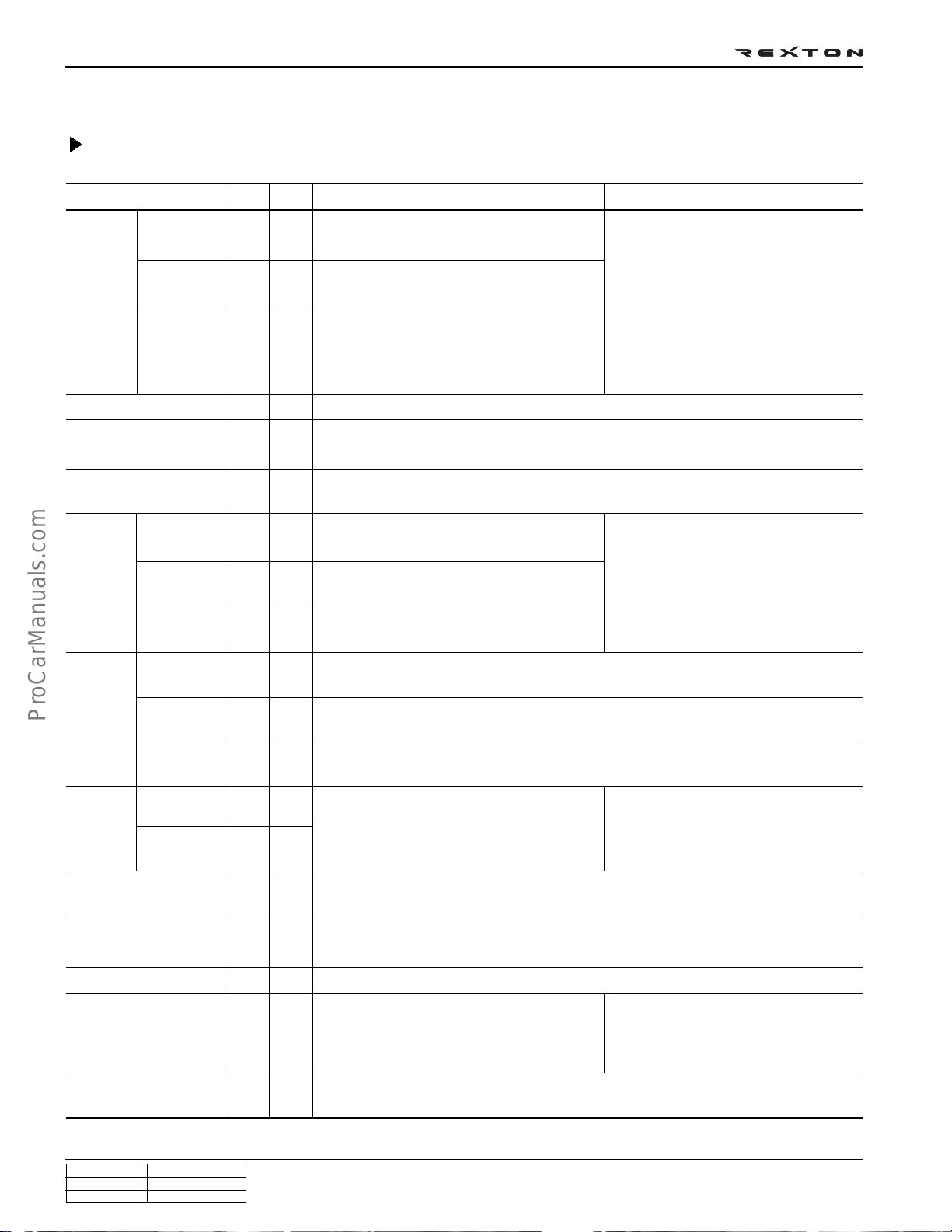

Specifications (Cont’d)

DI0A-25

Systems

Transfercase

Model

Type

Gear ratio

Clutch

Type

Disc type

Power

steering

Front axle

Type

Steering angle

Drive shaft type

Axle housing type

Rear axle

Drive shaft type

Axle housing type

Brake

Master cylinder type

Booster type

Type

Parking brake

Suspension

Front

Rear

Air

conditioner

Electrical

Refrigerant

Compressor type

Battery type/Capacity (V-AH)

Starter capacity (V-kW)

Alternator capacity (V-A)

Items

High

Low

Inner

Outer

Inner

Outer

Diesel

Part-time

Planetary gear type

1.000 : 1

2.483 : 1

Hydraulic [A/T: Torque converter]

Dry single diaphragm type

[A/T: 3 elements 1 stage 2 phases]

Rack and pinion

'

36° 17

32° 40

'

Ball joint type

Build-up type

Semi-floating type

Build-up type

Tandem type

Vacuum booster

Disc

Drum (Disc)

Cable type (internal expansion)

Wishbone + Coil spring

5-link + Coil spring

R134a

Vane type

MF / 12 - 90

Diesel : 12 - 2.2, Gasoline : 12 - 1.8

IDI

DI

Gasoline

12 - 75 (12 - 90)

12 - 140 (12 - 115)

12 - 115

Remark

( ): optional item

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 30

DI0A-26

MAINTENANCE

Major Components and Service Interval

* Use only Ssangyong Genuine Parts.

Components Service Interval Remarks

Engine

oil and

oil filter

Gasoline

engine

DI diesel

Daily Weekly

O-

O-

engine

IDI diesel

O-

engine

Coolant

Brake pipe and hose

Brake pad, shoe and

O-

--

--

disc

Air

cleaner

element

Gasoline

engine

DI diesel

-O

-O

engine

IDI diesel

-O

engine

Fuel filter

Gasoline

-

engine

DI diesel

engine

IDI diesel

--

--

engine

Auto-

4-speed

--

matic

transmission oil

5-speed

Manual transmission

--

--

oil

Transfer case oil

Axle oil

Air conditioner air

--

--

--

filter

Spark plug (gasoline

--

engine)

Initial change: 10,000 km

Replace at every 15,000 km

Initial change: 5,000 km

Replace at every 10,000 km or 12 months

More frequent maintenance is required if

the vehicle is operated under severe

condition.

Severe conditions?

- Frequent low-speed operation as in

stop-and-go traffic

- When most trips are less than 6 km (in

winter, less than 16 km)

- Driving in sandy, dusty, and salty road

- Driving in mountainous areas

- Extensive idling or high load operation

such as towing a trailer

Replace at every 60,000 km or 3 years

Initial inspection: 1,000 km

Inspect at every 20,000 km, replace if necessary

Inspect at every 10,000 km, check or adjust if necessary

Clean at every 15,000 km,

Replace at every 60,000 km

Initial clean: 5,000 km,

If vehicle is operated under dusty or sandy

area, frequently clean and inspect the air

cleaner system. If necessary, replace the air

cleaner element.

Clean at every 10,000 km, replace if

necessary,

Replace at every 30,000 km

Replace at every 60,000 km

-

Replace at every 30,000 km (Drain the water from fuel filter at every 10,000 km)

Replace at every 40,000 km

Inspect at every 30,000 km or 1 year,

replace if necessary (replace at every

60,000 km if the vehicle is operated

More frequent maintenance is required if the

vehicle is operated under severe condition.

- Driving in unpaved road

- Towing a trailer

under severe conditions)

Inspect at every 10,000 km,

Replace at every 60,000 km

Inspect at every 10,000 km,

Replace at every 60,000 km (but, frequently chexk the leaks)

Replace at every 30,000 km

Replace at every 10,000 km

More frequent maintenance is required if the

vehicle is operated under severe condition.

- Driving in sandy, dusty, and unpaved road

- Excessive operation of air conditioner or

heater

Replace at every 60,000 km

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 31

Lubrication Chart

Lubricant Capacity Classification

DI0A-27

Diesel

Engine oil

Gasoline

Engine coolant

(Antifreeze and soft water mixed)

Manual transmission oil

Brake/Clutch fluid (Level must be

maintained between MAX & MIN

level)

Power steering fluid

Automatic transmission fluid

IDI Engine

DI Engine

G23D

G32D/G28D

IDI Engine

DI Engine

G23D

G32D/G28D

6.0 ~ 8.0 L

6.8 ~ 8.3 L

5.5 ~ 7.5 L

7.0 ~ 9.0 L

10.5 ~ 11.0 L

11.0 ~ 12.0 L

10.0 ~ 10.5 L

11.3 ~ 11.5 L

4WD: 3.6 L, 2WD: 3.4 L

Properly

1.1 L

4-speed: 9.5 L

5-speed: 8.0 L

Quality

class**

API : CG grade or above,

ACEA : B2, B3 or B4

MB sheet : 229.1/3 (preferable)

Viscosity

Quality

class**

MB sheet No. 224.1

API : SJ grade or above,

ACEA : A2 or A3

MB sheet : 229.1/3 (preferable)

Viscosity

MB sheet No. 224.1

MB sheet 325.0

BASF GLYSANTIN G05-11,

HOECHST GENANTIN SUPER 8023/14

®

ATF DEXRON

II, III,

ATF S-2, S-3, S-4, TOTAL FLUID ATX

SAE J 1703, DOT 3 or DOT 4

®

ATF DEXRON

II, III

CASTROL TQ 95

SHELL or FUCHS ATF 3353

Transfer case fluid

IDI Engine

DI Engine

Part time

Part time

Full time(TOD)

1.2 ~ 1.4 L

1.4 ~ 1.5 L

1.4 ~ 1.5 L

ATF DEXRON

®

II, III,

ATF S-4, TOTAL FLUID ATX

Gasoline

Front

Axle fluid

Rear

Wheel bearing grease

Propeller shaft grease - Front/Rear

Full time(TOD)

1.4 ~ 1.5 L

2.2 L

Properly

Properly

1.4 ~ 1.5 L

SAE 80W/90, API GL-5

SHELL Retinax “A” grade

ALVANIA EP#2

* Please contact Ssangyong Dealer for approved alternative fluid.

**In only case not available MB 229.1 or 229.3, API or ACEA oil may be accepted, however it would rather recommend

to shorten the change interval around 30%.

IDI: Indirect Injection

DI: Direct Injection

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 32

DI0A-28

VEHICLE IDENTIFICATION

1. Vehicle identification Number

Vehicle identification number (VIN) is is on the right front

axle upper frame.

[KPTPOA19S1P 122357]

K.. Nation (K: Korea)

P .. Maker Identification (P: Ssangyong Motor Company)

T .. Vehicle Type (T: Passenger car - 4WD)

P .. Line Models (P: Rexton)

O . Body Type (O: 5-door)

A.. Trim Level (A: Standard, B: Deluxe,

C: Super deluxe)

1 .. Restraint System (0: No seatbelts, 1: 3-point

seatbelts, 2: 2-point seatbelt)

9 .. Engine Type (9: 3199cc, In-line 6 cylinders, Gasoline E32)

(D: 2874cc, Il-line 5 cylinders, Diesel)

S .. Check Digit (S: All area except North America)

1 .. Model Year (1: 2001, 2: 2002, 3: 2003)

P .. Plant Code (P: Pyungtaek plant)

122357 (Production serial number)

Y220_0A018

2. Certification Label

The certification label is affixed on the bottom of driver’s side

B-pillar.

Y220_0A019

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 33

3. Engine Serial Number

The engine serial number is stamped on the lower area of

cylinder block in exhaust manifold side.

4. Manual Transmission Number

The transmission label is affixed on the upper area of clutch

housing.

DI0A-29

Y220_0A020

5. Automatic Transmission Number

The transmisson label is affixed on the right area of transmission housing.

6. Transfer Case Number

The transfer case label is affixed on the transfer case housing.

Y220_0A021

GENERAL INFORMATION

DI ENG SM - 2004.4

Y220_0A022

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 34

DI0A-30

HOW TO USE AND MAINTAIN WORKSHOP MANUAL

CONSISTS OF WORKSHOP

MANUAL

1. Group: The manual is divided in large group like

engine, transmission, axle and others and this group

is also divided in small group by vehicle state.

2. Small group: Each small group consists of general,

vehicle service, unit repair and special tool usage.

MANUAL DESCRIPTION

• The contents of the manual consist of operational

principle of system, specifications, diagnosis, removal/

installation on vehicle, inspections, disassembly/

assembly of removed assembly, special tool usage.

Not providing simple removal/installation information

but focused on to describe much more functions, roles

and principles of system.

• Every automotive term like part name on the manual

is the same in parts catalog, technical bulletin and

drawings to avoid confusion among them.

Abbreviation of small

group and page

Consists of Small Group

1. Contents: In small group, included subjects and

detailed subjects are described in.

2. General: In the general, summary of the small group

(assembly), function and operational principle,

specifications, structure and components, diagnosis

and circuit diagram are described in.

3. Vehicle service: Service works on the vehicle like

replacement of parts and inspection repairs are

described in the order of repair works with actual

photos and illustrations. Also cautions in service

works, references and inspection methods after

completion of service are described in.

4. Disassembly and assembly of unit assembly:

Detailed service works like disassembly, inspection,

adjustment and assembly on removed component

(assembly) are described in with systematic contents

and photo illustration.

Vehicle model

Describes information on the manual

like modification, application date,

applicable V.I.N

Bolded: Notice, Installation Notice,

Note

Describes small group name, model

and publication date

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 35

GUIDELINES FOR SERVICE WORK SAFETY

DI0A-31

General

To maintain and operate the vehicle under optimum state

by performing safe service works, the service works should

be done by following correct methods and procedures.

Accordingly, the purpose of this manual is to prevent differences that can be caused by personal working method,

skill, ways and service procedures and to allow prompt/

correct service works.

Note, Notice

While using this manual, there are a lot of Note or Notice

having below meaning.

Note

Note means detailed description of supplementary

information on work procedure or skill.

Notice

Notice means precautions on tool/device or part

damages or personal injuries that can occur during

service works.

However, above references and cautions cannot be inclusive measures, so should have habits of taking concerns

and cautions based on common senses.

Y220_0A024

Cautions on Inspection/Service

Notice

During service works, be sure to observe below general

items for your safety.

•

For service works, be sure to disconnect battery

negative (-) terminal if not starting and inspection.

•

While inspecting vehicle and replacing various

consumable parts, be sure to take caution not to

damage vehicle and injure people.

•

Engine and transmission may be hot enough to

burn you. So inspect related locations when they

cooled down enough.

•

If engine is running, keep your clothing, tools, hair

and hands away from moving parts.

•

Even when the ignition key is turned off and

positioned to LOCK, electrical fan can be operated

while working on near around electrical fan or

radiator grille if air conditioner or coolant

temperature rises.

•

Every oil can cause skin trouble. Immediately wash

out with soap if contacted.

•

Painted surface of the body can be damaged if

spilled over with oil or anti-freeze.

•

Never go under vehicle if supported only with jack.

•

Never near the battery and fuel related system to

flames that can cause fire like cigarette.

•

Never disconnect or connect battery terminal or other

electrical equipment if ignition key is turned on.

•

While connecting the battery terminals, be cautious

of polarities (+, –) not to be confused.

•

There are high voltage and currency on the battery

and vehicle wires. So there can be fire if shortcircuited.

•

Do not park while running the engine in an

enclosed area like garage. There can be toxication

with CO, so make sufficient ventilation.

•

The electrical fan works electrically. So the fan can

be operated unexpectedly during working causing

injuries if the ignition key is not in LOCK position.

Be sure to check whether ignition key is in LOCK

position before work.

•

Be careful not to touch hot components like

catalytic converter, muffler and exhaust pipe when

the engine is running or just stopped. They may

burn you badly.

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 36

DI0A-32

Guidelines on Engine Service

To prevent personal injuries and vehicle damages that can

be caused by mistakes during engine and unit inspection/

repair and to secure optimum engine performance and

safety after service works, basic cautions and service work

guidelines that can be easily forgotten during engine service works are described in.

Cautions before service works

• Before work on engine and each electrical equipment,

be sure to disconnect battery negative (-) terminal.

• Before service works, be sure to prepare the works by

cleaning and aligning work areas.

• Always position the ignition switch to OFF if not

required. If not, there can be electrical equipment

damages or personal injuries due to short-circuit or

ground by mistake.

• There should be no leak from fuel injection system

(HP pump, fuel hose, high pressure pipe) of the D27DT

engine. So they should be protected from foreign

materials.

• While removing the engine, do not position the jack

and others under the oil pan or engine. To secure the

safety, use only safety hook on the engine.

Engine and accessories

Engine has a lot of precise portions so tightening torque

should be correct during disassembly/assembly and removal/installation and service work should be done in clean

ways during disassembly/assembly.

Maintaining working area clean and cautious service administration is essential element of service works while

working on the engine and each section of the vehicle. So

the mechanics should well aware of it.

• While removing the engine, related parts (bolts,

gaskets, etc.) should be aligned as a group.

• While disassembling/assembling internal components

of the engine, well aware of disassembly/assembly

section in this manual and clean each component with

engine oil and then coat with oil before installation.

• While removing engine, drain engine oil, coolant and

fuel in fuel system to prevent leakage.

• During service work of removal/installation, be sure to

check each connected portions to engine not to make

interference.

Fuel and lubrication system

Painted surface of the body can be damaged or rubber

products (hoes) can be corroded if engine oil and fuel are

spilled over. If spilled over engine, foreign materials in air

can be accumulated on the engine damaging fuel system.

• If work on the fluid system such as fuel and oil, working

area should be well ventilated and mechanic should

not smoke.

• Gasket or seal on the fuel/lubrication system should

be replaced with new and bolts and nuts should be

tightened as specified.

• After removal/installation works, be sure to check

whether there is leak on the connecting section.

If fine dust or foreign material enters into DI engine’s

fuel system, there can be serious damages between

HP pump and injectors. So, be sure to cover removed

fuel system components with cap and protect removed

parts not to be contaminated with dirt. (Refer to cleanness in this manual while working on DI engine fuel

system)

Electrical equipment

Electrical equipment should be handled more carefully.

Currently, the engine is equipped with a lot of electrical

equipments so there can be engine performance drops,

incomplete combustion and other abnormals due to short

and poor contact. Mechanics should well aware of vehicle’s

electrical equipment.

• If have to work on the electrical equipment, be sure to

disconnect battery negative (-) terminal and position

the ignition switch to off if not required.

• When replacing electrical equipment, use the same

genuine part and be sure to check whether ground or

connecting portions are correctly connected during

installation. If ground or connecting portion is loosened,

there can be vehicle fire or personal injury.

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 37

During Service Work - Inspection

1. Before lifting up the vehicle with lift, correctly support the

lifting points and lift up.

2. When using a jack, park the vehicle on the level ground

and block front and rear wheels. Position the jack under

the frame and lift up the vehicle and then support with

chassis stand before service work.

3. Before service work, be sure to disconnect battery

negative (-) terminal to prevent damages by bad wire and

short.

DI0A-33

Y220_0A025

4. If service from interior of the vehicle, use protection cover

to prevent damage and contamination of seat and floor.

5. Brake fluid and anti-freeze can damage painted surface

of body. So carefully handle them during service work.

6. Use recommended and specified tools to increase

efficiency of service work.

7. Use only genuine spare parts.

Y220_0A026

Y220_0A027

GENERAL INFORMATION

DI ENG SM - 2004.4

Y220_0A028

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 38

DI0A-34

Y220_0A029

Y220_0A030

8. Never reuse cotter pin, gasket, O-ring, oil seal, lock

washer and self-locking nut. Replace them with new.

If reused, normal functions cannot be maintained.

9. Align the disassembled parts in clean according to

disassembling order and group for easy assembling.

10. According to installing positions, the bolts and nuts have

different hardness and design. So be careful not to mix

removed bolts and nuts each other and align them

according installing positions.

11. To inspect and assemble, clean the parts.

12. Securely clean the parts that related with oil not to be

affected by viscosity of oil.

13. Coat oil or grease on the driving and sliding surfaces

before installing parts.

14. Use sealer or gasket to prevent leakage if necessary.

15. Damaged or not, never reuse removed gasket. Replace

with new and cautious on installing directions.

16. Tighten every bolt and nut with specified torque.

17. When service work is completed, check finally whether

the work is performed properly or the problem is solved.

18. If work on the fuel line between priming pump and injector

(including return line), be sure to cover the removed parts

with cap and be careful not to expose the connecting

passage and removed parts to external foreign materials

or dust. (Refer to cleanness.)

19. If remove high pressure fuel supply pipe between HP pump

and fuel rail and high pressure fuel pipe between fuel rail

and each injector, be sure to replace them with new.

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 39

During Service Work for Electric

Devices

Notice

Be careful not to modify or alter electrical system and

electrical device. Or there can be vehicle fire or serious

damage.

1. Be sure to disconnect battery negative (-) terminal during

every service work. Before disconnecting battery negative

(-) terminal, turn off ignition key.

2. Replace with specified capacity of fuse if there is bad,

blown or short circuited fuse. If use electrical wire or steel

wire other than fuse, there can be damages on the various

electrical systems. If replaced with over-capacity fuse,

there can be damages on the related electrical device

and fire.

3. Every wire on the vehicle should be fastened securely

not to be loosened with fixing clip.

4. If wires go through edges, protect them with tape or other

materials not to be damaged.

DI0A-35

Y220_0A031

5. Carefully install the wires not to be damaged during

installation/removal of parts due to interference.

6. Be careful not to throw or drop each sensor or relay.

7. Securely connect each connector until hear a “click”

sound.

Y220_0A032

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 40

DI0A-36

LIFTING POINTS

Lifting Positions

1. 4-post lift

As illustrated, position the vehicle on the 4-post lift securely and block the front and rear of each tire not to move during

working.

Notice

During lifting, be sure to check whether vehicle is empty.

•

Board-on lift connection device installed in front of vehicle should be positioned in front of sill locating

under the front door.

•

Install lift connecting device on the edge of front and rear of board-on lift.

Warning

•

Be sure to use attachment during lifting to prevent the lift from contacting with body floor.

•

While lifting the vehicle, widen the lift floor as far as possible to stabilize between vehicle front and rear. When

fixing the lift floor, be careful not to contact with brake tube and fuel lines.

2. Safety jack and safety stand

If lift up the vehicle with safety jack and stand, should be more

careful during works.

Warning

•

Never be under the vehicle if supported with only jack.

If have to be under the vehicle, be sure to use safety

block.

•

Use wheel block in front and rear of every wheel.

Y220_0A033

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

GENERAL INFORMATION

DI ENG SM - 2004.4

Page 41

TIGHTENING TORQUE OF STANDARD BOLTS

Tightening Torque By Bolt Specification

DI0A-37

Bolt

Diameter

M3

M4

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

Pitch

0.5

0.7

0.8

1.0

1.25

1.25

1.5

1.25

1.75

1.5

1.5

1.5

1.5

1.5

1.5

Tightening Torque (kg.cm)

Standard Tightening Torque

4T

5

12

24

41

88

190

190

350

330

550

830

1,200

1,700

2,300

2,900

7T

9

20

40

68

160

330

310

580

550

910

1,100

2,000

2,800

3,800

4,900

9T

13

30

57

99

230

470

450

840

790

1,300

2,000

2,900

4,000

5,400

7,000

Max. Allowable Tightening Torque

4T

7

16

32

55

130

260

250

460

440

730

1,100

1,600

2,200

3,000

3,900

7T

12

27

53

91

210

430

420

770

730

1,200

1,900

2,700

3,700

5,000

6,500

9T

17

40

77

130

310

620

600

1,100

1,000

1,900

2,700

3,800

5,300

7,200

9,400

2.0

1. Metric bolt strength is embossed on the head of each

bolt. The strength of bolt can be classified as 4T, 7T,

8.8T, 10.9T, 11T and 12.9T in general.

2. Observe standard tightening torque during bolt

tightening works and can adjust torque to be proper

within 15 % if necessary. Try not to over max.

allowable tightening torque if not required to do so.

2,800

4,700

6,800

3,800

6,300

9,100

Y220_0A034

3. Determine extra proper tightening torque if tightens

with washer or packing.

4. If tightens bolts on the below materials, be sure to

determine the proper torque.

• Aluminum alloy: Tighten to 80 % of above torque

table.

• Plastics: Tighten to 20 % of above torque table.

GENERAL INFORMATION

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 42

MEMO

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................................................................................................................................................................

Page 43

SECTION DI01

ENGINE ASSEMBLY

Page 44

00SECTION DI01

ENGINE ASSEMBLY

DI01-1

Table of Contents

STRUCTURE AND FUNCTION DESCRIPTIONS ........ DI01-3

D27DT engine ........................................................ DI01-3

Engine performance curve ..................................... DI01-8

General diagnosis................................................. DI01-10

DIAGNOSTIC INFORMATION AND PROCEDURE .. DI01-15

Oil leak diagnosis.................................................. DI01-15

Compression pressure test .................................. DI01-16

Cylinder pressure leakage test ............................ DI01-18

Tightening torque.................................................. DI01-19

REMOVAL AND INSTALLATION .............................. DI01-22

Engine mounting ................................................... DI01-22

DISASSEMBLY AND REASSEMBLY........................ DI01-32

Components and special tools ............................. DI01-32

ENGINE ASSEMBLY

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 45

Page 46

DI01-3

STRUCTURE AND FUNCTION DESCRIPTIONS

D27DT ENGINE

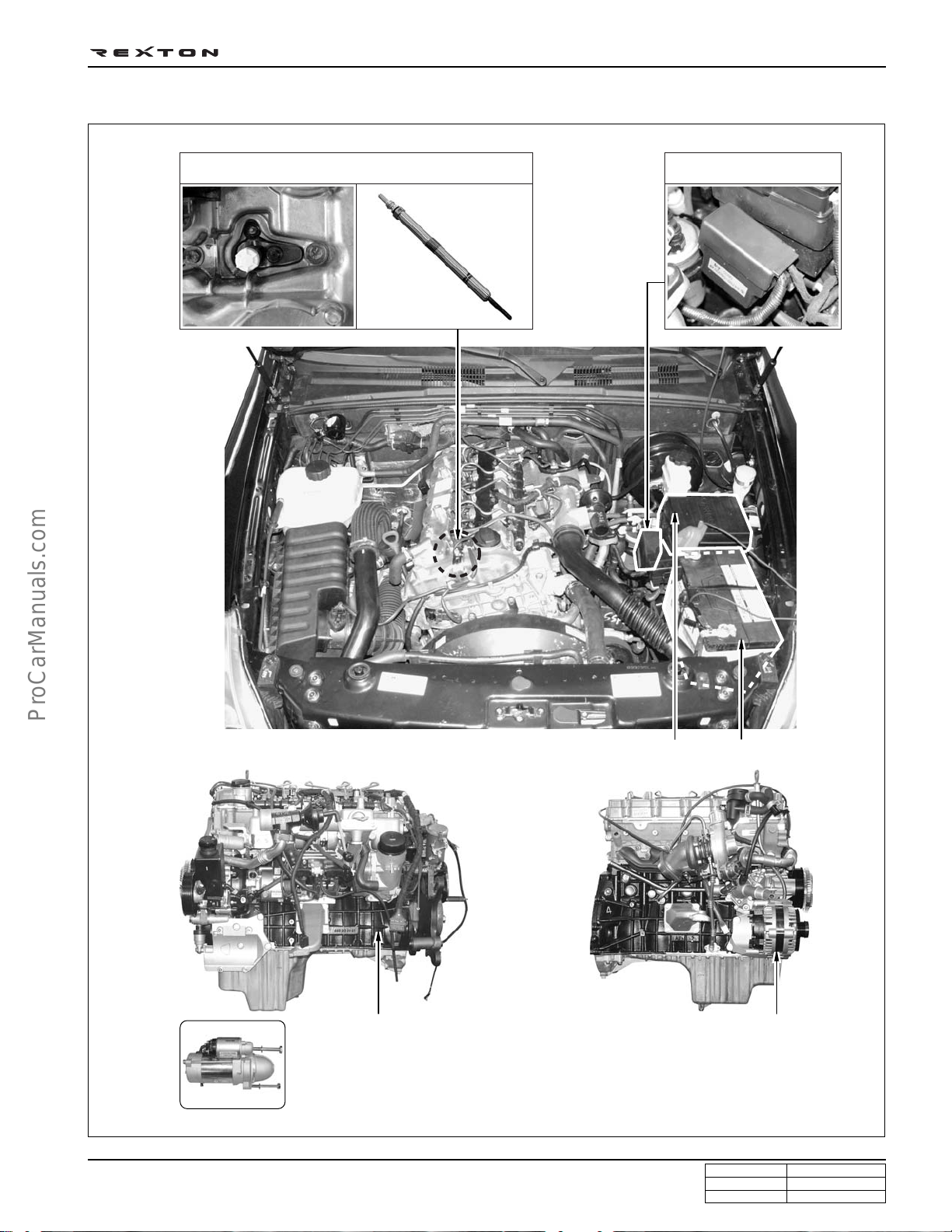

Major Components in Engine and Engine Compartment

The advanced electronically controlled D27DT engine that has high pressure fuel system has been introduced to this

vehicle. It satisfies the strict emission regulation and provides improved output and maximum torque.

1. Coolant reservoir

2. FFH device

3. Brake fluid reservoir

4. Washer fluid reservoir

5. Common rail

6. Fuse box

7. Battery

8. Fuel filter

9. Power steering pump

10. Priming pump

Y220_01001

11. EGR valve

12. Air cleaner assembly

13. Turbo charger

14. Oil dipstick

ENGINE ASSEMBLY

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 47

DI01-4

Engine Structure

Front View

Rear View

1. TVD (Torsional Vibration Damper)

2. Air conditioner compressor

3. Power steering pump pulley

4. Idle pulley

5. Coolant pump pulley

6. Alternator

7. Viscos fan clutch

8. Auto tensioner pulley

9. Auto tensioner

10. Poly-grooved belt

11. Cam position sensor

12. Drive plate (MT: DMF)

Y220_01002

13. Oil filter

14. Vacuum pump

15. Crank position sensor

16. EGR valve

17. Power steering pump

18. EGR to center pipe

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE ASSEMBLY

DI ENG SM - 2004.4

Page 48

Top View

DI01-5

19. Cylinder head cover

20. Intake manifold

21. Water outlet port

22. Common rail

23. Fuel pressure sensor

24. Fuel pipe

25. Injector

26. Fuel return line

27. Oil filler cap

28. Glow plug

Y220_01003

29. Booster pressure sensor

30. PCV valve and oil separator

31. Oil dipstick

32. EGR-LH pipe

ENGINE ASSEMBLY

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 49

DI01-6

Left Side View

Right Side View

33. Cylinder head

34. Cylinder block

35. Oil pan

36. Drain plug

37. Turbo charger

38. EGR-RH pipe

39. PCV valve and oil separator

40. Oil dipstick

41. High pressure pump

Y220_01004

42. Turbo charger booster vacuum

modulator

43. EGR valve vacuum modulator

44. EGR valve

45. Exhaust manifold

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE ASSEMBLY

DI ENG SM - 2004.4

Page 50

Specifications

DI01-7

Description Specification

Engine

Cylinder

Displacement (cc)

Compression ratio

Maximum output (ps/rpm)

Maximum torque (kg.m/rpm)

Idle speed

Valve

Camshaft

Fuel system

Type/Number of cylinders

Inner diameter (mm)

Stroke (mm)

For Manual Transmission

For Automatic Transmission

Intake

Opens (BTDC)

Closes (ABDC)

Exhaust

Opens (BBDC)

Closes (ATDC)

Type

Fuel type

Fuel pump type

Fuel supply pressure

D27DT/5-cylinder

86.2

92.4

2696

18:1

170/4,000

34.7/1,800

750 ± 50 rpm

750 ± 50 rpm

16°

33°

46°

21°

DOHC

Low sulfur diesel

Vane pump in HP pump

HP pump inlet port: max. 400 mbar

HP pump outlet port (with IMV fully open):

over 1,050 bar

Lubrication system

Cooling system

Water separation in fuel filter

Fuel tank capacity (

)

Oil specification

Lubrication type

Oil filter type

Oil capacity (

)

Cooling type

Cooling fan operation type

Thermostat: Fully

Open: 100°C)

Opening

temperature (°C)

Type

Coolant capacity (

)

at every 10,000 km

80

SAE 10W40, 5W40

(MB Sheet 229.1, 229.3 approved oil)

Forced delivery

Full flow, filter element type

6.8 ~ 8.3

Water cooling type

Belt operated typr

85

WAX pellet type

11.5

ENGINE ASSEMBLY

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 51

DI01-8

ENGINE PERFORMANCE CURVE

Output and Torque

Output [PS]

Torque [Nm]

Speed [rpm]

Y220_00025

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE ASSEMBLY

DI ENG SM - 2004.4

Page 52

Oil Temperature/Pressure and Boost Pressure

DI01-9

Boost pressure [bar] Oil pressure [bar]

Oil temperature [C]

Speed [rpm]

Y220_00026

ENGINE ASSEMBLY

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 53

DI01-10

GENERAL DIAGNOSIS

Condition

Hard Starting

(With normal

cranking)

Malfunction of

Ignition System

Malfunction of

Fuel System

Decline of

Compression

Pressure

Others

Probable Cause

Faulty fuse.

•

Faulty spark plug.

•

Electric leakage at the high

•

tension cable.

Poor connection of the high

•

tension cable or lead wires.

Improper ignition timing.

•

Faulty ignition coil.

•

Lock of fuel in the fuel tank.

•

Dirty or clogged fuel filter.

•

Clogged fuel pipe.

•

Malfunction of the fuel pump.

•

Malfunction of the fuel injector.

•

The foreign material in the fuel

•

tank.

Poor tightening spark plug.

•

Cracked cylinder head gasket.

•

Inadequate the valve clearance.

•

Leakage of the valve clearance.

•

Interference of the valve stem.

•

Low elasticity or damage of the

•

valve spring.

Abnormal interference of pistons

•

and cylinders.

Excessive wear of pistons,

•

rings, or cylinders.

Broken timing belt.

•

Loosening, damage or leakage

•

of the vacuum hose.

Leakage of intake system.

•

Correction

• Replace the fuse.

• Clean, adjust the plug gap or

replace.

Replace the cable.

•

Replace the cable or wires.

•

Adjust the ignition timing.

•

Replace the ignition coil.

•

Feed the fuel.

•

Replace the filter.

•

Clean the fuel pipe.

•

Replace the fuel pump.

•

Replace the injector.

•

Clean the fuel tank.

•

Tighten to the specified torque.

•

Compression

Replace the gasket.

•

Adjust the clearance.

•

Repair the valve.

•

Replace the valve or the valve

•

guide.

Replace the valve spring.

•

Replace the piston ring.

•

Replace the ring or the piston

•

and boring or replace the

cylinder.

Replace the belt.

•

Connect the hose correctly or

•

replace it.

Replace intake system.

•

Lack of Engine

Power

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Decline of

Compression

Pressure

Malfunction of

Ignition System

Refer to above in this page.

•

Improper ignition timing.

•

Faulty spark plug.

•

Electric leakage or poor

•

connection of the high tension

cable.

Refer to above in this page.

•

Adjust the ignition timing.

•

Adjust or replace the spark plug.

•

Connect the cable correctly or

•

replace it.

ENGINE ASSEMBLY

DI ENG SM - 2004.4

Page 54

GENERAL DIAGNOSIS (Cont’d)

DI01-11

Condition

Lack of Engine

Power

Rough Engine

Idling

Malfunction of

Fuel System

Others

Decline of

Compression

Pressure

Malfunction of

Fuel System

Malfunction of

Ignition System

Probable Cause

Clogged fuel pipe.

•

Clogged or contaminated fuel

•

filter.

Clogged exhaust system.

•

Clogged or contaminated air

•

cleaner element.

Leak of the intake manifold

•

gasket.

Dragging brakes.

•

Refer to “Compression Pressure

•

Test”.

Clogged fuel pipe.

•

Clogged or contaminated fuel

•

filter.

Malfunction of the fuel pressure

•

regulator.

Malfunction of the spark plug.

•

Electric leakage or poor connec-

•

tion of the high tension cable.

Correction

Clean the pipe.

•

Replace the filter.

•

Check and repair the system.

•

Clean or replace the air cleaner

•

element.

Replace the gasket.

•

Repair or replace the brakes.

•

Refer to “Compression Pressure

•

Test”.

Clean the pipe.

•

Replace the filter.

•

Replace the regulator.

•

Adjust or replace the spark plug.

•

Connect the cable correctly or

•

replace it.

Others

Engine Hesitate

(Upon pressing

accelerating

pedal, the

engine makes

delayed response This

situation is

remarkable

when cruising or

starting.)

Decline of

Compression

Pressure

Malfunction of

Ignition System

Others

Poor ignition timing.

•

Malfunction of the ignition coil.

•

Clogged or contaminated air

•

cleaner element.

Leak of the intake manifold

•

gasket.

Poor connection or damage or

•

leakage of the vacuum hose.

Refer to “Compression Pressure

•

Test”.

Poor ignition timing.

•

Poor spark plug or Poor adjust-

•

ment of the plug gap.

Electric leakage or poor connec-

•

tion of the high tension cable.

Malfunction of the air cleaner

•

system.

Leak of the intake manifold

•

gasket.

Adjust the ignition timing.

•

Replace the ignition coil.

•

Clean or replace the air cleaner

•

element.

Replace the gasket.

•

Connect the hose correctly or

•

replace it.

Refer to “Compression Pressure

•

Test”.

Adjust the ignition timing.

•

Replace the plug or adjust the

•

gap.

Connect the cable correctly or

•

replace it.

Clean or replace the air cleaner

•

system.

Replace the gasket.

•

ENGINE ASSEMBLY

DI ENG SM - 2004.4

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

Page 55

DI01-12

GENERAL DIAGNOSIS (Cont’d)

Condition

Engine Surging

(Engine power

makes

fluctuation in a

fixed speed and

speed changes

without

operating the

accelerating

pedal.)

Excessive

Detonation

(According to

the opening

range of Malfunction of

metallic is

made with

abnormal

explosion )

Overheat

Decline of

Compression

Pressure

Malfunction of

Fuel System

Malfunction of

Ignition System

Others

Overtheated

Engine

Malfunction of

Fuel System

Malfunction of

Ignition System

Others

Malfunction of

Cooling System

Malfunction of

Lubrication

System

Other

Probable Cause

Refer to “Compression Pressure

•

Test”.

Clogged fuel pipe.

•

Clogged or contaminated fuel

•

filter.

Malfunction of the fuel pressure

•

regulator.

Malfunction of the spark plug.

•

Electric leakage or poor

•

connection of the high tension

cable.

Poor ignition timing.

•

Leak of the intake manifold

•

gasket.

Leakage of the vacuum hose.

•

Refer to “Overheat” in this page.

•

Abnormal spark plug.

•

Poor ignition timing.

•

Electric leakage or poor

•

connection of the high tension

cable.

Clogged or contaminated fuel

•

filter and fuel pipe.

Leak of the intake manifold

•

gasket.

Excessive carbon deposit due to

•

abnormal combustion.

Lack of coolant.

•

Malfunction of the thermostat.

•

Malfunction of the cooling fan.

•

Poor water pump performance.

•

Clogged or leaky radiator.

•

Poor engine oil.

•

Blocking oil filter or strainer.

•

Lack of engine oil.

•

Poor oil pump performance.

•

Leakage of oil

•

Damaged cylinder head gasket.

•

Correction

Refer to “Compression Pressure

•

Test”.

Clean the pipe.

•

Replace the filter.

•

Replace the fuel pressure

•

regulator.

Adjust or replace the spark plug.

•

Connect the cable correctly or

•

replace it.

Adjust the ignition timing.

•

Clean or replace the gasket.

•

Connect the hose correctly or

•

replace it.

Refer to “Overheat” in this page.

•

Replace the spark plug.

•

Adjust the ignition timing

•

Connect the cable correctly or

•

replace it.

Clean or replace the fuel filter

•

and the fuel pipe.

Replace the gasket.

•

Remove the carbon.

•

Refill coolant.

•

Replace the thermostat.

•

Check or replace the cooling

•

fan.

Replace the pump.

•

Clean, repair or replace the

•

radiator.

Replace engine oil with the

•

specified one.

Clean or repair the oil filter or the

•

strainer.

Refill oil.

•

Replace or repair the pump.

•

Repair.

•

Replace the gasket.

•

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

ENGINE ASSEMBLY

DI ENG SM - 2004.4

Page 56

GENERAL DIAGNOSIS (Cont’d)

DI01-13

Condition

Poor Fuel

Consumption

Excessive

Consumption of

Engine Oil

Decline of

Compression

Pressure

Malfunction of

Fuel System

Malfunction of

Ignition System

Malfunction of

Cooling System

Others

Leakage of

Engine Oil

Oil Mixing in

Combustion

Chamber

Low Oil

Pressure

Malfunction of

Lubrication

System

Probable Cause

Refer to “Compression Pressure