SPP Pumps Auto Prime Q Workshop Manual

AUTOPRIME

Q RANGE PUMPS

WORKSHOP MANUAL

AUTOPRIME

Q RANGE

OF DIESEL DRIVEN

MOBILE PUMPS

SPP Pumps Limited.

Crucible Close

Mushet Industrial Park

Coleford, Glos

ENGLAND

GL16 8PS

Telephone:

+44 (0) 1594 832701

Fax:

+44 (0) 1594 836300

Document No. W72-021E

Revision No: 8

Revision Note No: R39573

Date Issued. Aug 2012

Produced at SPP Pumps

Limited, Coleford, England

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 2 of 36

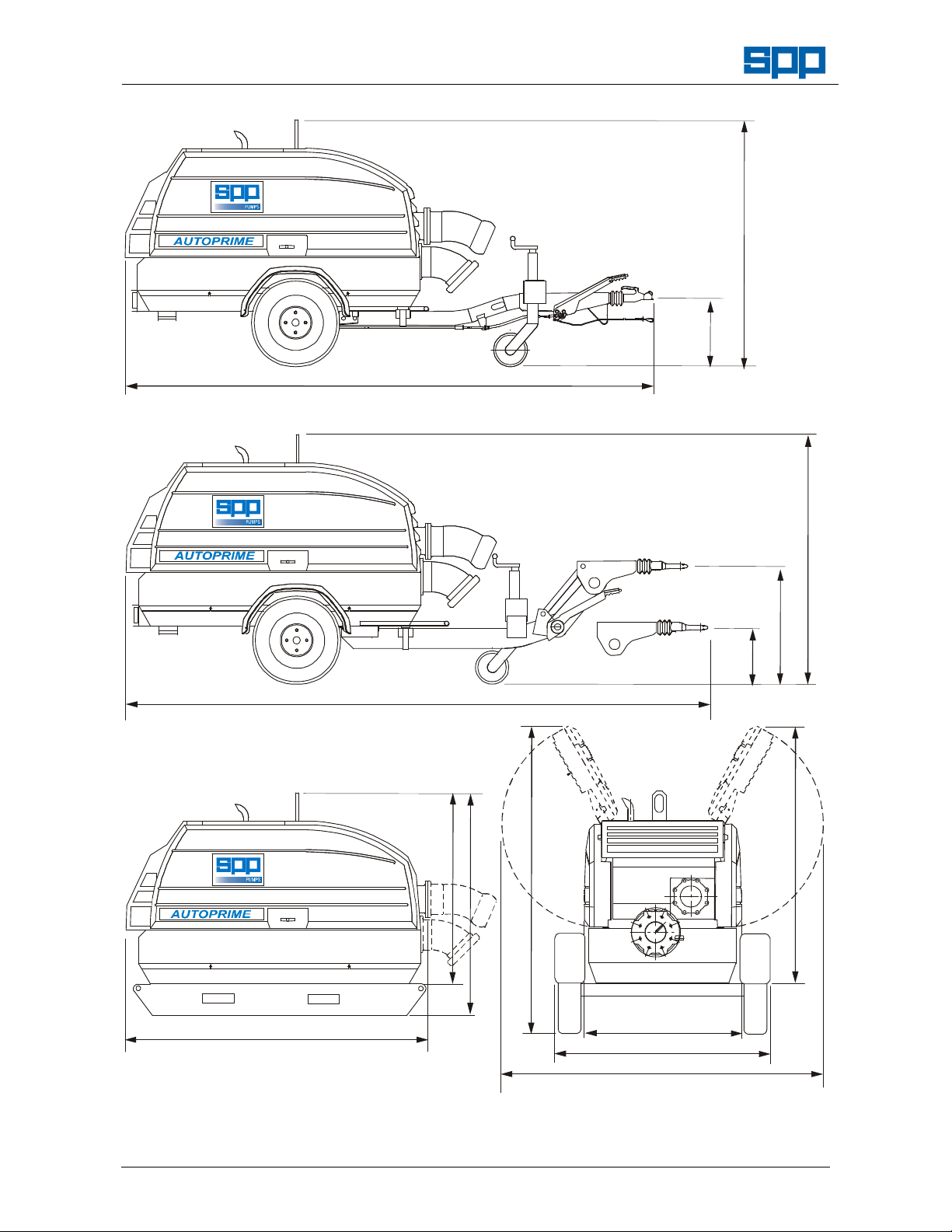

4050 MAX - 3960 MIN.

4352 MAX - 4262 MIN.

1778 MAX - 1718 MIN.

495 MAX

435 MIN

1778 MAX - 1718 MIN.

2115

1150

1600

2300

1350

1600

2150 MAX

1712

450

850

FIXED HEIGHT TOW HITCH

VARIABLE HEIGHT TOW HITCH

PUMP ‘POD’ & PUMP ON SKID

THE HITCH TYPE MAY BE

CHANGED TO SUIT CUSTOMER

REQUIREMENTS

TRAILER

END VIEW

1287kg max

1400kg max

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 3 of 36

CONTENTS

1. INTRODUCTION .................. 4

2. SAFETY PRECAUTIONS 5

2.1

Safety Symbols 5

2.2

Pump Safety Precautions 5

3. HANDLING & TRANSPORT 5

3.1

Lifting 5

3.2

Road Trailer Versions 5

3.3

Skid Mounted Units 5

3.4

Pod Units 5

3.5

Trailer or Wagon Carriage 5

4. SERIAL NUMBER 6

5. FAULT FINDING 6

5.1

Fault Finding Guide 6

5.2

Priming System Checks 6

5.3

Drive Belt Checks 6

5.4

Vacuum Pump Clutch Checks 6

5.5

Solenoid Valve Checks 7

5.6

Priming Filter Checks 7

5.7

Priming Tank Filter Checks 7

5.8

Non Return Valve Checks 7

5.9

Air Leak Checks 7

5.10

Vacuum Pump Checks 7

5.11

Electrical Checks 7

6. PUMP DISASSEMBLY 8

6.1

General Comments 8

6.2

Battery Removal Procedure 8

6.3

Preparation for Pump Removal 8

6.4

Disconnection of Controls Wiring 8

6.5

Louvre and Front Panel Removal 10

6.6

Canopy Removal Procedure 10

6.7

Pump & Engine Unit Removal 10

6.8

Pump Disassembly Procedure 10

6.9

Inspection of Pump Parts 11

6.10

Coalescer Disassembly 11

6.11

Vacuum Pump Disassembly 12

6.12

Priming Tank Disassembly 12

7. PUMP ASSEMBLY 13

7.1

General Comments: 13

7.2

Special Tools 13

7.3

Pump Assembly 13

7.4

Coalescer Assembly 17

7.5

Vacuum Pump Assembly 19

7.6

Priming Tank Assembly 20

7.7

Pump End Final Assembly 21

7.8

Chassis & Fuel Tank Assembly 22

7.9

Engine Assembly 24

7.10

Engine to Pump Assembly 25

7.11

Vacuum Pump Drive Assembly 25

7.12

Lifter Assembly 26

7.13

Pump Unit to Chassis Assembly 26

7.14

Canopy Assembly Procedure 26

7.15

Control Panel & Electrical Wiring 28

8. WIRING DIAGRAMS 29

8.1

Wiring Diagram for 3CE1 Engine 29

8.2

Wiring Diagram for 4LE2 Engine 30

8.3 Wiring Diagram for 3024 Engine 31

9. OPTIONAL EQUIPMENT 32

9.1

Label Sets in Foreign Languages 32

9.2

Trailer Plate for UK 32

9.3

Emergency Stop Button - Roof 32

9.4

Trailer Equipment for France 32

9.5

Trailer Hitches 32

9.6

Trailer Lights for Europe 32

9.7

Alternative Door Colours 32

9.8

Battery Isolator Switch 32

9.9

Spare Wheel 32

9.10

Speed Control 32

9.11

Spark Arrestor – 3CE1 33

9.12

Spark Arrestor – 4LE1 & 4LE2 33

9.13

Hose Fittings 33

10. INSPECTION & TESTING 33

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 4 of 36

1. INTRODUCTION

The purpose of this handbook is to give

instructions for the disassembly and

reassembly of the SPP AUTOPRIME Q

Range of diesel engine driven pumps.

Instructions and statements contained within

this handbook are given with our best

intentions and are correct at the time of

compilation. They are subject to alteration at

any time.

These pumps are most commonly supplied

mounted on 2 wheel road trailers but can

also be supplied on site trailers, skid

mounted, or as a pod unit for customer’s to

mount on suitable foundations.

A range of optional equipment is available.

Please refer to section 9 for details.

This manual covers the following pump configurations:

Standard Pump configuration from June 2007

Pump

Type

Engine

Fuel

Tank

Priming

System

Control

Panel

QI 100 Isuzu 3CE1 220L

Single

Probe

Electric

Prime

Fixed or

Variable

Speed

Control

QI 150 Isuzu 3CE1 220L

QI 150M Isuzu 4LE2 220L

QC150M Cat 3024 2.2 220L

QI 200

Isuzu 4LE2 220L

QHH80 Isuzu 4LE2 220L

omers to mount on vehicles or other equipment as required.

Note: For special, non standard specifications for pumps not listed above, many parts will be common

BUT refer to SPP Pumps Limited for confirmation of part numbers before ordering spare parts.

Pump Main Components

VACUUM

PUMP

COALESCER

(far side)

PRIMING TANK

AIR FILTER

CONTROL

PANEL

RADIATOR

FILLER CAP

EXHAUST

SILENCER

FRONT

PANEL

VACUUM PUMP

DRIVE BELT

AND CLUTCH

PRIMING

TANK

DRIVE END

SHAFT BEARING

FUEL

FILLER

PUMP END

SHAFT BEARINGS

SUCTION

FLANGE

DELIVERY

FLANGE

NON

RETURN

VALVE

UNIT

LIFTER

VOLUTE

SOLENOID

VALVE

MECHANICAL

SEAL OIL

RESERVOIR

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 5 of 36

ATTENTION

2. SAFETY PRECAUTIONS

2.1 Safety Symbols

Safety instructions within this manual are

marked with the following symbols:

This symbol refers to general mechanical

aspects of safety.

This symbol refers to electrical safety.

This symbol gives warning of a

hazard to the pump itself, which in

turn could cause a risk to personal

safety.

2.2 Pump Safety Precautions

Apply to all of the following:

1. This pump contains exposed moving parts

and hot surfaces DO NOT OPERATE THE

PUMP WITH THE DOORS OPEN. Guards

removed for maintenance must be replaced

before starting the pump.

2. Never insert anything into the pump casing

whilst the pump is running and the suction

and delivery hoses are disconnected.

3. Never use collapsible hoses on the suction

side of the pump and use all pump flange

holes to fit suction and delivery hose

connections.

4. Always lift pump sets vertically by the lifting

eye. Any side force will damage the lifter.

Never lift with suction or delivery hoses

attached. The increased weight of these

items may cause lifting gear failure.

5. Check the type of liquid being pumped before

working on pump ends. Residues could be

hazardous to your health. If in doubt flush out

with clean water before work commences.

6. Personnel working on the pump unit must

always wear clean correctly fitting clothing

and safety footwear. Clothing impregnated

with oil or fuel can constitute a health hazard

through prolonged contact with the skin and

may also constitute a fire hazard.

7. Always allow adequate ventilation for diesel

engines. Be aware of fire risks from items

such as exhaust pipes and silencers. Never

place flammable items around the unit.

3. HANDLING & TRANSPORT

3.1 Lifting

The central lifting point is designed

for vertical lifting only and must

NOT be used to pull the unit sideways.

Before lifting ensure that the lifting point is

not bent or damaged.

Do NOT use a lift truck with forks under the

fuel tank and do NOT lift with the hoses

attached.

3.2 Road Trailer Versions

Road trailers may be fitted with towing

hitches to suit customer requirements, the

trailers may have fixed or variable height

hitches. Lights are provided as standard but

customers may request provision for lighting

boards and must attach vehicle registration

plates to comply with local regulations.

3.3 Skid Mounted Units

In addition to the central lift point, the skid is

fitted with slots to allow use of a lift truck with

forks to lift and position the unit.

3.4 Pod Units

These are only to be lifted using the central

lifting point; do NOT use a lift truck with forks

under the fuel tank. The unit must be located

on firm level foundations.

For details of the attachment points provided

for pod units, refer to the SPP Pumps Limited

or the GA drawing supplied.

3.5 Trailer or Wagon Carriage

Transportation on a trailer or wagon will

require the unit to be strapped down.

Under no circumstances should straps

be passed over the top of the canopy or

around the doors.

For trailer-mounted units, level the unit with

the jockey wheel and pass a strap across the

draw bar just in front of the bracket that

retains the front of the pod. At the rear

underside of the trailer-mounted units, a

security bracket is provided to chain the unit

to an anchor point. This is also to be used to

strap the unit down for transport.

For skid-mounted units, holes are provided in

the front and rear of each skid for strapping

down.

Pods are supplied fitted to pallets that should

be firmly tied down to the wagon or trailer.

ATTENTION

ATTENTION

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 6 of 36

4. SERIAL NUMBER

The serial number plate is fitted inside the

control panel door.

This serial number must be quoted in any

enquiry for spare parts or service.

5. FAULT FINDING

5.1 Fault Finding Guide

Unit does not start

•

Fuel consumed.

•

Trip switches need resetting.

•

Warning lights on & shutdown circuit

activated.

•

Battery with low charge level.

•

Refer to engine supplier’s manual for

engine checks.

Unit does not prime

•

Volute drain tap open.

•

Air leak in priming system.

•

Air leak in suction hoses or fittings

•

Blockage in suction hoses or strainer.

•

Non-return valve not sealing.

•

Internal damage to hose from solenoid

valve to vacuum pump.

•

Solenoid valve not operating.

•

Solenoid valve blocked.

•

Priming tank air filter blocked.

•

Priming tank knitmesh blocked.

•

Vacuum pump belts loose or broken.

•

Vacuum pump electric clutch not

engaged.

•

Vacuum pump failure.

•

Suction head too great.

Unit does not pump

•

Blockage in delivery hoses.

•

Blockage in impeller.

•

Excessive impeller clearances.

•

Broken Impeller.

•

Pump drive coupling disengaged.

•

Delivery head too great.

5.2 Priming System Checks

Disconnect the suction hose. Place a flat

board over the suction fitting to check that

the priming system and vacuum pump is

working.

If a vacuum gauge is fitted to the suction

the vacuum pump should produce a

vacuum of at least 9 metres water.

5.3 Drive Belt Checks

The vacuum pump drive belts run between

the pump shaft and the electro magnetic

clutch on the vacuum pump. See the

maintenance instructions in section 7.11 for

the belt tensioning method.

5.4 Vacuum Pump Clutch Checks

The vacuum pump clutch is electrically

operated. If the clutch is disengaged the

belts still turn but the centre of the clutch

will be stationary.

The clutch requires 12 volts to actuate it.

This voltage controlled by a timer and

supplied via a relay by wire No 22 of the

wiring loom. If the wiring is disturbed during

investigations ensure that it is replaced

correctly.

The priming system electrical circuit is

protected by a circuit breaker mounted on

the control panel. If this trips out, push the

central button to reset. If the breaker will not

reset or is constantly tripped then there is

an electrical fault.

The level sensing probes control the

electrical supply to the clutch, with a timer.

If there is no electrical supply to the clutch,

check that the power light is illuminated on

the priming control box. If this is on then

disconnect the clutch and check if there is

12 Volts across the wires. If there is then

the clutch has failed and should be

replaced.

SPP Pumps Limited

Crucible Close, Mushet Industrial Park,

Coleford, Gloucestershire, ENGLAND,

GL16 8PS

Tel

: +44(0)1594 832701

Fax

: +44(0)1594

836300

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 7 of 36

If the 12 Volt supply is not provided to the

clutch, check the continuity of the cables

and rectify any bad connections.

If the control box does not provide the 12

Volt supply for the clutch the control box is

faulty and must be replaced.

5.5 Solenoid Valve Checks

The electrically operated solenoid valve is

connected to the top of the priming tank.

The valve is reliable but if a fault is

suspected it is most likely to be a problem

with the wiring. Wire No 28 of the loom

supplies 12 Volts, wire No 8 is an earth

return.

5.6 Priming Filter Checks

The priming tank air filter is mounted in the

top of the priming tank. To remove and

check the filter condition, follow the

instruction given in the maintenance section

of this manual.

5.7 Priming Tank Filter Checks

It is extremely unlikely that the priming tank

knitmesh filter will ever become sufficiently

blocked to prevent priming. Instructions for

dismantling the unit and removing and

cleaning the knitmesh filter are given in the

maintenance section of this manual.

5.8 Non Return Valve Checks

The volute non-return valve needs to seal if

the priming system is to function. The non-

return valve can be examined by removing

the discharge quick release coupling - see

the relevant section of the maintenance

instructions. Ensure that there is nothing

jammed under the valve especially at the

back around the valve hinge.

5.9 Air Leak Checks

It is extremely unlikely that there will be air

leaks at any of the priming system sealing

faces. Leaks may occur if the suction quick

release fitting has been moved or the

priming tank has recently been dismantled.

If the vacuum pump is working but not

achieving full vacuum fit a quick release

connection cap and gauge to the suction

hose. Run the unit to achieve a vacuum, as

indicated by the gauge, then turn the unit

off. Note how long the vacuum takes to

decay. A pump in full working order will

achieve a vacuum of 9 metres water and

hold it for in excess of five minutes.

5.10 Vacuum Pump Checks

If the vacuum pump is considered to be at

fault no attempt should be made to

dismantle it. Obtain a replacement unit.

To check the operation of the vacuum

pump, disconnect the hose running

between the priming tank and the vacuum

pump.

Warning: The hose is stiff and very difficult

to remove. Do not disconnect the hose

while the unit is running. If any solid

objects, grit or mud are drawn up the hose

they will cause serious damage to the

internals of the vacuum pump.

Disconnection of this hose should only be

considered as a last resort. Conduct other

investigations before resorting to this

course of action.

Once the hose between the vacuum pump

and the coalescer has been disconnected

start up the unit and place a small clean

board over the inlet to the vacuum pump.

The board should be held in place by the

action of the vacuum pump. Turn the unit

off before refitting the hose.

The oil in the coalescer is used to both

lubricate the vacuum pump and create an

effective seal. If the vacuum pump

performance is poor check the coalescer oil

level, after having drained any excess

water.

5.11 Electrical Checks

Please refer to SPP Pumps.

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 8 of 36

6. PUMP DISASSEMBLY

6.1 General Comments

Maintenance and repair that is outside the

scope of the operators handbook must be

done in a suitable location equipped with

lifting equipment with a capacity of at least

1500 kg.

A clean and sound floor with work stands or

benches will provide for ease of access and

a safe working environment.

To avoid the possibility of maintenance

personnel inhaling dangerous fumes or

vapours. It is recommended that

maintenance work be carried out away from

the pump location by removal of the pump

unit to a suitable maintenance area.

Disconnect the negative battery lead before

maintenance work is done. Electrical

checks and repair may require the battery

to be connected, refer to section 10 for

testing instructions.

On trailer units ensure that the rear prop

stand is lowered and the jockey wheel is

wound down to apply load to the rear prop

stand before removing any heavy pump

components. If the pump is removed from

the engine without removal of the engine,

support the chassis with wooden blocks or

adjustable stands to prevent toppling.

6.2 Battery Removal Procedure

1. Disconnect the negative battery lead then

the positive battery lead from the battery.

2. Remove the retaining nuts (4) and strap (1)

and lift out the battery.

3. If required, remove the retaining bolts (2)

and lift the battery tray assembly out from

the chassis.

6.2.1 Battery Parts List

ITEM

DESCRIPTION

PART No

QTY

1

Battery Support Assy. 21730 1

2

Bolt M12 X 30Flange Self Lock 18171 2

3

Nut M12 Self Locking Flanged 18175 1

4

Nut M8 Hex. SY9509652 2

5

Battery (Specification as advised by SPP Pumps)

1

6

Battery Lead Negative 18200 1

7

Battery Lead Positive 18199 1

6.2.2 Battery Parts Diagram

6.3 Preparation for Pump Removal

1. Drain the pump volute and flush out any

hazardous liquid from the pump casing and

priming tank.

2. Disconnect the flexible drain hoses from the

stop valve on the pump casing and from the

stop valve on the coalescer.

3. If the engine is to be overhauled, drain the

sump at this stage and disconnect the

engine sump drain hose from the stop valve

on the engine.

4. Disconnect the wiring loom from the engine.

Refer to the wiring diagrams in section8.

5. Disconnect the probe, solenoid and clutch

cables (where fitted) from the priming

control box.

6.4 Disconnection of Controls Wiring

Note: The single probe priming control system

may be fitted in place of the twin probe

system if required.

SPP recommends upgrading to the single

probe system in place of repairs to the twin

probe system.

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 9 of 36

6.4.1 Single Probe Priming Control System

Components Schematic Diagram

Single Probe System Parts List & Diagram

ITEM

DESCRIPTION

PART No

QTY

1

Priming Control Box & Probe

Assembly Complete

26174 1

2

Loom 21891 1

6.4.2 Pump Control Panel

ITEM DESCRIPTION PART No QTY

1

Control Panel with Shutdown 20115 1

2

Control Panel with Speed

Control, Tachometer and

Shutdown

20219 1

6

Autostart Control Panel with

speed Control, Tachometer

and Shutdown

23741 1

3

4LE2 Engine Loom 20167 1

3

3CE1 Engine Loom 24160 1

Pump Control Panel Parts Diagram

11

6

FUEL PUMP

3

2

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 36

6.5 Louver and Front Panel Removal

(Refer to Parts Diagram 7.14.3)

Note: To gain access to pump and priming tank,

the front panel and louver may be removed

without removal of the canopy.

1. Remove the 2 bolts (A) holding the front

canopy frame to the shroud supports on the

chassis.

2. Open both doors, remove the nuts (B) from

the studs in each upper corner of the

middle canopy support frame.

3. Pull the louver and front panel complete

with the support frame forward and lift off to

expose the pump.

4. If required the front shroud may also be

removed to give access to the pump

suction end for maintenance of the non-

return valve, priming tank and impeller.

6.6 Canopy Removal Procedure

(Refer to Parts Diagram 7.14.3)

1. Open both doors, remove the drive belt

guard, separate the internal sound baffle

into two halves and detach each half from

the canopy support frame. The baffle

halves may be secured temporarily to the

canopy frame, unless further disassembly is

necessary.

2. Disconnect the air supply hose from the

engine manifold by removal of the hose clip

and remove the short exhaust pipe to allow

lifting of the canopy.

3. Where speed control has been fitted,

disconnect the cable from the engine

throttle lever.

4. Disconnect the fuel tank vent pipe from the

fuel tank end.

5. Remove the 6 retaining screws (3), close

doors and lift off the canopy assembly

complete taking care to ensure that any

additional hoses or wires have been

disconnected.

6.7 Pump & Engine Unit Removal

1. Disconnect the fuel and return lines from

the fuel tank.

2. Connect crane hook to the lifter provided

and apply light pull just sufficient to take up

the slack in the crane cables.

3. Remove the 4 bolts from the engine and

pump mountings, and confirm that the

pump and engine assembly is free to be

lifted.

4. Lift the pump and engine assembly with

care and either pull away the chassis

assembly or move the engine and pump

unit to a suitable location for further

disassembly.

5. Place this unit on a sturdy low bench and

support the engine and pump end

separately.

6. Remove 8 nuts from the studs on the

suction flange and remove the priming tank

assembly complete from the pump.

7. Slacken the belt tension device and lift the

belts off the vacuum pump pulleys.

8. Remove the 4 screws and remove the

coalescer assembly complete with vacuum

pump from the pump.

9. Support the engine and pump to prevent

toppling and remove the 16 screws from the

flywheel housing to separate the pump from

the engine.

10. At this stage it is possible to disassemble

the lifter assembly and the drive pulley

arrangement for maintenance if required.

Refer to the parts diagram 7.12.1.

11. Similarly it is possible to replace the drive

coupling components if required, as these

are accessible in the flywheel housing on

the engine. Refer to the parts diagram

7.9.2.

6.8 Pump Disassembly Procedure

(Refer to Parts Diagram 7.3.2)

1. Drain the seal lubrication system into a

suitable container by removal of the lower

hose connection.

2. Remove any remaining nuts from the studs

on the suction flange of the pump casing.

3. Using a soft faced mallet tap the outer

diameter of the front wear plate and

withdraw it from the pump casing.

4. Lock the shaft with a C spanner and

remove the socket cap screw from the

centre of the impeller.

5. Tap the impeller lightly with a soft-faced

mallet on the outer diameter to break the

taper joint and withdraw the impeller from

the shaft. Remove the taper key and store

for carefully for reuse.

6. With a pair of circlip pliers, withdraw the

mechanical seal retaining circlip from the

shaft. Carefully withdraw the rotating part of

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 11 of 36

the mechanical seal from the shaft.

Note: Mechanical seals are usually replaced

during pump maintenance, if the seals are

not being replaced, great care must be

taken not to touch or damage the sealing

faces, and parts from each seal should kept

for reassembly together.

7. With a pair of circlip pliers, extract the

mechanical seal retaining circlip from the

shaft. Carefully withdraw the rotating part of

the mechanical seal from the shaft.

8. Remove the 6 nuts (25) from the bearing

side of the pump casing and carefully

withdraw the back wear plate from the

pump casing. Take care not to damage the

stationery element of the mechanical seal if

this to be reused.

9. With a pair of circlip pliers, extract second

the mechanical seal retaining circlip from

the shaft. Carefully withdraw the rotating

part of the mechanical seal from the shaft.

10. Remove the 8 nuts from the bearing

housing studs and detach the pump casing

from the bearing housing.

11. Remove the drive belts from the drive shaft

pulley, release the setscrews that lock the

drive pulley to the shaft and withdraw the

pulley.

12. Remove the four screws and withdraw the

bearing cap from the bearing housing.

13. Using a suitable C spanner undo and

remove the bearing retaining nut

14. Mount the bearing housing in a press and

push the shaft, complete with drive end

bearings out from the bearing housing.

15. If it is required to replace the bearings the

drive end bearings may be pushed of the

shaft, note that is important to replace them

as a pair.

16. The non-drive end roller bearing may be

pushed out from the bearing housing using

screws in the threaded holes provided.

17. The stationery part of the outer mechanical

seal may be pushed out from it’s seating in

the bearing housing, if it is to be replaced.

6.9 Inspection of Pump Parts

1. Wash all old lubricant from ball bearings,

housings, caps and fittings with kerosene or

white spirit, and dry bearings thoroughly by

spinning by hand, or gently with clean dry

compressed air. Renew them if they do not

then rotate smoothly with no sign of

jamming, and freely but without slackness,

or if running surfaces of balls or races show

any deterioration. Coat bearings with rust

preventive oil and wrap in greaseproof

paper.

2. Mount shaft between point centres or on

rollers, and place stem of dial indicator in

contact with shaft. Set the indicator dial at

zero and turn the shaft slowly by hand.

Reading at any point A, B, C, and D must

not vary more than 0.05mm (0.002").

A

B

C

D

3. Scour any rust or scale from internal iron

non-fitting surfaces.

4. Clean all threads followed by wire brushing,

and wrap shaft threads with protective

adhesive tape.

5. If the unit is not to be reassembled

immediately, brush all bright iron and steel

surfaces with Shell Ensis rust preventive

fluid.

6. Protect all parts (especially mechanical seal

parts and faces) against loss, weather or

mechanical damage.

7. Re-examine all old parts intended for re-

fitting. Worn, damaged or corroded parts

should either be re-conditioned or, if

beyond this, be discarded and replaced by

new.

8. Ensure that all parts to be refitted

(especially new parts) are free from burrs,

with screw threads and abutting faces clean

and free from damage.

9. Examine 'O' rings and all mechanical seal

parts and renew if showing wear or

deterioration.

10. Apply a few strokes of a grease gun to each

grease nipple and check that clean grease

comes through to the inside of the bearing

housing.

6.10 Coalescer Disassembly

(Refer to Parts Diagram 7.4.3)

Note The coalescer contains 5 litres of oil; this

must be drained for safe disposal before

disassembly.

SPP recommends that all filter elements and

mesh is replaced when the coalescer is

disassembled for maintenance.

Loading...

Loading...