Page 1

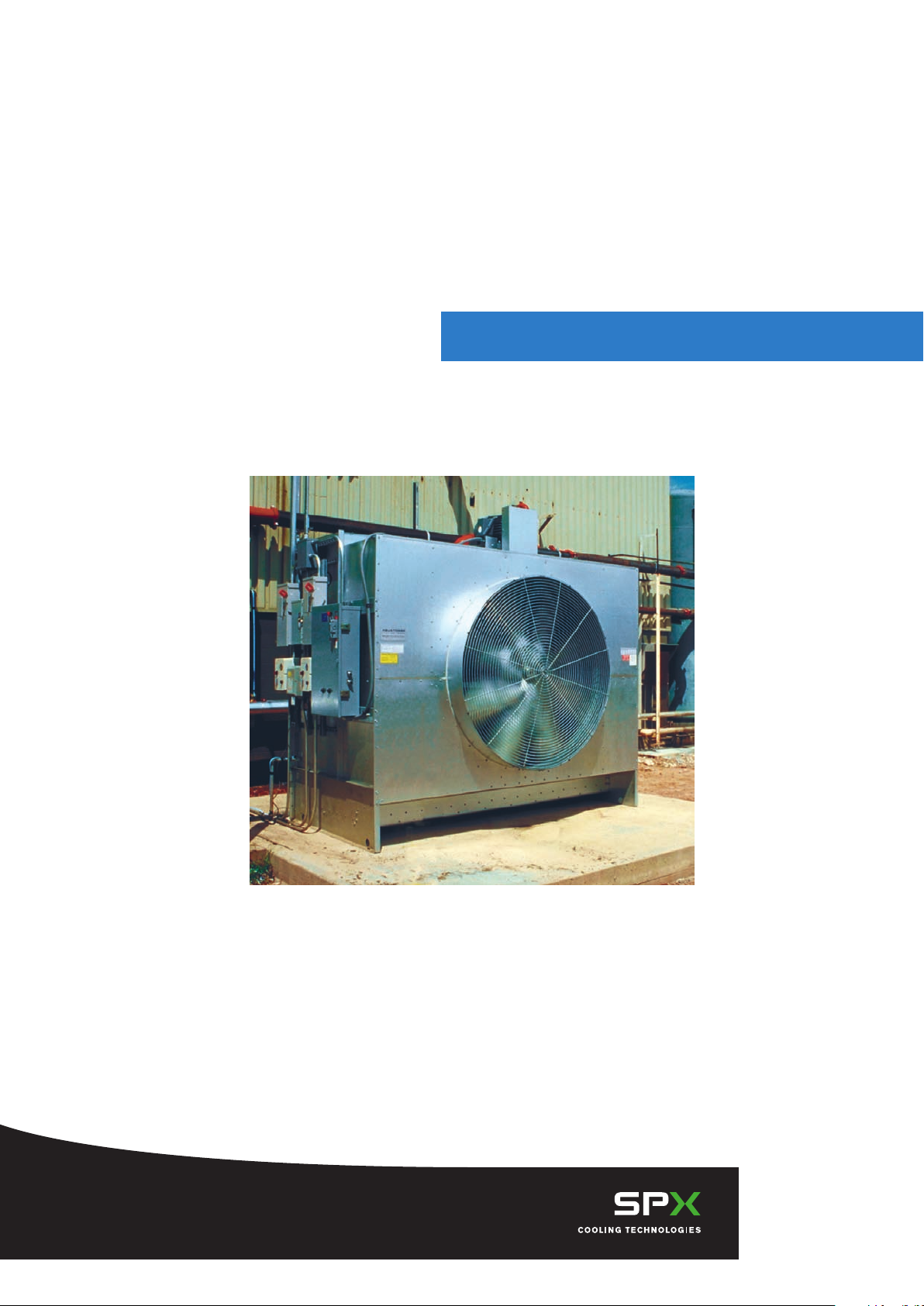

Marley Aquatower® Cooling Tower

/

/

Page 2

2

/ The Aquatower Advantage /

■ Proven Performance. CTI Certified. Plus SPX stands by

its responsibility for reliable thermal performance. We

designed it. We rate it. We guarantee it!

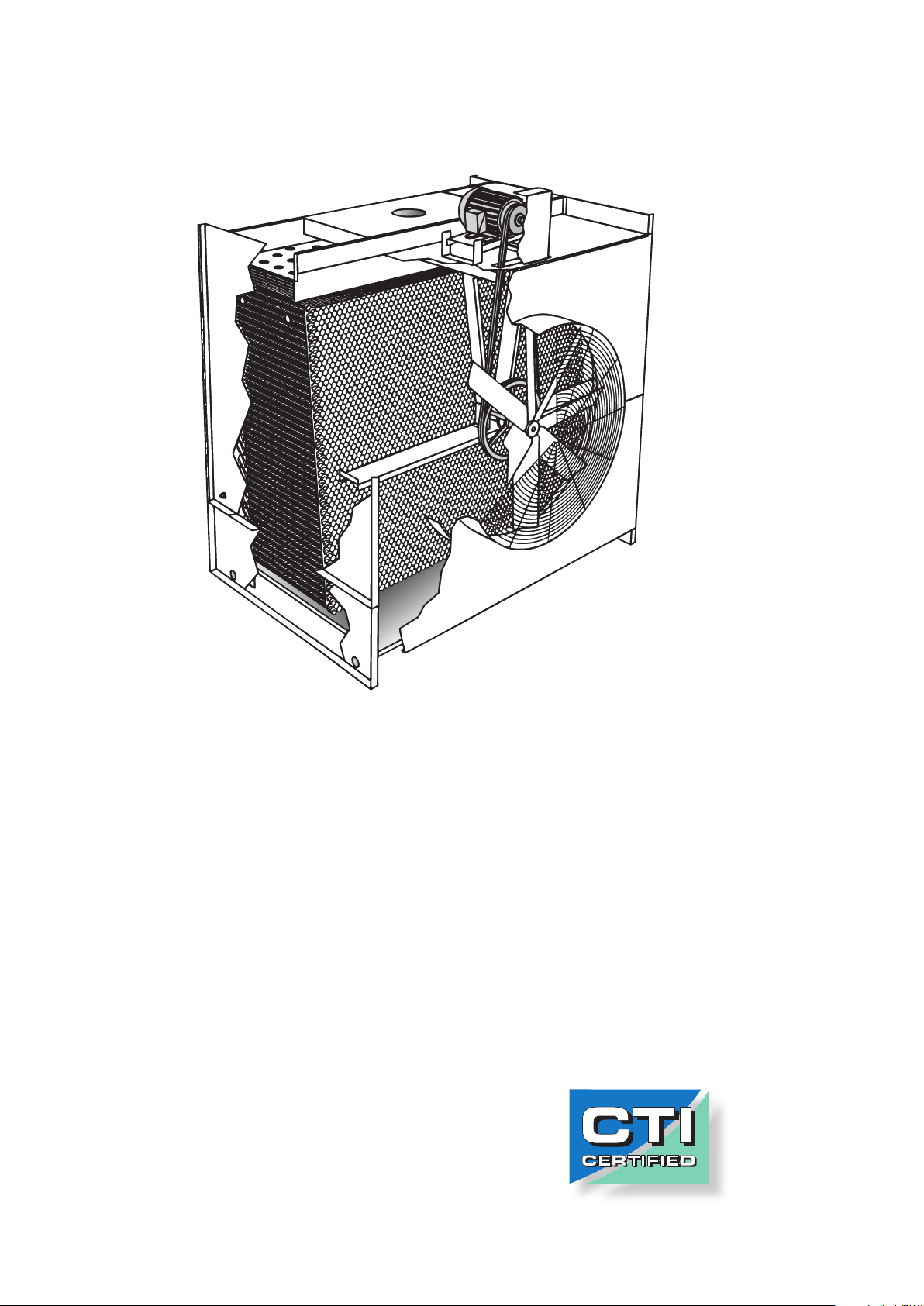

■ Induced-Draft Design. Save on fan power. The fan will

operate in a warm atmosphere even in winter, so you’ll

never have to work on frozen mechanical equipment.

■ Crossow Design. Save on pump power because you

only pay to move the water to the top of the tower. Gravity

does the rest. The mechanical equipment and water

distribution system are out where you can easily maintain

them.

■ All-Season Reliability. Aquatowers perform as specified

in the heat of summer. They respond well to energy

management techniques in the spring and fall and

with appropriate fan controls, they can operate virtually

ice-free in the dead of winter. Plus they offer simple

maintenance all year long.

■ Proven Corrosion Protection. Thousands of users

over more than 40 years confirm the value of heavy

galvanizing. And Marley’s Z-600 is the most effective

galvanizing used in the industry.

■ PVC Film Fill with Integral Drift Eliminators and

Louvers. If you’ve ever had to replace deteriorated

eliminators or louvers, you’ll appreciate this advantage.

Now those components are molded right in the PVC fill

sheets. Integral honeycomb louvers keep the circulating

water inside your tower—and off your roof!

■ Select Your Aquatower on Our Website. The Marley

UPDATE web-based selection software—available at

www.spxcooling.com—provides Aquatower model

recommendations based on your specific design

requirements

■ Simple, Flexible Installation. Just mount the motor, belts

and belt guard, install the outlet connection that suits

your needs—both side suction and bottom outlet are

provided, complete with screens—and adjust the float

valve. Attach air-inlet screens on models 494A and larger

and your Aquatower is ready for operation.

Page 3

3

/ The Marley Difference /

Today’s Aquatower may be the most space/energy-

efficient cooling tower available. Your needs have dictated

constant technological improvement. Thousands of

Aquatower users enjoy the benefits of eight major redesigns

and dozens of minor improvements in the past 40 years. For

example, PVC film-fill enables the Aquatower to reject more

heat per unit size. We also put the air inlet louvers and drift

eliminators right on the fill sheets. This new arrangement

saves you fanpower by improving airflow through the tower.

The Aquatower is a maintenance delight! You’ll

appreciate the way the Aquatower simplifies maintenance.

No hidden spray systems, tiny nozzles, or enclosed basins

here! You can easily replace and align V-belts from outside

the tower. You won’t have the chore and expense that goes

with high-power, blower fan towers.

All primary components of the Aquatower are open to

view. You can easily remove any debris from the upper basin

or nozzles while the tower is in operation.

Heavy mill galvanizing on all steel components prevents

base metal corrosion. You won’t have to worry about paint

chips clogging your strainers and nozzles, because there is

no paint to flake off. Heavy galvanizing also protects much

better than paint.

Above all, the Aquatower is readily available. You won’t

have to wait around—or accept second best—when you

need a cooling tower. We maintain an impressive stock of

completed towers at our own plants. A growing number of

local distributors can draw from that stock.

Contact your local distributor or Marley representative.

They’ll be glad to help you choose the proper model for

your needs. They can also help you with your layout and

piping.

You’ll enjoy single source responsibility and reliability

because we design and manufacture virtually all major

cooling tower components.

All Marley components are designed and selected to

be a part of an integrated system. For example, the spray

pattern from nozzles and the pressure drop through drift

eliminators both affect a fill’s heat transfer capacity. So, we

include that impact in our thermal analysis.

Drift eliminators must be effective at the air velocities

where fill is most efficient. So, we’ve carefully designed

both components to work together efficiently.

How many other cooling tower companies can offer

you this assurance? They may use Brand “A” nozzles with

Brand “B” fill and Brand “C” drift eliminators. When they all

come together, the whole may be less than the sum of the

parts.

Our total system approach assures that all the

parts work together to provide you the greatest total

performance.

And because we design specifically for cooling towers,

all our components will provide many years of service with

minimal maintenance.

Every Aquatower cooling tower carries a full one-year

warranty. The Aquatower you buy from us will work on

your job or we’ll make it right. Your warranty includes

thermal performance and every component of the tower.

The SPX Cooling Technologies warranty is your assurance

of performance—for a full year.

The Aquatower has inspired many imitators. Only

SPX Cooling Technologies can offer you the original.

Page 4

4

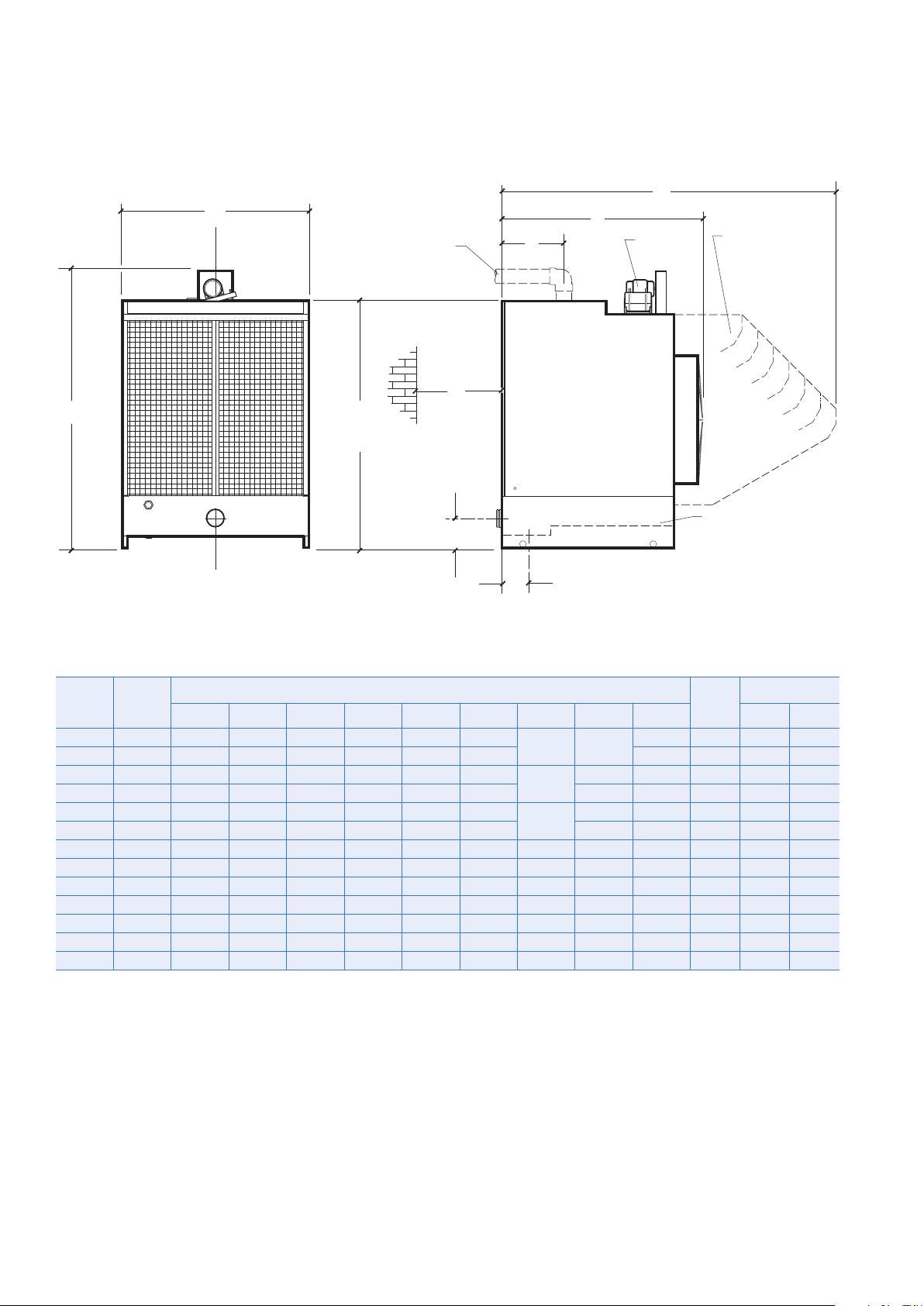

/ Schematic /

USE FOR

STATIC LIFT

L

INLET

C

L

TOWER

OUTLET

C

L

C

L

C

L

TOWER

W

D

S

E

C

B

H

MOTOR

INLET PIPING

(BY OTHERS)

A

SIDE OUTLET

BOTTOM OUTLET

TOWER COLLECTION

BASIN

VERTICAL

DISCHARGE

(OPTION-NOTE 3)

AIR INLET ELEVATION

Tower

Nominal Tons

Model

490A 8 902 1292 1610 4 02 175 610

490B 10 902 1292 1610 402 175 610 1318 .75 2" 2" F

492A 22 1206 1543 2248 432 241 1219

492B 28 1206 1543 2248 432 241 1219 203 195 6 1.5 4" 4" M

493A 36 1816 1549 2248 432 241 1524

493B 42 1816 1549 2248 432 241 1524 203 195 6 2.2 4" 4" M

494A 51 1816 1972 2743 608 292 1829 3251 235 2403 1.5 6" 6" MC

494B 57 1816 1972 2743 608 292 1829 3251 235 2403 2.2 6" 6" MC

494C 68 1816 1972 2743 608 292 1929 3251 235 2403 3.7 6" 6" MC

495A 80 2426 1975 2743 608 292 2134 3251 235 2403 3.7 6" 6" MC

495B 91 2426 1975 2743 608 292 213 4 3251 235 2403 5.5 6" 6" MC

496A 111 3035 1984 2953 589 292 2743 3345 235 2610 3.7 6" 6" MC

496B 126 3035 1984 2953 589 292 2743 3345 235 2610 5.5 6" 6" MC

1. Nominal tons are based upon 35°C HW, 29.5°C CW, 25.5°C WB

and .68 m

note1

L W H A B C note 2 D E S

3

/hr per ton. The Marley UPDATE web-based selection

software provides Aquatower model recommendations based

on specific design requirements.

2. Minimum clearance for adequate air supply. Consult your Marley

sales representative or your local distributor if this clearance is

impractical for your job.

3. Vertical discharge hood is for applications in restrictive enclosures

or other locations where horizontal discharge is not desirable. CTI

Certification does not apply when this option is selected. Available

Dimensions

note 3 note 6

note 3

note 3

4. Motors are 400 volt, 3-phase TEFC.

5. Motor, belt and belt guard ship uninstalled. Installation by others.

6. Outlet sizes shown are side outlets. All models except 490A and

490B have connections for both side and bottom outlet. Install the

desired connection and seal the unused opening with the coverplate provided. Pump suction should use side outlet. See page 9

for size and flow capacities of bottom outlets.

7. Overflow is a 2" F connecton located in side of collection basin.

8. Drain is a 2" F connection located in collection basin floor.

9. Makeup valve connection is 3/4" M located in tower side.

SIDE ELEVATION

Piping

Motor

kW

1318 .25 2" 2" F

203 195 6 .75 4" 4" M

203 195 6 1.5 4" 4" M

Connection

Inlet

Outlet

note 6

only on models 494A and larger.

Page 5

5

/ Support /

F

16mm DIAMETER HOLES

A

G

H

H

L

W

ANCHOR

BOLT

NORMAL

GAUGE

25mm

TOWER

COLLECTION BASIN

AIR INLET FACE AIR INLET FACE

25mm

25mm

ANCHOR

BOLT

C

L

C

L

F

L

ANCHOR

BOLT

25mm

25mm

ANCHOR

BOLT

C

L

C

L

ANCHOR

BOLT

ANCHOR

BOLT

C

L

C

L

G

H

H

W

ANCHOR

BOLT

ANCHOR

BOLT

C

L

C

L

SUPPORT

(BY OTHERS)

TOWER

COLLECTION

BASIN

16mm DIAMETER HOLES

TOWER

COLLECTION BASIN

B

NORMAL

GAUGE

MIN. BEARING WIDTH

AT EACH ANCHOR BOLT

51

SUPPORT

(BY OTHERS)

TOWER

COLLECTION

BASIN

SUPPORTING STEEL PLAN

OPTION ONE

Dimensions

Models with Vertical Discharge Hood Option

Tower

Model

490A-490B 902 1019 851 915 52

492A-492B 1206 1260 1156 1067 97

493A-493B 1816 1206 1765 1067 97

494A-49B 1816 1680 1765 1524 78

495A-495B 2426 1680 2375 1524 78 797 1294 437 338 213

496A-496B 3035 1680 29 85 1524 78 951 2155 539 497 290

L W F G H

494A-494C 1816 1680 1765 1524 78 816 1519 380 316 234

495A-495B 2426 1680 2375 1524 78 968 1920 480 338 234

496A-496B 3035 1680 29 85 1524 78 1178 2382 596 497 290

1. Use this bulletin for preliminary layouts only. Obtain current drawings from your Marley sales representative or your local distributor.

2. Purchaser to provide tower supports complete with holes and bolts

for anchorage. All supports must be framed flush and level at top.

Maximum deflection to be 1/360th of span, not to exceed 13mm.

3. Maximum weight occurs with basin full to overflow level at shutdown.

Actual operating weight varies with flowrate and piping scheme.

4. Wind loads are based on 1.4 kPa and are additive to operating

loads. Reactions due to wind loads exceed those resulting from

seismic loads based on the 1997 UBC code, Zone 4 and an Importance Factor of 1.00 per Section 1634—Towers Not on a Building.

Shipping Weight

kg

198 343

337 633

445

634

Use this data for preliminary layouts only.

Obtain current drawing from your Marley sales

representative.

The Marley UPDATE web-based selection software

—available at spxcooling.com provides

Aquatower model recommendations based on

customer's specific design requirements.

SUPPORTING STEEL PLAN

OPTION TWO

VIEW BSECTION A

Max. Vertical

Reaction at

Anchor

Wind Load kg

Maximum

Operating

kg

905 226 238

1337 334 252 161

Maximun

Operating Load

at Anchor

kg

84 82

158 161 95

Max. Horizontal

Reaction at

Anchor

52

129

Page 6

6

/ Construction And Components /

■ Water Distribution System

Warm water flows through external piping (not included

with the tower) into a splash box chamber at the top of the

Aquatower. A splash box prevents the incoming water from

spilling out of the basin and helps provide uniform water

distribution. Water then flows by gravity from the basin

through nozzles to the fill.

■ Fill/Louvers/Drift Eliminators

Fill sheets include integral louvers and drift eliminators,

designed to minimize resistance to airflow. This patented

arrangement prevents water from escaping the fill sheets,

assuring proper heat transfer throughout wide variations in

airflow. Users find this fill operates ice-free even in extremely

cold weather.

The thermoformed .4mm thick PVC fill sheets withstand

hot water temperatures as high as 52°C. Fill sheets are

immune to biological and corrosive decay and their flame

spread rating is less than 25 per ASTM E-84. Galvanized

structural tubes support and stabilize the fill. They also hold

the bottom of the fill sheets above the cold water basin

floor to simplify basin cleaning. Removable 25 x 25 mesh

galvanized air inlet screens keep larger airborne trash out of

the collection basin and fill area.

Eliminator air-seal removed showing distribution area above fill

Hot water distribution basin covers are provided as

standard equipment to keep the distribution basin free from

airborne debris and to reduce the likelihood of biological

growth.

All Aquatowers use Marley “Spiral Target” nozzles.

These inert polypropylene nozzles are evenly spaced

thoughout the distribution basin to assure uniform water

distribution over all portions of the fill. Their large openings

resist clogging. Nozzles are easy to remove and replace if

you ever want to change the design water flow rate.

Spiral-target distribution nozzle

MX Fill

■ Cold Water Collection Basin

The Aquatower’s collection basin reduces operating

weight, simplifies basin cleaning, and assures proper

outflow. Water flows from the elevated area under the fill

into the basin’s rear depressed section, where side suction

piping connects. A bottom outlet is also available for gravity

flow applications.

Standard equipment on each tower basin includes:

a screened suction connection; a threaded overflow

connection; a threaded and plugged drain connection;

and a float-operated make-up valve. Models 492A through

496B also include a bottom outlet conforming to flat flange

specification. A blank cover plate is provided to seal the

outlet connection not used.

Page 7

7

/ Construction And Components /

■ Mechanical Equipment

Belt-driven propeller fans insure design airflow at

minimum power. Fans are supported by an oil-lubricated

tapered roller bearing assembly with remote oil reservoir.

For ease of maintenance all drive components are

accessible from outside the tower.

Fan drive motor showing adjustable base and belt guard

■ Hoisting and Handling

Hoisting instructions on each tower explains how to use

a spreader-bar and slings beneath the cold water basin floor

to hoist the Aquatower. The tower’s design also allows easy

handling with a forklift.

Fan and fan guard. Guard is easily removed for access to

fan and drive belts

Fan drive motors are TEFC designed specifically for

cooling tower use. Kilowatts and electrical characteristics

appear in the table on page 4. Other types of motors are

available.

Caution

The cooling tower must be located at such distance and

direction to avoid the possibility of contaminated tower

discharge air being drawn into building fresh air intake

ducts. The purchaser should obtain the services of a

Licensed Professional Engineer or Registered Architect

to certify that the location of the tower is in compliance

with applicable air pollution, re, and clean air codes.

■ Safety

Standard Aquatower safety features include fan guards

and belt guards. Fan guards consist of welded heavy gauge

steel wire hoops and spokes, hot dip galvanized after

fabrication. The galvanized steel belt guard encloses both

belts and pulleys. Guards are easily removed for servicing.

■ Construction and Finish

Aquatowers offer the corrosion protection of Z-600

galvanized providing long term protection for the steel.

Assembly hardware is also galvanized.

Page 8

8

/ Freeze Prevention /

When the ambient air temperature falls below 0°C, the

water in a cooling tower can freeze. Marley Technical Report

#H-003 “Operating Cooling Towers in Freezing Weather”

describes how to prevent freezing during operation. Ask your

Marley sales representative for a copy or download from our

website.

Water collects in the cold water basin during shutdowns,

and may freeze solid. You can prevent freezing by adding

heat to the water left in the tower. Or, you can drain the tower

and all exposed piping at shutdown.

■ Electric Basin Heaters

Provide an electric immersion heater for each cell of the

tower to prevent freezing of water in the collection basin

during periods of shutdown. The rod type heater is installed

in the side of the cold water basin.

Each heater will include an integral thermostat, set

point nominally 4°C but adjustable to suit local operating

requirements.

Any exposed piping that is still filled with water at

shutdown —including the makeup water line—should be

electrically traced and insulated (by others).

■ Indoor Tank Method

In this type of system, water flows from an indoor tank,

through the load system, and back to the tower, where it is

cooled. The cooled water flows by gravity from the tower to

the tank located in a heated space. At shutdown, all exposed

water drains into the tank, where it is safe from freezing.

The table on page 9 lists typical drain-down capacities

for all Aquatower models. Although we do not produce

tanks, many of our representatives offer tanks supplied by

reputable manufacturers.

The amount of water needed to successfully operate

the system depends on the tower size, flow and the volume

of water contained in the piping system to and from the

tower. You must select a tank large enough to contain those

combined volumes—plus a level sufficient to maintain

a flooded suction on your pump. Control makeup water

according to the level where the tank stabilizes during

operation.

You should always use a bottom outlet for this type of

piping system. The following table lists the flow capacities for

bottom outlets.

Basin Heater Selection

Tower

Model

490A 2 kW 3 kW 2 kW 3 kW

490B 2 kW 3 kW 2 kW 3 kW

492A 2 kW 3 kW 2 kW 3 kW

492B 2 kW 3 kW 2 kW 3 kW

493A 2 kW 3 kW 3 kW 3 kW

493B 2 kW 3 kW 3 kW 3 kW

494A 2 kW 3 kW 4 kW 3 kW

494B 2 kW 3 kW 4 kW 3 kW

494C 2 kW 3 kW 4 kW 3 kW

495A 3 kW 3 kW 6 kW 4.5 kW

495B 3 kW 3 kW 6 kW 4.5 kW

496A 3 kW 4.5 kW 6 kW 6 kW

496B 3 kW 4.5 kW 6 kW 6 kW

-12°C Ambient -25°C Ambient

Tank Heater

Component

Heater

Tank Heater

Component

Heater

1. Required kw is the amount of heat needed to maintain +4.5°C basin

water temperature at the indicated ambient air temperature.

2. Tank heaters shown are 220 volts, single-phase.

3. Com p one nt hea ter s s how n a re 400 vo lts , t hre e-p has e.

Options or special heater selections may add several weeks to

delivery.

4. Heaters do not operate continuously. Heaters cycle on and off

automatically as basin water temperature dictates.

5. Contact your Marley sales representative for selections appropriate

for other ambient conditions than those shown here.

Page 9

9

/ Field Assembly /

Drain-Down Capacity

Tower Model

490A

490B

492A

492B

493A

493B

494A

494B

494C

495A

495B

496A

496B

Range of Tower Design m3/hr

3.4 - 5.9 106

6.2 - 11.6 114

11.8 - 19.3 125

19.5 - 34.7 136

4.77 - 12 185

12.6 - 209 204

21 - 34.3 227

34.5 - 47.9 246

7.5 - 18.8 291

19 - 32.7 318

32.9 - 54 356

54.2 - 74.5 382

13.6 - 32 507

32.3 - 51.5 549

51.7 - 85.4 613

85.6 - 127.8 674

18.6 - 43.6 689

43.8 - 61.3 727

61.5 - 116.5 829

116.7 - 173.3 912

23.6 - 44.5 863

44.7 - 64.9 920

65.1 - 112.8 1026

113.1 - 218.7 1211

Maximum Drain-Down

litres

Volumes shown are maximums for the flowrate ranges indicated.

Actual volumes will usually be less. Contact your local Marley sales

representative for more specific information.

Bottom Outlet Maximum m3/hr

Tower

Model

492A - 492B 27 51 51 na

493A - 493B 27 61 79 na

494a - 494B - 49 4C 32 70 79 142

495A - 495B 32 70 79 193

496A - 496B 32 70 79 193

4" 6" 8" 10"

Outlet Diameter

1. Maximum m3/hr applies to both pump and gravity flow piping systems. The outlet piping on gravity flow systems must have sufficient

vertical drop to overcome all other head losses in the system.

2. Bottom outlet is not available on Models 490A and 490B.

Note: For economical transportation, Aquatowers are normally

packaged unassembled when shipped from the UK by sea or air

freight.

■ Field Assembly

If you choose to assemble your Aquatower at the job site,

your Aquatower will be shipped unassembled with complete

assembly instructions.

The following table shows the sizes and weights of the

largest Aquatower components for each model. You can

use this information to plan your rigging and transportation

needs.

Unassembled tower shipment may add 3 to 5 weeks to

normal lead times. Your Marley sales representative will be

glad to help you plan for your unique needs.

Component Sizes and Weights

Tower Model

490A

490B

492A

492B

493A

493B

494A

494B

494C

495A

495B

496A

496B

Component Size mm Weight kg

Collection Basin End 305 x 330 x 914 7

Collection Basin Floor 76 x 762 x 813 11

Front Panel 51 x 914 x 112 10

Casing Panel 51 x 102 x 132 20

Distribution Basin 203 x 406 x 813 8

Collection Basin End 356 x 406 x 122 11

Collection Basin Floor 76 x 914 x 112 17

Front Panel 51 x 122 x 173 24

Casing Panel 51 x 66 0 x 1600 16

Distribution Basin 203 x 406 x 112 11

Collection Basin End 356 x 406 x 183 17

Collection Basin Floor 76 x 914 x 1727 26

Front Panel 51 x 940 x 183 16

Casing 51 x 660 x 1600 16

Distribution 203 x 406 x 173 17

Collection Basin End 457 x 457 x 1829 22

Collection Basin Floor 102 x 864 x 1727 26

Front Panel 51 x 1117 x 1829 19

Casing Panel 51 x 1016 x 1930 29

Distribution Basin 203 x 711 x 1727 24

Optional Discharge Side 51 x 1041 x 1956 17

Optional Discharge Floor 229 x 1143 x 1727 21

Collection Basin End 457 x 457 x 2438 29

Collection Basin Floor 102 x 864 x 2338 34

Front Panel 51 x 1118 x 2438 26

Casing 51 x 1016 x 1930 29

Distribution Basin 203 x 711 x 2337 32

Optional Discharge Side 51 x 1041 x 1956 17

Optional Discharge Floor 229 x 1143 x 1600 19

Collection Basin End 457 x 457 x 3048 36

Collection Basin Floor 102 x 864 x 2946 43

Front Panel 51 x 1168 x 3048 33

Casing Panel 51 x 1016 x 2134 32

Distribution Basin 203 x 711 x 29 46 40

Optional Discharge Side 51 x 1143 x 1956 17

Optional Discharge Floor 229 x 1143 x 1956 25

Page 10

10

/ Options /

Option Description Option Description

Field Assembly

Where unique space restrictions or

rigging conditions demand, Aquatowers

can be shipped ready for field assembly

by others. Complete step-by-step

assembly instructions are provided.

Stainless Steel

Construction

Control System

All Aquatower models are available

with stainless steel structure. Or you

can choose a galvanized tower with

a stainless steel cold water collection

basin. Your Marley sales representative

can help you choose the amount of

corrosion resistance necessary for your

installation.

Factory-installed control center in

IP55,IEC enclosure mounted on tower

casing. Complete with thermostat controller for single or two-speed motors to

maintain chosen cold water temperature.

Vertical

Discharge

Hood

This option is available on Models 494A

and larger. It provides vertical discharge

of the air leaving the tower. Hoods are

galvanized steel. They ship separately

for installation by others. A large access door provides entry to the fan and

mechanical equipment.

For use in restrictive enclosures or other

site situations where horizontal discharge

is not desirable. CTI Certification does

not apply when this option is selected.

Page 11

11

/ Specifications /

Base: Furnish and install an induced-draft, crossflow, factory-

assembled, steel cooling tower of ____ cell(s), as shown

on plans. Tower shall be similar and equal in all respects

to Marley Series 4900 Aquatower, Model _______. Tower

must be warranted by the manufacturer for one year from

date of shipment.

3

Performance: Tower shall cool ____ m

/hr of water from ____ °C

to ____ °C at a design entering air wet-bulb temperature

of ____ °C and its thermal rating shall be certified by the

Cooling Technology Institute.

Construction: Structural components of the tower, including

the cold water basin, framework, mechanical equipment

supports, casing, hot water basin, and fan cylinder shall

be fabricated of heavy-gauge steel, protected against

corrosion by Z-600 galvanizing per BS EN 10327:2004.

All components subjected to factory welding shall be hot

dip galvanized after fabrication per BS EN 150 1461:1999.

Cold galvanizing is not acceptable.

Motor: Motor(s) shall be ____ kW, Totally Enclosed, specially

insulated for cooling tower duty. Speed and electrical

characteristics shall be 1500 (or 1500/750) RPM, single-

winding, ____ phase, ____ hertz, ____ volts. The motor

must be located out of the saturated discharge air

stream.

Mechanical Equipment: Fan(s) shall be adjustable-pitch

propeller type. Fan shall be driven through V-belt(s) with a

minimum service factor of 1.5 based on full motor kW and

protected with a belt guard. The fan and fan pulley shall

be supported by oil lubricated tapered roller bearings in

a cast iron housing with externally accessible remote oil

reservoir for easy maintenance.

Fill, Louvers and Drift Eliminator: Fill shall be film-type,

thermoformed PVC, with louvers and drift eliminator

formed as part of each fill sheet. Fill shall be suspended

from hot dip galvanized structural tubing supported from

the upper tower structure, and shall be elevated above

the floor of the cold water basin to facilitate cleaning. Air

inlet faces of the tower shall be free of water splash-out.

Guaranteed drift losses shall not exceed 0.005% of the

design flow rate.

Hot Water Distribution System: An open basin above the fill

bank shall receive hot water piped to each cell of the

tower. The basins shall be equipped with removable

covers to keep out debris. This basin shall be installed and

sealed at the factory. Water shall enter the basin through

a removable wave-suppressor splash box. The basin

shall be no less than 162mm deep to provide adequate

freeboard against overflow and splash-out. Removable

and replaceable polypropylene nozzles installed in the

floor of the basin shall provide full coverage of the fill by

gravity flow. Nozzles must all have the same orifice size

and be spaced symmetrically in both longitudinal and

transverse directions.

Cold Water Basin and Accessories: The cold water basin shall

be factory sealed. For maximum installation flexibility,

basin accessories shall include both a side suction

connection and a hole and bolt circle in the basin floor

suitable for gravity flow. Both connections shall include

a debris screen and anti-cavitation device. A factory-

installed, float-operated, mechanical makeup valve shall

3

be included, having a

⁄4" diameter inlet connection.

Page 12

SPX COOLING TECHNOLOGIES UK LTD..

GREGORY'S BANK

WORCESTER WR3 8AB

UNITED KINGDOM

+44 (0) 1905 720 200

info.uk@spx.com

spxcooling.com

In the interest of technological progress,

all products are subject to design and/or

material change without notice.

©2008 SPX Cooling Technologies

uk_AQ-08

Loading...

Loading...