Page 1

DRIVELINE INSTALLATION

J3311-1-DSSP

AUGUST 2008

Supersedes

J3311-1-HVTSS, Dated

February 2005

Page 2

Safety Precautions

General Safety Information

To prevent injury to yourself and /or damage to the equipment:

• Read carefully all owners manuals, service manuals,

and/or other instructions.

• Always follow proper procedures and use proper

tools and safety equipment.

• Be sure to receive proper training.

WARNING: GUARDING AUXILIARY DRIVESHAFTS

We strongly recommend that a power take-off and a directly

mounted pump be used to eliminate the auxiliary driveshaft

whenever possible. If an auxiliary driveshaft is used and remains exposed after installation, it is the responsibility of the

vehicle designer and PTO installer to install a guard.

• Never work alone while under a vehicle or while repairing or maintaining equipment.

• Always use proper components in applications for

which they are approved.

• Be sure to assemble components properly.

• Never use worn-out or damaged components.

• Always block any raised or moving device that may

injure a person working on or under a vehicle.

• Never operate the controls of the power take-off or

other driven equipment from any position that could

result in getting caught in the moving machinery.

WARNING: USING SET SCREWS

Auxiliary driveshafts may be installed with either recessed or

protruding set screws. If you choose a square head set screw,

you should be aware that it will protrude above the hub of the

yoke and may be a point where clothes, skin, hair, hands, etc.

could be snagged. A socket head set screw, which may not

protrude above the hub of the yoke, does not permit the same

amount of torquing as does a square head set screw. Also a

square head set screw, if used with a lock wire, will prevent

loosening of the screw caused by vibration. Regardless of the

choice made with respect to a set screw, an exposed rotating

auxiliary driveshaft must be guarded.

WARNING: THIS SYMBOL WARNS OF POSSIBLE

PERSONAL INJURY.

WARNING: ROTATING DRIVESHAFTS

• Rotating auxiliary driveshafts are dangerous. You can

snag clothes, skin, hair, hands, etc. This can cause

serious injury or death.

• Do not go under the vehicle when the engine is running.

• Do not work on or near an exposed shaft when engine

is running.

• Shut off engine before working on power take-off or

driven equipment.

• Exposed rotating driveshafts must be guarded.

Page 3

Table of Contents

Introduction .............................................................................................................................................................. 1

Driveshaft Torque ...................................................................................................................................................... 2

Common Causes of Vibrations .................................................................................................................................. 3

Universal Joint Operating Angles .............................................................................................................................. 5

Eliminating Compound Angle Induced Vibrations ..................................................................................................... 11

Multiple Shaft Installations ........................................................................................................................................ 13

Mounting a Midship-Mounted PTO, Pump, or Auxiliary Transmission ...................................................................... 16

Maximum Safe Operating Speed ............................................................................................................................... 18

Table of Contents

Page 4

General Information

Introduction

This brochure is intended for:

• Installers who install Spicer driveshafts into an application where the transmission and axle are not in direct line with

each other, causing the driveshaft universal joints to operate at an angle.

• Anyone experiencing vibration problems with their application or their vehicle that driveshaft assembly balancing will not

correct.

• Truck Equipment Distributors who:

• Re-work a chassis to change the wheel base.

• Install a midship mounted power take-off or fire pump.

• Mount any other PTO-driven device such as a blower, hydraulic pump, or hydraulic motor.

Universal joint failures, as a rule, are of a progressive nature, which, when they occur, generally accelerate rapidly resulting in a

mass of melted trunnions and bearings.

Some recognizable signs of universal joint deterioration are:

1. Vibrations - Driver should report to maintenance.

2. Universal joint looseness - End play across bearings.

3. Universal joint discoloration due to excessive heat build-up.

4. Inability to purge all four trunnion seals when re-lubing universal joint.

Items 2) thru 4) should be checked at re-lube cycle and, if detected, reported to the maintenance supervisor for investigation.

Experience with universal joint failures has shown that a significant majority are related to lubricating film breakdown. This may

be caused by a lack of lubricant, inadequate lube quality for the application, inadequate initial lubrication, or failure to lubricate

properly and often enough.

Failures which are not the result of lubrication film breakdown are associated with the installation, angles and speeds, and manufacturing discrepancies.

Driveshaft failures through torque, fatigue, and bending are associated with overload, excessively high universal joint angles, and

drive shaft lengths excessive for operating speeds.

1

Page 5

Installation Techniques

Driveshaft Torque

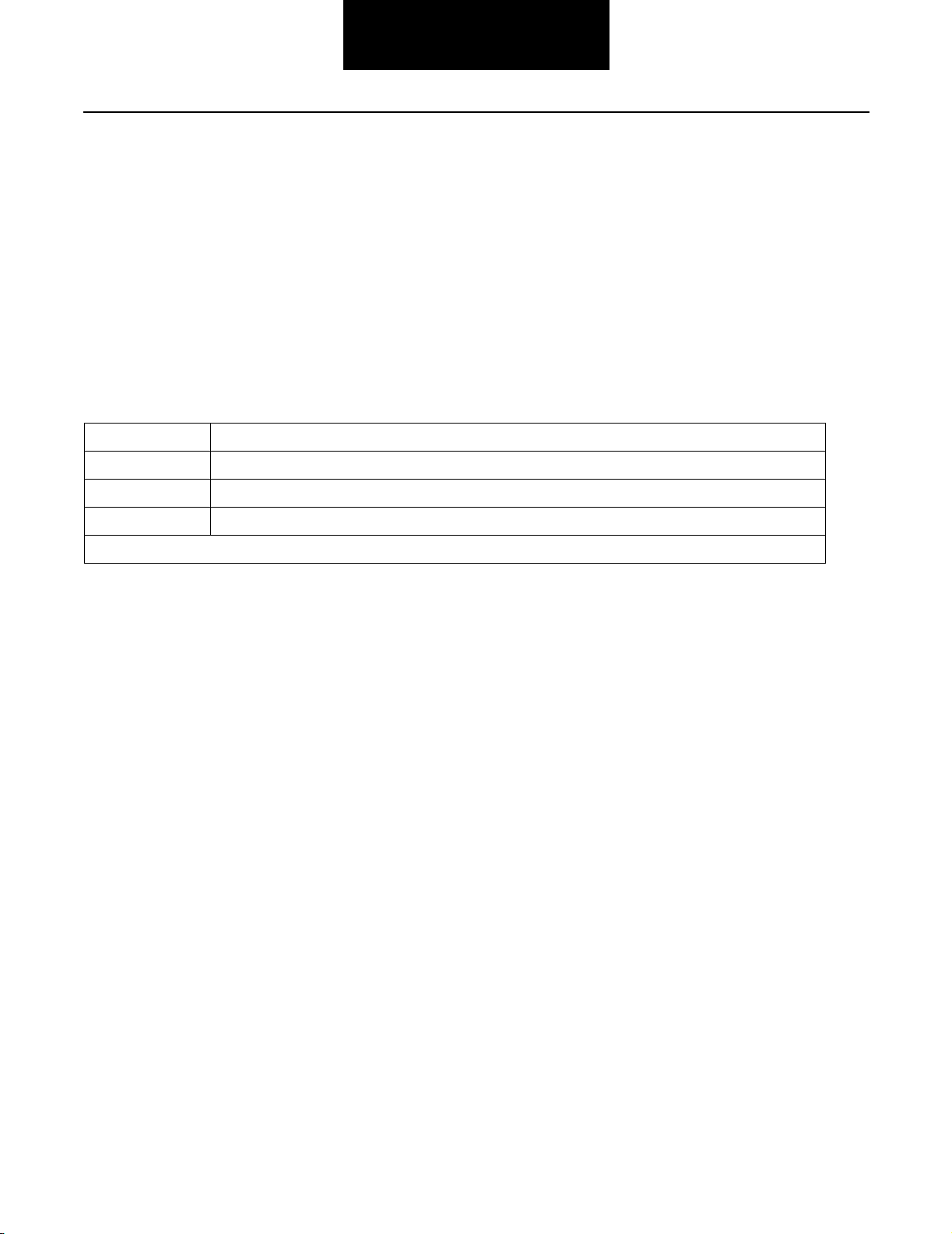

The following problems are usually a result of torque overloads:

Twisted driveshaft tube

Broken yoke shaft, slip yoke, tube yoke, flange yoke, end yoke

Broken journal cross

How much torque can be generated in your application?

Engine

Trans.

Axle

How to Calculate Torque:

LGT = T x TLGR x TE x SR x TCR x C

LGT = Maximum Driveshaft Low Gear Torque SR = Torque Converter Stall Ratio (if applicable)

T = Net Engine Torque or 95% of the Gross Engine Torque TCR = Transfer Case Ratio (if applicable)

TLGR = Transmission Low Gear Ratio (forward)* C = Transfer Case Efficiency (if applicable, 0.95)

TE = Transmission Efficiency (automatic = 0.8; manual = 0.85)

How to Calculate Wheel Slip:

WST = (.71 x W x RR) / (11.4 x AR)

WST = Wheel Slip Torque Applied to the Driveshaft RR = Tire Rolling Radius (in)

W = Axle Capacity (lbs) AR = Axle Ratio

For On Road Applications

Relate the lesser of above to Spicer universal joint ratings. If your torque exceeds the Spicer rating for the universal joint used in

your application, switch to a size with a rating compatible to your calculation. However, the series selected cannot be more than

one series below the series called for by the LGT calculation.

Driveshaft Torque

For Off Road or On-Off Road Applications

Use Low Gear Torque value only to verify or switch to a size with a rating compatible to your calculation.

2

Page 6

Installation Techniques

Common Causes of Vibrations

The three most common causes of driveshaft vibration are: Driveshaft Imbalance, Critical Speed, and Universal Joint Operating

Angles.

Driveshaft Imbalance

Eliminate the potential for balance problems before you undertake any other measures.

A driveshaft on a vehicle usually rotates at a higher rate of speed than the tire. For that reason, like tires, driveshafts should be

balanced.

Any time you build or rework a driveshaft, make sure it is dynamically balanced at, 3000 RPM for Light Duty or 2500 RPM for

Heavy Duty, to the following specifications:

Series Specification

1310, 1330 .375 oz-in total at each end of shaft *

1350, 1410 .500 oz-in total at each end of shaft *

1480 - 1880 1.00 oz-in for each ten pounds of driveshaft weight divided proportionally at each end of shaft

* Passenger Car, Light Truck, Van, and SUV only. Industrial, Mobile Off-Highway, PTO, etc. same as 1480 - 1880.

Critical Speed

Every driveshaft has a critical speed. Critical speed is the point at which a rotating driveshaft begins to bow off its normal rotating

centerline.

Driveshafts begin to vibrate as they approach critical speed. If they are operated at near critical speed for an extended period, they

often fail. This can damage the vehicle and possibly injure persons nearby.

As a driveshaft fabricator or installer, you are responsible for checking the safe operating speed of any driveshaft you fabricate or

specify into an application. Make sure it will not operate at a speed higher than Spicer’s recommended safe operating speed. Use

Spicer Calculator (P/N J 3253) to determine safe operating speed.

Checking for a Possible Critical Speed Problem

Here is what you must do to make sure you won’t have a critical speed problem:

• Determine the safe operating speed of the driveshaft you want to use in your application. Insert the tube diameter and

center-to-center installed length of the shaft you want to use into a Spicer Safe Operating Speed Calculator (P/N. J3253).

The calculator will tell you the safe operating speed of the shaft you have chosen.

• Determine the NORMAL and MAXIMUM POSSIBLE operating speed of the driveshaft.

REMEMBER:

• On vehicles with a standard transmission that have a 1:1 direct drive high gear and no overdrive, MAXIMUM POS-

SIBLE driveshaft RPM is the same as the maximum possible ENGINE RPM.

• On vehicles that have an overdrive transmission, MAXIMUM POSSIBLE driveshaft RPM is higher than maximum

possible ENGINE RPM.

3

Page 7

Installation Techniques

Maximum Possible Driveshaft RPM

To calculate the maximum possible driveshaft RPM in vehicles having an overdrive transmission, divide the maximum possible

engine RPM by the overdrive ratio. (See examples below.)

Example 1:

Max. engine RPM: 2100

Overdrive ratio: .79

2100/.79 = 2658 maximum possible driveshaft RPM

Example 2:

Max. engine RPM 6000

Overdrive ratio: .66

6000/.66 - 9091 maximum possible driveshaft RPM

Compare the maximum possible driveshaft RPM with the safe operating speed determined from the Safe Operating Speed Calculator. If the maximum possible driveshaft RPM meets or exceeds the safe operating speed determined from the calculator, you

must do whatever is required to raise the critical speed of the driveshaft you have chosen for the application.

Common Causes of

Sample Specification:

To specify a driveshaft for the application described in Example 1 above, compare the safe operating speed for the driveshaft selected with the maximum possible driveshaft RPM calculated (2658 RPM). Make sure the safe operating speed of the driveshaft

is greater than 2658 RPM.

Changing the Safe Operating Speed of a Driveshaft

A driveshaft’s safe operating speed can be raised by increasing its tube diameter or by shortening the installed center-to-center

length of the driveshaft. Changing the installed length of a driveshaft will require the use of multiple driveshafts with center bearings.

Important: The critical speed of an assembly can be affected by driveshaft imbalance, improper universal joint operating angles,

or improperly phased driveshafts. (A properly phased driveshaft has the in-board yokes of the shaft in line with each other.) Each

of the above items will tend to lower the true critical speed from the values shown on the calculator.

Since critical speed can ultimately cause driveshaft failure, it is extremely important to be very precise in all applications.

Vibration

4

Page 8

Installation Techniques

Universal Joint Operating Angles

Every Universal Joint that Operates at an Angle Creates a Vibration

Universal joint operating angles are probably the most common causes of driveline vibration in vehicles that have been reworked,

or in vehicles that have had auxiliary equipment installed.

Universal joint operating angles are a primary source of problems contributing to:

•Vibrations

• Reduced universal joint life

• Problems with other drivetrain components that may include:

- Transmission gear failures

- Synchronizer failures

- Differential problems

- Premature seal failures in axles, transmissions, pumps, or blowers

- Premature failure of gears, seals, and shafts in Power Take-Offs

When you rework a chassis or install a new driveshaft in a vehicle, make sure that you follow the basic rules that apply to universal

joint operating angles:

RULE 1: UNIVERSAL JOINT OPERATING ANGLES AT EACH END OF A DRIVESHAFT SHOULD ALWAYS BE AT LEAST 1 DEGREE.

RULE 2: UNIVERSAL JOINT OPERATING ANGLES ON EACH END OF A DRIVESHAFT SHOULD ALWAYS BE EQUAL WITHIN 1 DE-

GREE OF EACH OTHER (ONE HALF DEGREE FOR MOTOR HOMES AND SHAFTS IN FRONT OF TRANSFER CASE OR AUXILIARY

DEVICE).

RULE 3: FOR VIRTUAL VIBRATION FREE PERFORMANCE, UNIVERSAL JOINT OPERATING ANGLES SHOULD NOT BE LARGER

THAN 3 DEGREES. IF THEY ARE, MAKE SURE THEY DO NOT EXCEED THE MAXIMUM RECOMMENDED ANGLES.

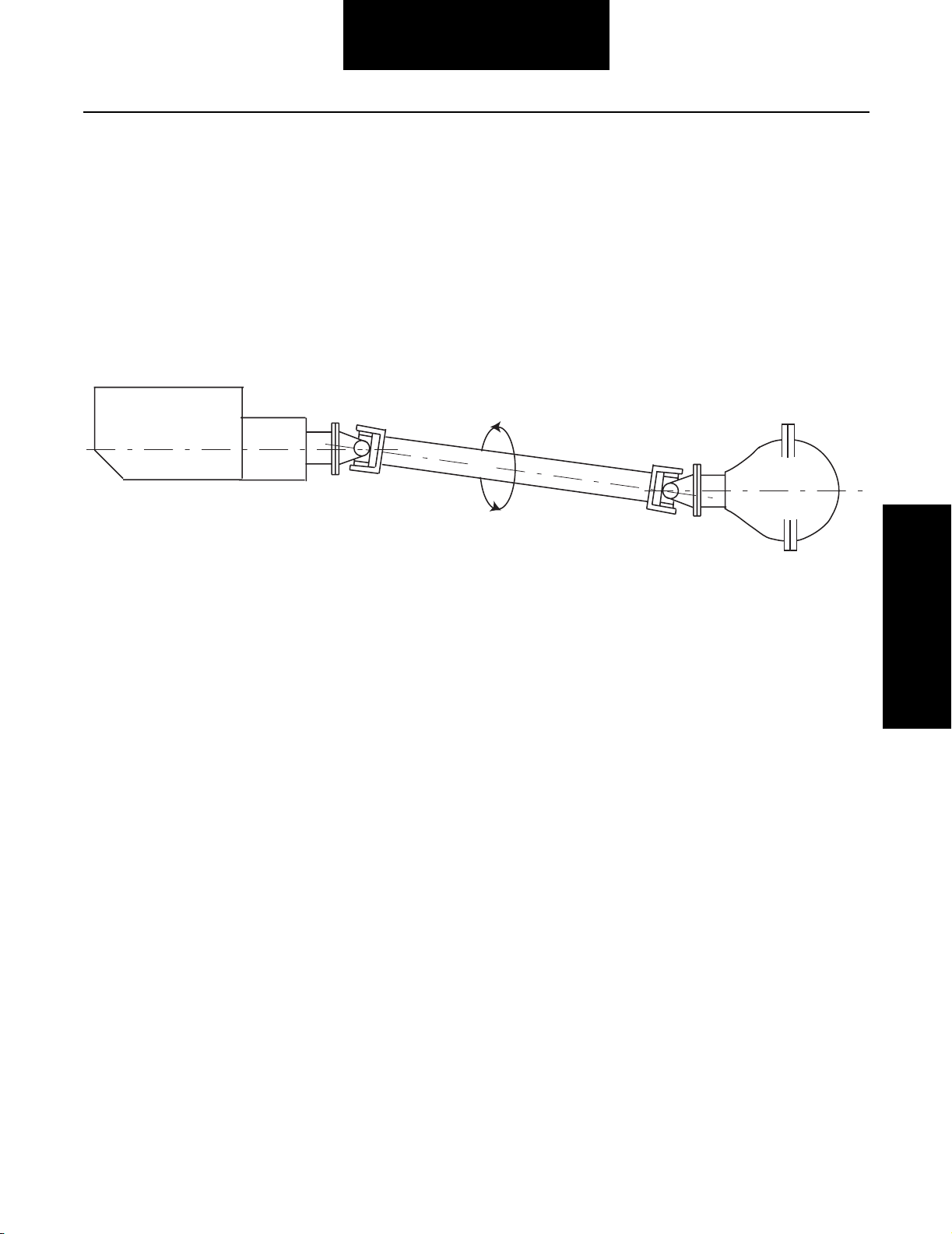

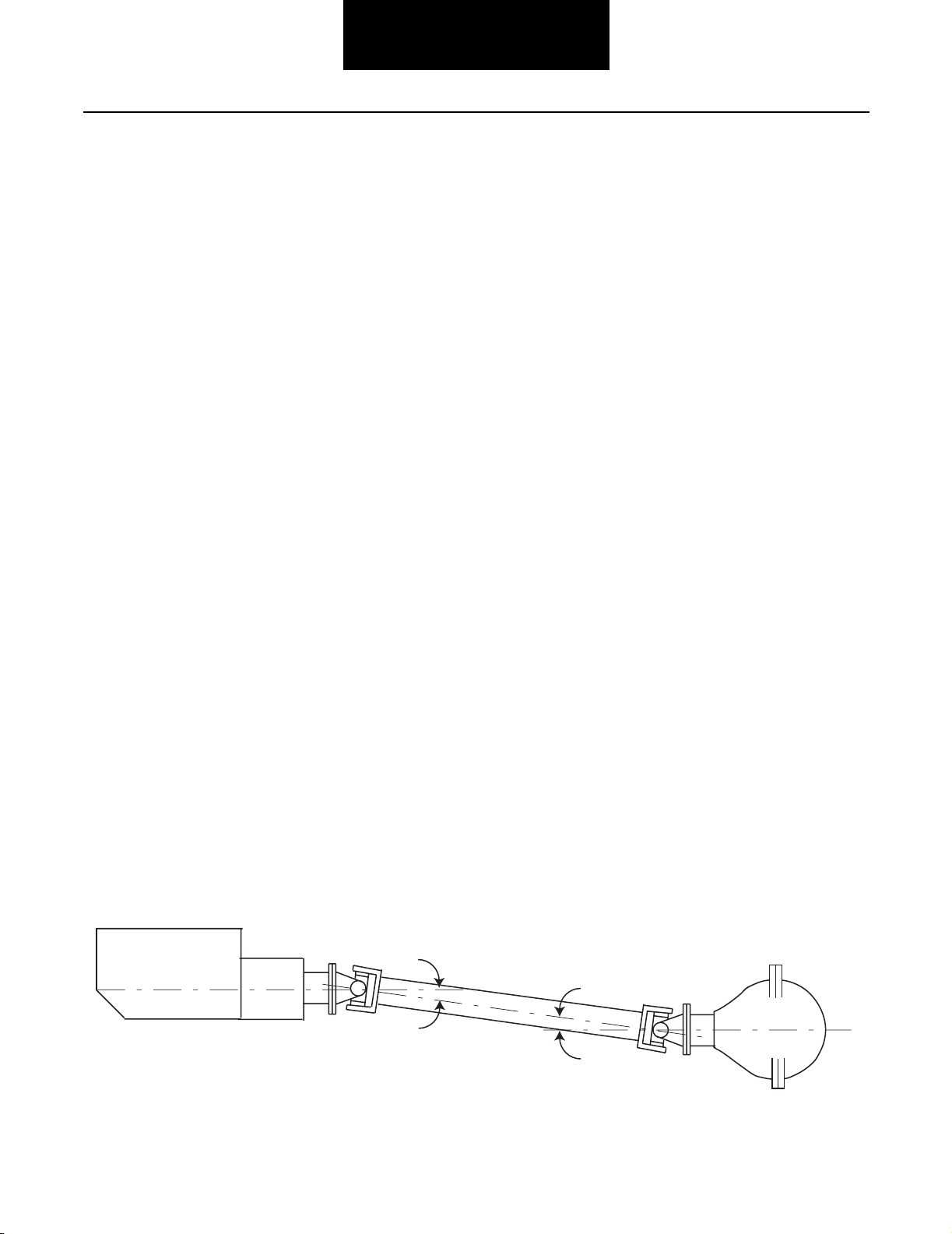

A universal joint operating angle is the angle that occurs at each end of a driveshaft when the output shaft of the transmission and

driveshaft and the input shaft of the axle and driveshaft are not in line. (See Fig 1)

The connecting driveshaft operates with an angle at each universal joint. It is that angle that creates a vibration.

Engine

Trans.

Axle

D

ri

v

es

ha

f

t

Figure 1

5

O

per

at

in

g

An

gl

es

Page 9

Installation Techniques

Reducing and Canceling Vibration

A key point to remember about universal joint operating angles: To reduce the amount of vibration, the angles on each end of a

driveshaft should always be SMALL.

To cancel an angle vibration, the universal joint operating angles need to be EQUAL within 1 degree at each end of a driveshaft.

On motor home applications and auxiliary transmission installations, the tolerance is 1/2 degree. (See Fig 2)

Figure 2

Make angles small

Axle

Trans.

Make angles equal

U-Joint Operating Angles

6

Page 10

Installation Techniques

Dana

Dana

Dana

Dana

Dana

Dana

Single Plane and Compound Universal Joint Operating Angles

There are two types of universal joint operating angles: Single Plane and Compound.

Single Plane

Single Plane angles occur when the transmission and axle components are in line when viewed from either the top or side, but

not both.

Determining the universal joint operating angle in an application where the components are in line when viewed from the top, but

not in line when viewed from the side, is as simple as measuring the slope of the components in the side view, and adding or

subtracting those slopes to determine the angle. (See Fig. 3)

These angles should be small and equal within 1 degree.

Legend

Anglemaster

Spicer

Dana

Spicer

Dana

Anglemaster

Spicer

Dana

5

d

6

Anglemaster

Engine

Spicer

Dan

a

Spicer

Anglemaster

Anglemaster

Spicer

Dana

Bubbletype

protractor

Tran s.

Anglemaster

Spicer

Dana

a

1

2

3

b

Anglemaster

4

c

Axle

Axle

Figure 3

The most convenient way to determine universal joint angles in the side view is through the use of a Spicer Anglemaster™ or a

bubble type protractor.

Using an Anglemaster or a bubble protractor, record inclination angles of drivetrain components. Set Anglemaster or protractor

on machined surfaces of engine, transmission, axle, or on machined lugs of transmission and axle yoke(s).

Note: Universal joint angles can change significantly in a loaded situation. Therefore, check vehicle loaded and unloaded to achieve

the accepted angle cancellation.

Example:

Engine-Transmission Output 4°30’ Down (1)

Main Driveshaft 7°00’ Down (2)

Input 1st Rear Axle 4°00’ Up (Input Shaft Nose Up) (3)

Output 1st Rear Axle 4°00’ Down (4)

Inter-axle Shaft 7°00’ Down (5)

Input 2nd Rear Axle 4°15’ Up (Pinion Shaft Nose Up) (6)

Note: If inclination of driveshaft is opposite connecting component, add angles to obtain the universal joint operating angle.

Angle a = (2) - (1) = 7°00’ - 4°30’ = 2°30’ (2.50°)

Angle b = (2) - (3) = 7°00’ - 4°00’ = 3°00’ (3.00°)

Angle c = (5) - (4) = 7°00’ - 4°00’ = 3°00’ (3.00°)

Angle d = (5) - (6) = 7°00’ - 4°15’ = 2°45’ (2.75°)

7

Page 11

Installation Techniques

Determining the universal joint operating angles on a driveshaft that is straight when viewed from the side and offset when viewed

from the top requires the use of a special chart (See Angle Chart). In this type of application, the centerlines of the connected

components must be parallel when viewed from the top as shown. These angles also should be small and equal within 1 degree.

(See Fig. 4)

B

x

Engine

Trans.

Axle

x

A

Angles in Top View

Figure 4

Measure dimensions "A" and "B" shown in figure 4. Use the instructions in the angle chart below to determine the size of the angle.

Look at the Angle Chart and note that the smaller the offset, the smaller the resultant angle.

To reduce the possibility of vibration, keep any offset between connected points to a minimum.

There are two things you can do to always make sure Single Plane angles are SMALL and EQUAL: Make sure the transmission

and axle are mounted so their centerlines are parallel when viewed from both the side and the top. Make sure the offset between

them is small in both views.

U-Joint Operating Angles

ANGLE CHART

12

Example: (See Fig. 4)

11

1. Measure Dimension "A"

2. Determine Dimension "B"

10

Using chart, determine angle "x" by

finding the intersection point of a

9

dimension "A" vertical line and a

dimension "B" horixontal line.

8

7

6

Dimension B (inches)

5

4

3

2

1

For Driveshafts Having An Angle in the Top View

15.0

Dimension A (inches)

o

14.0

o

13.0

o

12.0

o

11.0

o

10.0

o

9.0

8.0

o

7.0

o

o

o

6.0

o

5.0

o

4.0

o

3.0

o

2.0

o

1.0

70605040302010

Operating Angle x

8

Page 12

Installation Techniques

Compound Angles

Compound universal joint operating angles occur when the transmission and axle are not in line when viewed from BOTH the top

and side. Their centerlines, however, are parallel in both views. (See Fig. 5)

Engine

Trans.

Axle

Top View

Parallel Centerlines

Engine

Trans.

Axle

Dri

ve

s

haf

t

Side View

Parallel Centerlines

Figure 5

When you have a compound angle, you have to calculate the "True Universal Joint Operating Angle" of each universal joint. It is

the True Universal Joint Operating Angle that must meet the three rules shown on page 5.

9

Page 13

Installation Techniques

True Universal Joint Operating Angle

The True Universal Joint Operating Angle, which must be calculated for each end of the shaft with compound angles, is a combination of the universal joint operating angle in the top view, as determined from the chart, and the measured universal joint operating angle in the side view.

To determine the true universal joint operating angle for one end of a shaft, (compound angle C° in the formula shown in Fig. 6)

insert the universal joint operating angle measurement obtained in the side view and the universal joint operating angle obtained

from the chart into the formula.

o

(

2.5

0

)

S

o

(2.15 )

T

Angle in Top View (from Chart)

Compound Angle (C ) =

T = 2.15 (A calculated angle)

S = 2.5 (The measured angle)

C = 2.15 + 2.5

o

22

o

o

2 2

T + S

SideView

C = 10.873

C = 3.3 (True operating angle)

Figure 6

Do the same for the other end of the shaft. Compare the resultant calculated universal joint operating angle for each end. They

should be EQUAL within 1 degree. If they’re not, the driveshaft will vibrate.

o

U-Joint Operating Angles

10

Page 14

Installation Techniques

Eliminating Compound Angle Induced Vibrations

Compound universal joint operating angles are one of the most common causes of driveline vibration. To avoid theses problems,

remember these important points:

• When setting up an application that requires compound universal joint operating angles, always keep the centerlines of

the transmission and axle parallel in both views.

• Always keep the offset between their horizontal and vertical centerlines small.

Engine

Engine

Keep Angles Equal

Trans.

Trans.

Small Offset

Top View

Side View

and Offset Small

Less Than 3

Axle

o

Axle

Figure 7

Note: Centerlines of transmission and axle must be parallel in both top and side views to use this method of determining true

universal joint operating angle. Please contact Spicer Driveshaft Engineering if you have an application where the components cannot be installed with their centerlines parallel.

If adjustments must be made to the system:

• Install shims between the axle housing and springs to rotate the axle input yoke to change operating angles.

• Change operating angle on torque arm type suspensions by lengthening or shortening torque arms.

• Raise, lower, or shift side-to-side a pump, blower, or other piece of auxiliary equipment to change operating angles.

Note: It is important to remember to keep the centerlines of two components that are connected by a driveshaft parallel in both

the top and side views, so the operating angles will ALWAYS be equal.

11

Page 15

Installation Techniques

Angle Size

The magnitude of a vibration created by a universal joint operating angle is proportional to the size of the universal joint operating

angle. Spicer Engineers recommend true universal joint operating angles of 3 degrees or less.

Obtain the true universal joint operating angle, as explained above, and if it is greater than 3 degrees, compare it to this chart.

Driveshaft Maximum Interaxle

RPM Operating Angle Parallel Intersecting

5000 3.2° - -

4500 3.7° - -

4000 4.2° 3.8° 3.8°

3500 5.0° 4.4° 4.4°

3000 5.8° 5.1° 4.8°

2500 7.0° 6.0° 4.8°

2000 8.7° 6.0° 4.8°

1500 11.5° 6.0° 4.8°

The angles shown on this chart are the maximum universal joint operating angles recommended by Spicer Engineers and are directly related to the speed of the driveshaft. Any universal joint operating angle greater than 3 degrees will lower universal joint

life and may cause a vibration. Remember to check maximum safe driveshaft RPM by using the Spicer Safe Operating Speed Calculator.

Compound Angle

Vibrations

12

Page 16

Installation Techniques

Multiple Shaft Installations

Multiple Shaft Set Up Recommendations

In general, multiple shaft installations follow the same guidelines, except there are different recommendations for setting up the

driveline:

• For a 2-shaft application, set up the first coupling shaft (sometimes called a jackshaft) so that the universal joint operating

angle that occurs at the transmission end is 1 to 1-1/2 degrees. (See Fig. 8)

o

1 to 1-1/2

True Angle

o

Center

Bearing

Figure 8

• Try to avoid building a compound universal joint operating angle into the first coupling shaft by installing it in line with

the transmission.

• If it ends up being compound, make sure the true universal joint operating angle, determined by using the information

mentioned earlier, is 1 to 1-1/2 degrees.

Install or tilt the axle so it is mounted on the same angle as the first coupling shaft (the centerlines of the axle and the first coupling

shaft will be parallel).

Note: BY FOLLOWING THIS PROCEDURE, THE UNIVERSAL JOINT OPERATING ANGLE AT EACH END OF THE LAST SHAFT WILL

AUTOMATICALLY BE EQUAL. (See Fig. 9)

13

Page 17

Installation Techniques

True angle

o

1 to 1-1/2

o

Center

Bearing

Adjust the axle to be

on the same angle

as the first shaft

These angles will

automatically be equal

Figure 9

If there is an offset in the installation of the axle, make sure it does not create too large of a compound universal joint operating

angle. Whenever possible, mount the axle directly in line with the first coupling shaft (when viewed from the top).

Multiple Shaft

Installations

Check the actual universal joint operating angle at the rear of the first coupling shaft. If it is less than 1º and the transmission

universal joint operating angle is greater than 1.5º, rotate the end yoke at the center bearing position so that the ears of the yoke

are 90º to the ears of the tube yoke on the transmission end of the coupling shaft. (See Fig. 10) As an alternative, rotate the slip

yoke on the driveshaft 90º if the slip spline has 16 teeth.

On same angle

Rotate

Yoke

If this angle is

less than 1 , rotate yoke

as shown

o

Figure 10

14

Page 18

Installation Techniques

On applications having more than two shafts, mount the first coupling shaft as outlined in the preceding example, and each additional coupling shaft at a 1 to 1-1/2 degree universal joint operating angle to the previous coupling shaft.

Install or tilt the axle to the same angle as the last fixed coupling shaft so the centerline of the axle and the last fixed coupling shaft

are parallel.

Note: THIS ASSURES THE UNIVERSAL JOINT OPEARTING ANGLE AT EACH END OF THE LAST SHAFT WILL AUTOMATICALLY

BE EQUAL (See Fig. 11).

oo

1 to 1-1/2 Angle

Check size

of these angles.

Do not exceed

maximums.

Shaft 1

Shaft 2

Figure 11

Mount on same

angle as shaft #2

15

Page 19

Installation Techniques

Mounting a Midship-Mounted PTO, Pump, or Auxiliary Transmission

When installing a midship-mounted PTO, auxiliary transmission, or midship-mounted pump into the main driveline of a vehicle,

install it at the same angle as the transmission. Keep the offset to a minimum to reduce universal joint operating angles.

Note: Do not make the universal joint operating angle less than 1/2 degree.

Before bolting the device in place, check the universal joint operating angles that occur at each end of the driveshaft. They must

be 1 to 1-1/2 degrees and they must be equal to within 1/2 degree for this type of application.

If the device ends up being installed in direct line with the transmission, with little or no universal joint operating angle on the

joints, raise or lower it so there is enough offset to create the required 1 to 1-1/2 degree universal joint operating angle on each

end of the driveshaft. (See Fig. 12)

1/20 minimum

0

1

to 1-1/20 recommended

0

maximum

3

Equal within 1/2

0

Auxiliary

Device

Install at same angle

and in-line in top view

Figure 12

If there is only one driveshaft between the device and the rear axle, rotate the rear axle (using shims in the appropriate place) so

it is the same angle as the device. This makes the universal joint operating angle at each end of the driveshaft equal (See Fig. 13).

Check the size of the universal joint operating angles to determine if they meet recommendations.

1/20 minimum

0

to 1-1/20 recommended

1

0

maximum

3

Equal within 1/2

0

Check size of

these angles

Midship Mounted

Components

Figure 13

Install at same angle

and in-line in top view

Rotate axle to same

angle as Auxiliary

Device

16

Page 20

Installation Techniques

If there is more than one driveshaft between the device and the rear axle, install the driveshaft as outlined earlier with a 1 to

1-1/2 degree universal joint operating angle on the input end of each shaft. Then rotate the axle so it is on the same angle as the

last fixed shaft. The universal joint operating angle on each end of the last shaft will automatically be equal. (See Fig. 14)

1/20 minimum

0

to 1-1/20 recommended

1

0

3

maximum

Equal within 1/2

Install at same angle

and in-line in top view

0

1 to 1-1/2 angle minimum

o

o

Check these angles.

o

3 recommended

Mount on same angle

rotate axle if necessary

Figure 14

Mounting a Remote-Driven Pump, Blower, or Similar Device

Remote mounted-pumps, blowers, or similar devices are usually driven by a side, top, or bottom-mounted PTO and use an auxiliary driveshaft.

Many times these devices are mounted to the vehicle frame or cross member. The usual method of mounting, where the driven

device is mounted parallel with the ground without regard to the mounted angle of the PTO, will produce a vibration that may cause

failure of the PTO, pump, blower, or other driven device.

Any remote driven device must be mounted parallel and in line, if possible, with the PTO.

To select the appropriate auxiliary driveshaft for these types of applications, you should consider proper torque, safe operating

speed (which is different than the critical speed for tubular driveshafts), and angularity. (See Maximum Safe Operating Speed Chart

on page 18).

An auxiliary driveshaft must be capable of transmitting the maximum torque and RPM required by the driven equipment. For most

low-torque applications operating at less than 1200 RPM, solid bar-stock constructed driveshafts are adequate. For applications

requiring additional torque or RPMs, tubular shafts should be fabricated.

17

Page 21

Installation Techniques

Maximum Safe Operating Speed

MAXIMUM OPERATING SPEED* BY TUBE SIZE, SOLID SHAFT SIZE, AND LENGTH

*(For speeds over 6000 RPM, contact Spicer Universal Joint Division Engineering)

TUBING MAXIMUM INSTALLED LENGTH (IN INCHES) FOR GIVEN RPM

Diameter Centerline to Centerline of Joints for a Two Joint Assembly

&or

Wall Thickness Centerline of Joint to Centerline of Center Bearing for a Joint and Shaft

W - Welded RPM - Revolutions Per Minute

S - Seamless 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

1.750" x .065" W 82" 67" 58" 52" - - - - - - -

1.250" x .095" S 64" 52" 45" 40" 37" 34" 32" - - - -

2.500" x .083" W 87" 70" 62" 55" 50" 45" 43" 41" 39" 37" 35"

3.000" x .083" W - - 85" 76" 70" 64" 60" 57" 54" 51" 49"

SOLID SHAFT DIAMETER

.750" 42" 35" 30" 27" 25" - - - - - -

.812" 44" 36" 31" 28" 26" - - - - - -

.875" 46" 37" 32" 29" 27" - - - - - -

1.000" 49" 40" 35" 31" 28" - - - - - -

1.250" 55" 45" 39" 35" 32" - - - - - -

To prevent premature wear, auxiliary driveshaft breakage, and possible injury to people or equipment, be aware of the critical

speed of these types of driveshafts. Critical speed, explained earlier in this guide, is different for these solid shaft and small tube

driveshafts.

Refer to the chart above for maximum safe operating speed information on these types of shafts.

If the chart indicates that the critical speed may be a problem, use multiple shafts. Be sure to use support bearings where necessary and set up the true universal joint operating angles as indicated earlier in this guide.

As with all driveshafts, auxiliary driveshafts should be:

Maximum Operating

Speed

• Carefully installed to minimize vibrations caused by incorrect universal joint operating angles

• Capable of absorbing shock loads

• Capable of changing length as needed

• Guarded so as to prevent inadvertent entanglement

18

Page 22

Installation Techniques

Special Notes Regarding Auxiliary Driveshafts

WARNING: Working on or near an auxiliary driveshaft when the engine is running is extremely dangerous and should be avoided.

You can snag clothes, skin, hair, hands, etc. This can cause serious injury or death.

• Shut off engine before working on power take-off or driven equipment.

• Do not go under the vehicle when the engine is running.

• Do not engage or disengage driven equipment by hand from under the vehicle when the engine is running.

• Fasteners should be properly selected and torqued to the manufacturer’s specifications.

• If a setscrew protrudes above the hub of an end yoke, you may want to replace it with a recessed (Allen-type) setscrew.

• If you decide that a recessed setscrew does not have enough holding power for your application and you must use a

protruding setscrew, be sure no one can come in contact with the rotating driveshaft or the protruding setscrew.

• Exposed rotating driveshafts must be guarded!

• Lubricate auxiliary driveshafts according to manufacturer’s specifications.

19

Page 23

Page 24

Dana Holding Corporation

Spicer Service Parts

PO Box 321

Toledo, Ohio 43697-0321

1-800-SAY-DANA (729-3262)

www.spicerparts.com

Dana Holding Corporation

Spicer Service Parts - Canada

5095 South Service Road

Beamsville, Ontario LOR 1BO

Dana Holding Corporation

Spicer Service Parts - International

(419) 861-6325

J3311-1-DSSP

8/08

Printed in U.S.A

© Dana Limited 2008.

All rights reserved.

Loading...

Loading...