SPX Cooling Technologies Marley Sigma Wood CoolingTower 1000, Marley Sigma Wood CoolingTower 1200 User Manual

Page 1

Marley Sigma 1000/1200 Cooling Tower

/

/

Engineering Data & Specifications

Page 2

Marley / Sigma 1000/1200 Cooling Tower / Table of Contents

Engineering Data

1000 Schematic 4

1000 Piping 5

1000 Support 6

1200 Schematic 8

1200 Piping 9

1200 Support 10

Energy Management 12

Environmental 13

Specifications / Base

Base 14

Thermal Performance 15

Construction 16

Fan Deck and Fan Cylinder 17

Mechanical Equipment 18

Fill, Louvers and Drift Eliminators 19

Hot Water Distribution System 20

Casing 20

Access 20

Cold Water Collection Basin 21

Scope of Work 21

Specifications / Options

Control Options

Control System 22

Basin Heater 23

Fan Motor Variable Speed Drive 23

Marley Premium VFD System 24

Vibration Limit Switch 25

Convenience and Safety Options

Stairway 26

Plenum Walkway 26

Ladder Extension 26

Ladder Safety Cage 26

Oil Level Sight Glass 27

Miscellaneous Options

Wood Cold Water Basin 27

Redwood Components 27

Hot Water Basin Covers 27

Air Inlet Screens 27

Low Noise Tower 28

Watertight Partitions Between Cells 29

Fire Safety Options 29

Page 3

Marley / Sigma 1000/1200 Cooling Tower

/

3

igma 1000/1200 towers are field-erected, general

S

purpose crossflow wood cooling towers, designed to

serve normal air conditioning and refrigeration systems

as well as medium sized industrial loads. They evolve

from the crossflow concept of towers pioneered by

Marley in 1938, and incorporate over 65 years of design

advancements that our customers have found valuable.

Sigma cooling towers represent the current state of the

art in this cooling tower category.

This publication not only relates the language to use

in describing an appropriate Sigma cooling tower—but

also defines why certain items and features are important

enough to specify with the intention of insisting upon

compliance by all bidders. The left hand column of pages

15 through 29 provides appropriate text for the various

specification paragraphs, whereas the right hand column

comments on the meaning of the subject matter and

explains its value.

Pages 15 through 22 indicate those paragraphs which

will result in the purchase of a cooling tower which will

not only accomplish the specified thermal performance,

but which will include normal operation and maintenanceenhancing accessories and features. It will also

incorporate those standard materials which testing and

experience has proven to provide best results in normal

operating conditions.

Pages 23 through 29 provide some paragraphs

intended to add those features, components, and

materials that will customize the tower to meet the user's

requirements.

Space does not permit definition and explanation

of all of the possible options that can be applied to the

Sigma. SPX Cooling Technologies realizes that you, the

purchaser, must be happy with the tower's characteristics,

and we are prepared to provide—or provide for—any

reasonable enhancement that you are willing to define

and purchase.

Your needs will become part of the continuing

improvement of this Marley product line.

Page 4

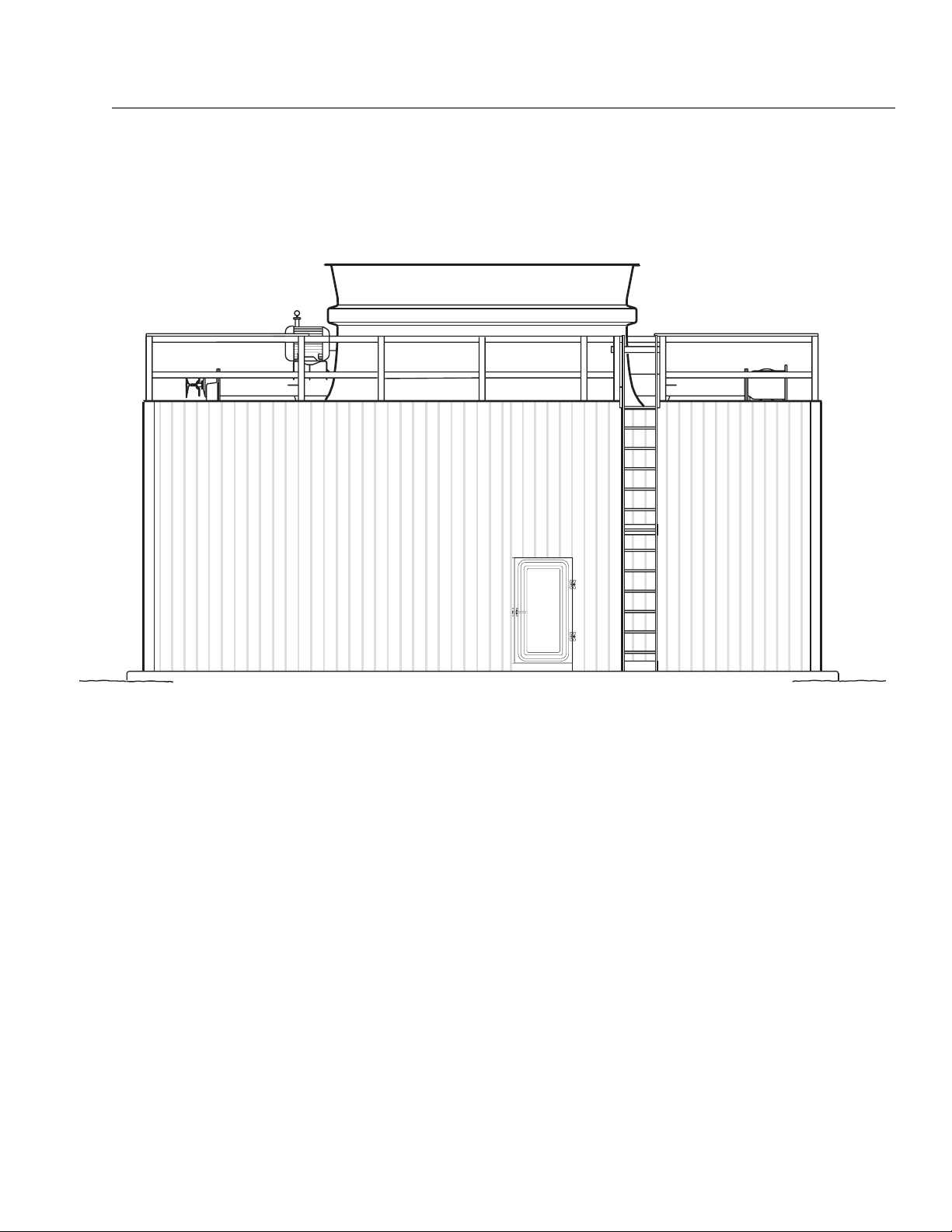

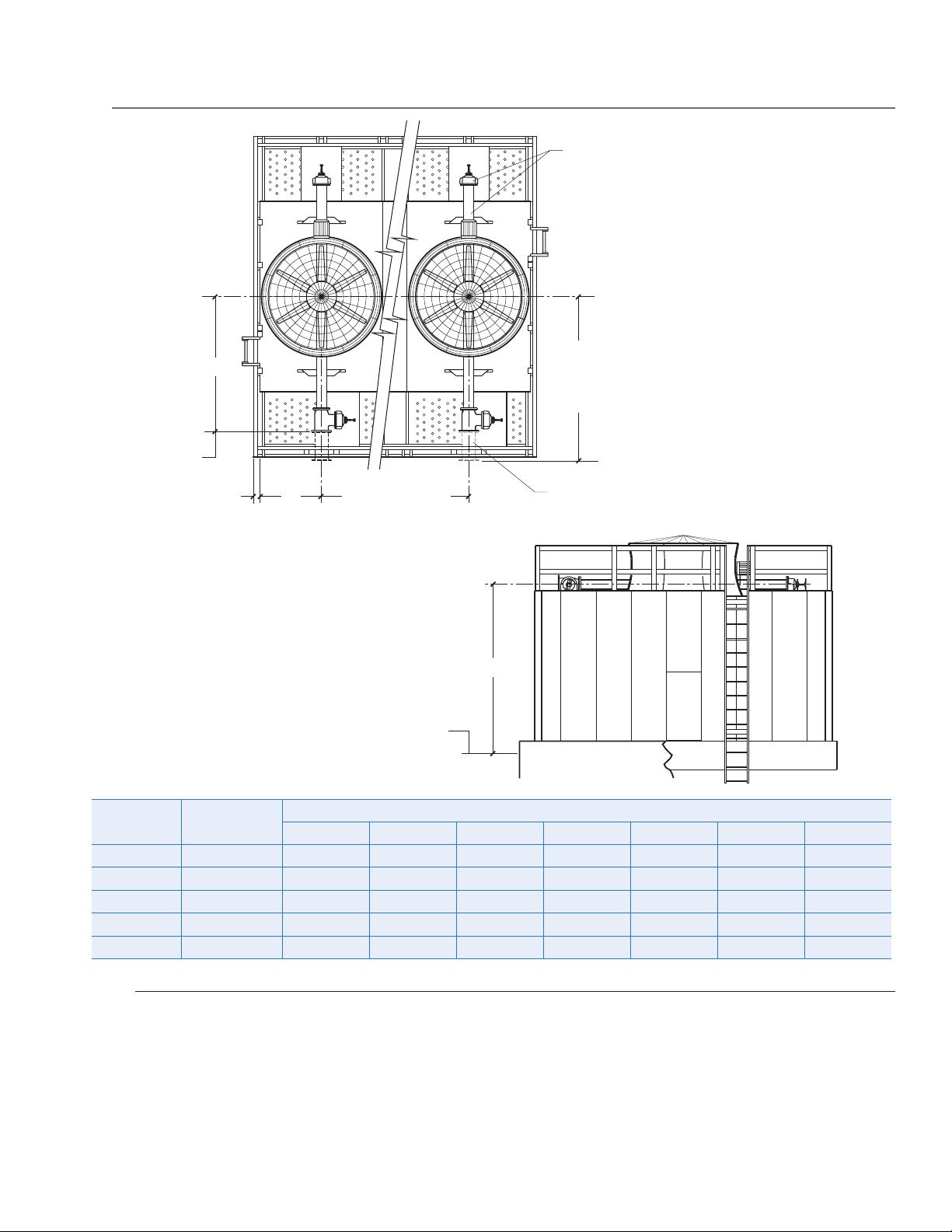

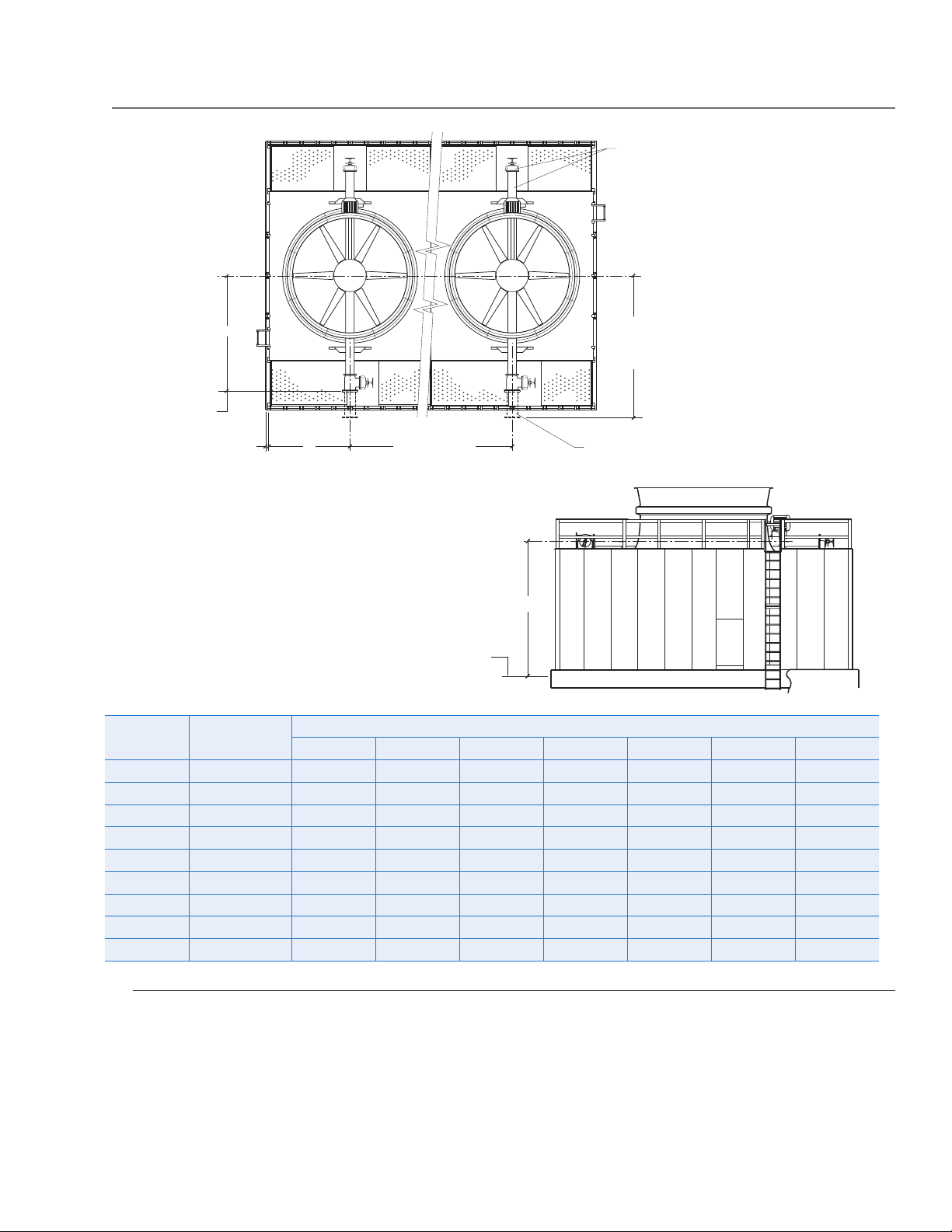

Marley / Sigma 1000 Cooling Tower / Engineering Data : Schematic

B

H

TOP OF

FAN CYLINDER

BASE OF

TOWER COLUMNS

TOP OF

FAN DECK

W OUT TO OUT OF TOWER

5"

C

L

COL.

A BAYS @ 4'-0 = L

C

L

COL.

C

L

COL.

5"

C DIA. FAN

PLAN

4

Tower

Model

1011 380 - 2140 21'-5" 8'-0" 11'-8

1021 580 - 3220 21'-5" 12'-0" 11'-8

1031 580 - 3220 23'-9" 12'-0" 11'-8

1041 790 - 4300 26'-0" 16'-0" 11'-8

GPM

per cell

Width

W

Length

L

NotE

1 Last number of model indicates number of cells. Change as

appropriate for your selection. Primary engineering data is per

cell.

2 Fan hp is usually less than shown here.

ENdwALL

ELEvAtioN

Height

H

5

⁄8" 2 3'-8" 84" 30 11.7'

5

⁄8" 3 3'-5" 96" 30 11.7'

5

⁄8" 3 3'-8" 120" 50 11.7'

5

⁄8" 4 4'-0" 144" 60 11.7'

A B C

3 Height shown is from base of tower columns to fan deck.

Wood basin, if used, elevates tower 6

used, subtract 1'-6" for height above top of basin curb.

Maximum

Motor hp

1

⁄4". If concrete basin is

Static

Lift

Page 5

Marley / Sigma 1000 Cooling Tower / Engineering Data : Piping

F MINIMUM

C

L

INLET

C

L

COL.

C

C

L

INLET

D TYP. MULTI-CELL

PIPING SHOWN WITH

DASHED LINES IS BY OTHERS

E

FACE OF A DIA.

INLET PIPING

C

L

TOWER FAN

C

L

TOWER FAN

B DIA. FLOW CONTROL

VALVE AND CROSS OVER

PIPING

G

BASE OF

TOWER COLUMNS

C

L

INLET

PLAN

5

ENdwALL

ELEvAtioN

Tower

Model

1011 380 - 2140 10" 8" 4'-0" 8'-0"

1021 580 - 3220 10" 8" 6'-0" 12'-0"

1031 580 - 3220 10" 8" 6'-0" 12'-0"

1041 790 - 3240 10" 8" 8'-0" 16'-0"

1041 3241 - 4300 16" 12" 8'-0" 16'-0"

NotE

1 Use this bulletin for preliminary layouts only. Obtain current

drawings from your Marley sales representative.

2 Pumping head contributed by the tower is static lift shown

on page 5. Actual pumping head will vary according to tower

circulating GPM. Total pumping head will be furnished at time

of proposal.

3 If your application requires a bypass system, recommended

location is through tower endwall into plenum area. Review

of the system by SPX Cooling Technologies engineering is

required.

GPM

per cell

A B C D E F G

4 Marley piping terminates at face of a cast iron flat face flange

which conforms to class 125 lb ASME B 16.1 specifications.

5 Supports on tower for crossover piping are part of the tower

design. Do not support the riser’s dead load or operating load

from the tower. Do not brace the riser’s seismic or thrust

loads against the tower.

Dimensions

8'-11

8'-11

10'-1

11'-2

11'-5

1

⁄8"

1

⁄8"

1

⁄8"

5

⁄8"

5

⁄8"

11'-8" 12'-57⁄8"

11'-8" 12'-57⁄8"

12'-10" 12'-57⁄8"

13'-111⁄2" 12'-57⁄8"

13'-111⁄2" 12'-87⁄8"

Page 6

Marley / Sigma 1000 Cooling Tower / Engineering Data : Support

W

OVERALL WIDTH OF BASIN

C

BAYS @ 4'-0 =

L

EACH ADDITIONAL CELL =

L

7

1/2

" 7

1/2

"

AIR INLET FACE

11

1/2

"

A

C

L

C

L

OVERALL LENGTH OF BASIN

C

L

C

L

B

A

B

C

L

TOWER

C

L

C

L

AIR INLET FACE

ENDWALL FACE

ENDWALL FACE

OVERFLOW

SUMP

ADDITIONAL SUMP

WHEN REQUIRED

11

1/2

"

7/8" ANCHOR

BOLT HOLES

7/8" ANCHOR

BOLT HOLES

7/8" ANCHOR

BOLT HOLES

C

L

7/8" ANCHOR

BOLT HOLES

7/8" ANCHOR

BOLT HOLES

6

NotE

1 Use this bulletin for preliminary layouts only. All

dimensions show anchor bolt locations. Obtain current

drawings from your Marley sales representative before

designing supports.

2 Other contractors or purchaser must design and erect

supporting steel.

3 If steel beams are used, they must include

accept anchor bolts provided. If concrete beams or pilasters

are used,

be provided by others.

Tower

Model

W A B C L Single Cell Each Cell Add

Dimensions Operating Weight lb

PLAN

1011 22'-1" 4'-10" 5'-3" 2 8'-0" 23620 20500

1021 22'-1" 4'-10" 5'-3" 3 12'-0" 32140 28980

1031 24'-5" 4'-10" 6'-5" 3 12'-0" 34440 31020

1041 26'-8" 4'-10" 7'-6

1

⁄2" 4 16'-0" 47620 44000

4 Maintain no less than 2'-0" of clear space at endwall faces for

construction purposes. Air inlet faces must have unobstructed

air supply. Consult your Marley sales representative if nearby

obstructions may interfere.

5 Operating weight is wet weight of tower and wood basin,

7

⁄8" dia. holes to

3

⁄4" dia. anchor bolts embedded in the concrete must

including 6" of water in the collection basin. This is the

recommended operating water level for all models.

Page 7

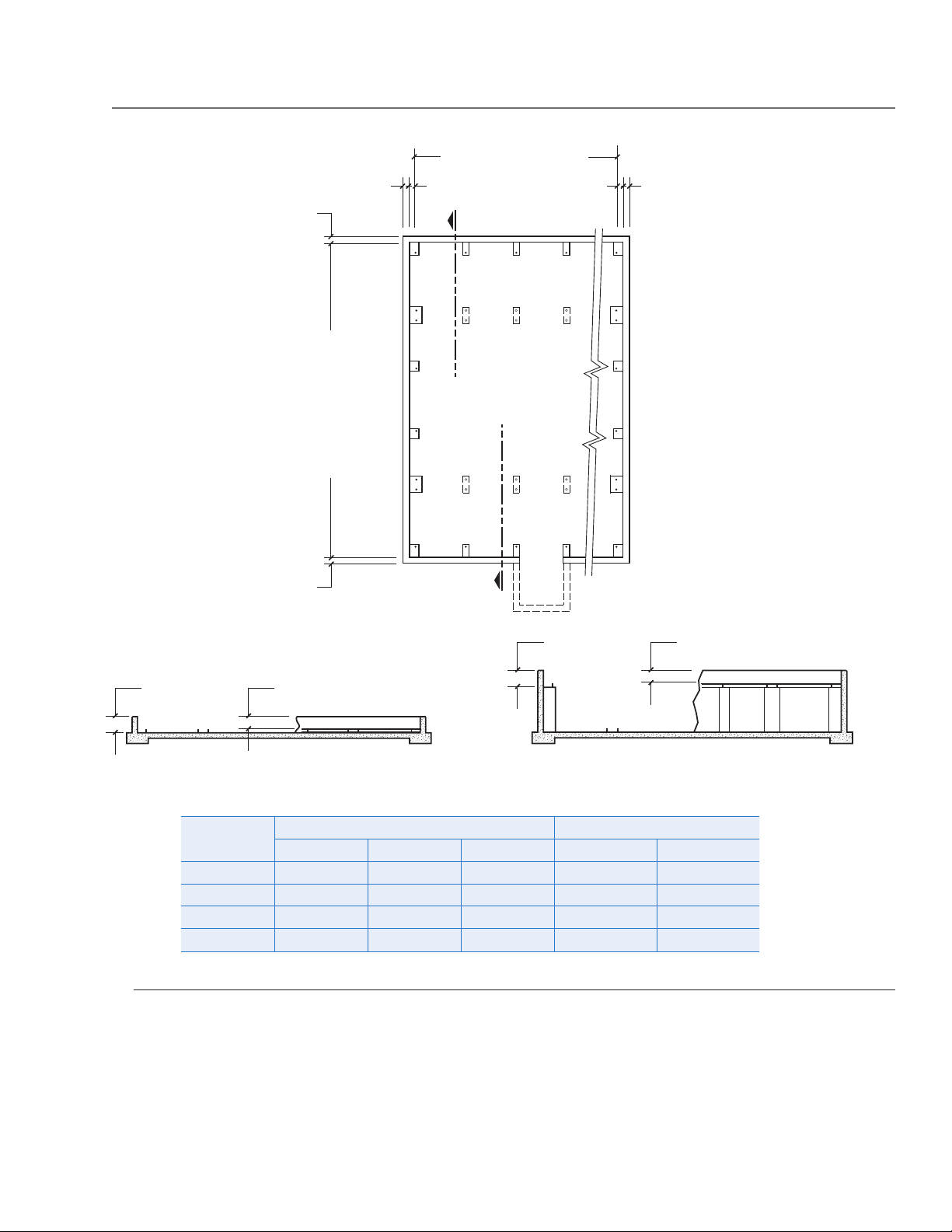

Marley / Sigma 1000 Cooling Tower / Engineering Data : Concrete Basin

1’-6

1'-0 RECOMMENDED

OPERATING WATER LEVEL

1’-6

1'-0 RECOMMENDED

OPERATING WATER LEVEL

A

BAYS @ 4'-0" = B PER CELL

6"

AIR INLET FACE

C

L

COL.

C

L

COL.

6" MIN. 6" MIN.

6"

W

IN TO IN OF BASIN WALLS

AIR INLET FACE

ENDWALL FACE

ENDWALL FACE

6" MIN.

6" MIN.

PLAN

7

FLAt BAsiN sEctioN dEEP BAsiN sEctioN

Tower

Model

Dimensions Operating Weigt lb

W A B Single Cell Each Cell Add

1011 21'-10" 2 8'-0" 15120 13500

1021 21'-10" 3 12'-0" 20160 18400

1031 24'-2" 3 12'-0" 21240 19500

1041 26'-5" 4 16'-0" 29020 27200

NotE

4 Minimum basin depth is 1'-6". Maximum basin depth is 5'-6".

Extended interior columns for deep basins are available as an

option. Perimeter columns remain at 1'-6" below top of basin

curb.

5 All anchor bolts complete with nut and washer must be

furnished by others. Bolts must be

projection.

6 Other contractors or purchaser must design, construct, and

furnish sump and overflow to suit requirements.

1 Use this bulletin for preliminary layouts only. Do not use for

construction. Obtain current drawings from your Marley sales

representative. Concrete basin design and construction are by

other contractors or purchaser.

2 Operating weight is total wet operating weight of tower only,

excluding water in concrete basin.

3 Maintain at least 2'-0" of clear space at endwall faces for

construction purposes. Air inlet faces must have unobstructed

air supply. Consult your Marley sales representative for

recommendations if nearby obstructions may interfere.

3

⁄4"diameter with 2" all-thread

Page 8

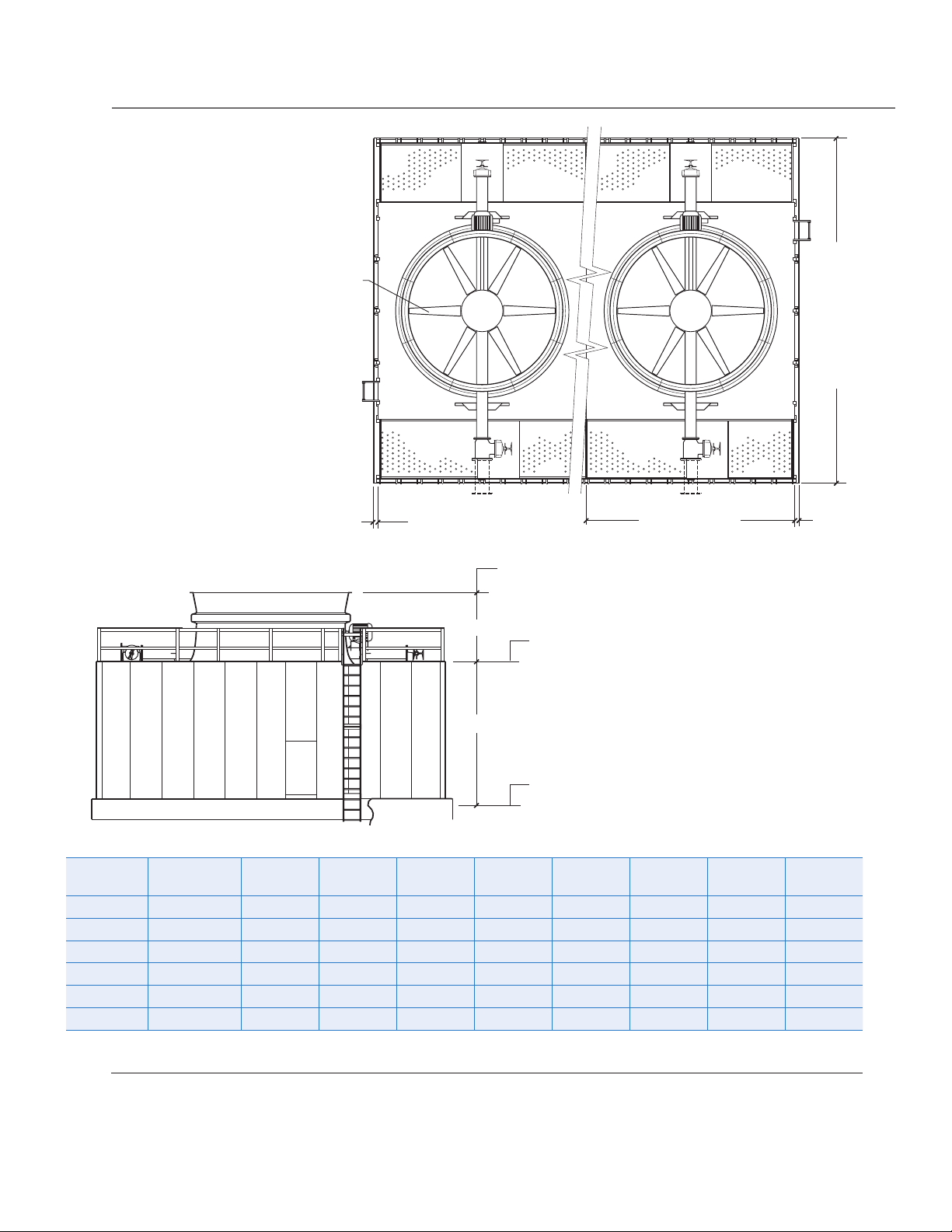

Marley / Sigma 1200 Cooling Tower / Engineering Data : Schematic

B

H

TOP OF

FAN CYLINDER

BASE OF

TOWER COLUMNS

TOP OF

FAN DECK

W OUT TO OUT OF TOWER

5"

C

L

COL.

A BAYS @ 4'-0 = L

C

L

COL.

C

L

COL.

5"

C DIA. FAN

PLAN

8

Tower

Model

GPM

Per Cell

Width

W

Length

L

Height

1211 1050 - 5750 31'-2" 16'-0" 14'-5

1221 1050 - 5750 33'-2" 16'-0" 14'-5

1231 1320 - 7200 33'-2" 20'-0" 14'-5

1241 1500 - 8650 33'-2" 24'-0" 14'-5

1251 1500 - 8650 37'-2" 24'-0" 14'-5

1261 1850 - 10100 37'-2" 28'-0" 14'-5

NotE

1 Last number of model indicates number of cells. Change as

appropriate for your selection. Primary engineering data is per

cell.

2 Fan hp is usually less than shown here.

ENdwALL

ELEvAtioN

H

1

⁄8" 4 6'-0" 144" 60 14.5'

1

⁄8" 4 7'-0" 168" 75 14.5'

1

⁄8" 5 7'-0" 168" 75 14.5'

1

⁄8" 6 7'-0" 168" 75 14.5'

1

⁄8" 6 7'-0" 216" 10 0 14.5'

1

⁄8" 7 7'-0" 216" 10 0 14.5'

A B C

3 Height shown is from base of tower columns to fan deck. Wood

basin, if used, elevates tower 6

subtract 1'-6" for height above top of basin curb.

Maximum

Motor hp

1

⁄4". If concrete basin is used,

Static

Lift

Page 9

Marley / Sigma 1200 Cooling Tower / Engineering Data : Piping

G

BASE OF

TOWER COLUMNS

C

L

INLET

F

MINIMUM

C

L

INLET

C

L

COL.

C

C

L

INLET

D

TYP. MULTI-CELL

PIPING SHOWN WITH

DASHED LINES IS BY OTHERS

E

FACE OF A DIA.

INLET PIPING

C

L

TOWER FAN

C

L

TOWER FAN

B

DIA. FLOW CONTROL

VA LV E AND CROSS OVER

PIPING

PLAN

9

ENdwALL

ELEvAtioN

Tower

Model

1211 1050 - 5750 16" 12" 8'-0" 16'-0" 13'-2

1221 1050 - 5750 16" 12" 8'-0" 16'-0" 14'-2

1231 1320 - 7200 16" 12" 10'-0" 20'-0" 14'-2

1241 1500 - 7050 16" 12" 12'-0" 24'-0" 14'-2

1241 7051 - 8650 20" 16" 12'-0" 24'-0" 14'-5

1251 1500 - 7050 16" 12" 12'-0" 24'-0" 16'-2

1251 7051 - 8650 20" 16" 12'-0" 24'-0" 16'-5

1261 1850 - 7050 16" 12" 14'-0" 28'-0" 16'-2

1261 7051 - 10100 20" 16" 14'-0" 28'-0" 16'-5

NotE

1 Use this bulletin for preliminary layouts only. Obtain current

drawings from your Marley sales representative.

2 Pumping head contributed by the tower is static lift shown

on page 9. Actual pumping head will vary according to tower

circulating GPM. Total pumping head will be furnished at time

of proposal.

3 If your application requires a bypass system, recommended

location is through tower endwall into plenum area. Review

of the system by SPX Cooling Technologies engineering is

required.

GPM

Per Cell

A B C D E F G

Dimensions

3

⁄4" 16'-63⁄8" 15'-63⁄8"

3

⁄4" 17'-63⁄8" 15'-63⁄8"

3

⁄4" 17'-63⁄8" 15'-63⁄8"

3

⁄4" 17'-63⁄8" 15'-63⁄8"

3

⁄4" 17'-63⁄8" 15'-83⁄8"

3

⁄4" 19'-63⁄8" 15'-63⁄8"

3

⁄4" 19'-63⁄8" 15'-83⁄8"

3

⁄4" 19'-63⁄8" 15'-63⁄8"

3

⁄4" 19'-63⁄8" 15'-83⁄8"

4 Marley piping terminates at face of a cast iron flat face flange

which conforms to class 125 lb. ASME B 16.1 specifications.

5 Supports on tower for crossover piping are are part of the tower

design. Do not support the riser’s dead load or operating load

from the tower. Do not brace the riser’s seismic or thrust loads

against the tower.

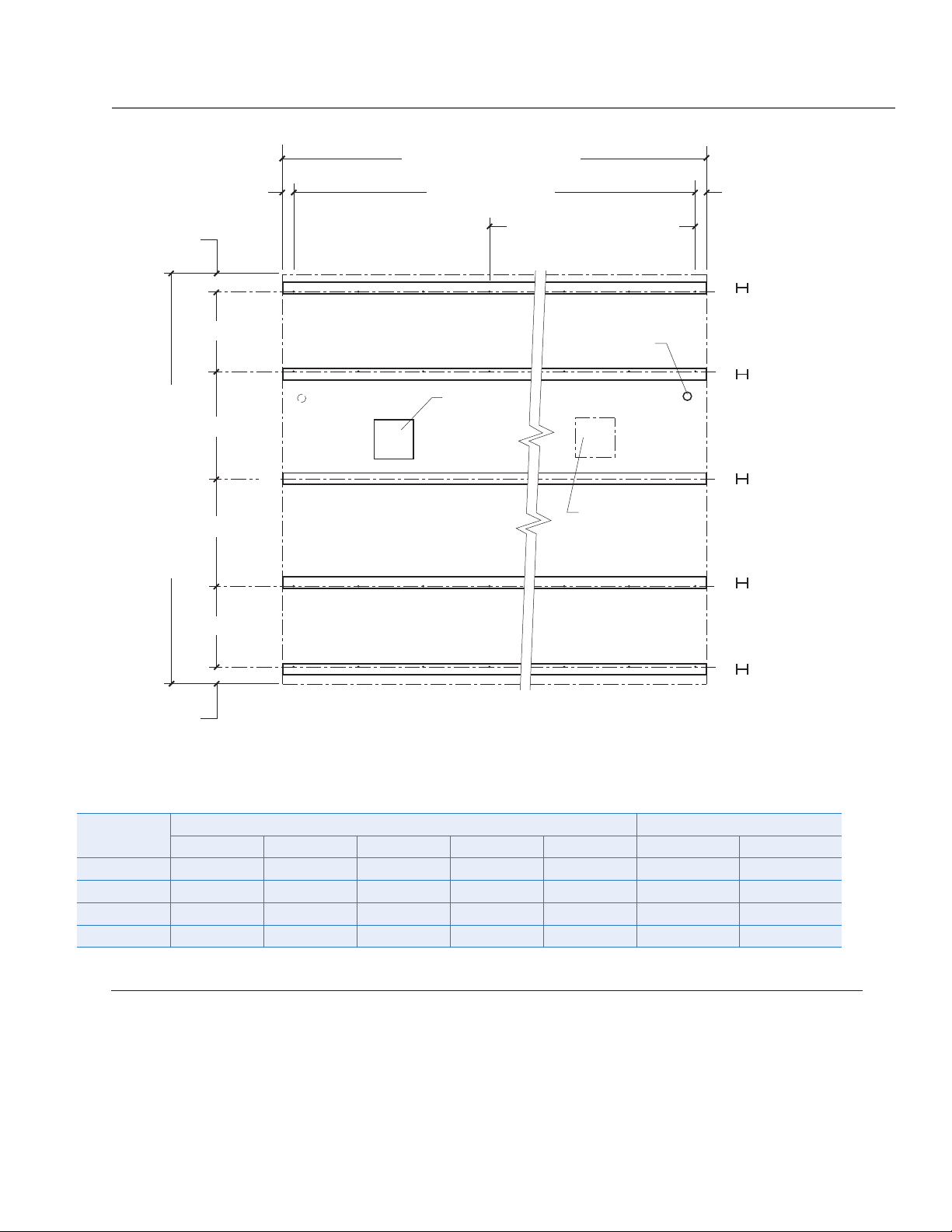

Page 10

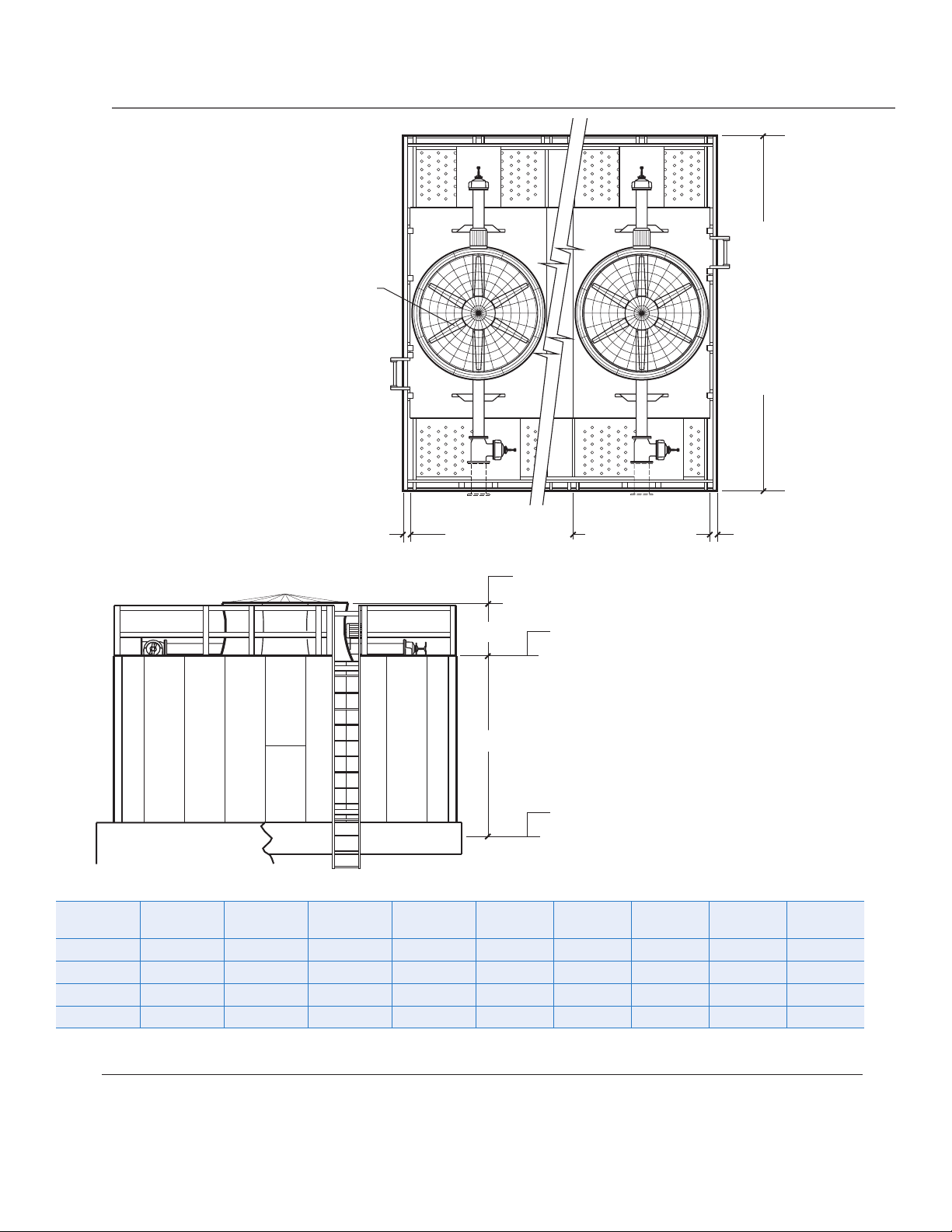

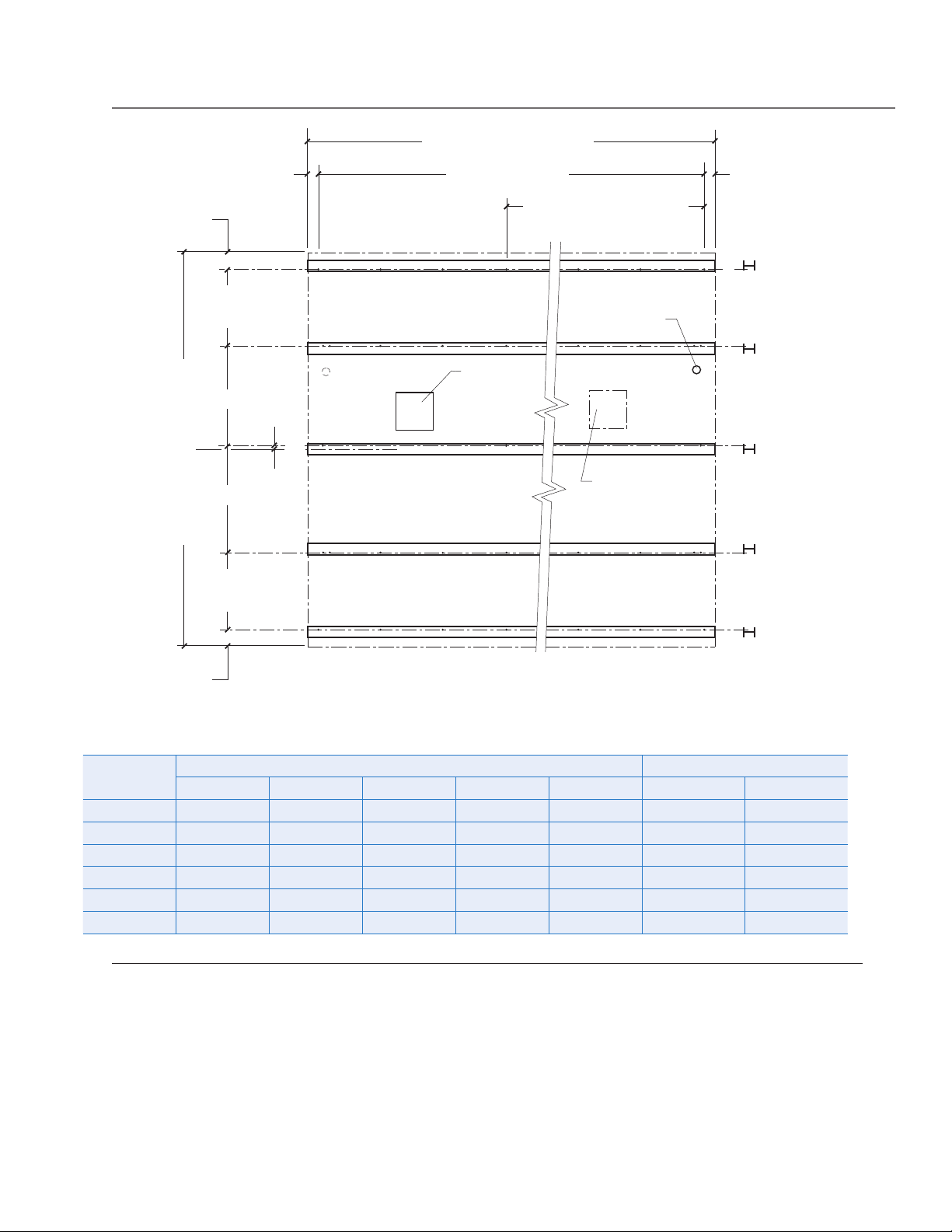

Marley / Sigma 1200 Cooling Tower / Engineering Data : Support

W

OVERALL WIDTH OF BASIN

C

BAYS @ 4'-0 =

L

EACH ADDITIONAL CELL =

L

7

1/2

" 7

1/2

"

AIR INLET FACE

OVERALL LENGTH OF BASIN

C

L

C

L

C

L

COL.

B

A

C

L

TOWER

C

L

ANCHOR

BOLT

C

L

ANCHOR

BOLT

C

L

ANCHOR

BOLT

C

L

ANCHOR

BOLT

C

L

ANCHOR

BOLT

ANCHOR BOLT ANCHOR BOLT

AIR INLET FACE

ENDWALL FACE

ENDWALL FACE

OVERFLOW

SUMP

ADDITIONAL SUMP

WHEN REQUIRED

11

5/8

"

11

5/8

"

6'-9

3/8

"

4"

6'-9

3/8

"

BASIN

10

NotE

1 Use this bulletin for preliminary layouts only. All

dimensions show anchor bolt locations. Obtain current

drawings from your Marley sales representative before

designing supports.

2 Note carefully anchor bolt location relative to beam orientation.

See plan above.

3 Other contractors or purchaser must design and erect

supporting steel.

4 If steel beams are used, they must include

accept anchor bolts provided. If concrete beams or pilasters

are used,

be provided by others.

Tower

Model

W A B C L Single Cell Each Cell Add

Dimensions Operating Weight lb

PLAN

1211 31'-10" 8'-6" 7'-10" 4 16'-0" 61250 55900

1221 33'-10" 9'-6" 8'-10" 4 16'-0" 65530 60660

1231 33'-10" 9'-6" 8'-10" 5 20'-0" 77960 73110

1241 33'-10" 9'-6" 8'-10" 6 24'-0" 93790 88940

1251 37'-10" 11'-6" 10'-10" 6 24'-0" 101020 95740

1261 37'-10" 11'-6" 10'-10" 7 28'-0" 116260 111 0 0 0

5 Maintain no less than 2'-0" of clear space at Endwall Faces for

construction purposes. Air Inlet Faces must have unobstructed

air supply. Consult your Marley sales representative if nearby

obstructions may interfere.

6 Operating weight is wet weight of tower and wood basin,

including 6" of water in the collection basin. This is the

recommended operating water level for all models.

7

⁄8" dia. holes to

3

⁄4" dia. anchor bolts embedded in the concrete must

Page 11

Marley / Sigma 1200 Cooling Tower / Engineering Data : Concrete Basin

1’-6

1'-0 RECOMMENDED

OPERATING WATER LEVEL

1’-6

1'-0 RECOMMENDED

OPERATING WATER LEVEL

A

BAYS @ 4'-0" = B PER CELL

6"

AIR INLET FACE

C

L

COL.

C

L

COL.

6" MIN. 6" MIN.

6"

W

IN TO IN OF BASIN WALLS

AIR INLET FACE

ENDWALL FACE

ENDWALL FACE

6" MIN.

6" MIN.

PLAN

11

FLAt BAsiN sEctioN dEEP BAsiN sEctioN

Tower

Model

1211 31'-6

1221 33'-6

1231 33'-6

1241 33'-6

1251 37'-6

1261 37'-6

NotE

1 Use this bulletin for preliminary layouts only. Do not use for

construction. Obtain current drawings from your Marley sales

representative. Concrete basin design and construction are by

other contractors or purchaser.

2 Operating weight is total wet operating weight of tower only,

excluding water in concrete basin.

3 Maintain at least 2'-0" of clear space at endwall faces

for construction purposes. Air inlet faces must have

an unobstructed air supply. Consult your Marley sales

representative for recommendations if nearby obstructions may

interfere.

W A B Single Cell Each Cell Add

3

3

3

3

3

3

Dimensions Operating Weight lb

⁄4" 4 16'-0" 39040 35910

⁄4" 4 16'-0" 41960 39420

⁄4" 5 20'-0" 49100 46560

⁄4" 6 24'-0" 59020 56470

⁄4" 6 24'-0" 61200 58530

⁄4" 7 28'-0" 70900 68240

4 Minimum basin depth is 1'-6". Maximum basin depth is

5'-6". Extended interior columns for deep basins are available as

an option. Perimeter columns remain at 1'-6" below top of basin

curb.

5 All anchor bolts complete with nut and washer must be

furnished by others. Bolts must be

thread projection.

6 Other contractors or purchaser must design, construct, and

furnish sump and overflow to suit requirements.

3

⁄4" diameter with 2" all-

Page 12

Marley / Sigma 1000/1200 Cooling Tower / Engineering Data: Energy Management

12

Cooling towers are usually selected to produce a specific

cold water temperature at the higher summer-time wet-bulb

temperatures. During the remainder of the year, the cooling

tower is capable of producing much colder water. Unless your

system will benefit from the coldest possible water temperature, you should consider controlling cold water temperatures

to higher levels. You’ll also save energy by using such control.

See Marley Technical Report #H-001A, “Cooling Tower Energy

and its Management”.

Always control leaving water temperature by manipulating

the quantity of air that the fan moves through the tower. Varying the quantity of water flow is not normally recommended

and can be harmful in freezing weather. You can alternately

start and stop single-speed motors to maintain water temperatures within an acceptable range. However, exceeding a total

acceleration time of 30 seconds per hour can overheat the motor, causing the insulation to fail. Limiting the number of motor

starts, on the other hand, can produce significant variations in

the temperature of the water delivered to the process.

Increased flexibility can simplify your operating procedures

and save you money in the long run, both on operation and on

maintenance. Here are two of the more popular options.

Two-Speed Motors

Two-speed motors improve operating flexibility by increasing the number of potential operating modes. Users in northern climates will find that the tower can carry winter loads at

half-speed; reducing fan power requirements by 85+% during

that time. Two-speed motors also help to control icing during

wintertime operation. See Marley Technical Report #H-003,

“Operating Cooling Towers During Freezing Weather”.

Normally, two-speed motors are provided in 1800/900

RPM, single winding configuration, which is the least expensive two-speed option. They are also available in other combinations including the more expensive double winding.

Variable Speed Control

Frequency modulation devices work well on induced draft,

propeller fan cooling towers such as the Sigma. However, their

design must include the capability to lock out any critical fan

speeds and the very low fan speed ranges.

Marley VFD drive systems are designed to combine absolute temperature control with ideal energy management. The

cooling tower user selects a cold water temperature and the

drive system will vary the fan speed to maintain that temperature. Precise temperature control is accomplished with

far less stress to the mechanical equipment components. The

improved energy management provides fast payback. Indeed,

many utilities offer generous rebates for users having installed

VFD drives.

Page 13

Marley / Sigma 1000/1200 Cooling Tower / Engineering Data: Environmental

13

Enclosures

Occasionally, cooling towers are located inside architectural

enclosures for aesthetic reasons. Although Sigma towers

adapt well to enclosures, a poorly designed enclosure can

impair proper operation. An effective design includes generous air inlet paths, with the tower’s fan cylinder discharge at

or above the top of the enclosure. See Marley Technical Report

#H-004, “ External Influences on Cooling Tower Performance”, for design recommendations.

It may also be advisable to increase your design wet-bulb

temperature by 1°F to compensate for potential recirculation

initiated by the enclosure. You’ll benefit from discussing your

project with your Marley sales representative.

Sound Control

A Sigma tower operating in an unobstructed environment

will meet all but the most restrictive noise limitations – and

will react favorably to natural attenuation. Where the tower will

operate within an enclosure, the enclosure itself will usually

have a damping effect on sound. Distance will also reduce

sound – by about 5 dBA each time the distance is doubled.

Where noise at a critical point is likely to exceed an acceptable

limit, you have several options, listed below in ascending order

of cost impact:

Noise concerns are often limited to nighttime, when ambient noise levels are lower and neighbors are trying to sleep.

You can usually resolve these situations by using two-speed

motors in either 1800/900 or 1800/1200 RPM configuration;

and operating the fans at reduced speed without cycling “after

hours”. This relatively inexpensive solution pays for itself quickly

in reduced energy costs.

System Cleanliness

Cooling towers are very effective air washers. Atmospheric

dust able to pass through the relatively small louver openings

will enter the circulating water system. Increased concentrations can intensify system maintenance by clogging screens

and strainers; and smaller particulates can coat system heat

transfer surfaces. In areas of low flow velocity (such as the

cold water basin), sedimentary deposits can provide a breeding ground for bacteria.

In areas prone to dust and sedimentation, you should consider installing some means for keeping the cold water basin

clean. Typical devices include side stream filters and a variety

of filtration media.

You should also plan ahead to develop a consistent, effective program of water treatment. A good water treatment

program will help to assure long service life, while keeping

your tower free of potentially harmful biological growths.

CAUTION

The cooling tower must be located at such distance

and direction to avoid the possibility of contaminated

discharge air being drawn into building fresh air

intake ducts. The purchaser should obtain the services

of a Licensed professional Engineer or Registered

Architect to certify that the location of the cooling

tower is in compliance with applicable air pollution,

fire and clean air codes.

Where the problem can exist at all times (such as near a

hospital), the best solution is to oversize the tower so it can

operate continuously at reduced (1200 or 900 RPM) motor

speed. Typical sound reductions are 7 dB at 2/3 fan speed or

10 dB at 1/2 fan speed.

Extreme cases may require inlet and discharge sound attenuator sections; however, the static pressure loss imposed

by attenuators may necessitate an increase in tower size.

This is the least desirable approach because of its significant

cost impact – and because it obstructs normal maintenance

procedures.

Your Marley sales representative can help you meet your

sound requirements.

Page 14

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

14

Specifications

1.0 Base:

1.1 Furnish and install an induced-draft,

crossflow-type, field-erected, woodframed, PVC fill, industrial-duty cooling

tower of _____ cell(s), as shown on

Plans. The limiting overall dimensions

of the tower shall be _____ wide, ___

__ long, and _____ high to the top of

the fan cylinder. Total operating horsepower of all fans shall not exceed

____ hp, consisting of ___ @ _____ hp

motor(s). Tower shall be similar and

equal in all respects to Marley Model

_______.

Specification Value

■ Your specification base establishes the type, configuration, base

material, and physical limitations of the cooling tower to be

quoted. During the planning and layout stages of your project,

you will have focused your attention on a cooling tower selection

that fits your space allotment, and whose power usage is acceptable. Limitations on physical size and total operating horsepower

avoid the introduction of unforeseen operational and site-related

influences. Specifying the number of cells, and the maximum fan

hp/cell will work to your advantage.

Crossflow towers are noted for the accessibility and maintainability of all operating components. The spacious interior provides

easy access to fill, drift eliminators, all basin accessories—and is

one of two primary accessways to the fan, Geareducer, and other

mechanical components.

At the fan deck level, the hot water distribution basins are easily

inspected and cleaned—while the tower is operating, if you wish.

The mechanical equipment can also be readily accessed from this

level.

Except for the cold water basin, no counterflow tower component

requiring routine maintenance is as easily accessed. The confined

areas that typify counterflow designs can make difficult work for

maintenance personnel!

Page 15

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

55°

50° 55° 60° 65° 70° 75° 80°

5°F RANGE

10°F RANGE

15°F RANGE

60°

65°

70°

75°

COLD WATER TEMP. (°F)

WET BULB TEMP. (°F)

80°

85°

90°

95°

15

Specifications

2.0 Thermal Performance:

2.1 The tower shall be capable of cooling

_____ GPM of water from ____ °F to

_____ °F at a design entering air wetbulb temperature of _____ °F. The cooling tower manufacturer shall guarantee

that the tower supplied will meet

the specified performance conditions

when the tower is installed according

to plans.

2.2 The purchaser will arrange for an

on-site thermal performance test, to

be conducted in the presence of the

manufacturer and owner, and under

the supervision of a qualified, disinterested third party in accordance with

CTI (Cooling Technology Institute) ATC105 standards during the first full year

of operation. If the tower fails to perform within the limits of test tolerance,

then the cooling tower manufacturer

will install additional cells and/or make

such corrections as are agreeable to

the owner and shall pay for the cost of

a retest. If the tower still fails to perform as specified, then the manufacturer shall make such reimbursements

as are appropriate and agreeable to the

owner to compensate for the performance deficiency.

Specification Value

■ Your reason for purchasing a cooling tower is to obtain a con-

tinuing flow of cooled water as defined in the first paragraph at

left. If the tower that you purchase is incapable of performing

as specified, then you will not have received full value for your

money.

Bear in mind that the size—and cost—of a cooling tower varies directly with its true thermal capability. This paragraph is

intended to protect you against either intentional or inadvertent

under sizing of the tower by the manufacturer. Judging the level

of performance of a cooling tower on critical processes is never

easy, and the potential risk of a non-performing cooling tower

usually causes the requirement for a mandatory acceptance test

to be very desirable.

Your contract with the successful bidder should establish the

acceptable remedies for missed performance, which might

include:

• The addition of one or more cells of tower, as necessary, to

bring the cooling tower to the specified level of performance.

This is usually limited to the scope of work as defined in the

specs, which means that you (the owner) will have to pay for

the additional basin, wiring, starters, piping, etc.

• The reimbursement of a portion of the total contract price equal

to the percentage deficiency in performance.

Under no circumstances should you allow the manufacturer to

re-pitch the fans to increase motor brake horsepower above that

shown in the proposal. That creates additional operating costs

that will continue for the life of the tower—and imposes no penalty on the manufacturer.

Typical cooling tower performance curve.

Page 16

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

16

Specifications

3.0 Construction:

3.1 The tower shall be capable of with-

standing water having a pH of 6.5 to

8.0; a chloride content (NaCl) up to 750

ppm; a sulfate content (SO4) up to

1200 ppm; a sodium bicarbonate content (NaHCO3) up to 200 ppm; a calcium content (CaCO3) up to 800 ppm;

silica (SiO2) up to 150 ppm; and design

hot water temperatures up to 120°F.

The circulating water will contain no

oil, grease, fatty acids, or organic solvents.

3.2 The structural framework of the tower

shall be Douglas Fir, designed in accordance with CTI STD-114. Nylon shear

plates shall be utilized to transmit loads

at critical joints, and all fasteners shall

be in accordance with CTI STD-119.

Basic design criteria shall be 30 psf

wind load and 5%g seismic load.

3.3 All wood components shall be treated

after fabrication with chromated copper arsenate (CCA) by the full-cell

process to a chemical retention of 0.4

3

lbs/ft

.

3.4 Structural columns and diagonals shall

be 4"x4". Framing girts may be 2"x4",

except for those supporting the hot

water basins and fill. Those girts shall

be 2"x6" minimum, located both sides

of the support columns.

3.5 Multicell towers shall include treated

Douglas Fir plywood partitions

between cells in the plenum area.

Partitions shall extend the full height of

the tower from the base of fill to the

underneath side of the fan deck.

3.6 Column lines shall be on no greater

than 4'-0" longitudinal centers, and

the base of all perimeter columns

shall be firmly anchored to galvanized

steel base plates. Framing joints shall

be made with 1/2" diameter or larger

series 300 stainless steel machine

bolts, nuts and washers.

Specification Value

■ The limiting water quality values indicated are those which are

acceptable for the normal materials of construction specified. If

water of more aggressive quality is anticipated please change

hardware material requirement to 300 Series stainless steel, as

indicated below and following.

Cooling Technology Institute standards take into account the hot,

humid environment in which a cooling tower normally operates.

This environment can render the limits of customary construction

standards inadequate for cooling tower design.

The importance of shear plates is discussed at length in

Marley Difference, “Item S-3”. Ask your Marley representative for

a copy.

See notes on page 27 regarding the use and availability of redwood.

Specification of minimum member sizes assures that all offerings

will conform to an industrial level of construction.

Multicell towers must have plenum partitions between cells.

Otherwise, air will be induced downward through an inoperative

fan, bypassing the fill entirely. Without these partitions, part-load

or off-season operation of the tower would be completely unsatisfactory.

Page 17

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

17

Specifications

4.0 Fan Deck and Fan Cylinder:

4.1 The fan deck shall act as a working

platform for maintenance personnel.

It shall be fabricated of no less than

1" thick, 7 ply, exterior grade, treated

Douglas Fir plywood, and shall be

designed for a uniform live load of

60 psf or a concentrated load of 600

pounds.

4.2 Fan cylinders shall be molded FRP.

They shall be anchored to the fan deck

structure to provide a consistently

stable operating shroud for the fan.

Fan cylinders less than 72" in height

shall be equipped with a heavy gauge,

removable, hot-dip galvanized steel fan

guard for the protection of operating

personnel.

Specification Value

■ The indicated design values for framing and decking not only give

you assurance that the tower can withstand long term operation

in a hostile environment—but that it will accept many years of

inspection and maintenance traffic by your operating personnel.

Fiberglass-reinforced polyester fan cylinders provide the close tip

clearances and smooth airflow contour necessary for good fan

performance. The inert, noncorroding nature of FRP assures that

these characteristics will persist.

Even in aggressive water conditions, the heavy construction of

the fan guard normally precludes the need for stainless steel.

Diagonal and Column Anchorage

Diagonal Connector

Page 18

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

18

Specifications

5.0 Mechanical Equipment:

5.1 Fan(s) shall be propeller-type, incorpo-

rating heavy duty blades of cast aluminum or high strength, inert composite

material. Blades shall be individually

adjustable and replaceable. Fan(s) shall

be driven through a rightangle, industrial-duty, oil-lubricated, geared speed

reducer. Speed reducers employing

pulleys and belts will not be accepted.

5.2 Motor(s) shall be ____ hp maximum,

TEFC, 1.15 service factor, and specially

insulated for cooling tower duty. Speed

and electrical characteristics shall be

1800 (1800/900) RPM, single winding,

___ phase, ___ hertz, ___ volts.

5.3 Motor shall be located outside the fan

cylinder at the fan deck, and shall be

connected to the speed reducer by

a tubular stainless steel, dynamically

balanced driveshaft equipped with neoprene flexible coupling elements.

5.4 A galvanized oil gauge and drain line

shall extend from the gear reducer to

the vicinity of the motor, and shall be

equipped with a dip stick for oil level

measurement.

5.5 The complete mechanical equipment

assembly for each cell shall be supported by a rigid, unitized support that

resists misalignment between the

motor and the gear reducer. Support

shall be heavy-wall tubular steel, to

which heavy plate platforms for the

motor and gear reducer have been

welded and the assembly shall be hotdip galvanized after fabrication. The

support assembly shall also provide

an inlet connection for incoming hot

water, and shall serve as a crossover

pipe to deliver water to both sides of

the tower.

5.6 The mechanical equipment assembly

shall be warranted for no less than five

(5) years. This warranty shall cover the

fan(s), speed reducers, driveshafts and

couplings, and the unitized supports.

Specification Value

■ Standard fan drives of other manufacturers may use V-belts.

Considering the size of fans involved—and the horsepowers

applied—this is not good design practice. Geareducer

far more reliable and trouble free, and is currently offered as an

option by at least two other cooling tower manufacturers.

Unless otherwise specified, motor speed will be 1800 RPM in

60 Hertz areas and 1500 RPM in 50 Hertz areas. If you prefer the

operating flexibility of two-speed operation, please specify the

RPM to be 1800/900 (1500/750 in 50 Hertz regions).

The driveshaft turns at the motor speed and is, therefore, most

sensitive to operational imbalance. Stainless steel manufacture

assures that the driveshaft will not become unbalanced as a

result of corrosion.

The extended oil line to an external dip stick provides a convenient means of checking the level of oil in the Geareducer. As

indicated on page 27, a sight glass is also available in lieu of the

dip stick.

Fans of the

size used on

large cooling

towers are

applied at

speeds and

horsepowers

that generate

considerable

torque—and

structural

tubular steel

resists this

torque very

effectively. The Marley torque-tube assures that all of the mechanical equipment remains aligned, and that the rotating fan is properly positioned within the fan cylinder. Hot-dip galvanizing after

fabrication assures that all steel surfaces will be heavily coated

with zinc for long-term protection against corrosion.

Even in aggressive water conditions, the heavy construction of

the unitized support normally precludes the need for stainless

steel.

The value of a 5 year mechanical equipment warranty speaks for

itself. Except for the motor, all of the mechanical equipment on

a Marley tower is made by SPX Cooling Technologies. Cooling

tower vendors who purchase commercial fans, gear boxes,

driveshafts, etc. may require that you deal directly with those

commercial suppliers for warranty satisfaction.

®

drive is

Page 19

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

19

Specifications

6.0 Fill, Louvers and Drift Eliminators:

6.1 Fill shall be film-type, 15 mil thick,

thermoformed PVC, with louvers

formed as part of each fill sheet. Fill

shall be suspended from stainless

steel structural tubing supported from

the upper tower structure, and shall

be elevated above the floor of the cold

water basin to facilitate cleaning. Air

inlet faces of the tower shall be free of

water splash-out.

6.2 Drift eliminators shall be PVC, triple-

pass, and shall limit drift losses to no

more than 0.010% of the design GPM

flow rate.

Specification Value

■ Louvers integral with the fill

keep the flowing water within

the confines of the fill. The separate external louvers used by

others permit water to escape

the fill and form ice or produce

an unsightly situation adjacent

to the tower. If you plan to use

your tower in the wintertime,

particularly for free cooling,

integral louvers will put your

operating concerns to rest.

Vertical blade-type eliminators, as

well as misdirected cellular types, cause

much of the fan power to be wasted in turning the horizontal flow of air vertical for its exit through the fan

cylinder. This power is, of course, not available for contribution to

thermal performance.

Drift rate varies with design water loading and air rate, as well

as drift eliminator depth and number of directional changes. The

indicated rate of 0.010% or less is easily achievable without premium cost. If a lower rate is required, please discuss with your

Marley sales representative.

Louver

Section

Drift Eliminator

Section

Fill Section

Page 20

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

20

Specifications

7.0 Hot Water Distribution System:

7.1 The mechanical equipment support/

crossover pipe shall deliver water to

two open hot water basins per cell

at the fan deck elevation. Water shall

exit these basins to the fill by gravity

through metering orifice-type polypropylene nozzles situated in the basin

floor. Nozzles shall be easily removable

and replaceable.

7.2 Heavy-duty, industrial grade flow-

control valves shall be provided at

the inlet to each basin. These valves

shall permit both flow balancing and

maintenance shut-off to selected cells,

or portions of cells. Valves shall have

machined cast iron bodies, with stainless steel operating stems, and heavyduty locking handles.

8.0 Casing:

8.1 Tower endwalls shall be cased with

ribbed FRP panels, lapped and sealed

to prevent leakage. Tower corners shall

be finished with FRP corner rolls.

Specification Value

■ Gravity-flow distribution basins are a feature of crossflow type

towers. These basins are out where they can be easily inspected—even maintained—while the tower is in operation. Spray

systems of counterflow towers, sandwiched between the top of

the fill and the drift eliminators, are extremely awkward to access

and maintain.

Marley flow-control valves remain serviceable for the life of

the tower, and provide a continuing means of flow-regulation

between hot water basins—and between cells of multicell towers

as well. Towers without valves do not provide this valuable operating flexibility.

9.0 Access:

9.1 Single cell towers shall include a 33"

wide by 61" high molded FRP access

door in one endwall casing for access

to the interior of the tower. Casing

access door shall be hinged and

equipped with a latch operable from

both inside and outside the tower.

Multicell towers shall have an access

door in both endwalls, and shall include

a lift-out door in each transverse partition to give free access through the

tower.

9.2 The top of the tower shall be equipped

with a sturdy 42" high wood guardrail

system; top rails, intermediate rails,

and toeboards; conforming to OSHA

standards. Posts shall be 4"x4", on no

greater than 8'-0" centers. Guardrails

shall be 2"x4". Single 2"x4" top rail will

be acceptable up to 6'-0" span. Above

6'-0" span, an additional 2"x4" cap strip

shall be included.

➠

■ The access doors on other towers may be unreasonably small.

Specifying the size of the door will cause those bidders to take

exception, alerting you to a potential maintenance headache.

Good maintenance practice requires periodic access to the top of

the tower to inspect the distribution basins, as well as the structural integrity of the fan deck, fan cylinder, and fan—especially the

fan blade securing hardware. And there are no induced-draft cooling tower designs that are immune to this need!

Page 21

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Base

21

Specifications

9.3 Each endwall of the tower shall be

equipped with a 20" wide aluminum

vertical ladder, through-bolted to the

endwall structure. Ladder shall rise

from the cold water basin level to the

top of the fan deck guardrail, and shall

be designed and installed in conformance with OSHA standards.

10.0 Cold Water Collection Basin:

10.1 The cold water collection basin shall be

of poured-in-place concrete, provided

under scope of work done by others.

The concrete basin design shall be

based upon certified loads and dimensions provided by the cooling tower

manufacturer.

11.0 Scope of Work:

11.1 The cooling tower manufacturer shall

be responsible for the design, fabrication, and delivery of materials to the

project site, and for the erection of

the tower over supports provided by

others. Unless otherwise specified, all

external piping, pumps, controls, and

electrical wiring will be outside the

cooling tower manufacturer's scope of

work.

Specification Value

For the comfort and safety of your operating personnel, the Sigma tower includes a

ladder and guardrail of the quality and

design indicated—and we strongly

recommend that you require it of all

bidders! Portable ladders and other

“make-do” access means are inappropriate for equipment of this size and

complexity.

■ This basic specification assumes that the tower will be erected

over a concrete basin at grade level. If the tower is to be installed

on an elevated supporting platform, the plywood cold water

collection basin indicated on page 17 should be included in the

specifications.

■ Please be clear in your specifications

and inquiry documents regarding

the full scope of work expected.

That will help assure that your bid

comparisons will be made on as

equal a basis as possible—and

will help to avoid any misunderstandings during the execution

and implementation of the

contract.

Page 22

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

22

Specifications

Control Options

Control System:

Add the following paragraph in

5.7

the Mechanical Equipment section:

Each cell of the cooling tower shall

be equipped with a UL listed control

system in a NEMA 3R or 4X outdoor

enclosure capable of controlling

single-speed or two-speed motors

as required, and designed specifically for cooling tower applications.

The panel shall include a main fused

disconnect with an external operating

handle, lockable in the off position for

safety. Across-the-line magnetic starters or solid state soft-start starters

as required shall be controlled with a

thermostatic or solid state temperature controller. Door mounted selector

switches shall be provided to enable

automatic or manual control and wired

for 120VAC control. Control circuit

to be wired out to terminal blocks for

field connection to a remote vibration

switch and for access to extra 120VAC

50VA control power, overload trip

alarms and remote temperature control

devices. The temperature controller

shall be adjustable for the required cold

water temperature. If a thermostatic

controller is used it shall be mounted

on the side of the tower with the temperature sensing bulb installed in the

cold water basin using a suspension

mounting bracket. If a solid state temperature controller is used the controller will be door mounted on the control

panel. The temperature controller will

display two temperatures, one for

outgoing water and the other for set

point. Water temperature input shall be

obtained using a three-wire RTD with

dry well in the outlet water piping and

wired back to the solid state temperature controller in the control panel.

Specification Value

■ If it is your opinion that the control system for the cooling tower

should be part of the tower manufacturer’s responsibility, we are

in wholehearted agreement with you. Who better to determine

the most efficient mode and manner of a tower’s operation—and

to apply a system most compatible with it—than the designer

and manufacturer of the cooling tower?

Page 23

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

23

Specifications

Basin Heater:

10.2 Add the following paragraph in the

Cold Water Basin section: Provide

a system of electric immersion heaters and controls for each cell of the

tower to prevent freezing of water in

the collection basin during periods of

shutdown. The system shall consist

of one or more stainless steel electric immersion heaters installed in a

galvanized steel heat shield provided

in the floor of the basin. A NEMA

4 enclosure shall house a magnetic

contactor to energize heaters; a transformer to provide 24 volt control circuit

power; and a solid state circuit board

for temperature and low water cutoff.

A control probe shall be located in the

basin to monitor water level and temperature. The system shall be capable

of maintaining 40°F water temperature

at an ambient air temperature of __ °F.

Wiring of the heaters and controls shall

be the responsibility of the purchaser.

Fan Motor Variable Speed Drive:

Specification Value

■ The basin heater components described at left represent our rec-

ommendation for a reliable automatic system for the prevention

of basin freezing. They are shipped separately for installation at

the jobsite.

If aggressive operating conditions are anticipated, change “galvanized” in paragraph 10.2 to “Series 300 SS”.

The ambient air temperature that you fill in should be the lowest

1% level of winter temperature prevalent at site.

Ask for Marley drawing 92-3627.

Marley All Weather ACH550 System

6.4 Add the following paragraph in the

Mechanical Equipment section when

VFD is used with customers Building

Management System: A complete

UL listed Variable Speed Drive system

in a NEMA 1 indoor, NEMA 12 indoor

or NEMA 3R outdoor enclosure shall

be provided. The VFD shall use PWM

technology with IGBT switching and

integrated bypass design. VFD out put

switching shall not cause mechanical

issues with gearbox teeth or drive shafts.

The VFD shall catch a fan spinning in

the reverse direction without tripping.

The panel shall include a main disconnect with short circuit protection and

external operating handle, lockable in the

off position for safety. The VFD system

shall receive a speed reference signal

from the Building Management System

monitoring the tower fluid temperature.

As an option to receiving the speed

reference signal from a building management system, the drive must have the

capability to receive a 4-20 ma temperature signal from an RTD transmitter. The

VFD shall have an internal PI regulator

■ Marley VFD drive systems are designed to combine absolute

temperature control with ideal energy management. The cooling tower user selects a cold water temperature and the drive

system will vary the fan speed to maintain that temperature.

Precise temperature control is accomplished with far less stress

to the mechanical equipment components. The improved energy

management provides fast payback. Indeed, many utilities offer

generous rebates for users having installed VFD drives.

➠

Page 24

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

24

Specifications

to modulate fan speed maintaining set

point temperature. The drive's panel display shall be able to display the set-point

temperature and cold-fluid temperature

on two separate lines. The bypass shall

include a complete magnetic bypass

circuit and with capability to isolate the

VFD when in the bypass mode. Transfer

to the bypass mode shall be manual in

the event of VFD failure. Once the motor

is transferred to the by-pass circuit the

fan motor will run at constant full speed.

The bypass circuit will not modulate ON

and OFF based on fluid temperature. The

application must be able to handle very

cold fluid temperatures while the VFD

is in a by-pass mode. Operator controls

shall be mounted on the front of the

enclosure and shall consist of start and

stop control, bypass/VFD selection, Auto/

Manual selections, manual speed control.

To prevent heating problems in the fluid

cooloer fan motor and to assure proper

gear reducer lubrication the VFD system

shall de energize the motor once 25%

motor speed is reached and cooling is no

longer required. The fluid cooler manufacturer shall supply VFD start-up assistance. Tower vibration testing throughout

the speed range is required to identify

and lockout any natural frequency vibration levels which may exceed CTI guidelines.

Specification Value

Marley Premium VFD System

6.4 Add the following paragraph in the

Mechanical Equipment section when

VFD is used as a stand alone system:

A complete UL listed Variable Speed

Drive system in a NEMA 12 indoor

or NEMA 3R outdoor enclosure shall

be provided. The VFD shall use PWM

technology with IGBT switching and

integrated bypass design. VFD output

switching shall not cause mechanical

issues with gearbox teeth or drive shafts.

The VFD shall catch a fan spinning in the

reverse direction without tripping. The

panel shall include a main disconnect

with short circuit protection and external

operating handle, lockable in the off position for safety. The system shall include

a solid state, PI temperature controller

to adjust frequency output of the drive

in response to the tower fluid temperature. The temperature of the fluid and

Page 25

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

25

Specifications

set point shall be displayed on the door

of the control panel. The bypass shall

include a complete magnetic bypass

circuit with capability to isolate the VFD

when in the bypass mode. Transfer to

the bypass mode shall be automatic in

the event of VFD failure or for specific

trip conditions allowing safe transfer of

utility voltage to the motor. Automatic

bypass with an earth ground condition

is not allowed. The bypass contactor

shall be cycled on and off while operating in bypass, to maintain the set-point

temperature of the cold water. The drive

design shall be operated as a stand-alone

system without the need for a BMS system. Operator controls shall be mounted

on the front of the enclosure and shall

consist of start and stop control, bypass/

VFD selector switch, Auto/Manual selector switch, manual speed control, and

solid-state temperature controller. An

emergency bypass selector switch internal to the panel allowing the fluid cooler

fan motor to be run at full speed shall be

furnished. To prevent heating problems in

the fluid cooler fan motor and to assure

proper gear box lubrication the VFD system shall de energize the motor once

25% motor speed is reached and cooling is no longer required. The VFD shall

include de-icing logic with auto canceling

and adjustable time. Speed in De-Ice

mode shall not exceed 50% motor

speed. The fluid cooler manufacturer

shall supply VFD start-up assistance.

Tower vibration testing throughout the

speed range is required to identify and

lockout any natural frequency vibration

levels which may exceed CTI guidelines.

Specification Value

Vibration Limit Switch:

5.8 Add the following paragraph in the

Mechanical Equipment section: A

single-pole, double-throw vibration limit

switch in a NEMA 4 housing shall be

installed on the mechanical equipment

support for wiring into the owner’s

control panel. The purpose of this

switch will be to interrupt power to the

motor in the event of excessive vibration. It shall be adjustable for sensitivity, and shall require manual reset.

■ Unless specified otherwise, a Metrix

switch will be provided. A double-pole,

double-throw model is also available. If

purchased in conjunction with the Control

System, it is also factory-wired. The

requirement for manual reset assures that

the tower will be visited to determine the

cause of excess vibration.

Page 26

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

26

Specifications

Convenience and Safety Options

Stairway:

9.3 Replace paragraph 9.3 with the fol-

lowing: A 30" wide, column supported,

45° stairway with 8" rise and run of

treated Douglas Fir shall be provided

at the tower endwall rising from grade

(roof) to the fan deck elevation. Stair

columns shall be 4x4. Guardrails shall

be 2"x4". The upper guardrail shall have

an eased edge for the protection of

operating personnel. Stairway foundation shall be by others, designed in

accordance with drawings provided by

the cooling tower manufacturer. The

stairway shall conform to OSHA standards.

Plenum Walkway:

9.1 Add the following to the end of this

paragraph: Provide a 30" wide walkway

extending from one endwall access door

to the other through the length of the

tower. Walkway shall be constructed of

treated Douglas Fir, and the top of the

walkway shall be above the cold water

basin overflow level. If the cold water

basin is deeper than 4'-0", the walkway

shall be equipped with guardrails.

Specification Value

■ Although they are not neces-

sary for routine operation and

maintenance, stairways do

provide a safe and comfortable means of access to the

top of the tower that is often

overlooked in the initial cooling tower purchase. They are

designed in straight-run or

double-back configurations

to accommodate your site

requirements.

■ This option permits freedom of movement for inspection or maintenance within the tower without the need for wading boots or

tower drainage. It also helps prevent maintenance personnel from

damaging submerged accessories in the cold water basin (such

as screens, probes, basin heaters, etc.).

Ladder Extension:

9.4 Add the following paragraph in the

Access and Safety section: Provide

a ladder extension for connection to

the base of the ladder attached to

the tower casing. This extension shall

be long enough to rise from the roof

(grade) level to the base of the tower.

Anchorage and lateral bracing of the

ladder extension shall be by others.

Ladder Safety Cage:

9.3 Add the following to the end of this

paragraph: A heavy gauge galvanized

steel safety cage shall surround the

ladder, extending from a point approximately 7'-0" above the base of the

ladder to the top of the guardrail surrounding the fan deck.

■ Many towers are installed such that the base of the tower is 2’-0”

or more above the roof or grade level. This makes it difficult to

get up to the base of the attached ladder. The ladder extension

alleviates this problem. Marley ladder extensions are available in

standard 5’-0” and 11’-0” lengths, and will be field-cut to fit.

■ To meet OSHA guidelines, towers whose

fan decks are 20'-0" or more above roof or

grade, and which are equipped with ladders, are required to have safety cages surrounding the ladders.

Page 27

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

27

Specifications

Oil Level Sight Glass:

5.4 Replace paragraph 5.4 with the fol-

lowing: A galvanized oil gauge and

drain line shall extend from the gear

reducer to the vicinity of the motor,

and shall be equipped with a bronzebodied oil level sight glass.

Miscellaneous Options

Wood Cold Water Basin:

10.1 Replace paragraph 10.1 with the fol-

lowing: Include a cold water collection

basin constructed of pressure treated

Douglas Fir plywood. Basin floor shall

be 3/4" thick 5-ply, supported by 6"

deep joists on 2'-0" centers. Basin

sides shall be 1" thick, 7 ply. The basin

floor shall lock into a dado groove in

the sides to form a watertight seal. A

depressed, side outlet sump of either

FRP or hot-dip galvanized steel having

a 1/4" thick faceplate drilled for a standard class 125 ASME flange connection will be included. An appropriately

sized (4" diameter or larger) galvanized

standpipe overflow shall be provided.

The standpipe shall be removable for

flush-out cleaning of the basin. A floatoperated, mechanical makeup valve

shall also be included, installed adjacent to the endwall access door.

Specification Value

■ The oil level sight glass is a convenience

item that is preferred by many users. The

same purpose is, of course, served by either

the dip stick or the sight glass.

■ Marley basins are used to permit the installation of towers on

elevated platforms or foundations. The cross section drawing on

page 4 shows the relationship of the optional basin, sump and

overflow to a typical steel I-beam support platform.

Redwood Components:

Hot Water Basin Covers:

7.3 Add the following paragraph in

the Hot Water Distribution System

section: The distribution basins shall

include treated Douglas Fir plywood

covers at least 3/4" thick. These covers

shall be designed to withstand 60 psf

live load, and shall be easily removable

for maintenance.

Air Inlet Screens:

6.3 Add the following paragraph to the

Fill, Louvers and Drift Eliminators

Section: The air inlet faces of the

tower shall be covered by 1" mesh

hot-dip galvanized welded wire

screens. Screens shall be mounted in

galvanized steel U-edging and shall be

removable.

■ Most of the wood components in the tower are available of pres-

sure treated redwood. However, redwood lacks the strength of

Douglas Fir, which may require structural modifications of the

tower. Please discuss the available redwood options with your

Marley sales representative.

■ These covers are designed to keep leaves and debris out of the

circulating water system. They also serve to suppress algae formation by shielding the incoming hot water from direct sunlight.

■ In wooded or windy areas, these screens help to keep leaves or

blowing debris out of the cooling tower and circulating water

system.

Page 28

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

28

Specifications

Low Noise Tower:

1.1 Add the following at the end of this

paragraph: The cooling tower shall be

quiet operating, and shall produce an

overall level of sound no higher than ____

dBA at the critical location indicated on

the Plans.

Specification Value

■ Sound produced by a Sigma Steel tower operating in an unob-

structed environment will meet all but the most restrictive noise

limitations – and will react favorably to natural attenuation.

Where the tower has been sized to operate within an enclosure,

the enclosure itself will have a damping effect on sound. Sound

also declines with distance – by about 5 or 6 dBA each time

the distance doubles. Where noise at a critical point is likely to

exceed an acceptable limit, you have several options – listed

below in ascending order of cost impact:

• Where only a slight reduction in noise will satisfy — and the

source of concern is in a particular direction — merely turning

the tower may be the answer. Less sound emanates from the

cased face of the tower than does from the air intake face.

• In many cases, noise concerns are limited to nighttime, when

ambient noise levels are lower and neighbors are trying to

sleep. You can usually resolve these situations by using twospeed motors in either 1800/900 or 1800/1200 RPM configuration; and operating the fans at reduced speed without cycling

“after hours”. (The natural nighttime reduction in wet-bulb temperature makes this a very feasible solution in most areas of the

world, but the need to avoid cycling may cause the cold water

temperature to vary significantly.)

• Variable speed drives automatically minimize the tower's noise

level during periods of reduced load and/or reduced ambient

without sacrificing the system's ability to maintain a constant

cold water temperature. This is a relatively inexpensive solution,

and can pay for itself quickly in reduced energy costs.

• Where noise is a concern at all times (for example, near a hospital), the best solution is to oversize the tower so it can operate

continuously at reduced (1200 or 900 RPM) motor speed even at

the highest design wet-bulb temperature. Typical sound reductions are 7 dBA at 2/3 fan speed or 10 dBA at 1/2 fan speed, but

larger reductions are often possible.

• Extreme cases may require inlet and discharge sound attenuator sections; however, the static pressure loss imposed by

attenuators may necessitate an increase in tower size. This is

the least desirable approach because of the significant cost

impact – and because of the obstruction to normal maintenance

procedures.

Y

our Marley representative can help you meet your sound

requirements.

Page 29

Marley / Sigma 1000/1200 Cooling Tower / Specifications: Options

29

Specifications

Watertight Partitions Between Cells:

3.5 Replace the last sentence in this

paragraph with the following:

Partitions shall be 3/4" x 5-ply, factoryfabricated, grooved and splined treated

Douglas Fir plywood sheets, installed

and sealed watertight to permit independent cell operation.

Fire Safety Options:

Specification Value

■ In addition to the normal partition function of preventing air

bypass (page 17), this option allows you to use each partitioned

cell of your tower independently. This is valuable where a single

multicell tower is serving several separate systems—or where

winter operation may require less than full tower capability.

■ Occasionally, critical processes or local codes may require you to

install a fire-protection sprinkler system on a wood tower—or pay

higher insurance premiums—or both. Our first recommendation

in such a case would be for you to consider using a Sigma Steel

cooling tower, as listed in the Factory Mutual Approval Guide.

Another alternative that could be acceptable to your insurance

carrier, and which you may wish to evaluate, would be to make

your Sigma tower as fire resistant as possible. This can be done

by any or all of the following measures:

• FRP casing having a ame spread rating of 25 or less. (Para. 8.1)

• Fan cylinders of re-retardant FRP having a ame spread rating

of 25 or less. (Para. 4.2)

• 1⁄4" thick fireproof fiber reinforced cement overlay over the fan

deck—and will provide FRC overlaid distribution basin covers.

(Para. 4.1)

• 3⁄4" thick plywood partitions both sides of the column line

between cells to achieve a fire rating of at least 30 minutes.

(Para. 3.5 and this page.)

Page 30

Page 31

Page 32

7401 WEST 129 STREET

OVERLAND PARK, KANSAS 66213

UNITED STATES

913 664 7400

spxcooling@spx.com

spxcooling.com

In the interest of technological progress,

all products are subject to design and/or

material change without notice.

©2008 SPX Cooling Technologies, Inc.

Printed in USA | SIG-TS-08A

Loading...

Loading...