Page 1

AUTOPRIME PRODUCT

50_7514A

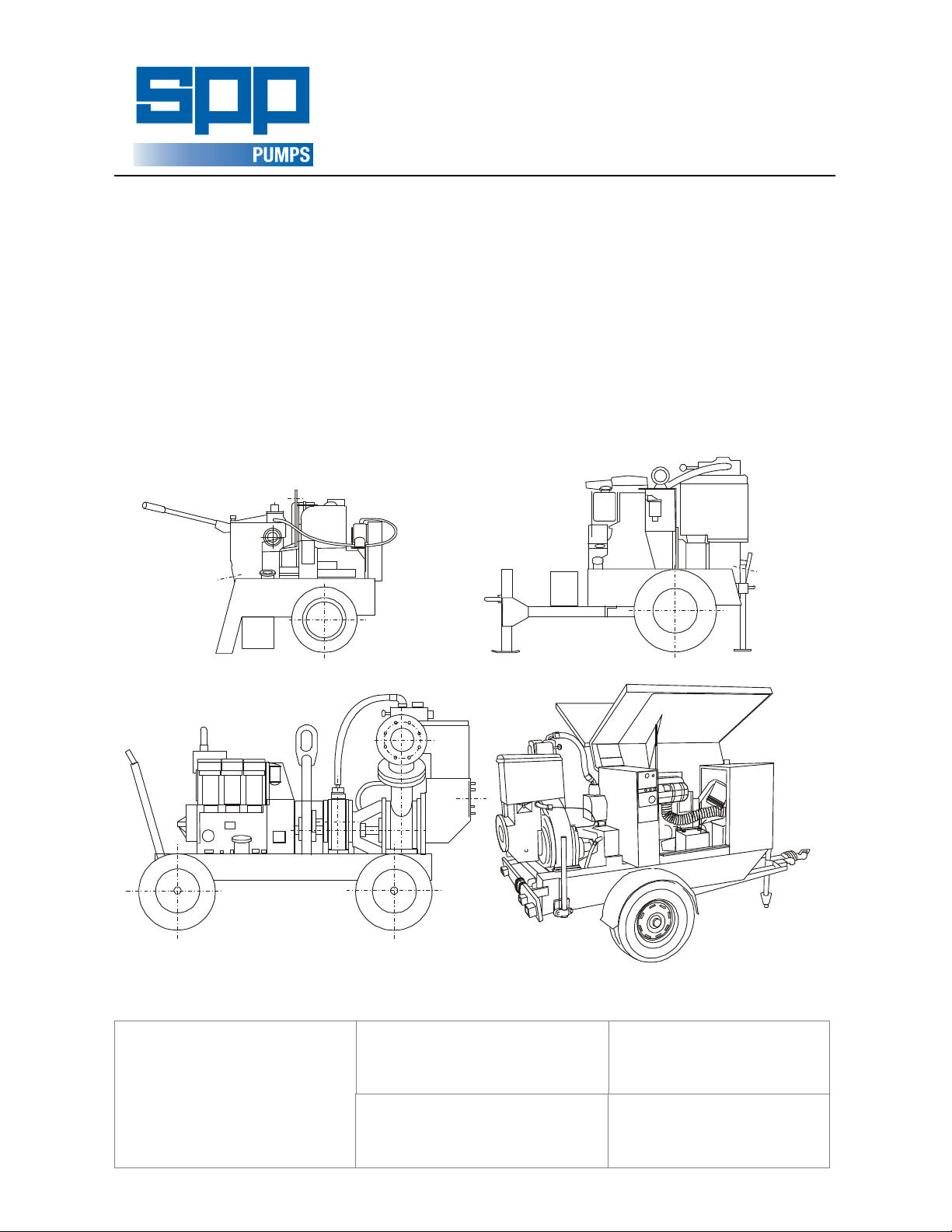

AC50 & AC75

100M & 150M

AC80 & AC100

OPERATORS HANDBOOK

AUTOPRIME

DIESEL DRIVEN

PUMPSETS

100M_31A

SPP Pumps Ltd.

Crucible Close

Mushet Industrial Park

Coleford

Gloucestershire

ENGLAND

GL16 8PS

Telephone:

01594 832 701

Fax:

01594 836 300

8010019A

A

0

3

_

M

0

0

1

Document No: . W72-002E

Revision No: .................. 12

Revision Note No: . R 39552

Date Issued . August 2012

Produced at SPP Pumps,

Coleford, England

Page 2

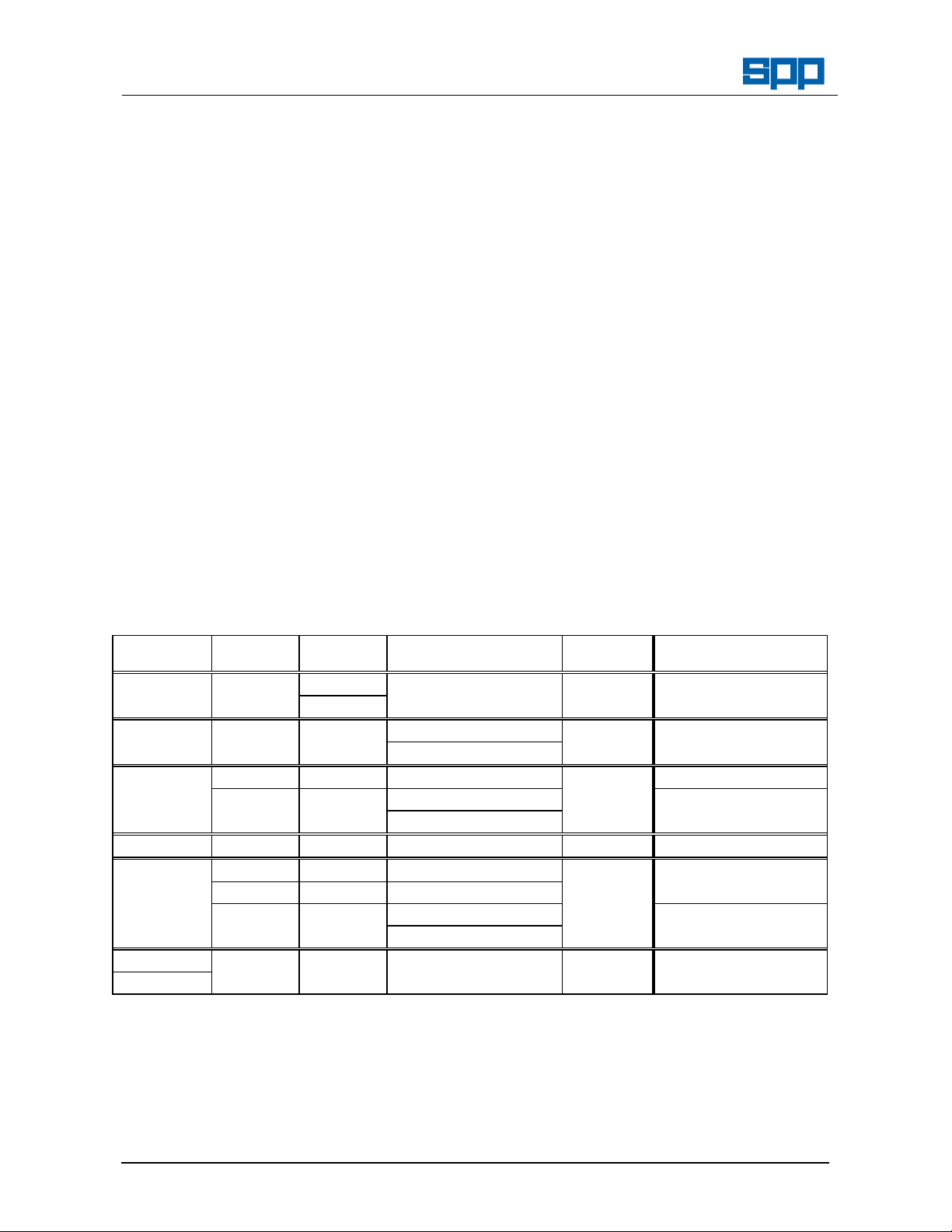

We SPP Pumps Limited

Sound Level (dB)

Pump Model Measured Guaranteed LWA

AC50 & AC75 105 108

AC80 & AC100 106 109

100M & 150M 103 106

Of Crucible Close

Mushet Industrial Park

Coleford

Gloucestershire

England

GL16 8PS

Declare that:

Equipment: DIESEL DRIVEN CENTRIFUGAL PUMPS

Model/Type: AC50 & AC75, AC80 & AC10, 100M & 150M

Serial Number: As shown on the Pump Nameplate

in accordance with the following Directives:

Cross 2000/14/EC- Guaranteed sound power level.

The conformity assessment procedure followed was in

according with ANNEX V of the Directive.

DECLARATION OF

CONFORMITY

2004/108/EC The Electromagnetic Compatibility Directive and its amending directives

2006/42/EC The Machinery Directive and its amending directives

2000/14/EC The Noise Emissions Directive and its amending directives

have been designed and manufactured to the following specifications:

EN 809:1998+A1:2009 Pump and pump unit for liquids – common safety requirements

EN 12162: 2001 Liquid pumps – Safety requirements – Proceedure for hydrostatic testing.

EN 292-2: 1991 Safety of Machinery- Basic concepts, general principles for design.

EN 61000-6-4: 2001 Electromagnetic compatibility (EMC). Generic standards. Emission standard

for industrial environment.

EN 61000-6-1: 2001 Electromagnetic compatibility (EMC). Generic standards. Immunity for

residential, commercial and light-industrial environments.

EN 3744: 1995 Acoustics- Determination of sound power levels of noise sources using sound

pressure- Engineering method in an essentially free field over a reflecting

plane

We hereby declare that the equipment named above has been designed to comply with the relevant sections

of the above referenced specifications. The units comply with all essential requirements of the Directives

Signed:

Name: John Hollins

Position: Engineering Manager - Authorised to sign on behalf of SPP Pumps Limited

Mushet Industrial Park, Coleford, Gloucestershire, England, GL16 8PS

Date: 12 February 2010

W72-002E

A copy of this certificate has been submitted to the European Commission and UK Authority

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 2 of 16

Page 3

Operators Handbook for

Diesel Driven Pump Sets

Manual No/Rev

W72-002E / 11

CONTENTS

1. INTRODUCTION .................................................................................... 4

1.1 PUMP DESIGNATIONS ........................................................................................... 4

1.2 PUMP TYPES .......................................................................................................... 4

2. SAFETY PRECAUTIONS ...................................................................... 6

2.1 SAFETY SYMBOLS ................................................................................................. 6

2.2 PUMP SAFETY PRECAUTIONS ............................................................................. 6

3. TRANSPORT ......................................................................................... 6

3.1 ROAD TOWED ........................................................................................................ 6

3.2 TRAILER OR WAGON CARRIAGE ......................................................................... 6

3.3 MOVEMENT BY LIFTING ........................................................................................ 6

4. SERIAL NUMBER ................................................................................. 7

5. OPERATING INSTRUCTIONS .............................................................. 7

5.1 BEFORE STARTING ............................................................................................... 7

5.2 STARTING ............................................................................................................... 7

5.2.1 Canopy sets ................................................................................................... 7

5.2.2 Open sets ...................................................................................................... 8

5.3 AFTER STARTING .................................................................................................. 8

5.4 STOPPING ............................................................................................................... 8

5.4.1 Canopy sets ................................................................................................... 8

5.4.2 Open sets ...................................................................................................... 8

6. PUMP MAINTENANCE CHART ............................................................ 9

7. MAINTENANCE INSTRUCTIONS ....................................................... 10

7.1 COALESCER (100M, 150, 150M, 200) ................................................................ 10

7.2 OIL RESERVOIR (AC50, AC75, AC80 & AC100).................................................. 10

7.2.1 AC50 & AC75 .............................................................................................. 10

7.2.2 AC80 & AC100 .............................................. Error! Bookmark not defined.

7.3 COUPLING (open coupled sets) ............................................................................ 10

7.4 DRIVE BELT ADJUSTMENT ................................................................................. 10

7.5 PUMP VACUUM PRESSURE SEAL ..................................................................... 11

7.5.1 Close coupled AC50, AC75, AC80 and AC100 pumps ............................... 11

7.5.2 Open coupled pumps .................................................................................. 11

7.6 MECHANICAL SEALS ........................................................................................... 12

7.7 NON-RETURN VALVE .......................................................................................... 12

7.8 PUMP BEARINGS (Open coupled pump sets only) .............................................. 12

7.9 VACUUM PUMP .................................................................................................... 12

7.10 VACUUM PUMP AIR FILTER .............................................................................. 12

7.10.1 Standard air filter ....................................................................................... 12

7.10.2 High Capacity Air Filter .............................................................................. 13

7.11 VALVE GEAR ....................................................................................................... 13

7.12 SURGE CONTROL VALVE ................................................................................. 14

8. FAULT FINDING GUIDE ..................................................................... 15

9. TECHNICAL DATA .............................................................................. 16

10. SPARES & SERVICE ........................................................................ 16

11. COUPLING DETAILS (where applicable) ........................................ 16

12. ENGINE OPERATORS HANDBOOK ................................................ 16

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 3 of 16

Page 4

Manual No/Rev

Pump

W72-002 / 11

Operators Handbook for

Diesel Driven Pump Sets

1. INTRODUCTION

The purpose of this handbook is to lay down

operating guidelines and simple routine

maintenance for the AUTOPRIME range of

diesel engine driven mobile pump sets fitted

with vacuum pumps.

Instructions and statements contained within

this handbook are given with our best

intentions and are correct at the time of

compilation. They are subject to alteration at

any time.

1.1 PUMP DESIGNATIONS

These are derived from the nominal size of the

pump discharge and suction pipes with prefix

and suffix letters to signify:

A = Air Cooled

C = Close Coupled

M = High Capacity Pump Design

e.g. An AC100 pump set has an air cooled

engine, is close coupled and has

100mm (4”) bore suction and delivery

connections, and -

1.2 PUMP TYPES

Pump Type Driver Starting Trailer

A 100M pump set is a 100m (4”) high

capacity pump. Note that these can be

supplied in open or canopied form with

either a four wheeled site trailer or two

wheeled road trailer chassis.

Vacuum pumps are supplied to suit pumping

requirements, there are four main sizes:-

10.2m3/hr (6ft3/min)

30.6m3/hr (18ft3/min)

42.6m3/hr (25ft3/min)

102m3/hr (60ft3/min).

This manual covers the range of units shown

below. Note that some units can be fitted with

either vacuum pressure seals or tandem

mechanical seals. Ensure that the correct

instructions and diagrams are being referred to

for the particular unit under consideration.

Other order specific components may also be

fitted. If in doubt over any item consult the unit

supplier.

Vacuum

Features

AC50 & AD1 Hand 2 wheel site -hand 6 cfm Close coupled

AC75 Electric

AC80 TR1 Electric 2 wheel site - towed 18 cfm Close coupled

AC100 2 wheel road - towed

100M TR2 Electric 4 wheel site - towed 25 cfm

LPW3 Electric 4 wheel site - towed Noise reducing canopy

2 wheel road - towed

150 TS3 Hand 2 wheel site towed 60 cfm Bronze internals/coated

150M TS3 Hand 2 wheel site towed 60 cfm Bronze internals

TR3 Hand 4 wheel site towed

LPW4 Electric 4 wheel site towed Noise reducing canopy

2 wheel road - towed

200 CD4 Electric 4 wheel site - towed 25 cfm

200 60 cfm

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 4 of 16

Page 5

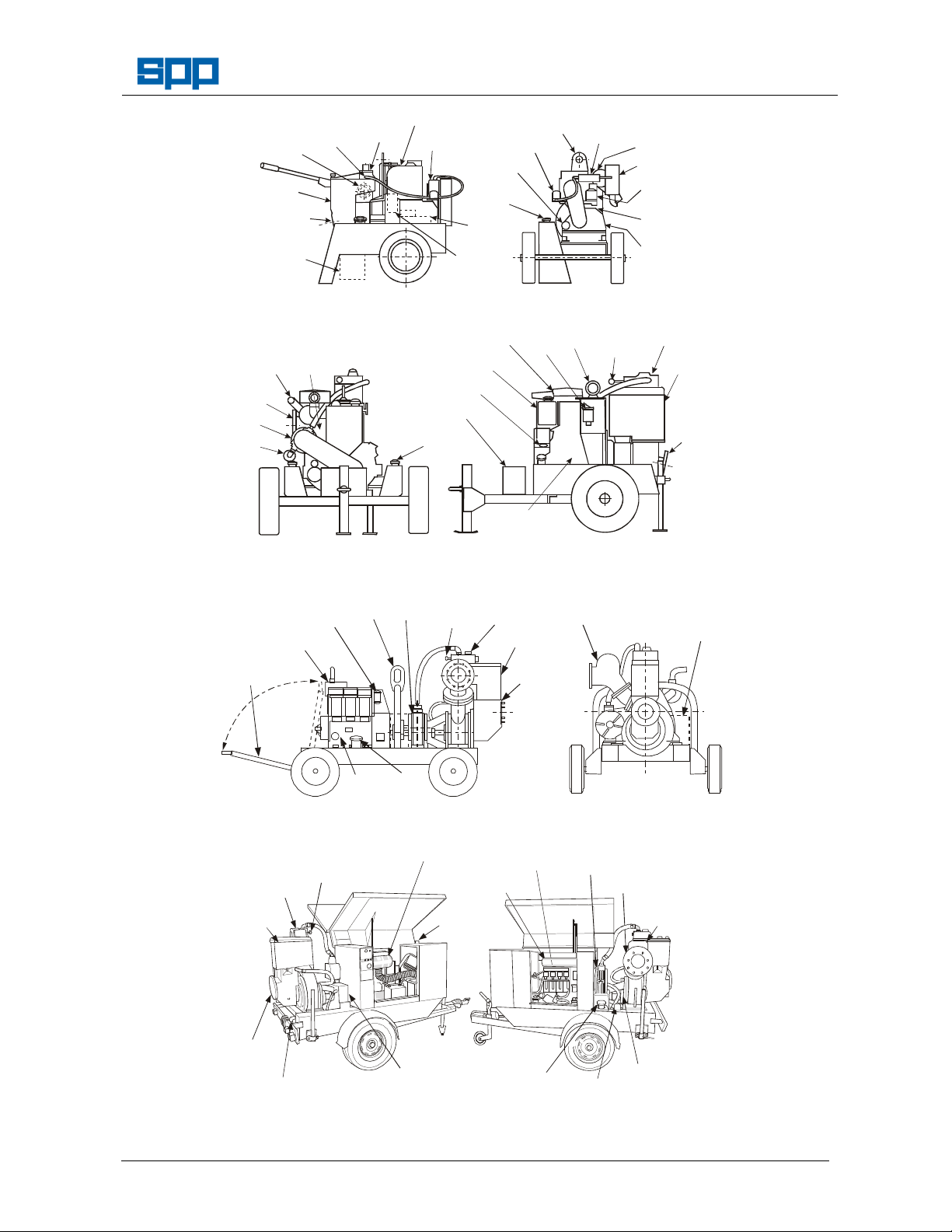

Operators Handbook for

EXHAUST

SILENCER

LUB OIL

DIPSTICK

(on underside

of filler cap)

VACUUM

LUB OIL

RESERVOIR

SILENCER

ENGINE

FILTER

UNIT

ENGINE

PRIMING

CONTROL

SUCTION

AIR

FILLERS

ENGINE

PRIMING

VALVE

COVER

CONTROL

UNIT

ENGINE

NON RETURN

BATTERY

REFLUX BOX

(NON RETURN

PUMP VACUUM

PRESSURE SEAL

AIR

COALESCER

Diesel Driven Pump Sets

DELIVERY

FLANGE

(on far side)

PRIMARY

TANK

SUCTION

FLANGE

BATTERY

(electric start

only)

50_75GAB

MINI BALL

VALVE

(in line)

Figure 0-1 AC50 Pump

EXHAUST

DELIVERY

FLANGE

VACUUM

PUMP

VACUUM

PUMP

SILENCER

VALVE

COVER

ENGINE

VACUUM

PUMP

KEYSWITCH

& RUNNING

HOUR RECORDER

(electric start only)

(2” Bauers)

VACUUM

PUMP OIL

RESERVOIR

ENGINE OIL

FILLER

BATTERY

FUEL

(both sides)

PUMP

ENGINE

LUB OIL

FILTER

FUEL

TANK

FILLER

STARTER

MOTOR

(if fitted)

and AC75 Pump

FUEL

FILTER

FILTER

LIFTER

UNIT

LIFTER

VACUUM

PUMP

(3" Bauers)

SURGE

VALVE

AIR

CLEANER

FUEL

STOP

LEVER

Site Trailer

VALVE

COVER

TANK

Manual No/Rev

W72-002E / 11

FLANGE

8010023A

Figure 0-2 AC80 Pump

(3" Bauers)

and AC100 Pump

ENGINE OIL

DIPSTICK

(4" Bauers)

Site Trailer

VACUUM

PUMP

FUEL

FILLER

SURGE

VALVE

TANK

SUCTION

FLANGE

VALVE

100M_32A

EXHAUST

SILENCER

PIVOTING

TOWBAR

FUEL

FILTER

LIFTER

ENGINE

DIPSTICK

Figure 0-3 100M-25 Pump and 150M-60 Pump - Site Trailer - Open Set

ENGINE OIL

FILLER AND

DIPSTICK

EXHAUST

VACUUM

PUMP

DELIVERY

FLANGE

VALVE)

VALVE

COVER

PRIMING

TANK

SURGE

CONTROL

VALVE

FILTER

ENGINE

COOLANT

SUCTION

FLANGE

COALESCER

VENT

100M_33A

VACUUM

PUMP

FUEL

FILLER

FUEL

GAUGE

Figure 0-4 100M-25 Pump and 150M-60 Pump - Road Trailer. - Canopied Set

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 5 of 16

Page 6

Manual No/Rev

W72-002 / 11

2. SAFETY PRECAUTIONS

2.1 SAFETY SYMBOLS

Safety instructions within this manual are

marked with the following symbols:

This symbol refers to general mechanical

aspects of safety.

This symbol refers to electrical safety.

ATTENTION

This symbol gives warning of a hazard

to the pump itself, which in turn could

cause a risk to personal safety.

Operators Handbook for

Diesel Driven Pump Sets

2.2.8

2.2.9

3. TRANSPORT

3.1 ROAD TOWED

Always allow adequate ventilation for

diesel engines. Be aware of fire risks

from items such as exhaust pipes

and silencers. Never place

flammable items around the unit.

Collapsible hoses must not be used

on the suction side of the pump.

Lighting boards are provided for road

going trailers.

2.2 PUMP SAFETY PRECAUTIONS

ATTENTION

apply to all the following:-

2.2.1

Never insert anything into the pump

casing whilst the pump is running and

the suction or delivery hoses are

disconnected.

2.2.2

Moving parts are guarded to protect you.

Guards removed for maintenance must

be replaced before starting the pump.

2.2.3

If the supplied Bauer connections are

not utilised, then use all flange bolts

when fitting suction and delivery hoses.

2.2.4

Always lift pump sets vertically by the

lifting eye. Do not lift with the forks of a

fork truck under the fuel tanks. Never lift

with suction or delivery hoses attached.

The increased weight of these items

may cause lifting gear failure.

2.2.5

Check the condition and security of the

lifter frame or bracket at regular

intervals.

2.2.6

Check the type of liquid being pumped

before working on pump ends. Residues

could be hazardous to your health. If in

doubt flush out with clean water before

work commences.

2.2.7

Personnel working on the pump unit

must always wear clean, correctly fitting

clothing and safety footwear. Clothing

impregnated with oil or fuel can

constitute a health hazard through

prolonged contact with the skin and may

also constitute a fire hazard.

3.2 TRAILER OR WAGON CARRIAGE

Transportation on a trailer or wagon will

require the unit to be strapped or roped

down. Always strap/rope the unit around

the chassis - NEVER over the engine,

pump or canopy (if fitted).

Ensure that the straps/ropes do not

come into contact with any items

(switches, drain taps, etc..) which may

be vulnerable to damage during transit.

3.3

MOVEMENT BY LIFTING

ATTENTION

If the unit is moved by lifting then the

condition and security of the lifter must

be checked before use.

The lift must always be vertical on the

eye provided.

Never allow the unit to be subject to a

‘snatch’ loading.

Do not allow the unit to swing whilst

being lifted.

Keep people away from the area

underneath the lifted unit and the

immediate surrounding area.

Failure to observe any of the above

could result in personnel injury or death

due to failure of the lifting gear.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 6 of 16

Page 7

Operators Handbook for

SPP Pumps Limited

Reading, RG31 7SP

Tel: ++44(0)118 932 3123

Diesel Driven Pump Sets

Manual No/Rev

W72-002E / 11

4. SERIAL NUMBER

A serial number plate is attached to the unit on the side of the priming tank. This serial number must be

quoted in any enquiry for spares or service.

Type

ENGLAND

Fax: 118 932 3302++44(0)

5. OPERATING INSTRUCTIONS

5.1 BEFORE STARTING

5.1.1

Read this Handbook carefully.

5.1.2

Level the unit and jack or chock to

prevent movement in use.

5.1.3

Check the engine fuel and

lubricating oil levels. Top up as

necessary.

5.1.4

If mechanical seals are fitted check

ATTENTION

5.1.8

the reservoir coolant or lubricant

level.

5.1.5

Check the vacuum pump drive belt

is correctly tensioned.

5.1.6

Hand start engines:- Check that

the starting handle is serviceable.

Electric start engines:- Ensure that the

batteries are charged and ready for

use.

5.1.7

Radiator cooled engines:- Check

the coolant level and that the

radiator is free from any debris.

Note that these units are fitted with

‘puller’ fans and therefore it is the

external face of the radiator which

may become blocked.

Air cooled engines:- Check that air inlets

are unobstructed and that the

cylinder vanes are free from debris.

AC50, AC75, AC80 & AC100:Check oil levels in vacuum pump

reservoirs.

Other units:- Draw off any water from the

vacuum pump coalescer oil sump

via the tap in the side. Check the oil

level which should be level with the

underside of the cap.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

5.2 STARTING

Page 7 of 16

Nett

Serial No.

5.1.9

Check that the discharge non return

valve is seating properly and that

there is no debris in the ball

chamber that may prevent correct

operation.

5.1.10

Select and fit a suitable strainer for

the job in hand. Note that most ‘off

ATTENTION

the shelf’ strainers are for general

purpose use. As such they may not

protect the pump against oversize

solids. For applications where

stones, etc., may be drawn in, then

a strainer with holes slightly smaller

than the pump handling capacity

must be employed. Refer to the

Technical Data section for details

on specific pumps.

5.1.11

Connect suction and delivery hoses

making sure that there are no sharp

bends in the lines. Where the

hoses pass over sharp edges or

abrasive surfaces ensure that they

are protected by suitable means to

prevent chafing. Ensure that the

suction hose end is fully

submerged.

5.1.12

AC50 & AC75: Ensure that the mini

ball valve connecting the suction

line to the top cover of the pump is

in the open position (screwdriver

slot aligns with the axis of the

body).

Other units: Check that the surge control

valve is fully screwed in. This is the

large indented nut surrounding the

surge control valve knob on the top

of the priming tank.

5.2.1 Canopy sets

The starting panel on these units is under the

right hand door (looking from the tow bar

end) and comprises:-

kg

Page 8

Manual No/Rev

W72-002 / 11

a) three position keyswitch (Off, 1, &

b) protection override push button

c) circuit breaker

d) hours run counter

e) four warning indicator lamps:: Charge

Oil pressure

Water temperature

Coalescer oil level

Turn the ignition switch to the '1' position.

All four warning lights will illuminate,

providing a check that all circuits are

healthy.

Press and hold the override push-button

whilst turning the keyswitch to the 'Start'

position. Release the keyswitch and pushbutton once the engine has fired and got

away. Do not keep the override pushbutton depressed for more than 5 seconds

after the engine is up to speed.

5.2.2 Open sets

Read the manufacturer’s instructions for

the specific engine in conjunction with the

following.

Hand start engines:-

1.

Push the decompressor lever(s) to the

‘Stop’ position.

2.

Ensure the stop/run lever is in the

‘Run’ position.

3.

Hand crank the engine as fast as

possible and move the decompressor

lever(s) to the run position while

continuing to crank briskly until the

engine starts.

4.

Remove the starting handle.

Electric start engines:-

1.

Push the decompressor lever(s) to the

‘Run’ position.

2.

Ensure the stop/run lever is in the

‘Run’ position.

3.

Turn the keyswitch to the ‘Start’

position whilst pressing the shutdown

override push button (if fitted).

4.

Release the keyswitch and push-button

once the engine has fired and got

away. Do not keep the override pushbutton depressed for more than 5

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Start)

Operators Handbook for

Diesel Driven Pump Sets

5.3 AFTER STARTING

The pump will prime automatically once

the suction hose is submerged. If the

pump fails to prime refer to the fault

finding guide.

5.4 STOPPING

5.4.1 Canopy sets

Turn the keyswitch to the 'Off' position.

The unit will stop and the key can be

removed.

Open the volute cock to drain the volute.

Close after draining is complete.

5.4.2 Open sets

Read the manufacturer’s instructions for

the specific engine in conjunction with the

following:-

1.

ATTENTION

2.

ATTENTION

3.

1.

Page 8 of 16

seconds after the engine is up to

speed.

Turn the engine stopping lever to the

‘Stop’ position and hold until the engine

comes to rest. Never use the

decompressor lever(s) for this purpose

Turn the keyswitch to the ‘Off’ position.

Failure to turn the keyswitch off will

leave the running hour recorder

energised and counting which will

result in a flat battery. Note that turning

the keyswitch off does NOT stop the

unit.

Open the volute cock to drain the

volute. Close after draining is

complete.

Page 9

Operators Handbook for

Diesel Driven Pump Sets

Manual No/Rev

W72-002E / 11

6. PUMP MAINTENANCE CHART

For engine maintenance periods refer to the engine operators handbook at the back of this publication.

PERIOD PUMP SET TASK

Daily All units Visually check for leaks

Check for vibration

Mechanical seal

units

100M,

150, 150M,

& 200

Check mechanical seal coolant/lubricant level and top up as

required

Drain any water from coalescer, check oil level and top up as

required

Hand test bearing housing for any sign of temperature rise

Weekly or

100 hrs

Monthly

or 500

hrs

AC80 & AC100 Check oil level of vacuum pump reservoir

6 monthly

or 1500

hrs

Vacuum pressure

Mechanical seal

All units Check all fastener security

Check the condition of the lifter bracket/frame and check the

security of attachment to the unit

Check tension of vacuum pump drive belt

AC50 & AC75

100M,

150, 150M,

& 200

All units Check reflux ball is sealing on its seat

seal units

units

Check oil level of suction line reservoir

Remove primary tank assembly and check pump internals

for wear

Check valve gear - clean or renew filter element

Change coalescer sump oil

Clean coalescer sump oil filter mesh

Remove front cover and check pump internals for wear

Check valve gear - clean or renew standard filter element.

Check high capacity filter element.

Grease bearings

Check and if necessary renew vacuum pump drive belt

Dismantle and clean valve gear, tank and connecting pipes

Dismantle and clean pump vacuum pressure seal

Renew packing

Change mechanical seal coolant/lubricant

Annually

or 6000

hrs

100M,

The above schedule is given for guidance but site operating conditions may override the suggested

maintenance intervals.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

All units Check vacuum pump blade condition

Check bearing condition

150, 150M,

& 200

Renew coalescer filter mesh

Page 9 of 16

Page 10

Manual No/Rev

Force (kg)

producing

‘X’)

AC75

AC

100

belt

Canopied

Low noise

units

link belt

W72-002 / 11

Operators Handbook for

Diesel Driven Pump Sets

1.

7. MAINTENANCE INSTRUCTIONS

7.1 COALESCER (100M, 150, 150M, & 200)

Check the oil level in the coalescer tank and

drain any water daily. The top of the oil

should be level with the underside of the filler

cap. Water is removed by means of the drain

tap fitted to the side of the coalescer sump.

The filter mesh is accessed by removing the

coalescer lid and must be cleaned regularly

by washing in petrol or a similar spirit. When

refitting ensure filter mesh is below exhaust

port. The oil feed pipe should be cleaned in a

similar manner and blown through with an air

line.

7.4 DRIVE BELT ADJUSTMENT

Figure 0-2 Belt tensioning

Pump

sets

AC50 &

AC80 &

Others Timing

Belt type Deflec-

‘X’mm

V belt 5 1.5

V-belt 4 1.5

(toothed)

tion

deflection

4 1.5

Figure 0-1 Coalescer detail

7.2 OIL RESERVOIR (AC50, AC75, AC80 &

AC100)

7.2.1 AC57 &AC75

Ensure that oil reservoir is always kept

topped up.

7.2.2 AC80 & AC100

Maintain the oil level between the

maximum and minimum levels marked

on the bottle.

7.3 COUPLING (open coupled sets)

Coupling details are provided at the back of

this manual.

PowerTwist

A section

1.6 1.5-2.0

To adjust belt tension, loosen the vacuum

pump holding nuts and slide the

vacuum pump outward. When the

correct belt tension is obtained retighten holding nuts. Ensure that the

pump drive is in line after tightening.

Link belt drives can be further adjusted by

removing links.

DO NOT OVERTIGHTEN BELTS UNDER

ATTENTION

ANY CIRCUMSTANCES.

For AC50, AC75, AC80 & AC100 pumps

fitted with V belts and other pumps

fitted with PowerTwist link belts, the

belts can be replaced by slackening the

vacuum pump holding down bolts. For

other pumps it is necessary to

disconnect the coupling to replace the

belts.

7.5

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 16

Page 11

Operators Handbook for

Diesel Driven Pump Sets

PUMP VACUUM PRESSURE SEAL

The seal is product lubricated and therefore

requires only regular inspections of condition,

signified by rate of leakage, and eventual

replacement. To replace the packing:-

7.5.1 Close coupled AC50, AC75, AC80 &

AC100 pumps

1.

Ensure the volute is drained and

contains no harmful residues. A drain

tap is located on the bottom of the

volute.

2.

Disconnect the vacuum pump suction

line from the top of the priming tank

assembly. On AC80 and AC100 units

disconnect the back priming line.

3.

Remove the complete priming tank and

sump assembly from the volute. Note

the number of gaskets fitted between the

sump and volute. Examine their

condition and either replace or retain for

reuse

Manual No/Rev

W72-002E / 11

material is graphite impregnated

braided P.T.F.E.

7.

Place the packing into the holder

(see Figure 7-4), butting the two

ends first then pressing the

remainder of the packing into the

holder (NB the length of the

packing is greater than the

circumference of the holder and

some difficulty may therefore be

experienced. The packing will

protrude slightly from the face of

the holder on completion.

Figure 0-3 Removing impeller (AC50 shown)

4.

Unscrew the impeller (LH thread for

AC50 & AC75; RH thread for AC80 &

AC100). See Figure 7-3. Note that this

figure shows a AC50 unit. On an AC80

or AC100 unit the impeller would be

tapped in the opposite direction of

rotation. Record the number of shims

fitted behind the impeller and retain for

re use. Removal of the impeller exposes

the vacuum pressure seal.

5.

Remove old packing from packing

holder. Clean the holder. Examine the

spring for signs of corrosion. Replace if

necessary.

6.

Cut a length of packing (see Technical

Data section for dimensions) ensuring

the ends are square. The packing

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 11 of 16

Figure 0-4 Replacing vacuum pressure

seal packing

1.

Refit the impeller ensuring that it

secures the shims and spacer

sleeve.

2.

Refit the complete priming tank

assembly complete with gaskets.

7.5.2 Open coupled pumps

1.

Ensure the volute is drained and

contains no harmful residues. A

drain tap in the bottom of the

volute is provided for this purpose.

2.

Remove guard from around pump

shaft.

3.

Release screws holding the spring

carrier to the rear cover plate and

slide the spring carrier back along

the pump shaft.

Note these are the protruding hexagon

headed screws NOT the

countersunk recessed Alan

screws which should not be

touched. This will automatically

withdraw the packing holder.

4.

Follow steps 5, 6 and 7 in section

7.5.1. above.

Page 12

Manual No/Rev

W72-002 / 11

Operators Handbook for

Diesel Driven Pump Sets

5.

Slide the seal assembly back along the

shaft to locate on backplate. Tighten

securing nuts and screws evenly.

6.

Refit the shaft guard.

7.6

MECHANICAL SEALS

ATTENTION

1. Ensure that the coolant/lubricant level is

maintained. It is imperative that the seals are

never run dry. Immediate seal failure will

result.

2. Any contamination of the fluid should be

investigated immediately. Should a large loss

of fluid be experienced then the pump must

be stopped immediately.

3. Replacement of the seals is considered a

workshop operation where higher standards

of cleanliness can be maintained and the

specialised tooling required is more readily

available.

7.7 NON-RETURN VALVE

1. A ball type non return valve is fitted to the

pump discharge.

2. The ball should be regularly checked for

freedom of movement and absence of debris

by inspection through the discharge.

3. On larger pumps the correct seating of the ball

can be checked through the delivery flange of

the valve body. The valve body should be

removed to check the seat for damage or

wear.

7.8 PUMP BEARINGS (Open coupled pump sets

only)

1. The pump ends employ grease lubricated

bearings which will give long service life

provided they are:-

a)

Correctly lubricated at regular intervals

b)

Cleaned and, if removed, refitted with

care

c)

Serviced with clean tools and in a clean

area.

2. The early stages of bearing failure can be

detected by noting either unusual vibration,

bearing housing temperature rise or unduly

noisy operation. If any of these signs be

exhibited, the pump should be stopped and

the cause investigated.

3. Greased bearings are pre-packed with

lubricant during pump manufacture. Shrinkage

and normal loss of grease necessitates re-

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 12 of 16

lubrication at regular intervals. These

intervals will largely be determined by

site conditions. The recommendations

given in Table 1 are therefore for

guidance only.

Radial Bearing

Non drive end

(NDE)

4 months

3000 hrs

Radial & Thrust

Bearing

Drive end (DE)

4 weeks

750 hrs

Table 1 Guidance Intervals for bearing regreasing

4. The table is based on running speeds

of 1450rpm with a bearing temperature

not exceeding 70°C. Reduce the

interval by half for every 15°C above

70°C.

5. Clean both the grease fittings and

grease gun nozzle before use. For a

hand grease gun apply 2 or 3 strokes

to each nipple.

6. Overfilling can be as harmful to

bearings as under-lubrication.

Compaction of grease leads to it being

churned by the rolling action of the

bearings. This leads to overheating,

breakdown of the lubricant and bearing

failure.

7. Immediately after re-lubrication it is

normal for the temperature of the

bearing housing to rise in service. The

temperature should soon drop to

normal after a short period of running.

If the temperature remains elevated or

continues to rise, temporarily remove

the grease nipples and allow any

excess grease to escape.

7.9 VACUUM PUMP

Vacuum pump overhaul is beyond the

scope of this manual. Should the

vacuum pump be suspect then it is

recommended that an exchange unit is

fitted and the suspect unit returned for

examination.

7.10 VACUUM PUMP AIR FILTER

7.10.1 Standard air filter

Standard air filters are located in the

valve cover of the primary tank and

should be checked regularly for

cleanliness, distortion or damage (see

Page 13

Operators Handbook for

AIR FILTER

25PTFLTA

AIRFILTER

60PTFLT

A

60AFELE

A

X

Diesel Driven Pump Sets

Manual No/Rev

W72-002E / 11

Figure 7-5, Figure 7-6, Figure 7-7). Replace if

distorted or damaged

1

2

Figure 0-8 High capacity air filter

25 & 60 cfm units

Undo the screws holding the retaining

cover and remove (1) the cover to

inspect the filter. The element pulls out

(2). Note that the orientation of the unit

should be as shown so that any debris

from the filter falls away from the outlet

connection when the unit is opened. It

can then can easily be swept out with

little chance of it entering the outlet.

Replace the cover O ring when the

filter is changed.

Figure 0-5 Air filter AC50 & AC75

Remove the four screws holding the filter

cover and remove to expose the air filter

element.

7.11 VALVE GEAR

Typical main valve assemblies are

shown in Figure 7-9 and Figure 7-10

The areas arrowed should be checked

regularly for wear or damage. Worn

parts should be replaced. The main

valve is located on the underside of the

top cover.

Figure 0-6 Air filter 18 & 25cfm units

Undo the central nut holding the air filter

cover and remove to expose the filter

element.

Figure 0-7 Air filter 60cfm units

Undo the six nuts holding the top cover and

remove the top cover complete to expose the

air filter element.

7.10.2 High Capacity Air Filter

25cfm and 60cfm vacuum pumps have the

option of a high capacity air filter which is

located externally as shown in Figure 7-8 The

high capacity filter is fitted in lieu of the

standard element.

25PLTVLVA.PC

Figure 0-9 6cfm main valve assembly

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 13 of 16

Page 14

Manual No/Rev

W72-002 / 11

Operators Handbook for

Diesel Driven Pump Sets

Figure 0-10 25 & 60cfm main valve assembly

7.12 SURGE CONTROL VALVE

Figure 0-11 Surge control valve

On 25 and 60cfm priming tanks a

surge control valve is fitted. This

should be checked regularly for signs

of wear or damage. Components

arrowed in Figure 7-11 are vulnerable

to wear and should be replaced if worn

excessively. The valve seat should be

greased to prevent seizure.

---“---

60PTVLVA.PCX

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 14 of 16

Page 15

8. FAULT FINDING GUIDE

Pump Fails to Prime

Are

NO

all plugs

tight?

NO YES

Operators Handbook for

Diesel Driven Pump Sets

Disconnect suction hose

Blank off suction entry

Fit vacuum gauge

Reading

between

85 - 89 .5 kpa

(28.5 0 30 ft H20)?

Manual No/Rev

Check vertical

suction lift

W72-002E / 11

Rectify

Fit Vacuum Gauge

(28.5 0 30 ft H20)?

NO

Is oil level

correct?

YES

YES

Type of

unit?

OTHERS

Test the Vacuum

Pump directly

Reading

between

85 - 89 .5 kpa

NO

Rectify

AC

50/75

YES

Is vacuum

pressure seal

leaking?

Rectify

Is the

mini ball valve

open?

YES

Is reflux

ball seating

properly?

YES

NO

YES

NO

YES

NO

Rectify

Rectify

Is Vacuum

Pump filter

blocked?

6.1m (20ft) for AC50/75

8.53m (28ft) for AC80/100

9.75m (32ft) for others?

leaking, collapsed

or blocked?

NO

Rectify

Lift< or =

NO

Are hoses

NO

Is intake

blocked?

NO

Is impeller

blocked?

YES

Move

Pump

YES

Rectify

YES

Rectify

YES

Rectify

YES

Rectify

Is belt drive

tension OK?

YES

Excessive wear.

Remove pump &

either overhaul or fit

new or exchange

Vacuum Pump

NO

Rectify

NO

Rectify

Is float

gear free and

intact?

Rectify

casing free from

NO

Is pump

holes?

RectifyNO

YES

Are all

joints sound &

leak free?

YES

YES

Check impeller wear

plate clearances

and rectify

Is the

pump or NRV

blocked or

damaged?

NO

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 15 of 16

Page 16

Manual No/Rev

W72-002 / 11

Operators Handbook for

Diesel Driven Pump Sets

9.TECHNICAL DATA

PUMP TYPE AC50 &

AC75

VACUUM PUMP (f3/m) 6 18 25 60 25 60

SOLIDS HANDLING

CAPABILITY (mm dia)

LISTER ENGINE TYPE AD1 TR1 TR2 LPW3 TS3 TR3 LPW 4 CD4

FUEL TANK CAPACITY

(litres)

APPROX. RUNNING TIME

ON FULL TANK (hrs)

IMPELLER BACK PLATE

CLEARANCE

IMPELLER FRONT PLATE

CLEARANCE

MECHANICAL SEAL

COOLANT/LUBRICANT

PACKING 9.5 mm

COUPLING AXIAL N/A 0.5 mm (0.020")

ALIGNMENT ANGULAR N/A 1 degree

BEARING LUBRICATION N/A Grease: Texaco Multifak All Purpose EP2

VACUUM above 300C Texaco Regular Motor oil 30 *

PUMP OIL below 300C Texaco Ursatex 10W-30 *

28 40 44 50 52 48

14 69 75 69 122 130 122

14 20 21 20 28 10

0.50

0.019 - 0.059"

0.50

0.019 - 0.059"

square x 205

mm long

3/8" square x

8.07" long

* or equivalents conforming to API CC 5F, CCMC G2.D1, MIL-L-2104B or MIL-L-46152B

AC80 &

AC100

- 1.5 mm

- 1.5 mm

100M 150

0.30

0.012 - 0.024"

0.40

0.015 - 0.024"

Mobil Velocite Oil No. 6

Texaco Rando HD10

12.7 mm square x 270 mm long

½" square x 10.6" long

or equivalent to DIN 51825: KP2\K-30

150M 200

- 0.60 mm

- 0.60 mm

10. SPARES & SERVICE

SPP Pumps operate a comprehensive Spares and Service support network throughout the world, and can be

contacted as follows:

SPARES & SERVICE Telephone: **44 (0) 1189 323123

For spare parts, supply only

For breakdowns, spare parts and on-site fitting, pump installation and commissioning, and service contracts.

ask for -

For breakdowns outside office hours.

Spares & Service Office

1420 Lakeview

Arlington Business Park

Reading, Berkshire Direct Fax line:

RG7 4SA

ENGLAND

Copies of this manual are available from the SPP Pumps Spares & Service Department by quoting reference

number W72-002E and the relevant issue number.

. ask for -

Telephone :

Spares Dept.

Service Dept.

**44 (0) 1189 323123

**44 (0) 1189 303259

11. COUPLING DETAILS (where applicable)

12. ENGINE OPERATORS HANDBOOK

The specific engine Operators Handbook from the manufacturer follow.

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 16 of 16

Loading...

Loading...