Page 1

AUTOPRIME

Q RANGE PUMPS

WORKSHOP MANUAL

AUTOPRIME

Q RANGE

OF DIESEL DRIVEN

MOBILE PUMPS

SPP Pumps Limited.

Crucible Close

Mushet Industrial Park

Coleford, Glos

ENGLAND

GL16 8PS

Telephone:

+44 (0) 1594 832701

Fax:

+44 (0) 1594 836300

Document No. W72-021E

Revision No: 8

Revision Note No: R39573

Date Issued. Aug 2012

Produced at SPP Pumps

Limited, Coleford, England

Page 2

Manual No/Rev

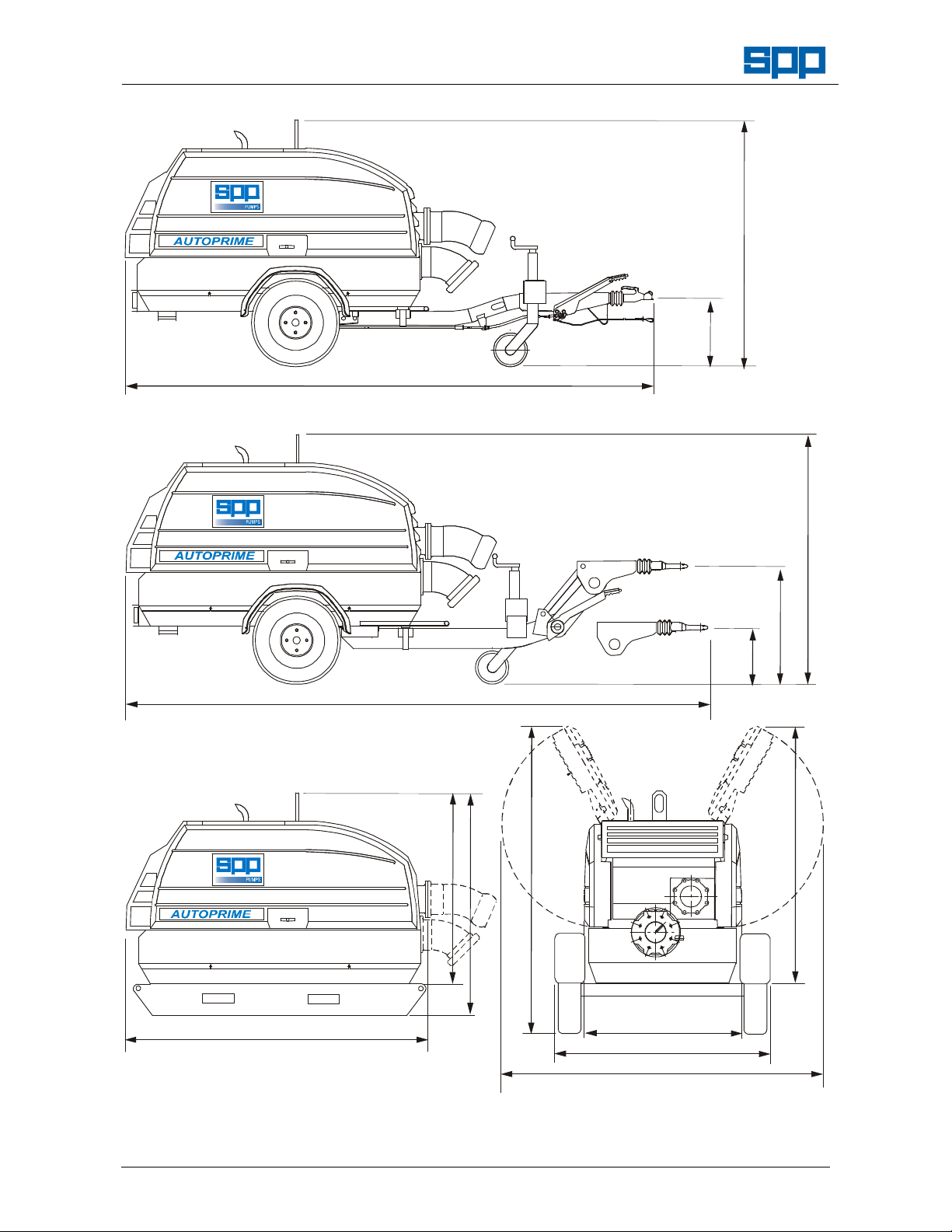

FIXED HEIGHT TOW HITCH

VARIABLE HEIGHT TOW HITCH

PUMP ‘POD’ & PUMP ON SKID

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

THE HITCH TYPE MAY BE

CHANGED TO SUIT CUSTOMER

REQUIREMENTS

4050 MAX - 3960 MIN.

1778 MAX - 1718 MIN.

435 MIN

495 MAX

1287kg max

2115

4352 MAX - 4262 MIN.

1400kg max

1778 MAX - 1718 MIN.

850

450

TRAILER

END VIEW

1350

1600

2150 MAX

1150

1600

2300

1712

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 2 of 36

Page 3

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

CONTENTS

1. INTRODUCTION .................. 4

2. SAFETY PRECAUTIONS 5

2.1 Safety Symbols 5

2.2 Pump Safety Precautions 5

3. HANDLING & TRANSPORT 5

3.1 Lifting 5

3.2 Road Trailer Versions 5

3.3 Skid Mounted Units 5

3.4 Pod Units 5

3.5 Trailer or Wagon Carriage 5

4. SERIAL NUMBER 6

5. FAULT FINDING 6

5.1 Fault Finding Guide 6

5.2 Priming System Checks 6

5.3 Drive Belt Checks 6

5.4 Vacuum Pump Clutch Checks 6

5.5 Solenoid Valve Checks 7

5.6 Priming Filter Checks 7

5.7 Priming Tank Filter Checks 7

5.8 Non Return Valve Checks 7

5.9 Air Leak Checks 7

5.10 Vacuum Pump Checks 7

5.11 Electrical Checks 7

6. PUMP DISASSEMBLY 8

6.1 General Comments 8

6.2 Battery Removal Procedure 8

6.3 Preparation for Pump Removal 8

6.4 Disconnection of Controls Wiring 8

6.5 Louvre and Front Panel Removal 10

6.6 Canopy Removal Procedure 10

6.7 Pump & Engine Unit Removal 10

6.8 Pump Disassembly Procedure 10

6.9 Inspection of Pump Parts 11

6.10 Coalescer Disassembly 11

6.11 Vacuum Pump Disassembly 12

6.12 Priming Tank Disassembly 12

7. PUMP ASSEMBLY 13

7.1 General Comments: 13

7.2 Special Tools 13

7.3 Pump Assembly 13

7.4 Coalescer Assembly 17

7.5 Vacuum Pump Assembly 19

7.6 Priming Tank Assembly 20

7.7 Pump End Final Assembly 21

7.8 Chassis & Fuel Tank Assembly 22

7.9 Engine Assembly 24

7.10 Engine to Pump Assembly 25

7.11 Vacuum Pump Drive Assembly 25

7.12 Lifter Assembly 26

7.13 Pump Unit to Chassis Assembly 26

7.14 Canopy Assembly Procedure 26

7.15 Control Panel & Electrical Wiring 28

8. WIRING DIAGRAMS 29

8.1 Wiring Diagram for 3CE1 Engine 29

8.2 Wiring Diagram for 4LE2 Engine 30

8.3 Wiring Diagram for 3024 Engine 31

9. OPTIONAL EQUIPMENT 32

9.1 Label Sets in Foreign Languages 32

9.2 Trailer Plate for UK 32

9.3 Emergency Stop Button - Roof 32

9.4 Trailer Equipment for France 32

9.5 Trailer Hitches 32

9.6 Trailer Lights for Europe 32

9.7 Alternative Door Colours 32

9.8 Battery Isolator Switch 32

9.9 Spare Wheel 32

9.10 Speed Control 32

9.11 Spark Arrestor – 3CE1 33

9.12 Spark Arrestor – 4LE1 & 4LE2 33

9.13 Hose Fittings 33

10. INSPECTION & TESTING 33

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 3 of 36

Page 4

Manual No/Rev

Pump

Engine

Fuel

Priming

Control

SHAFT BEARING

FILLER

SHAFT BEARINGS

DELIVERY

VOLUTE

SOLENOID

MECHANICAL

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

1. INTRODUCTION

The purpose of this handbook is to give

instructions for the disassembly and

reassembly of the SPP AUTOPRIME Q

Range of diesel engine driven pumps.

Instructions and statements contained within

this handbook are given with our best

intentions and are correct at the time of

compilation. They are subject to alteration at

any time.

These pumps are most commonly supplied

mounted on 2 wheel road trailers but can

also be supplied on site trailers, skid

mounted, or as a pod unit for customer’s to

mount on suitable foundations.

A range of optional equipment is available.

Please refer to section 9 for details.

This manual covers the following pump configurations:

Standard Pump configuration from June 2007

Type

Tank

System

Panel

QI 100 Isuzu 3CE1 220L

QI 150 Isuzu 3CE1 220L

QI 150M Isuzu 4LE2 220L

QC150M Cat 3024 2.2 220L

QI 200

Isuzu 4LE2 220L

Single

Probe

Electric

Prime

Fixed or

Variable

Speed

Control

QHH80 Isuzu 4LE2 220L

omers to mount on vehicles or other equipment as required.

Note: For special, non standard specifications for pumps not listed above, many parts will be common

BUT refer to SPP Pumps Limited for confirmation of part numbers before ordering spare parts.

Pump Main Components

CONTROL

PANEL

RADIATOR

FILLER CAP

EXHAUST

SILENCER

VACUUM PUMP

DRIVE BELT

AND CLUTCH

COALESCER

(far side)

PRIMING TANK

AIR FILTER

VACUUM

PUMP

PRIMING

TANK

FRONT

PANEL

UNIT

LIFTER

VALVE

SEAL OIL

RESERVOIR

NON

RETURN

VALVE

DRIVE END

FUEL

PUMP END

SUCTION

FLANGE

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 4 of 36

FLANGE

Page 5

Workshop Manual for

AUTOPRIME Q Range Pump Unit

2. SAFETY PRECAUTIONS

2.1 Safety Symbols

Safety instructions within this manual are

marked with the following symbols:

This symbol refers to general mechanical

aspects of safety.

This symbol refers to electrical safety.

ATTENTION

2.2 Pump Safety Precautions

Apply to all of the following:

1. This pump contains exposed moving parts

and hot surfaces DO NOT OPERATE THE

PUMP WITH THE DOORS OPEN. Guards

removed for maintenance must be replaced

before starting the pump.

2. Never insert anything into the pump casing

whilst the pump is running and the suction

and delivery hoses are disconnected.

3. Never use collapsible hoses on the suction

side of the pump and use all pump flange

holes to fit suction and delivery hose

connections.

4. Always lift pump sets vertically by the lifting

eye. Any side force will damage the lifter.

Never lift with suction or delivery hoses

attached. The increased weight of these

items may cause lifting gear failure.

5. Check the type of liquid being pumped before

working on pump ends. Residues could be

hazardous to your health. If in doubt flush out

with clean water before work commences.

6. Personnel working on the pump unit must

always wear clean correctly fitting clothing

and safety footwear. Clothing impregnated

with oil or fuel can constitute a health hazard

through prolonged contact with the skin and

may also constitute a fire hazard.

7. Always allow adequate ventilation for diesel

engines. Be aware of fire risks from items

such as exhaust pipes and silencers. Never

place flammable items around the unit.

This symbol gives warning of a

hazard to the pump itself, which in

turn could cause a risk to personal

safety.

ATTENTION

Manual No/Rev

W72-021E / 8

3. HANDLING & TRANSPORT

3.1 Lifting

ATTENTION

NOT be used to pull the unit sideways.

Before lifting ensure that the lifting point is

not bent or damaged.

Do NOT use a lift truck with forks under the

fuel tank and do NOT lift with the hoses

attached.

3.2 Road Trailer Versions

Road trailers may be fitted with towing

hitches to suit customer requirements, the

trailers may have fixed or variable height

hitches. Lights are provided as standard but

customers may request provision for lighting

boards and must attach vehicle registration

plates to comply with local regulations.

3.3 Skid Mounted Units

In addition to the central lift point, the skid is

fitted with slots to allow use of a lift truck with

forks to lift and position the unit.

3.4 Pod Units

These are only to be lifted using the central

lifting point; do NOT use a lift truck with forks

under the fuel tank. The unit must be located

on firm level foundations.

For details of the attachment points provided

for pod units, refer to the SPP Pumps Limited

or the GA drawing supplied.

3.5 Trailer or Wagon Carriage

Transportation on a trailer or wagon will

require the unit to be strapped down.

For trailer-mounted units, level the unit with

the jockey wheel and pass a strap across the

draw bar just in front of the bracket that

retains the front of the pod. At the rear

underside of the trailer-mounted units, a

security bracket is provided to chain the unit

to an anchor point. This is also to be used to

strap the unit down for transport.

For skid-mounted units, holes are provided in

the front and rear of each skid for strapping

down.

Pods are supplied fitted to pallets that should

be firmly tied down to the wagon or trailer.

The central lifting point is designed

for vertical lifting only and must

Under no circumstances should straps

be passed over the top of the canopy or

around the doors.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 5 of 36

Page 6

Manual No/Rev

Fax

: +44(0)1594

836300

W72-021E / 8

4. SERIAL NUMBER

The serial number plate is fitted inside the

control panel door.

Workshop Manual for

AUTOPRIME Q Range Pump Units

This serial number must be quoted in any

enquiry for spare parts or service.

Crucible Close, Mushet Industrial Park,

Coleford, Gloucestershire, ENGLAND,

SPP Pumps Limited

GL16 8PS

Tel

: +44(0)1594 832701

5. FAULT FINDING

5.1 Fault Finding Guide

Unit does not start

•

Fuel consumed.

•

Trip switches need resetting.

•

Warning lights on & shutdown circuit

activated.

•

Battery with low charge level.

•

Refer to engine supplier’s manual for

engine checks.

Unit does not prime

•

Volute drain tap open.

•

Air leak in priming system.

•

Air leak in suction hoses or fittings

•

Blockage in suction hoses or strainer.

•

Non-return valve not sealing.

•

Internal damage to hose from solenoid

valve to vacuum pump.

•

Solenoid valve not operating.

•

Solenoid valve blocked.

•

Priming tank air filter blocked.

•

Priming tank knitmesh blocked.

•

Vacuum pump belts loose or broken.

•

Vacuum pump electric clutch not

engaged.

•

Vacuum pump failure.

•

Suction head too great.

Unit does not pump

•

Blockage in delivery hoses.

•

Blockage in impeller.

•

Excessive impeller clearances.

•

Broken Impeller.

•

Pump drive coupling disengaged.

•

Delivery head too great.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

5.2 Priming System Checks

Disconnect the suction hose. Place a flat

board over the suction fitting to check that

the priming system and vacuum pump is

working.

If a vacuum gauge is fitted to the suction

the vacuum pump should produce a

vacuum of at least 9 metres water.

5.3 Drive Belt Checks

The vacuum pump drive belts run between

the pump shaft and the electro magnetic

clutch on the vacuum pump. See the

maintenance instructions in section 7.11 for

the belt tensioning method.

5.4 Vacuum Pump Clutch Checks

The vacuum pump clutch is electrically

operated. If the clutch is disengaged the

belts still turn but the centre of the clutch

will be stationary.

The clutch requires 12 volts to actuate it.

This voltage controlled by a timer and

supplied via a relay by wire No 22 of the

wiring loom. If the wiring is disturbed during

investigations ensure that it is replaced

correctly.

The priming system electrical circuit is

protected by a circuit breaker mounted on

the control panel. If this trips out, push the

central button to reset. If the breaker will not

reset or is constantly tripped then there is

an electrical fault.

The level sensing probes control the

electrical supply to the clutch, with a timer.

If there is no electrical supply to the clutch,

check that the power light is illuminated on

the priming control box. If this is on then

disconnect the clutch and check if there is

12 Volts across the wires. If there is then

the clutch has failed and should be

replaced.

Page 6 of 36

Page 7

AUTOPRIME Q Range Pump Unit

If the 12 Volt supply is not provided to the

clutch, check the continuity of the cables

and rectify any bad connections.

If the control box does not provide the 12

Volt supply for the clutch the control box is

faulty and must be replaced.

5.5 Solenoid Valve Checks

The electrically operated solenoid valve is

connected to the top of the priming tank.

The valve is reliable but if a fault is

suspected it is most likely to be a problem

with the wiring. Wire No 28 of the loom

supplies 12 Volts, wire No 8 is an earth

return.

5.6 Priming Filter Checks

The priming tank air filter is mounted in the

top of the priming tank. To remove and

check the filter condition, follow the

instruction given in the maintenance section

of this manual.

5.7 Priming Tank Filter Checks

It is extremely unlikely that the priming tank

knitmesh filter will ever become sufficiently

blocked to prevent priming. Instructions for

dismantling the unit and removing and

cleaning the knitmesh filter are given in the

maintenance section of this manual.

Workshop Manual for

To check the operation of the vacuum

pump, disconnect the hose running

between the priming tank and the vacuum

pump.

Warning: The hose is stiff and very difficult

to remove. Do not disconnect the hose

while the unit is running. If any solid

objects, grit or mud are drawn up the hose

they will cause serious damage to the

internals of the vacuum pump.

Disconnection of this hose should only be

considered as a last resort. Conduct other

investigations before resorting to this

course of action.

Once the hose between the vacuum pump

and the coalescer has been disconnected

start up the unit and place a small clean

board over the inlet to the vacuum pump.

The board should be held in place by the

action of the vacuum pump. Turn the unit

off before refitting the hose.

The oil in the coalescer is used to both

lubricate the vacuum pump and create an

effective seal. If the vacuum pump

performance is poor check the coalescer oil

level, after having drained any excess

water.

Manual No/Rev

W72-021E / 8

5.8 Non Return Valve Checks

The volute non-return valve needs to seal if

the priming system is to function. The nonreturn valve can be examined by removing

the discharge quick release coupling - see

the relevant section of the maintenance

instructions. Ensure that there is nothing

jammed under the valve especially at the

back around the valve hinge.

5.9 Air Leak Checks

It is extremely unlikely that there will be air

leaks at any of the priming system sealing

faces. Leaks may occur if the suction quick

release fitting has been moved or the

priming tank has recently been dismantled.

If the vacuum pump is working but not

achieving full vacuum fit a quick release

connection cap and gauge to the suction

hose. Run the unit to achieve a vacuum, as

indicated by the gauge, then turn the unit

off. Note how long the vacuum takes to

decay. A pump in full working order will

achieve a vacuum of 9 metres water and

hold it for in excess of five minutes.

5.10 Vacuum Pump Checks

If the vacuum pump is considered to be at

fault no attempt should be made to

dismantle it. Obtain a replacement unit.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

5.11 Electrical Checks

Please refer to SPP Pumps.

Page 7 of 36

Page 8

Manual No/Rev

ITEM DESCRIPTION

PART No

QTY

1

2

4

7

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

6. PUMP DISASSEMBLY

6.1 General Comments

Maintenance and repair that is outside the

scope of the operators handbook must be

done in a suitable location equipped with

lifting equipment with a capacity of at least

1500 kg.

A clean and sound floor with work stands or

benches will provide for ease of access and

a safe working environment.

To avoid the possibility of maintenance

personnel inhaling dangerous fumes or

vapours. It is recommended that

maintenance work be carried out away from

the pump location by removal of the pump

unit to a suitable maintenance area.

Disconnect the negative battery lead before

maintenance work is done. Electrical

checks and repair may require the battery

to be connected, refer to section 10 for

testing instructions.

On trailer units ensure that the rear prop

stand is lowered and the jockey wheel is

wound down to apply load to the rear prop

stand before removing any heavy pump

components. If the pump is removed from

the engine without removal of the engine,

support the chassis with wooden blocks or

adjustable stands to prevent toppling.

6.2 Battery Removal Procedure

1. Disconnect the negative battery lead then

the positive battery lead from the battery.

2. Remove the retaining nuts (4) and strap (1)

and lift out the battery.

3. If required, remove the retaining bolts (2)

and lift the battery tray assembly out from

the chassis.

6.2.1 Battery Parts List

Battery Support Assy. 21730 1

Bolt M12 X 30Flange Self Lock 18171 2

3

Nut M12 Self Locking Flanged 18175 1

Nut M8 Hex. SY9509652 2

5

Battery (Specification as advised by SPP Pumps) 1

6

Battery Lead Negative 18200 1

Battery Lead Positive 18199 1

6.2.2 Battery Parts Diagram

6.3 Preparation for Pump Removal

1. Drain the pump volute and flush out any

hazardous liquid from the pump casing and

priming tank.

2. Disconnect the flexible drain hoses from the

stop valve on the pump casing and from the

stop valve on the coalescer.

3. If the engine is to be overhauled, drain the

sump at this stage and disconnect the

engine sump drain hose from the stop valve

on the engine.

4. Disconnect the wiring loom from the engine.

Refer to the wiring diagrams in section8.

5. Disconnect the probe, solenoid and clutch

cables (where fitted) from the priming

control box.

6.4 Disconnection of Controls Wiring

Note: The single probe priming control system

may be fitted in place of the twin probe

system if required.

SPP recommends upgrading to the single

probe system in place of repairs to the twin

probe system.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 8 of 36

Page 9

Workshop Manual for

ITEM DESCRIPTION

PART No

QTY

2

1

11

6

2

AUTOPRIME Q Range Pump Unit

6.4.1 Single Probe Priming Control System

Components Schematic Diagram

Manual No/Rev

W72-021E / 8

Single Probe System Parts List & Diagram

Priming Control Box & Probe

1

Assembly Complete

Loom 21891 1

26174 1

Pump Control Panel Parts Diagram

6.4.2 Pump Control Panel

ITEM DESCRIPTION PART No QTY

Control Panel with Shutdown 20115 1

Control Panel with Speed

2

Control, Tachometer and

Shutdown

Autostart Control Panel with

6

speed Control, Tachometer

and Shutdown

3

4LE2 Engine Loom 20167 1

3

3CE1 Engine Loom 24160 1

20219 1

23741 1

FUEL PUMP

3

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 9 of 36

Page 10

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

6.5 Louver and Front Panel Removal

(Refer to Parts Diagram 7.14.3)

Note: To gain access to pump and priming tank,

the front panel and louver may be removed

without removal of the canopy.

1. Remove the 2 bolts (A) holding the front

canopy frame to the shroud supports on the

chassis.

2. Open both doors, remove the nuts (B) from

the studs in each upper corner of the

middle canopy support frame.

3. Pull the louver and front panel complete

with the support frame forward and lift off to

expose the pump.

4. If required the front shroud may also be

removed to give access to the pump

suction end for maintenance of the nonreturn valve, priming tank and impeller.

6.6 Canopy Removal Procedure

(Refer to Parts Diagram 7.14.3)

1. Open both doors, remove the drive belt

guard, separate the internal sound baffle

into two halves and detach each half from

the canopy support frame. The baffle

halves may be secured temporarily to the

canopy frame, unless further disassembly is

necessary.

2. Disconnect the air supply hose from the

engine manifold by removal of the hose clip

and remove the short exhaust pipe to allow

lifting of the canopy.

3. Where speed control has been fitted,

disconnect the cable from the engine

throttle lever.

4. Disconnect the fuel tank vent pipe from the

fuel tank end.

5. Remove the 6 retaining screws (3), close

doors and lift off the canopy assembly

complete taking care to ensure that any

additional hoses or wires have been

disconnected.

6.7 Pump & Engine Unit Removal

1. Disconnect the fuel and return lines from

the fuel tank.

2. Connect crane hook to the lifter provided

and apply light pull just sufficient to take up

the slack in the crane cables.

3. Remove the 4 bolts from the engine and

pump mountings, and confirm that the

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 36

pump and engine assembly is free to be

lifted.

4. Lift the pump and engine assembly with

care and either pull away the chassis

assembly or move the engine and pump

unit to a suitable location for further

disassembly.

5. Place this unit on a sturdy low bench and

support the engine and pump end

separately.

6. Remove 8 nuts from the studs on the

suction flange and remove the priming tank

assembly complete from the pump.

7. Slacken the belt tension device and lift the

belts off the vacuum pump pulleys.

8. Remove the 4 screws and remove the

coalescer assembly complete with vacuum

pump from the pump.

9. Support the engine and pump to prevent

toppling and remove the 16 screws from the

flywheel housing to separate the pump from

the engine.

10. At this stage it is possible to disassemble

the lifter assembly and the drive pulley

arrangement for maintenance if required.

Refer to the parts diagram 7.12.1.

11. Similarly it is possible to replace the drive

coupling components if required, as these

are accessible in the flywheel housing on

the engine. Refer to the parts diagram

7.9.2.

6.8 Pump Disassembly Procedure

(Refer to Parts Diagram 7.3.2)

1. Drain the seal lubrication system into a

suitable container by removal of the lower

hose connection.

2. Remove any remaining nuts from the studs

on the suction flange of the pump casing.

3. Using a soft faced mallet tap the outer

diameter of the front wear plate and

withdraw it from the pump casing.

4. Lock the shaft with a C spanner and

remove the socket cap screw from the

centre of the impeller.

5. Tap the impeller lightly with a soft-faced

mallet on the outer diameter to break the

taper joint and withdraw the impeller from

the shaft. Remove the taper key and store

for carefully for reuse.

6. With a pair of circlip pliers, withdraw the

mechanical seal retaining circlip from the

shaft. Carefully withdraw the rotating part of

Page 11

Workshop Manual for

ABC

D

AUTOPRIME Q Range Pump Unit

the mechanical seal from the shaft.

Note: Mechanical seals are usually replaced

during pump maintenance, if the seals are

not being replaced, great care must be

taken not to touch or damage the sealing

faces, and parts from each seal should kept

for reassembly together.

7. With a pair of circlip pliers, extract the

mechanical seal retaining circlip from the

shaft. Carefully withdraw the rotating part of

the mechanical seal from the shaft.

8. Remove the 6 nuts (25) from the bearing

side of the pump casing and carefully

withdraw the back wear plate from the

pump casing. Take care not to damage the

stationery element of the mechanical seal if

this to be reused.

9. With a pair of circlip pliers, extract second

the mechanical seal retaining circlip from

the shaft. Carefully withdraw the rotating

part of the mechanical seal from the shaft.

10. Remove the 8 nuts from the bearing

housing studs and detach the pump casing

from the bearing housing.

11. Remove the drive belts from the drive shaft

pulley, release the setscrews that lock the

drive pulley to the shaft and withdraw the

pulley.

12. Remove the four screws and withdraw the

bearing cap from the bearing housing.

13. Using a suitable C spanner undo and

remove the bearing retaining nut

14. Mount the bearing housing in a press and

push the shaft, complete with drive end

bearings out from the bearing housing.

15. If it is required to replace the bearings the

drive end bearings may be pushed of the

shaft, note that is important to replace them

as a pair.

16. The non-drive end roller bearing may be

pushed out from the bearing housing using

screws in the threaded holes provided.

17. The stationery part of the outer mechanical

seal may be pushed out from it’s seating in

the bearing housing, if it is to be replaced.

6.9 Inspection of Pump Parts

1. Wash all old lubricant from ball bearings,

housings, caps and fittings with kerosene or

white spirit, and dry bearings thoroughly by

spinning by hand, or gently with clean dry

compressed air. Renew them if they do not

then rotate smoothly with no sign of

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 11 of 36

Manual No/Rev

W72-021E / 8

jamming, and freely but without slackness,

or if running surfaces of balls or races show

any deterioration. Coat bearings with rust

preventive oil and wrap in greaseproof

paper.

2. Mount shaft between point centres or on

rollers, and place stem of dial indicator in

contact with shaft. Set the indicator dial at

zero and turn the shaft slowly by hand.

Reading at any point A, B, C, and D must

not vary more than 0.05mm (0.002").

3. Scour any rust or scale from internal iron

non-fitting surfaces.

4. Clean all threads followed by wire brushing,

and wrap shaft threads with protective

adhesive tape.

5. If the unit is not to be reassembled

immediately, brush all bright iron and steel

surfaces with Shell Ensis rust preventive

fluid.

6. Protect all parts (especially mechanical seal

parts and faces) against loss, weather or

mechanical damage.

7. Re-examine all old parts intended for refitting. Worn, damaged or corroded parts

should either be re-conditioned or, if

beyond this, be discarded and replaced by

new.

8. Ensure that all parts to be refitted

(especially new parts) are free from burrs,

with screw threads and abutting faces clean

and free from damage.

9. Examine 'O' rings and all mechanical seal

parts and renew if showing wear or

deterioration.

10. Apply a few strokes of a grease gun to each

grease nipple and check that clean grease

comes through to the inside of the bearing

housing.

6.10 Coalescer Disassembly

(Refer to Parts Diagram 7.4.3)

Note The coalescer contains 5 litres of oil; this

must be drained for safe disposal before

disassembly.

SPP recommends that all filter elements and

mesh is replaced when the coalescer is

disassembled for maintenance.

Page 12

Manual No/Rev

W72-021E / 8

1. Drain the oil from the chamber into a

suitable container by use of the valve on

the primary chamber.

2. Remove the two cap screws connecting the

cover to the secondary chamber and

remove cover.

3. Remove the four filter elements and

disassemble by removing the filter retainer

and the filter carrier from the stud.

4. Remove the secondary chamber from the

primary chamber by removing the 8 M6

nuts from the studs in the primary chamber.

5. Remove gasket and filter mesh retainer.

Remove all other parts including studs, the

dipstick, the filter mesh block and the back gasket.

Workshop Manual for

AUTOPRIME Q Range Pump Units

6.11 Vacuum Pump Disassembly

(Refer to Parts Diagram 7.5.1)

1. Remove connection inlet, gasket by

removing the rapid fitting and the 3 M10

nuts. Remove the pulley.

2. Remove the M10 nuts and washers from

the DE (drive end) end plate and remove

the lip seal.

3. Break the taper and remove the end plate

as well as the DE bearing and wave spring

washer. Remove the key and store carefully

for reuse.

4. Remove the NDE (non-drive end) plate by

removing the M10 nuts and washers.

Remove studs, O-Rings, dowels grub

screws and plug.

5. Remove rotor and vanes carefully, the grub

screws and the plug.

6.12 Priming Tank Disassembly

(Refer to Parts Diagram 7.6.1)

1. Remove the solenoid valve from the filter

housing by unscrewing the three M8 nuts.

2. Disassemble the parts connected to the

solenoid valve such as the vacuum hose,

the elbows, the breather cap, the filter

carrier, etc.

3. Remove the filter element from the filter

housing by removing the filter cover and

retainer.

4. Remove the filter housing and gasket from

the priming tank and remove the knitmesh

filter from inside the priming tank.

5. Remove the priming tank and gasket from

the inlet duct.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 12 of 36

Page 13

Workshop Manual for

AUTOPRIME Q Range Pump Unit

7. PUMP ASSEMBLY

7.1 General Comments:

These instructions cover full manufacturing

assembly, where units have partially

stripped for maintenance or repair, use only

the instructions that apply for the stages of

assembly required.

Re-examine all old parts intended for refitting. Worn, damaged or corroded parts

should either be re-conditioned or, if

beyond this, be discarded and replaced by

new.

Ensure that all parts to be refitted

(especially new parts) are free from burrs,

with screw threads and abutting faces clean

and free from damage.

Examine 'O' rings and renew them if

showing wear, damage or deterioration.

The sequence of build for sub assemblies

may vary to suit current stocking policy.

7.2 Special Tools

Some special tools are required for quick

and correct assembly. With care however,

most assembly procedures can be done

without these tools. It is important to ensure

the suitable lifting equipment is available

and that the work is carried out in a clean

area.

DESCRIPTION PART NO.

Mech. Seal Assembly Sleeve

Door Tool

Belt Tension Checking Tool

Vacuum Pump Anti-rotation Tool

7.3 Pump Assembly

7.3.1 Pump Parts List - QI100, 150 & 200

ITEM

1 Bearing Housing 23909.123 1

2 End Cap 13664.123 1

3 ‘O’ Ring 13767 1

4 Lip Seal 13778 1

5 Screw M8 x 25 21863-136-959-4 4

5a Washer Spring M 8 21174-305-927-9 4

6 Spacer/Sleeve 13750.221 1

7 Shaft 13749.375 1

8 Bearing DE 13765 2

9 Bearing NDE 13764 1

10 Locknut - M45 13773 1

11 Key - Drive End 13936 1

12 Key - Impeller End 13937 1

13 Plug - 3/8” Square Headed 25221-383-915-0 1

15 Grease Nipple-1/8” SY9219001 1

16 G Nipple-1/8” 90º SY9219010 1

17 Filter Silencer-1/8” 14623 1

18 Screw M6 x 12 21836-201-977-3 2

DESCRIPTION PART No. QTY

Refer to SPP

Refer to SPP

Refer to SPP

Refer to SPP

Manual No/Rev

W72-021E / 8

ITEM

19 Washer-6.2 x 17.5 25115-019-781-2 2

20 Mechanical Seal 13763 2

21 Washer Mech./seal 13938 2

22 Circlip - Ext 45mm 13772 2

23 Volute 18799.123 1

24 Stud M12 x 35 21815-361-955-3 8

25 Nut M12. 21882-675-958-7 8

25a Washer Spring M 12 21174-307-927-3 8

27 ‘O’ Ring 13770 1

28 Valve - 1” BSP 13132 1

29 Barrel Nipple-1”BSP 25212-046-915-4 1

30 Elbow M/F 1”BSP SY9209045 1

31 Valve ½” BSP 12974 1

32 Nipple ½” BSP 25212-044-915-0 1

33 Hose Tail ½” PSP 12149 1

34 Hose ¾” Clear - NRV Drain 15446 2000mm

35 Hose Clip 25742-205-000-9 1

36 Back Wear Plate 13659.123 1

37 Screw C/S M10x16 14524.347 2

38 Stud M8 x 60 21815-267-955-2 4

39 Nut M8 21882-672-958-6 4

39a Washer Spring M 8 21174-305-927-9 4

40 ‘O’ Ring 13768 1

41 ‘O’ Ring 13769 1

42 Cover N.R.V. 13669.123 1

43 Gasket N.R.V. 14063 1

44 Flapper N.R.V. 13908 1

45 Stud M16 x 32 SY9509210 4

46 Stud M16 x 60 SY9509217 2

47 Nut M16 21882-677-958-1 6

47a Washer Spring M 16 21174-308-927-0 6

48 Impeller Q#100 15693.168 1

48 Impeller Q#150 19640.165 1

48 Impeller Q#150M 19639.165 1

48 Impeller Q#200 16133.168 1

49 Screw Socket M16x65 21835-317-977-4 1

50 Spring Washer 21174-308-927-0 1

51 Impeller Washer 18656.374 1

52 Front Wear Plate Q#100 15694.123 1

52 Front Wear Plate Q#150 & M 13658.123 1

52 Front Wear Plate Q#200 18126.123 1

53 Shim Pack 13766 1

54 Stud M16 x 45 SY9509215 8

55 Nut M16 21882-677-958-1 8

55a Washer Spring M 16 21174-308-927-0 8

55b Washer M16 21172-213-722-9 8

56 ‘O’ Ring for QI100 13770 1

56 ‘O’ Ring for QI150 & QI200 13771 1

57 ‘O’ Ring for QI100 18210.017 1

57 ‘O’ Ring for QI150 & QI200 13774 1

58 Restrictor for QI100 SY3804417 1

59 Diffuser for QI200 & QI150M 14454.123 1

60 Gasket 150 mm SY5004419 2

61 Stud M16 x 45 SY9509214 16

62 Nut M16 21882-677-958-1 16

63 Washer Spring M 16 21174-308-927-0 16

64 Washer M16 21172-213-342-9 16

65 Hose Tail 1” 05840 1

66 Hose Clip 25742-205-000-9 1

67 Tube PVC 1” ID x 1 ¼” OD 17351-711-108-3 2000mm

Spares: Impeller kit Q100 21214

Spares: Impeller kit Q150 21215

Spares: Impeller kit Q200 21216

DESCRIPTION PART No. QTY

Impeller spares kits

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 13 of 36

Page 14

Manual No/Rev

B

u

nde

d

Q

Pum

p P

a

rts

40

38

42

27

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

7.3.2 Pump Parts Diagram - QI100, 150 & 200

32

31

47 & 47a

43

45-46

44

23

39 & 39a

33

61 62 63 64

36

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 14 of 36

Page 15

7.3.3 Pump Parts Diagram - QHH80

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 15 of 36

Page 16

Manual No/Rev

ITEM DESCRIPTION

PART No.

QTY

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

7.3.4 Pump Assembly Procedure

1. Apply a light smear of grease to the nondrive end bearing assembly.

2. Locate the outer race of non-drive end,

roller bearing inside the bearing housing

and push it through the drive-end bearing

diameter.

3. Set it square with the bore and push it

home to seat fully against the shoulder at

the pump end of the bearing housing.

4. Insert the bearing spacer into the bearing

housing.

5. Heat the inner ring of the non-drive end,

roller bearing to 110°C and place over the

pump end of the shaft to locate fully against

the shoulder on the shaft.

6. Heat the drive-end ball bearings to 110°C

and place the first bearing over the shaft

ensuring that the thicker end of the inner

ring is facing the shoulder on the shaft.

Press the bearing home and ensure that

the bearing abuts the shoulder and is

seated squarely on the shaft.

7. Heat as above and place the second

bearing on the shaft but with the thinner

end of the inner ring facing the first bearing.

Press home to abut fully with the first

bearing.

8. When cool, apply grease to pack the

bearings to fill about half the space

between the balls, and rotate the bearings

several times to distribute the grease

evenly.

9. Place the bearing housing in the vertical

position and lower the shaft into the bearing

housing.

10. Press home the shaft until the drive-end

bearings are seated fully on the bearing

spacer.

11. Fit the locknut to the shaft and tighten to

200Nm.

12. Lubricate and fit the O ring in the groove

and fit the lip seal with its lip facing inwards

in the housing on the bearing cap.

13. Fit the bearing cap and secure with four M8

x 25 screws.

14. Invert the bearing housing, lubricate and

insert the stationery element of the

mechanical seal in it’s housing on the pump

end of the bearing housing.

15. Lubricate and fit the rotating assembly of

the mechanical seal on the shaft, add the

washer and circlip, compress the seal and

locate the circlip in it’s groove.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 16 of 36

ATTENTION

Take great care when handling the

mechanical seal parts, do not touch the

sealing faces and use only lint free wipers if

cleaning is required. If lubrication is

required to assist assembly us clean and

thin oil only.

16. Attach the pump casing to the bearing

housing by attaching the 8 M8 nuts to the

bearing housing studs.

17. Replace the back wear plate and secure

with 6 M12 nuts screwed onto the studs at

the bearing side of the pump casing.

18. Lubricate and insert the second stationery

element of the mechanical seal in it’s

housing on the pump end of the bearing

housing.

19. Lubricate and fit the rotating assembly of

the mechanical seal on the shaft, add the

washer and circlip, compress the seal and

locate the circlip in it’s groove.

20. Replace the taper key and place the

impeller over the shaft taper.

21. Ensure the shaft is locked and Insert the

socket screw into the impeller and the shaft.

Then unlock the shaft using the C spanner.

22. Insert the front wear plate complete with Orings into the pump casing and screw nuts

(M16) onto the studs on the front wear plate

of the pump casing.

23. Fit the mechanical seal lubrication tank and

connect the pipes as shown on the

diagram.

7.3.5 Seal Lubrication System Parts List

1 Washer M10 21172-211-342-5 2

2 Spring Washer -M10 21174-306-927-6 2

3 Cable Tie TY1003 2

4 Cable Base TY1029 2

5 Hose Tail 12149 1

6 Bolt M10 x 90 12204 1

7 Plastic Tube 12501 1

8 Bracket - Oil Bottle 14640.221 1

9 Spacer Set 14641 1

10 Oil Bottle 15430 1

11 Cap - Oil Bottle 15431 1

13 Hose Clip 7/8-1.1/2 25742-205-000-9 1

13a Hose Clip 05837 1

14 Bolt - M8 x 16 Self Locking 18163 4

15 Hose ¾” 16882 460mm

Page 17

6

15

13

ITEM DESCRIPTION

PART No

QTY

Seal Lubrication System Diagram

11

10

7

9

14

8

Workshop Manual for

AUTOPRIME Q Range Pump Unit

8. Fit elbow M/F and rapid fitting to outside of

scavenge boss.

9. Fit the filter elements (23) and filter

2

1

9

retainers (24). Do not over tighten the

retainers.

10. Fit coalescer seal onto top edge. Fit cover

and position correctly.

11. Press down on cover to compress rubber.

12. Fit the two cap screws with washers two fix

the cover to the secondary chamber.

7.4.2 Coalescer Parts List

Manual No/Rev

W72-021E / 8

3

5

4

7.4 Coalescer Assembly

7.4.1 Coalescer Assembly Instructions

1. Feed the mesh filter (2) into the rear of the

chamber (1). Ensure it completely covers

vacuum pump port.

2. Fit stud coupling (1/4” BSP) and copper

pipe (5/16”) into rear of filter boss. Ensure

copper pipe is correctly orientated and

positioned.

3. Fit nipple, dipstick, O-ring and oil filter.

Lubricate seal with clean oil. Fit rapid fitting

to top of filter boss.

4. Fit 8 M6 x 25 studs into flange, blanking

plugs into bosses and reducing bush into

drain boss. Fit pipe into reducing bush.

5. Fit studs for mounting to the bearing

bracket (M12 x 35) and to the vacuum

pump (M12 x 40).

6. Fit gasket to underside of secondary

chamber (15) and bolt secondary to primary

chamber (1) with the 8 M6 nuts. Do not

over tighten.

7. Fit stud coupling (1/8” BSP) and copper

pipe (5/16”). Ensure copper pipe is correctly

orientated and positioned.

1 Primary Chamber 14127.524 1

2 Filter Block Mesh 14508 1

3 Nipple - ¾” x 25mm 13787 1

4 Oil Filter 13782 1

5 Reduce Bush ¾”- ½ 25243-702-906-7 1

6 Sight Glass No 2 07270 1

7 Barrel Nipple 25212-044-915-0 1

8 Valve 12974 1

8a Hose Tail ½” 19mm 12149 1

9 Dipstick 14373 1

10 ‘O’ Ring 25154-024-716-1 1

11 Stud coupling - ¼”BSP 25345-611-000-5 1

12 Tube 5/16” OD 14173-711-044-5 200mm

13 Stud - M6 x 25 SY9509007 7

14 Filter Mesh Retainer 16876 1

15 Screw M6 x 35 21863-110-259-2 1

16 Washer 27336-035-000-3 1

17 Gasket 15584 1

18 Secondary Chamber 14128.524 1

19 Filter Carrier 14130 4

20 Stud - M6 x 260 13798 4

21 Self locking Nut - M6 SY9509863 8

22 Washer Nylon - M6 SY9509696 8

23 Filter Element 14074 4

24 Filter Retainer 14470 4

24a Nut M6 Self Locking 16898 4

25 Stud Coupling-1/8”BSP 25345-610-000-8 1

26 Elbow M/F - 1/8” BSP SY9209040 1

27 Rapid Fitting - 1/8”BSP 14008 2

28 Tube PTFE 4 ID x 6 OD 15487 1500mm

29 Coalescer Seal 14422.01 1

30 Cover 14129.524 1

31 Cap screw M8 x 40 21835-142-971-8 2

32 Washer 2117-210-222-8 2

33 Gasket Coalescer/V.P 13929 1

34 Stud - M12 x 40 SY9509133 4

35 Stud - M12 x 35 21815-361-955-3 4

36 Nut M12 21882-675-958-7 8

37 Washer Spring M12 21774-307-927-3 8

38 Reducing Bush SY9209068 1

39 Plug - 1” BSP 25221-386-1 1

40 Level Switch & Cable Assy. 20013 1

41 Hose ¾ “ ID Clear Braided 15446 1400mm

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 17 of 36

Page 18

Manual No/Rev

2

3

5

4

39

35

34

40

41

38

7

8

8a

13

27

12

11

1

37 & 36

26

C

O

A

L

E

S

C

E

R

V

6

A

B

C

C

B

A

W72-021E / 8

7.4.3 Coalescer Parts Diagram

24a

Workshop Manual for

AUTOPRIME Q Range Pump Units

30

29

31

32

18

19

24

20

23

22

21

19

18

9 & 10

12

25

17

47

33

28

27

14

6

16

15

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 18 of 36

Page 19

10

2

3

11

456

8

9

15

18

24

262728

121314

20 - MAGNETIC CLUTCH ASSY

31

DIRECT DRIVE PULLEY

ITEM DESCRIPTION

PART No

QTY

7.5 Vacuum Pump Assembly

7.5.1 Vacuum Pump Parts Diagram

7

25

9

21

Workshop Manual for

AUTOPRIME Q Range Pump Unit

19

29

Manual No/Rev

W72-021E / 8

30

11

23

22

10

1

7.5.2 Vacuum Pump Parts List

1

Stator 13695.123 1

2

Rotor 13692.165 1

3

Bearing NDE 14068 1

4

Bearing DE 14067 1

5

Endplate NDE 13694.123 1

6

Spacer 15488 1

7

Stud M10 x 40 SY9509093 6

8

Stud M10 x 25 SY9509087 6

9

Dowel - 6MM x 25 21123-478-347-4 4

10

‘O’ Ring 18079 2

11

‘O’ Ring 18078 2

12

Nut M10 21882-673-958-3 15

13

Washer Spring M 10 21174-306-927-6 15

15

Vane 14132 4

16

Lip seal 18080 1

17

End plate DE 13693.123 1

18

Wave spring washer 14069 1

19

Key 13986 1

20

Magnetic clutch assy. 13777 1

21

Plug male 1/8” Solid SY9209159 1

22

Grub screw M10 x 12 21828-170-977-9 1

23

Grub screw M12 x 16 21828-212-977-6 1

24

Shim pack 15730 1

25

Stud M10 x 25 SY9509087 3

26

Connection inlet 13699.123 1

27

Gasket 14075 1

28

Rapid fitting 14008 2

29

Pulley – Direct drive 19131 1

30

Washer 19099 1

31

Screw 19098 1

65cfm BD @1

28

17

13

12

16

7.5.3 Vacuum Pump Assembly Instructions

1. Fit bearing to rotor (DE). Use blocks to

raise rotor and fit the inside of the other

bearing. (NDE)

2. Fit the spacer and 0.003” shim into the bore

of the NDE cover plate.

3. Place the rotor into the bore and spin.

Check the gap between the rotor and plate

using a feeler gauge.

4. Fit M10 grub screw to the base to plug hole.

Place rotor inside stator.

5. Adjust plate so that rotor is not rubbing

against stator wall. Fit M10 x 25

6. Fit 6 M10 x 40 studs to stator on NDE and

fit dowel and O-Rings. Fit stator and nondrive end plate together using M10 nuts

and flat washers.

7. Oil the vanes and slide them into the stator

on the drive end.

8. Fit the lip seal into the DE plate. Note that

the lip seal is to be fitted with the lip and

spring facing outward to prevent ingress of

dirt and air.

9. Place the wave spring washer and the rest

of the bearing into the bore of the plate.

10. Fit the plate to the stator, ensuring that the

dowel is located.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 19 of 36

Page 20

Manual No/Rev

13127861814

21

25a

2

1

24

24a

24b

3

22

23 & 23a

3029262728

W72-021E / 8

11. Fit a spring washer, flat washer and a nut

on every stud and tighten them up. Spin the

rotor with an air drill and the shaft

attachment. Fit M10 x 35 studs to top of

Stator

12. Fit remaining dowels, the inlet connection

and gasket. The side tapping on the inlet

connection must face towards the oil

connection on the drive end plate. Secure

with nuts and washers.

13. Fit the static part of the magnetic clutch

assembly to the drive-end bearing housing

using the UNC screws provided.

14. Remove the grub screw from the drive end

bearing housing and insert the anti-rotation

Workshop Manual for

AUTOPRIME Q Range Pump Units

7.6 Priming Tank Assembly

7.6.1 Priming Tank Parts Diagram

tool.

15. Fit the key (19), coat the shaft taper with

anti-seize grease and fit the pulley using

the washer and screw supplied with the

clutch.

16. Remove the anti-rotation tool and replace

the grub screw having sealed the threat

with PTFE tape.

Note: Where required, the magnetic clutch may

be replaced by a direct drive pulley (29) that

is fitted as per paragraphs 14, 15 & 16

above but with Loctite 270 applied to the

retaining screw (31) before final assembly.

31

25

11 16 4

Note: Items 32 to 35 are not shown

15

17

19

10

5

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 20 of 36

Page 21

Workshop Manual for

ITEM DESCRIPTION

PART No

QTY

AUTOPRIME Q Range Pump Unit

7.6.2 Priming Tank Parts List

imin

1

Inlet Duct - Q#100 18204.123 1

1

Inlet Duct - Q#150 17083.123 1

1

Inlet Duct - Q#150M 25529.123 1

1

Inlet Duct – Q#200 18104.123 1

2

Gasket SY5004397 1

3

Tank – Priming 17084.524 1

4

Housing – Filter 13661.524 1

5

Gasket-P/Tank-Filter 13934 1

6

Stud-M8 x 25 21816-257-962-6 8

7

Nut – M8 21882-672-958-6 8

8

Washer Spring M8 21174-305-927-9 8

10

Filter Block-Knitmesh 13796 1

11

Carrier – Filter 13662.524 1

12

Stud – M6 x 260 lg 13798 1

13

Nut – M6 Self Locking SY9509863 1

14

Stud – M6 x 65 13799 3

15

Washer – M6 Flat 21172-209-342-6 3

16

‘O’ Ring – 79.5 I/d x 3 25154-079-017-1 1

17

Knob – M6 Scallop 13797 3

18

Element – Filter 14006 1

19

Retainer – Filter 14470 1

20

Cover – Filter 13663.524 1

21

‘O’ Ring – 87 I/d x 3 13942 1

22

Stud M8 x 25 21816-257-962-6 3

23

Nut M8 21882-672-958-6

23a

Washer Spring M8 21174-305-927-9 3

24

Screw M12 x 30 21863-218-959-1 6

24a

Washer Spring M12 21174-307-927-3 6

24b

Plain Washer M12 21172-212-342-2 6

25

Adapter – 1” BSP 14176 1

25a

Fibre Washer 22115 1

26

Valve – Solenoid 13794 1

27

Bush-Red 1” x ¾” BSP 25243-706-906-5 1

28

Cap – Breather 13925 1

29

Elbow-1” BSP x 90 M/F SY9209045 1

30

Elbow-1” BSP x 45 M/F SY9209340 1

31

Pipe Adapter SY3734296 1

32

Superclamp-40/43mm SY3804409 2

33

Vacuum Hose – 32mm 20094 1

34

Nut M8 Self Lock 18173 4

35

Based on 23531 as on 16-09-05

Stud M5 x 50mm 21815-265-955-8 4

3

7.6.3 Priming Tank Assembly Instructions

Note:This may be done before fitting the Inlet duct

(1) to the pump casing but is best done

after fitting to the pump to ensure stability

and ease of assembly.

1. Insert the knitmesh filter (10) into the

priming tank (3)

2. Fit the gasket (2) to the inlet duct (1), mount

the priming tank in position and fasten in

place with screws (24) and washers (24a &

24b).

3. Fit the long stud (12) to the filter carrier (11)

using the nut (13) to lock it into position and

fit ‘O’ ring (16) to filter carrier (11).

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 21 of 36

Manual No/Rev

W72-021E / 8

4. Fit the carrier assembly to the filter housing

(4) and retain by three studs, washers and

nuts (22, 23 &23a).

5. Feed the fine filter element (18) into the

housing and fit the filter retainer (19), do not

over-tighten the retainer as this may

damage the filter element.

6. Fit the ‘O’ ring (21) to the filter cover (20)

and fit this to the filter housing, retained in

position with three washer and knobs (15 &

17).

7. Mount the filter assembly on the priming

tank using gasket (5) and eight studs

washers and nuts (6,8 & 7).

8. Fit the fibre washer (25a) on the adaptor

(25) and using PTFE tape to seal it fit this to

the filter carrier.

9. Again using PTFE tape fit the solenoid

valve (26) to the adaptor having fitted the

bush (27) and breather cap (28) to the

solenoid valve.

10. Finally using PTFE tape to seal the threads

fit the pipe fittings (29, 30 & 31) to suit the

required direction of the vacuum hose.

7.7 Pump End Final Assembly

(Refer to Pump Parts Diagram 7.3.2)

1. If the Inlet duct was not fitted to the pump

casing for assembly of the priming tank, fit

the priming tank assembly to the pump

using ‘O’ ring (57) to seal the joint and

retain by studs washers and nuts (54 55,

55a & 55b).

(Refer to Coalescer Parts Diagram 7.4.3)

2. Fit the vacuum pump to the coalescer using

the gasket 33 and retain by studs, washers

and nuts (34 36 & 37).

3. Fit the coalescer assembly complete with

the vacuum pump to the pump bearing

housing using studs (35) and washers and

nuts (36 & 37).

(Refer to Drive Belt Parts Diagram 7.11.1)

4. Fit the key (pump parts diagram item 11) to

the pump shaft, fit the Taperlock bush (2) to

the pulley (1) and slide this assembly on to

the pump shaft.

5. Align the pulley with the vacuum pump

pulley and tighten the grub screws to lock

the pulley into position on the shaft.

6. Remove each grub screw in turn and apply

Loctite 577 to the threads, refit and tighten.

Page 22

Manual No/Rev

ITEM DESCRIPTION

PART No

QTY

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

7. Position the drive belts over the pulleys and

fit the belt tensioner (7) to the bearing

housing, adjust to give slight tension to the

belts.

8. Fit the vacuum hose between the solenoid

valve and the vacuum pump using hose

clips to ensure an airtight joint.

(Refer to Lifter Parts Diagram 7.12.1)

9. Fit the lifter (1) to the pump bearing housing

using the three screws (2) with washers (4).

10. Fit the lifter support strut to the pump

casing using bolt (6) and washer (7), do not

tighten at this stage.

11. Fit the spacer (5) between the lifter and the

strut and fit bolts (8) with washer (9) and

nuts (10). Tighten all bolts securely.

7.8 Chassis & Fuel Tank Assembly

7.8.1 Chassis Assembly Notes

The support leg (22), light bracket (17) and

security bracket (19) are not fitted when

building a Q pump unit as a pod.

For trailers intended for use in France, the

pedestrian guard rail must be fitted.

For trailers that are to be used in Europe

the European VIN number plate must be

fitted.

For single fuel tanks the drain hose kit

comprises a 90deg hose socket in place of

the ‘T’ piece used with twin tanks.

The drain hoses for the pump, coalescer

and engine are specified with their

assemblies.

7.8.2 Chassis Assembly Instructions

1. Mount the chassis (1) on suitable support

stands.

2. Fit the sound insulation kit (2) to the

chassis.

3. Fit foam strip (3) to the chassis in three

positions on under the fuel tanks and at

each end of the fuel tank channels.

4. Fit foam strip also to the inside of the two

shrouds (1 & 10).

5. Prepare the fuel tanks by fitting the short

drain hoses (26 or 27) to the fuel tanks and

secure with hose clamps.

6. Fit the fuel gauge and the fuel pipe fitting

(Fuel Tank diagram items 4 & 5) to the

primary fuel tank.

7. Feed the drain hose through the slots in the

chassis frame members and retain the fuel

tanks within the side channels using the

square washers and fasteners specified.

8. Fit the remaining items for the fuel tank

drain assembly. Use Loctite 577 sealant on

all screwed pipe connections

9. Fit the hose tails (28 & 29) and plugs (30 &

31) to the drain points on the chassis.

10. Fit the side shrouds (9 & 10), but leave the

front and rear shrouds (14 & 15) for fitting

after the pump and engine unit have been

installed, tighten all bolts.

After Pump Installation Is Complete:

11. If the chassis is not already mounted on

suitable supports, lift the unit and provide

support to give access to the eight

mounting hole un the underside and located

in pairs in the centre or each side and end.

12. Remove all dirt and grease, apply

degreasing agent to each of the mounting

holes to clean the threads and surrounding

area for application of sealant.

13. Clean the shorter thread end of the

mounting studs and apply Loctite 577 to

this thread, fit the studs to the chassis

tighten to approximately 61 Nm.

14. Apply a continuous bead of Loctite 5220

around each stud to seal the gaps in the

welds etc.

15. For skid mounted units, mount the chassis

on the skid (35) and retain with washers

and nuts.

16. For trailer mounted units, fit the support leg

(22) and mount the chassis on the required

trailer and retain with washers and nuts.

17. For trailer units, fit the lighting and security

brackets (17 & 19), note that the two

screws securing the rear shroud must be

replaced by longer screws (18).

7.8.3 Fuel Tank Assembly

Primary Fuel Tank

1

2 Fuel Tank Only 21321 1

3 Filler Cap 21343 1

4 Fuel Gauge 21341 1

5 Fuel Pipe Fitting 21342 1

Gasket Fuel Pipe

6

7 Screw M5 x 12 MS1267 6

Secondary Fuel Tank and Air Vent Pipe – not illustrated

Secondary Fuel Tank 21322 1

Sec. Tank Vent Pipe 21636

Cable Base TY1029 3

Cable Tie TY1000 3

21340 1

21674 1

900mm

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 22 of 36

Page 23

Workshop Manual for

5

7

6

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

4

3

2

28 29

30 31

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 23 of 36

Page 24

Manual No/Rev

2

3

4

8

12

13

18

19

20

24

25

26

2

3

4

8

9

10

14

15

16

20

21

22

26

27

28

29

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

7.8.4 Chassis Parts List

ITEM DESCRIPTION PART No QTY

1 Chassis 21349 1

2 Insulation Kit 21421 1

3 Foam Strip 13920 6m

Fuel Tank Assembly

4

5 Fuel Tank Assembly LH 21322 1

6 Square Washer 21707 10

7 12mm Spring Washer 21174-307-927-3 6

8 Bolt Hex M12 x 50mm 21867-224-961-4 6

9 Shroud RH 21356 1

10 Shroud LH 21355 1

11 Shroud Support 21365 6

12 Bolt Hex M12 x 30mm 18171 6

13 Bolt M8 x 16 Self Lock 18163 6

14 Front Shroud 21358 1

15 Rear Shroud 21364 1

16 Bolt M8 x 12 Self Lock 21423 18

17 Light Bracket 21368 1

18 Bolt M8 x 16 Self Lock 18163 3

19 Security Bracket 21424 1

20 Special Stud 23619 8

21 Nut M12 Self Locking 18175 8

22 Support Leg 21370 1

23 Knob 21583 1

24 Bolt Hex M12 x 70 21867-228-961-2 1

25 Pin 12mm x 148mm 21436 1

26 Twin Tank Drain Kit 21465 1

27 Single Tank Drain Kit 21419 1

28 Hose Tail 19mm hose 12149 3

29 Hose Tail 1” Hose 05840 1

30 Plug 1” SY9209164 3

31 Plug ½” SY9209162 3

32 Hose Clip 25742-205-000-9 8

33 Fixed Height Trailer 21359 1

34 Variable Height Trailer 21360 1

35 Skid 22123

21321 1

7.9 Engine Assembly

7.9.1 Isuzu 3CE1 Engine Parts List

ITEM

1

5

6

7

14

15

16

21

22

23

27

DESCRIPTION PART No QTY

Engine 3CD1 24109 1

Coupling Complete 18315 1

Screw M10 X 30 21863-178-259-8 8

Washer Spring M10 21174-306-927-6 8

Hose ¾ ID Clear Braided 15446 1400mm

Kit Eng Oil Drain 3cyl 18386 1

Clip Hose 20mm to 32mm 25742-205-000-9 2

Mount Anti-Vibration 25519 2

Silencer Isuzu 3CD1 24101 1

Bracket Exhaust 3 Cyl. 24102 1

Nut M8 Self Locking SY9509864 6

Bolt M8 X 16 Self Lock 18163 6

Washer M8 21172-210-342-8 6

Clip Hose 2” to 2 ¾” 25742-212-000-3 4

Hose Air Inlet 2” Bore 09677 1000mm

Hose Air Flex 09677 1000mm

Air Filter Monitor 13913 1

Air Intake Adaptor 2” 20315 1

Pop Rivet 18635 3

Stud M10 x 55 SY9509096 7

Nut M10 Self Locking 21882-673-958-3 7

8mm Fuel Feed Pipe 22415 750mm

6mm Fuel Bleed Pipe 22414 1300mm

ITEM

28

29

DESCRIPTION PART No QTY

Cable Tie TY1000 20

Cable Base TY1003 10

Note – Items 5 & 26 to 29 not illustrated.

Isuzu 3CE1 Engine Fittings

1

7.9.2 Isuzu 4LE2 Engine Parts List

ITEM

1

5

6

7

11

12

13

17

18

19

23

24

25

30

DESCRIPTION PART No QTY

Engine 21779

Coupling Complete 18177 1

Screw Hex. M10 X 30 21863-178-959-8 8

Washer Spring M10 21174-306-927-6 8

Hose ¾ Id Clear Braided 15446 1400mm

Kit Eng Oil Drain Valve 18386 1

Clip Hose 7/8” To 1 ½” 25742-205-000-9 2

Mount Anti-Vibration 25519 2

Rebound 13791 2

Bolt ½ UNF X 3 ¾ Lg. 13788 2

Nut Jam ½-20 UNF 13789 2

Silencer Lagged 4LE2 21829 1

Bracket. Exhaust 4LE2 20339.221 1

Nut M8 Self Locking 18173 4

Bolt M8 x 16 Self Lock 18163 2

Bolt M8 x 25 Self Lock 18165 1

Clip Hose 2 ¾ To 3 ½ 25742-214-000-7 3

Clip Hose 2” To 2 ¾” 25742-212-000-3 1

Hose Air Inlet 3” Bore 18224 1000mm

Hose Air Flex Refer to Engine Manual 1

Air Filter Monitor 13913 1

Air Intake Adaptor 3” 18163 1

Pop Rivet 18635 3

Stud M10 x 40 SY9509093 12

Nut M10 Self Locking 18174 12

Fuel Feed Pipe Assy. 21467 1

Fuel Bleed Pipe Ass y. 21468 1

Cable Tie TY1000 20

Cable Base TY1003 10

Radiator Recovery bottle Isuzu 8943704500. 1

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 24 of 36

Page 25

AUTOPRIME Q Range Pump Unit

ITEM DESCRIPTION

PART No

QTY

BELTENS1

ITEM

31

DESCRIPTION PART No QTY

4LE2 air cleaner element ESPAR05615 1

Note – Items 5 & 26 to 31 not illustrated.

Workshop Manual for

7.11 Vacuum Pump Drive Assembly

7.11.1 Vacuum Pump Drive Parts Diagram

Manual No/Rev

W72-021E / 8

Isuzu 4LE1 & 4LE2 Engine Fittings

7.9.3 Engine Preparation Instructions

1. Fit the engine ancillary items as shown in

the diagram, leaving the air filter assembly

aside until the engine is mounted inside the

canopy.

7.10 Engine to Pump Assembly

1. Apply anti-seize grease to the pump shaft

and fit the coupling sleeve to the shaft. Set

in place 18mm from the pump shaft end

and to the shoulder of the coupling.

2. Fix in place using the grub screw and

secure this by application of Loctite 577 to

the threads.

3. Offer the pump to the engine, ensure that

the coupling is aligned and the bearing

housing ring is fully seated on the engine

flywheel housing.

4. Fix in place with the twelve nuts on the

studs on the engine flywheel housing and

three cap screws on the coupling.

5. Fit the lifter wire round the flywheel housing

and secure it to the lifter using bolt, spacers

and nut (14,12 & 15).

7

3

7.11.2 Vacuum Pump Drive Parts List

1 Pulley Taper Lock 13776 1

2 Taper Lock Bush 23686-669-000-2 1

3 Drive Belts 13928 2

4 Coupling 18177 1

5 Screw M10 x 30 21863-178-959-8 8

6 Spring Washer 21174-306-927-8 8

7 Belt Tensioning Device 13909.221 1

8 Screw M10 x 30 21862-178-959-8 1

9 Bolt M10 x 20 21863178-347-8 1

10 Plain Washer M10 21172-211-342-5 2

11 Washer Spring M10 21174-306-927-6 2

12 Belt Guard Assy. 22225 1

13 Bolt M10 x 12 Self Locking 21423 4

To adjust the belt tension, loosen the pivot

and locking bolts and using a spanner on

the adjustment aid, slide the pulley outward.

When the correct belt tension is obtained

re-tighten the locking bolt and the pivot bolt.

ATTENTION

Do not under-tension the belts

under any circumstances.

PIVOT

BOLT

LOCKING

BOLT

1/2" SQ

ADJUSTMENT

AID

5kgs

6mm

190mm

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 25 of 36

Page 26

Manual No/Rev

1

3

4

6

7

9

10

12

15

W72-021E / 8

7.12 Lifter Assembly

7.12.1 Lifter Parts Diagram

Workshop Manual for

AUTOPRIME Q Range Pump Units

7.14 Canopy Assembly Procedure

7.14.1 Door Preparation

1. Clean and adjust the position of the hinge

support tube to be flush with the front hinge

face.

2. Fit the spacer washer (18) and the hinge

bracket (17) over the tube that protrudes at

the rear hinge face.

3. Attach the bracket to the door with three

crews (19).

4. Fit the gas spring (23) to the hinge bracket

using the pin, two spacers and clevis pin

(30, 28 & 29).

5. Fit the lock plate (20) and the lock (22)

using the bolts (21).

7.14.2 Canopy Assembly & Fitting

7.12.2 Lifter Parts List

ITEM DESCRIPTION PART No QTY

Lifter A/Prime Heavy Duty 18447 1

2

Screw M20 X 50 21863-394-959-6 3

Washer Spring M20 21174-309-927-7 3

Strut Lifter Support 13743 1

5

Spacer Lifter Strut 5mm 14459.221 1

Bolt M16 X 40 21863-312-959-2 2

Washer Spring M16 21174-308-927-0 2

8

Bolt M12 X 35 21863-220-959-0 2

Washer Spring M12 21174-307-927-3 2

Nut M12 21882-675-959-7 2

11

Rope Wire Lifting 15483 1

Spacer Lifter Cable 15499 1

13

Washer 50 OD X 21 ID X 5

14

Bolt Hexagon M20 X 90 21867-402-374-6 1

Nut M20 Self Locking SY9509868 1

15500 2

7.13 Pump Unit to Chassis Assembly

1. Raise the engine & pump unit with a crane

using the lifter position the unit above the

chassis assembly with the engine to the

rear end.

2. Ensure that the pump and engine

mountings are correctly fitted and

orientated to align with the chassis fixing

holes.

3. Lower the unit into the chassis and connect

the drain hoses for the engine sump, pump

volute, non-return valve and the coalescer.

4. Lower the unit into its final position and fix

in place with the bolts provided.

5. Fit the battery tray and battery as per the

diagram in section 6.2.2.

6. Fit the priming system sensing probe

assembly and leave the control box loose

ready for mounting on the baffle plate on

the canopy support frame.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 26 of 36

Note The canopy may be partly assembled

before fitting to the chassis if required, but

may also by assembled after mounting on

the chassis for ease of access.

1. Assemble and fit the control panel door

complete with instruction label in the

required language. (The label may be fitted

later, if preferred)

2. Fit the insulation materials and cable clips

where possible at this stage.

3. For QI 100 & QI150 pumps, fit the radiator

extension to the radiator panel and fit the

panel to the support frame.

4. Using suitable lifting equipment, lower the

canopy support assembly on to the chassis

ensuring that the lifter passes through the

central slot in the roof.

5. Grease the door hinge pins (31) and insert

into the outer ends of the hinge blocks in

the canopy support frame (2).

6. Fit the main canopy doors and push he

hinge pins into the hinge support tubes.

7. Fit the lower end of the gas springs to the

canopy support frame using cap screw,

washers and nut (25, 24, 26 & 27). Apply

copper grease to the cap screw threads.

8. Fit the rear air duct to the radiator panel

and support frame.

9. Fit the louver tray to the louver and mount

these in position on the support frame.

10. Note The louver and front cover may be

fitted later to allow access to the pump and

priming system end during assembly.

11. Mount the six shroud supports (Chassis

Diagram Item –11) on the chassis frame

12. Secure the canopy assembly to the chassis

Page 27

Workshop Manual for

AUTOPRIME Q Range Pump Unit

with 6 bolds that pass through the shroud

supports and retain the shrouds.

13. Fit the internal noise baffle and all

remaining sound insulation items roof drain

7.14.3 Canopy Parts Diagram

Manual No/Rev

W72-021E / 8

pipes, cables and hose retaining clips.

14. Fit the priming system control box, air filter

gauge and any other items that are

attached to the inside of the canopy.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 27 of 36

Page 28

Manual No/Rev

3

4

5

9

10

11

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

7.14.4 Canopy Parts List

ITEM DESCRIPTION PART No. QTY

Canopy Assembly Complete 21418 1

1

2

Canopy Roof Support 21823 1

3 Bolt M 8 X 16 Flange Self Lock 18163 6

4 Door Control Panel Autoprime 15462 1

5 Hinge Offset “A” 96-50-510-50 15460 1

6 Hinge Offset “B” 96-50-520-50 15461 1

7 Socket Screw Cap M 5 X 10 21835-068-347-7 8

8 Control Panel Door Seal 16899 1

9 Control Panel Door Spacer 16969 1

10 Vise Action Door Latch 13775 1

11 Plastic Plug M16 Yellow 18338 4

12 Insulation Hanger for 25mm 14431 5

13 Sound Insulation Kit 23594 1

Door Assembly Pair Yellow 21924 1

14

15 Left Hand Yellow Door 14349 1

16 Right Hand Yellow Door 14350 1

17 Gas Strut Hinge Bracket

18 Door Hinge Nylon Spacer 6mm 14125 4

19 Bolt M 8 X 16 Flange Self Lock 18163 8

20 Door Lock Plate 13734 2

21 Nut M6 Self Locking Flanged 18172 8

22 Vise Action Door Latch 13775 2

23 Gas Spring 700n 13781 2

24 Washer M8 Nylon SY9509700 8

25 Socket Screw Cap M 8 X 40 21835-142-347-8 2

26 Washer M 8 21172-210-342-8 2

27 Nut Hex M8 – Nyloc 21882-672-347-6 2

28 Spacer 14430 4

29 Clip Retaining Clevis 89001 13941 2

30 Clevis Pin 5/16”Dia X 1.5”Long 13940 2

31 Hinge Pin Canopy Door Nylon 13921 4

32 Louver Panel 16410 1

33 Stud M8 x 25 21816-257-962-6 3

34 Louver Tray 21537 1

35 Nut M8 self Locking 18173 5

36 Washer Nylon 18205 5

37 Front Panel 21671 1

38 Bolt M8 x 16 Self Locking 18163 6

39 Foam Strip 13920 1

40 Noise Reducing Baffle 13744 1

41 Bolt M 6 X 10 Flange Self Lock 18162 2

42 Bolt M 8 X 16 Flange Self Lock 18163 6

43 Cover QI 100 21690 1

44 Cover QI 150 21691 1

44 Cover QI 150M 26450 1

45 Cover QI 200 21692 1

46 Radiator Panel 21672 1

47 Bolt M8 x 16 Self Locking 18163 2

48 Nut M8 self Locking 18173 2

49 Washer Nylon 18205 4

Radiator Panel Extension

50

51 Bolt M6 x 10 Self Locking 18162 4

52 Nut M6 self Locking 18172 4

53 Radiator Duct Seal Strip 13920 1

13733 2

21673 1

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 28 of 36

ITEM DESCRIPTION PART No. QTY

54 Duct – Air Outlet 21586 1

55 Gasket Rear Air Duct 21687 1

56 Bolt M10 x 40 Self Locking 18167 2

57 Nut M10 Self Locking 18174 2

58 Washer Nylon 18205 4

59 Bolt M8 x 16 Self Locking 18163 2

60 Nut M8 Self Locking 18173 2

61 Tube Plastic 8 ID x 1.5 wall 12501 6

62 Cable Base TY 14

63 Cable Tie 100 x 2.5mm TY1000 14

64 Lifter Cover 21686 1

65 Strip Extruded Side Balloon 21587 7.5M

7.15 Control Panel & Electrical Wiring

7.15.1 Additional Electrical Parts

ITEM DESCRIPTION PART No QTY

1

Screw Hex M10 x 20 21863-174-347-0 2

2

Insulating Boot 08797 1

Retainer 16385 4

Wear Cup 16386 4

Stud 16387 4

6

Bolt M6 x 10 Self Lock 18162 2

7

Nut M6 Self Locking 18172 3

8

Screw Tap 3.5 x 9.5 18211 2

Plate for Loom Mtg. 18228-221 1

Conduit Clip 25 mm 18293 5

Screw Hex M6 x 12 21863-100-347-7 5

7.15.2 Wiring Loom & Control Panel Fitting.

1. Pass the control panel end of the loom

through the canopy support frame at the

rear of the control panel housing and fit the

loom mounting plate (9) to the canopy