SPP Pumps Thrustream User Manual

THRUSTREAM RANGE

HORIZONTAL SPLIT CASE PUMPS

OPERATORS INSTRUCTIONS

THRUSTREAM

EXTENDED RANGE

Horizontal Split Case

Centrifugal Pumps

And Pump Sets

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPP Pumps Limited |

|

|

|

|

|

|

|

|

|

|

|

|

Telephone: |

|

Document No: |

W12-005E |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Crucible Close |

|

|

|

|

|

|

|

|

|

|

+44 (0)1594 832 701 |

|

|

|

|

Revision No: |

|

3 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mushet Industrial Park |

|

|

|

|

|

|

|

|

|

|

|

|

|

Revision Note No: |

R 39552 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Coleford, Glos |

|

|

|

|

|

|

|

|

|

|

|

|

Fax: |

|

Date Issued: |

August 2012 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ENGLAND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

+44 (0)1594 836 300 |

|

|

|

|

|

|

|

|

Produced at SPP Pumps |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RG31 7SP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Limited Coleford |

England |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DECLARATION OF CONFORMITY

We |

SPP Pumps Limited |

Of |

Crucible Close |

|

Mushet Industrial Park |

|

Coleford |

|

Gloucestershire |

|

England |

|

GL16 8PS |

Declare that: |

|

Equipment: HORIZONTAL SPLIT CASE CENTRIFUGAL PUMP

Model/Type: Models TL to TV (As per the table on page 3) Serial Number: As shown on the Pump Nameplate

For pumps supplied with electric motors:

in accordance with the following Directives:

2006/42/EC |

The Machinery Directive and its amending directives |

2006/95/EC |

Low Voltage Directive |

have been designed and manufactured to the following specifications:

EN 809:1998+A1:2009 |

Pumps & Pump Units for Liquids - Safety Requirements |

EN 12100:2003 |

Parts 1 and 2 - Safety of Machinery |

EN 60204-1:2006 |

Safety of Machinery - Electrical Equipment |

We hereby declare that the equipment named above has been designed to comply with the relevant sections of the above referenced specifications. The units comply with all essential requirements of the Directive.

For pumps supplied without motors:

We hereby declare that this equipment is intended to be incorporated into, or assembled with other machinery to constitute relevant machinery to comply with the essential health and safety requirements of the Directive.

The machinery covered by this declaration must NOT be put into service until the relevant machinery into which it is to be incorporated has been declared in conformity with the provisions of the Directive.

Signed: |

|

Name: |

John Hollins |

Position: |

Engineering Manager - Authorised to sign on behalf of SPP Pumps Limited |

|

Mushet Industrial Park, Crucible Close, Coleford, Gloucestershire, GL16 8PS |

Date: |

25 February 2010 |

W12-005E |

|

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time Page 2 of 28

Operators Instructions for Horizontal |

Manual No/Rev |

Extended Thrustream Centrifugal Pumps |

W12-005E / 3 |

|

|

CONTENTS

Section |

|

|

Page |

|

1. |

General Information & Safety Instructions |

4 |

||

2. |

Transport Handling and Storage |

|

4 |

|

3. |

General Description |

|

5 |

|

4. |

Assembly and Installation |

|

6 |

|

5. |

Commissioning and Operation |

|

8 |

|

6. |

Maintenance and Service |

|

10 |

|

|

6.1 |

Preparation for Maintenance |

|

11 |

|

6.2 |

Repacking the Stuffing Box |

|

11 |

|

6.3 |

Maintenance of Mechanical Seals |

12 |

|

|

6.4 |

Bearing Lubrication |

|

12 |

|

6.5 |

Bearing Replacement |

|

12 |

|

6.6 |

Mechanical Seal Replacement |

|

14 |

|

6.7 |

Pump Overhaul & Repairs |

|

14 |

7. |

Faults and Remedial Action |

|

19 |

|

8. |

Pump Details: |

|

20 |

|

|

8.1 |

Typical Pump Section Single Stage |

20 |

|

|

8.2 |

Parts Identification List Single Stage |

21 |

|

|

8.3 |

Typical Pump Section Two Stage |

|

22 |

|

8.4 |

Parts Identification List Two Stage |

23 |

|

9. |

Metric Bolt Torque Recommendations |

24 |

||

10. |

Spares & Service |

|

28 |

|

Manufacturer’s Information (Where applicable) |

|

|||

|

|

Electric Motor |

Appendix I |

|

|

|

Coupling |

Appendix II |

|

|

|

Mechanical Seal |

Appendix III |

|

Introduction |

|

|

||

This manual gives the safety, installation, operation and maintenance instructions for pumps in the SPP Pumps Ltd Thrustream Extended range of horizontal split case centrifugal pumps for general water and industrial use.

Thrustream pumps are identified by their pump designation and by their size code, the first number is the delivery branch diameter and the second number is the nominal diameter of the impeller in centimetres.

The pump sizes covered by this manual are:

Extended Single Stage

Thrustream Range:

Size |

Pump |

Module |

|

|

|

200/58 |

TR20A |

1E |

|

|

|

300/34 |

TL30A |

1E |

|

|

|

250/42 |

TN25A |

2E |

|

|

|

250/51 |

TQ25A |

2E |

|

|

|

250/68 |

TT25A |

2E |

|

|

|

300/59 |

TR30A |

2E |

|

|

|

350/39 |

TM35A |

2E |

|

|

|

300/48 |

TP30A |

3E |

|

|

|

300/77 |

TV30A |

3E |

|

|

|

350/44 |

TN35A |

3E |

|

|

|

350/54 |

TQ35A |

3E |

|

|

|

350/66 |

TT35A |

3E |

|

|

|

Extended Two Stage

Thrustream Range:

150/48-2 |

TP15T |

2T |

|

|

|

200/58-2 |

TR20T |

3T |

|

|

|

This manual covers the Extended Range of Thrustream pumps that are built for use in the horizontal position. For information on pumps built for vertical applications, please refer to a separate manual that can be obtained from SPP Pumps Limited.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time Page 3 of 28

Manual No/Rev |

Operators Instructions for Horizontal |

W12-005E / 3 |

Extended Thrustream Centrifugal Pumps |

|

|

1.General Information and Safety Instructions

The products supplied by SPP Pumps Ltd. have been designed with safety in mind. Where hazards cannot be eliminated, the risk has been minimised by the use of guards and other design features. Some hazards cannot be guarded against and the instructions below MUST BE COMPLIED WITH for safe operation. These instructions cannot cover all circumstances: YOU are responsible for using safe working practices at all times.

1.1SPP Pumps Ltd. products are designed for installation in designated areas, which are to be kept clean and free of obstructions that may restrict safe access to the controls and maintenance access points.

A pump nameplate is fitted to each unit and must not be removed. Loss of this plate could make identification impossible. This in turn could affect safety and cause difficulty in obtaining spare parts. Should accidental loss or damage occur, contact SPP Pumps Ltd. immediately.

1.2Access to the equipment should be restricted to the personnel responsible for installation, operation and maintenance and they must be trained, adequately qualified and supplied with the appropriate tools for their respective tasks.

1.3SPP Pumps Ltd. requires that all personnel that are responsible for installation, operation or maintenance of the equipment, have access to and study the product instruction manual BEFORE any work is done and that they will comply with all local and industry based safety instructions and regulations.

1.4Ear defenders should be worn where the specified equipment noise level exceeds locally defined safe levels. Safety glasses or goggles should be worn where working with pressurised systems and hazardous substances. Other personal protection equipment must be worn where local rules apply.

1.5Do NOT wear loose or frayed clothing or jewellery that could catch on the controls or become trapped in the equipment.

1.6Check and confirm that the manual is the relevant copy by comparing the serial number on the identification plate with that on the manual.

1.7Note any limits to the pump application specified in the contract documentation. Operation of the equipment outside these limits will increase the risk from hazards noted below and may lead to premature and hazardous pump failure.

1.8Clear and easy access to all controls, gauges and dials etc. MUST be maintained at all times. Hazardous or flammable materials must NOT be stored in pump rooms unless safe areas or racking and suitable containers have been provided.

1.9IMPROPER INSTALLATION, OPERATION OR MAINTENANCE OF THIS SPP PUMPS LTD PRODUCT COULD RESULT IN INJURY OR DEATH.

1.10Within the manual, safety instructions are marked with safety symbols.

Hazard

This symbol refers to general mechanical aspects of safety.

Hazard

This symbol refers to electrical safety.

ATTENTION |

This symbol gives warning of a |

|

|

hazard to the pump itself, which in turn, could |

|

cause a risk to personal safety. |

|

2.Transport Handling and

Storage Instructions

2.1Transport

Horizontal Extended Thrustream pumpsets are despatched fully assembled except where stability or handling constraints require the motor to be packed and delivered separately.

Pumps are protected against corrosion and packed for transport by normal road, rail and sea carriers.

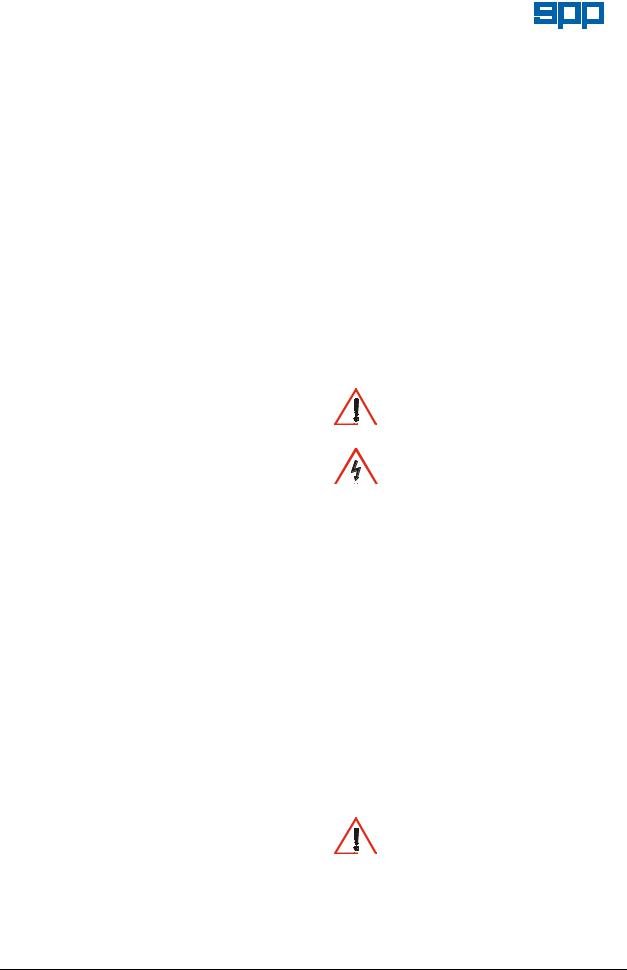

2.2Handling

Crushing Hazard

When lifting the pump unit, use lifting equipment having a safe working load rating suitable for the weight specified.

Use suitable slings for lifting any pump not provided with lifting points.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time Page 4 of 28

Operators Instructions for Horizontal |

Manual No/Rev |

Extended Thrustream Centrifugal Pumps |

W12-005E / 3 |

|

|

The use of suitable forklift truck and four-chain crane sling equipment is recommended but locally approved equipment of suitable rating maybe used.

Pumps are usually supplied on pallets for handling by forklift truck, to lift from the pallet the pump should be slung as shown.

Pump weight is shown on the general arrangement drawing supplied with each pump or pumpset.

2.3Storage

Shearing Hazard

Do NOT place fingers or hands etc. into

the suction or discharge pipe outlets and do NOT touch the impeller. If rotated this may cause severe injury. To prevent ingress of any objects, retain the protection covers or packaging in place until removal is necessary for installation. If the packaging or suction and discharge covers are removed for inspection purposes, replace afterwards to protect the

the suction or discharge pipe outlets and do NOT touch the impeller. If rotated this may cause severe injury. To prevent ingress of any objects, retain the protection covers or packaging in place until removal is necessary for installation. If the packaging or suction and discharge covers are removed for inspection purposes, replace afterwards to protect the

pump and maintain safety.

2.3.1Temporary Storage for up to Six Weeks

If the pump is not to be used immediately, it should be stored carefully in a horizontal position, in a sheltered, dry location. Additional rust preventative should be applied to all unpainted carbon steel or cast iron parts. Fit or retain in place the covers to the suction and discharge flanges and all other pipe connections. Rust preventative and flange covers should not be removed until final installation.

When pumps are not in use, the pump shaft should be rotated several turns, every six weeks.

2.3.2Long Term Storage

It is recommended that the pump is stored in a clean dry place that is not subject to a wide temperature variation. Pack the bearings with the specified grease and periodically inspect the bearing housings to ensure that they are free from damp and moisture. Leave the covers for the suction and discharge flanges in place or replace with suitable covers to prevent ingress of dirt or moisture. Rotate the shaft several turns monthly, to distribute the grease and prevent pitting of bearing surfaces.

If storage in the open cannot be avoided, cover the pump with a tarpaulin sheet, but allow dry air to circulate around the pump.

For special protection of electric motors and mechanical seals, refer to the manufacturer’s instructions in Appendix l & III.

2.3.3Exposed or Extreme Conditions Storage

For exposed storage or extreme variants in atmospheric or environmental conditions, please refer to SPP Pumps Ltd.

3.General Description

SPP Pumps Ltd. Thrustream Pumps are a range of centrifugal pumps that are usually supplied as pumpsets with electric motors but can be supplied separately for customers to fit to drivers of their own preference.

3.1.Pumps

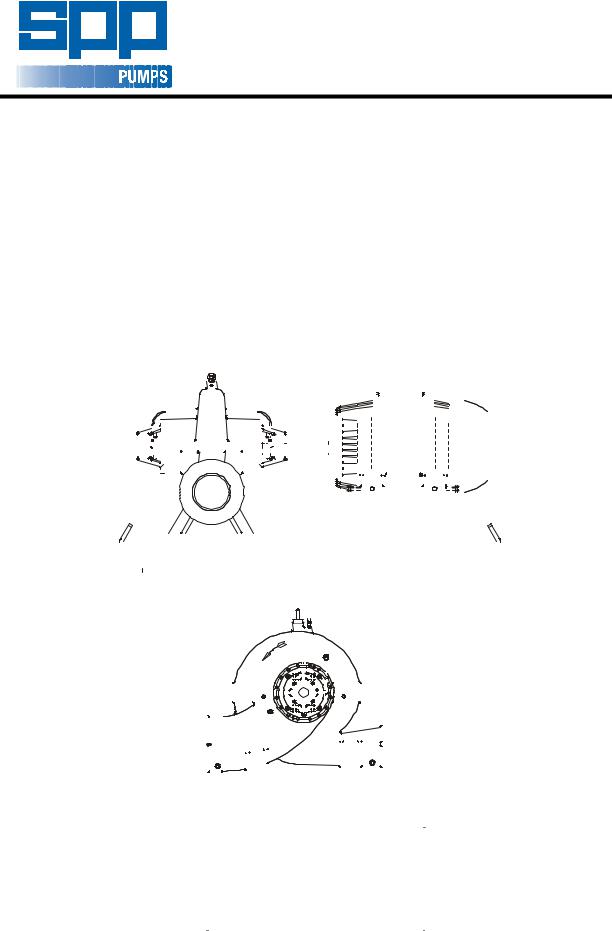

The mechanical assembly comprises a rigid shaft, supported by grease-lubricated ball bearings at each end of the pump shaft. The pump casing is fitted with wear rings and houses a double entry shrouded type impeller mounted on a stiff shaft. Some pumps in the range are fitted with a pair of single side entry impellers. The seal chamber is housed in the casing inserts retained within the casing. Some impellers may be fitted with wear rings if required. When the top half casing is removed, the bearing housings, inserts, shaft and impeller assembly can be removed from the bottom casing for maintenance without disconnection of pipework.

The suction and discharge branch flanges are positioned horizontally at 90 degrees to and below the shaft centreline. The pump casings allow for construction to suit different rotations.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time Page 5 of 28

Manual No/Rev |

Operators Instructions for Horizontal |

W12-005E / 3 |

Extended Thrustream Centrifugal Pumps |

|

|

The standard pump is soft packed but the option to fit internal component mechanical seals or selected external cartridge mechanical seals is provided to suit customer’s requirements. These pumps are normally supplied with a cast iron casing and impeller but bronze may be supplied where required. Other parts may be supplied in a variety of materials to suit the pump application.

In standard form, these pumps are designed to pump liquids at temperatures up to 80oC. Where pumps are needed to suit higher temperatures, please refer to SPP Pumps Ltd.

Nameplate details are shown on the back cover of this manual, full pump specification can be supplied on a data sheet, if requested.

Note 1) The head specified is the Duty Head generated by the pump only.

2) - Suction pressure must be included when assessing the Maximum Working Pressure.

3.2Electric Motor Driven Pumpsets

event of a handling accident, carefully check that the pump is not damaged before installation and commissioning.

4.2Preparation for Mounting

Before installation, check that the pump mounting location is suitable for accepting the pump. Refer to the certified General Assembly drawing, for details of pump installation dimensions.

4.3Location of Pump

The pump should be located as near the liquid source as practical, with adequate accessibility for inspection and repair and sufficient headroom for lifting tackle if necessary.

Where pumps are electric motor driven, power source electrical characteristics should match those shown on motor data plate. A qualified electrical contractor should be used to make the electrical connection.

4.4Foundations

Pumpsets are supplied mounted on a substantial fabricated baseplate; the complete assembly is of a rigid construction, being intended for mounting on suitable foundations.

These pumpsets are supplied fitted with a proprietary high efficiency electric motor adequately sized for the duty specified. For details of the motor supplied, refer to the manufacturer’s instructions in Appendix I.

The proprietary flexible coupling has been selected to meet the power transmission and other operating requirements for the pumpset. Coupling fitting and maintenance details are given in the manufacturer’s instructions in Appendix II.

4.Assembly and Installation

Shearing Hazard

Do NOT place fingers or hands etc. into the suction or discharge pipe outlets and do NOT touch the impeller, if rotated this

may cause severe injury. To prevent ingress of any objects, retain the protection covers or packaging in place until removal is necessary for installation.

4.1Initial Inspection for Damage

During transport and storage, accidental damage to the pump may have occurred. When the pump is to be installed, or in the

The pump is to be mounted on a substantial floor or plinth and secured with suitable foundation bolts to minimise vibration. The foundation must have a flat level surface and be of sufficient depth to contain the foundation bolts. The pump unit should be installed with the flange faces set in a vertical position. Packers may be placed under the baseplate near the bolt holes to level the unit if the floor is uneven. The foundation bolts should be tightened and the shaft alignment checked again before commissioning and putting the pump into operation.

For full installation instructions and guidance on the design of suitable foundations for pumpsets refer to the SPP Guide to Pump Installation, obtainable on request from SPP Pumps Ltd.

4.5Pump Preparation

Abrasion & Entrapment Hazard

Do NOT touch any moving or rotating

parts. Guards are provided to prevent access to these parts, where they have been removed for maintenance they MUST be

parts. Guards are provided to prevent access to these parts, where they have been removed for maintenance they MUST be

replaced before operating the equipment.

For soft packed pumps the packing rings and related components are often supplied loose. Ensure that the packing is installed as per instructions in section 6.2 paragraphs 10 to 20.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time Page 6 of 28

Operators Instructions for Horizontal |

Manual No/Rev |

Extended Thrustream Centrifugal Pumps |

W12-005E / 3 |

|

|

Remove packaging but leave the flange covers in place, check that impeller rotates freely by hand by turning the shaft.

If the pump has been in storage, remove any protective coatings. If the bearing housings were filled with grease flush, and re-lubricate the bearings.

4.6Suction Pipework

The run of suction pipework must be such that air can NOT become trapped where it would be drawn into the pump on starting. The bore of the suction pipe is recommended to be one or two sizes larger than the pump suction branch and reducers if used must be eccentric to eliminate the possibility of an air pocket being formed.

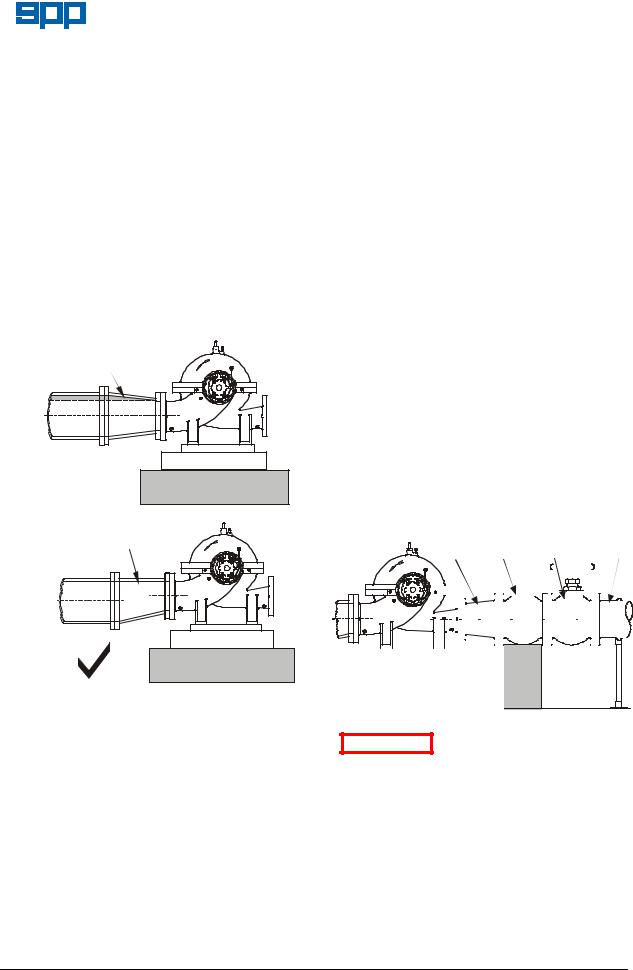

CONCENTRIC REDUCER

WILL TRAP AIR IN THE

SUCTION PIPE

X |

Foundation Plinth |

|

FLAT TOP REDUCER

WILL NOT TRAP AIR IN

THE SUCTION PIPE

Foundation Plinth

Bends in the suction pipeline should be as large as possible, the pipe made as short and as straight as possible and all joints must be fully airtight. A gradual rise in the suction pipeline is recommended to prevent formation of air pockets. If fitting a foot valve, it should have a free area of one and a half times the area of the suction pipe.

Where pumping water at temperatures above 70°C, care must be taken to ensure that enough pressure is available at the impeller entry to prevent vaporisation. Expansion joints are recommended to prevent strain on the pump casing.

An appropriate fine strainer is recommended to prevent foreign matter from being drawn

into the pump. A screen or basket strainer may also be required to hold back larger items. These should be sized to maintain the flow through them to below 0.6 m/s.

The suction pipe work must be flushed clean to ensure that site debris is not drawn into the pump when it is commissioned.

4.7Discharge Pipework

The bore of the discharge pipe should ideally be sized to ensure a flow velocity of 2.5 to 3 m/s is not exceeded. This is usually one size larger than the discharge branch. Pipework should be as short and straight as possible to reduce friction head loss.

A non-return valve is usually fitted to prevent the pump from excessive backpressure and reverse rotation and a discharge valve is usually fitted for isolation purposes to allow for inspection and maintenance on the pump.

Where adverse suction conditions may cause the pump to lose its prime, the use of an external automatic priming device, such as a vacuum pump, is recommended.

The suction and discharge pipework must be independently supported and positioned such that no excessive forces and moments are exerted on the pump flanges.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHECK |

DISCHARGE |

|

DISCHARGE |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

INCREASER VALVE |

|

|

|

VALVE |

|

|

|

PIPE |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check |

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve |

|

Foundation Plinth |

|

Support |

|||

|

|

|

|

|

|

|

Failure to support suction and ATTENTION delivery pipework may result in

distortion of the pump casing, with the possibility of early pump failure.

4.8Guards

If guards have been removed to install packing or to check mechanical seal connections, they MUST be replaced to maintain safe operation of the pump. Refer to the General Arrangement drawing for specific fixing methods for the guarding supplied.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time Page 7 of 28

Loading...

Loading...