Page 1

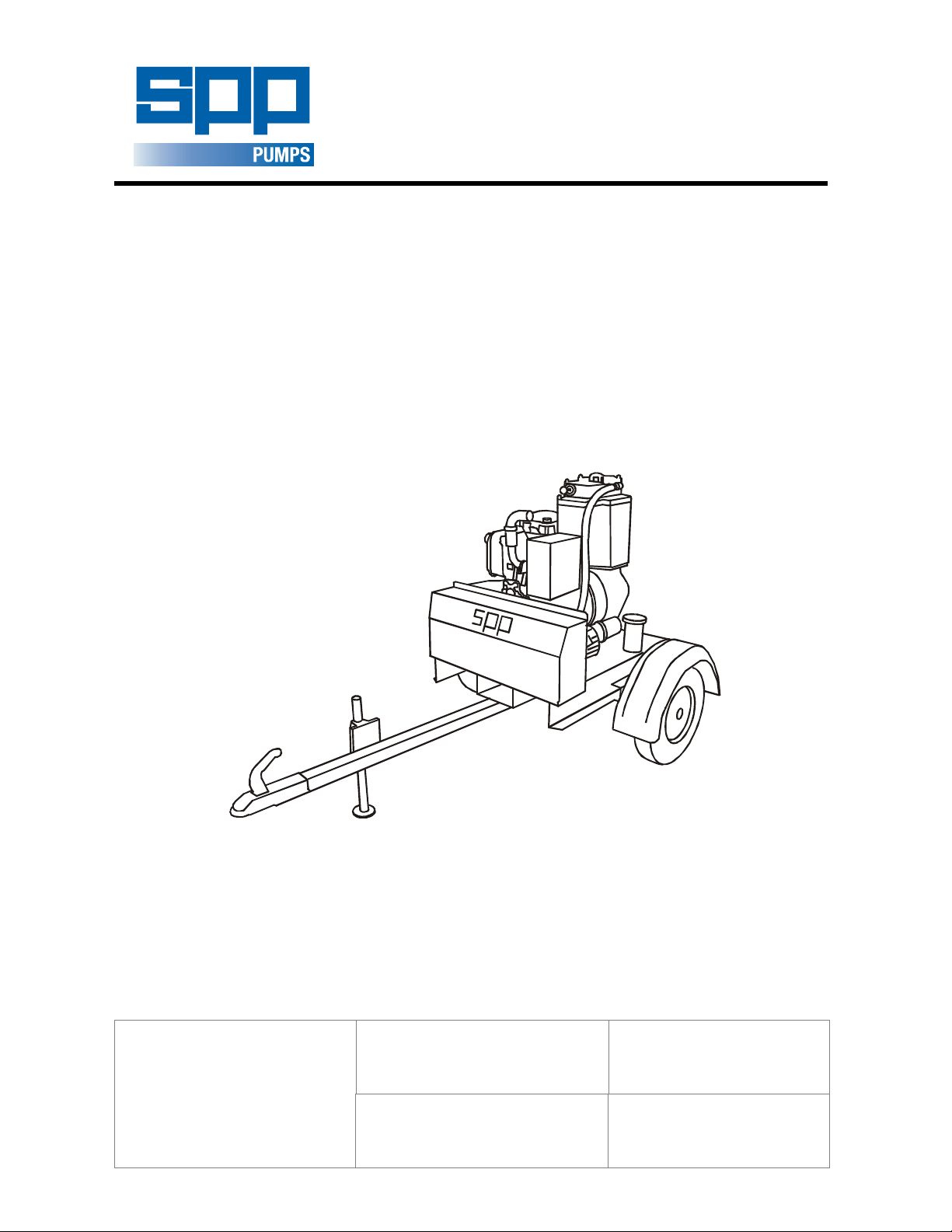

AUTOPRIME ACE RANGE

CENTRIFUGAL PUMP

OPERATORS INSTRUCTIONS

AUTOPRIME

ACE RANGE

DIESEL DRIVEN

MOBILE PUMPS

SPP Pumps Limited

Crucible Close

Mushet Industrial Park

Coleford, Glos

ENGLAND

GL16 8PS

Telephone:

++44(0) 1594 832701

Fax:

++44(0) 1594 836300

Document No: W72-019E

Revision No: 4

Revision Note No: R 39552

Date Issued. August 2012

Produced at SPP Pumps

Limited, Coleford, England

Page 2

We

Of

SPP Pumps Limited

Crucible Close

Mushet Industrial Park

Coleford

Gloucestershire

England

GL16 8PS

Declare that:

Equipment:

Model/Type:

Serial Number:

in accordance with the following Directives:

MOBILE DIESEL DRIVEN CENTRIFUGAL PUMPS

ACE80 & ACE100

As shown on the Pump Nameplate

DECLARATION OF

CONFORMITY

Sound Level (dB)

Pump Model Measured Guaranteed LWA

ACE80 106 109

ACE100 106 109

2000/14/EC- Guaranteed sound power level.

The conformity assessment procedure followed was in

according with ANNEX V of the Directive

2004/108/EC

2006/42/EC

2000/14/EC

have been designed and manufactured to the following specifications:

EN 809:1998+A1:2009

EN 12162: 2001

EN 292-2: 1991

EN 61000-6-4: 2001

EN 61000-6-1: 2001

EN 3744: 1995

We hereby declare that the equipment named above has been designed to comply with the relevant sections

of the above referenced specifications. The units comply with all essential requirements of the Directives

The Electromagnetic Compatibility Directive and its amending directives

The Machinery Directive and its amending directives

The Noise Emissions Directive and its amending directives

Liquid pumps – Safety requirements – Proceedure for hydrostatic testing.

Safety of Machinery- Basic concepts, general principles for design.

Electromagnetic compatibility (EMC). Generic standards. Emission standard

for industrial environment.

Electromagnetic compatibility (EMC). Generic standards. Immunity for

residential, commercial and light-industrial environments.

Acoustics- Determination of sound power levels of noise sources using sound

pressure- Engineering method in an essentially free field over a reflecting

plane

Pump and pump unit for liquids – common safety requirements

Signed:

Name: John Hollins

Position: Engineering Manager - Authorised to sign on behalf of SPP Pumps Limited

Mushet Industrial Park, Coleford, Gloucestershire, England, GL16 8PS

Date: 12 February 2010

W72-019E

A copy of this certificate has been submitted to the European Commission and UK Authority

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 2 of 12

Page 3

Operators Instructions for

ACE80/100 Diesel Driven Centrifugal Pumps

Manual No/Rev

W72-019E / 4

CONTENTS

1. INTRODUCTION.............................................. 4

2. SERIAL NUMBER ........................................... 4

3. SAFETY PRECAUTIONS ................................ 5

3.1 Safety Symbols ................................................................. 5

3.2 Pump Safety Precautions ................................................. 5

4. HANDLING & TRANSPORT ........................... 5

4.1 Lifting ................................................................................ 5

4.2 Road Trailer Version ......................................................... 5

4.3 Trailer or Wagon Carriage ................................................ 5

5. OPERATING INSTRUCTIONS ........................ 6

5.1 Before Starting .................................................................. 6

5.2 Starting ............................................................................. 6

5.3 After Starting ..................................................................... 6

5.4 Stopping ............................................................................ 6

6. PUMP MAINTENANCE CHART ...................... 7

7. MAINTENANCE INSTRUCTIONS ................... 7

7.1 Mechanical Seal Oil Reservoir .......................................... 7

7.2 Drive Belt Adjustment ....................................................... 7

7.3 Mechanical Seals .............................................................. 7

7.4 Mechanical Seal Removal ................................................ 7

7.5 Mechanical Seal Assembly ............................................... 8

7.6 Non-Return Valve ............................................................. 8

7.7 VACUUM PUMP ............................................................... 8

7.8 Vacuum Pump Air Filter .................................................... 8

7.9 Valve Gear ........................................................................ 8

8. FAULT FINDING GUIDE ................................. 9

9. TECHNICAL DATA ........................................ 10

10. SPARES & SERVICE .................................... 12

Page 4

Manual No/Rev

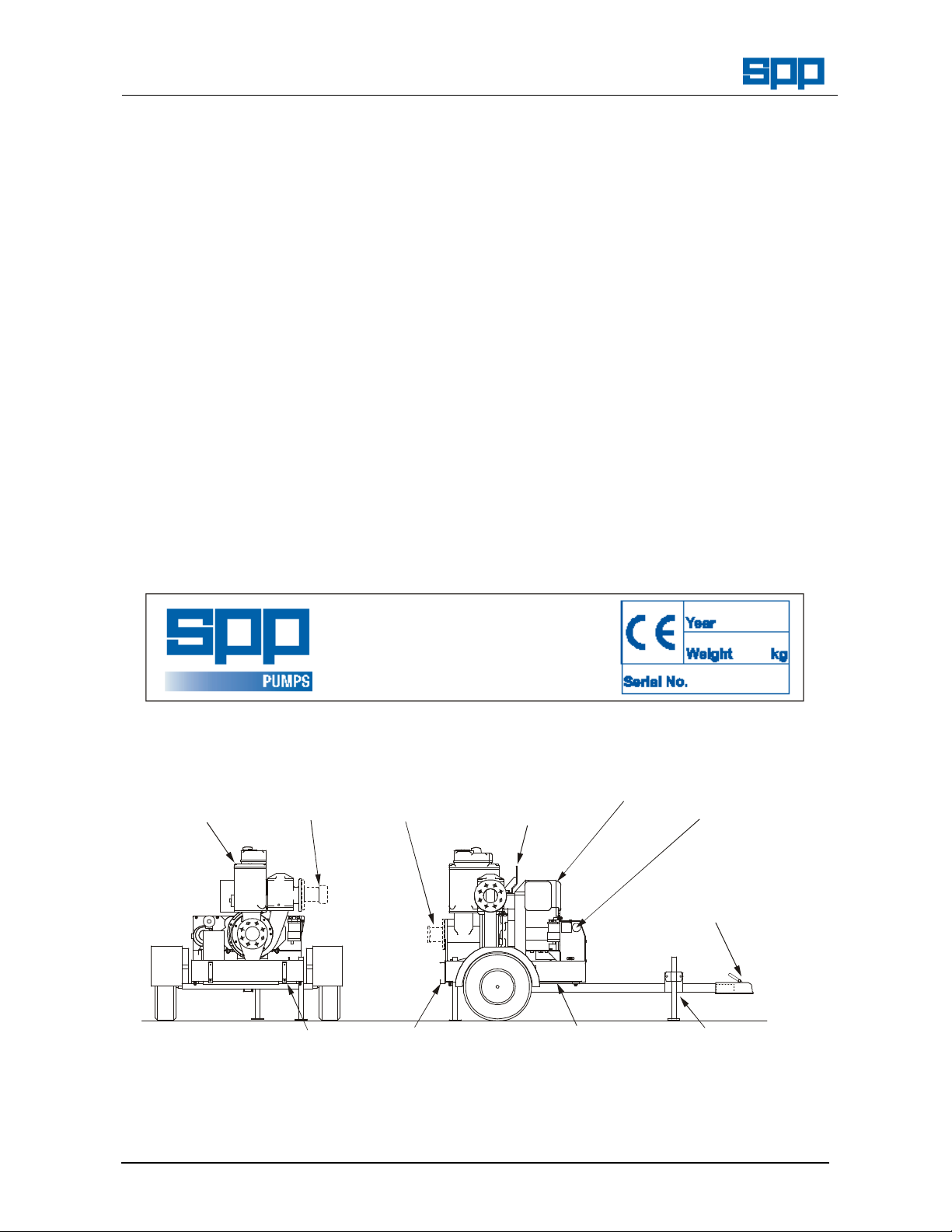

LIFTING

KEY

MOUNTING

STAND

DELIVERY

SUCTION

PRIMING

ENGINE

TANK

W72-019E / 4

ACE80/100 Diesel Driven Centrifugal Pumps

1. INTRODUCTION

The purpose of this handbook is to provide

operating guidelines and routine maintenance

instructions for the SPP AUTOPRIME ACE

Range of mobile diesel engine driven pumps.

Instructions and statements contained within

this handbook are given with our best

intentions and are correct at the time of

compilation. They are subject to alteration at

any time.

These pumps are most commonly supplied

mounted on 2 wheel road trailers but can also

be supplied skid mounted, or as a pump unit

for customer’s to mount on a suitable chassis

or foundations.

ACE pumps are primed by a 25cfm vacuum

pump and are driven by a close coupled, aircooled diesel engine.

Crucible Close, Mushet Industrial Park,

Coleford, Gloucestershire, ENGLAND,

ACE Range Pump Components

TANK

BAUER

Operators Instructions for

This Handbook covers the following pumps:

ACE80

driven by a Hatz 1D90 diesel engine mounted

on a fuel tank and road trailer or skid. This

unit is fitted with 3” Bauer hose connections.

ACE100

pump driven by a Hatz 1D90 diesel engine

mounted on a fuel tank and road trailer or

skid. This unit is fitted with 4” Bauer hose

connections.

2. SERIAL NUMBER

The serial number plate is attached to the

unit on the side of the priming tank.

This serial number must be quoted in any

enquiry for spares or service.

Where required, a trailer registration plate is

fitted to the front of the unit as required by

local regulations and the VIN number is

stamped on the fuel tank.

SPP Pumps Limited

GL16 8PS

Tel: +44(0)1594 832701

Fax: +44(0)1594 836300

BAUER

EYE

– An automatic priming mobile pump

– An automatic priming mobile

START

TOW

HITCH

LIGHTING BOARD

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 4 of 12

FUEL

JACK

Page 5

Operators Instructions for

ACE80/100 Diesel Driven Centrifugal Pumps

3. SAFETY PRECAUTIONS

3.1 Safety Symbols

Safety instructions within this manual are

marked with the following symbols:

This symbol refers to general mechanical

aspects of safety.

This symbol refers to electrical safety.

ATTENTION

3.2 Pump Safety Precautions

apply to all the following:-

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.2.8

2.2.9

This symbol gives warning of a hazard

to the pump itself, which in turn could

cause a risk to personal safety.

ATTENTION

Hot surfaces and moving parts are guarded

to protect you. If these guards are removed

for maintenance, they must be replaced

before starting the pump.

Never insert anything into the pump casing

whilst the pump is running with the suction

and delivery hoses disconnected.

Collapsible hoses must not be used on the

suction side of the pump

Where the standard Bauer connections are

not used, use all pump flange holes to fit

suction and delivery hose connections.

Do not lift with fork of fork lift truck under the

fuel tank. Never lift with suction or delivery

hoses attached. The increased weight of

these items may cause lifting gear failure.

Always lift pump sets vertically by the lifting

eye. Check the condition of the lifter bracket

at regular intervals.

Check the type of liquid being pumped

before working on pump ends. Residues

could be hazardous to your health. If in

doubt flush out with clean water before work

commences.

Personnel working on the pump unit must

always wear clean correctly fitting clothing

and safety footwear. Clothing impregnated

with oil or fuel can constitute a health hazard

through prolonged contact with the skin and

may also constitute a fire hazard.

Always allow adequate ventilation for diesel

engines. Be aware of fire risks from items

such as exhaust pipes and silencers. Never

place flammable items around the unit.

Manual No/Rev

W72-019E / 4

2.2.10

When working near to the pump or in a

confined space with the pump running

personal ear protection is recommended.

4. HANDLING & TRANSPORT

4.1 Lifting

The central lifting eye is designed for lifting

only the pump unit as supplied by SPP

Pumps Limited. Due to the additional weight

of skid-mounted units, these may be fitted

with alternative lifting points and fork-lift truck

slots on the skid.

The central lifting eye is suitable only for

vertical lifting and must not be used to

pull the unit sideways.

4.1.1

Check the condition of the central lifting eye

or bracket before use.

4.1.2

Do NOT use a lift truck with forks under the

fuel tank and do NOT lift with the hoses

attached.

4.1.3

Never allow the unit to be subject to a

‘snatch’ loading.

4.1.4

Control the unit while lifting to prevent

swinging and keep personnel away from the

area below the unit and the immediate area.

4.2 Road Trailer Version

There is provision for a lighting board to be

fitted to the rear of the unit. Place the

lighting board in the two brackets and insert

pins to retain the lighting board in place.

4.3 Trailer or Wagon Carriage

Transportation on a trailer or wagon will

require the unit to be roped or strapped

down. On the road trailer mounted units, set

the unit level with the front and rear prop

stands lowered and clamped. Place ropes

or straps over the chassis to hold the unit in

place. Do NOT place ropes or straps over

the engine or the pump unit and ensure that

ropes or straps do not come into contact with

controls, switches, taps or other vulnerable

parts.

Page 6

Manual No/Rev

W72-019E / 4

ACE80/100 Diesel Driven Centrifugal Pumps

Operators Instructions for

5. OPERATING INSTRUCTIONS

5.1 Before Starting

5.1.1

Read this Handbook carefully.

5.1.2

Level the unit and jack or chock to prevent

movement in use.

5.1.3

Check the engine fuel and lubricating oil

levels. Top up as necessary.

5.1.4

Check the mechanical seal oil level using

the dipstick fitted to the filler plug.

5.1.5

Check the vacuum pump drive belt is

correctly tensioned.

5.1.6

Starting:- Ensure that the battery is charged

and ready for use.

5.1.7

Check that air inlets are unobstructed and

that the cylinder vanes are free from debris.

5.1.8

Check that the discharge non-return valve

is seating properly and that there is no

debris in the ball chamber that may prevent

correct operation.

5.1.9

Select and fit a suitable strainer for the job

in hand. Note that most ‘off the shelf’

strainers are for general purpose use. As

such they may not protect the pump against

oversize solids. For applications where

stones, etc., may be drawn in, then a

strainer with holes slightly smaller than the

pump handling capacity must be employed.

Refer to the Technical Data section for

details.

5.1.10

Connect suction and delivery hoses making

sure that there are no sharp bends in the

lines. Where the hoses pass over sharp

edges or abrasive surfaces ensure that they

are protected by suitable means to prevent

chafing. Ensure that the suction hose end

is fully submerged.

5.1.11

Check that the surge control valve is fully

screwed in. This is the large indented nut

surrounding the surge control valve knob on

the top of the priming tank.

5.2 Starting

5.3 After Starting

5.3.1

The pump will prime automatically once the

suction hose is submerged. If the pump

fails to prime refer to the fault finding guide.

(Section 8)

5.3.2

If the pump continually snores, gradually

release the surge control valve until the

vibrations reduce.

5.4 Stopping

5.4.1

Read the manufacturer’s instructions for the

Hatz engine in conjunction with the

following:-

5.4.2

Turn the keyswitch to the ‘Off’ position.

5.4.3

Open the volute cock to drain the volute.

Close after draining is complete. This must

be done before removing the suction and

delivery hoses.

5.4.4

When you take the pipes off there is a

chance that there will still be water in the

pipes so caution is advised.

5.2.1

Read the manufacturer’s instructions for the

Hatz engine in conjunction with the

following:

5.2.2

Push the decompressor lever(s) to the ‘Run’

position.

5.2.3

Turn the keyswitch to the ‘Start’ position

5.2.4

Release the keyswitch once the engine has

fired and got away.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 6 of 12

Page 7

Operators Instructions for

FORCE

LOCKING

NUT

DEFLECTION

BOLT

Manual No/Rev

ACE80/100 Diesel Driven Centrifugal Pumps

6. PUMP MAINTENANCE CHART

For engine maintenance periods refer to the engine operators handbook supplied with this manual.

PERIOD TASK

Daily Visually check for leaks.

Check for vibration.

Check the mechanical seal oil level and top up as required.

Weekly or

100 hrs

6 monthly

or 1500 hrs

Annually or

6000 hrs

The above schedule is given for guidance but site operating conditions may override the suggested

maintenance intervals

.

7. MAINTENANCE INSTRUCTIONS

7.1 Mechanical Seal Oil Reservoir

Maintain the oil level between the maximum

and minimum levels marked on the dipstick.

7.2 Drive Belt Adjustment

7.2.1

Remove guard.

7.2.2

Slacken the locking nut and the retaining

bolt, rotate the tensioner to adjust the

tension of the belt. Tighten the locking nut

and the retaining bolt and check the tension

thus:

RETAINING

7.2.3

V Belt tension is correct when the deflection

is 4mm with a force of 1.5kg applied at the

centre of the longest run.

Note: DO NOT OVERTIGHTEN BELTS

UNDER ANY CIRCUMSTANCES.

7.3 Mechanical Seals

Check all fastener security.

Check the condition of the lifter bracket/frame and check the security of attachment to

the unit.

Check tension of vacuum pump drive belt.

Check reflux ball is sealing on its seat.

Check and if necessary renew vacuum pump drive belt.

Dismantle and clean valve gear, tank, connecting pipes and priming tank.

Change mechanical seal oil.

Check vacuum pump blade condition

are never run dry. Immediate seal failure

will result.

7.3.2

Any contamination of the fluid should be

investigated immediately. Should a large

loss of fluid be experienced then the pump

must be stopped immediately.

7.3.3

Replacement of the seals is considered a

workshop operation where higher standards

of cleanliness can be maintained and the

specialised tooling required is more readily

available.

7.4 Mechanical Seal Removal

7.4.1

Remove the Tee piece and priming tank,

place oil tray under mechanical seal oil

drain plug to drain oil.

7.4.2

Remove the non-return valve and volute to

access the impeller. Unscrew impeller anticlockwise with the aid of a mallet until

undone, note the number of shims fitted

behind and retain for reuse.

7.4.3

Once the impeller is removed, remove the

rotating part of the primary mechanical seal

Belt Tensioning

and remove rear wear plate. Then press

the seat out of the back wearplate.

7.4.4

Remove the circlip and washer off the shaft.

Then remove the secondary mechanical

seal and engine adaptor plate. Then press

out the seat.

7.4.5

Check the condition of the ’O’-rings and

replace if necessary.

W72-019E / 4

7.3.1

Ensure that the coolant/lubricant level is

maintained. It is imperative that the seals

Page 8

Manual No/Rev

AIR FILTER

25PTFLTA

M4 SELF LOCK NU T

MAIN INLET VALVE

AIR OUTLET VALVE

M10 STARLOCK WASHER

KNOB (NOT SHOWN)

SPRING

W72-019E / 4

ACE80/100 Diesel Driven Centrifugal Pumps

7.5 Mechanical Seal Assembly

7.5.1

Assemble the engine adaptor plate on to

the engine and press the stationary seat in

to the plate ensuring not to damage the

face. Replace the rotating part of the seal

preferably with SPP tool no 22743 and push

it up until the circlip groove is exposed

behind the seal. Replace the circlip washer

and circlip and ensure the mechanical seal

is securely in place and against the washer.

7.5.2

Assemble the back wear plate onto the

engine adaptor and press the mechanical

seal seat into the wear plate. Replace the

rotating part of the seal so that the faces

meet. Assemble the impeller with the

reused shims and tap with a mallet to

tighten.

7.5.3

Assemble the non-return valve and volute.

Ensure that the impeller still moves without

touching the wearplate. Measure the

clearance between the wearplates and the

impeller and if they do not fall within the

range specified in the table in Section 9,

then shim as necessary to avoid loss of

efficiency.

7.5.4

Replace the Tee piece and priming tank

and tighten mechanical seal oil plug. Add

oil as indicated on dipstick

7.6 Non-Return Valve

7.6.1

A ball type non-return valve is fitted to the

pump discharge.

7.6.2

The ball should be regularly checked for

freedom of movement and absence of

debris by inspection through the discharge.

7.6.3

The correct seating of the ball can be

checked through the delivery flange of the

valve body. The valve body should be

removed to check the seat for damage or

wear.

7.7 VACUUM PUMP

Vacuum pump overhaul is beyond the

scope of this manual. Should the vacuum

pump be suspect then it is recommended

that an exchange unit is fitted and the

suspect unit returned to the manufacturers

for examination.

Operators Instructions for

7.7.2

To remove the air filter undo the central nut

holding the air filter cover and remove to

expose the filter element.

7.9 Valve Gear

The valve assemblies are shown below.

The valves, seats and pins should be

checked regularly for wear or damage.

Worn parts should be replaced. The main

valve is located on the underside of the top

cover.

Air Filter Location

NYLON WASHER

AIR INLET VALVE

M4 WASHER

SPRING

DIAPHRAGM

O RING

VALVE SEAT

VALVE ROD

GASKET

FULCRUM BRACKET

M6 WASHER

M6 CAPSCREW

FULCRUM ARM

FULCRUM PIN

M8 SELF LOCK NUT

M8 WASHER

VALVE SUPPORT PIN

M6 STARLOCK WASHER

Main Valve Assembly

VALVE SEAT

VALVE SPINDLE

KLIP RING

VALVE

M8 WASHER

7.8 Vacuum Pump Air Filter

7.7.1

Air filters are located in the valve cover of

the primary tank and should be checked

SPRING RETAINER

Surge Control Valve Assembly

KLIP RING

regularly for cleanliness, distortion or

damage see the figure below. Replace if

distorted or damaged.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 8 of 12

Page 9

ACE80/100 Diesel Driven Centrifugal Pumps

8. FAULT FINDING GUIDE

Pump Fails to Prime

Are

NO

all plugs

tight?

NO YES

Operators Instructions for

Disconnect suction hose

Blank off suction entry

Fit vacuum gauge

Reading

between

85 - 89 .5 kpa

(28.5 0 30 ft H20)?

Manual No/Rev

W72-019E / 4

Check vertical

suction lift

Rectify &

re-test

Fit vacuum gauge

(28.5 0 30 ft H20)?

NO

Is belt drive

tension OK?

YES

Test the Vacuum

Pump directly

Reading

between

85 - 89 .5 kpa

NO

YES

Rectify YES

Rectify NO

Is

Reflux Valve

Ball seating

properly?

YES

Is Vacuum

Pump filter

blocked?

NO

Is Main

Valve float

gear free and

intact?

YES

Move

Pump

YES

NO

Rectify

Lift< or =

8.53m (28ft) for

ACE80/100

NO

Are hoses

leaking, collapsed

or blocked?

NO

Is intake

blocked?

NO

Is impeller

blocked?

YES

Rectify

YES

Rectify

YES

Rectify

Rectify

YES

Excessive wear.

Remove Vacuum

Pump & either

overhaul or fit new or

exchange pump

NO

Rectify

YES

Is pump

casing free from

holes?

ACE80-100 Fault Finding Chart

Are all

joints sound &

leak free?

YES

Check impeller wear

plate clearances

and rectify

NO

Rectify

Is the

pump or NRV

blocked or

damaged?

NO

YES

Rectify

Page 10

Manual No/Rev

Weight

(With full fuel tank)

470 Kg

1036 lbs

Hitch Weight Dry

32 Kg

70 lbs

2320mm

135mm

1

2

3

3

m

m

91.34”

81.3”

5.31”

4

8

.

5

4

”

W72-019E / 4

ACE80/100 Diesel Driven Centrifugal Pumps

Operators Instructions for

9. TECHNICAL DATA

CHARACTERISTICS ACE80/100 ACE80/100

Vacuum Pump 25 ft3/min 25 ft3/min

Solids Handling Capability 40 mm Diameter 1.5” Diameter

Engine Type Hatz 1D90 Air cooled Hatz 1D90 Air cooled

Fuel Tank Capacity 55 Litres 14.5 Gal (US)

Approx. Running Time On Full Tank 24 Hours 24 Hours

Impeller Back Plate Clearance 0.5 - 1.5mm 0.019 - 0.059”

Impeller Front Plate Clearance 0.38 - 0.5mm 0.015 - 0.019”

Mechanical Seal Coolant/Lubricant Mobil Velocite Oil No. 6, Texaco Rando HD10 Or equivalent

Weight Dry (No fuel in tank) 420 Kg 925 lbs

Towing Hitch Types Towing Eye or Ball Hitch

Flange Drilling PN16 is standard, ANSI flange drilling is optional

1363mm

53.66”

4.72”

2065mm120mm

Note - These dimensions are approximate and may vary to suit the selected customer options.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 12

Page 11

Operators Instructions for

ACE80/100 Diesel Driven Centrifugal Pumps

Manual No/Rev

W72-019E / 4

Page 12

Manual No/Rev

W72-019E / 4

ACE80/100 Diesel Driven Centrifugal Pumps

Operators Instructions for

10. SPARES & SERVICE

SPP Pumps operate a comprehensive Spares and Service support network throughout the world, and

can be contacted as follows:

SPARES & SERVICE Telephone: **44 (0) 1189 323123

For spare parts, supply only. Ask for - Spares Dept.

For breakdowns, spare parts and on-site fitting, pump installation and

commissioning, and service contracts. Ask for - Service Dept.

For breakdowns outside office hours. Telephone : **44 (0) 1491 201613

Spares & Service Office

SPP Pumps Limited General Fax line: **44 (0) 1189 323302

1420 Lakeview

Arlington Business Park

Reading, Berkshire Direct Fax line: **44 (0) 1189 303259

RG7 4SA

ENGLAND

Copies of this manual are available from the SPP Pumps Limited Spares & Service Department by

quoting the manual reference number and the relevant revision number.

ENGINE OPERATORS HANDBOOK

The specific engine operator’s handbook from the manufacturer is included within the pump

documentation pack.

---“---

Your Local Supplier’s contact details may be shown here:

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 12 of 12

Loading...

Loading...