Page 1

Cofimco Fan – Adjustable Hub

/

/

User Manual 03-11A

Page 2

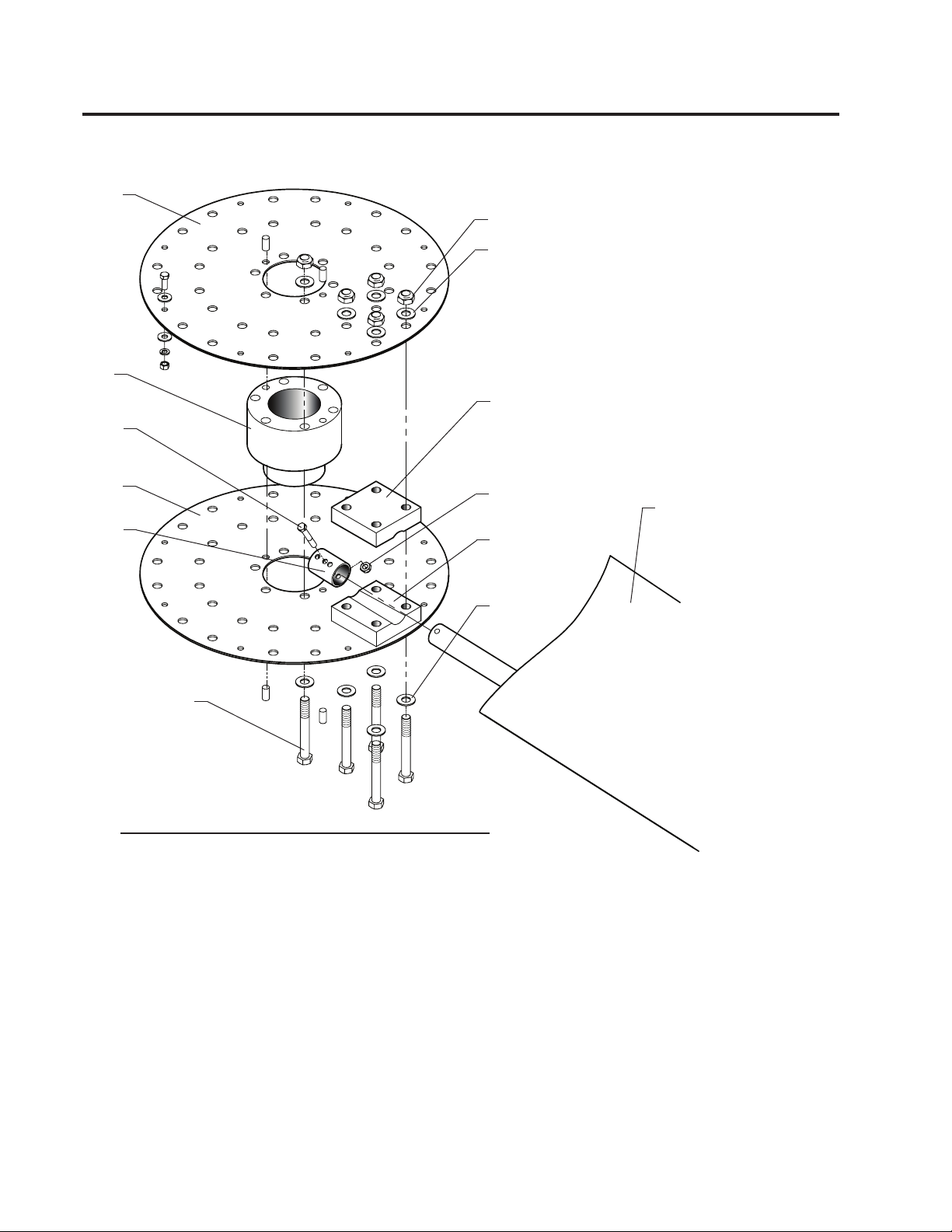

Fan Components

102

101

V11

X14

W29

101

103

104

102

104

VBA

Figure 1—Typical Fan Assembly

X12

200

103

W29

Order No. _______________________________________

Trial Pitch Angle _________________________________

Final Pitch Angle _________________________________

Speed-rpm _____________________________________

Contract hp _____________________________________

2

Page 3

Note

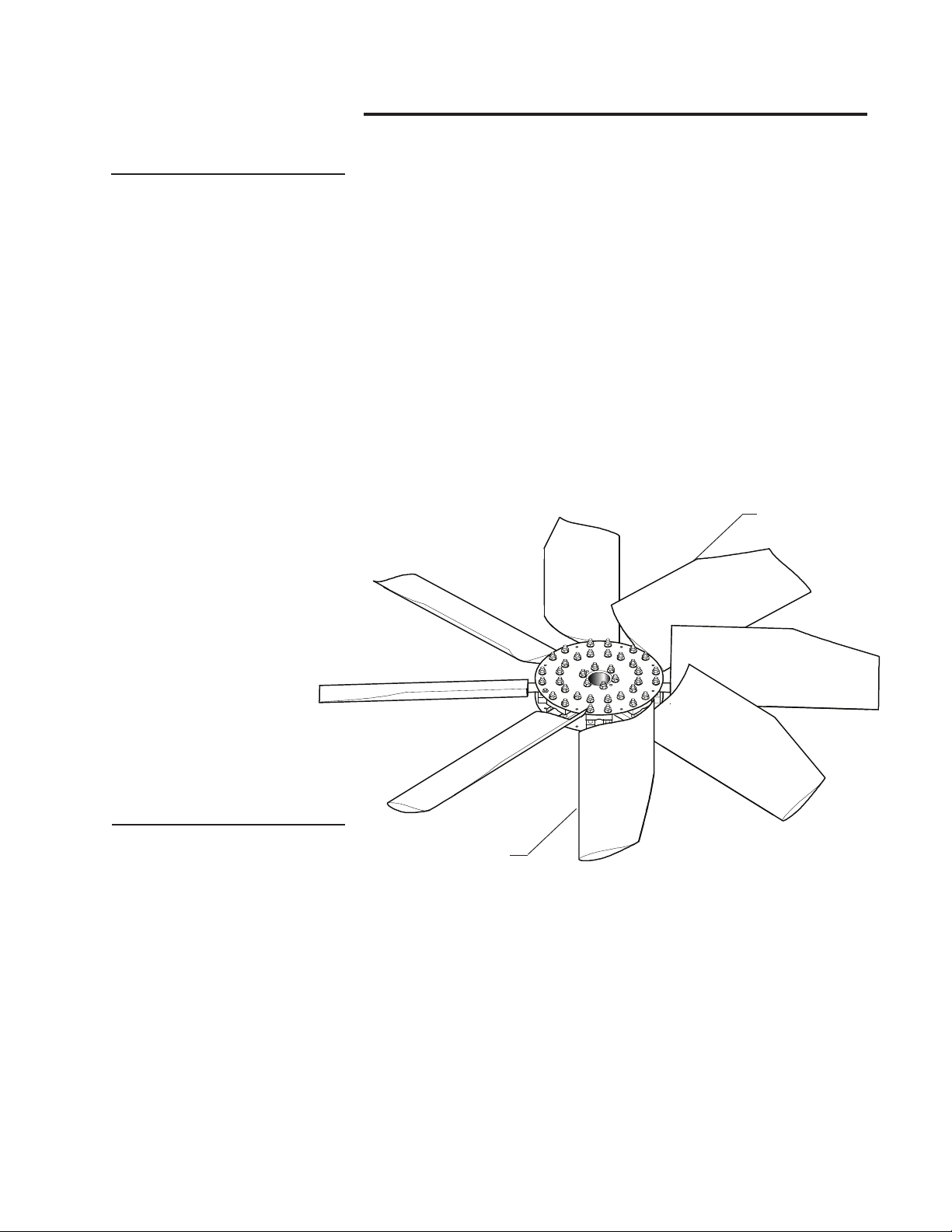

Fan Assembly Instructions

The following instructions apply to installations having straight

bores or tapered output shafts without split taper bushings.

It is convenient to preassemble the fan prior to installation on

the driving shaft.

1—Select a large open area corresponding to the fan diameter.

2—Position the fan hub in the center of the work area with the center

spool 101 oriented as shown in Figure 1.

3—Secure blade retention sleeves 104 to the blade 200 using

3

machine bolt V11 and locking nut X12. Tighten

40 ft·lb

.

ƒ

⁄8" nut X12 to

4—Position the blade clamp blocks 103 around the blade shank so

that the blade 200 droops slightly downward when the blade clamp

hardware is tight.

TRAILING

EDGE

Figure 2

LEADING

EDGE

5—Position the blade clamps and blade between the hub plates

5

102 to align bolt holes. Loosely install

⁄8" bolts VBA, flat washers

W29 and self locking nuts X14 to secure blades. Finger tighten all

5

⁄8" nuts.

6—On fans where the blades overlap at the hub be sure to have

the leading edge under the trailing edge of the forward blade. Refer

to Figure 2.

7—Pull the blades radially outward until the blade retention sleeve

bears against the back side of the blade clamp.

➠

3

Page 4

8—Repeat steps 3 through 7 for all blades.

9—Progressively tighten all blade clamp nuts X14 until the blades

are barely able to move when twisting the blade.

Figure 3

RETENTION

SLEEVE

TIGHTEN BLADE

CLAMP BOLTS TO

100 FT·LB LUBRICATED

TIGHTEN RETENTION

SLEEVE NUT TO

40 FT·LB

10- Measure the final fan diameter. By using a different hole in the

blade retention sleeves the fan diameter can be altered for the ap-

1

propriate fit within the cylinder.

blade tips and the fan cylinder is recommended.

⁄2" minimum clearance between all

Fan Installation Instructions

1—Be sure motor is locked out.

2—Clean the hub bore and driving shaft extension for the full length

of the key.

3—Insert the key in the keyway. The top of the key must be below

the top of the shaft by not more than

fit across the width and must never be altered.

4—After cleaning, apply a coat of anti-seize compound to the engagement portion of the shaft.

5—Raise the fan assembly above the shaft and slowly lower the

hub onto the shaft with the keyways aligned. Make certain the key

does not slide down during installation.

6—Install the Hub Retention Cap Screw with Lock Washer. Torque

hub retention cap screw to 40 ft·lb

4

1

⁄8" (3 mm) . The key is a tight

(54 N·m).

ƒ

Page 5

Note

Adjusting Fan Blade Pitch

The trial pitch is the calculated setting for design conditions

(water rate , heat load, air density, and brake horsepower). The trial

pitch is provided by SPX (see page 2).

1–Select a position on the fan circumference and rotate each blade

to this common location when setting or checking blade pitch. Support the blade tip to maintain a common rotation plane while setting

3

the fan pitch. The pitch is set

by placing a protractor on top of a parallel sided straight edge that

extends across blade width as shown in Figure 4.

2–Be sure all blades are positioned correctly on hub, then set the

pitch. Blades should be within ±

the desired setting is obtained, progressively tighten the hardware

according to Table 5. Recheck the pitch angle. If required, loosen

the hex nuts and reset the pitch as necessary until the proper pitch

angle is obtained.

⁄16" (5 mm) inboard of the blade tip

1

⁄4° of the desired pitch angle. After

Figure 4

Table 5

Bolt

Diameter

3

⁄8"

5

⁄8"

Torque Wrench Setting

ft·lb

100

ƒ

40

N·m

55

136

5

Page 6

Fan Maintenance

Preventative maintenance will prolong useful life and assure continued trouble-free operation. After the first week and subsequently

at six month intervals:

• Torque all hardware to specications referenced in this manual.

• Visually inspect the fan for airborne debris damage, contact with

fan cylinder segments, and corrosive attack. Correct any situations

determined detrimental to fan operation.

• Remove any accumulated scale or dirt.

• Clear blade drain holes at fan tip.

Service

Proper identification of your fan is necessary to insure you receive

correct replacement parts. The Marley cooling tower serial number

can be used to determine the fan and any components installed and

maintained as original equipment on a Marley cooling tower. Please

provide the Marley sales representative the necessary information

when ordering replacement fans or components.

Blades can be replaced without rebalancing the entire fan.

If rebalancing is desired, contact the Marley sales representative

in your area.

6

Page 7

Motor Load

The corrected horsepower should be close to but not exceed the

contract horsepower specified by SPX. Determine corrected horsepower using the following equation.

Actual volts and amperage must be obtained with the fan running

and the specified rate of water flowing over the tower after the motor

and Geareducer have reached operating temperature (approximately

30 minutes of operation).

Note

HP

C

VOLTS

AMPS

DENSITY

A

A

HP

= Corrected Horsepower

= Actual Volts

= Actual Amperage

= Actual Air Density

A

VOLTSA × AMPSA × DENSITY

=

C

VOLTSN × AMPSN × DENSITYA

VOLTS

AMPS

HP

N

DENSITY

D

× HP

N

= Nameplate Volts

N

= Nameplate Amperage

N

= Nameplate Horsepower

= Design Air Density

D

Measurements taken on motors operating with Variable Frequency Drive controls may read up to 15% high from errors in

measuring the approximated sine wave. Instruments capable of

measuring a squared off wave form accurately should be used

for measuring power in this situation.

Do not exceed 30 sec/hour total motor starting time as motor

may overheat.

7

Page 8

7401 WEST 129 STREET | OVERLAND PARK, KANSAS 66213 UNITED STATES | 913 664 7400 | spxcooling@spx.com | spxcooling.com

In the interest of technological progress, all products are subject to design and/or material change without notice.

©2008 SPX Cooling Technologies, Inc. | Printed in USA

Manual 03-11A

Loading...

Loading...