Page 1

SECTION 1B3

OM600 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

Specifications. . . . . . . . . . . . . . . . . . . . . . . 1B3-2

Fastener Tightening Specifications. . . . . . . . 1B3-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B3-4

Special Tools Table. . . . . . . . . . . . . . . . . . . . 1B3-4

Maintenance and Repair . . . . . . . . . . . . . 1B3-12

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1B3-12

Engine Assembly . . . . . . . . . . . . . . . . . . . . 1B3-12

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-21

Tensioning Device. . . . . . . . . . . . . . . . . . . . 1B3-23

Poly V-Belt Alignment & Inspection. . . . . . . 1B3-26

Prechamber . . . . . . . . . . . . . . . . . . . . . . . . 1B3-29

Milling of Prechamber Sealing Surface . . . . 1B3-32

TDC (TDC Sensor Bracket) Setting . . . . . . 1B3-35

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B3-37

Timing Case Cover . . . . . . . . . . . . . . . . . . . 1B3-63

Crankshaft End Cover . . . . . . . . . . . . . . . . 1B3-71

Vibration Damper and Hub . . . . . . . . . . . . . 1B3-74

Crankshaft Front Radial Seal . . . . . . . . . . . 1B3-80

Crankshaft Ball Bearing . . . . . . . . . . . . . . . 1B3-82

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-83

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-93

Machining of Flywheel . . . . . . . . . . . . . . . . 1B3-97

Flywheel Ring Gear . . . . . . . . . . . . . . . . . . 1B3-98

Hydraulic Valve Clearance Compensation

Element Check . . . . . . . . . . . . . . . . . . . . 1B3-101

Valve Tappets . . . . . . . . . . . . . . . . . . . . . . 1B3-103

Valve Spring Check . . . . . . . . . . . . . . . . . 1B3-105

Valve Springs (Cylinder Head Removed) . 1B3-106

Valve Springs (Cylinder Head Installed) . . 1B3-109

Valve Stem Seals . . . . . . . . . . . . . . . . . . . 1B3-112

Check and Replacement of

Valve Guides . . . . . . . . . . . . . . . . . . . . . 1B3-116

Valve Seat Rings . . . . . . . . . . . . . . . . . . . 1B3-122

Check and Machining of Valves . . . . . . . . 1B3-127

Machining of Valve Seat . . . . . . . . . . . . . . 1B3-132

Camshaft Timing Test . . . . . . . . . . . . . . . . 1B3-137

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-139

Chain Tensioner . . . . . . . . . . . . . . . . . . . . 1B3-145

Timing Chain. . . . . . . . . . . . . . . . . . . . . . . 1B3-147

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . 1B3-151

Cylinder Head Guide Rail . . . . . . . . . . . . . 1B3-152

Timing Case Cover Guide Rail . . . . . . . . . 1B3-156

Crankshaft Sprocket . . . . . . . . . . . . . . . . . 1B3-158

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-163

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-169

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-171

Oil Spray Nozzle . . . . . . . . . . . . . . . . . . . . 1B3-174

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-175

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B3-177

Cylinder Head Pressure Leakage Test . . . 1B3-177

Facing Cylinder Head Mating Surface. . . . 1B3-178

Replacement of Crankcase Core Plug . . . 1B3-180

Facing Crankcase Contacting Surface . . . 1B3-182

Oil Gallery Steel Ball . . . . . . . . . . . . . . . . . 1B3-183

Cylinder Bore Measurement . . . . . . . . . . . 1B3-187

Page 2

1B3-2 OM600 ENGINE MECHANICAL

SPECIFICA TIONS

F ASTENER TIGHTENING SPECIFICATIONS

Engine Assembly

Application

Skid Plate Bolt

Drain Plug Bolt

Coolong Fan Shroud Bolt

Control Linkage Nut

Clutch Linkage Cylinder Nut

Exhaust Manifold Bolt

Propeller Shaft Bolt & Nut (Axle)

Propeller Shaft Bolt & Nut (T/C)

Engine Mounting Nut

Crankshaft Assembly

Application

Cooling Fan Belt Pulley Bolt

Socket Bolt

Tighten The Bolt

End Cover Bolt

Crankshaft Bearing Cap Bolt

Ball Bearing

Camshaft Sprocket Bolt

Oil Pump Sprocket Bolt

••

N

•m

••

28 - 47

30

3 - 7

8 - 18

20 - 34

30

70 - 80

81 - 84

50 - 75

••

N

•m

••

10

23

200 / 90°

10

55 / 90°

45 / 90°

25 / 90°

25

Piston

Application

Connecting Rod Bolt

Flywheel

Application

12-Sided Stretch Bolt

Cylinder Head

Application

Prechamber Threaded Ring

Cylinder Head Cover Bolt

Fuel Injsction Pipe Nut

Socket Bolt

Fuel Filter Pipe Bolt

Idle Pulley Bolt

Damper Bolt

••

N

•m

••

35 / 90°

••

N

•m

••

45 / 90°

••

N

•m

••

130

10

18

25

25

23

21

Page 3

Cylinder Head

OM600 ENGINE MECHANICAL 1B3-3

Application

Camshaft Bearing Cap Bolt

Camshaft Sprocket Bolt

Exhaust Pipe Bolt& Nut

Chain Tensioner

Injection Nozzle

Intake Manifold Not

Injection Nozzle Pipe Not

Oil Dipstick Tube Bolt

Screw Plug M18 x 15

Cam Support & Shaft

Application

Stud Bolt

Exhaust Manifold Not

CamShaft Bearing Cap Bolt

12-Sided Bolt (M11)

Timing Cover

Application

Oil Pan Bolt-Socket Bolt

Oil Pan Bolt- M6

Oil Pan Bolt- M23

Belt Pulley Bolt

Guide Pulley Bolt

Guide Pulley Bracket Nut

Chain Tensioner

Tesioning Lever Bolt

••

N

•m

••

25

25 / 90°

25

80

40

25

18

10

50

••

N

•m

••

12

25

25

25 / 90°

••

N

•m

••

10

10

23

32

4

23

80

23

Page 4

1B3-4 OM600 ENGINE MECHANICAL

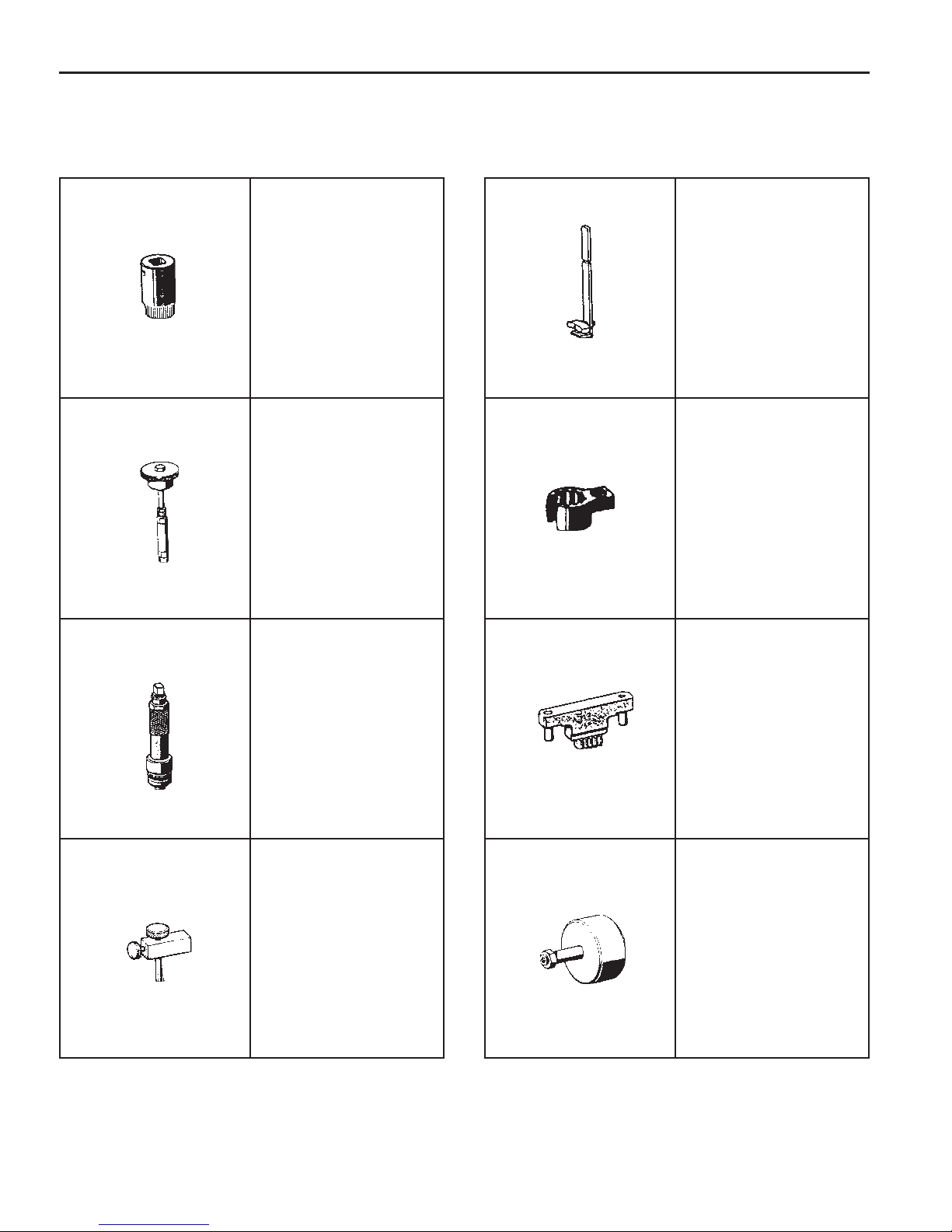

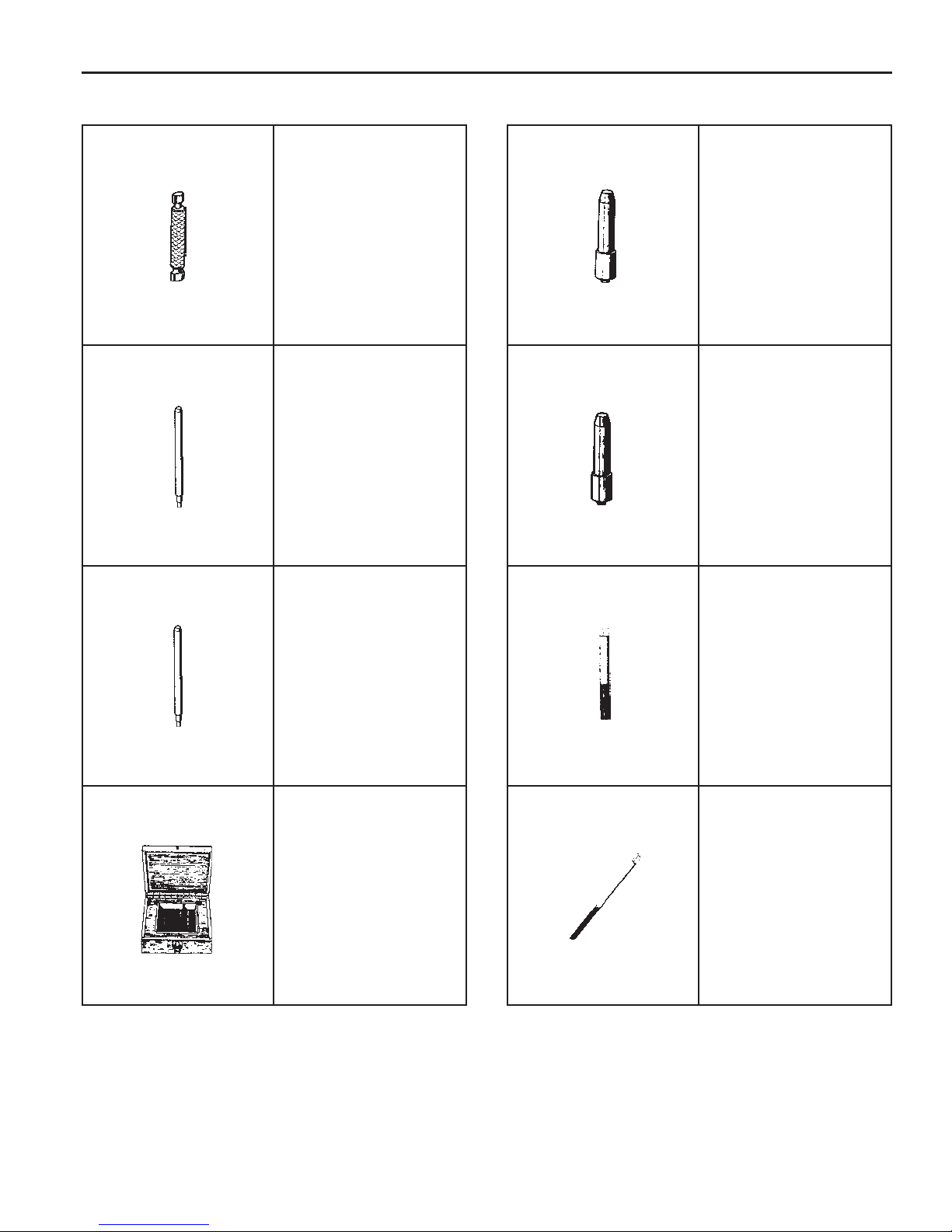

SPECIAL TOOLS

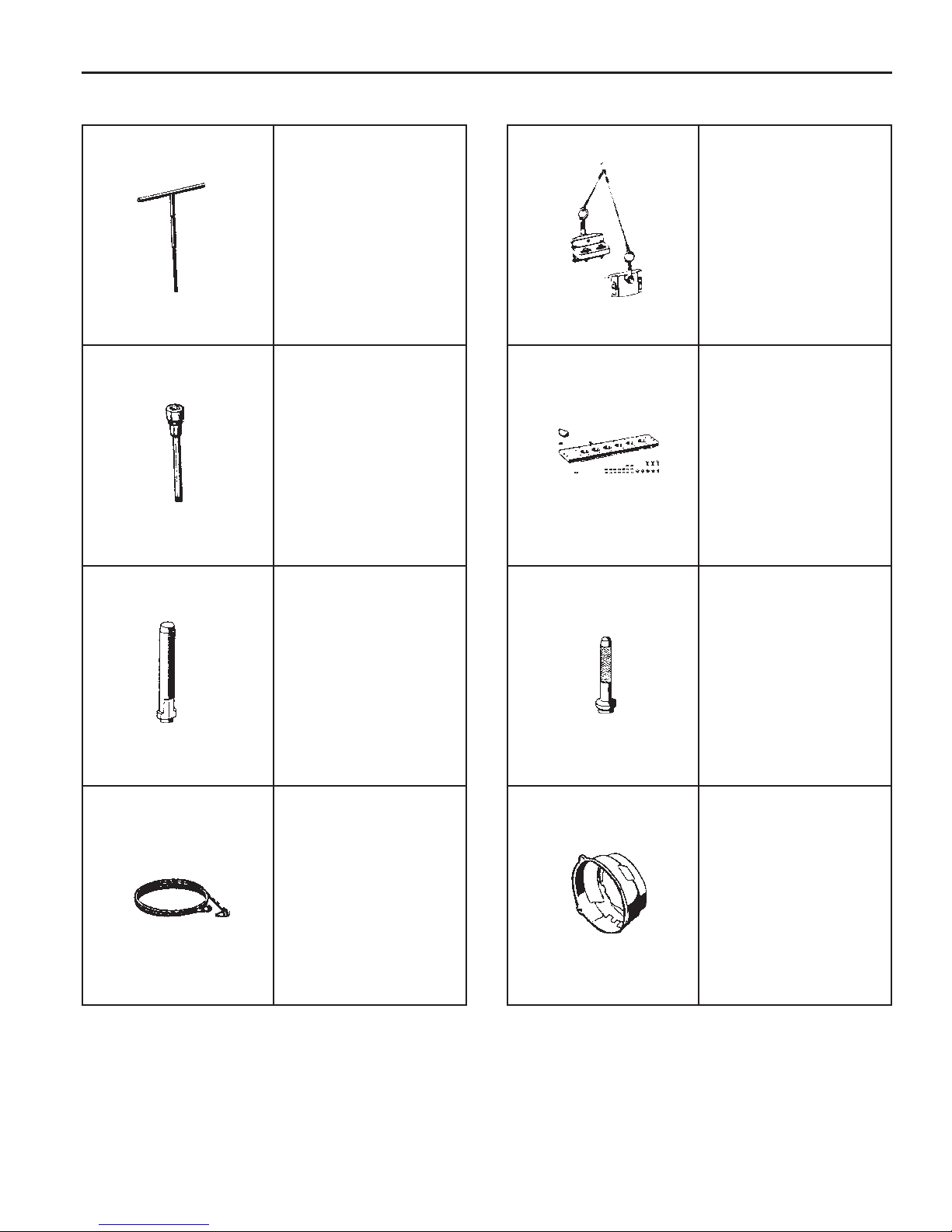

SPECIAL TOOLS TABLE

603 589 00 09 00

Serration Wrench

657 589 03 63 00

Sliding Hammer

601 589 00 66 00

Counter Sink

603 589 00 40 00

Counter Holder

000 589 77 03 00

Box Wrench Insert

602 589 00 40 00

Engine Lock

667 589 00 23 00

Height Gauge

116 589 20 33 00

Sliding Hammer

Page 5

OM600 ENGINE MECHANICAL 1B3-5

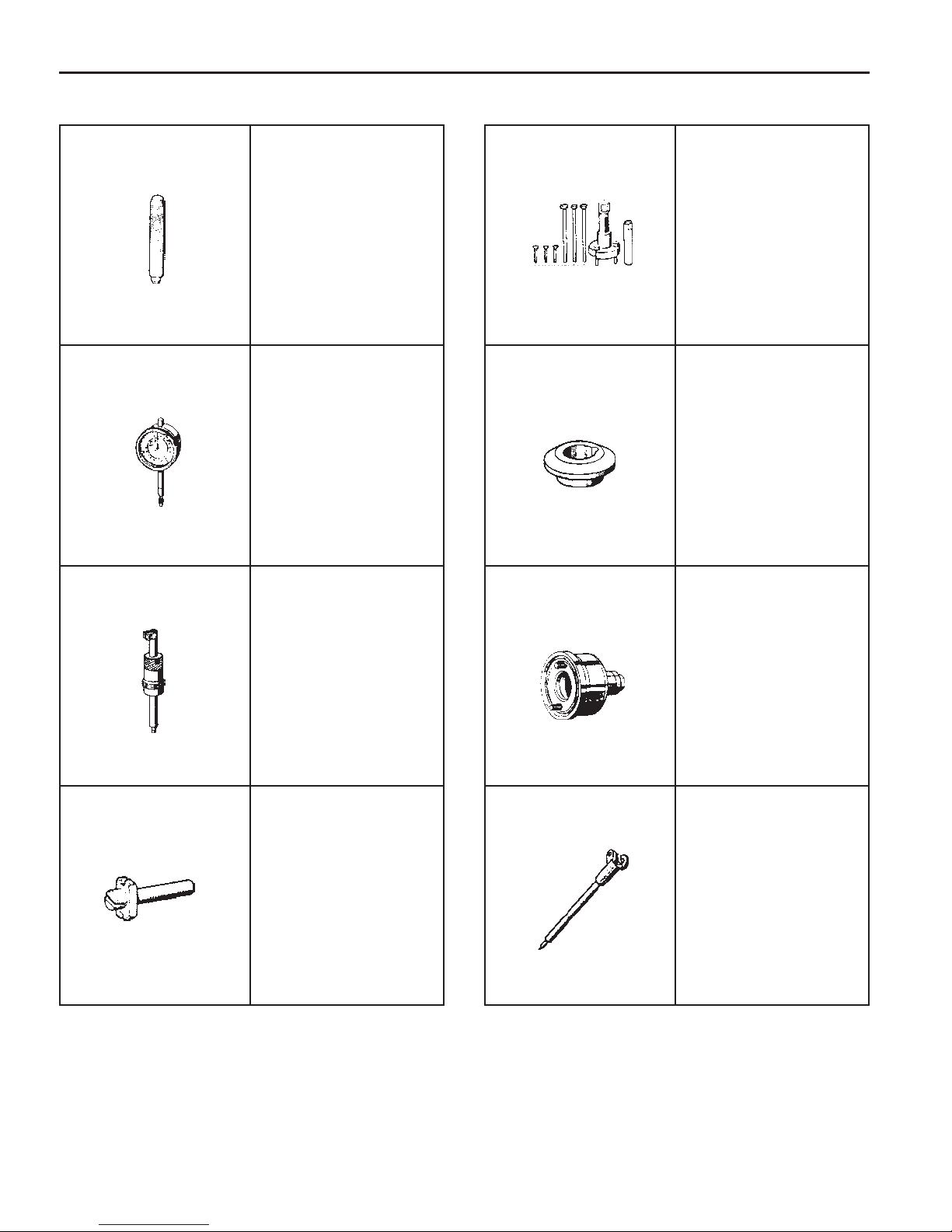

SPECIAL TOOLS TABLE (Cont’ d)

116 589 03 07 00

T Type Socket Wrench

601 589 00 10 00

Cylinder Head Bolt 102

102 589 12 15 00

φφ

φ

φφ

(

17) Drift

1 15 589 34 63 00

601 589 00 25 00

102 589 00 15 00

φφ

φ

φφ

(

34) Drift

617 589 10 21 00

RI Sensor

601 589 05 14 00

Assembly Cage

Page 6

1B3-6 OM600 ENGINE MECHANICAL

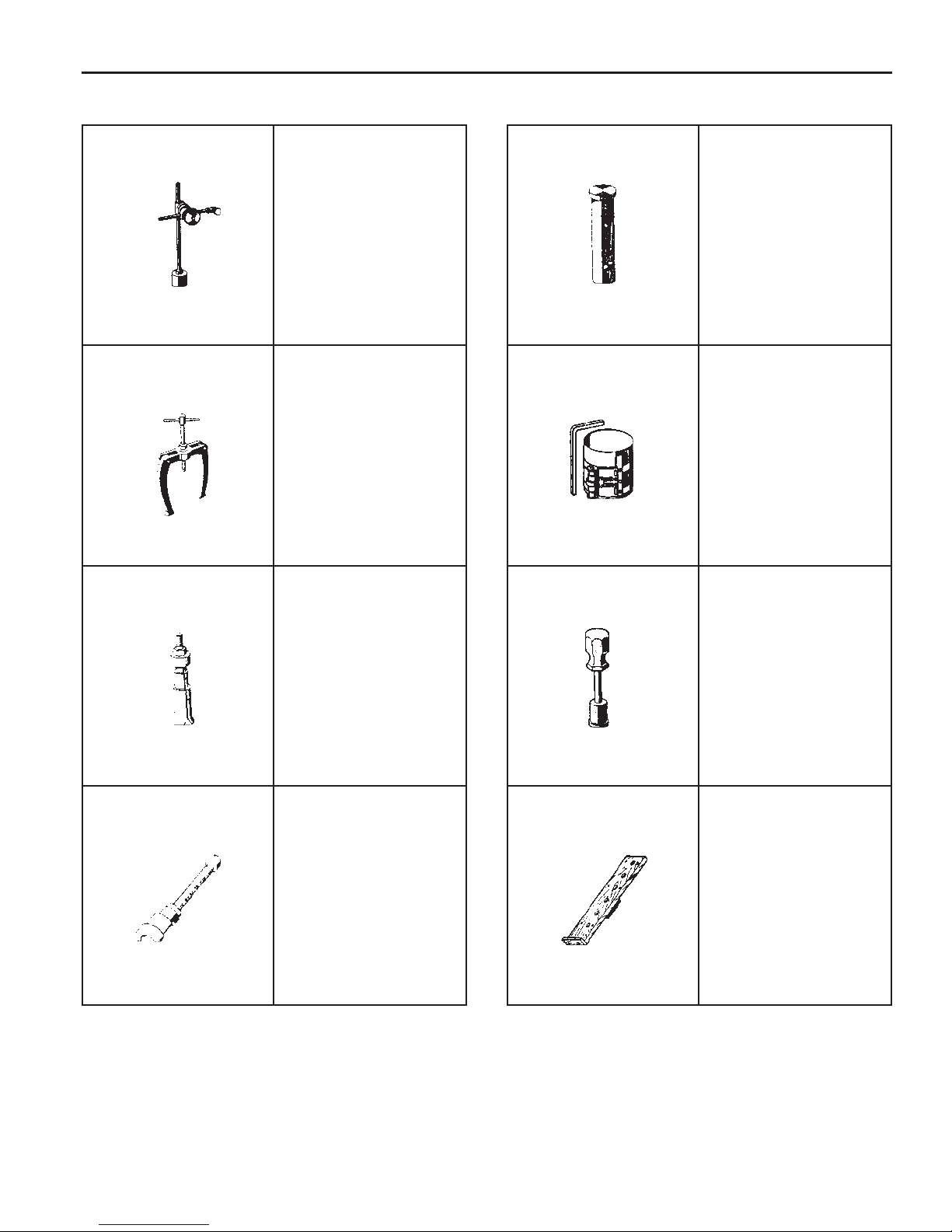

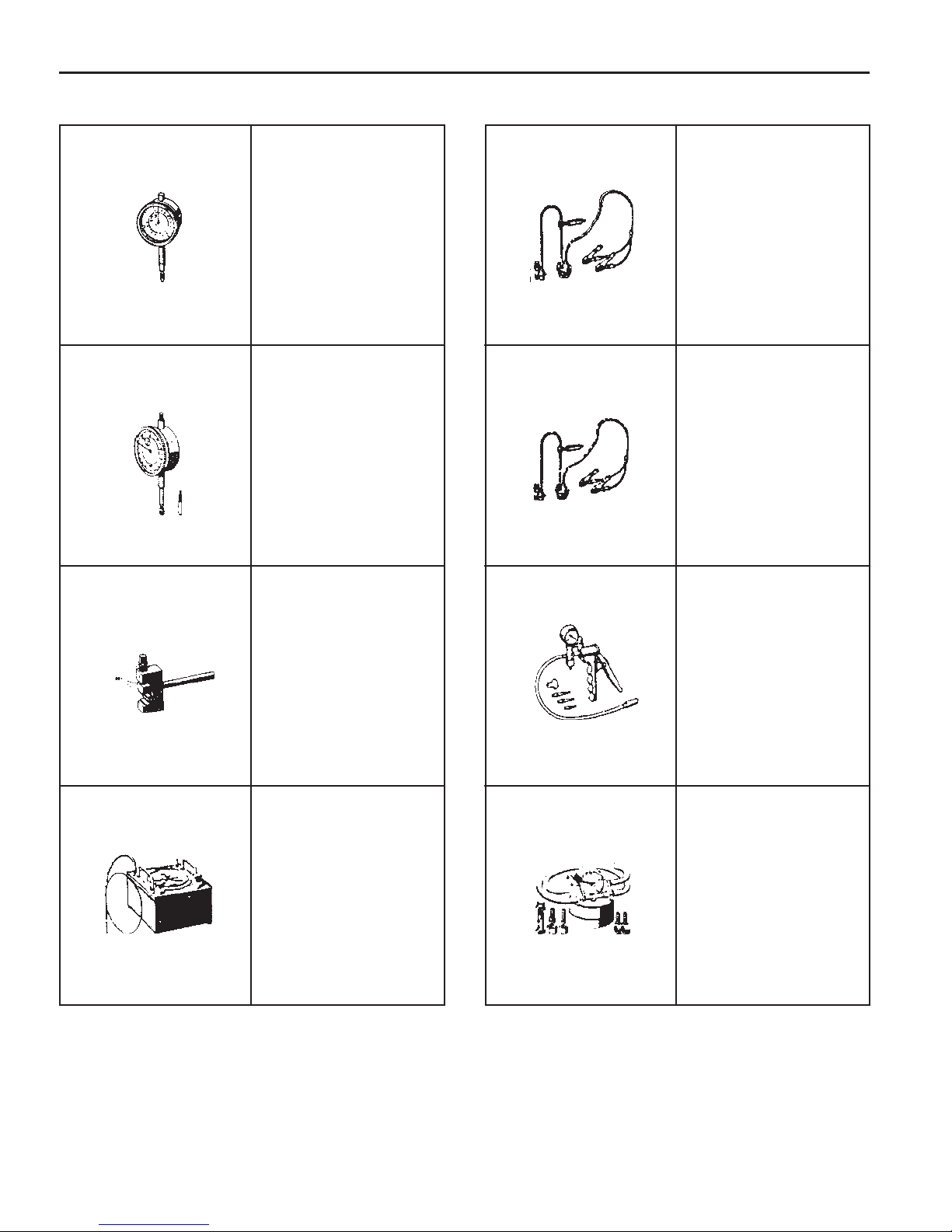

SPECIAL TOOLS TABLE (Cont’d)

601 589 08 15 00

Drift

001 589 53 21 00

Dial Gauge

601 589 07 21 00

Depth Gauge

103 589 00 33 00

Puller

601 589 03 14 00

Sleeve

601 589 03 43 00

Oil Seal Assembler

667 589 01 21 00

Fixing Device

366 589 00 21 05

Extension

Page 7

OM600 ENGINE MECHANICAL 1B3-7

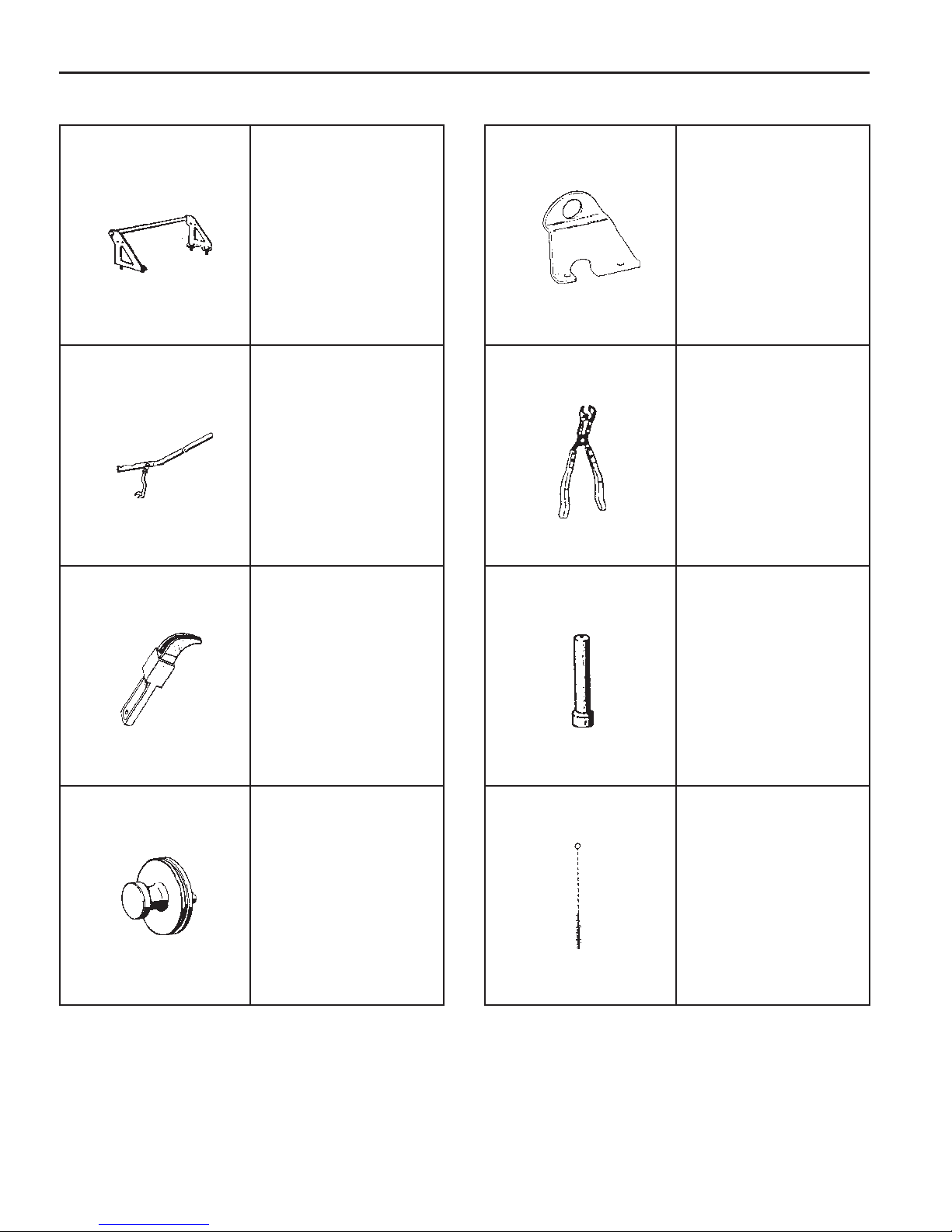

SPECIAL TOOLS TABLE (Cont’ d)

363 589 02 21 00

Dial Gauge Holder

000 589 33 33 00

Counter Support

000 589 25 33 00

Internal Extractor

1 16 589 07 15 00

Drift

000 589 04 14 00

Tensioning Strap

102 589 03 40 00

Magnetic Bar

102 589 05 33 00

Puller

601 589 01 59 00

Assembling Board

Page 8

1B3-8 OM600 ENGINE MECHANICAL

SPECIAL TOOLS TABLE (Cont’d)

601 589 02 59 00

Supporting Bridge

667 589 00 31 00

Press Lever

116 589 06 63 00

Magnetic Finger

667 584 02 63 00

Supporting Bar

104 589 00 37 00

Pliers

601 589 02 43 00

Drift

603 589 01 40 00

Holding Wheel

000 589 10 68 00

Cylinder Brush

Page 9

OM600 ENGINE MECHANICAL 1B3-9

SPECIAL TOOLS TABLE (Cont’ d)

601 589 02 23 00

Go/No Go Gauge

105 589 03 15 00

Drift (for Intake)

103 589 02 15 00

Drift (for Exhaust)

601 589 05 15 00

Drift (for Intake)

601 589 06 15 00

Drift (for Exhaust)

000 589 10 53 00

Reamer (for Exhaust)

346 589 00 63 00

Super Cooling Box

000 589 21 53 00

Reamer (for Intake)

Page 10

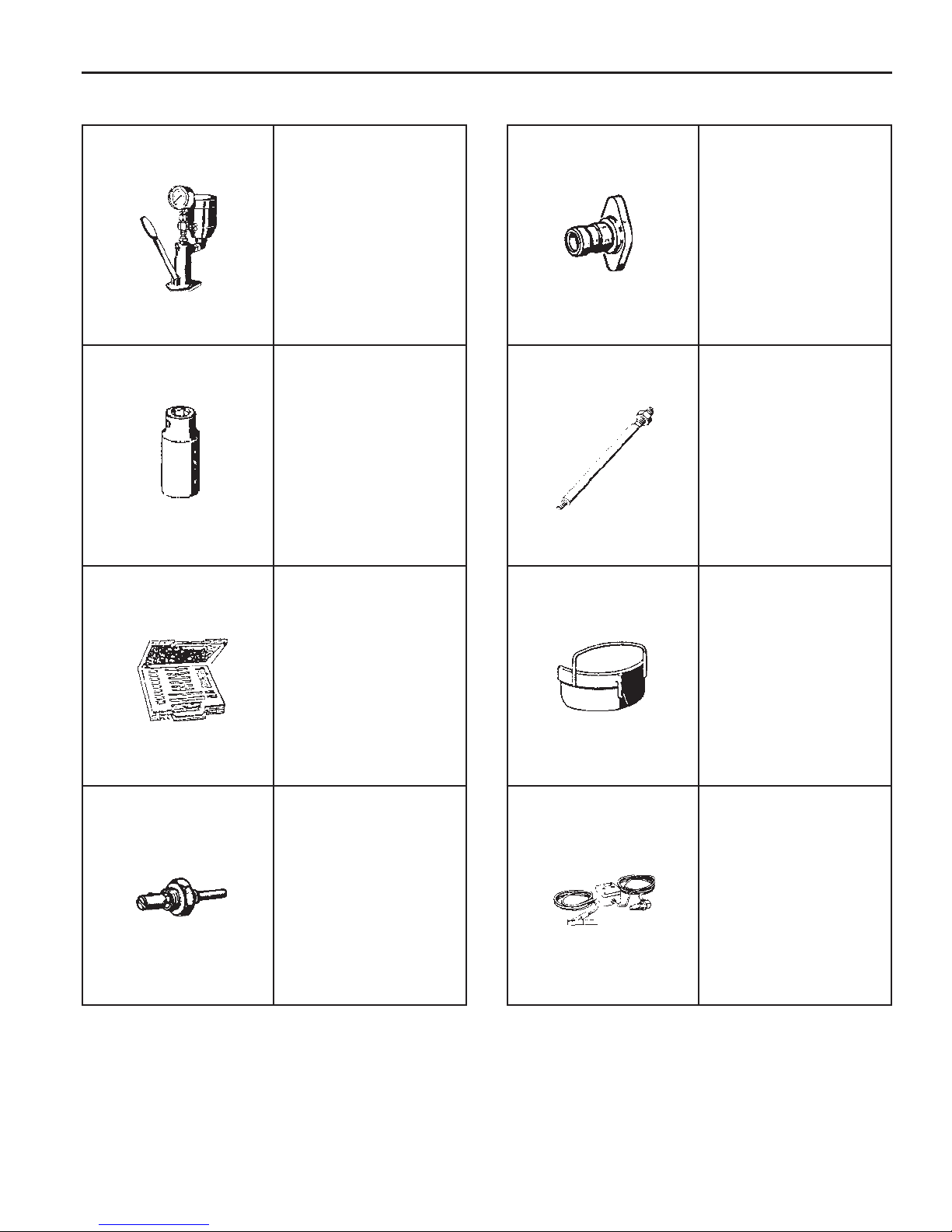

1B3-10 OM600 ENGINE MECHANICAL

SPECIAL TOOLS TABLE (Cont’ d)

001 589 32 21 00

Dial Gauge

001 589 53 21 00

Dial Gauge

000 589 58 43 00

Chain Assembling

Device

124 589 15 21 00

T ester

667 589 02 21 00

TDC Pulse Generator

501 589 73 21 00

Vacuum Pump

201 589 13 21 00

Vacuum Tester

617 589 04 21 00

T ester

Page 11

OM600 ENGINE MECHANICAL 1B3-11

SPECIAL TOOLS TABLE (Cont’ d)

000 589 14 21 00

T ester

001 589 65 09 00

Serration Wrench

000 589 00 68 00

Cleaning Set

601 589 00 08 00

Flange

116 589 02 34 00

Thread Bolt

667 589 04 63 00

Retaining Plate

601 589 05 21 00

Looking Screw

617 589 08 21 00

Position Sensor

Page 12

1B3-12 OM600 ENGINE MECHANICAL

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ENGINE ASSEMBLY

Page 13

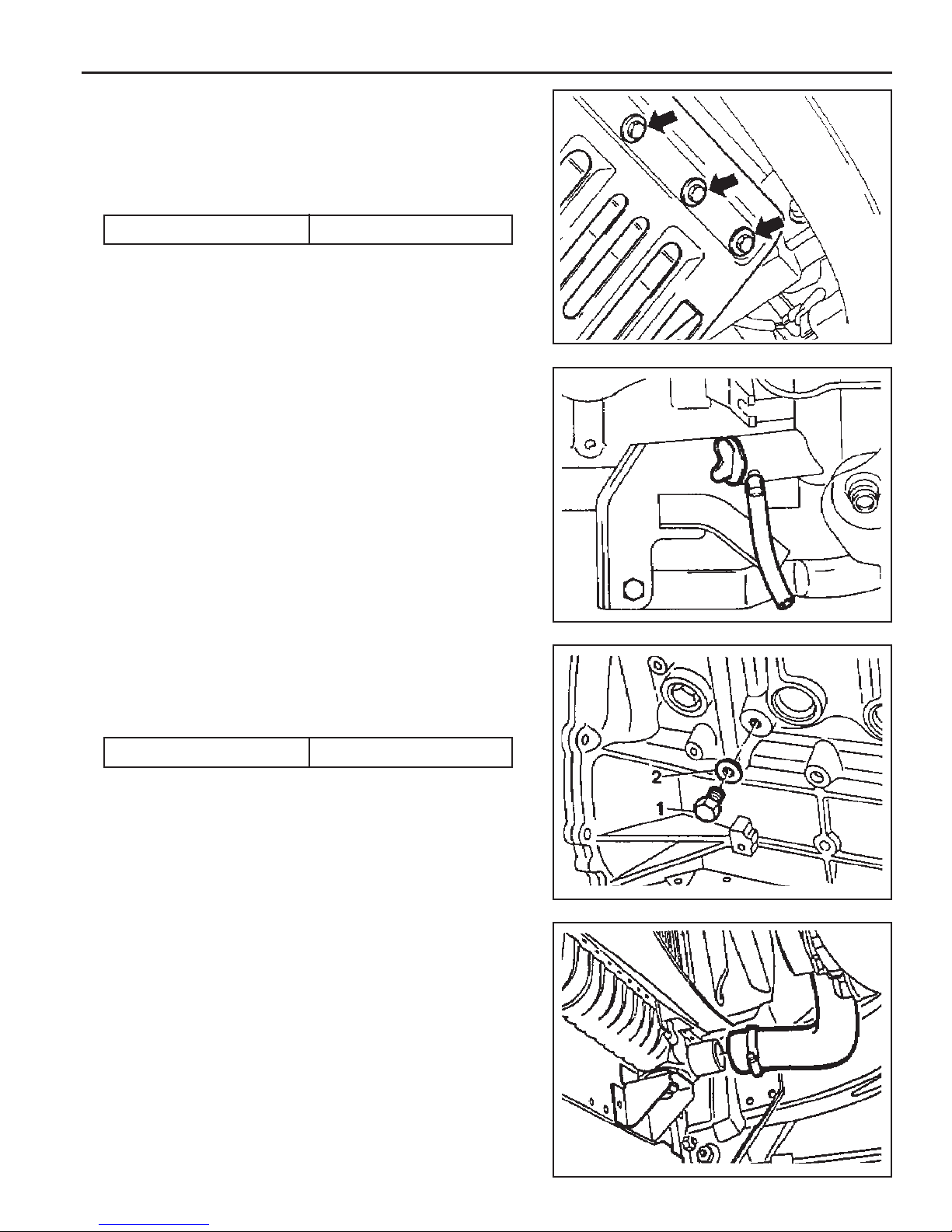

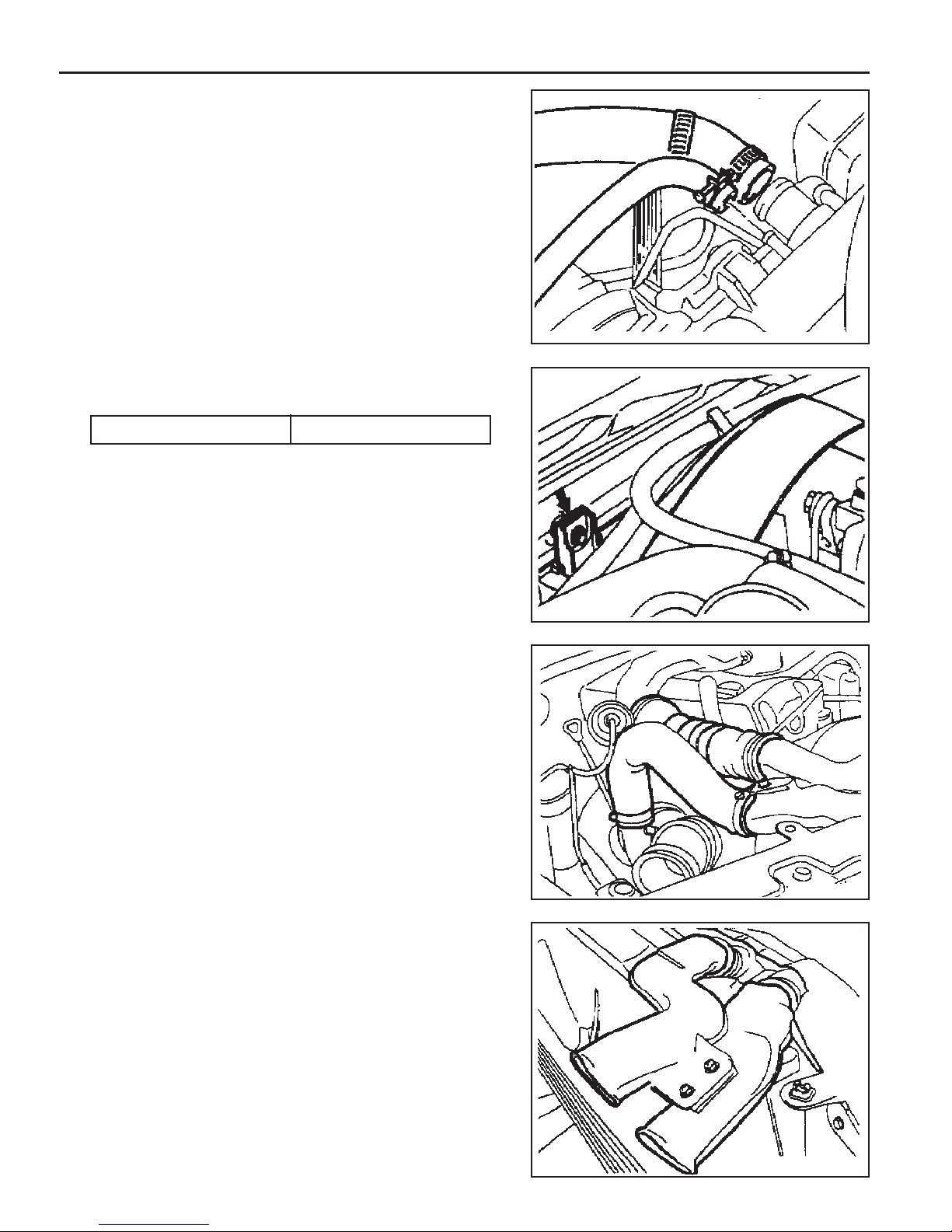

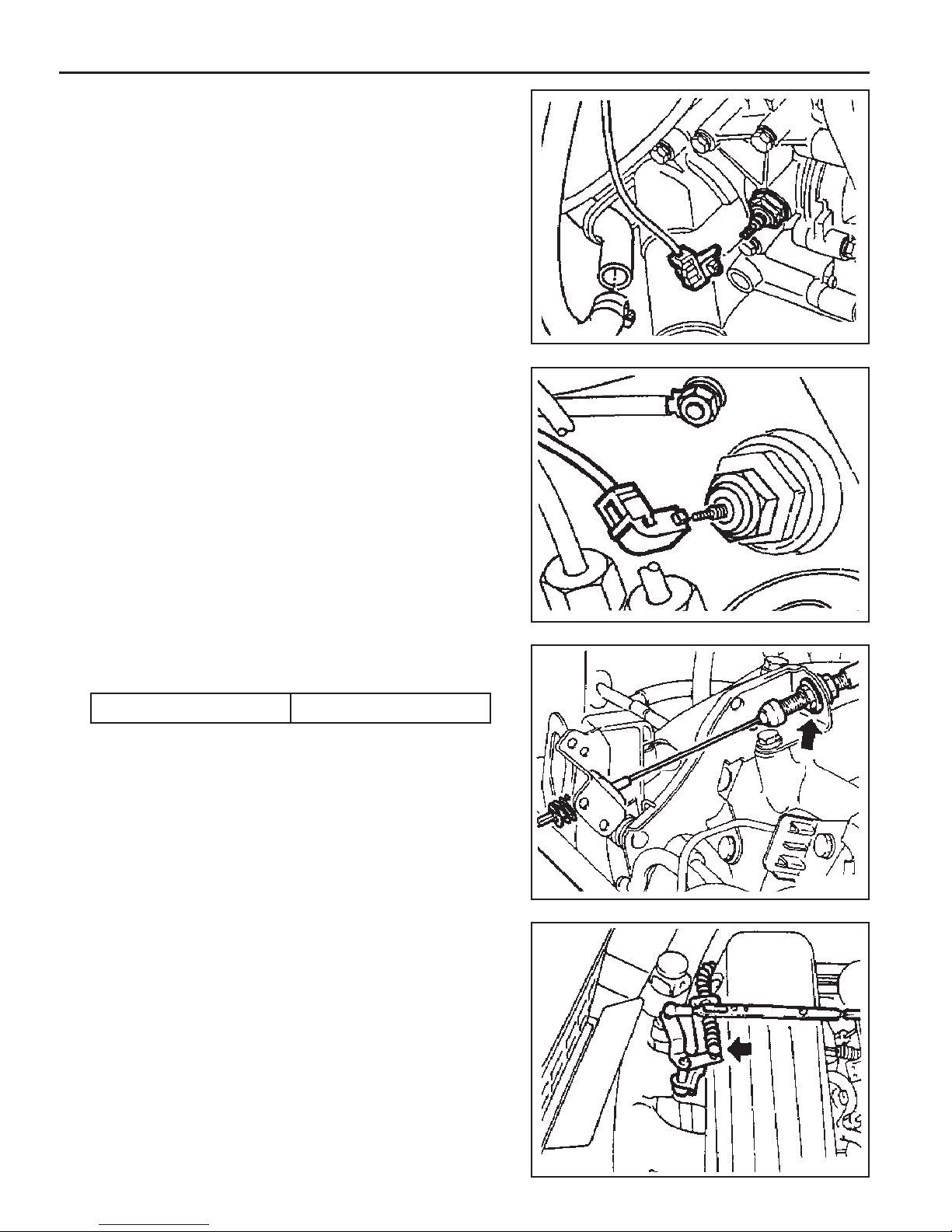

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the skid plate.

Installation Notice

T ightening Torque 28 - 47 Nm

4. Remove the radiator drain cock and drain the coolant.

Notice

Open the coolant reservoir tank cap.

OM600 ENGINE MECHANICAL 1B3-13

5. Remove the drain plug (1) and seal (2) from the cylinder

block and drain the coolant completely.

6. After draining, replace the seal and reinstall the drain plug.

Installation Notice

Tightening Torque 30 Nm

7. Disconnect the lower coolant hose from the radiator.

Page 14

1B3-14 OM600 ENGINE MECHANICAL

8. Disconnect the upper coolant hose from the radiator.

9. Loosen the bolt and remove the coolant pipe and cooling

fan shroud.

Tightening Torque 3 -7 Nm

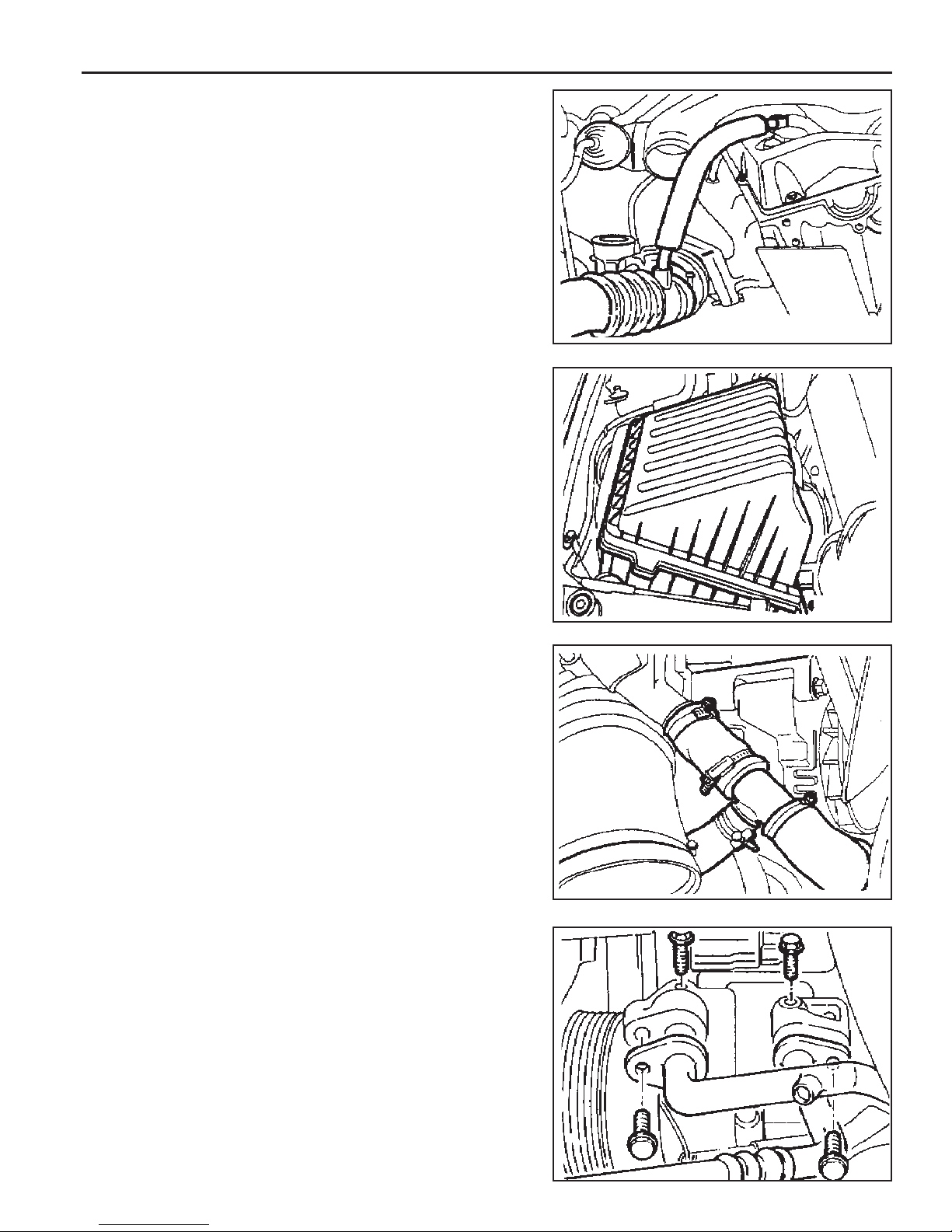

10. Remove the hoses (air intake to intercooler, intercooler to

intake duct).

11. Remove the pipes connected to intercooler.

Page 15

12. Remove the hose(air cleaner to turbocharger) with blow

by hose.

13. Disconnect the air cleaner intake hose and remove the air

cleaner cover and element.

OM600 ENGINE MECHANICAL 1B3-15

14 . Disconnect the coolant hose from the water inlet.

15 . Remove the air-conditioner lines from the compressor.

Notice

Evacuate the refrigerant before removal.

Page 16

1B3-16 OM600 ENGINE MECHANICAL

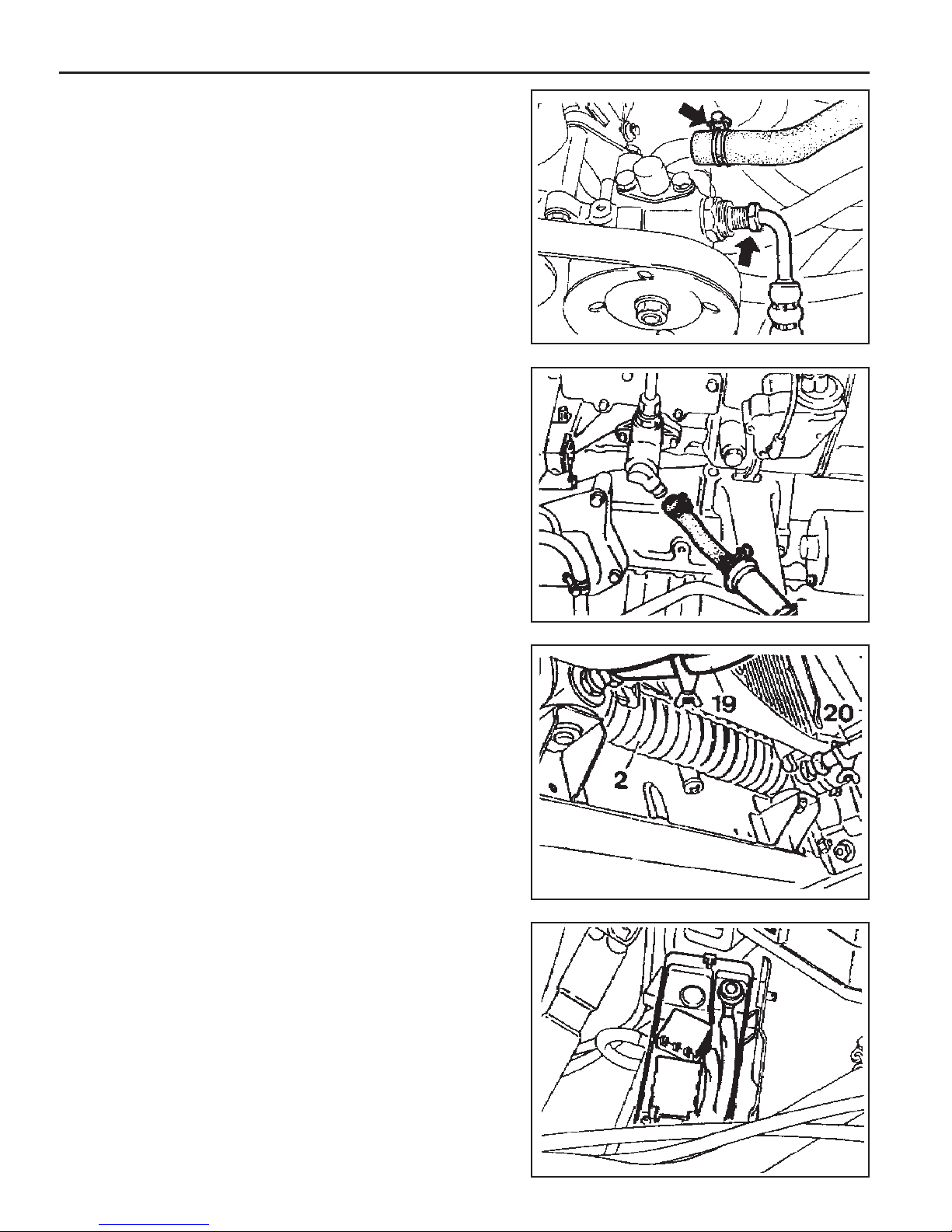

16 . Remove the power steering pump lines.

Notice

Completely drain the fluid.

17 . Disconnect the fuel feed line with prefilter from the feed

pump on injection pump.

18. Vehicle with automatic transmission.

Remove the hydraulic lines (19, 20) from oil cooler (2).

19 . Disconnect the engine harness.

20 . Disconnect the preheating time relay cable.

Page 17

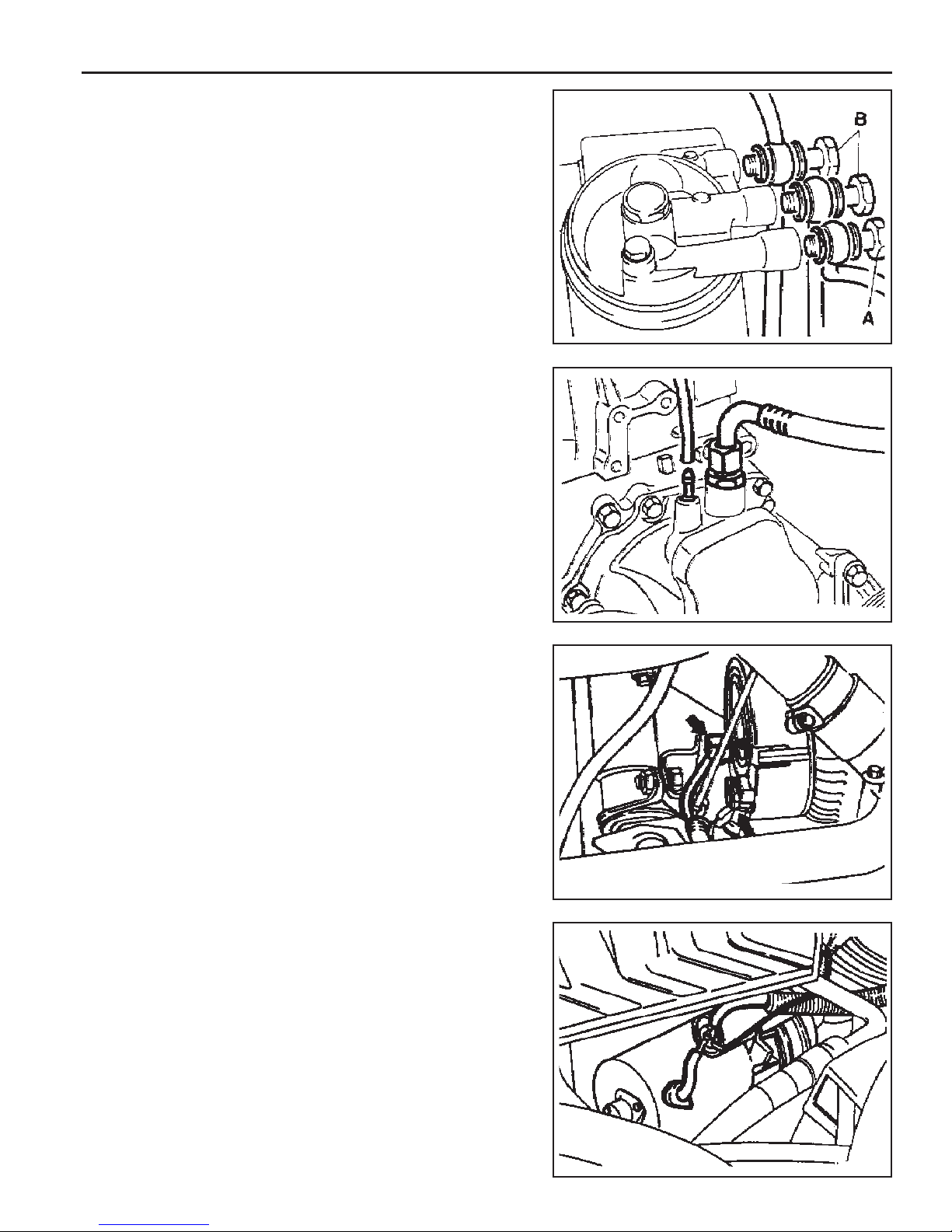

21 . Remove the fuel lines from the fuel filter and cover the

filter with plug.

22 . Disconnect the brake booster hose from vacuum pump.

23. Disconnect the other vacuum lines.

OM600 ENGINE MECHANICAL 1B3-17

24 . Disconnect the ground cable.

25 . Disconnect the alternator wires.

26. Disconnect the starter motor wires and remove the starter

motor.

Page 18

1B3-18 OM600 ENGINE MECHANICAL

27 . Disconnect the preheating time relay sensor plug.

28 . Disconnect the coolant temperature sensor plug.

29. Disconnect the accelerator cable from the control linkage.

Installation Notice

Tightening Torque 8 - 18 Nm

30. Loosen the connection of control pressure cable (an arrow)

used in auto transmission.

Page 19

31 . Separate the exhaust pipe flange from the turbo charger.

Installation Notice

Tightening Torque 30 Nm

32 . Loosen the installing bolt of clutch release cylinder and

remove the clutch release cylinder.

Installation Notice

Tightening Torque 20 - 34 Nm

OM600 ENGINE MECHANICAL 1B3-19

33. Disconnect the exhaust pipe flange from the exhaust

manifold.

Installation Notice

Tightening Torque 30 Nm

34 . Remove the propeller shaft from the transmission.

Installation Notice

Tightening Torque

35 . Remove the shift control cable.

36 . Remove the transmission.

Axle 70 ~ 80 Nm

T/C 81 ~ 89 Nm

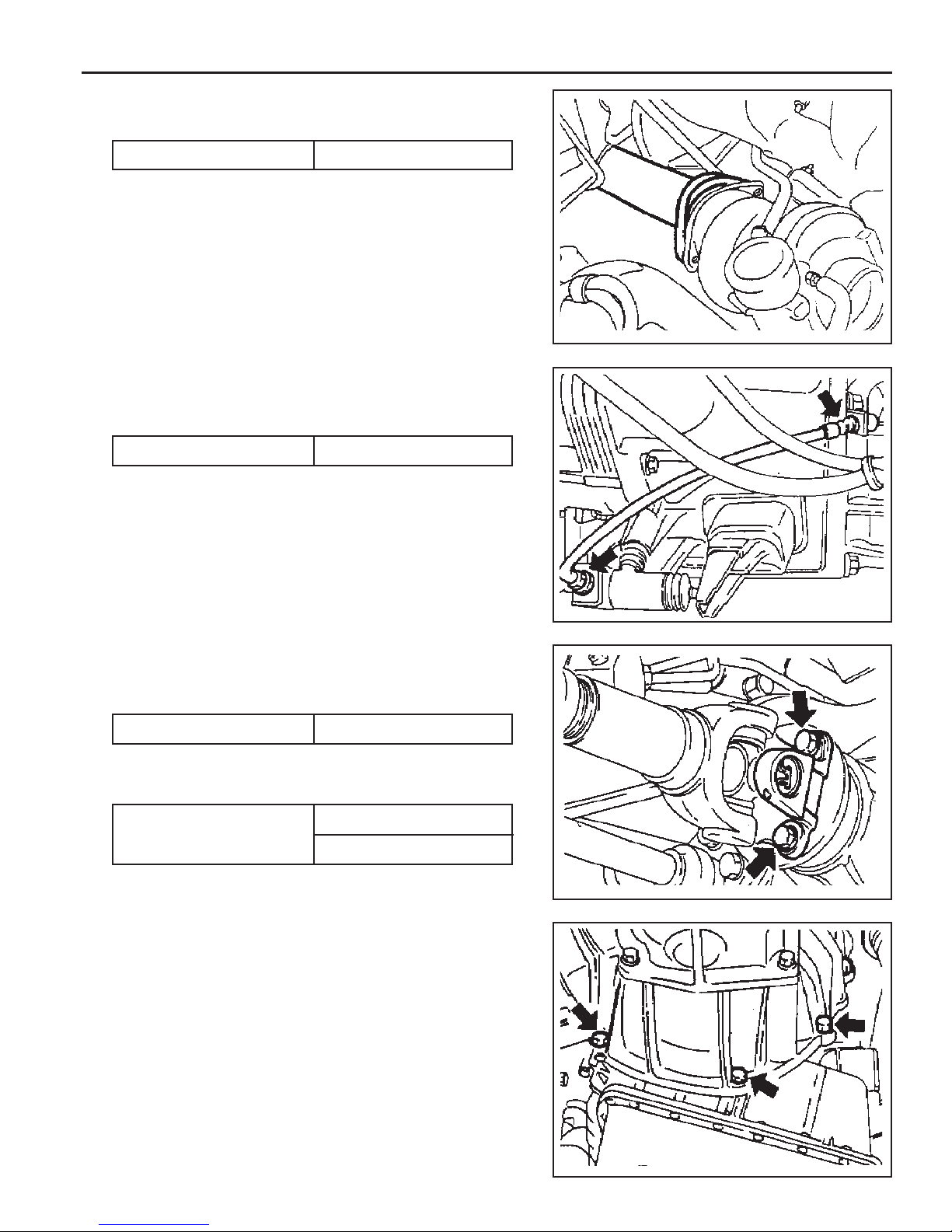

Page 20

1B3-20 OM600 ENGINE MECHANICAL

37 . Loosen the engine mounting bracket nut.

Installation Notice

Tightening Torque 50 - 75 Nm

38. Remove the engine assembly from the vehicle by using a

hoist or crane.

39. Installation should follow the removal procedure in the

reverse order.

Page 21

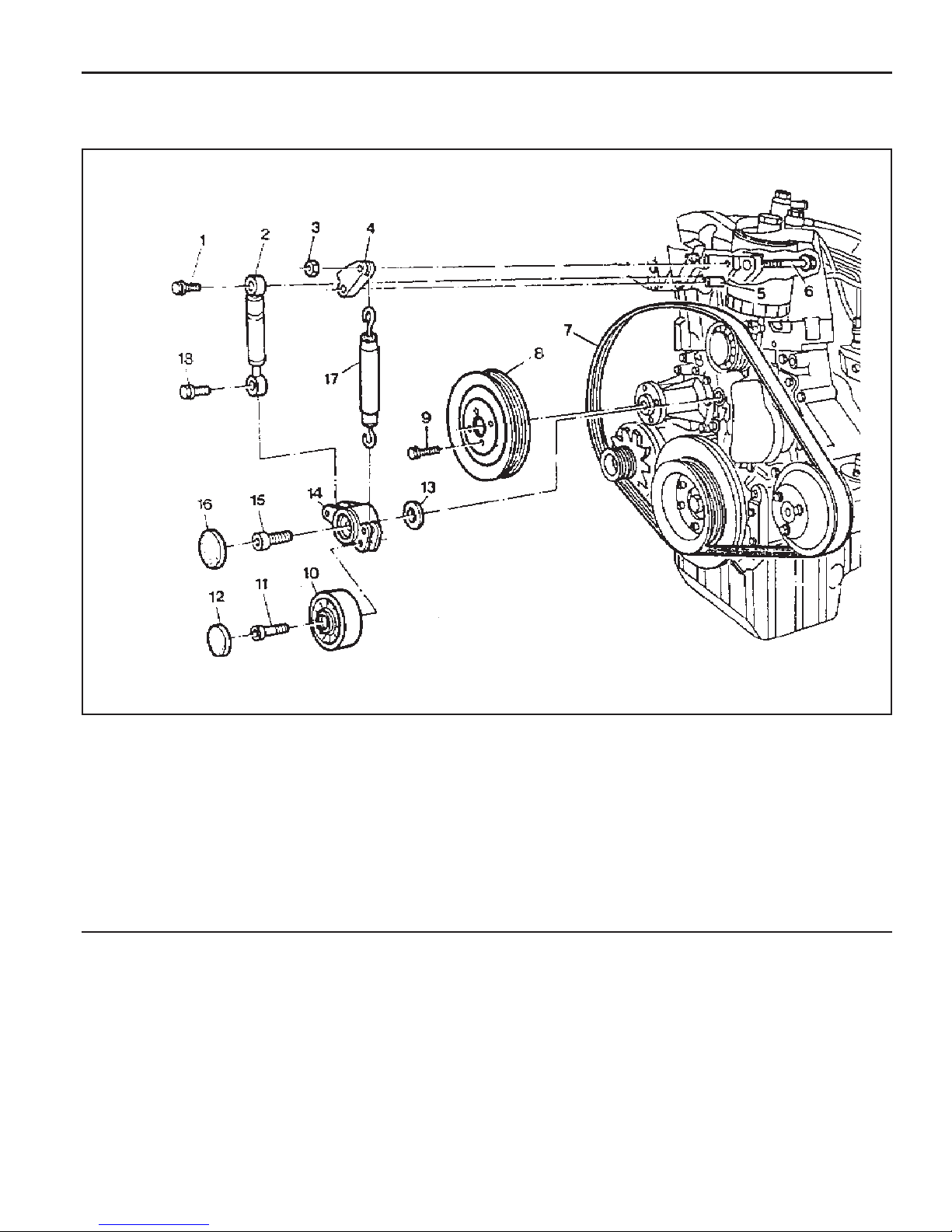

POLY V-BELT

OM600 ENGINE MECHANICAL 1B3-21

1 Nut............................................................. 23Nm

2 Tensioning Lever

3 Bolt

4 Spring

5 Tensioning Lever

6 Poly V-Belt

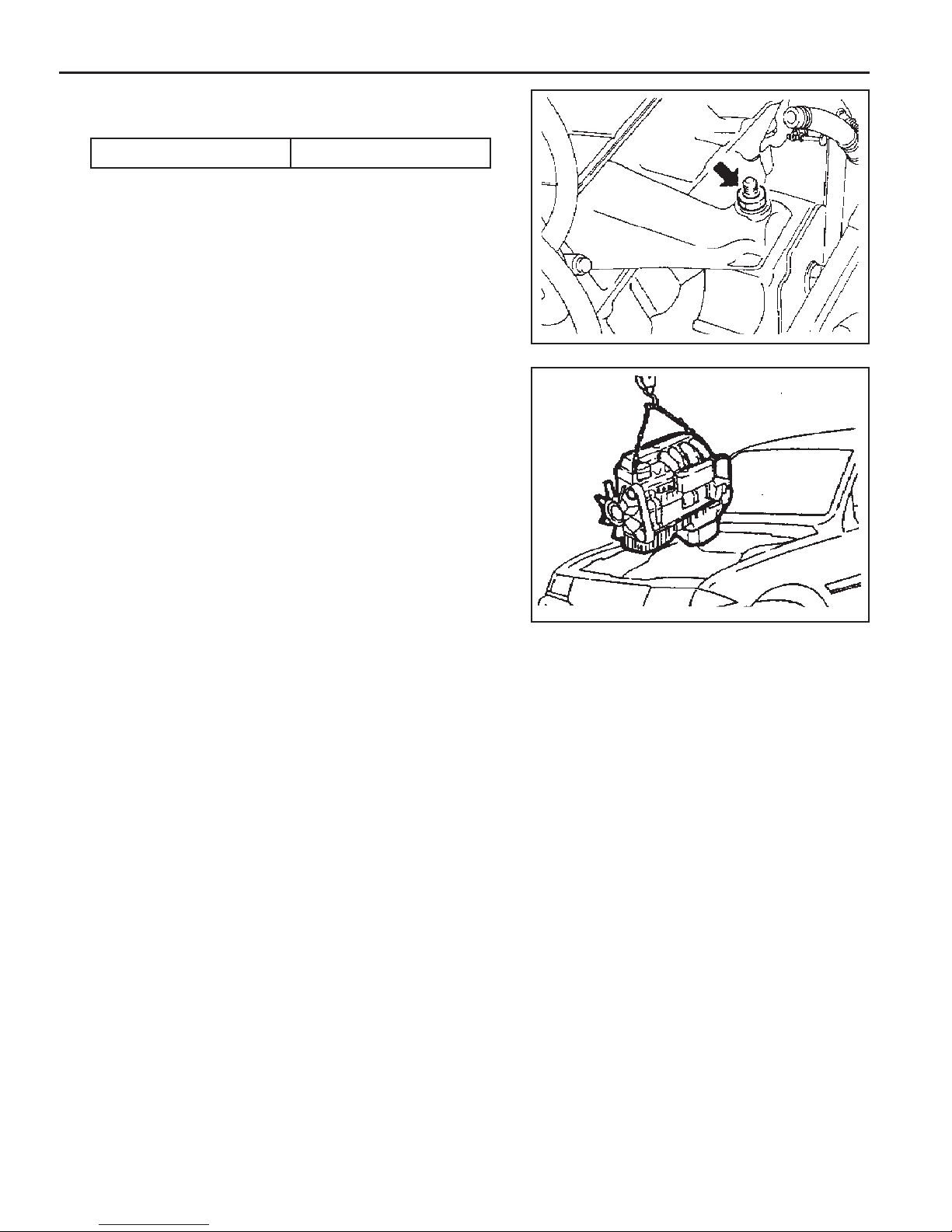

Page 22

1B3-22 OM600 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the nut.

2. Push the tensioning lever in direction of arrow with a rod

(F12 ´ 180mm) and pull out the bolt to the rear.

3. Push back the tensioning lever (arrow direction) to release

the spring tension and remove the belt.

4. Install the poly V-belt beginning at the tensioning pulley (7).

7 Tensioning Pulley

8 Crankshaft

9 Alternator

10 Coolant Pump

11 Guide Pulley

12 Power Steering Pump

13 Aircon. Compressor

Lengthe of Belt

With Air Conditioner

2,100 mm

Length (L)

Without Air Conditioner

2,040 mm

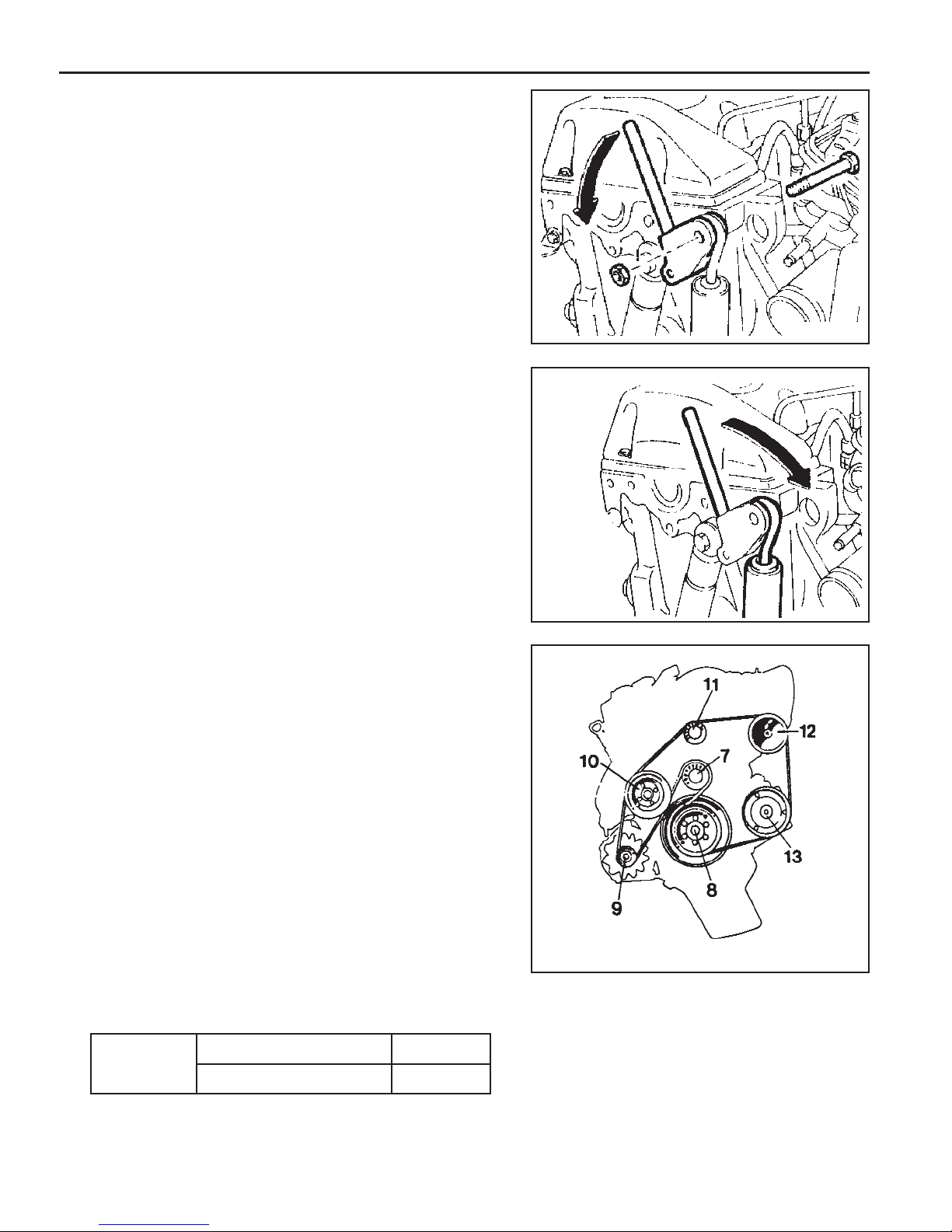

Page 23

TENSIONING DEVICE

Preceding Work : Removal of cooling fan

OM600 ENGINE MECHANICAL 1B3-23

1 Bolt ............................................................ 21Nm

2 Damper

3 Nut............................................................. 21Nm

4 Tensioning Lever

5 Guide Rail Pin

6 Bolt

7 Poly V-Belt

8 Belt Pulley

9 Bolt ............................................................ 10Nm

10 Tensioning Pulley

11 Socket Bolt ................................................ 29Nm

12 Closing Cover

13 Washer

14 Tensioning Lever

15 Fit Bolt ..................................................... 100Nm

16 Closing Cover

17 Spring

18 Bolt ............................................................ 20Nm

Page 24

1B3-24 OM600 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the nut.

Installation Notice

Tightening Torque 10 Nm

2. Push the tensioning lever in direction of arrow with a rod

( F12 ´ 180mm ) and push out the bolt to the rear.

3. Push back the tensioning lever to release the spring tension

and remove the belt.

4. Remove the bolt (9) and then remove the belt pulley (8).

5. Remove the bolt (1, 18) and take off the damper (2).

Notice

Pay attention to installation position of the damper.

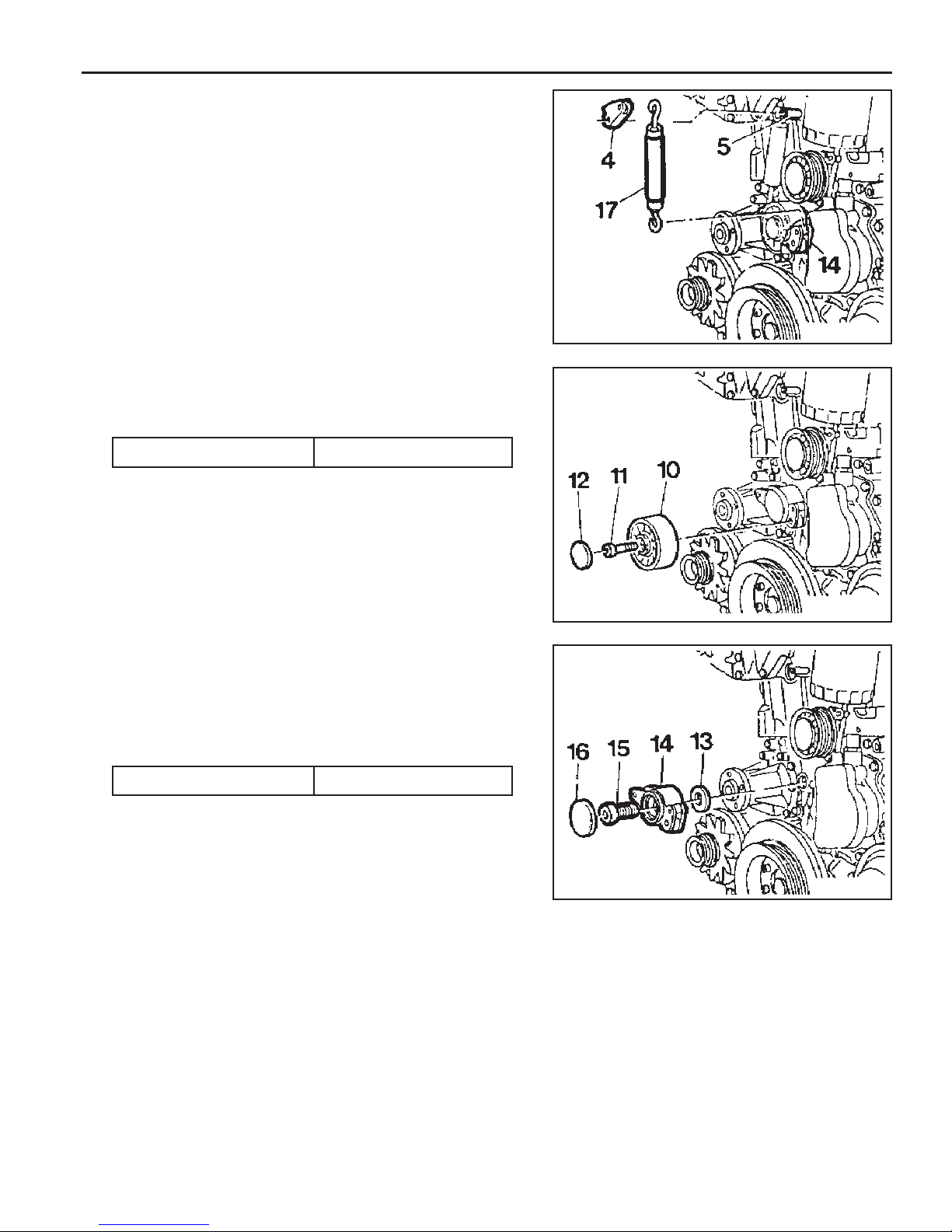

Page 25

6. Pull off the tensioning lever (4) from guide rail pin.

7. Remove the spring (17).

Installation Notice

Insert spring (17) with color coding (blue/violet) facing up.

8. Pry off the closing cover (12) and remove the socket bolt

(11) and then remove the tensioning pulley (10).

Installation Notice

Tightening Torque 29 Nm

OM600 ENGINE MECHANICAL 1B3-25

9. Pry off the closing cover (16) and remove the fit bolt (15).

10 . Remove the tensioning lever (14) and washer (13).

11. Clean thread in the timing case cover and fit bolt.

Installation Notice

Apply Loctite on thread of fit bolt.

Tightening Torque 100 Nm

12. Installation should follow the removal procedure in the

reverse order.

Page 26

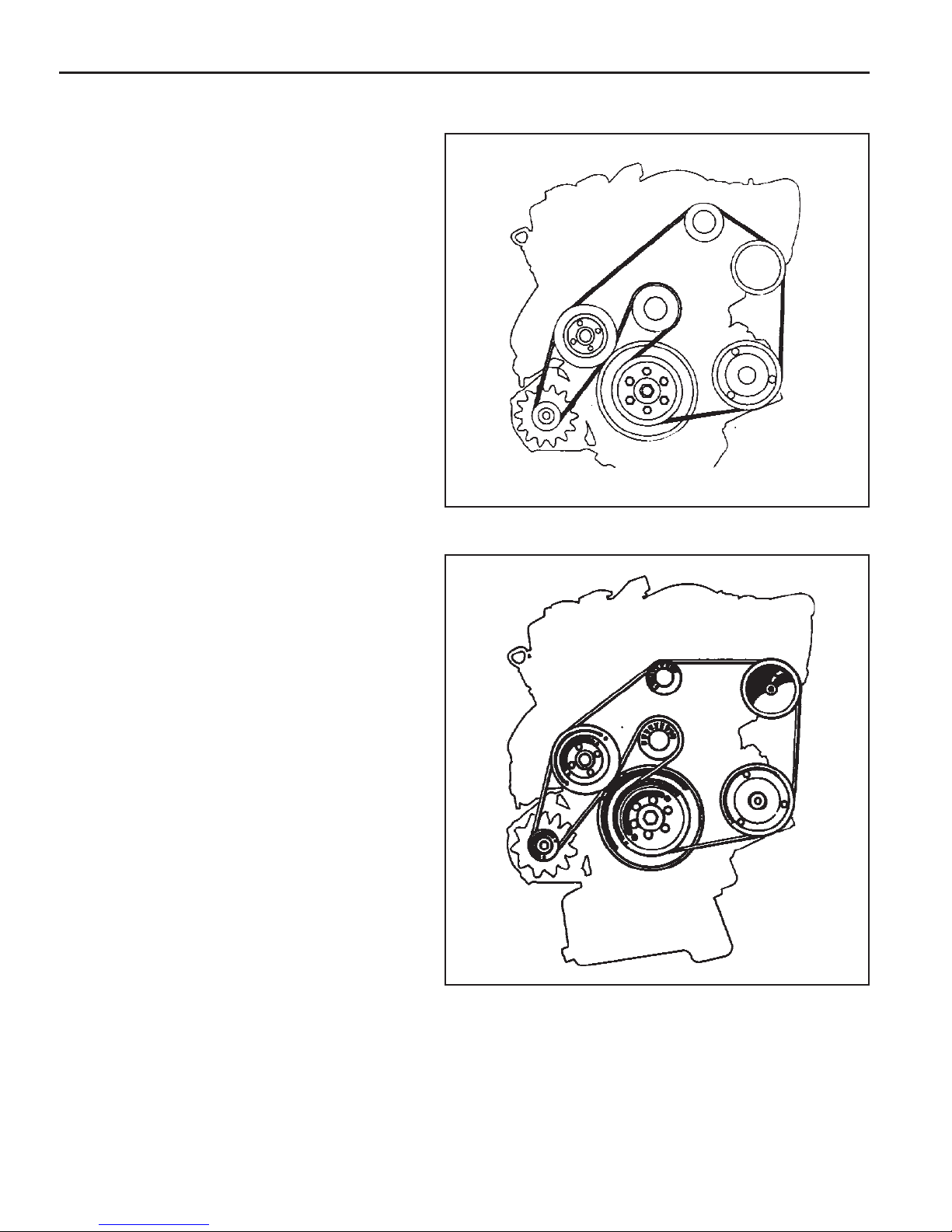

1B3-26 OM600 ENGINE MECHANICAL

POLY V-BELT ALIGNMENT & INSPECTION

Without Air Conditioner

With Air Conditioner

Page 27

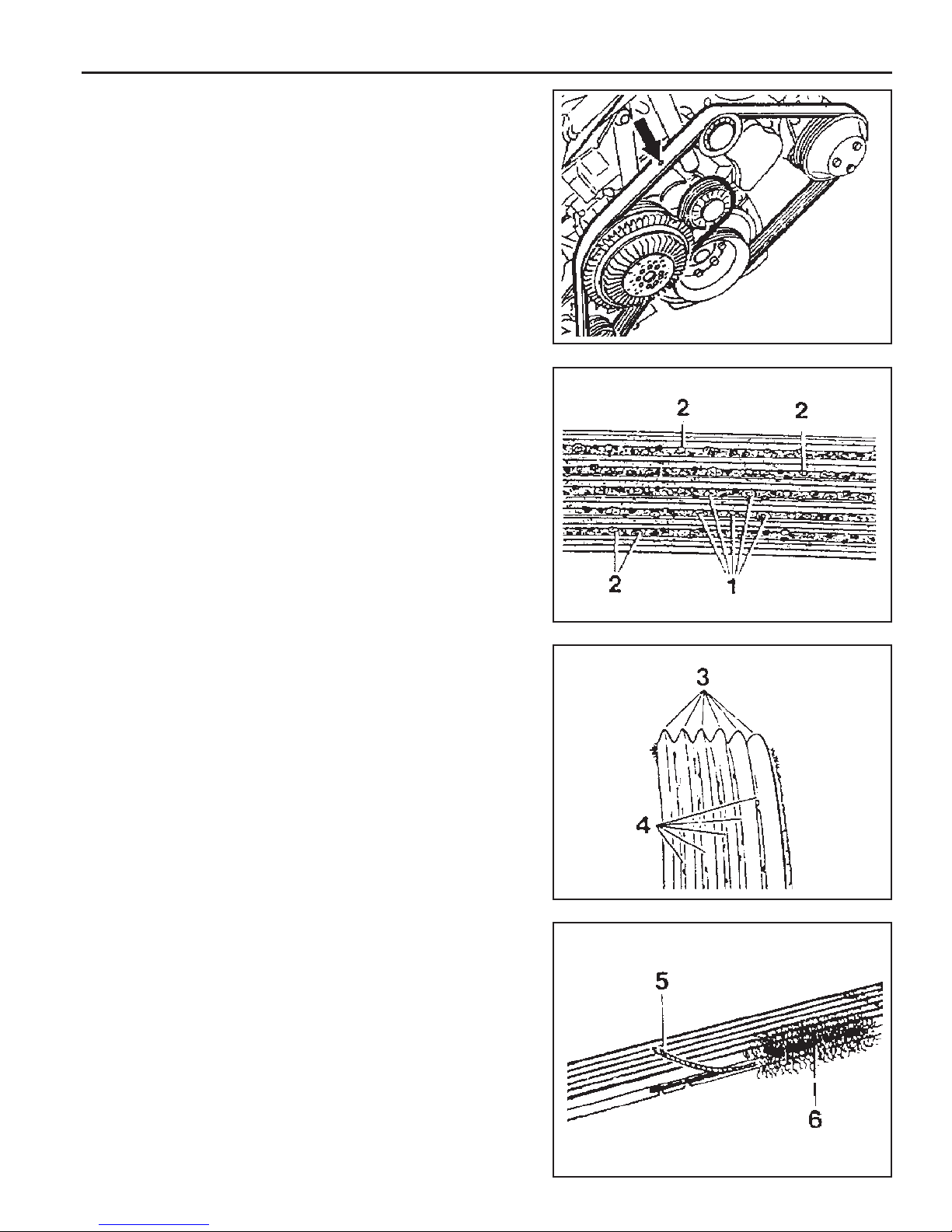

Inspection Procedure

l Mark poly V-belt at a clearly visible point with chalk.

l Rotate the engine and check the belt.

Notice

If one of the following types of damage is found, replace

the belt.

1. Rubber lumps in the base of rips.

2. Dirt or grit ingrained.

OM600 ENGINE MECHANICAL 1B3-27

3. Pointed rips.

4. Belt cord visible in the base of rips.

5. Cord torn out at the side.

6. Outer cords frayed.

Page 28

1B3-28 OM600 ENGINE MECHANICAL

7. Belt detached from the base of rip.

8. Splits across the rips.

9. Sections of rip torn out.

10 . Splits across several rips.

11. Splits across the back.

Page 29

PRECHAMBER

Preceding Work : Removal of glow plug

Removal of fuel injection nozzle

OM600 ENGINE MECHANICAL 1B3-29

1 Threaded Ring ........................................ 130 Nm

2 Prechamber

3 Cylinder Head

Page 30

1B3-30 OM600 ENGINE MECHANICAL

Tools Required

603 589 00 09 00 Serration Wrench

667 589 03 63 00 Sliding Hammer

Removal & Installation Procedure

1. Using the serration wrench (4), remove the threaded ring

(1).

Serration Wrench 603 589 00 09 00

2. Install the sliding hammer into the prechamber.

Sliding Hammer 667 589 03 63 00

3. Remove the perchamber (2).

Notice

After removing the prechamber, cover over the bores with

clean rag.

4. Inspect the prechamber.

Notice

If the prechamber seats in the cylinder head are leaking or

if the prechambers are replaced, the sealing surfaces in

the cylinder head must be remachined.

Page 31

Assembly Procedure

Notice

In case the prechambers are reused, inspect the

prechambers thoroughly, if the ball pin by heat and fire is

broken, it can not be used.

1. Clean the sealing surface of the prechamber.

2. Insert the prechamber into the cylinder head at the same

time aligning the cam on the collar of the prechambers with

the slots in the cylinder head.

Notice

If the spacer rings are fitted to the prechambers, the spacer

rings should be replaced with rings of the same thickness.

Thickness of Spacer Ring 0.3, 0.6, 1.0 mm

3. Coat the threaded ring with oil and assemble the ring by

using the serration wrench.

Tightening Torque 130 Nm

OM600 ENGINE MECHANICAL 1B3-31

Page 32

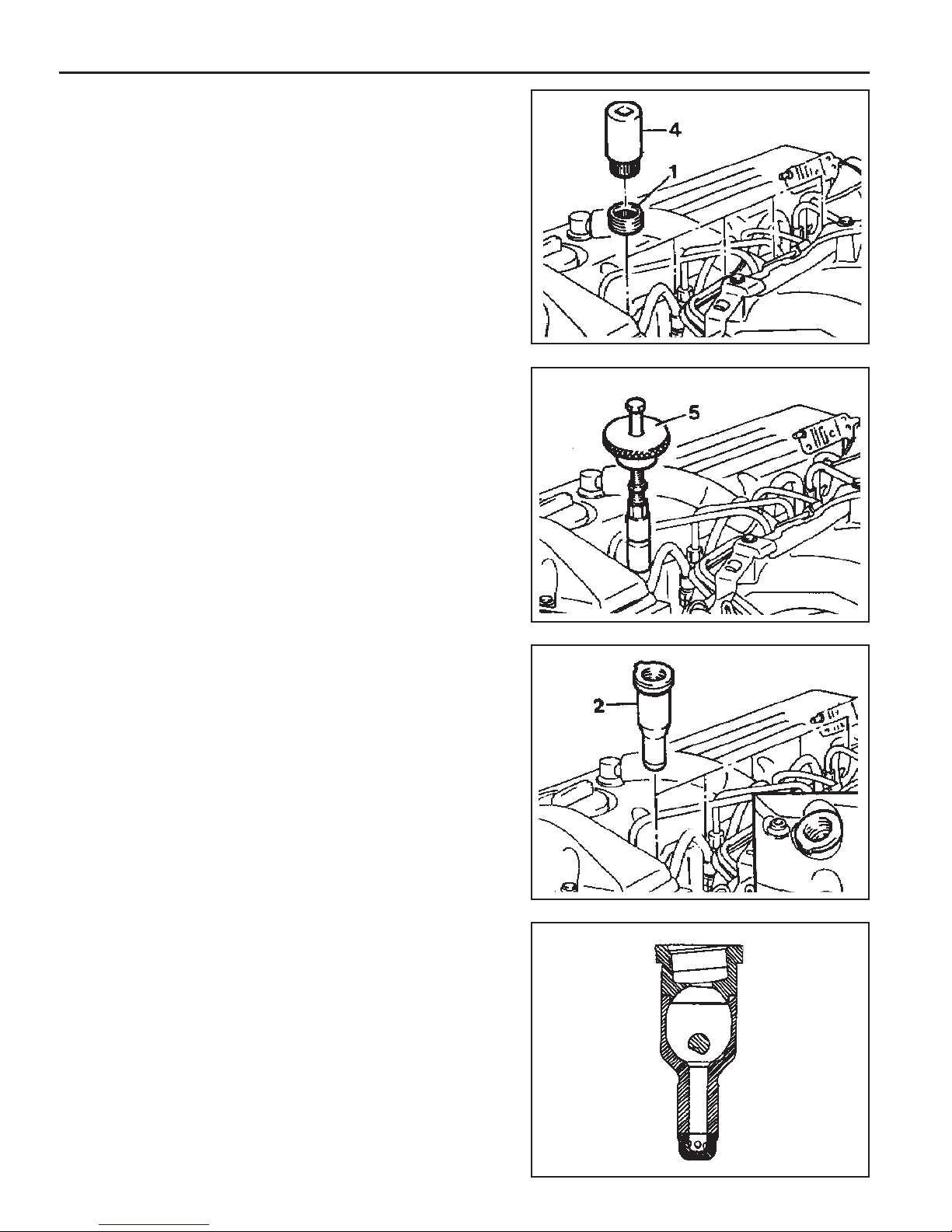

1B3-32 OM600 ENGINE MECHANICAL

MILLING OF PRECHAMBER SEALING SURFACE

1 Drift

2 Sleeve

3 Milling Cutter

Tools Required

601 589 00 66 00 Counter Sink

667 589 00 23 00 Height Gauge

Milling of the Prechamber Sealing Surface

Notice

The prechamber sealing surface may only be remachined

once with the cylinder head fitted. It is essential to adhere

to the specified projection ‘C’ of the prechamber of 7.6 -

8.1mm.

This ensures that the required clearance exists between

prechamber and piston crown with the piston in TDC. For

this reason, spacer rings should be inserted on remachined

sealing surfaces.

Tightening Torque 0.3, 0.6, 1.0 mm

4 Counter Sink (Special Tool - 601 589 00 66)

5 Cylinder Head

If a spacer ring is already fitted, or a marking is made on the

cylinder head, the cylinder head must be removed and size

‘C’ measured if further remachining is necessary on a

prechamber sealing surface.

Page 33

1. Remove the injection nozzle.

2. Remove the prechamber.

3. Cover the prechamber bore to avoid any chips dropping

into the combustion chamber.

4. Remove the protective sleeve from the countersink and

rotate the countersink into the prechamber bore to be

machined as far as the stop.

Counter Sink 601 589 00 66 00

5. Maintain size ‘X’ from the top edge of mandrel to the top

edge of the sleeve with the gauge.

Height Gauge 667 589 00 23 00

OM600 ENGINE MECHANICAL 1B3-33

6. Measure the ‘X’ by using a vernier caliper.

7. Mount the turning tool onto the countersink tool and rotate

to the right approx. 5 revolutions by applying slight pressure.

Page 34

1B3-34 OM600 ENGINE MECHANICAL

8. Remeasure size ‘X’ and compare it with the first

measurement and determine the thickness of spacer ring.

Ex

Size before machining 25.7 mm

Size after machining 25.5 mm

The spacer ring should be selected so that it is at least

0.1mm and not more than 0.3mm thicker than the

measured on the sealing surface. In this example, the

necessary thickness of spacer ring should be within

0.3 ~ 0.5mm and the thickness of spacer ring to be

installed is 0.3mm.

9. Remove the countersink tool and clean the chips.

Notice

If the sealing surface is not completely flat, remachine the

sealing surface.

10. emove rag from the prechamber bore and crank the engine

with starter motor to threw out any chips which may have

got into the combustion chamber.

11. Insert the proper spacer ring into the prechamber sealing

surface.

12. Punch a mark on the cylinder head above the prechamber

sealing surface which has been machined.

13. Install the prechambers.

Notice

If the cylinder head is removed, the projection ‘C’ is

measured in place of size ‘X’ and the appropriate size of

spacer ring selected.

Normal Projection (c) 7.6 - 8.1mm

Page 35

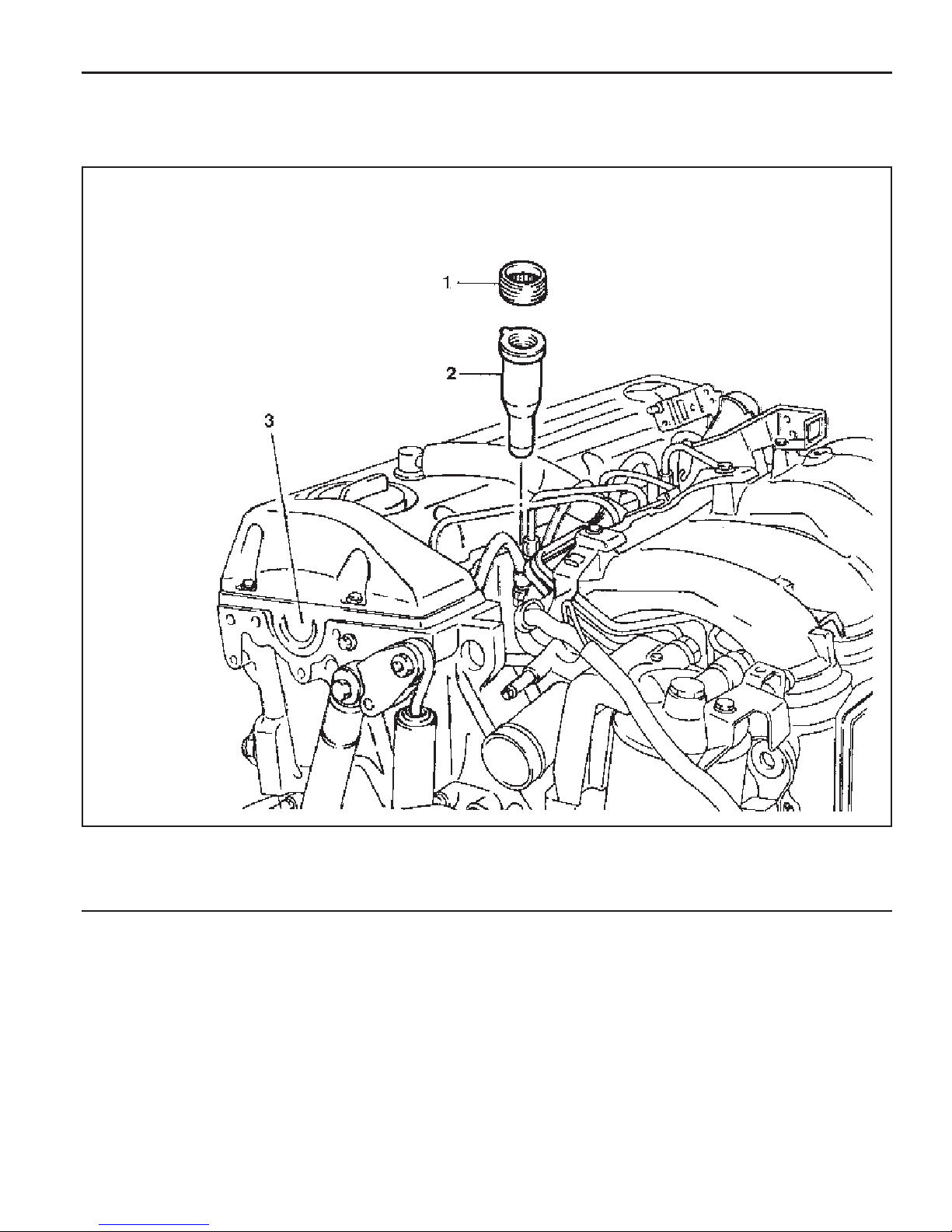

TDC (TDC SENSOR BRACKET) SETTING

Preceding Work : Removal of No.1 cylinder prechamber

OM600 ENGINE MECHANICAL 1B3-35

Tools Service

001 589 32 21 00 Dial Gauge

601 589 07 21 00 Deqth Gauge

667 589 01 21 00 Fixing Device

Notice

l The TDC sensor bracket must be adjusted in case of

followings.

l When replacing the TDC sensor bracket.

l When replacing the crankshaft, the hub or the vibration

damper.

l When replacing or installing the timing case cover.

l After engine overhauling.

1 Measuring Device

2 Dial Gauge

3 Cylinder Head

4 Piston ................................................Set at TDC

∗ If the cylinder head is removed, the measuring pin of the

dial gauge can be positioned on the piston crown.

This is done by placing the magnetic dial holder on the

mating surface of the crankcase.

Page 36

1B3-36 OM600 ENGINE MECHANICAL

Setting (with cylinder head installed)

1. Remove the prechamber of No. 1 cylinder.

2. Position the piston of No.1 cylinder at BTDC 10.

3. Install the measuring device into the prechamber bore and

position the dial gauge with a preload of 5mm.

Dial Gauge 001 589 53 21 00

Depth Gauge 601 589 07 21 00

4. Slowly rotate the crankshaft in the direction of engine rotation

until the large pointer on the dial gauge stops (TDC position).

Notice

The position of TDC is when the large pointer on the dial

gauge is stopped before moving back.

5. remove the reinstall the measuring device and position the

dial gauge scale at ‘0’.

6. Slowly rotate the crankshaft in the direction of engine rotation

until the dial gauge has moved back (counterclockwise) by

3.65mm.

7. Insert fixing device into the sensor bracket.

Notice

The pin on the vibration damper must engage into the slot

of the fixing device.

Fixing Device 667 589 01 21 00

8. If the pin does not engage, adjust the setting of the sensor

bracket by removing and tightening of the sensor bracket

bolts.

Tightening Torque 10 Nm

Notice

The timing mark on the damper must be positioned at A TDC

20.

Page 37

CYLINDER HEAD

OM600 ENGINE MECHANICAL 1B3-37

1 Fuel Injection Pipe ..................................... 18Nm

2 Cylinder Head

3 Gasket ................................................... Replace

4 Bolt ............................................................ 25Nm

5 Washer

6 Clamp

7 Heater Feed Pipe

8 Bolt

9 Washer

10 Bolt

11 Nozzle Washer ....................................... Replace

12 Fuel Injection Nozzle ............................35-40 Nm

13 Hexagon Socket Bolt ................................. 25 Nm

14 Washer

15 Bolt ........................................................... 25 Nm

16 Cylinder Head Bolt .............................. See Table

17 Cylinder Head Cover

18 Bolt ........................................................... 10 Nm

19 Gasket

20 Camshaft

21 Camshaft Drive Sprocket ....................... Replace

22 Washer

23 Bolt(12-Sided).................................. 25Nm + 90°

24 Sliding Rail

25 Sliding Rail Pin

26 Sliding Rail Pin

27 Chain Tensioner ....................................... 80 Nm

28 Gasket................................................... Replace

29 Cooling Fan.............................................. Check

30 Hexagon Socket Bolt................................. 45 Nm

31 Tensioning Lever

32 Bolt ........................................................... 25 Nm

33 Bolt

34 Nut............................................................ 23 Nm

35 Fuel Filter

36 Turbo Charger

37 Intake Duct

38 Gasket................................................... Replace

39 Intake Manifold

Page 38

1B3-38 OM600 ENGINE MECHANICAL

Tightening T orque

Cylinder Bolts (12-sided socket head)

(Engine cold)

M8 Cylinder Head Bolts

T ools Required

000 589 77 03 00 Box Wrench Insert

001 589 65 09 00 Socket Wrench Insert

102 589 03 40 00 Magnetic Bar

116 589 02 34 00 Threaded Pin

116 589 03 07 00 T Type Socket Wrench

116 589 20 33 00 Sliding Hammer

601 589 00 10 00 Cylinder Head Bolt Wrench

602 589 00 40 00 Engine Lock

603 589 00 40 00 Counter Holder

stage1

stage2

stage3

10 Nm

35 Nm

180°

25 Nm

Tightening Sequence for Cylinder Head Bolts

OM 662LA Engine

OM 661LA Engine

Page 39

Notice

The cylinder head may only be removed when the engine

has cooled down. The cylinder head is removed together

with the exhaust manifold. As the cylinder head bolts

undergo a permanent tightening. They require to be

replaced if they exceed the maximum lengthes indicated

in the table.

OM600 ENGINE MECHANICAL 1B3-39

Thread Dia.

M10

M10

M10

The twelve-sided socket head bolts are tightened with each

stages of torque and torque angle.

It is not necessary to retighten the cylinder head bolts at

the 1000~1500km inspection or after 1000~1500km of

repairs.

Length(L) When New

80mm

102mm

115mm

Max. Length(L)

82mm

104mm

117mm

Page 40

1B3-40 OM600 ENGINE MECHANICAL

Disassembly Procedure

1. Completely drain the coolant from the radiator and cylinder

block.

2. Remove the cooling fan shroud.

3. Hold the fan with counter holder and remove the bolt and

then remove the cooling fan.

Notice

Keep the fan in vertical position.

Counter Holder 603 589 00 40 00

4. Remove the bracket oil dipstick tube.

5. Remove the nut.

6. Remove the nut on the tensioning lever and insert the

rod(F12 ´ 180mm). By pushing the rod to the arrow direction,

pull back the bolt.

7. Push the tensioning lever to the opposite direction to release

the spring tension and remove the poly V-belt.

Page 41

8. Remove the air cleaner cover and element and then

remove the air cleaner housing.

9. Remove the oil return hose and plug.

Notice

Cover them to prevent chips from coming into.

10 . Unscrew the EGR pipe mounting bolts onto the exhaust

manifold.

11. Remove the duct bracket from the cylinder head.

OM600 ENGINE MECHANICAL 1B3-41

12 . Unscrew the intake duct mounting bolts onto the intake

manifold.

13 . Separate the connecting rod from the control lever.

Page 42

1B3-42 OM600 ENGINE MECHANICAL

14 . Pull out the accelerator control linkage.

15. Remove the fuel injection line(1) from the fuel injection

nozzle(12).

Box Wrench Inset 000 589 77 03 00

16. Remove the fuel injection line from the fuel injection pump.

Box Wrench Insert 000 589 77 03 00

17 . Remove the bracket mounting bolts and then remove the

fuel injection line(1).

Page 43

18. Disconnect the booster hose connected to intake manifold.

19 . Remove the intake manifold and gasket.

OM600 ENGINE MECHANICAL 1B3-43

20. Remove the cylinder head cover and gasket with the blowby gas hose.

21 . Disconnect the glow plug cables.

Page 44

1B3-44 OM600 ENGINE MECHANICAL

22 . Remove the cable channel.

23. Disconnect the cables from the glow plug sensor and

coolant temperature sensor.

24 . Remove the heater pipe bracket from the oil filter.

25. Pry off the clamp and push the heater feed pipe forward

and then pull out the pipe.

Page 45

26 . Disconnect the fuel lines from the fuel filter.

27 . Disconnect the fuel lines from the injection pump.

OM600 ENGINE MECHANICAL 1B3-45

28 . Remove the fuel filter(35).

29. Remove the fuel injection nozzle(12) and nozzle

washer(11).

Socket Wrench Insert 001 589 65 09 00

Page 46

1B3-46 OM600 ENGINE MECHANICAL

30 . Rotate the crankshaft and set the no.1 cylinder at TDC.

Notice

Do not rotate the crankshaft to the opposite direction of

engine revolution.

31 . Place alignment marks on the camshaft gear and timing

chain.

32. Ensure that the camshaft and the bearing cap marking

are aligned.

33. Remove the starter motor and install the engine lock onto

the flywheel ring gear.

Engine Lock 602 589 00 40 00

Page 47

34 . Remove the turbocharger.

35. Remove the exhaust manifold and gasket.

OM600 ENGINE MECHANICAL 1B3-47

36 . Remove the chain tensioner and seal.

37 . Remove the bolt and separate the drive sprocket(21).

Notice

During removal, be careful not to drop the sprocket and

chain into the timing case.

Carefully pull off the chain and then pull out the sprocket.

Page 48

1B3-48 OM600 ENGINE MECHANICAL

38 . Remove the camshaft bearing cap bolts according to the

numerical sequence.

Notice

Remove the No.1 bolts first and then remove the No. 2

bolts. Do not remove the bolts at a time completely but

remove them step by step evenly or camshaft can be

seriously damaged.

OM662LA

OM661LA

39. Remove the bearing caps and then pull out the

camshaft(20) upward.

Notice

Be careful not to miss the locking washer.

40. Remove the locking washer.

Notice

Check the locking washer and replace if necessary.

Page 49

41 . Remove the bolt(32).

42 . Separate the spring and pull out the tensioning lever(31).

OM600 ENGINE MECHANICAL 1B3-49

43. Pry off the closing cover . Remove the bolt and then remove

the idle pulley.

44 . Using the sliding hammer(36) and the threaded pin(37),

pull out the sliding rail pins(25, 26) and remove the sliding

rail(24).

Sliding Hammer 116 589 20 33 00

Threaded Pin 1 16 589 02 34 00

Page 50

1B3-50 OM600 ENGINE MECHANICAL

45. Remove the vacuum line from the vacuum pump.

46 . Disconnect the vacuum pipe from thermo valve.

47 . Remove the socket bolts(13) of the chain box.

T T ype Socket Wrench 1 16 589 03 07 00

Magnetic Bar 102 589 03 40 00

48 . Remove the cylinder head bolts in numerical se-quence.

Cylinder Head Bolt Wrench 601 589 00 10 00

OM 662LA

Page 51

49 . Remove the cylinder head(2) and gasket(3).

OM600 ENGINE MECHANICAL 1B3-51

OM 661LA

Page 52

1B3-52 OM600 ENGINE MECHANICAL

Assembly Procedure

1. Replace the cylinder head gasket.

2. Install the cylinder head onto the crankcase.

Notice

Align the cylinder head holes with the guide pins.

3. Measure the length(L) of cylinder head bolts.

Notice

If the max. length is exceeded, replace the bolts.

4. Coat the head contact surface of bolts and thread with oil

and insert them as shown.

- Cylinder head bolts arrangement

Bore

1 ........................................... M10

2 ........................................... M10 × 102

3 ........................................... M10 × 115

4 ........................................... M 8 × 50

5 ........................................... M 8 × 80

× 80

Thread Dia. Max. Limit(L)

M10

M10

M10

OM662LA

Length(L)

when new

80mm

102mm

115mm

82mm

104mm

117mm

Page 53

5. Tighten the cylinder head bolts to specified torque and

torque angle.

OM600 ENGINE MECHANICAL 1B3-53

Stage 1

Stage 2

Torque angle

Wait for

Torque angle

OM 661LA

15 Nm

35 Nm

90°

10 minutes

90°

OM 662LA

6. Install the socket bolts in the chain box.

Tightening Torque 25 Nm

7. Connect the vacuum pipe to the thermo valve.

Page 54

1B3-54 OM600 ENGINE MECHANICAL

8. Connect the vacuum lines to the vacuum pump.

9. Install the fuel filter and connect the pipe.

Tightening Torque 25 Nm

Notice

Be careful not to be confused the connections and hoses.

10 . Connect the fuel pipe to the injection pump.

1 1. Install the sliding rail(24) and insert the sliding rail pins(25,

26).

Notice

Apply sealing compound on the each collar of the sliding

rail pins.

Sliding Hammer 116 589 20 33 00

Threaded Pin 1 16 589 02 34 00

Page 55

12 . Install the idle pulley and fit the closing cover.

Tightening Torque 25 Nm

13 . Insert the tensioning lever(31) and install the spring.

OM600 ENGINE MECHANICAL 1B3-55

14. Install the damper.

Tightening Torque 23 Nm

Notice

Insert the tensioning lever bolts onto the mounting hole.

15. Insert the locking washer.

16. Inspect the valve tappet and check that the tappet moves

smoothly.

Page 56

1B3-56 OM600 ENGINE MECHANICAL

17. Coat the camshaft with oil and install the camshaft on the

cylinder head to be TDC mark(arrow) upward.

18 . Measure the axial end play of the camshaft.

End Play 0.06 - 0.21mm

Notice

If out of standard, adjust it with the proper thickness of

locking washer.

19 . Install the bearing caps on the camshaft according to the

number on the caps.

20 . Tighten the bearing cap bolts according to the numerical

sequence.

Tightening Torque 25 Nm

Notice

Tighten the No. 1 bolts(light arrow) first and then tighten

the No. 2 bolts(dark arrow) stage by stage.

OM662LA

OM661LA

Page 57

21. Position the camshaft on marking and install the camshaft

sprocket.

Notice

Align the alignment marks on the chain and sprocket.

OM600 ENGINE MECHANICAL 1B3-57

22 . Check the TDC position of the crankshaft.

23 . Install the camshaft sprocket bolt.

Tightening Torque 25 Nm + 90°

Page 58

1B3-58 OM600 ENGINE MECHANICAL

Notice

Measure the max. length ‘L ’ and replace the bolt if it exceeds

53.6mm.

24 . Install the exhaust manifold and gasket.

25 . Install the turbocharger.

26 . Install the exhaust pipe onto the turbocharger.

Tightening Torque 25 Nm

Page 59

27 . Replace the seal and then install the chain tensioner.

Tightening Torque 80 Nm

28 . Remove the engine lock.

OM600 ENGINE MECHANICAL 1B3-59

29 . Insert the nozzle washer into the hole to face round part

downward.

30. Install the fuel injection nozzle.

Tightening Torque 40 Nm

31 . Connect the fuel hose.

32. Install the cable channel and connect the cables to glow

plugs.

Page 60

1B3-60 OM600 ENGINE MECHANICAL

33 . Replace the gasket and install the cylinder head cover.

Tightening Torque 10 Nm

34 . Install the blow-by hose.

35 . Connect the wires to the coolant temperature sensor and

the glow plug sensor.

36 . Replace the intake manifold gasket.

37 . Install the intake manifold.

Tightening Torque 25 Nm

Page 61

38. Replace the O-ring of heater feed pipe and install it to the

cylinder head.

Notice

For installation, clean the hole.

39 . Install the bracket of heater feed pipe to the oil filter.

OM600 ENGINE MECHANICAL 1B3-61

40 . Install the fuel pipe and the accelerator control linkage.

41 . Connect the fuel lines to the injection nozzles and to the

injection pump.

Box Wrench Insert 000 589 77 03 00

Tightening Torque 18 Nm

Page 62

1B3-62 OM600 ENGINE MECHANICAL

42 . Install the poly V-belt.

Notice

Be careful not to contaminate the belt.

43. By inserting a rod into the tensioning lever upper hole and

pulling the rod, install the bolt and then tighten the nut.

Tightening Torque 23 Nm

44 . Install the oil dipstick tube bracket.

Tightening Torque 10 Nm

45. Hold the cooling fan with the counter holder and tighten

the bolt.

Page 63

TIMING CASE COVER

Preceding Work : Removal of the cooling fan

Rmoval of the V-belt tensioning device

Removal of the vibration damper and hub

Removal of the alternator

OM600 ENGINE MECHANICAL 1B3-63

1 Bolt ............................................................ 10Nm

2 Cylinder Head Cover

3 Gasket ................................................... Replace

4 Socket Bolt ................................................ 25Nm

5 Fuel Filter

6 Square Nut

7 Oil Pan

8 Socket Bolt ................................................ 10Nm

9 Bolt .................................................... M6 : 10Nm

M8 : 23Nm

10 Power Steering Pump

11 Bolt

12 Belt Pulley

13 Bolt ............................................................ 32Nm

14 T iming Case Cover

15 Bolt ............................................................ 23Nm

16 Alternator Bracket

17 Bolt ............................................................ 45Nm

18 Bolt ............................................................ 25Nm

19 Bolt ............................................................ 10Nm

20 Closing Cover

21 Socket Bolt ................................................ 23Nm

22 Guide Pulley

23 Bolt .............................................................. 9Nm

24 Guide Pulley Bracket

25 Nut ............................................................. 23Nm

Page 64

1B3-64 OM600 ENGINE MECHANICAL

T ools Required

116 589 03 07 00 Socket Wrench

Removal Procedure

1. Remove the fan clutch and cooling fan belt pulley.

2. Drain the engine oil completely.

3. Remove the oil dipstick tube bracket bolts.

4. Remove the crankshaft pulley.

5. Loosen the bolt (1) and then remove the cylinder head cover

(2) and gasket.

6. Remove the vacuum pump.

7. Detach the closing cover (20). Remove the bolts(21) and

then remove the guide pulley (22).

8. Remove the guide pulley bracket (24).

Page 65

9. Disconnect the pipes of power steering pump and remove

the belt pulley.

Notice

Be careful not to lose the key.

10. Remove the nut and pull out the bolt and then remove the

power steering pump.

OM600 ENGINE MECHANICAL 1B3-65

11. Remove the alternator bracket (16).

12 . Remove the fuel filter.

Page 66

1B3-66 OM600 ENGINE MECHANICAL

13 . Remove the camshaft.

14. Remove the socket bolts(4) in the chain box.

Socket Wrench 1 15 589 03 07 00

15 . Remove the injection pump.

Notice

See the ‘Removal of fuel injection pump’.

16. Remove the oil pan bolts (8, 9) in the area of the timing

case cover (14).

17. Slightly loosen the remaining oil pan bolts.

18. Remove the timing case cover (19) bolts and then remove

the timing case cover (14).

Notice

Be careful not to damage the cylinder head gasket or oil

pan gasket.

Page 67

Installation Procedure

1. Thoroughly clean the sealing surface and apply sealant.

2. Install the timing case cover.

Tightening Torque 10 Nm

OM600 ENGINE MECHANICAL 1B3-67

Notice

Bolts arrangement

1.M6 x 60

2.M6 x 70

3.M6 x 40

3. Tighten the socket bolts in the chain box.

Tightening Torque 23 Nm

4. Tighten the oil pan bolts.

Socket bolt

Tightening Torque

M6 bolt

M8 bolt

10 Nm

10 Nm

23 Nm

Page 68

1B3-68 OM600 ENGINE MECHANICAL

5. Install the flange, vibration damper and crankshaft belt

pulley.

Notice

Replace front radial seal if necessary.

6. Install the alternator bracket.

Tightening Torque

7. Install the alternator

Tightening Torque

Front

Side

Upper - 25 Nm

Low - 25 Nm

25 Nm

25 Nm

8. Install the cylinder head cover.

Tightening Torque 10 Nm

9. Tighten the injection pump mounting bolts.

Tightening Torque 23 Nm

Page 69

10 . Install the fuel filter.

Tightening Torque 25 Nm

11. Install the vacuum pump.

Tightening Torque 10 Nm

12. Install the power steering pump.

Tightening Torque 23 Nm

OM600 ENGINE MECHANICAL 1B3-69

13. Install the power steering pump pulley.

Tightening Torque 32 Nm

14 . Install the guide pulley bracket.

Tightening Torque 9 Nm

Page 70

1B3-70 OM600 ENGINE MECHANICAL

15 . Install the guide pulley (22) and fit the closing cover (20).

Tightening Torque 23 Nm

16. Replace the gasket (3) and install the cylinder head cover

(2).

Tightening Torque 10 Nm

17 . Install the cooling fan belt pulley and fan clutch.

18 . Install the belt tensioning device and then install the belt.

19 . Install the cooling fan.

20. Fill the engine oil and check oil leaks by running the engine.

Page 71

CRANKSHAFT END COVER

Preceding Work : Removal of flywheel and driven plate.

OM600 ENGINE MECHANICAL 1B3-71

1 Crankshaft Flange

2 End Cover.............................. Clean, Loctite 573

3 Bolt .........................................10Nm, Loctite 573

4 Radial Seal ............................................ Replace

5 Dowel Sleeve

6 Bolt .........................................10Nm, Loctite 573

Page 72

1B3-72 OM600 ENGINE MECHANICAL

Tools Required

601 589 03 43 00 Oil Seal Assmbler

Removal Procedure

1. Remove the bolts (3, 6) from end cover, By pulling out the

lugs (arrow), remove the cover.

Notice

Be careful not to damage the oil pan gasket.

2. Remove the radial seal (4) with care not to damage the

sealing surface.

Installation Procedure

1. Thoroughly clean the sealing surface of end cover and apply

Loctite 573.

2. Clean the groove of radial seal.

3. Apply Loctite 573 on the bolts and install the end cover.

Tightening Torque 10 Nm

Notice

Be careful not to damage the oil pan gasket.

4. Install the inner oil seal assembler to the crankshaft flange.

Oil Seal Assembler 601 589 03 43 00

Page 73

5. Coat a little oil on the sealing lip of new radial seal and

contacting surface.

Notice

Don’t use grease.

6. Insert the new radial seal (4) onto the oil seal assembler

(7).

Notice

The sealing lip of the repair radial seal is offset to the inside

by 3mm to ensure that it does not run in any groove which

the standard radial seal may have left on the crankshaft

flange.

A Standard Radial Seal

B Repair Radial Seal

OM600 ENGINE MECHANICAL 1B3-73

7. Install the outer oil seal assembler on he seal and by

tightening the bolts, press the radial seal into the end cover

as far as the stop.

Notice

The seal must be positioned exactly at right angles in the

end cover to ensure that it provides a proper seal.

Oil Seal Assembler 601 589 03 43 00

Page 74

1B3-74 OM600 ENGINE MECHANICAL

VIBRATION DAMPER AND HUB

Preceding Work : Removal of the cooling fan

Removal of poly V-belt

1 Bolt ............................................................ 10Nm

2 Cooling Fan Belt Pulley

3 Socket Bolt ................................................ 23Nm

4 Crankshaft Belt Pulley

5 Vibration Damper

6 Bolt ................................................ 200Nm + 90°

7 Washer

8 Straight Pin

9 Hub

10 Oil Pan

Page 75

Sectional View

OM600 ENGINE MECHANICAL 1B3-75

3 Socket Bolt

4 Crankshaft Belt Pulley

5 Vibration Damper

6 Bolt

7 Washer

8 Straight Pin

Notice

The mounting position of vibration damper is fixed by straight

pin (8).

Tools Required

602 589 00 40 00 Engine Lock

103 589 00 30 00 Puller

9 Hub

11 Radial Seal

12 Timing Gear Case Cover

13 Key

14 Crankshaft Sprocket

16 Crankshaft

Page 76

1B3-76 OM600 ENGINE MECHANICAL

Removal Procedure

1. Remove the starter motor and install the engine lock into

the wheel ring gear.

Engine Lock 602 589 00 40 00

2. Remove the poly V-belt.

3. Remove the cooling fan.

Notice

Keep the fan in vertical position.

4. Remove the cooling fan belt pulley (2).

5. Place alignment marks (arrow) on the vibration damper (5)

and crankshaft belt pulley (4).

6. Remove the timing sensor bracket.

Notice

Remove if necessary.

Page 77

7. Remove the socket bolts (3) and then remove the belt

pulley (4) and vibration damper (5).

8. Remove the washer and bolt.

OM600 ENGINE MECHANICAL 1B3-77

9. Remove the hub by using a puller.

10. Replace the radial seal.

Puller 103 589 00 33 00

Page 78

1B3-78 OM600 ENGINE MECHANICAL

Installation Procedure

1. Install the hub.

Notice

Exactly align the woodruff key and the groove of hub (arrow).

2. Install the washer (7) and tighten the bolt (6).

Washer (new) : 1 EA 200 Nm + 90°

3. Install the vibration damper.

Notice

Exactly align and insert onto the straight pin.

4. Install the belt pulley.

Tightening Torque 25 Nm

Notice

Align the alignment marks.

Page 79

5. Install the timing sensor bracket.

Notice

See the ‘TDC setting’.

6. Install the cooling fan pulley.

Tightening Torque 10 Nm

7. Install the cooling fan.

8. Install the fan belt.

OM600 ENGINE MECHANICAL 1B3-79

9. Remove the engine lock.

Page 80

1B3-80 OM600 ENGINE MECHANICAL

CRANKSHAFT FRONT RADIAL SEAL

1 Radial Seal

2 Timing Case Cover

Tools Required

601 589 03 14 00 Sleeve

3 Woodruff Key

Page 81

Notice

The sealing lip of the repair radial seal is offset to the inside

by 2mm to ensure that is does not run in any groove which

the standard radial seal may have left on the crankshaft

flange.

A Standard Radial Seal

B Repair Radial Seal

Replacement Procedure

1. Pull out the radial seal (1) and be careful not to damage the

sealing surface of timing case cover.

2. Thoroughly clean the mounting bore of the radial seal.

OM600 ENGINE MECHANICAL 1B3-81

3. Coat a little oil on the sealing lip of new radial (1) and contact

surface.

Notice

Don’t use grease.

4. Install the radial seal (1) by using a sleeve (4).

Notice

Align the groove of sleeve and woodruff key(arrow).

Sleeve 601 589 03 14

Page 82

1B3-82 OM600 ENGINE MECHANICAL

CRANKSHAFT BALL BEARING

1 Spacer

2 Cover......................................... Replace

Notice

Manual transmission only.

Tools Required

000 589 33 33 00 Counter Support

000 589 25 33 00 Internal Extractor

Removal & Installation Procedure

1. Remove the manual transmission.

2. Using a puller, pull out the locking ring and ball bearing

together.

3 Ball Bearing

4 Bolt .......................................45Nm + 90°

Counter Support 000 589 33 33 00

Internal Extractor 000 589 25 33 00

3. Apply Loctite 241 on the new ball bearing and then insert

the ball bearing to be stopped at the spacer ring by using a

proper mandrel.

Page 83

CRANKSHAFT

Preceding Work : Removal of the end cover

Removal of the piston

Removal of the crankshaft sprocket

OM600 ENGINE MECHANICAL 1B3-83

3 Crankshaft Main Bearing Shells (Upper)

4 Trust Bearings (Upper)

5 Crankshaft

6 Crankshaft Main Bearing Shells (Lower)

Tools Required

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder

366 589 00 21 05 Extension

7 Thrust Bearings (Lower)

8 Crankshaft Bearing Cap

9 Crankshaft Bearing Cap (Fit Bearing)

10 12-sided Stretch Bolts.......................55Nm + 90°

Page 84

1B3-84 OM600 ENGINE MECHANICAL

Thrust W asher and Bearing Arrangement

OM662LA Engine

3 Crankshaft Main Bearing Shells (Upper)

4 Thrust Bearings (Upper)

5 Crankshaft

6 Crankshaft Main Bearing Shells (Lower)

7 Thrust Bearings (Lower)

Notice

The gaps between the bearing shell and bore and

between the bearing shell and journal are different

each other. Refer to service data.

A Radial Bearings

B Radial and Axial Bearings (Thrust Bearing)

Page 85

OM661LA Engine

OM600 ENGINE MECHANICAL 1B3-85

3 Crankshaft Main Bearing Shells (Upper)

4 Thrust Bearings (Upper)

5 Crankshaft

6 Crankshaft Main Bearing Shells (Lower)

7 Thrust Bearings (Lower)

Notice

The gaps between the bearing shell and bore and

between the bearing shell and journal are different

each other. Refer to service data.

A Radial Bearings

B Radial and Axial Bearings (Thrust Bearing)

Page 86

1B3-86 OM600 ENGINE MECHANICAL

Crankshaft Standard and Repair Sizes

Crankshaft bearing

journal diameter

Standard size 50.950 - 57.965

Repair size 1

Repair size 2

Repair size 3

Repair size 4

57.500 - 57.715

57.450 - 57.465

57.200 - 57.215

56.950 - 56.965

Bearing Clearances

Radial clearances

New

Limit

Axial clearances

New

Limit

Matching Fit Bearing Journal Width to Thrust Bearings

Thrust bearing

journal width

Thrust bearing

journal diameter

24.500 - 24.533

24.600 - 24.633

24.700 - 24.733

24.900 - 24.933

25.000 - 25.033

-

47.950 - 47.965

47.700 - 47.715

47.450 - 47.650

47.200 - 47.215

46.950 - 46.965

Thrust bearing Crankshaft bearing

0.027 - 0.051

Max. 0.070

0.100 - 0.254

Max. 0.300

0.026 - 0.068

Max. 0.080

-

-

mm

mm

mm

Fit bearing journal width Thrust bearings thickness

24.500 - 24.533

24.600 - 24.633

24.700 - 24.733

24.900 - 24.933

25.000 - 25.033

Notice

l Measure crankshaft axial clearance and adjust with proper thrust Bearing.

l The same thickness of washer must be installed on both sides of the fit bearing.

2.15

2.20

2.25

2.35

2.40

Page 87

OM600 ENGINE MECHANICAL 1B3-87

Matching Crankshaft Bearing Shells to Basic Bearing Bore in Crankshaft

Marking of basic bearing bore in lower Color code of relevant crankshaft

Matching Crankshaft Bearing Shells to Basic Bearing Journal of Crankshaft

Marking of bearing journals on crank webs

parting surface

1 punch mark or blue

2 punch marks or yellow

3 punch marks or red

Blue or white-blue

Yellow or white-blue

Red or white-blue

bearing shell

Blue or white-blue

Y ellow or white-yellow

Red or white-red

Color code of relevant crankshaft

bearing shell

Blue or white-blue

Y ellow or white-yellow

Red or white-red

Page 88

1B3-88 OM600 ENGINE MECHANICAL

Removal & Installation Procedure

1. Remove the bearing cab bolt.

2. Remove the bearing caps (8).

Notice

The crankshaft bearing caps are marked with stamped

numbers. Remove the bearing cap from the vibration

damper side.

3. Remove the crankshaft bearing caps (9) and lower thrust

bearings (7).

4. Remove the lower thrust bearings (6) from the bearing cap

(9).

5. Remove the crankshaft (5).

6. Remove the upper thrust bearings(4).

7. Remove the upper bearing shells (3) from crankcase.

Page 89

8. Thoroughly clean the oil gallery.

9. Select a proper new bearing shells with reference to table.

10 . Coat the new bearing shells with oil and insert into the

crankcase and into the crankshaft bearing caps.

Notice

Do not mix up upper and lower crankshaft bearing shells.

11. Install the bearing caps according to marking and tighten

the 12-sided stretch bolts.

Tightening Torque 35 - 40 Nm

Notice

No. 1 is vibration damper side.

12. Measure crankshaft bearing diameters (E).

Extension 366 589 00 21 05

OM600 ENGINE MECHANICAL 1B3-89

13. Measure at 3 points (A, B and C) and if the average value

of B and C is less than A’ s value, the average value of B

and C is the mean value and if more than A’ s value, A’ s

value is the mean value.

14 . Measure crankshaft bearing journal diameter (F).

Notice

When measured in A and B, the runout should not exceed

0.010mm.

Page 90

1B3-90 OM600 ENGINE MECHANICAL

15 . Measure radial clearance of crankshaft bearing (G).

Clearance ‘G’ 0.027 - 0.051mm

Notice

If ‘G’ is out of standard, replace the bearing shells and

adjust the radial clearance of crankshaft bearing.

Example) Measured value ‘E’ = 57.700mm

Measured value ‘F’ = 57.659mm

Clearance ‘G’ = 0.041mm

16 . Remove the crankshaft bearing cap.

17. Measure width of thrust bearing journal (H) and adjust with

proper thrust bearings (see table).

Notice

The same thickness of thrust washers should be installed

on both sides of the thrust bearing.

18 . Coat the upper thrust bearing (4) with oil and insert into

the crankcase so that the oil grooves are facing the crank

webs (arrow).

19. Coat the lower thrust bearing (7) with oil and insert into the

crankshaft bearing cap so that the oil grooves are facing

the crank webs (arrow).

Notice

The retaining lugs should be positioned in the grooves

(arrow).

Page 91

Notice

If the max. length of bolts(L) exceed 63.8mm, replace them.

19. Coat the new crankshaft with engine oil and place it on the

crankcase.

20 . Install the crankshaft bearing caps according to marking

and tighten the bolts.

Tightening Torque 55 Nm + 90°

Notice

Install from No. 1 cap.

OM600 ENGINE MECHANICAL 1B3-91

22. Rotate the crankshaft with hand and check whether it

rotates smoothly.

23 . Measure crankshaft bearing axial clearance.

Clearance 0.100 - 0.245mm

Notice

If the clearance is out of standard, adjust the axial clearance

of crankshaft bearing by replacing the thrust washers.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Notice

The same thickness of thrust washers should be installed

on both sides of the thrust bearing.

Page 92

1B3-92 OM600 ENGINE MECHANICAL

24. Insert the new connecting rod bearing shells into the

connecting rod and connecting rod bearing cap and tighten

the 12-sided stretch bolts (11).

T ightening Torque 40 Nm + 90°

25 . Measure inner diameter of connecting rod bearing.

26 . Measure connecting rod bearing journal diameter (K).

Notice

Refer to measurement of the crankshaft bearing journal

diameter.

27. Measure the radial clearance (L) of the connecting rod

bearing.

Example) Measured value ‘J’ = 47.700mm

Measured value ‘K’ = 47.653mm

Clearance ‘L’ = 0.047mm

Radial Clearance ‘L ’ 0.026 - 0.068mm

Notice

If the clearance is out of standard, adjust the radial

clearance of connecting rod bearing by replacing the

connecting rod bearing shells.

28 . Remove the connecting rod bearing cap.

29 . Install the piston.

30. Rotate the crankshaft by hand and check whether it rotates

smoothly .

31 . If the bearings are damaged,

- replace the oil presser relief valve.

- clean the oil pump and oil filter housing carefully and

replace the hose if necessary.

Notice

After assembling the engine, check the camshaft timing,

adjust the start of fuel injection and check the TDC sensor

bracket setting.

32 . Fill oil and run the engine and then check the oil pressure

and oil level.

Notice

Install the original oil filter element and then change the

engine oil and oil filter element after 1,000 - 1,500km.

Page 93

FLYWHEEL

Preceding Work : Removal of the transmission

Removal of the clutch

OM600 ENGINE MECHANICAL 1B3-93

1 Oil Pan

2 Straight Pin

3 Flywheel

4 12-Sided Stretch Bolt ............Check, 45Nm + 90°

5 Drive Plate (Automatic Transmission)

6 Flywheel (Automatic Transmission)

Page 94

1B3-94 OM600 ENGINE MECHANICAL

l Manual transmission flywheel

OM662LA

OM661LA

l Automatic transmission flywheel

Page 95

Tools Required

602 589 00 40 00 Engine Lock

Removal & Installation Procedure

1. Install the engine lock.

Engine Lock 602 589 02 40 00

2. Remove the 12-sided stretch bolts (4).

Installation Notice

Tightening Torque 45 Nm + 90°

OM600 ENGINE MECHANICAL 1B3-95

Notice

If the length ‘L’ of bolts exceeds 22.5mm, replace the bolts.

3. Remove the flywheel (3), if equipped with manual

transmission.

Installation Notice

Correctly align the position of dowel pin (2).

Page 96

1B3-96 OM600 ENGINE MECHANICAL

4. Remove the flywheel (6) and driven plate (5), if equipped

with automatic transmission.

Installation Notice

Correctly align the position of dowel pin (2).

5. Installation should follow the removal procedure in the

reverse order.

Page 97

MACHINING OF FLYWHEEL

OM600 ENGINE MECHANICAL 1B3-97

1 Flywheel

Machining of Flywheel

Notice

Flywheels which have scorch marks, scoring or cracks in

the clutch surface should be machined by grinding or

precision-turning. If the scores or cracks are severe than

permissible specifications, replace the flywheel.

Distance ‘a’

Distance ‘b’

Repair up to

Max. axial runout

l When machining the clutch surface ‘A’, the mounting

surface (B) for the clutch pressure plate should also be

machined in accordance with ‘A’ to keep the distance ‘a’.

l Do not machine under ‘b’ value.

l When machining, fix the flywheel exactly not to exceed the

standard runout.

19.3 - 19.5 mm

New

16.6 mm

15.6 mm

0.05 mm

OM662LAOM662LA

Page 98

1B3-98 OM600 ENGINE MECHANICAL

FLYWHEEL RING GEAR

Preceding Work : Removal of flywheel

1 Ring Gear

2 Flywheel

Tools Required

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder

3 Centering Collar Diameter

Page 99

Replacement Procedure

1. Drill a hole into the ring gear (1) (arrow) and snap

with a chisel.

2. Thoroughly clean the collar surfaces of ring gear.

3. Measure diameter (a) of centering collar.

Diameter ‘a’ 275 + 0.5mm

Notice

If out of standard, replace the flywheel.

OM600 ENGINE MECHANICAL 1B3-99

4. Heat up the new ring gear up to 220°C by using a

heating device.

Notice

Use temperature measuring chalk.

5. Install the new ring gear (1) onto the flywheel by using a

drift.

Page 100

1B3-100 OM600 ENGINE MECHANICAL

6. Measure axial runout of ring gear (1) on a surface plate.

Limit Max. 0.4mm

Notice

For correct measurement, put the flywheel on the flat

measuring board.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Loading...

Loading...