Page 1

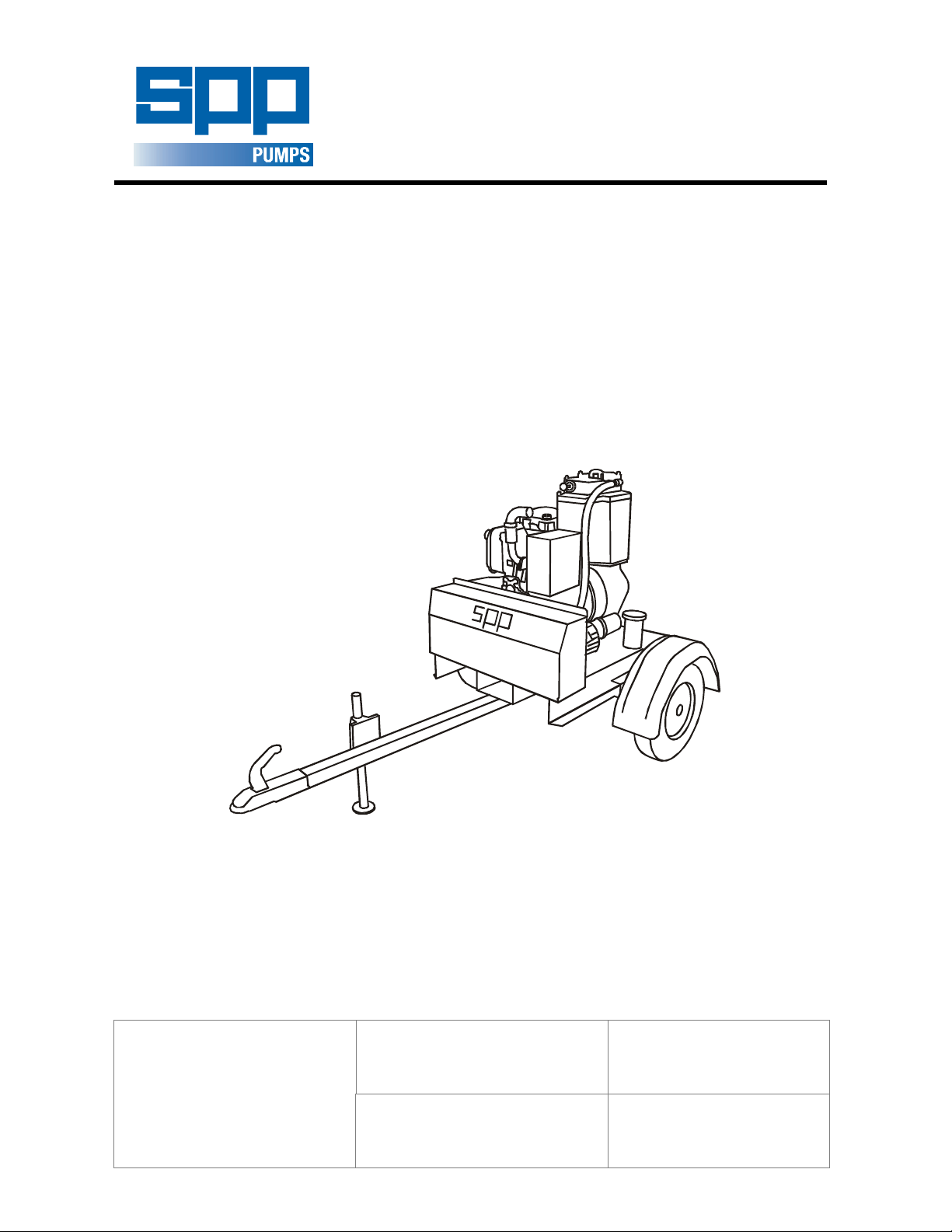

AUTOPRIME ACE RANGE

CENTRIFUGAL PUMP

WORKSHOP MANUAL

AUTOPRIME

ACE RANGE

DIESEL DRIVEN

MOBILE PUMPS

SPP Pumps Limited

Crucible Close

Mushet Industrial Park

Coleford

Gloucestershire

GL16 8PS

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

Telephone:

+ 44 (0)1594 832 701

Fax:

+ 44 (0)1594 836 300

Page 1 of 21

Document No: W72-020E

Revision No: Preliminary 2

Revision Note No: Windchill

Date Issued. Aug 2012

Produced at SPP Pumps

Limited, Coleford, England

Page 2

Manual No/Rev

Workshop Manual for

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

CONTENTS

1. INTRODUCTION...................................................... 3

2. SERIAL NUMBER ................................................... 3

3. SAFETY PRECAUTIONS ........................................ 4

6.1 Safety Symbols ................................................................ 4

6.2 Pump Safety Precautions ................................................. 4

4. HANDLING & TRANSPORT ................................... 4

6.1 Lifting ................................................................................ 4

6.2 Road Trailer Version ........................................................ 4

6.3 Trailer or Wagon Carriage ................................................ 4

5. FAULT FINDING GUIDE ......................................... 5

6. MAINTENANCE & REPAIR .................................... 6

6.1 A - Check & Service the Non Return Valve ...................... 6

6.2 B -Check & Service the Vacuum Air Filter ....................... 6

6.3 C - Check & Service the Priming Tank ............................. 6

6.4 D - Check Vacuum Pump Belt Tension ............................ 6

6.5 F – Full Pump Stripdown for Overhaul ............................. 7

7. PUMP ASSEMBLY PROCEDURE .......................... 8

6.1 Pump End Section Drawing ............................................. 8

6.2 Pump End Parts List: ........................................................ 9

6.3 Pump End Assembly (See section 7.1) ............................ 9

6.4 Priming Tank Parts List: ................................................. 10

6.5 Priming Tank Section Drawing ....................................... 10

6.6 Priming Tank Assembly .................................................. 12

6.7 Basic Pump Unit Construction........................................ 12

6.8 Option Builds .................................................................. 14

6.9 Final preparation ............................................................ 15

8. PUMP TEST PROCEDURE ....................................15

6.1

ENGINE, DRIVE, BATTERY & FITTINGS ..................... 16

6.2

BAUER FITTINGS .......................................................... 18

9.1

80-18 .............................................................................. 18

9.1

100-18 ............................................................................ 18

9.1

LABELS & TRANSFERS ................................................ 18

9.2

WIRING DIAGRAM ........................................................ 19

10. PARES & SERVICE ...............................................21

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 2 of 21

Page 3

Workshop Manual for

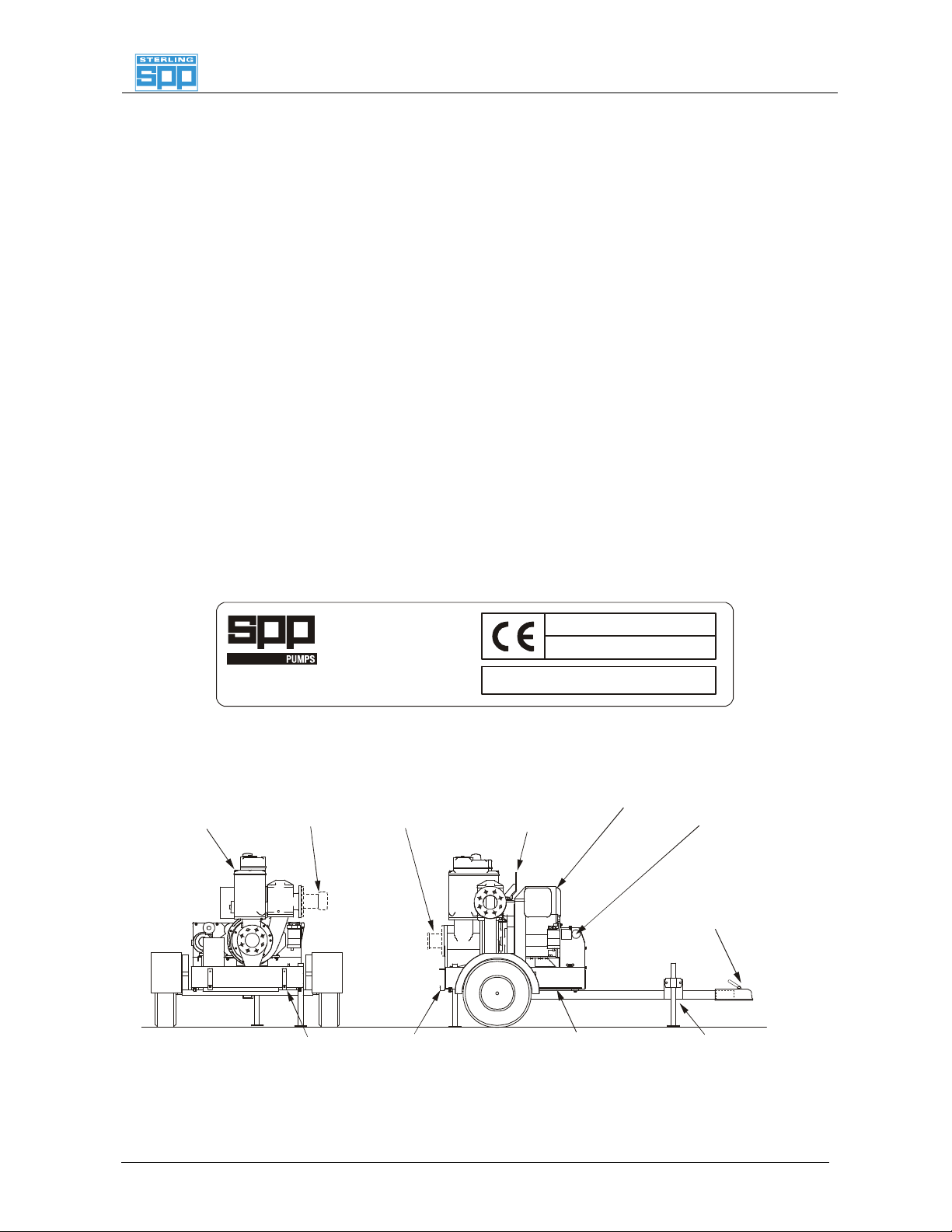

ACE80/100 Diesel Driven Centrifugal Pumps

LIFTING

KEY

MOUNTING

STAND

DELIVERY

SUCTION

PRIMING

ENGINE

TANK

SPP Pumps Limited

Reading, RG31 7SP

Tel: ++44(0)118 932 3123

1. INTRODUCTION

The purpose of this handbook is to provide

repair and assembly instructions for the SPP

AUTOPRIME ACE Range of mobile diesel

engine driven pumps.

Instructions and statements contained within

this handbook are given with our best

intentions and are correct at the time of

compilation. They are subject to alteration at

any time.

These pumps are most commonly supplied

mounted on 2 wheel road trailers but can

also be supplied skid mounted, or as a pump

unit for customer’s to mount on a suitable

chassis or foundations.

ACE pumps are primed by a 25cfm vacuum

pump and are driven by a close coupled, aircooled diesel engine.

Manual No/Rev

W72-020E / 1

This Handbook covers the following pumps:

ACE80

driven by a Hatz 1D90 diesel engine

mounted on a fuel tank and road trailer or

skidThis unit is fitted with 3” Bauer hose

connections.

ACE100

pump driven by a Hatz 1D90 diesel engine

mounted on a fuel tank and road trailer or

skid. This unit is fitted with 4” Bauer hose

connections.

– An automatic priming mobile pump

– An automatic priming mobile

2. SERIAL NUMBER

The serial number plate is attached to the

unit on the side of the priming tank.

This serial number must be quoted in any

enquiry for spares or service.

Where required, a trailer registration plate is

fitted to the front of the unit as required by

local regulations and the VIN number is

stamped fuel tank.

TANK

Type

Nett

Fax: 118 932 3302++44(0)

BAUER

ENGLAND

Serial No.

ACE Range Pump Components

BAUER

EYE

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

LIGHTING BOARD

FUEL

kg

START

TOW

HITCH

JACK

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 3 of 21

Page 4

Manual No/Rev

Workshop Manual for

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

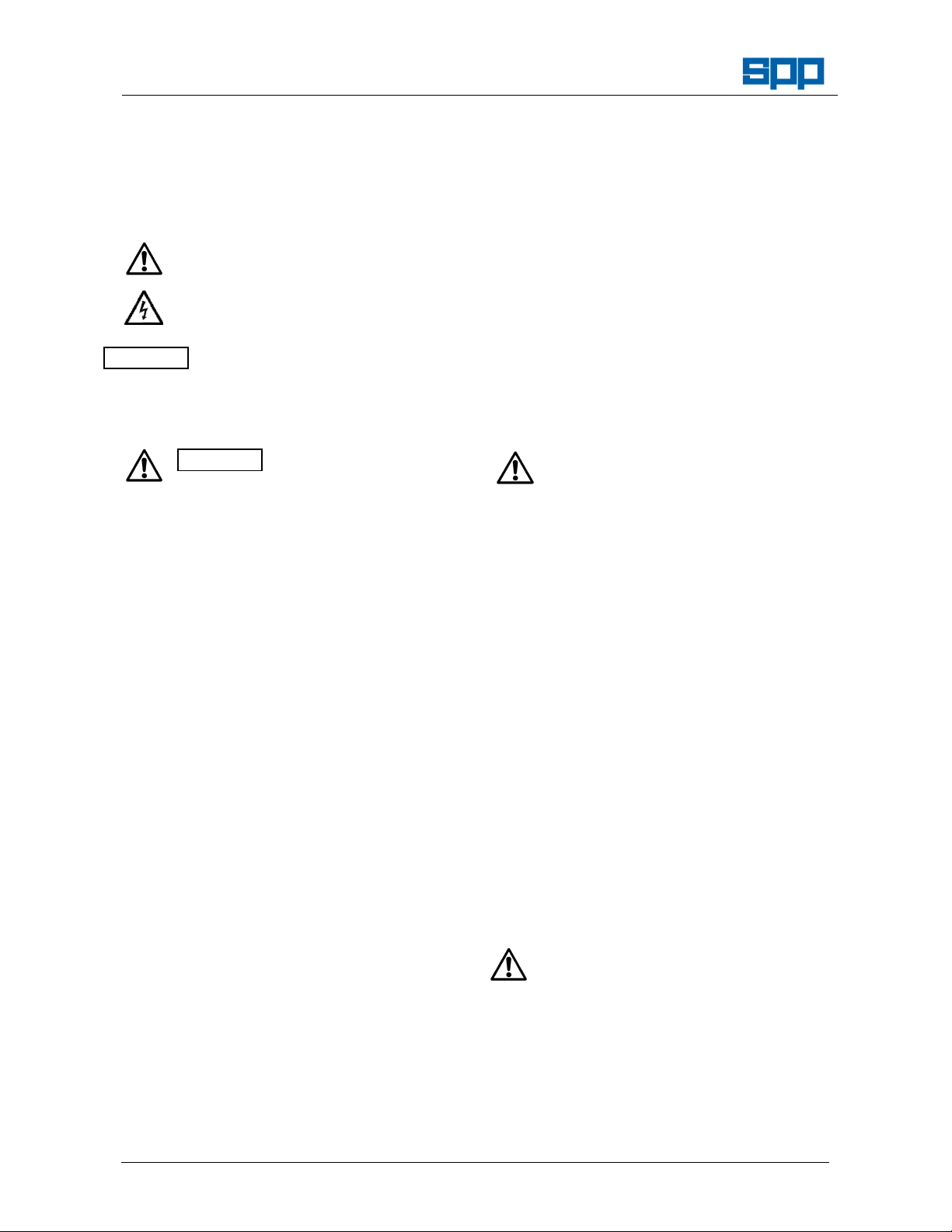

3. SAFETY PRECAUTIONS

6.1 Safety Symbols

Safety instructions within this manual are

marked with the following symbols:

This symbol refers to general mechanical

aspects of safety.

This symbol refers to electrical safety.

ATTENTION

6.2 Pump Safety Precautions

apply to all the following:-

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.2.8

2.2.9

This symbol gives warning of a hazard

to the pump itself, which in turn could

cause a risk to personal safety.

ATTENTION

Hot surfaces and moving parts are guarded

to protect you. If these guards are removed

for maintenance, they must be replaced

before starting the pump.

Never insert anything into the pump casing

whilst the pump is running with the suction

and delivery hoses disconnected.

Collapsible hoses must not be used on the

suction side of the pump

Where the standard Bauer connections are

not used, use all pump flange holes to fit

suction and delivery hose connections.

Do not lift with fork of fork lift truck under the

fuel tank. Never lift with suction or delivery

hoses attached. The increased weight of

these items may cause lifting gear failure.

Always lift pump sets vertically by the lifting

eye. Check the condition of the lifter bracket

at regular intervals.

Check the type of liquid being pumped

before working on pump ends. Residues

could be hazardous to your health. If in

doubt flush out with clean water before work

commences.

Personnel working on the pump unit must

always wear clean correctly fitting clothing

and safety footwear. Clothing impregnated

with oil or fuel can constitute a health hazard

through prolonged contact with the skin and

may also constitute a fire hazard.

Always allow adequate ventilation for diesel

engines. Be aware of fire risks from items

such as exhaust pipes and silencers. Never

place flammable items around the unit.

2.2.10

When working near to the pump or in a

confined space with the pump running

personal ear protection is recommended.

4. HANDLING & TRANSPORT

6.1 Lifting

The central lifting eye is designed for lifting

only the pump unit as supplied by SPP

Pumps Limited. Due to the additional weight

of skid-mounted units, these may be fitted

with alternative lifting points and fork-lift

truck slots on the skid.

The central lifting eye is suitable only for

vertical lifting and must not be used to

pull the unit sideways.

4.1.1

Check the condition of the central lifting eye

or bracket before use.

4.1.2

Do NOT use a lift truck with forks under the

fuel tank and do NOT lift with the hoses

attached.

4.1.3

Never allow the unit to be subject to a

‘snatch’ loading.

4.1.4

Control the unit while lifting to prevent

swinging and keep personnel away from the

area below the unit and the immediate area.

6.2 Road Trailer Version

There is provision for alighting board to be

fitted to the rear of the unit. Place the

lighting board in the two brackets and insert

pins to retain the lighting board in place.

6.3 Trailer or Wagon Carriage

Transportation on a trailer or wagon will

require the unit to be roped or strapped

down. On the road trailer mounted units, set

the unit level with the front and rear prop

stands lowered and clamped. Place ropes

or straps over the chassis to hold the unit in

place. Do NOT place ropes or straps over

the engine or the pump unit and ensure that

ropes or straps do not come into contact

with controls, switches, taps or other

vulnerable parts.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 4 of 21

Page 5

Worksh

op Manual for

ACE80/100 Diesel Driven Centrifugal Pumps

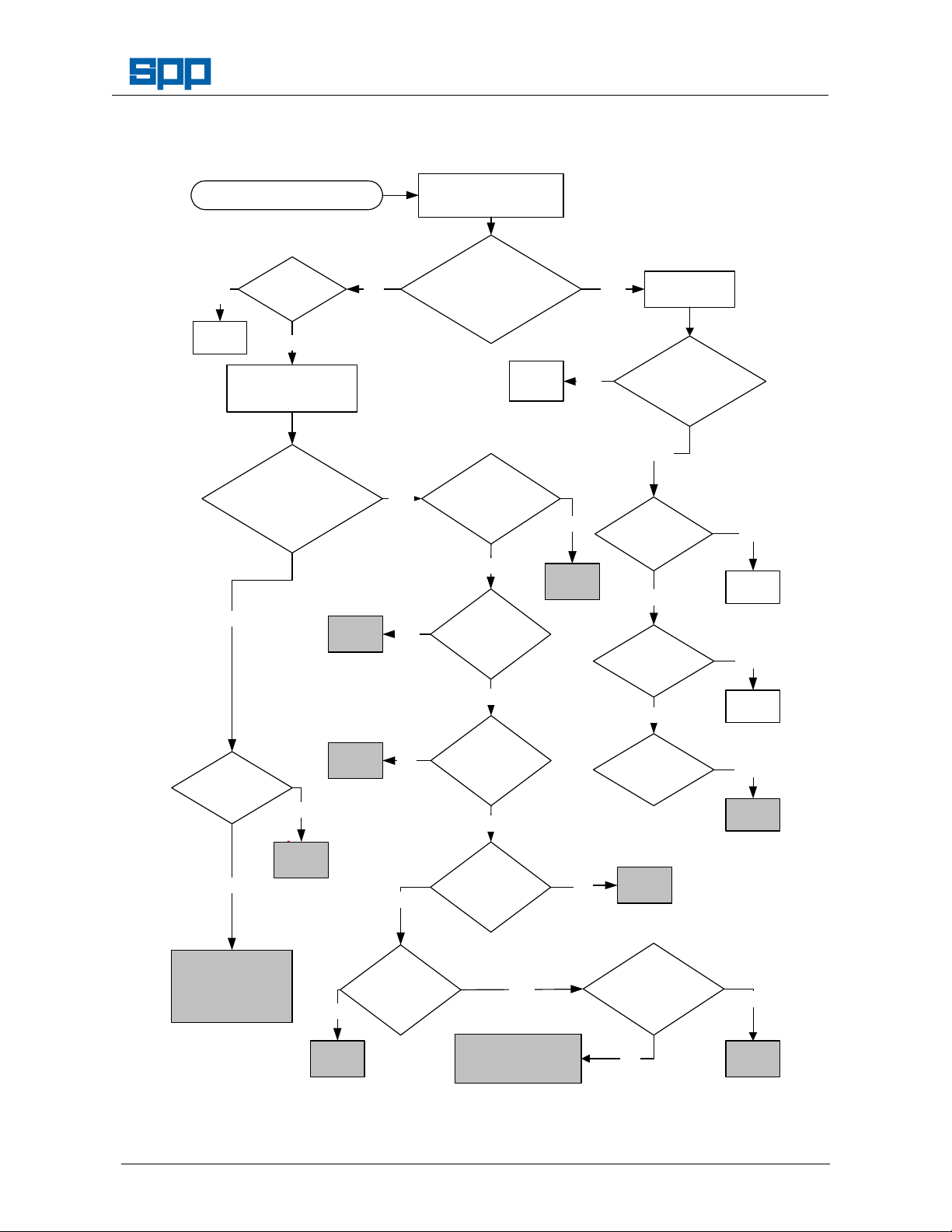

5. FAULT FINDING GUIDE

Pump Fails to Prime

Are

NO

all plugs

tight?

NO YES

Disconnect suction hose

Blank off suction entry

Fit vacuum gauge

Reading

between

85 - 89 .5 kpa

(28.5 0 30 ft H20)?

Manual No/Rev

W72-020E / 1

Check vertical

suction lift

Rectify &

re-test

Fit vacuum gauge

(28.5 0 30 ft H20)?

NO

Is belt drive

tension OK?

YES

Test the Vacuum

Pump directly

Reading

between

85 - 89 .5 kpa

NO

Rectify

B

Rectify

C

YES

YES

NO

Is

Reflux Valve

Ball seating

properly?

YES

Is Vacuum

Pump filter

blocked?

NO

Is Main

Valve float

gear free and

intact?

YES

Move

Pump

YES

NO

Rectify

C

Lift< or =

8.53m (28ft) for

ACE80/100

NO

Are hoses

leaking, collapsed

or blocked?

NO

Is intake

blocked?

NO

Is impeller

blocked?

YES

Rectify

YES

Rectify

YES

Rectify

F

Rectify

This manual is a preliminary issue

YES

D

for information only,

YES

Are all

joints sound &

leak free?

NO

Rectify

F

pending formal issue of

Excessive wear.

Remove Vacuum

Pump & either

overhaul or fit new or

exchange pump

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

the complete manual.

NO

Rectify

F

Is pump

casing free from

holes?

ACE80-100 Fault Finding Chart

Page 5 of 21

YES

Check impeller wear

plate clearances

and rectify F

Is the

pump or NRV

blocked or

damaged?

NO

YES

Rectify

A

Page 6

Manual No/Rev

Wor

kshop Manual for

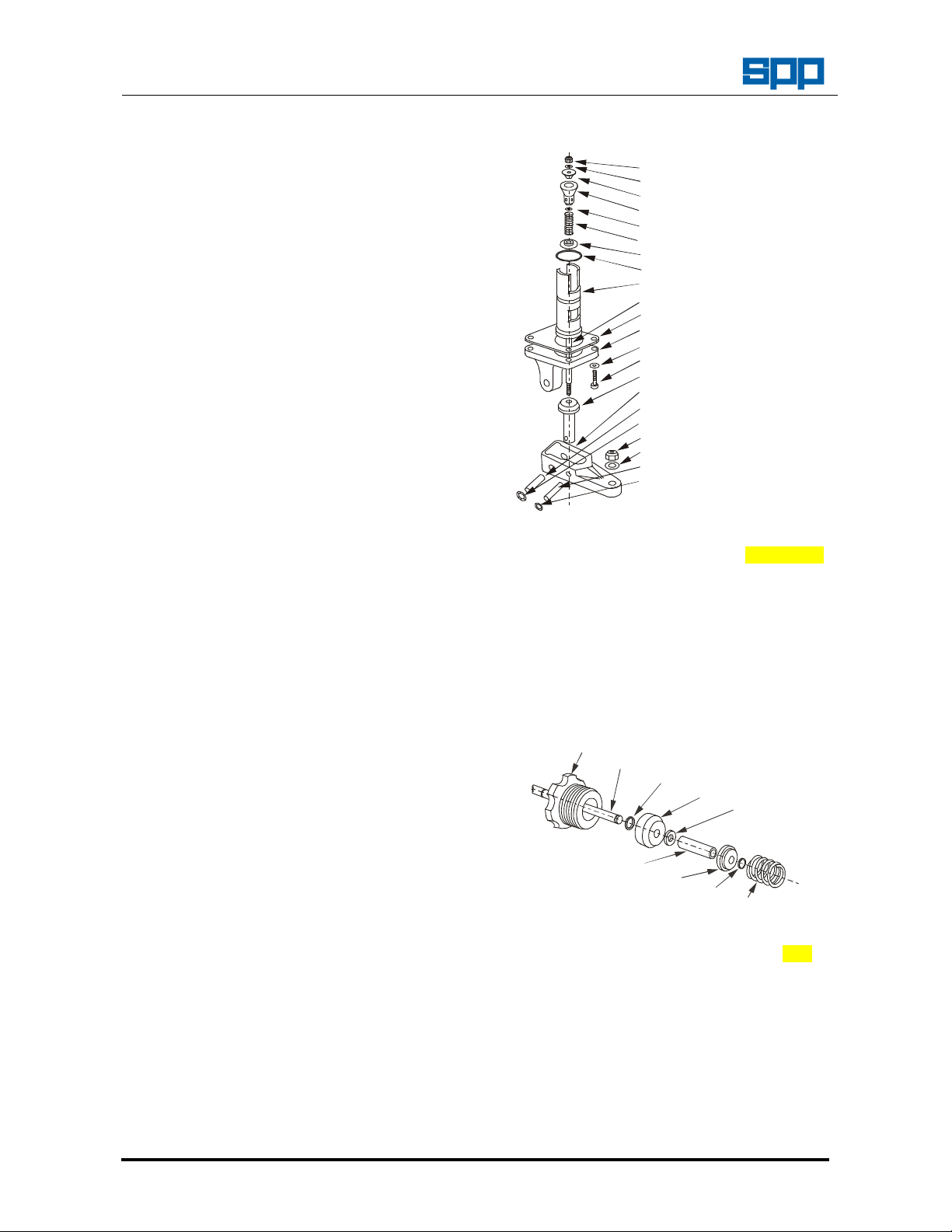

61 M4 SELF LOCK NUT

9 MAIN INLET VALVE

29 AIR OUTLET VALVE

64 M10 STARLOCK WASHER

24 KNOB (NOT SHOWN)

27 SPRING

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

6. MAINTENANCE & REPAIR

The extent of disassembly will depend upon the

faults identified for rectification from the fault

finding guide in section 5. The code letters relate

to the workshop rectification procedures outlined

below:

6.1 A - Check & Service the Non Return Valve

1. Refer to the pump end section drawing in

section 7.1

2. the Remove the Bauer hose connection from

the delivery flange.

3. Remove the four long bolts (83) and lift off

the non-return valve body (80).

4. Remove the non-return valve ball (81),

examine for surface damage and replace if

damaged sufficiently to prevent a good seal

with the valve seat (82).

5. Lift and examine the valve seat, refurbish if

possible or replace if damaged sufficiently to

prevent a good seal with the ball.

6.2 B -Check & Service the Vacuum Air Filter

1. Refer to the priming tank section drawing in

section 7.5

2. Remove the air filter cover (6) by unscrewing

the nut (50).

3. Lift out the filter assembly (17) and examine.

4. If the filter is damaged, replace, if blocked or

dirty, clean the filter with a suitable solvent,

dry and replace.

6.3 C - Check & Service the Priming Tank

1. Refer to the priming tank section drawing in

section 7.5

2. Remove the eight M10 nuts (51) that retain

the top cover of the priming tank and lift off

the cover complete with float valve. Set

aside on a clean surface for examination.

3. Check that the float (14) is intact and not

punctured, replace if damaged.

4. Check that the fulcrum arm moves freely

and is connected to the air outlet valve (29).

Look for signs of wear on the fulcrum and

valve pins (15 &16) and replace if worn.

5. Remove the four M6 capscrews (66) and

carefully withdraw the main valve assembly

from the top cover.

6. Disassemble the valve and examine all

valves, seats and pins for wear and replace

as necessary.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 6 of 21

56 NYLON WASHER

10 AIR INLET VALVE

57 M4 WASHER

13 SPRING

11 DIAPHRAGM

32 O RING

8 VALVE SEAT

7 VALVE ROD

36 GASKET

30 FULCRUM BRACKET

58 M6 WASHER

66 M6 CAPSCREW

31 FULCRUM ARM

15 FULCRUM PIN

62 M8 SELF LOCK NUT

59 M8 WASHER

16 VALVE SUPPORT PIN

63 M6 STARLOCK WASHER

Main Valve Assembly

7. Reassemble as per paragraphs XXX to XXX

8. Check the condition of reflux ball valve (19)

and the valve seat (18) replace if damaged

and confirm that the pipe (2) is securely

fitted to the valve seat.

9. Check the surge control valve for general

condition and cleanliness, confirm that the

valve and spring retainer are not worn,

replace if necessary.

20 VALVE SEAT

28 VALVE SPINDLE

65 KLIP RING

21 VALVE

67 M8 WASHER

23 DISTANCE PIECE

22 SPRING RETAINER

65 KLIP RING

Surge Control Valve

10. Refit the top cover as per paragraphs XXX

6.4 D - Check Vacuum Pump Belt Tension

1. Remove guard.

2. Slacken the locking nut and the retaining

bolt, rotate the tensioner to adjust the

tension of the belt. Tighten the locking nut

and the retaining bolt and check the tension

thus:

Page 7

Worksh

op Manual for

ACE80/100 Diesel Driven Centrifugal Pumps

FORCE

LOCKING

NUT

DEFLECTION

BOLT

RETAINING

Belt Tensioning

3. V Belt tension is correct when the deflection

is 4mm with a force of 1.5kg applied at the

centre of the longest run.

Note: DO NOT OVERTIGHTEN BELTS UNDER

ANY CIRCUMSTANCES.

Manual No/Rev

W72-020E / 1

6.5 F – Full Pump Stripdown for Overhaul

1. Refer to the pump assembly instructions in

section 7.

2. Full pump disassembly for examination of

internal clearances or for worn or damaged

parts is done generally in the reverse order

to pump assembly.

3. The use of suitable lifting equipment is

necessary to prevent injury and care must

be taken to remove any pumped liquids or

solids that may be hazardous to health

before commencing pump stripdown.

4. No special tools are required but the

installation of new mechanical seals will be

aided by the use of special tool no 22743.

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 7 of 21

Page 8

Manual No/Rev

Wor

kshop Manual for

10

11

12

13

14

15

16

21

22

23

24

20

30

31

32

40

41

50

51

52

53

61

63

64

60

62

63

64

74

75

76

71

72

73

83

100

110

120

130

140

150

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

7. PUMP ASSEMBLY PROCEDURE

6.1 Pump End Section Drawing

80

81

260

82

90

91

92

93

94

70

77

78

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 8 of 21

Page 9

Worksh

op Manual for

ACE80/100 Diesel Driven Centrifugal Pumps

210 Elbow:Male Stud

25346

-

221-000-7 1

250 Plug:3/8" Bsp

25221

-

383-915-0 1

6.2 Pump End Parts List:

Item Description Part No Qty

10 Engine:Hatz 1d90 *E41853B001* 1

11 Stud:M10x60 SY9509097 8

12 Washer:Spring M10 21174-306-927-6 8

13 Nut:Hex Full M10 21882-673-958-3 8

14 Stubshaft 22319 1

15 Capscrew:M8x25 21835-136-977-1 4

16 Washer:Spring M8 21174-305-927-9 4

20 Adaptor:Engine/Pump 22318 1

21 Stud:M10x30 SY9509089 8

22 Washer:Spring M10 21174-306-927-6 8

23 Nut:Hex Full M10 21882-673-958-3 8

24 'O'RING 199.5ID X 3.0 22384.017 1

30 Mech Seal 45 13763 1

31 Washer:Mech Seal 13938 1

32 Circlip: Ext 45 13772 1

40 Wearplate:Back Hsg 22317 1

41 O'RING 219.5ID X 3.0 22385.017 1

50 Mech Seal 45 13763 1

51 Impeller 22321 1

52 Shim:Impeller 1mm 22323 1

53 Shim:Impeller 0.5mm 22324 1

60 Volute 22655 1

61 Stud:M10x30 SY9509089 6

62 Stud:M10x25 SY9509087 6

63 Washer:Spring M10 21174-306-927-6 12

64 Nut:Hex Full M10 21882-673-958-3 12

70 Tee Piece 22320 1

71 Gasket SY5004439 1

72 Gasket SY5004432 1

73 Wear Plate SY3874016 1

74 Stud:M10x30 SY9509089 4

75 Washer:Spring M10 21174-306-927-6 4

76 Nut:Hex Full M10 21882-673-958-3 4

77 Screw:Hex Hd M12x40 21863-222-959-4 2

78 Nut:Hex Full M12 21882-673-958-3 2

80 Valve:Non-Return 22325 1

81 Ball:Nrv (Green) 8075 1

82 Seat:Nrv SY3874014 1

83 Bolt:Hex Hd M12x230 22326 4

90 Assy:Priming Tank SY3802500 1

91 Gasket SY5004373 1

92 Stud:M12x40 SY9509133 8

93 Washer:Spring M12 21174-307-927-3 8

94 Nut:Hex Full M12 21882-675-958-7 8

100

110 Adaptor:Male 15533 2

120 Valve:Ball 1/2" Bsp 22416 1

130 Hosetail 12149 1

140 Clip:Hose:18-25mm 5837 1

150 Hose 15446 600

160 Assy:Backprime Line *E41853A007* 1

170 Adaptor:Male 22606 1

180 Valve:Non Return SY3714105 1

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 9 of 21

Manual No/Rev

W72-020E / 1

Item Description Part No Qty

190 Dipstick 14373 1

200 'O'RING 24.5ID X 3.0 25154-024-716-1 1

220 Clip:'P' Type 14150 1

230 Tube 17341-711-076-4 500

240 Adaptor:Male 22607 1

260 Plug:1/4" Bsp 25221-382-915-3 2

6.3 Pump End Assembly (See section 7.1)

1.1 Refer to the pump end section drawing in

section 7.1

1.2 Place engine (10) on a workbench that is

equipped with lifting equipment suitable to

lift the pump and engine assembly complete.

1.2 Fit eight M10 x 60 studs (11) onto the

engine flywheel casing.

1.3 Fit the stubshaft (14) onto the flywheel on

the engine with four M8 x 25 capscrews (15)

and spring washers (16).

1.4 Place the engine/pump adapter (20) over

the stubshaft and secure using the studs on

the engine with nuts (13) and spring

washers (12).

1.5 Fit eight M10 x 30 studs (21) into adapter.

1.6 Place the 199.5ID ‘O’ ring (24) over the

adapter.

1.7 Fit the secondary mechanical seal stationary

element (30) over the shaft and press it into

the adapter plate ensuring not to damage

the face.

1.8 Fit the rotating element of the mechanical

seal (30) and push it onto the shaft until the

circlip groove is exposed behind the seal.

1.9 Fit the circlip washer (31) followed by the

circlip (32) and ensure the mechanical seal

is securely in place and pulled back against

the circlip.

1.10 Fit the back wearplate (40) over the shaft

and secure using the studs in the adapter

plate with nuts (23) and spring washers (22).

1.11 Fit the remaining ‘O’ ring (41).

1.12 Fit the stationary seat of the primary

mechanical seal (50) over the shaft and

press into the wearplate.

1.13 Fit the rotational part of the mechanical seal

so that it touches the stationary seal face.

1.14 Screw on the impeller (51) (clockwise) and

check the back vane to wear plate clearance

is 0.5-1mm. If it does not fall within this

range, add shims (52 & 53) to give the

required clearance.

Page 10

Manual No/Rev

Wor

kshop Manual for

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

1.15 Pressure test the mechanical seal assy.

1.16 Fit six M10 x 30 studs (61) onto the back of

the volute (60).

1.17 Fit volute over the back wearplate and the

impeller and secure with M10 spring

washers (63) and nuts (64).

1.18 Fit six M10 x 25 studs (62) onto the front of

the volute.

1.19 Fit the large gasket (71) onto the studs on

the volute.

1.20 Fit four M10 x 30 studs (74) into the front

wear plate.

1.21 Fit the small gasket (72) onto the studs on

the front wearplate.

1.22 Fit wear plate onto the tee piece (70) using

four M10 nuts (76) and spring washers (75).

1.24 Fit tee piece onto volute using studs on

volute and secure with nuts (64) and spring

washers (63) check the clearance between

impeller and front wearplate if it is not within

the range of 0.5-1mm, adjust accordingly.

1.25 Fit the push off screws (77) and nuts (78).

1.26 Fit non-return valve ball (81) into non-return

valve (80).

1.27 Fit the seat (82) into the non-return valve.

1.28 Fit the non-return valve to the pump end

assy. using four M12 x 230 bolts (83)

screwed into the volute.

1.29 Fit the eight M12 x 40 studs (92) to the

bottom of the priming tank assembly (90).

1.30 Fit the gasket (91) onto the bottom of the

priming tank.

1.31 Fit the priming tank assembly onto the top of

the pump end assembly and secure with

nuts (94) and spring washers (93).

1.32 Fit non-return valve drain plug (260).

6.4 Priming Tank Parts List:

ITEM

1 Valve ball SY1544001 1

2 PVC Hose SY3404502 250

3 Float disc SY3404509 1

4 Top cover SY3474510 1

5 Valve cover SY3474511 1

6 Cover - air filter SY3474519 1

7 Valve rod SY3474521 1

8 Valve seat - in/out SY3474522 1

9 Main valve inlet SY3474523 1

10 Valve air inlet SY3474524 1

11 Diaphragm SY3474525 1

DESCRIPTION PART No QTY

ITEM

12 Float rod SY3474526 1

DESCRIPTION PART No QTY

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 21

ITEM

13 Compression spring SY3474527 1

14 Float SY3474547 1

15 Fulcrum pin SY3564037 1

16 Valve support pin SY3564038 1

17 Element - air filter SY3564044 1

Including - Rubber seats SY3804418 2

18 Valve seat SY3564293 1

19 Valve ball SY3564294 1

20

21 Valve - control valve SY3564297 1

22

23 Distance piece SY3564300 1

24 Knob - control valve SY3564302 1

26 Instruction plate SY3564350 1

27 Spring SY3564354 1

28 Spindle - control valve SY3564425 1

29 Air outlet valve SY3614033 1

30 Fulcrum bracket SY3614035 1

31 Fulcrum arm SY3614036 1

32 O ring SY3614043 1

33 Primary tank SY3804002 1

34 Joint - copper SY5004075 1

36 Joint-fulcrum bracket SY5004235 1

37 Joint -top cover 15494 1

38 Joint - valve cover 15495 1

39 Joint -a. filter cover SY5004268 1

40 Joint - primary tank SY5004373 1

41 Elbow: 3/4"BSP M/F SY9209044 1

42 Plug: 3/4"BSP SY9209148 2

43 Plug: 1/2" BSP brass SY9209420 1

44 Stud: M8 x 80 SY9509061 1

45 Stud: M10 x 60 SY9509097 6

46 Stud: M10 x 95 SY9509104 4

47 Stud: M10 x 150 SY9509113 1

48 Stud: M10 x 135 SY9509119 3

49 Stud: M12 x 40 SY9509133 8

50 Nut: M8 SY9509652 1

51 Nut: M10 SY9509653 14

52 Nut: M12 SY9509654 8

53 Washer: M8 SY9509678 1

54 Washer: M10 SY9509679 14

55 Washer: M12 SY9509680 8

56 Washer: M4 nylon SY9509693 1

57 Washer: M4 brass SY9509694 1

58 Washer: M6 brass SY9509697 4

59 Washer: M8 nylon SY9509700 1

60 Washer: spring M12 SY9509808 8

61 Nut - self lock M4 SY9509861 1

62 Nut - self lock M8 SY9509864 1

63 Washer: starlock M6 SY9519256 2

64 Washer: starlock M10 SY9519260 2

65 Klipring: 1/4" SY9519482 2

66 Screw: Skt cap M6 x 20 SY9529201 4

67 Washer: M8 brass SY9509701 1

DESCRIPTION PART No QTY

Adjustable seat-control

valve

Spring retainer-control

valve

SY3564296 1

SY3564298 1

6.5 Priming Tank Section Drawing

Page 11

Worksh

op Manual for

ACE80/100 Diesel Driven Centrifugal Pumps

Manual No/Rev

W72-020E / 1

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 11 of 21

Page 12

Manual No/Rev

Wor

kshop Manual for

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

6.6 Priming Tank Assembly

1.1 Refer to priming tank section drawing in

section 7.5.

1.2 If tank is new, fit all studs in the positions

indicated on the section drawing.

1.3 Fit the drain plug (43) with the washer (34).

1.4 Assemble tube (2) and valve seat (18) and

fit to the primary tank (33) using a soft faced

hammer.

1.5 Assemble the surge valve as per the section

drawing using items 24, 28, 20, 21, 67, 23,

22 & 27.

1.6 Assemble the main valve as per the section

drawing using items 29, 7, 8, 32, 11, 13, 57,

9, 10, 56 & 61. Tighten the self-locking nut

to expose two threads only.

1.7 Fit the plug (42) to the top cover (4)

1.8 Fit the main valve assembly into the top

cover, using gasket (36) and fulcrum bracket

(30) retained by three M6 screws and

washers (66 & 58).

1.9 Fit the float (14) to the fulcrum arm (31)

using disc, float rod, washer & M8 nut (3, 12,

59 & 62).

1.10 Fit the fulcrum arm and float assembly to the

fulcrum bracket (30) and air outlet valve (29)

using pins and spring washers (15, 16, 63 &

64).

1.11 Place the ball (19) on the valve seat, place

gasket (37) on the studs on the primary tank

and lower float and top cover assembly into

position on the primary tank. Secure with

washer and M10 nuts (51 & 51).

1.12 Fit the filter (17) to the valve cover (5)

retained by cover (6), gasket (39), M8 stud,

washer and nut (53, 44 & 50).

1.13 Fit the valve cover assembly to the top

cover, using gasket (38) retained by M10

washers and nuts (54 & 51).

1.14 Fit gasket (40) and mount the priming Tank

on the Tee Piece (70) retained with washers,

spring washers and M12 nuts (55, 60, 52).

NOTE: When the lifting point bracket is fitted

remove the lifter from the engine. Turn the

lifter over and fit it upside down so it isn’t

used to lift the whole unit when complete.

4.3 Fit the volute drain line.

4.3.1 Fit the ½” BSPT - ⅜” BSPT adapter to the

45° elbow and the volute.

4.3.2 Fit the hosetail into the ball valve and

connect to elbow.

4.3.3 Fit the hose to the hose tail with a hose clip.

4.4 Fit the sump drain line.

4.4.1 Fit the 90° elbow onto the M22 - ½” BSP

adapter and fit to the sump.

4.4.2 Fit the hosetail to the ball valve and fit to the

elbow.

4.4.3 Fit the hose to the hose tail with a hose clip.

Figure 2

6.7 Basic Pump Unit Construction

4.1 Fit engine foot to engine by using two M12 x

45 bolts and spring washers in the tapped

holes on the front of the engine and use

M12 bolts and nuts for the remaining two

holes.

4.2 Fit the lifting point bracket using two M16 x

25 bolts.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 12 of 21

Figure 3

4.5 Set approximate engine speed and fit four

M6 nuts to secure speed control.

4.6 Dress chassis and tank with a plug, cap and

strainer.

Page 13

Worksh

op Manual for

ACE80/100 Diesel Driven Centrifugal Pumps

4.7 Fit pump/engine assy. to chassis using two

M12 x 40 bolts for the pump three M12 x 35

bolts for the engine feet. (See Figure 4)

Figure 4

4.8 Wire up engine and fit engine switch and

hour meter using the switch bracket. (See

photo and wiring diagram (Figures 6 &7).

4.9 Fit fuel filter and fuel lines. (Figure 5)

4.9.1 Fit fuel filter using two M10 x 30 flanged,

self-locking bolts and M10 flanged, selflocking nuts.

4.9.2 Fit banjo inserts with a banjo bolt and

copper washers to one input and one output

on the top of the filter.

4.9.3 Connect pipe with jubilee clips to engine and

the output banjo insert.

4.9.4 Connect pipe with jubilee clips to fuel tank

and input banjo insert.

This manual is a preliminary issue

Manual No/Rev

W72-020E / 1

Figure 6

4.10 Fit back prime. (See sectional drawing parts

150, 160, 170 and 230)

4.10.1 Fit adapter ½” BSP – ½” BSPT and adapter

½” BSPT - ⅜ BSPT to the non-return valve

4.10.2 Connect the above assy. to the tee piece.

4.10.3 Fit adapter ½” BSP - ⅜ BSPT to the back

wear plate.

4.10.4 Connect the two adapters using the hose

and fittings assy.

4.11 Fit Seal oil vent line to the top of the seal oil

chamber. (See parts 210-220 on Figure 1)

4.12 Make battery leads and connect battery to

engine and start motor (See figs 6 and 7).

4.13 Fit battery with two M12 x 30 bolts, taperlock washers and self-locking flanged nuts.

As well as the mat and the plate. (Figure 6)

4.14 Fit battery leads. (Figure 6)

4.15 Clip down cables. (Figure 6)

4.16 Fit hours run meter and wire up. (Figures 6

& 7)

for information only,

pending formal issue of

the complete manual.

Figure 5

Figure 7

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 13 of 21

Page 14

Manual No/Rev

Wor

kshop Manual for

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

4.17 Fit vac pump and bleed filter with four M8

flanged bolts. (Figure 8)

4.18 Fit taper locks and pulleys to vac pump and

engine. (Figure 9)

4.19 Fit belt over the pulleys, fit the tensioner with

two M8 bolts, tension belt and mark bolt

heads on tensioner. (Figure 9)

4.20 Fit vac pump exhaust system and inlet pipe

work. (Figure 8)

4.20.1 Fit reducing bush and hose tail together and

fit bush to vac pump casing

4.20.2 Fit pipe with clips to hose tail on the vac

pump and hose tail on the priming tank

Fig

ure 10

5.2 Fit Bauers using the bolts supplied. See

diagram below (Figure 11)

Figure 8

Figure 9

6.8 Option Builds

5.1 Fit spark arrester and Chalwyn valve.

(Figure 10)

5.1.1 Remove air filter assy.

5.1.2 Fit Chalwyn valve and inlet manifold

5.1.3 Remove tail pipe then fit spark arrester to

exhaust.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 14 of 21

Figure 11

5.3 Fit unit to skid using four M12 x 30 self

locking bolts and nuts. (Figure 12)

Figure 12

5.4 Fit unit to the trailer. (Figure 13)

5.4.1 Assemble trailer if necessary.

5.4.2 Fit unit to trailer assy. using six flanged, selflocking M12 x 30 bolts and nuts.

Page 15

Worksh

op Manual for

ACE80/100 Diesel Driven Centrifugal Pumps

5.4.3 Fit angle bracket onto the chassis with two

M12 x 30 flanged bolts and flanged nuts.

5.4.4 Fit clamp onto bracket with two M12 x 30

flanged bolts andflanged nuts

5.4.5 Place rear leg into clamp and tighten.

5.4.6 Bolt two lighting board brackets onto back of

chassis using two M6 x 10 flanged bolts and

two flanged nuts per bracket.

Manual No/Rev

W72-020E / 1

6.9 Final preparation

6.1 Test unit.

6.2 PDI unit.

6.3 Fit the labels and manual.

8. PUMP TEST PROCEDURE

Figure 12

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 15 of 21

Page 16

Manual No/Rev

Wor

kshop Manual for

ITEM DESCRIPTION

PART No

QTY

1

5

6

14

15

19

24

ITEM DESCRIPTION

PART No

QTY

27

30

31

NOT ILLUSTR

ATED

38

46

47

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

9.

6.1 ENGINE, DRIVE, BATTERY & FITTINGS

Stub shaft SY3874015 1

2

Bracket: lifter 13756 1

4

Key SY3874036 1

Eye nut SY3874040 1

Fuel pipe: return SY3354065 1

10

Engine: TR1 13757 1

Fuel pipe: suction SY3804064 1

Joint: copper SYK01322350 2

16

Union bolt SYK35121610 1

Screw: M12 x 35 21863-220-347-0 2

Washer: spring M12 SY9509808 4

26

Stud: 3/8"UNC x 1 ½” SY9019093 12

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

28

29

37

39

Page 16 of 21

Screw: M20 x 40 21863-392-959-2 1

Washer: M20 SY9509684 1

Washer: spring M20 SY9509812 1

Bolt: M12 x 70 SY9509556 2

Nut: M12 SY9509654 4

Washer SY3874103 2

Shim: 0.25 SY3804141 8

Shim: 0.5 SY3804142 12

Spacer SY3804084 1

Exhaust lagging 11260 1

Page 17

Worksh

op Manual for

Manual No/Rev

1

Battery box

13165

1

3

4

6

7

9

10

12

13

15

16

18

19

ACE80/100 Diesel Driven Centrifugal Pumps

W72-020E / 1

ITEM DESCRIPTION PART No QTY

2

Battery box lid 13166 1

Battery clamp 12483 2

Screw: M12 x 35 21863-220-347-0 2

5

Washer: M12 SY9509680 2

Washer: spring M12 SY9509808 2

Nut: M12 SY9509654 2

8

Battery mat SY3874047 1

Battery: 12v SY7004404 1

Screw: M8 x 16 21863-132-347-6 2

This manual is a preliminary issue

for information only,

pending formal issue of

ITEM DESCRIPTION PART No QTY

11

Washer: spring M8 SY9509806 4

Washer: M8 SY9509678 4

Lead: battery +ve 13761 1

14

Lead: battery -ve SY3872002 1

Screw: M8 x 20 SY9519097 2

Nut: M8 SY9509652 2

17

Screw: M6 x 16 21863-102-422-1 6

Washer: spring M6 SY9509805 6

Washer: M6 SY9509676 6

the complete manual.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 17 of 21

Page 18

Manual No/Rev

Wor

kshop Manual for

flange

comprises:

W72-020E / 1

6.2 BAUER FITTINGS

ACE80/100 Diesel Driven Centrifugal Pumps

9.1 80-18

ITEM DESCRIPTION PART No QTY

3" Bauer male/4"

1

2

Nut: M16 SY9509656 8

3

Washer: spring M16 SY9509810 8

4

Gasket SY5004418 2

5

Bolt: M16 x 55 21867-315-959-9 8

3" Bauer female/ 4"

6

flange, includes

3" Sealing ring SY3194288 1

13502 1

13503 1

9.1 100-18

ITEM DESCRIPTION PART No QTY

1

4" Bauer male, SY3194022 1

2

Nut: M16 SY9509656 8

3

Washer: spring M16 SY9509810 8

4

Gasket SY5004418 2

5

Bolt: M16 x 55 21867-315-959-9 8

4" Bauer female,

6

includes

4" Sealing ring SY3194289 1

SY3194023 1

ITEM DESCRIPTION PART No QTY

3" Split intake assy.

7

3" Intake half SY1814187 2

3” Restrictor 14675 1

4" Sealing ring SY3194289 1

ITEM DESCRIPTION PART No QTY

4" Split intake assy.

7

comprises:

4" Intake half SY1814185 2

4” Restrictor 14674 1

6" Sealing ring SY3194284 1

14697 1

14696 1

9.1 LABELS & TRANSFERS

(not illustrated)

DESCRIPTION PART No QTY

Weight plate 12628 1

Label: frost warning SY2994128 1

Transfer - pump guard SY2994065 1

Transfer - Lift here SY2994109 1

Transfer - Surge control

valve

Label - warning oil tank SY2994147 1

Label - oil tank SY2994148 1

Label - oil cap SY2994149 1

Transfer: safety 12627 1

Transfer: 100-18 12253 1

Transfer: A/prime SSPP 12263 1

Transfer: Chevrons 12264 2

SY2994092 1

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 18 of 21

Page 19

Worksh

op Manual for

9.2 WIRING DIAGRAM

ACE80/100 Diesel Driven Centrifugal Pumps

Manual No/Rev

W72-020E / 1

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 19 of 21

Page 20

Manual No/Rev

Wor

kshop Manual for

W72-020E / 1

ACE80/100 Diesel Driven Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 20 of 21

Page 21

Worksh

op Manual for

Manual No/Rev

ACE80/100 Diesel Driven Centrifugal Pumps

W72-020E / 1

10. SPARES & SERVICE

SPP Pumps Limited operate a comprehensive Spares and Service support network

throughout the world, and can be contacted as follows

SPARES & SERVICE Telephone +44 (0)118 932 3123

For spare parts, supply only.

For breakdowns, spare parts and,

on-site fitting, pump installation and, ask for commissioning, and service contracts.

For breakdowns outside office hours.

Spares & Service Office

SPP Pumps Limited General Fax line

Theale Cross

Reading

Berkshire Direct Fax line

RG31 7SP

ENGLAND

Associated Publications W72-008E AUTOPRIME Q Range Pump Operators Handbook

Latest copies of this manual and associated publications are available from the SPP Pumps Spares &

Service Department by quoting the appropriate reference number.

ask for -

+44 (0)118 932 3123

+44 (0)118 932 3302

+44 (0)118 930 3259

---“---

Spares Dept.

Service Dept.

.

This manual is a preliminary issue

for information only,

pending formal issue of

the complete manual.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 21 of 21

Loading...

Loading...