Page 1

Marley Ultra Low-Noise Fan

/

/

User Manual 07-1126

Page 2

Page 3

Contents

General Information ...................................................................... 4

Installation .................................................................................... 5

Operation .................................................................................... 11

Maintenance

Parts List .................................................................................... 16

Trouble Shooting ........................................................................ 17

..............................................................................

13

3

Page 4

General Information

Description

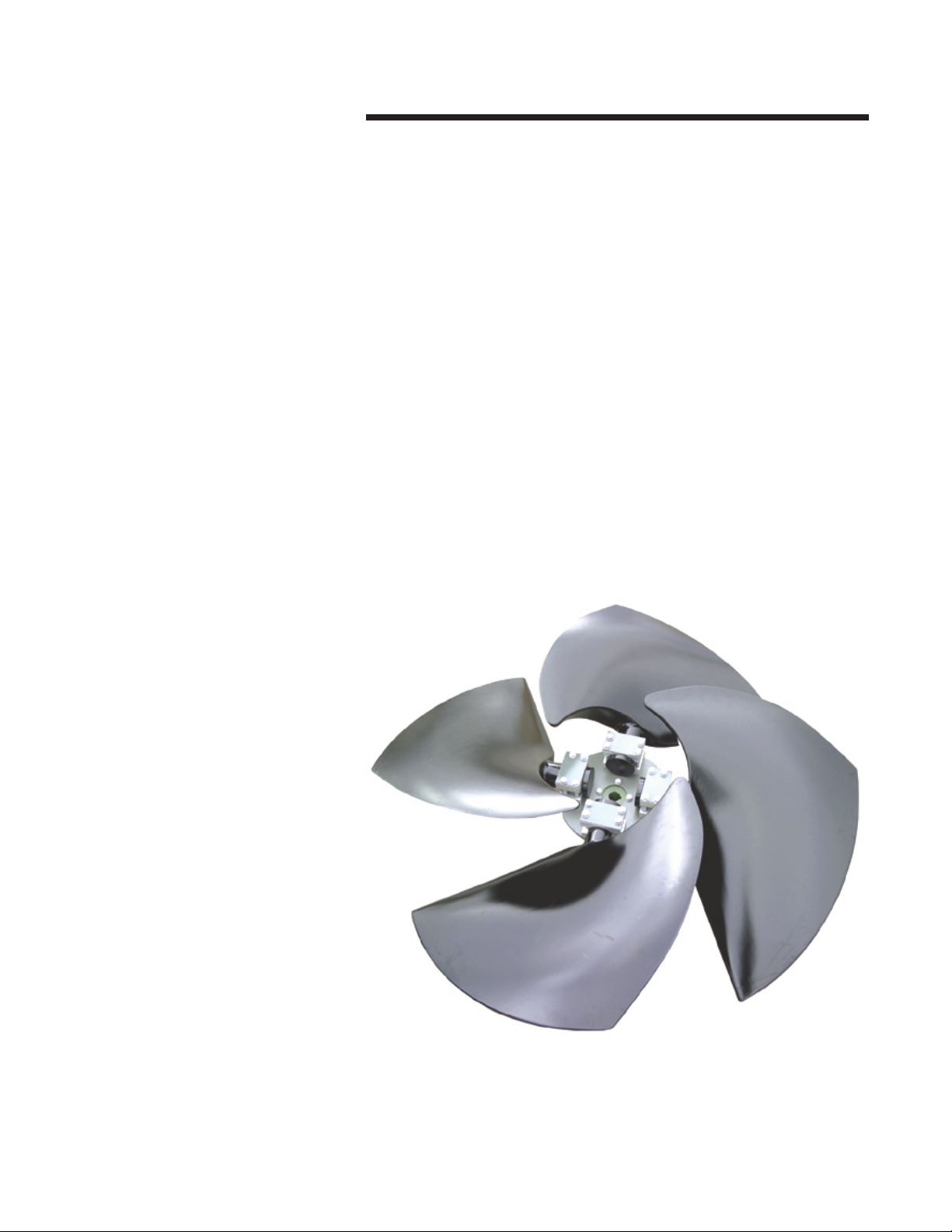

The Marley Ultra Low-Noise series of fans represent the top in the

new generation of super low noise fans—the FRP blades have been

developed to meet the most stringent noise limitations. The fans

permit variable pitch adjustment at standstill and feature a simplified

design. Each blade is fixed to the hub with two bolted aluminum

pillow blocks.

Balancing

When the rotor is dispatched in assembled form, each unit is dynamically balanced within a degree of G = 6.3 in accordance with

ISO 1940/1.

When the fan is dispatched disassembled, the hub is dynamically

balanced and the blades are statically balanced so that the reassembled unit correspond to a degree of G = 6.3 in accordance with

ISO 1940/1. In this case, the blades have the same static moment,

so that they can be positioned in any order on the hub; the blades

of the same supply, are interchangeable.

Storage

Upon unloading the fan, inspect it for any damage. If damage occurred, file a claim immediately against the carrier and mark the bill

of loading accordingly.

After the fan delivery, check the full compliance between order and

delivered goods. Shortages or inconformities have to be reported

within two weeks from receipt of shipment at destination.

If not installed immediately, it is recommended to store the fan in

a dry and shaded area, and do not put any heavy materials of any

kind upon the blades. For long-term storage, it is necessary to check

the condition of the corrosion preventive coating on all machined

surfaces.

4

Page 5

Installation

Rotation and Flow Direction

The rotation direction is correct when the airflow moves from the

convex back (suction surface) of the blade, to the concave side

(pressure surface). Figure 1 shows the conventional clockwise direction of rotation and normal direction of airflow as viewed from

the discharge face of the rotor.

Flow Direction

Flow Direction

Figure 1

Installation Instructions

1––Remove blade pillow block and fasteners 4, 5, 6, 7, 15 from the

hub disk, one set a time (Figure 2).

2––If the hub has not been supplied already assembled to the flange,

install the coupling flange 2 on the disk 3, complying with torque

settings, bolt orientation, tightening order, and pins as shown in the

table following Figure 2.

5

Page 6

Installation

10B

10A

1

5

9

3

7

2

6

104

8

Figure 2

6

Page 7

Installation

Torque hub assembly bolts 11 according to the following table:

Fan Diameter

inches

84" to 96" Type 115

108" to 168" Type 190

3––Hub into driveshaft installation (Figure 2).

• As for the hub with cylindrical bore, the hub is bored to attach

directly to the drive shaft.

Coat the output drive shaft with a thin layer of silicon grease.

If a space ring 10A is supplied, drive it into the drive shaft until it

comes in contact with the drive shaft shoulder.

Drive the hub with cylindrical bore into the drive shaft until it comes

in contact with the drive shaft shoulder (or space ring shoulder if

supplied).

Flange Type Bolt Type

M16 cl. 8.8 230 169

M16 cl. A4-70 126 93

M16 cl. A4-80 168 124

M20 cl. 8.8 447 329

M20 cl. A4-70 246 181

M20 cl. A4-80 328 241

Bolt Torque

N·m ft·lb

Warning

Never power the drive shaft with special washer 16 and the retaining bolt 17 missing or loose.

• As for the hub with tapered bushing hole, be sure drive shaft,

bushing and hub bore are not greased. Slide the bushing into the

drive shaft to your design position.

Position the hub core over the bushing taper; insert bushing screws

through the bushing flange into the threaded hole in the hub coupling;

torque bushing screws according to the following table:

Screw Torque

Bushing Type

N·m ft·lb

Q1 and Q2 40 29

R1 and R2 40 29

7

Page 8

Caution

Warning

Installation

The drive shaft end must remain recessed at least 1⁄32" in the hub

bore to prevent dangerous rotor vertical translation once retaining

bolt 16 has been tightened to the shaft end.

Never power the drive shaft with bushing bolts not torqued or

bushing improperly positioned.

4––Install the blade.

Sandwich the blade shank between the pillow blocks 4 and 5, ensuring both the pins 7 are in proper position (Figure 2).

Fit pillow blocks 4 and 5, pins 7, pillow block plate 6, blade and

pillow block fasteners 15 on hub disk as shown in previous Figure

3 without tightening bolts.

Rotate fan to check tip clearance is in accordance with the specified

value (tip clearance ratio x/D, where x = the distance from the blade

tip to the fan ring and D = the rotor diameter). The gap between

blade tip and fan ring must be measured along blade axis.

Tighten the pillow block bolts 15, to hold the blade in extended

position, leaving enough clearance to allow blade rotation on its

own axis for pitch setting.

5––Setting blade pitch.

The pitch angle of each blade has to be set at the A° value specified

in the rotor identification plate with a 0.5° maximum tolerance: in

order to set the pitch, the quotes shown in following Figure 3 must

be observed; note these quotes are shown on the fan data sheet, and

are specific for each diameter of the Marley Ultra Low-Noise fan.

8

Page 9

Figure 3

U

V

S

T

K

øF

øE

øC

FAN DIAMTER (A)

Z

R

D

G X øH

1

2

3

4

Installation

Rotate the blade on its axis until the required pitch angle is obtained.

Check there is no gap between each blade shaft shoulder and corresponding pillow block.

Torque pillow block bolts 15 according to the following tables,

complying with bolt orientation and tightening order as shown in

Figure 4.

Figure 4

4 Bolt Pillow Block Tightening Order

6––Repeat for each blade steps described in points 4 and 5. Before

starting the pitch angle setting procedure, turn the fan till the blade

to be set is at the same point in the fan ring where previous pitch

angle was set.

In order to determine the torque setting of standard bolts 15, with

the 8.8 stamping, search in the following table the bolt type set for

the diameter of the fan in object.

9

Page 10

Installation

Note

Note

Fan Diameter

inches

84" to 96" M18 282.5 208

108" to 120" M20 400.3 294

132" to 144" M24 679.8 500

The screw class information is shown in the fan documentation part list.

Stainless steel bolts 15 with the A4-80 stamping:

Fan Diameter

inches

84" to 96" M18 175.6 129

108" to 120" M20 246.2 181

132" to 144" M24 425.7 313

In the case of a structure equipped with multiple fans, before

setting the pitch angle to all the fans, set the pitch on one fan

only and follow the instructions for operation starting on page

11.

Bolt 15

Bolt 15

Bolt Torque

N·m ft·lb

Bolt Torque

N·m ft·lb

10

Page 11

Operation

Prior to Start-Up

1––Make sure all the pillow blocks are fixed to the hub boss—if any

movement of the blocks is detected, do not operate the fan and

check the torque of bolts 15.

2––Rotate fan to check tip clearance is in accordance with the specified value (tip clearance ratio x/D, where x = the distance from the

blade tip to the fan ring and D = the rotor diameter). The gap between

blade tip and fan ring must be measured along blade axis.

3––Check gear box oil level or belt tension to be as indicated by

the manufacturer.

4––Remove all tools from the area.

5––Connect motor to power supply.

6––Start fan for a few seconds, and then switch it off. While the fan

is still turning, check that the direction of the blade rotation is correct (see Rotation and Flow Direction).

Note

Post Start-Up

1––Check power absorption: if excessive, reduce the blade pitch

angle until the desired power is achieved (set the new pitch on all

the fans of a same structure); if lower than predicted, increase the

blade pitch angle until the desired power is achieved (set the new

pitch angle on all the fans of a same structure).

Power absorption varies in inverse proportion to the air temperature.

2––Check the vibrations level in the position shown in Figure 5.

Do not exceed the most restrictive amplitude values between the

limits imposed by the normative of the structure where the fan is

installed and the limits imposed by the VDI 2056 normative. In this

case, shut down the unit and trace the cause of such excessive

vibration by referring to section Possible Causes of Vibration in the

following section.

11

Page 12

Operation

Figure 5

12

3––After the rotor has been running for one hour, check the torque

of the hub screws 15.

4––Repeat the check of screws 15 after 24 hours from start-up.

Page 13

Maintenance

Maintenance and Operation

1––Inspect the overall fan condition periodically.

Inspection intervals depend on fan operating conditions and may

vary from a minimum of 2 weeks to a maximum of 6 months.

The following components should be specifically inspected when

inspecting the overall fan conditions:

- Screw torque.

- Fasteners corrosion.

- General condition of blade surface.

2––Ice formation on the blades of operating fans must be strictly

avoided.

3––If ice has formed on a stationary fan, it must be removed prior

to start-up to avoid damaging the blades. Snow formed on a stationary fan must be periodically removed, according to the snow

accumulation itself.

4––Turn off 2-speed motor for at least 30 seconds before switching

to low speed.

5––Stop the unit completely before reversing the fan direction.

6––Check the vibrations level in the position shown in Figure 5 at

regular intervals.

The vibration level must not exceed the most restrictive amplitude

values between the limits imposed by the normative of the structure

where the fan is installed and the limits imposed by the VDI 2056

normative. In this case, shut down the unit and trace the cause of

such excessive vibration by referring to page 14.

It is advisable to keep a record of the readings taken on each occasion for comparison. Always take readings at the same positions

and in the same manner. Observe the safety precautions insuring

power supply is turned off. The fan vibration levels constitute an

invaluable indication of the state of the plant and should be monitored frequently (e.g. monthly).

Temperature Range

This series of fans are designed to operate at these temperatures.

Minimum is -20ºC (-4ºF)

Maximum is +82ºC (+180ºF)

13

Page 14

Maintenance

Possible Causes of Vibration

The actual causes of vibration may change considerably. Some of

the most common are as follows.

1–– Unbalance of one or more blades: the vibration caused by blade

imbalance occurs on the tip path plane with a frequency equal to

the fan RPM and at an amplitude which is dependent on the degree

of imbalance and the square of the rotational speed.

2––Blade pitch angle not included in the ± 0.5° tolerance: this condition causes vibration outside the tip path plane at a frequency

equal to the fan RPM and at an amplitude which is dependent on

the square of the rotational speed.

3–– Blades too close to supports (periodic aerodynamic turbulence):

this condition is characterized by vibration outside the tip path plane

at a frequency equal to the product of the number of fan blades and

RPM. The amplitude depends upon the extent of the aerodynamic

turbulence.

4––Resonance between one of the possible forcing frequencies of

the fan and one or more of the vibration modes of the structure on

which it is installed. The main forcing frequencies generated by the

fan, normally correspond to the following frequencies:

- Fan RPM

- The product of fan RPM and the number of blades

- The product of fan RPM and the number of structural

supports capable of generating aerodynamic turbulence

(if they are arranged in an axial-geometric fashion).

5–– Vibration transmitted by the structure on which the fan is installed:

the frequencies of such vibration depend on both the external forcing

frequencies and the resonant frequencies of the structure.

6––Resonance of the blades with one of the possible forcing frequencies; in the vast majority of cases the vibration occurs outside

of the tip path plane.

7––Misalignment of the drive shaft: this generates vibration with a

frequency that is once or twice the RPM.

8––Loosening of blade and/or speed reducer fixing bolts. The behavior

of the rotor under these circumstances is totally unpredictable, as

it depends upon the extent and location of the loosening.

14

Page 15

Note

Maintenance

9––Worn output shaft bearing: this condition generates vibration on

the tip path plane at a frequency equal to the rotor RPM.

10––The fan and/of the structure bolts are not tightened: in this case

all the bolts have to be tightened.

11––The draining holes of the blades are obstructed: they have to

be opened.

The amplitude of the fan vibrations is determined by the rigidity

of its support. Vibration that would not be critical to a fan supported by a sufficiently rigid structure is amplified by an overly

flexible support. This support rigidity may also cause unexpected

variations in the resonant frequencies of the blades.

15

Page 16

Parts List

Item

Figure 6

1 Blade FRP ––

2 Coupling Flange Steel Epoxy Paint

3 Hub Disk Steel Epoxy Paint

4 Lower Pillow Block Aluminum ––

5 Upper Pillow Block Aluminum ––

6 Pillow Block Plate Steel Epoxy Paint

7 Pins Steel Zinc Plated

8 Coupling Flange Washer Steel - R40 HDG

9 Coupling Flange Lock Washer Steel - R40 HDG

10 Coupling Flange Nut Steel - 8.8 class HDG

10A Space Ring (if needed) Steel Zinc Plated

10B Taper Bushing (if required) Malleable Cast Iron Burnished

11 Coupling Flange Bolt Steel - 8.8 class HDG

12 Pillow Block Washer Steel - R40 HDG

13 Pillow Block Lock Washer Steel - R40 HDG

14 Pillow Block Nut Steel - 8.8 class HDG

15 Pillow Block Bolt Steel - 8.8 class HDG

16 Screw (not included) –– ––

17 Washer (not included) –– ––

Description

Standard

Material

Standard

Protection

Note

16

For special applications, materials and protective coatings

could be different. In this case, make reference to the fan documentation.

Page 17

Parts List

16

10B

10A

14

13

12

3

7

4

6

5

12

15

11

8

2

1

17

16

10

9

8

Figure 6

17

Page 18

Troubleshooting

Trouble Cause Remedy

System congestion. Clean the entire system.

Check the real obstacles area and the inlet shape towards

the original design.

Low air flow

Low power absorption

High power absorption

Rubbing between the

blades and the fan ring

High vibration level

Obstacles to the air flow.

Static pressure higher than the specified

one.

Pitch angle lowered by blade rotation

(e.g. screw (15) not tightened at the right

torque).

Temperature higher than the design.

Temperature lower than the design.

Static pressure lower than the design.

Screws and bolts of the fan and/or the

structure loosened.

Fan not centered.

Tip clearance too small.

Unbalance of one or more blades. Contact SPX Cooling.

Blade pitch angle not included in the 0.5º

tolerance.

Blades too close to supports (periodic aero-

dynamic turbulence).

Resonance between one of the possible

forcing frequencies of the fan and one or

more of the vibration modes of the structure

on which it is installed.

Vibration transmitted by the structure on

which the fan is installed.

Resonance of the blades with one of the

possible forcing frequencies.

Misalignment of the drive shaft. Realign of the drive shaft.

Worn output shaft bearing. Contact the supplier.

The fan and/or the structure bolts are not

tightened.

The draining holes of the blades are ob-

structed.

In dry-coolers the minimum free height of the inlet area has

to be 1 time the fan diameter at least; this height has to be

higher in case of multiple units in line.

Increase blade pitch angle (till 3º after checking the data

sheet selection.

Set the right pitch angle and refer to the operation manual

to set the right torque of screws and bolts.

Increase blade pitch angle (till 3º after checking the data

sheet selection.

Decrease blade pitch angle (till 3º after checking the data

sheet selection.

Decrease blade pitch angle (till 3º after checking the data

sheet selection.

Torque all screws and bolts.

Center the fan.

Increase the fan ring diameter.

Set right blade pitch angle.

Contact SPX Cooling.

Contact SPX Cooling.

Contact SPX Cooling.

Contact SPX Cooling.

Tighten screws and bolts at the right torque.

Open the draining holes.

18

Page 19

Page 20

7401 WEST 129 STREET | OVERLAND PARK, KANSAS 66213 UNITED STATES | 913 664 7400 | spxcooling@spx.com | spxcooling.com

In the interest of technological progress, all products are subject to design and/or material change without notice.

©2009 SPX Cooling Technologies, Inc. | Printed in USA

M07-1126

Loading...

Loading...