Page 1

PUMP INSTALLATION GUIDE

GUIDE TO THE INSTALLATION

OF SPP PUMPS

SPP Pumps Limited.

Crucible Close

Mushet Industrial Park

Coleford

Gloucestershire

GL16 8PS

Telephone:

+ 44 (0)1594 832 701

Fax:

+ 44 (0)1594 836 300

Document No: W00-002E

Revision No: .................. 4

Revision Note No: Windchill

Date Issued. Aug 2012

Produced at SPP Pumps,

Limited, Coleford, England

Page 2

Manual No/Rev

W00-002E / 4

Pump Installation Guide

General Safety Instructions

The products supplied by SPP Pumps Limited have been designed with safety in

mind. Where hazards cannot be eliminated, the risk has been minimised by the

use of guards and other design features. Some hazards cannot be guarded

against and the instructions below MUST BE COMPLIED WITH for safe operation.

These instructions cannot cover all circumstances, YOU are responsible for using

safe working practices at all times.

1 SPP Pumps products are designed for installation in designated areas, which are to

be kept clean and free of obstructions that may restrict safe access to the controls

and maintenance access points.

2 Access to the equipment should be restricted to the personnel responsible for

installation, operation and maintenance and they must be trained, adequately

qualified and supplied with the appropriate tools for their respective tasks.

3 SPP Pumps Limited requires that all personnel that are responsible for installation,

operation or maintenance of the equipment, have access to and study the product

instruction manual BEFORE any work is done and that they will comply with all local

and industry based safety instructions and regulations.

4 Ear defenders should be worn where the specified equipment noise level exceeds

locally defined safe levels. Safety glasses or goggles should be worn where

working with pressurised systems and hazardous substances. Other personal

protection equipment must be worn where local rules apply.

5 Do NOT wear loose or frayed clothing or jewellery that could catch on the controls

or become trapped in the equipment.

6 Read the instruction manual before installation, operation or maintenance of the

equipment. Check and confirm that the correct instruction manual is being used by

comparing the serial number on the equipment with the documentation.

7 Refer to the data plates on the equipment supplied, operation of the equipment

outside these specifications will increase the risk to operators and may lead to

premature and hazardous pump failure.

8 IMPROPER INSTALLATION, OPERATION OR MAINTENANCE OF THIS SPP

PUMPS PRODUCT COULD RESULT IN INJURY OR DEATH.

9 Within the manual, safety instructions are marked with safety symbols.

Hazard

This symbol refers to general mechanical

aspects of safety.

Hazard

This symbol refers to electrical safety.

ATTENTION

personal safety.

This symbol gives warning of a hazard to the

pump itself, which in turn, could cause a risk to

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 2 of 12

Page 3

Pump Installation Guide

CONTENTS

Section Page

1 Pump Hazards .......................................... 3

2 Introduction ............................................... 5

3 Installation................................................. 5

4 Connection to Services ............................. 9

5 Commissioning ....................................... 10

6 Grouting .................................................. 10

1 Pump Hazards

These instructions have been categorised in

relation to each Hazard Type that may occur,

some hazards listed may not occur on the

equipment supplied but are included to cover the

potential hazards with equipment of this type.

1.1 Pump Hazards and Safety

Instructions

Refer to the isolation instructions for electric

motors or diesel engines BEFORE working

on the pump.

1.3.1 Crushing

When lifting the pump set, use the lifting

points specified on the General

Arrangement Drawing. Use lifting

equipment having a safe working load rating

suitable for the weight specified. Lift the

component parts from their lifting points

where provided, or use suitable slings for

lifting any part not provided with lifting

points. Refer to the manual for special lifting

instructions where applicable.

1.3.2 Shearing

Do NOT place fingers or hands etc. into the

suction or discharge pipe outlets and do

NOT touch the impeller, if rotated this may

cause severe injury. To prevent ingress of

any objects, retain the protection covers or

packaging in place until removal is

necessary for installation. If the packaging

or suction and discharge covers are

removed for inspection purposes, replace

afterwards to protect the pump and

maintain safety.

Manual No/Rev

W00-002E / 4

1.3.3 Abrasion and Entrapment

Do NOT touch any moving or rotating parts.

Guards are provided to prevent access to

these parts, where they have been removed

for maintenance they MUST be replaced

before operating the equipment.

1.3.4 Fluid Pressure Jets

Check and ensure that the pump operates

at below the Maximum Working Pressure

specified in the manual or on the pump

nameplate and before maintenance, ensure

that the pump is drained down.

1.3.5 Hot Surfaces

Do NOT touch surfaces which during

normal running will be sufficiently hot to

cause injury. These are marked with the

HOT warning symbol. Note that these

surfaces will remain hot after the pump has

stopped, allow sufficient time for cooling

before maintenance. Be cautious and note

that other parts of the pump may become

hot if a fault is developing.

1.3.6 Cold Conditions

Do NOT operate water pumps in

temperatures below freezing point, without

first checking that the pumped fluid is not

frozen and the pump is free to turn. Pumps

in these environments should be drained

down during inactivity and re-primed before

starting.

1.3.7 Hazardous Noise

In addition to local or site regulations for

noise protection, SPP PUMPS recommend

the use of Personal Ear Protection

equipment in all enclosed pump rooms and

particularly those containing diesel engines.

Care must be taken to ensure that any

audible alarm or warning signal can still be

heard with ear defenders worn.

1.3.8 Hazardous Materials

Wear a suitable mask or respirator when

working with Packing and Gasket

components which contain fibrous material

as these can be hazardous when the

fibrous dust is inhaled. Components

containing hazardous materials will be

accompanied by warnings in the manuals.

Be cautious, if other supplier's components

have been substituted for genuine SPP

PUMPS parts, these may then contain

hazardous materials.

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 3 of 12

Page 4

Manual No/Rev

W00-002E / 4

1.3.9 Gases, Mists, Sprays and Leaks

Be aware of the hazards relating to the

pumped fluid, especially the danger from

inhalation of noxious and toxic gases, skin

and eye contact or penetration. Obtain and

understand the hazardous substance

(COSHH) data sheets relating to the

pumped fluid and note the recommended

emergency and first aid procedures.

1.3.10 Access Hazards

Clear and easy access to all controls,

gauges and dials etc. MUST be maintained

at all times. Hazardous or flammable

materials must NOT be stored in pump

rooms unless safe areas or racking and

suitable containers have been provided.

1.2 Electric Motor Hazards and Safety

Instructions

These instructions relate generally to

electric motor installations, for specific

safety instructions for the electric motor

supplied, read the supplier's instruction

manual.

1.2.1 Electric Shock

ISOLATE the equipment before any

maintenance work is done. Switch off the

mains supply, remove fuses, apply lockouts where applicable and affix suitable

isolation warning signs to prevent

inadvertent re-connection.

1.2.2 Magnetic Fields

Note the existence of magnetic fields where

shown by the MAGNETIC FIELD warning

symbol.

1.3 Diesel Engine Hazards and Safety

Instructions

These instructions relate generally to diesel

engine installations, for specific safety

instructions for the diesel engine supplied,

read the supplier's instruction manual.

1.3.1 Electrical Hazards

DISCONNECT the Batteries by removal of

the NEGATIVE terminal connector.

ISOLATE the equipment before any

maintenance work is done. Switch off the

mains supply, remove fuses, apply lockouts where applicable and affix suitable

isolation warning signs to prevent

inadvertent re-connection.

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Pump Installation Guide

Do NOT place tools on or near the Batteries

such that a short circuit may be caused.

INSPECT all cables for damage or signs of

failure and replace immediately.

1.3.2 Hot Surfaces

Do NOT touch any part of the engine, its

cooling system or exhaust system when it is

running or afterwards until it has cooled.

1.3.3 Unexpected Noise Hazard

Wear Ear Defenders when working near the

engine even if it is not running, as it may

start unexpectedly when fitted with an

automatic start control system.

1.3.4 Fluids, Gases and Fumes

Fuel fumes are highly flammable. Do NOT

refuel the engine when it is running or is still

hot from recent running.

When refuelling, avoid breathing the fuel

fumes, particularly if the pump is installed in

an enclosed pump room. Maintain

maximum ventilation to clear the fumes

quickly.

Do NOT start the engine whilst fuel fumes

remain evident or may be present..

Exhaust gases are hazardous, the exhaust

system MUST be maintained free from

leaks and be directed to discharge in a safe

area.

Battery gases are hazardous and

flammable. The battery area MUST be well

ventilated to clear these gases quickly.

Do NOT store lubricants or other volatile

substances near the engine. These should

be placed in a designated area having a

suitable storage enclosure.

ISOLATE the fuel supply to the engine

BEFORE working on any part of the fuel

supply and control system.

1.3.5 Stored Energy

Where Mechanical, Hydraulic, or Pneumatic

systems are fitted, refer to the supplier's

manual for instructions to ISOLATE or DEENERGISE the system BEFORE

maintenance on the engine and to DEENERGISE the equipment BEFORE

maintenance on this equipment.

Page 4 of 12

Page 5

Manual No/Rev

W00-002E / 4

W

2 Introduction

This manual specifies SPP Pumps Limited

requirements for the installation of SPP

horizontal and vertical split case and end

suction pumpsets.

SPP Pumps Limited requires that this

document is given to all contractors with

responsibility for site preparation, electrical

supply and connection, pump installation

and pipework etc.

On completion of all stages that apply, a

signature should be obtained from the

contractor's representative confirming

compliance with SPP requirements.

If SPP Pumps Limited Service Department

have been requested to perform initial

testing, these documents MUST be

submitted signed before commissioning can

be undertaken.

This guide covers the installation,

connection and initial testing of a SPP

Pumps pumpset, comprising baseplate with

electric motor, flexible coupling and

centrifugal pump or close coupled pump

unit.

All other items required for the installation

must be provided by the customer or the

contractors responsible for the installation.

2.1 Review of Equipment Received

On receipt of the pumpset it is important to

check for any damage or loss that may

have occurred in transit. Any damage or

missing items should be referred in the first

instance to the haulage contractor

responsible.

Pump Installation Guide

re-circulation, must be provided in the pump

house structure.

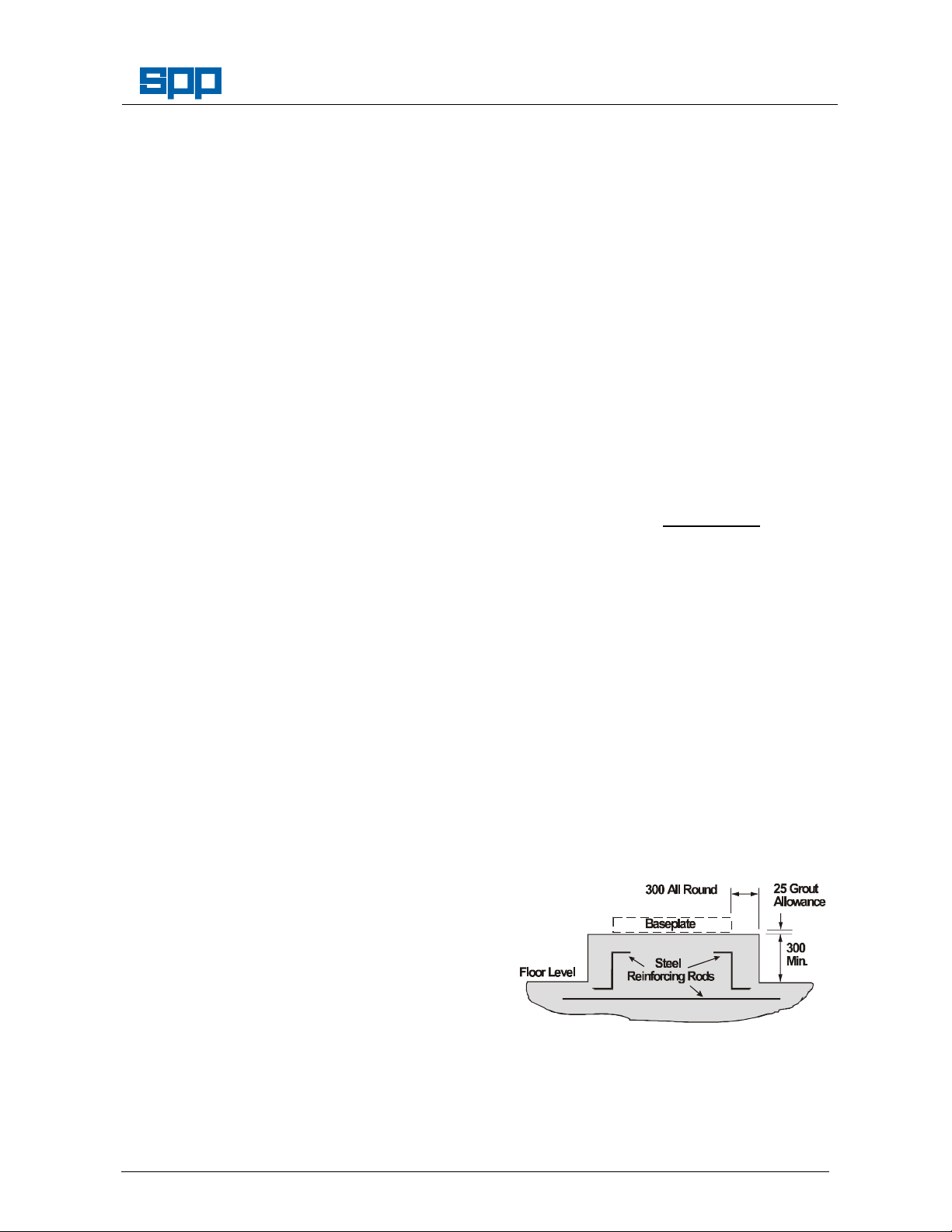

3.2 Foundations

A foundation plinth should be constructed to

support each pumpset on a floor area free

from expansion joints. These foundation

plinths should be sufficiently substantial to

absorb vibrations and rigid enough to avoid

any twisting or misalignment.

As a rough guide, they should be at least

300mm wider than the pumpset on all sides

and weigh between 1 and 1.5 times the

weight of the pumpset. Plinths for pumps

are recommended to have a minimum

height of 300mm but height should be

sufficient to achieve the necessary weight

and to accommodate the pockets for fixing

bolts.

Foundation height may be calculated thus:

Height (m) =

2400 x B x L

where:

W (kg) = total weight of pumpset

2400 (kg/m3) = concrete density

B (m) = foundation width

L (m) = foundation length

Use a suitable concrete mixture by volume

is 1:2:3 (Cement : Sand : Aggregate) with a

maximum 100mm slump, and a 28 day

compressive strength of 27,000 N/mm2.

Foundation concrete should be poured

without interruption to within 25mm of the

finished height.

The foundation should be reinforced with

layers of 150mm square No.8 gauge steel

wire fabric, or equivalent, horizontally

placed 150mm apart.

3 Installation

3.1 Pump Location

The pump should be installed as near to the

liquid source as possible, with the shortest

and most direct suction pipe practical.

Allow sufficient access for inspection and

maintenance with enough headroom for an

overhead crane or hoist of sufficient

capacity to lift the heaviest item of

equipment.

Adequate ventilation is required for cooling

purposes, inlet and outlet apertures,

suitably sized and positioned to prevent air

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 5 of 12

The top surface should be well scored and

grooved before the concrete sets to provide

a bonding surface for the grout. The

foundation should be allowed to cure for

several days before installation of the

baseplate.

Page 6

Manual No/Rev

B

C

A

A

CHANNEL SECTION

GROUT

FOLDED BASEPLATE

FLAT WASHER

FOUNDATION BOLT

GROUT

FLANGED FOLDED

FOUNDATION BOLT

GROUT

W00-002E / 4

Plinth Sized and Made to

Specifications.

Signed Date

3.3 Foundation Bolts

Two types of foundation bolts are normally

used; either rag bolts set into pre cast

pockets in the plinth or, chemical anchor

bolts for which pockets are drilled into the

plinth after casting.

Pump Installation Guide

BASE FRAME

FOUNDATION BOLT

FLAT WASHER

SHIMS OR

PACKERS

GROUT

CONCRETE

FOUNDATION

PLINTH

3.3.1 Rag Bolts

Rag Bolt Dimensions

Bolt size

Clearanc

e hole

Bolt dimensions

(see Figure 1)

size

Dia.

16 160/240

20 300/350

24

Length

350

Dia.

19

24

28

B C

32 80 40

40 100 50

48 120 60

Tapered pockets are recommended for all

pump installations.

3.3.2 Chemical Anchor Bolts

For Chemical Anchor Bolts, refer to the

manufacturers installation instructions.

3.4 Horizontal Pump Baseplate Types

There are three main types of baseplate as

illustrated below. Note that these figures

show chemical type anchor bolts.

SHIMS OR

PACKERS

FORMWORK

GROUT

CONCRETE

FOUNDATION

PLINTH

BASEPLATE

FLAT WASHER

SHIMS OR

PACKERS

GROUT

CONCRETE

FOUNDATION

PLINTH

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 6 of 12

Page 7

FOUNDATION BOLT

CAST PUMP STOOL

SLING FOR

CRANE LIFTING

COUPLING

Manual No/Rev

W00-002E / 4

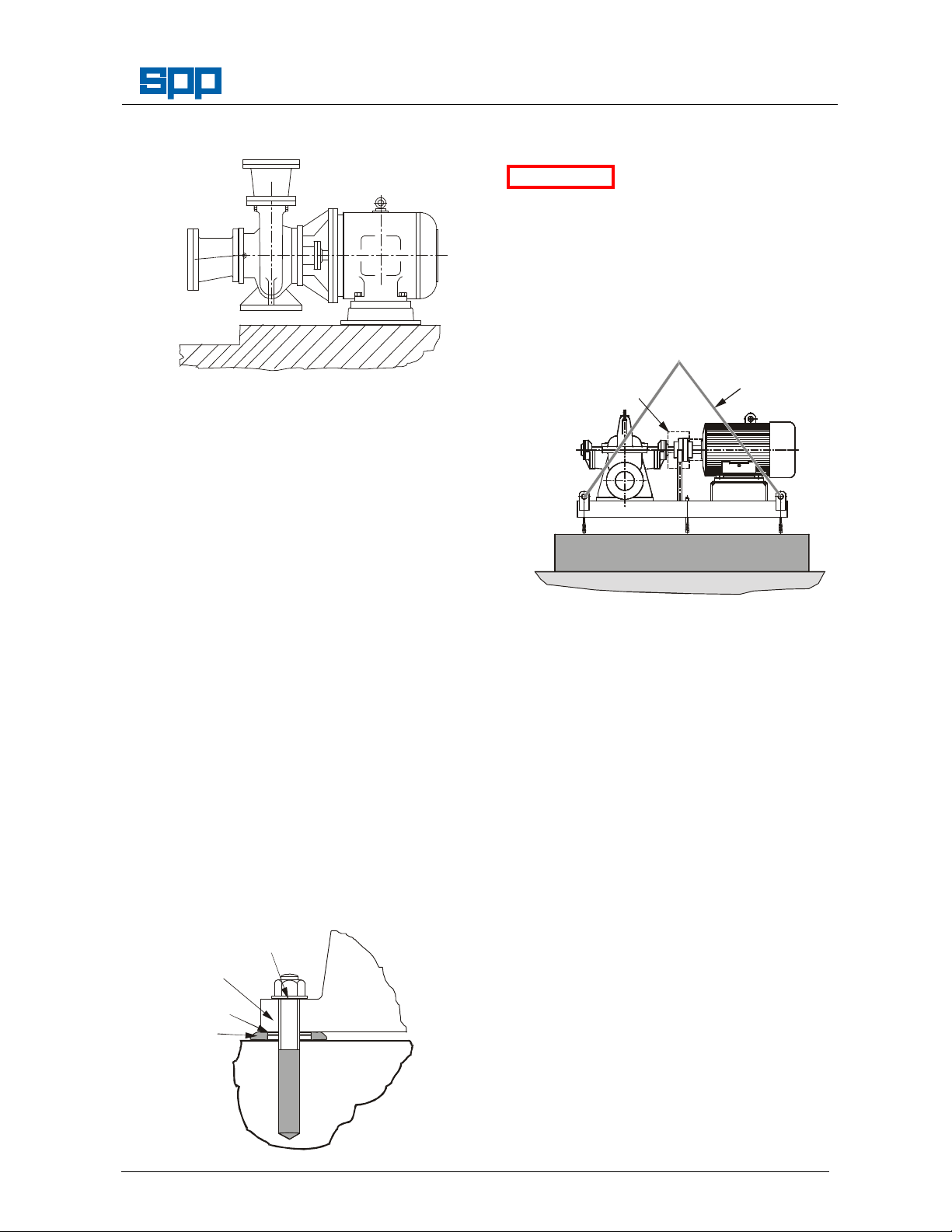

3.5 Slide Rail Mounting

Pump Installation Guide

3.7 Installing the Pumpset

It is important to install

ATTENTION

pumpsets BEFORE

installing the main suction and delivery

pipework. This is to ensure that the pipes

are positioned to match the pump location

and do not transmit load and induce strain

in the pump casing.

For long coupled pumpsets, remove the

coupling guard to provide access to the

shaft and coupling.

Close coupled pumpsets are supplied with

GUARD

REMOVED

the pump mounted directly on the motor.

These motors may also be fitted with slide

rails under the motor feet to permit

withdrawal of the impeller from the casing

without disconnecting the pipework.

The motor, with or without slide rails,

requires foundation support but where

supplied, feet cast onto the pump housing

must NOT be bolted down. It is, however

recommended that the plinth extends under

the pump to prevent accidental damage.

Installation follows the same procedure as

for pumpsets except for the alignment

checks. Pump/driver alignment is

maintained by the spigot/recess

construction of the pumpset and cannot be

adjusted.

3.6 Vertical Pump Mountings

Vertical pump are supplied with cast or

fabricated motor stools. Mountings for

fabricated pump stools are as shown for the

channel section base frame, above.

Cast pump stools are mounted typically

thus

When using rag bolt fixing, suspend the

pumpset over the plinth and hang the

foundation bolts from their holes using

tapered washers for channel base frames

and plain washers for other types, with the

nuts showing at least one full thread

through.

Place sufficient metal packing pieces on

both sides of each foundation bolt hole to

support the base frame at about 25mm

above the plinth surface. Lower the

pumpset and insert the rag bolts into their

pockets. Continue lowering until the

pumpset is supported by the packing.

Adjust the height of the packing with shims

in each position until the shaft is horizontal

PLINTH

FLOOR

and the pump suction flange face is

vertical, do not level from the baseplate as

this may not be true to the shaft and

FLAT WASHER

SHIMS OR

PACKERS

GROUT

CONCRETE

FOUNDATION

PLINTH

flanges.

Ensure that the foundation bolts are vertical

to permit easy lifting of the pumpset, then

grout in with non-shrinking grout. Allow

sufficient time for the grout to harden,

usually 24 hours or as recommended in the

grout manufacturer's instructions.

For chemical anchor fixing with channel

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 7 of 12

section base frames it will be necessary to

Page 8

MOTOR

MOTOR

MOTOR

Manual No/Rev

W00-002E / 4

Pump Installation Guide

mount the pumpset, mark the foundation

bolt positions and lift off the pumpset to give

access for drilling. Hang the anchor bolts in

their holes and lower the pumpset in

position having inserted the anchors into

their fixing holes.

When the pump is resting evenly on all

packers, check the coupling alignment and

record the initial dial indicator readings

Initial Alignment Readings

Taken

Signed Date

Lateral TIR. ………….. Angular TIR. ………….

To check coupling alignment, refer to the

pump and coupling instruction manuals for

details of shaft alignment procedures and

tolerances, or proceed generally thus:

1 Lateral Alignment

Mount a dial gauge on

the motor shaft or

PUMP

coupling with the

gauge running on the

outer-machined

surface of the pump

coupling. Turn the motor shaft and note the

total indicator reading.

2 Angular Alignment

Mount a dial gauge on

PUMP

the motor shaft or

coupling to run on a

face of the pump

coupling as near the

outside edge as

possible. Turn the motor shaft and note the

total indicator reading.

3 Confirm Lateral Alignment

Mount the dial gauge

on the pump shaft or

coupling with gauge

PUMP

running on the outermachined surface of

the motor coupling.

Turn the pump shaft

in the direction of

pump rotation, and note the total indicator

reading.

4 Adjustment

The motor must be shimmed and repositioned to align the shafts to well within

the coupling manufacturer’s specifications.

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 8 of 12

Note Poor alignment is a major factor

contributing to shortening of pump

bearing and seal life. It is recommended

that alignment is checked frequently and

maintained at below 10% of the

manufacturer’s specified figure.

As the pump and motor feet are accurately

machined, any discrepancy may be due to

foreign matter between any of the mating

faces. These should be checked for

cleanliness before assembly and before

resorting to using shims under the motor

flange.

ATTENTION

Shaft alignment must be

checked again after the

final positioning of the pump unit and

connection to pipework as this may have

disturbed the pump or motor mounting

positions.

After allowing sufficient time for the bond to

cure, tighten the chemical anchor bolts to

the torque setting recommended in the

manufacturer's instructions, or for rag bolts,

tighten the nuts to the torque figures below.

Bolt Size

Torque Nm

16 20 24

95 185 320

ATTENTION

After tightening the fixing

bolts check and measure

the coupling alignment and if the figures

have changed significantly, the baseplate

will have been distorted. Release the

anchor bolts and adjust the packers to

maintain the shaft level and the coupling

alignment within acceptable figures.

Bolted Down and

Alignment Confirmed.

Signed Date

Lateral TIR. ………….. Angular TIR. ………….

3.7 Suction & Delivery Piping

Ensure that bolt grouting or chemical

anchors have been allowed to cure or dry

thoroughly before connecting any pipework.

Both suction and discharge piping should

be supported independently and close to

the pump so that no strain is transmitted to

the pump when the flange bolts are

tightened. Use pipe hangers or other

supports at intervals necessary to provide

support. When expansion joints are used in

the piping system, they must be installed

Page 9

INCREASER

DISCHARGE

DISCHARGE

FLAT TOP REDUCER

WILL NOT TRAP AIR IN

beyond the piping supports closest to the

pump.

PUMP FOUNDATION PLINTH

CHECK

VALVE

VALVE

Install piping as straight as possible,

avoiding unnecessary bends. Where

necessary, use 45ΕΕΕΕ or long sweep 90ΕΕΕΕ

fitting to decrease friction losses.

Where reducers are used, eccentric or 'flat

top' reducers are to be fitted in suction lines

and concentric or straight taper reducers in

discharge lines. Undulations in the pipe

runs are also to be avoided. Failure to

comply with this may cause the formation of

air pockets in the pipework and thus

prevent the correct operation of the pump.

Make sure that all piping joints are air tight.

CONCENTRIC REDUCER

WILL TRAP AIR IN THE

SUCTION PIPE

Pump Installation Guide

not recommended, however if unavoidable

there should be a distance of at least 5 pipe

diameters between the valve and the pump

PIPE

inlet flange.

The suction pipe should be as short and

direct as possible, and should be flushed

clean before connecting to the pump.

Where suction lift is not very high, it is

advisable to use a foot valve. Horizontal

suction lines must have a gradual rise to the

pump. If the pumped fluid is likely to

contain foreign matter then a filter or coarse

strainer should be fitted to prevent ingress

to the pump.

The discharge pipe is usually preceded by a

non-return valve or check valve and a

discharge gate valve. The check valve is to

protect the pump from excessive back

pressure and reverse rotation of the unit

and to prevent back flow into the pump in

case of stoppage or failure of the driver.

The discharge valve is used in priming,

starting and when shutting down the pump.

Refer to the operating manual for the pump

for instructions on the use of the control

valves

ATTENTION

final positioning of the pump unit and

connection to pipework as this may have

disturbed the pump or motor mounting

positions. To restore alignment shims

between the pump or motor feet and the

baseplate should be varied to suit.

Pipework Connected and

Alignment Confirmed.

Manual No/Rev

W00-002E / 4

Shaft alignment must be

checked again after the

Signed Date

Lateral TIR. ………….. Angular TIR. ………….

4 Connection to Services

The requirements for each installation will

vary depending upon the equipment

THE SUCTION PIPE

The use of butterfly valves in suction lines is

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 9 of 12

supplied.

Ensure that site electrical power supply

characteristics match the data on the

equipment data plates.

If the control panels were manufactured or

supplied by Sterling, wiring diagrams will be

included with the instruction manual. If the

panels have been supplied by others, refer

to their literature for electrical details and

wiring instructions.

4.1 Electrical Supply Connection

Page 10

Manual No/Rev

Steel packers position the base frame 25 mm

W00-002E / 4

Pump Installation Guide

Install the electric motor starter panel in a

convenient position for use and wire up to

mains supply and to the electric motor.

Earth bonding connections are provided on

all base frames and must be connected to a

suitable earth point.

4.2 Seal Flush and Cooling Systems

Where applicable, if a separate supply for

the pump seal is to be used, connect the

feed pipes.

4.3 Waste and Drain Lines

Waste water lines should be run from all

ancillary connections such as gland drains

or tundish etc. W here applicable, these are

shown on the General Arrangement

Drawing provided.

When installed under positive suction head

conditions, pumps should be provided with

an air release valve on the top of the pump

casing to provide a means of exhausting

trapped air.

Services connected to

specification.

Signed

Date

5 Commissioning

5.1 Pre-commissioning Checks

1

Installation:

Mounting plinths comply with instructions for

a

size, construction and location.

b

above the top surface of the plinth.

c The pump shaft is horizontal (or vertical).

The fixing bolts are grouted as instructed and

d

tightened to the required torque.

The shaft alignment has been checked and

e

set to within the stated tolerances.

Suction and delivery pipework is adequately

f

supported and NEGLIGIBLE forces are

transmitted to the pump casing.

Where applicable, all drain, minimum flow,

2

and test pipe lines are fitted, together with

valves gauges and flow meters.

Sufficient water supply is available for the

3

commissioning proof run.

Pre - Commissioning

Check List Completed

Signed

If SPP Pumps Limited Service Department

is contracted to carry out the initial test run,

the check-list shows items to be completed

Date

before the engineer arrives. It is SPP

Pumps Limited policy that service engineers

will give as much assistance as possible to

the customer in solving site problems.

However, if due to incomplete installation or

failure of equipment not supplied by SPP

Pumps Limited, further visits are required to

complete commissioning then, additional

charge will be made.

5.2 Initial Test Run

It is recommended that the initial test run is

done by an SPP Pumps Limited

commissioning engineer.

ATTENTION Refer to the pump

instruction manual for instructions for

commissioning pumpsets.

6 Grouting

After successful testing, grouting is required

to compensate for uneven foundations,

distribute the weight of the pumpset,

prevent movement and reduce vibration.

Use only an approved high-strength grout,

prepared and poured in accordance with the

manufacturer's instructions.

Build any formwork required to contain the

grout. If an epoxy grout is to be utilised

then the foundation surface should remain

dry. For other types of grout, soak the top

of the concrete foundation thoroughly with

water until absorption stops then, remove

any excess.

Fit temporary formwork (shuttering) to the

preferred height around the baseplate to

prevent grout running out when poured. Fill

the space inside the baseframe level with

top of the channels or to the level of the top

plate with grout ensuring that there are no

air pockets. DO NOT use vibration

techniques to aid this procedure. Dress

to a smooth finish and allow the grout to

harden.

After the grout has thoroughly hardened

remove the temporary shuttering, check the

foundation bolts and re-tighten if necessary.

Re-check the shaft alignment and adjust

if necessary. The pump is now ready for

normal use.

Approximately 14 days after the grout has

been poured or when it has thoroughly

dried, apply an oil based paint to the

exposed faces of the grout to prevent air

and moisture from coming into contact.

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 10 of 12

Page 11

Pump Installation Guide

SPP Pumps Limited operate a comprehensive Spares and Service support network throughout the world,

and can be contacted as follows:

Manual No/Rev

W00-002E / 4

SPARES & SERVICE Telephone:

For spare parts, supply only. ask for -

For breakdowns, spare parts and,

on-site fitting, pump installation and, ask for -

commissioning, and service contracts.

For breakdowns outside office hours.

Spares & Service Office

SPP Pumps Limited General Fax line:

1420 Lakeview

Arlington Business Park

Reading

Berkshire

RG7 4SA Direct Fax line:

Telephone :

+44 (0)118 932 3123

Spares Dept.

Service Dept.

+44 (0)118 932 3123

+44 (0)118 932 3302

+44 (0)118 930 3259

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 11 of 12

Loading...

Loading...