Page 1

Spicer® Tandem Drive Axles

Sevice Manual

Spicer® Tandem Drive Axles

AXSM-0042

September 2007

Models:

D/R440 D/R460

D/R480 D/R485

D/R461 D/R462

D/R463 D/R521

D/R581 D/R601

D/R651 D/R652

D/R653

Page 2

Warnings and Caution

Warning

The description and specifications contained in this service

publication are current and the time of printing.

Dana Corporation reserves the right to discontinue or to modify its models and/or procedures and to change specifications

at any time without notice.

Important Notice

This symbol is used throughout this manual to call

attention to procedures where carelessness or failure

to follow specific instructions may result in personal

injury and/or component damage.

Departure from the instructions, choice of tools,

materials and recommended parts mentioned in this

publication may jeopardize the personal safety of the

service technician or vehicle operator.

Always use genuine Dana replacement parts.

Any reference to brand names in this publication is made simply as an example of the types of tools and materials recommended for use and should not be considered an

endorsement. Equivalents, if available, may be used.

WARNING

Failure to follow indicated procedures creates a high

risk of personal injury to the servicing technician.

CAUTION

Failure to follow indicated procedures may cause

component damage or malfunction.

IMPORTANT

Highly recommended procedures for proper service

of this unit.

NOTE: Additional service information not covered in

the service procedures.

TIP: Helpful removal and installation procedures to

aid in the service of this unit.

i

Page 3

Table of Contents

Table of Contents - Visual

Wheel

Differential

Assembly

Page 68-82

Carrier Assembly

Page 45-56

Drive Pinion

Page 57-67

Wheel End

Page 99-101

Power Divider

Page 24-44

Seals

Page 92-93

Table of Contents

Ring Gear

Page 82-83

Wheel End Seal

Page 95-96

Wheel Adjustment

Systems

Page 97-98

Wheel

Differential Lock

Page 83-90

Housing and

Rear Cover

Assembly

Page 91

Housing Breather

Page 94

Differential

Lockout

Page 17-22

Differential

Carrier Assembly

Page 11-16

Lubrication

Page 102-106

Torque Chart

Page 107-108

ii

Page 4

Table of Contents

Introduction .........................................................1

Failure Analysis ...................................................7

Inspection ...........................................................9

Differential Carrier Assembly - Parts .................11

Differential Lockout ...........................................17

Power Divider

Power Divider - Parts Exploded View........................23

Remove Power Divider............................................. 24

Remove Power Divider from Differential Carrier

(with carrier removed from axle housing)................ 25

Disassemble, Assemble and Overhaul

the Power Divider.....................................................27

Install Power Divider on Differential Carrier

(with carrier assembled to axle housing) .................. 38

Install Power Divider on Differential Carrier

(with carrier removed from axle housing) ................. 40

Dissasemble Differential Carrier

(with power divider removed) ...................................54

Drive Pinion

Drive Pinion - Parts Exploded View............................ 57

Disassemble and Overhaul Drive Pinion.................... 58

Install Drive Pinion Assembly.................................... 65

Wheel Differential Assembly

Wheel Differential Assembly

- Parts Exploded View ............................................... 68

Housing and Rear Cover Assembly

- Parts Exploded View ............................................... 91

Seals.................................................................. 92

Housing Breather .............................................. 94

Wheel End Seal - Parts Exploded View .............95

Remove and Overhaul Wheel End Seal .............96

Wheel Adjustment Systems ..............................97

Verify Wheel End-play Procedure ......................99

Lubricate Wheel End ....................................... 100

Lubrication ......................................................102

Lube Change Intervals ....................................103

Change Lube ...................................................104

Standpipes ......................................................105

Torque Chart ...................................................107

Appendix

Wheel Differential Lock ...........................................109

Differential Lock Theory of Operation ....................110

Control Systems ....................................................111

Dual Range Axle Shift Systems ..............................113

Troubleshooting .....................................................120

Proper Vehicle Towing ...........................................122

Axle Shift System Components ..............................124

Inter-Axle Differential Lockout

With Interlock Control Valve (straight-air type) ......126

Theory of Operation ...............................................129

Power Flow and Torque Distribution ......................130

Lubrication .............................................................132

Torque Distribution in Low Range .........................136

iii

Page 5

Introduction

General Information

Dana Corporation, Axle & Brake Division, presents this publication to aid in maintenance and overhaul of Dana tandem

drive axles. Instructions contained cover the models listed.

Their design is common, with differences in load capacity. Capacity variations are achieved by combining basic differential

carrier assemblies with different axle housings, axle shafts and

wheel equipment.

The suffix letter “P” in the model number indicates lube pump

is standard. Pump models are equipped with a gerotor pump,

designed to provide additional lubrication to the inter-axle differential and related parts.

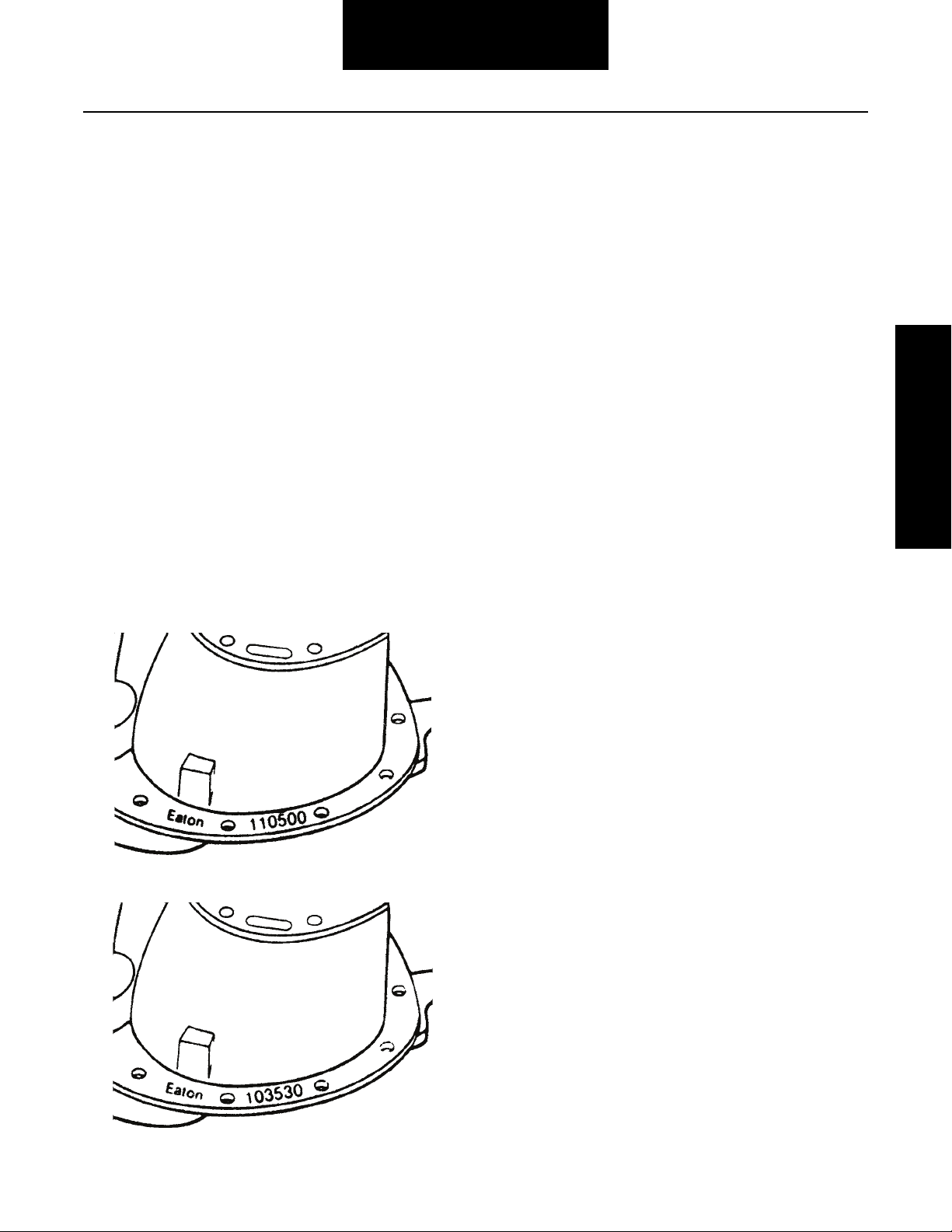

Carrier Design and Identification

(DT440-P, DT460-P, DT480-P and DP440-P through DP650P)

On August 1, 1981, these axles were converted to a new configuration which includes redesign of the axle differential carrier; input shaft bearing, involute side gear and axle shaft spline

configuration. For carrier identification, see illustrations:

Axles built after August 1, 1981 with Carrier Casting No.

110500

Note: Refer to Dana Parts Book AXIP-0108 for parts informa-

tion.

Input Shaft

Input shaft with Carrier Casting 110500 is equipped with a tapered roller bearing. Casting 103530 uses a ball bearing.

Input Shaft Bearing Spacer

Used only with Carrier Casting 110500.

Pinion Bearing Sleeve

Used only with Carrier Casting 103530.

Pinion Helical Gear Spacer

Used only on DT/DP440-P and DT/DP460-P (ratios 3.90-6.17).

Output Shaft Rear Bearing Retaining Washer

Used only on DT440-P - DT485-P and DP440-P - DP650-P.

Lube Pump Drive Shaft

The drive shaft on early pump design is equipped with a woodruff key. On late pump design, the key is eliminated. The drive

shaft end has two machined flats and the drive gear mounting

hole is shaped to accommodate these flats.

General Information

Axles built before August 1, 1981 with Carrier Casting No.

103530

1

Page 6

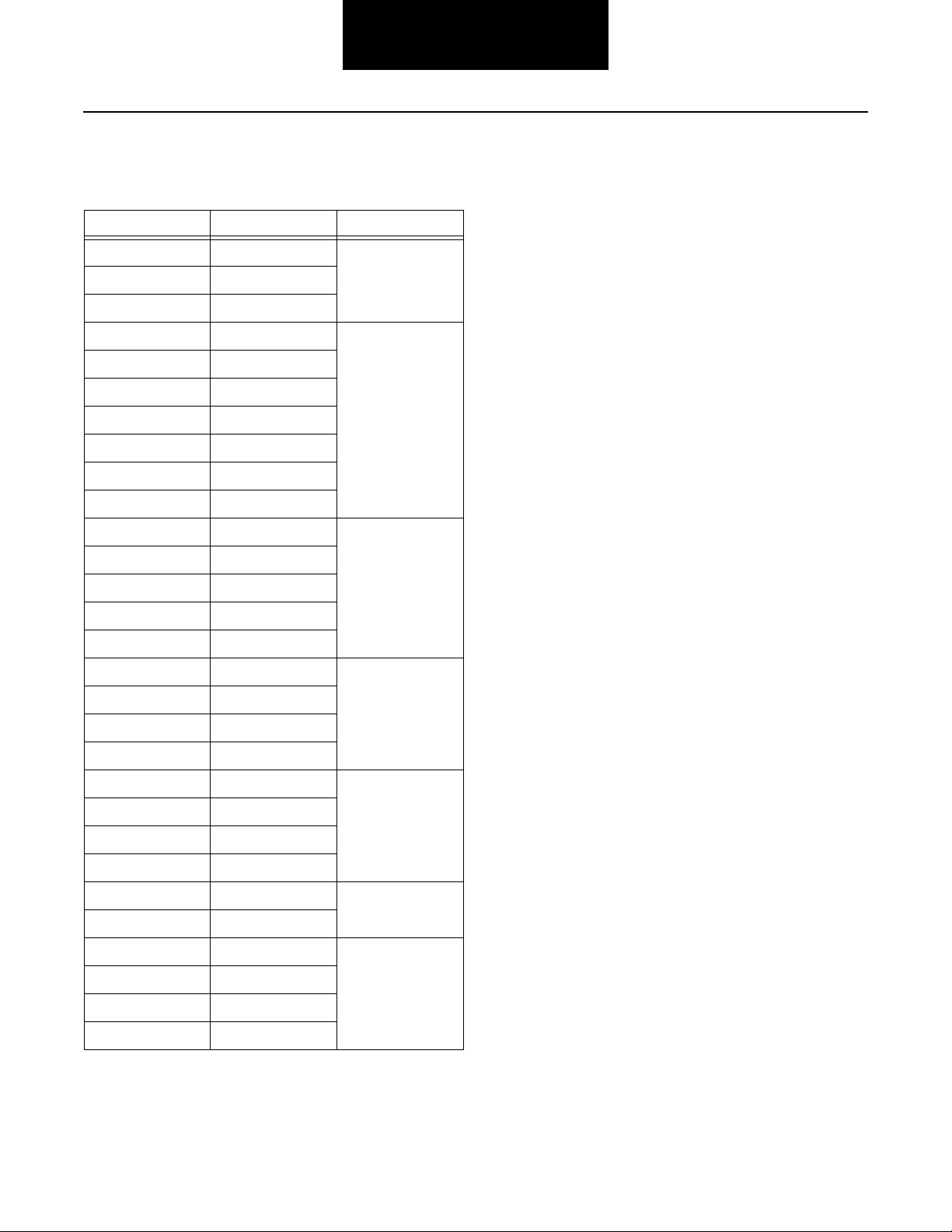

Model Listing

General Information

The following models are included in this publication:

Forward Axle Rear Axle Load Capacity

DP440-P 44,000 lbs.

DS440-P RS440

DT440-P

DP460-P 46,000 lbs.

DS460-P RS460

DT460-P

DD461-P RD461

DP461-P

DS461-P RS461

DT461-P

DP480-P 48,000 lbs.

DS480-P RS480

DT480-P

DP485-P

The suffix letter "P" in the model number indicates the axle is

equipped with a lube pump which provides positive lubrication

in the inter-axle differential and other power divider parts.

Model variations and parts identification information is included throughout this manual. For more detailed parts information, refer to your Dana parts books.

DT485-P

DD521-P RD521 52,000 lbs.

DP521-P

DS521-P RS521

DT521-P

DP580-P 58,000 lbs.

DD581-P RD581

DS581-P RS581

DP581-P

DP601-P 60,000 lbs

DT601-P

DP650-P 65,000 lbs

DP651-P

DT461-P

DP652-P

2

Page 7

Model Information

General Information

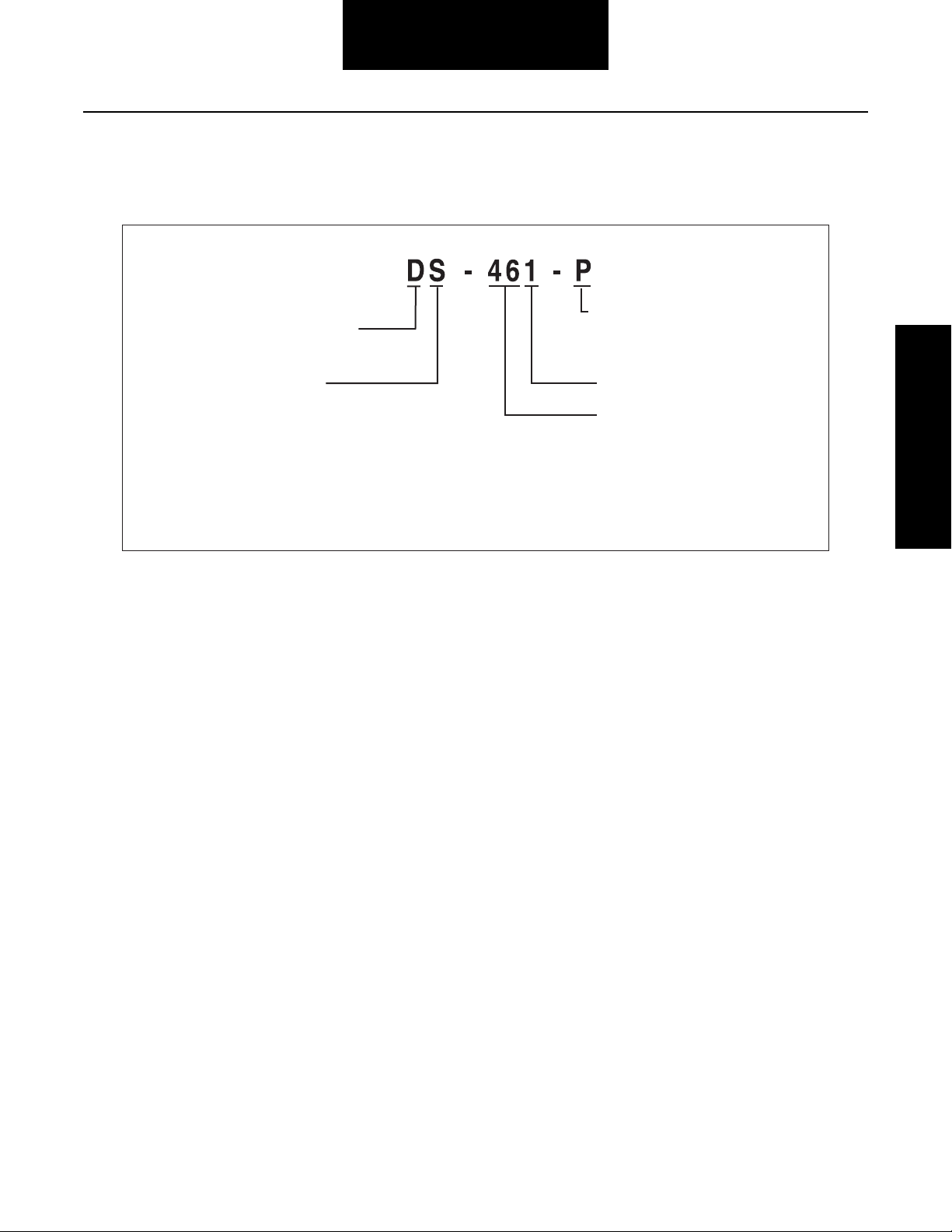

Gearing

D - Forward Tandem Axle

R - Rear Tandem Axle

S - Single Reduction

D - Single Reduction with Wheel

Differential Lock

T - Dual Range

P - Planetary Double Reduction

Example:

DS = Forward Tandem Axle/Single Reduction

RS = Rear Tandem Axle/Single Reduction

Lube Pump

P = Standard

(P) = Optional

Design Level

Capacity (x 1000 lbs.)

Example: 46 = 46,000 lbs.

General Information

3

Page 8

General Information

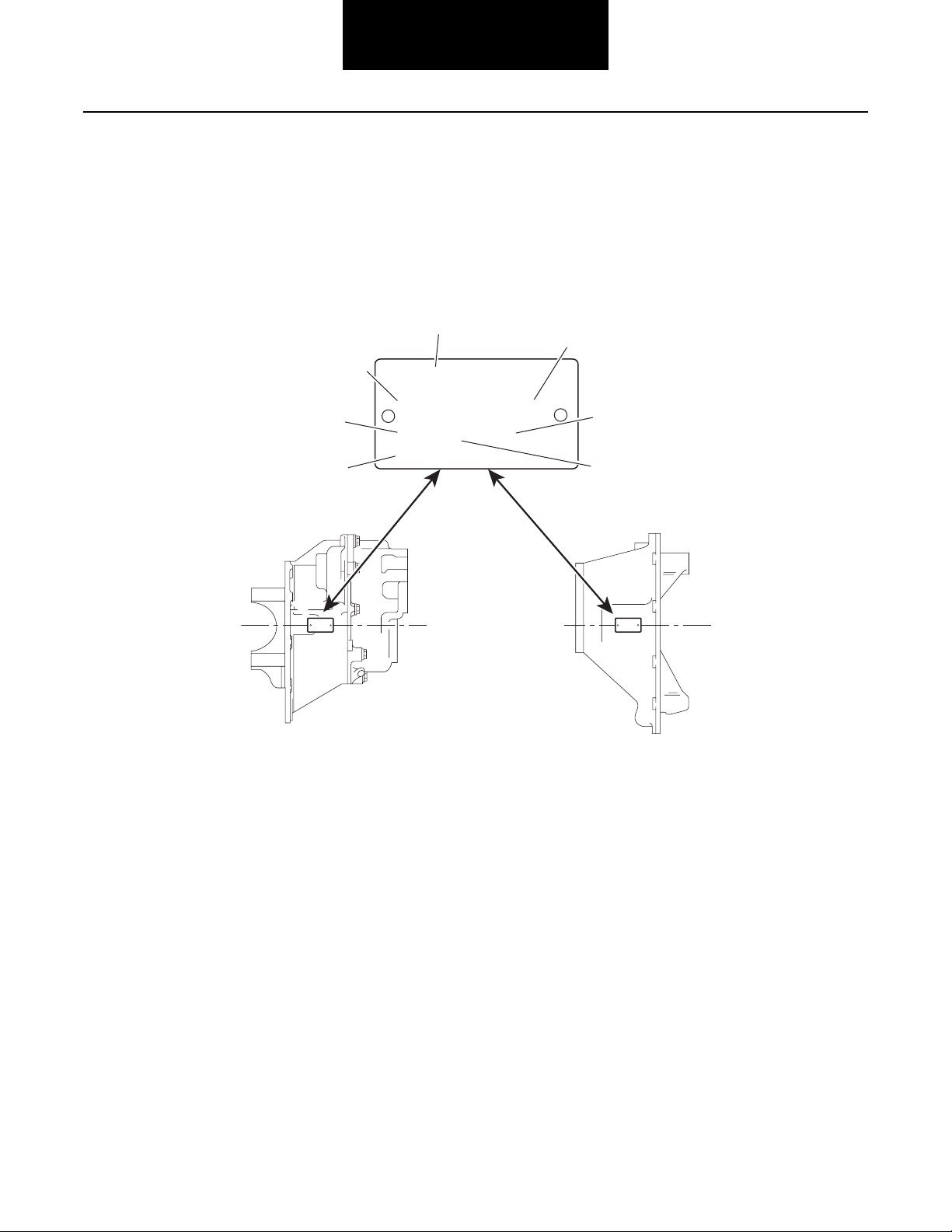

Model Identification

Drive Axle

Note: Tags that do not include all the information shown here

are older models (before May 1987).

4

3

CUST. PART NO.

Spicer

SPEC. SERIAL NO.

2

5

®

6

MODEL PART NO. RATIO

1

®

CUST. PART NO.

Spicer

SPEC. SERIAL NO.

MODEL PART NO. RATIO

MADE IN:

MADE IN:

Data plate is located on

the axle centerline

7

®

CUST. PART NO.

Spicer

SPEC. SERIAL NO.

MODEL PART NO. RATIO

MADE IN:

Forward Axle (Side View) Rear Axle (Top View)

1 - Country or origin

2 - Axle model identification

3 - Specification number assigned to the axle built by Spicer. Identifies all component parts of the axle including special OEM

requirements such as yokes or flanges.

4 - OEM part number assigned to the axle build

5 - Carrier assembly serial number assigned by the manufacturing plant

6 - Axle gear ratio

7 - Carrier assembly production or service part number

4

Page 9

General Information

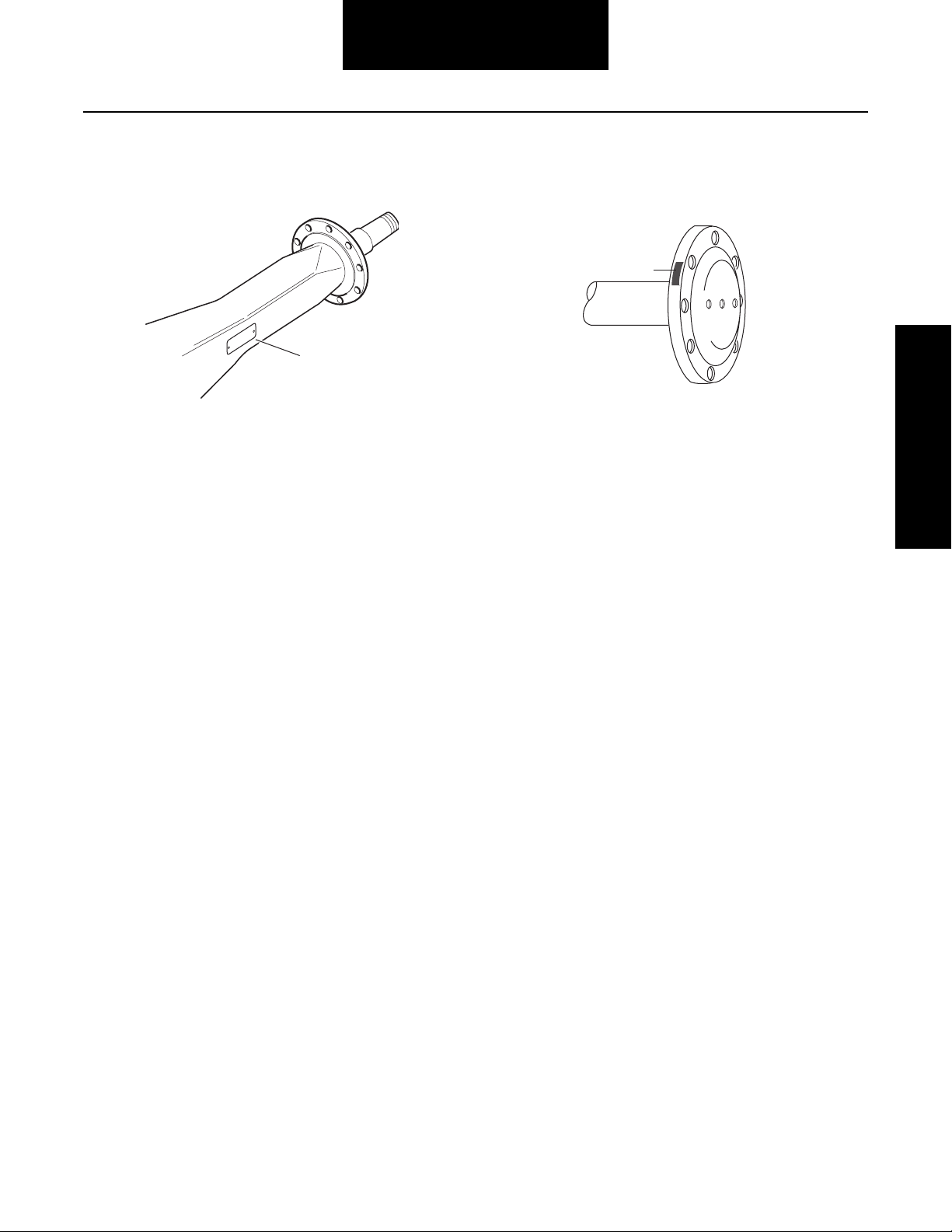

Part Identification

Axle Housing Axle Shaft

®

Spicer

PT. NO.

O.

HSG. CAP. LBS.

E IN

HSG. I.D. N

HOUSING MAD

1 - ID Tag 2 - Axle shaft part number

1

2

General Information

5

Page 10

General Information

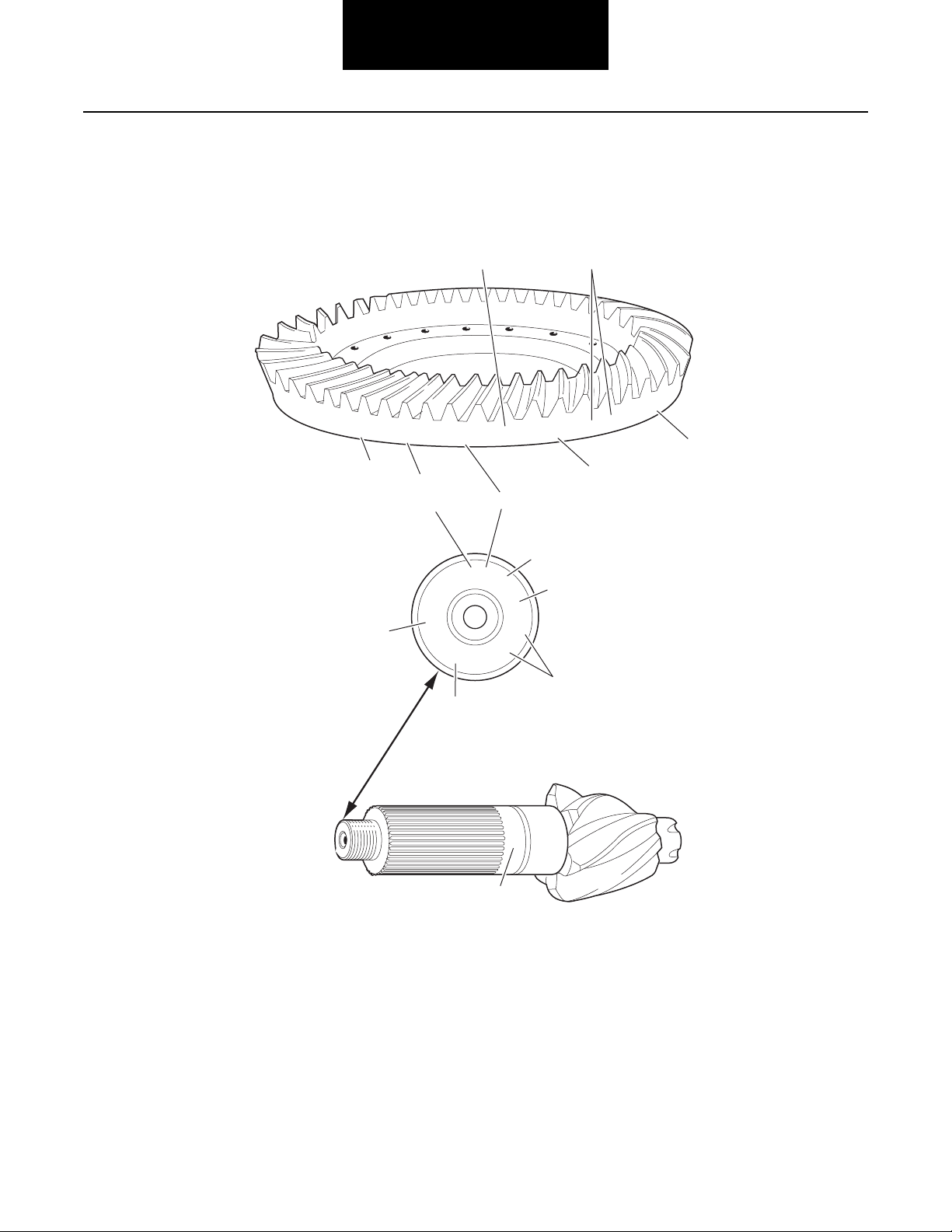

Ring Gear and Pinion

Note: Ring gear and drive pinion are matched parts and must

be replaced in sets.

127381

1

SPICER

7

7

5

SPICER

127

1

41-8

8-41

127428

8

NL2

3

L7038

G

17

OF

4

6

2

8

127

G

0H

6

17

3

1 - Part number

2 - Number of ring gear teeth

3 - Manufacturing numbers

4 - Matching gear set number

5 - Number of pinion teeth

6 - Date code

7 - Indicates genuine Spicer parts

8 - Heat code

6

L

7

6-39

JD77

85405

86

0

3

8

4

Page 11

Failure Analysis

Failure Analysis

Failure analysis is the process of determining the original

cause of a component failure in order to keep it from happening again. Too often, when a failed component is replaced without determining its cause, there will be a recurring failure. If a

carrier housing is opened, revealing a ring gear with a broken

tooth, it is not enough to settle on the broken tooth as the

cause of the carrier failure. Other parts of the carrier must be

examined. For a thorough understanding of the failure and

possible insight into related problems, the technician needs to

observe the overall condition of the vehicle.

No one benefits when a failed component goes on the junk pile

with the cause unknown. Nothing is more disturbing to a customer than a repeat failure. Systematically analyzing a failure

to prevent a repeat occurrence assures quality service by

avoiding unnecessary downtime and further expense to the

customer.

The true cause of a failure can be better determined by knowing what to look for, determining how a piece of the equipment

was running and learning about previous problems. In the case

of a rebuilt rear axle, mismatched gears may have been installed. The more successful shops prevent repeat equipment

failures by developing good failure analysis practices. Knowing

how to diagnose the cause of a premature failure is one of the

prerequisites of a good heavy-equipment technician.

How to Diagnose a Failure

The following five steps are an effective approach to good failure diagnostics.

1. Document the problem.

2. Make a preliminary investigation.

3. Prepare the parts for inspection.

4. Find the cause of the failure.

5. Correct the cause of the problem.

Document the Problem

Here are some guidelines for starting to learn about a failure,

including questions to ask:

• Talk to the operator of the truck.

• Look at the service records.

• Find out when the truck was last serviced.

• Ask: In what type of service is the truck being used?

• Ask: Has this particular failure occurred before?

• Ask: How was the truck working prior to the failure?

Failure Analysis

You need to be a good listener. Sometimes, insignificant or unrelated symptoms can point to the cause of the failure.

• Ask: Was the vehicle operating at normal temperatures?

• Ask: Were the gauges showing normal ranges of operation?

• Ask: Was there any unusual noise or vibration?

After listening, review the previous repair and maintenance

records. If there is more than one driver, talk to all of them and

compare their observations for consistency with the service

and maintenance records. Verify the chassis Vehicle Identification Number (VIN) number from the vehicle identification

plate, as well as the mileage and hours on the vehicle.

7

Page 12

Failure Analysis

Make a Preliminary Investigation

These steps consist of external inspections and observations

that will be valuable when combined with the results of the

parts examination.

• Look for leaks, cracks or other damage that can point

to the cause of the failure.

• Make note of obvious leaks around plugs and seals.

A missing fill or drain plug would be an obvious cause

for concern.

• Look for cracks in the carrier housing (harder to see,

but sometimes visible).

• Does the general mechanical condition of the vehicle

indicate proper maintenance or are there signs of neglect?

• Are the tires in good condition and do the sizes

match?

• If equipped with a torque-limiting device, is it working

properly?

During the preliminary investigation, write down anything out

of the ordinary for later reference. Items that appear insignificant now may take on more importance when the subassemblies are torn down.

Find the Cause of the Failure

Here begins the real challenge to determine the exact cause of

the failure. Keep in mind that there is no benefit to replacing a

failed part without determining the cause of the failure. For example, after examining a failed part and finding that the failure

is caused by a lack of lubrication, you must determine if there

was an external leak. Obviously, if there is an external leak, just

replacing the failed gear is not going to correct the situation.

Another important consideration here is to determine the specific type of failure which can be a valuable indicator for the

cause of failure. The following pages show different types of

failures and possible causes. Use this as a guide in determining types of failures and in correcting problems.

Correct the Cause of the Problem

Once the cause of the problem has been determined, refer to

the appropriate service manual to perform the repairs.

Prepare the Parts for Inspection

After the preliminary investigation, locate the failure and prepare the part for examination. In carrier failure analysis, it may

be necessary to disassemble the unit.

• When disassembling subassemblies and parts, do

not clean the parts immediately since cleaning may

destroy some of the evidence.

• When tearing down the drive axle, do it in the recommended manner. Minimize any further damage to the

unit.

• Ask more questions when examining the interior of

the carrier. Does the lubricant meet the manufacturer

specifications regarding quality, quantity and viscosity? As soon as you have located the failed part, take

time to analyze the data.

8

Page 13

Inspection

Inspection

Clean

1. Wash steel parts with ground or polished surfaces in

solvent. There are many suitable commercial solvents available. Kerosene and diesel fuel are acceptable.

WARNING

Gasoline is not an acceptable solvent because of its extreme

combustibility. It is unsafe in the workshop environment.

2. Wash castings or other rough parts in solvent or

clean in hot solution tanks using mild alkali solutions.

Note: If a hot solution tank is used, make sure parts are heated

thoroughly before rinsing.

3. Rinse thoroughly to remove all traces of the cleaning

solution.

4. Dry parts immediately with clean rags.

5. Oil parts.

• If parts are to be reused immediately: Lightly oil.

• If parts are to be stored: Coat with oil, wrap in

corrosion resistant paper and store in a clean,

dry place.

Note: Replace conventional gaskets with silicone rubber gas-

ket compound (included in many repair kits). The compound provides a more effective seal against lube

seepage and is easier to remove from mating surfaces

when replacing parts.

1

Inspection

2

1 - Axle housing

2 - Machined surface

Inspect Components

Inspect all steel parts for:

• Notches, visible steps or grooves created by wear

Inspect Axle Housing

Axle housing inspection and repairs are limited to the following

checks or repairs:

• Visually inspect axle housing for cracks, nicks and

burrs on machined surfaces.

• Check carrier bolt holes and studs for foreign material.

• Replace damaged fasteners. Look for loose studs or

cross threaded holes.

CAUTION

Any damage which affects the alignment or structural integrity of the housing requires housing replacement. Do not repair by bending or straightening . This process can affect

the material's properties and cause it to fail completely under load.

• Check all seals and gaskets.

• Pitting or cracking along gear contact lines

• Scuffing, deformation or discolorations. These are

signs of excessive heat in the axle and are usually related to low lubrication levels or improper lubrication

practices.

In addition, inspect the following for damage:

• Differential gearing

• Bearings for loose fit on drive pinion, pilot bearing,

and differential bearings

• All fasteners for rounded heads, bends, cracks or

damaged threads.

• Inspect machined surfaces of cast or malleable parts.

They must be free of nicks, burrs, cracks, scoring,

and wear.

• Look for elongation of drilled holes, wear on surfaces

machined for bearing fits and nicks or burrs in mating

surfaces.

9

Page 14

Inspection

Inspect Primary Gearing

Before reusing a primary gear set, inspect teeth for signs of excessive wear. Check tooth contact pattern for evidence of incorrect adjustment.

Check Input Shaft End-play (Forward Axle)

Note: Before disassembling the power divider, measure and

record input shaft end-play.

See illustration for steps 1-3.

1. Position dial indicator at yoke end of input shaft.

2. Push in on input shaft and zero the dial indicator.

3. Using a pry bar, move input shaft axially and measure/record end-play.

3

Check Output Shaft End-play

(Forward Axle)

See illustration for steps 1-3.

1. Position dial indicator at yoke end of output shaft.

2. Push in on output shaft and zero the dial indicator.

3. Using a pry bar, move input shaft axially and measure/record end-play.

3

2

1

2

1

Adjustment

Correct end-play for a new assembly is .003" to .007". The

maximum end-play for a used assembly is no more than .014".

If end-play is incorrect, determine shim pack changes as follows:

Add shims to increase end-play

Desired end-play (New Parts) 0.003" to 0.007"

Measured end-play (Step 3) 0.001”-0.001”

Add shims to provide desired end-play 0.002" to 0.006"

Remove shim to decrease end-play

Measured end-play (Step 3) 0.015" – 0.015"

Desired end-play (New Parts) 0.003” to 0.007”

Remove shims to provide desired endplay

0.012” to 0.008”

Adjustment

Correct end-play for a new assembly is .001" to .005". The

maximum end-play for a used assembly is no more than .005".

If end-play is incorrect, contact Dana.

10

Page 15

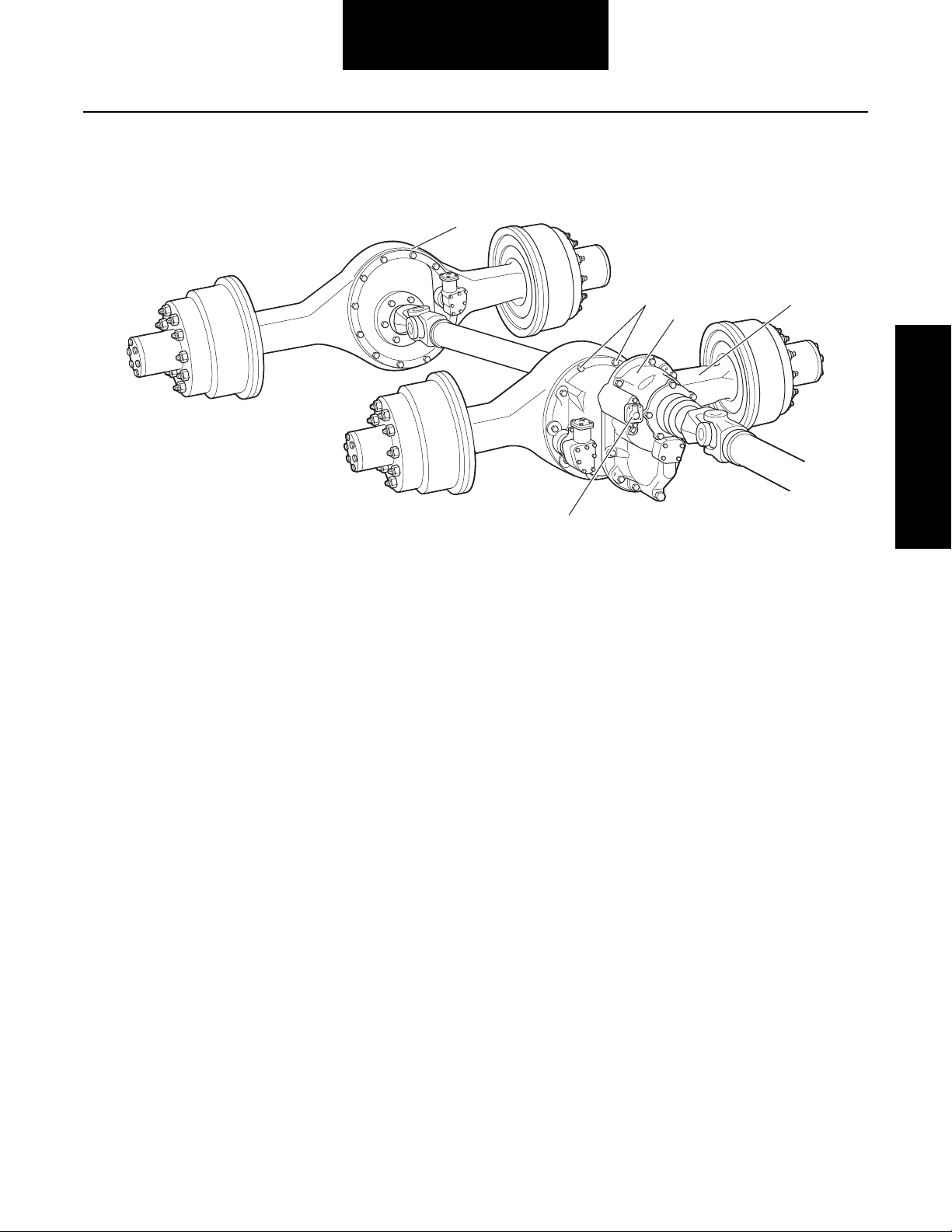

Differential Carrier Assembly

y

Differential Carrier Assembly - Parts

5

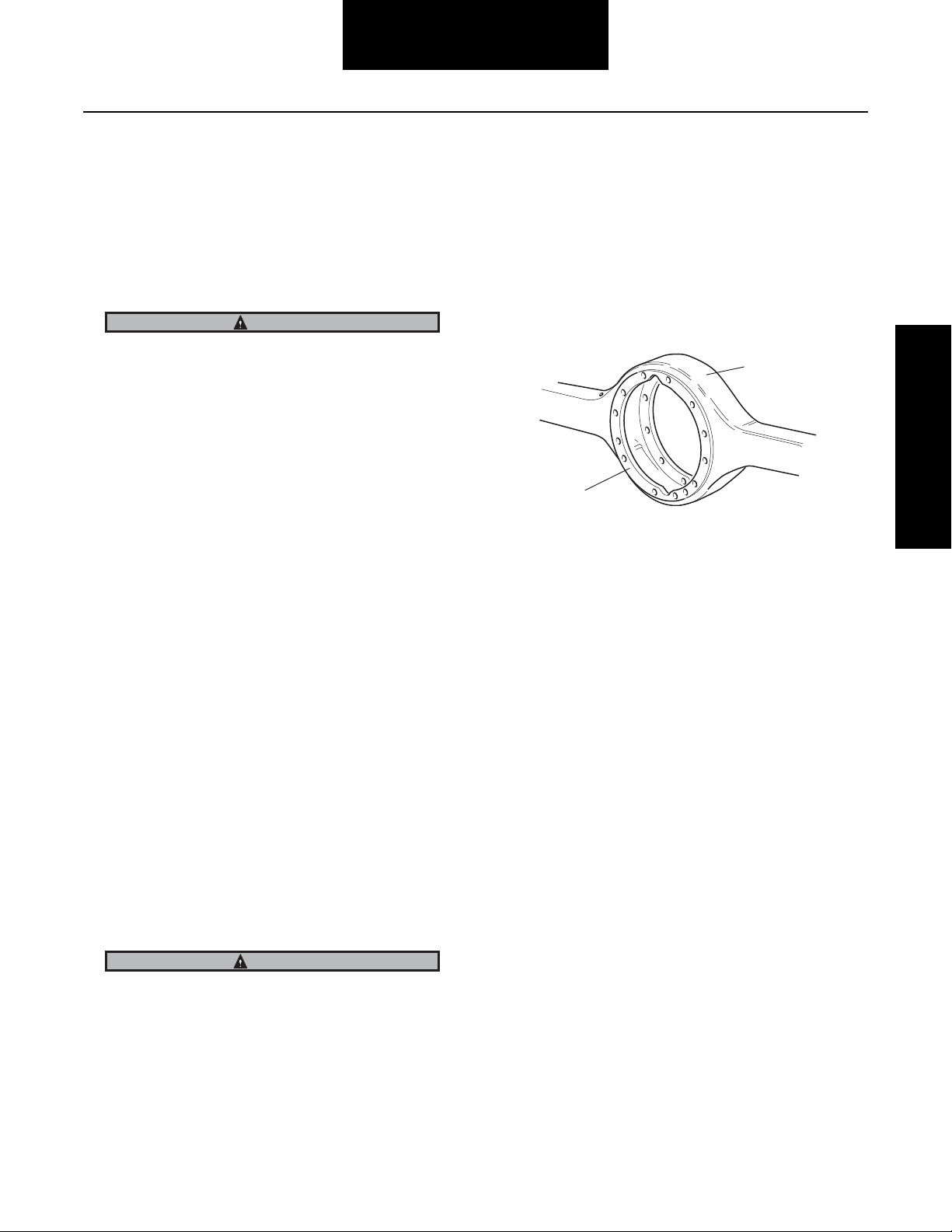

1 - Carrier fasteners

2 - Carrier assembly

3 - Forward axle assembly

4 - Inter-axle differential lockout

5 - Rear axle assembly

1

2

3

Differential Carrier

Assembl

4

11

Page 16

Differential Carrier Assembly

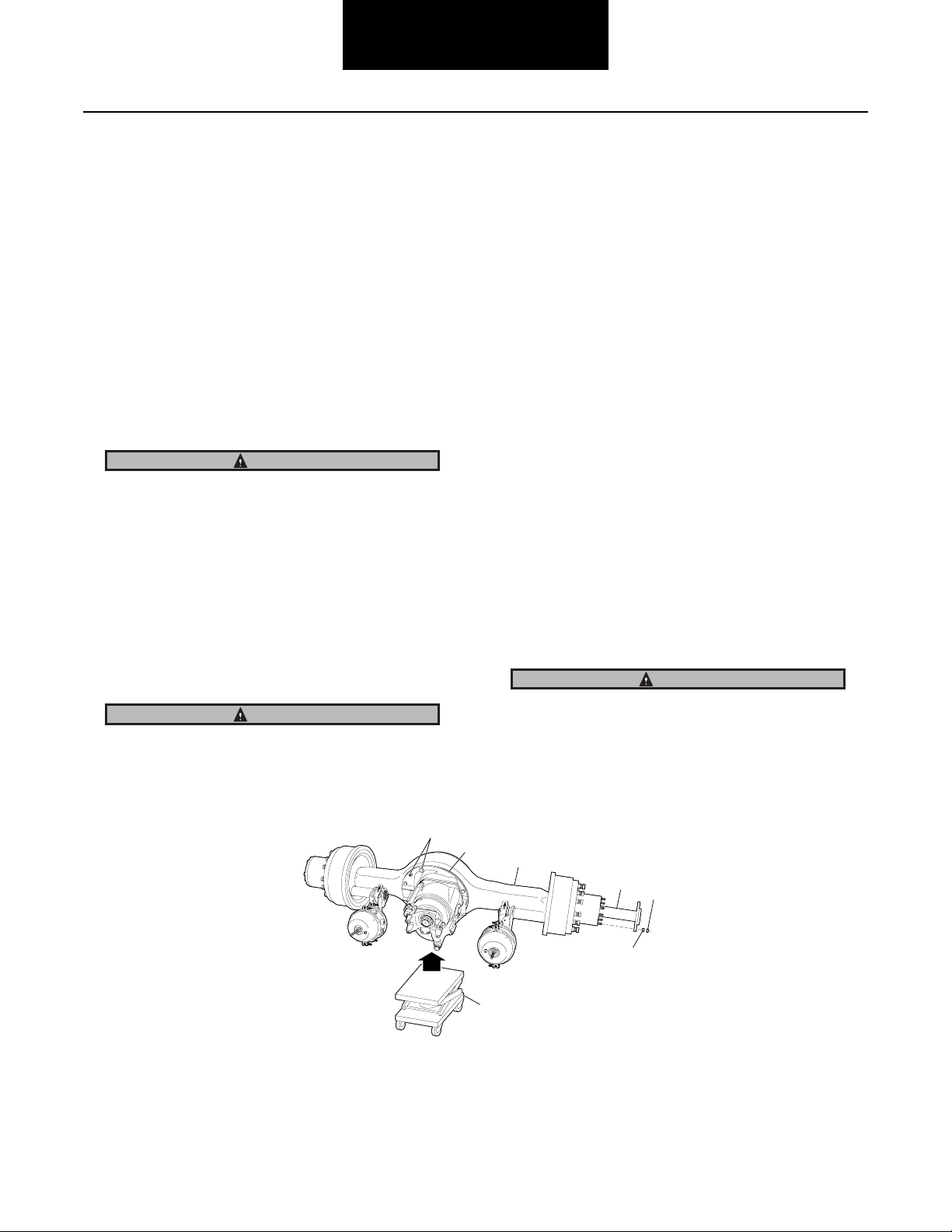

Forward Axle Differential Carrier Removal and Installation

Removal of Forward Differential Carrier

Note: The removal of the forward carrier requires disconnect-

ing of the inter-axle driveline and removal of the output

shaft yoke assembly.

1. Block the vehicle.

2. Drain axle lubricant.

3. Disconnect all air lines to the axle.

4. Disconnect inter-axle and main drivelines.

5. Remove axle stud nuts and axle shafts (If used, remove lock washers and taper dowels).

WARNING

The differential lock 461/521/581 models use axle shafts

with different spline length (4" or 11"). Axle shafts may also

be location specific with various wheel equipment. Do not

misplace axle shafts from their intended location.

TIP: To loosen dowels, hold a brass drift in the center of the

shaft head and strike drift with a sharp blow using a hammer.

Do not lie under carrier after fasteners are removed. Use

transmission jack to support differential carrier assembly

prior to loosening fasteners.

6. Remove carrier capscrews, nuts and lock washers.

7. Forward Models Only: Remove output shaft shoulder nut and yoke.

8. Remove differential carrier assembly.

Removal of Forward Axle Housing Cover

Tip: The bearing parts can be serviced separately

without removing the housing cover form the axle

housing

1. Block the vehicle.

2. Drain axle lubricant.

3. Disconnect inter-axle driveline.

4. Remove output shaft shoulder nut and yoke.

5. Remove capscrews, nuts, and lock washers fastening cover to axle housing.

6. Remove oil seal and discard.

7. Remove bearing retaining washer, if used.

8. If replacement is necessary, remove snap ring, bearing and bearing sleeve.

WARNING

CAUTION

Do not strike the shaft head with a steel hammer. Do not use

chisels or wedges to loosen shaft or dowels.

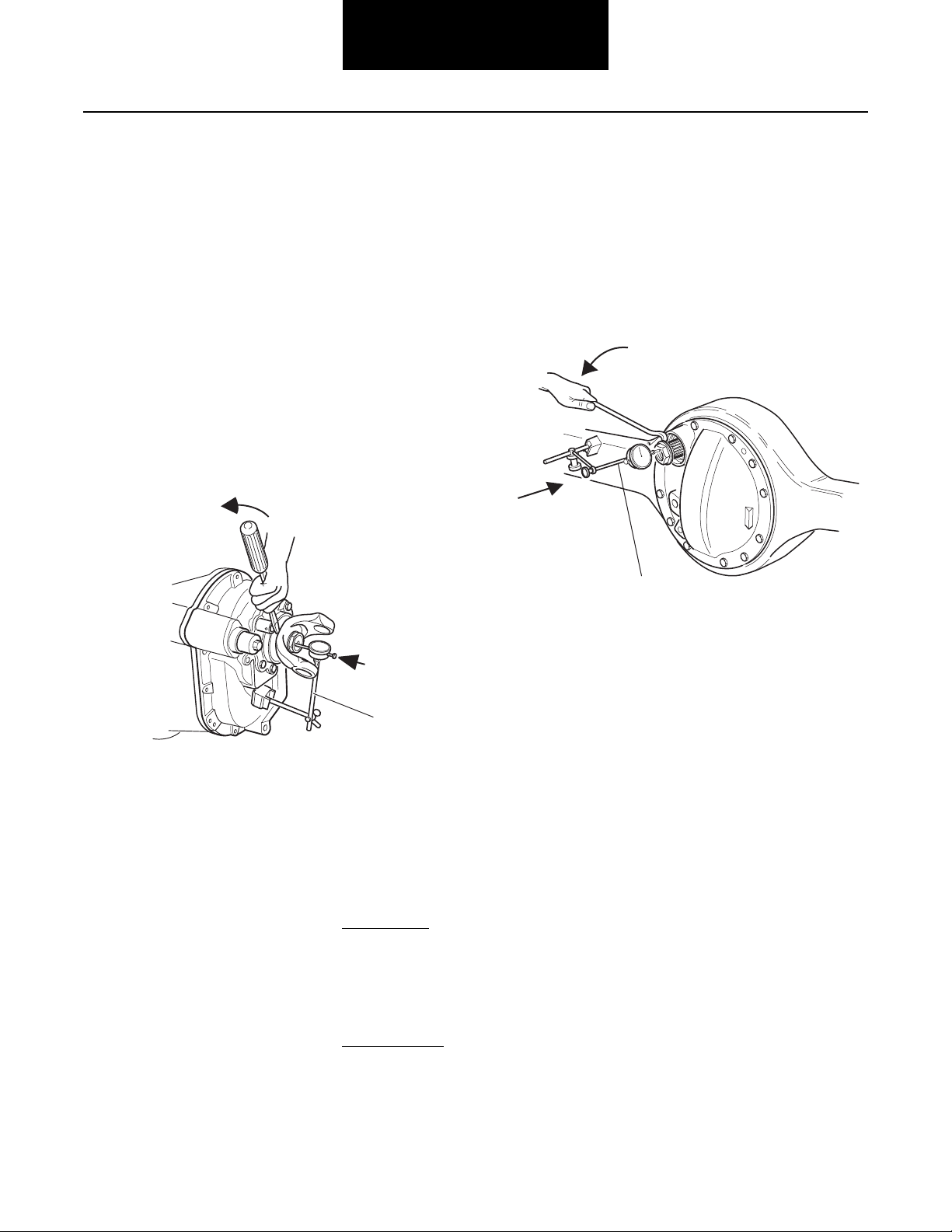

1

1 - Carrier fasteners

2 - Carrier assembly

3 - Forward axle assembly

4 - Axle shaft

Snap ring is spring steel and may pop off. Wear safety glasses when removing.

2

3

4

5

6

7

5 - Nut

6 - Lock washer

7 - Lift and support

12

Page 17

Inspection

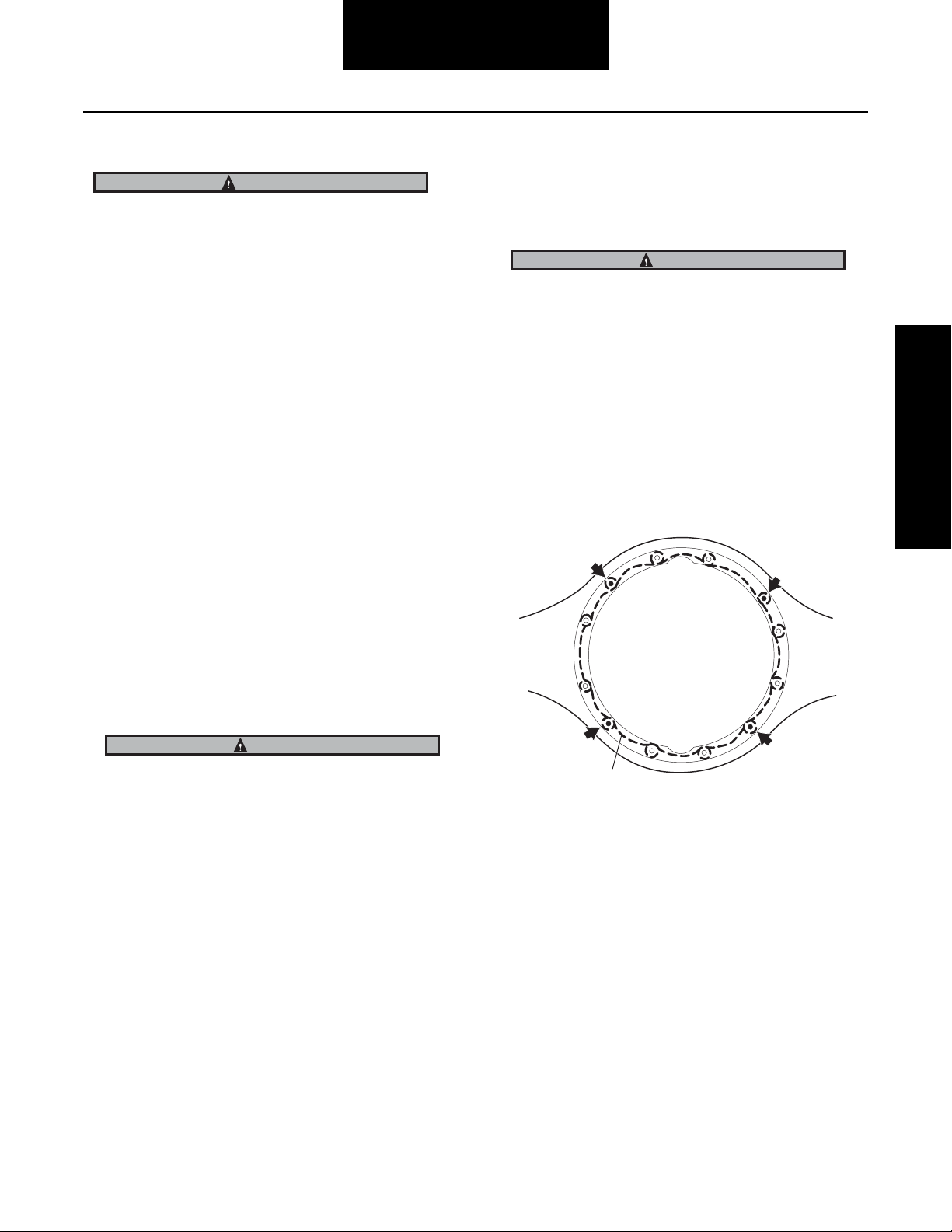

Installation of Forward Differential Carrier

IMPORTANT

Before installing carrier assembly, inspect and thoroughly

clean interior of axle housing using an appropriate solvent

and clean rag.

IMPORTANT

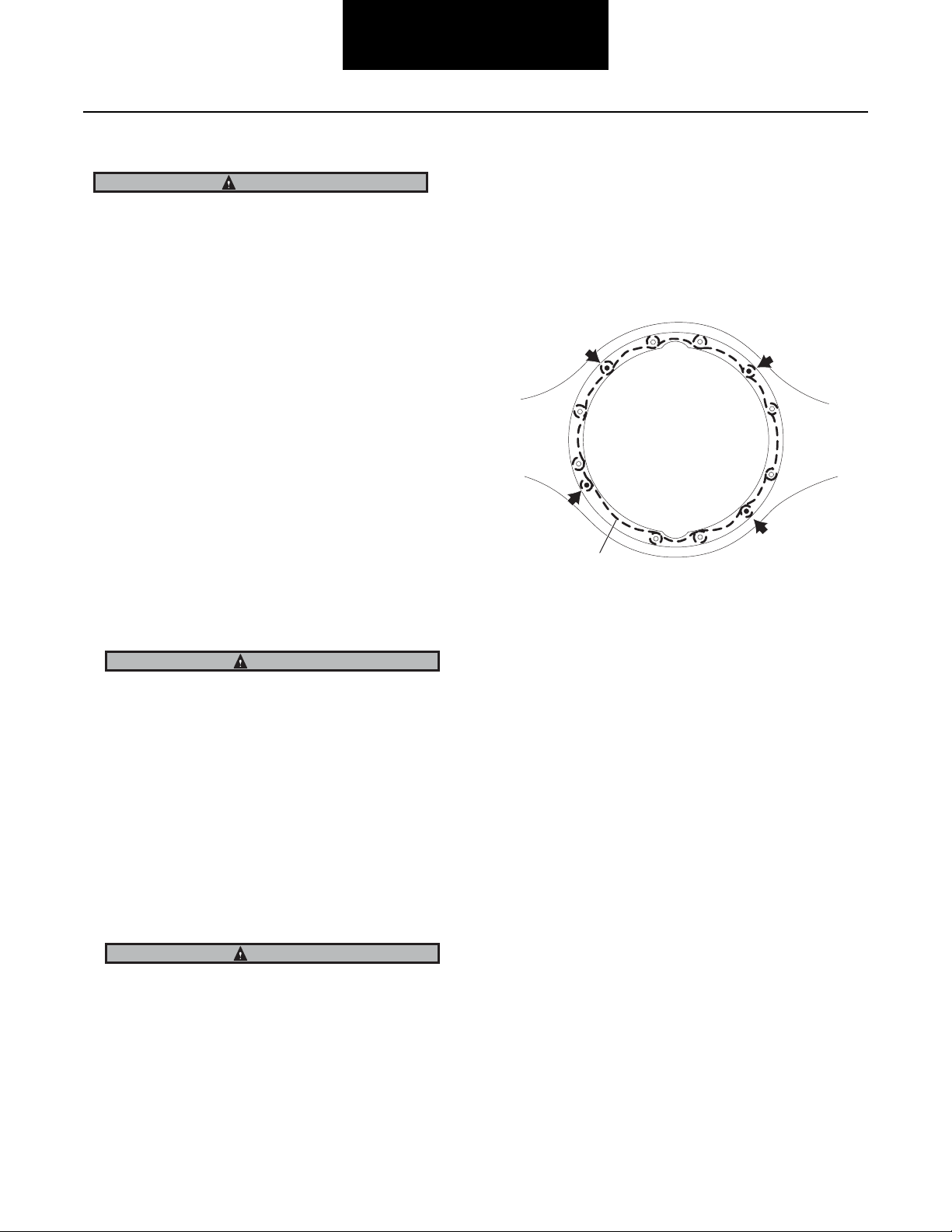

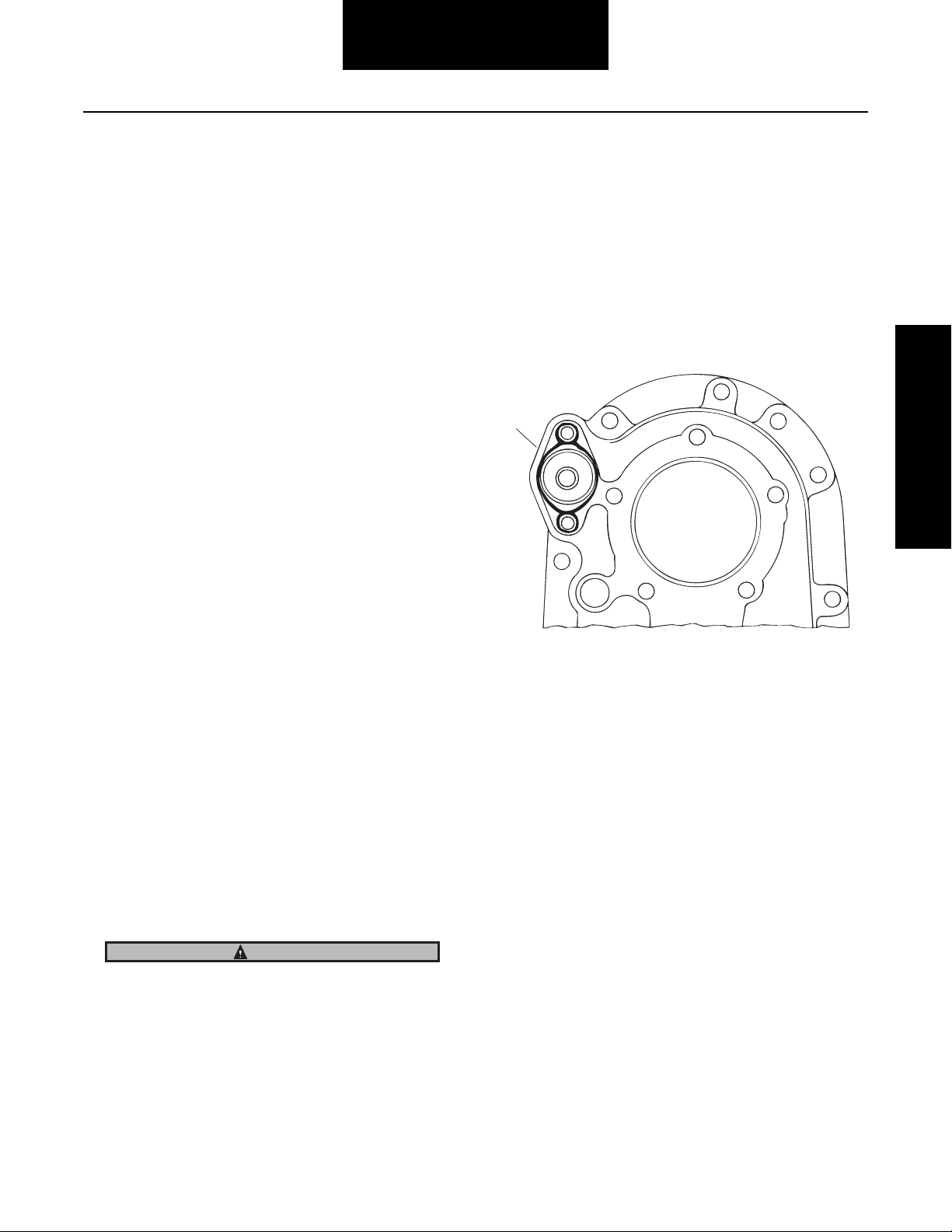

1. Use silicone rubber gasket compound on axle housing mating surface as shown in the illustration. Completely remove all old gasket material prior to

applying new material. Compound will set in 20 minutes. Install carrier before compound sets or reapply.

TIP: To assist in installing complete differential carrier, use two pieces of threaded rod (5/8"- 11 UNS)

threaded into carrier capscrew holes. Rod should be

approximately 6" long. Use these to pilot the carrier

into the housing.

2. Install differential carrier assembly to axle housing

using lockwashers, capscrews and nuts. Torque to

proper specification (see Torque Chart on page 107).

3. With the forward axle now assembled to the housing,

proceed with Installation of Forward Axle Housing

Cover and Output Shaft Bearing Parts, on next page.

4. Install output yoke and self-locking nut. Tighten to

specified torque (see Torque Chart on page 107).

Reference Yoke Installation Section page 92.

5. Install axle shafts and axle stud nuts (If used, also install lock washers and taper dowels).

WARNING

When axle has been disassembled

or housing, axle shafts or wheel equipment re

placed, check axle assembly for proper differen-

tial action before operating vehicle. Wheels must

rotate freely and independently.

Road test vehicle to bring axle lubricant up to temperature. Recheck joints, drain and fill plugs for leakage. Re-tighten as necessary.

Differential Carrier Side of Axle Housing

2

Inspection

The differential lock 461/521/581 models use axle shafts

with different spline length (4" or 11"). Axle shafts may also

be location specific with various wheel equipment. Do not

misplace axle shafts from their intended location.

6. Connect main and inter-axle driveline. Ensure drivelines are properly phased. Lubricate U-joints.

7. Add axle lubricant. See Lube Fill Capacities on page

104 for correct amount.

Note: Oil fill plug removed from D461/462/463 Differential

Carriers. The oil fill plug hole located in the differential

carrier was removed. Lube capacity is not affected, customers to fill axle with lube through rear cover fill hole or

through the breather hole in housing. February 1, 2000.

8. Connect air lines to differential.

1

Axle Housing Silicone Gasket Compound Pattern

1 - Apply silicone gasket in this pattern

2 - Typical stud locations

13

Page 18

Differential Carrier Assembly

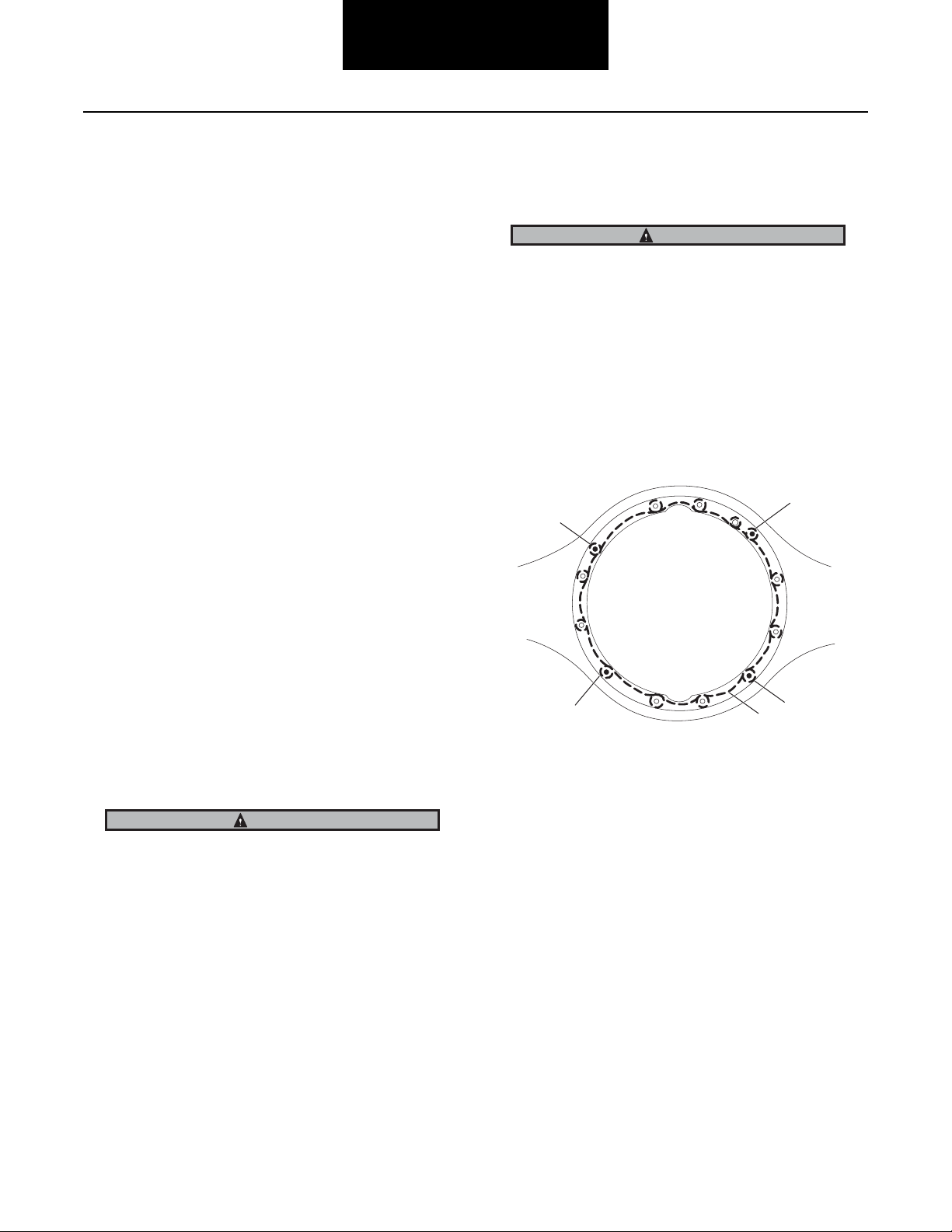

Installation of Forward Axle Housing Cover and Output Shaft Bearing Parts

Note: Forward axle should be assembled to the axle housing

before proceeding with the following procedure.

1. If removed, install housing cover and fasten with

nuts, capscrews and lock washers. Tighten to proper

torque specifications (see Torque Chart on page

107).

Note: Use silicone rubber gasket compound on axle housing

mating surface as shown in illustration. Completely remove all old gasket material prior to applying new material. Compound will set in 20 minutes. Install axle

housing cover and output shaft assembly before compound sets or reapply.

2. Install output shaft rear bearing. Tap the outer race

(with a sleeve or brass drift) until it is seated firmly in

the machined pocket of the cover. Secure with snap

ring.

IMPORTANT

When axle has been disassembled or housing, axle shafts or

wheel equipment replaced, check axle assembly for proper

differential action before operating vehicle. Wheels must rotate freely and independently.

Road test vehicle to bring axle lubricant up to temperature. Recheck joints, drain and fill plugs for leakage. Re-tighten as necessary.

Cover Side of Axle Housing

2

2

3. Lubricate and install the rear bearing sleeve on the

output shaft. Make certain it fits snugly against the

shoulder at the forward edge of the shaft splines.

4. Install the output shaft seal in the axle housing cover.

Note: Some axles require the use of a rear bearing retaining

washer. Install the washer over the splines of the output

shaft flush against the output shaft bearing.

5. Install output yoke and self-locking nut. Tighten to

specified torque (see Torque Chart on page 107).

Reference Yoke Installation Section page 92.

6. Install axle shafts and axle stud nuts (If used, also install lock washers and taper dowels).

WARNING

The differential lock 461/521/581 models use axle shafts

with different spline length (4" or 11"). Axle shafts may also

be location specific with various wheel equipment. Do not

misplace axle shafts from their intended location.

7. Connect main and inter-axle driveline. Ensure drivelines are properly phased. Lubricate U-joints.

8. Add axle lubricant. See Lube Fill Capactities on page

104 for correct amount.

2

1 - Apply silicone gasket in this pattern

2 - Stud locations (varies by model)

2

1

Note: Oil fill plug removed from D461/462/463 Differential

Carriers. The oil fill plug hole located in the differential

carrier was removed. Lube capacity is not affected, customers to fill axle with lube through rear cover fill hole or

through the breather hole in housing. February 1, 2000.

9. Connect air lines to differential.

14

Page 19

Differential Carrier Assembly

y

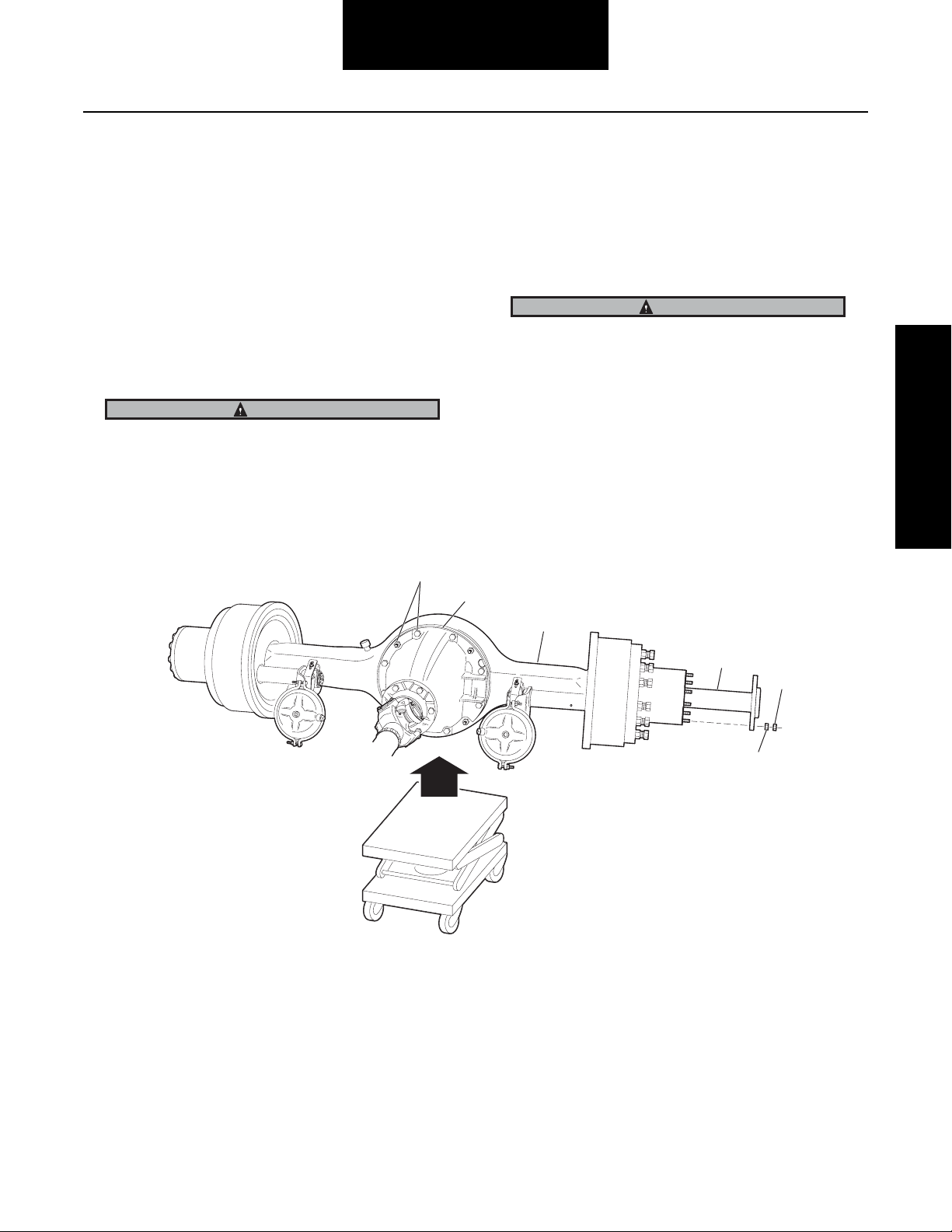

Rear Axle Differential Carrier Removal and Installation

Removal of Rear Differential Carrier

Perform the following steps:

1. Block the vehicle.

2. Drain axle lubricant.

3. Disconnect air line if working on a differential lock axle. (See Differential Lockout Section).

4. Disconnect inter-axle driveline.

5. Remove axle stud nuts and axle shafts (If used, remove lock washers and taper dowels).

WARNING

The differential lock 461/521/581 models use axle shafts

with different spline length (4" or 11"). Axle shafts may also

be location specific with various wheel equipment. Do not

misplace axle shafts from their intended location.

1

TIP: To loosen dowels, hold a brass drift in the center of the

shaft head and strike drift with a sharp blow using a hammer.

Do not lie under carrier after fasteners are removed. Use

transmission jack to support differential carrier assembly

prior to loosening fasteners.

CAUTION

Do not strike the shaft head with a steel hammer. Do not use

chisels or wedges to loosen shaft or dowels.

6. Remove capscrews, nuts and lock washers.

7. Remove differential carrier assembly.

2

3

Differential Carrier

Assembl

1 - Carrier fasteners

2 - Carrier assembly

3 - Rear axle assembly

4

5

6

4 - Axle shaft

5 - Nut

6 - Lock washer

15

Page 20

Differential Carrier Assembly

Rear Differential Carrier “Installation”

IMPORTANT

Before installing carrier assembly, inspect and thoroughly

clean interior of axle housing using an appropriate solvent

and clean rag.

Note:

Note:

Note: Apply silicone rubber gasket compound on axle housing

mating surface as shown in illustration. Completely remove all old gasket material prior to applying new material. Compound will set in 20 minutes. Install carrier

before compound sets or reapply.

1. Install differential carrier assembly.

TIP: To assist in installing complete differential carrier use two pieces of threaded rod (5/8"- 11 UNS)

threaded into carrier capscrew holes. Rod should be

approximately 6" long. Use these to pilot the carrier

into the housing.

2. Install carrier to axle housing lock washers, capscrews and nuts. Torque to proper specification. See

“Torque Chart” on page 107.

3. Install axle shafts and axle stud nuts (If used, also install lock washers and taper dowels).

WARNING

Road test vehicle to bring axle lubricant up to temperature. Recheck joints, drain and fill plugs for leakage. Re-tighten as necessary.

2

1

1 - Apply silicone gasket in this pattern

2 - Typical stud locations

The differential lock 461/521/581 models use axle shafts

with different spline length (4" or 11"). Axle shafts may also

be location specific with various wheel equipment. Do not

misplace axle shafts from their intended location.

4. Connect inter-axle driveline, making sure driveline is

in phase. Lubricate U-joints.

5. Add axle lubricant. Fill to bottom of filler hole. See

“Change Lube” on page 104. Reference Lube Fill Capacities for correct amount.

6. Connect air line to differential if working on a differential lock model axle.

IMPORTANT

When axle has been disassembled or housing axle shafts or

wheel equipment replaced, check axle assembly Afor proper

differential action before operating vehicle. Wheels must rotate freely and independently.

16

Page 21

Differential Lockout

Differential Lockout

Inter-Axle Lockout Types

All are air-operated to engage the lockout and spring-released

to disengage the lockout with the exception of the “ReverseAir” lockout. The “Reverse-Air” lockout is spring-released to

engage the lockout and air-operated to disengage the lockout.

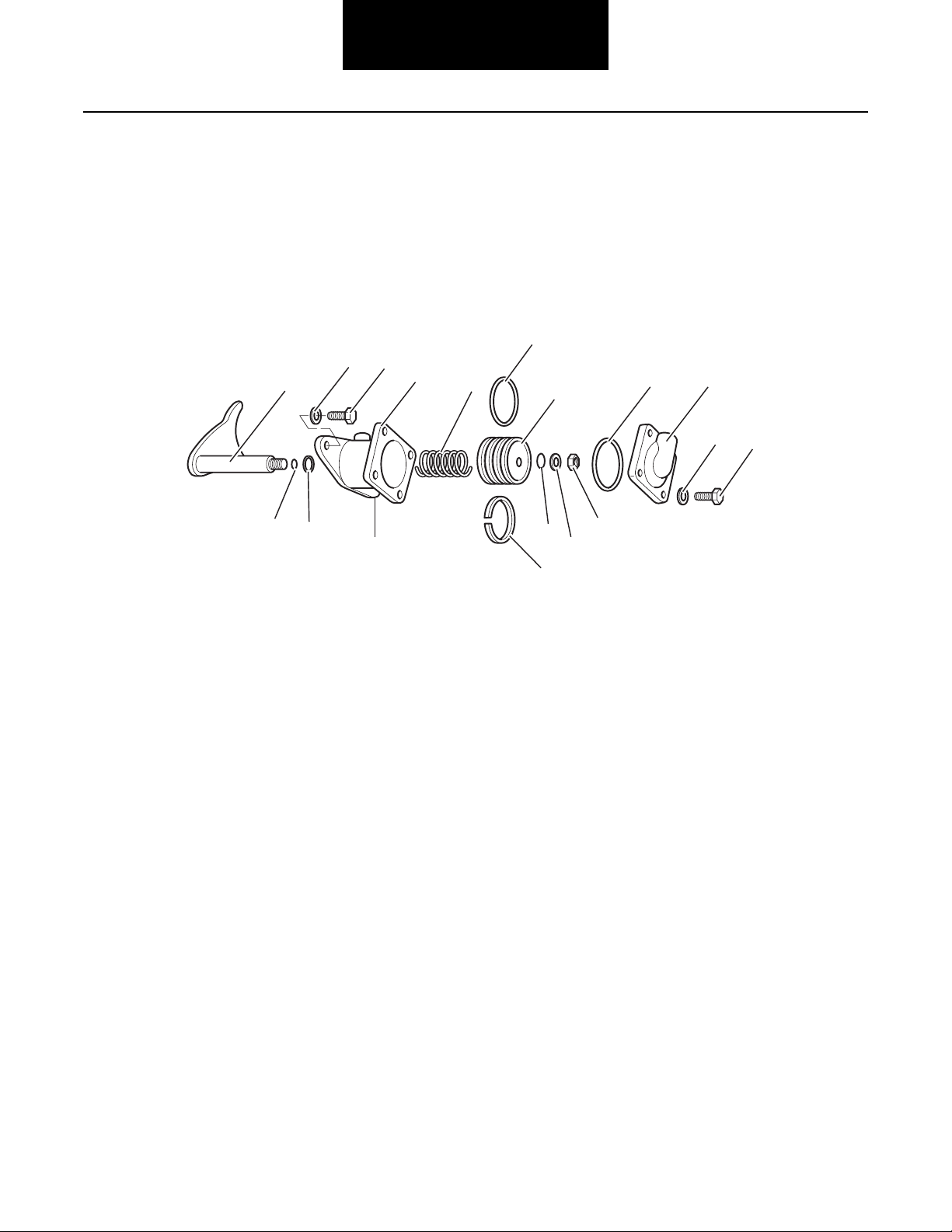

1

Cast Iron Cover Lockout - February 1996 to

Present (Single Reduction Models)

• External type lockout

• Cast iron piston cover

2

3 4

5

6 7

Differential Lockout

8

1 - Shift fork assembly

2 - Compression spring

3 - Piston driver

4 - O-ring

5 - Piston

6 - Lock nut

7 - Cast iron piston housing

8 - Capscrew

17

Page 22

Differential Lockout

Original Design Lockout - 1948 to Present

(*Optional design for use with all dual

range tandem axles)

• Die cast body

• Square Top

4

5

1

2

3

Original

design

6

• Interchangeable with cast iron lockout*

“In 1985, a “Protective Shift System” was released into production axles. Dana bulletin 85-03 explains this popular OEM

option. This option can only work with the “original” design

lockouts.

7

13

1514

8

16

17

10

12

11

9

1 - Shift fork assembly

2 - Push rod o-ring

3 - Body o-ring

4 - Lock washer

5 - Cap screw

6 - Original design lockout body

7 - Piston o-ring

8 - Piston

9 - Felt oilers

10 - O-ring

11 - Flat washer

12 - Lock nut

13 - Compression spring

14 - Cover o-ring

15 - Cover

16 - Lock washer

17 - Capscrew

18

Page 23

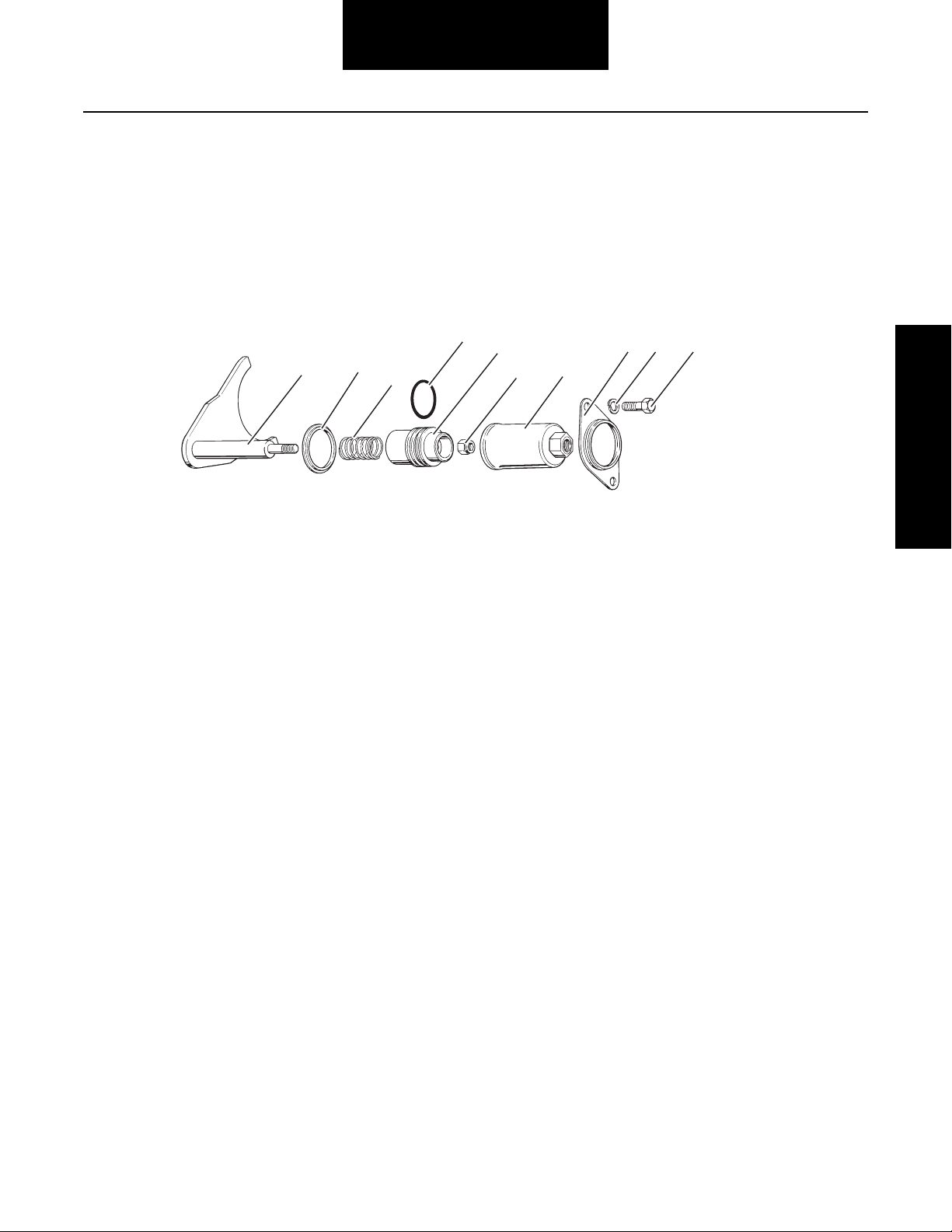

Differential Lockout

Cylindrical Design Lockout - October 1989

to February 1996

• External type lockout

1

2

3

• Stamped steel piston cover

• Interchangeable with the cast style cover only as a

complete assembly

4

5

6

7

8 9

10

Differential Lockout

1 - Shift fork assembly

2 - Shoulder washer

3 - Compression spring

4 - O-ring

5 - Piston

6 - Lock nut

7 - Cylindrical design piston housing

8 - Mounting bracket

9 - Lock washer

10 - Capscrew

19

Page 24

Differential Lockout Overhaul

Differential Lockout

Instructions for the three different designs are on the following

pages:

Cast Iron Cover Lockout - Overhaul on page 20

Original Design Lockout - Overhaul on page 21

Cylindrical Design Lockout - Overhaul on page 22

Cast Iron Cover Lockout - Overhaul

Disassemble and Remove Lockout

Note: With axle installed in vehicle, place differential lock se-

lector valve in the disengaged (or unlocked) position.

Disconnect the air line at the lockout piston cover.

1. Remove capscrews and lock washers fastening piston housing to power divider cover. Remove the cast

iron piston housing.

2. Remove lock nut, piston with o-ring, piston driver

and compression spring from push rod.

Assemble and Install Lockout - Cast Iron

Cover Design

1. With shift fork and sliding clutch installed, install

compression spring on push rod.

2. Place piston driver on push rod against compression

spring. The large diameter end of piston driver must

face power divider cover.

3. Lubricate o-ring with silicone-based lubricant and install o-ring on piston.

4. Place piston assembly on push rod against piston

driver.

5. Install lock nut on push rod and tighten to 13-17 lbs.

ft. (18-23 N•m).

6. Apply silicone gasket compound to mounting surface

on power divider cover.

Note: The shift fork and push rod cannot be removed with

power divider cover installed (see Remove Power Divider on

page 24).

Lockout Interchangeability

The cast iron design lockout assembly is interchangeable with

previously designed lockouts, only as a complete assembly.

The original shift fork and push rod can be used for all three

design type lockouts and need not be replaced.

Retrofit kits are available to convert the non-current design

lockouts to the current cast iron cover design lockout. For additional information, refer to Dana Parts Books AXIP-0085.

Retrofit as follows:

1. Disassemble and remove the old design lockout.

2. Assemble and install the cast iron cover lock-out.

CAUTION

Mounting screws are not interchangeable between the various design style lockouts. They are a different length and

size.

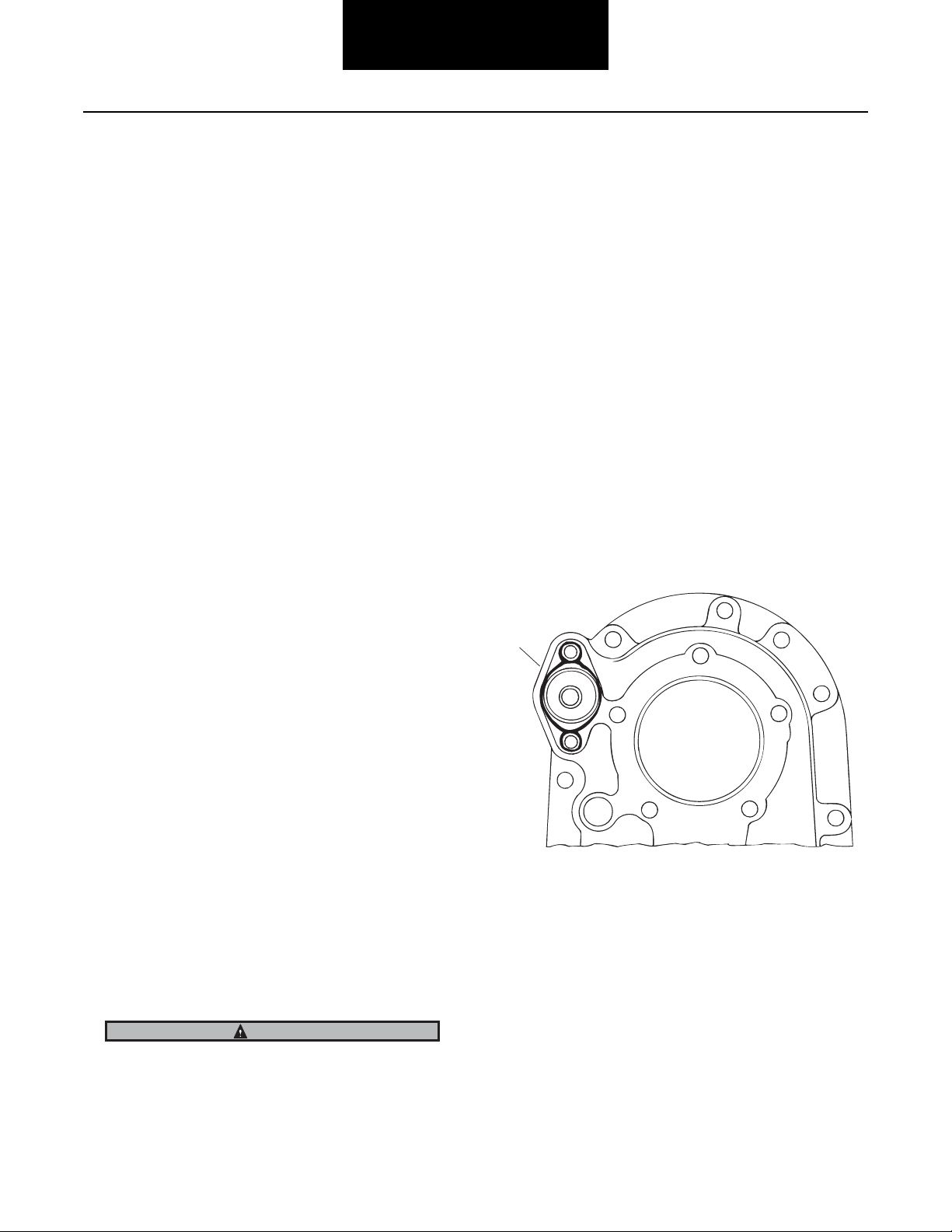

1

1 - Lockout silicone gasket pattern

7. Install piston housing cover.

8. Install capscrews and tighten to 48-56 lbs. ft.

(65-76 N•m).

9. If axle is installed in vehicle, apply sealant to air line

fitting and connect air line.

20

Page 25

Original Design Lockout Overhaul

Differential Lockout

Note: Find instructions for:

Cast Iron Cover Lockout - Overhaul on page 20

Cylindrical Design Lockout - Overhaul on page 22

Disassemble and Remove Lockout

Note: With axle installed in vehicle, place differential lock se-

lector valve in the disengaged (or unlocked) position.

Disconnect the air line at the lockout piston cover.

1. Remove capscrews and lock washers fastening cover to the body. Remove cover and o-ring.

2. Remove nut, flat washer and o-ring from push rod.

3. Remove body capscrews and lock washers, then remove body and piston as an assembly. Remove oring and felt oilers from the piston.

Note: The shift fork and push rod cannot be removed with

power divider cover installed (see Remove Power Divider on

page 24).

Retrofit Original Design to Cast Iron Cover

Design Lockout

Assemble and Install Original Design Lockout

With shift fork and sliding clutch installed in power divider cover, assemble and install lockout as follows:

1. Apply silicone gasket compound to mounting surface

on power divider cover.

Differential Lockout

1

1 - Lockout silicone gasket pattern

The cast iron cover design lockout assembly is interchangeable with the original design lockout, only as a complete assembly. The original shift fork and push rod can be used for

either model lockout and need not be replaced.

Retrofit kits are available to convert the non-current design

lockouts to the current cast iron cover design lockout. For additional information, refer to Dana Parts Books AXIP-0085.

Retrofit as follows:

1. Disassemble and remove the original design lockout.

2. Assemble and install the cast iron cover lockout.

CAUTION

Mounting screws are not interchangeable between the various design style lockouts. They are a different length and

size.

2. Install lockout body. Secure with capscrews and lock

washers. Torque capscrews to 48-56 lbs. ft.

(65-76 N•m).

Note: Before installation, soak piston felt oilers in SAE 30 en-

gine oil and lubricate o-rings with a high-viscosity silicone oil or barium grease o-ring lubricant.

3. Install felt oilers and large o-ring on piston.

4. Install compression spring over shift fork push rod.

Install piston over end of shift fork into lockout body.

Secure with lock washers and lock nut. Torque locknut (see Torque Chart on page 107).

5. Install o-ring in lockout body cover. Install cover and

secure with capscrews and lock washers. Torque

capscrews to 96-108 lbs. in. (10-13 N•m).

21

Page 26

Differential Lockout

Cylindrical Design Lockout - Overhaul

Note: Find instructions for:

Cast Iron Cover Lockout - Overhaul on page 20

Original Design Lockout - Overhaul on page 21

Disassemble and Remove Lockout

Note: With axle installed in vehicle, place differential lock se-

lector valve in the disengaged (or unlocked) position.

Disconnect the air line at the lockout piston cover.

1. Remove capscrews and lock washers fastening

mounting bracket to power divider cover. Remove

bracket and piston housing.

2. Remove lock nut, piston with o-ring, compression

spring and shoulder washer from push rod.

Note: The shift fork and push rod cannot be removed with

power divider cover installed (see Remove Power Divider

on page 24).

Retrofit Cylindrical Design to Cast Iron

Cover Design Lockout

Assemble and Install Lockout-Cylindrical

Design

1. With shift fork and sliding clutch installed, place the

shoulder washer (white plastic) over push rod. The

large diameter side of the washer must face the power divider cover.

2. Install compression spring on push rod.

3. Lubricate o-ring with silicone-based lubricant and install o-ring on piston.

4. Place piston assembly on push rod. The large diameter end of piston must face power divider cover.

5. Install lock nut on push rod and tighten to 13-17 lbs.

ft. (18-23 N•m).

6. Install piston housing, making sure the housing is

correctly seated and piloted in the shoulder washer.

The cast iron cover design lockout assembly is interchangeable with the cylindrical design lockout, only as a complete assembly. The original shift fork and push rod can be used for

either type lockout and need not be replaced.

Retrofit kits are available to convert the non-current design

lockouts to the current cast iron cover design lockout. For additional information, refer to Dana Parts Books AXIP-0085.

Retrofit as follows:

1. Disassemble and remove the cylindrical design lockout.

2. Assemble and install the cast iron cover lockout.

CAUTION

Mounting screws are not interchangeable between various

design style lockouts. They are a different length and size.

1

1 - Shoulder washer must seat properly

7. Place mounting bracket over housing and position on

power divider cover. Install capscrews and lock

washers and tighten to 48-56 lbs. ft. (65-76 N•m)

Note: If axle is installed in vehicle, apply sealant to air line fit-

ting and connect air line. When tightening air line, hold

piston housing in mounting position using a wrench applied to the hexagon configuration at outer end of housing.

22

Page 27

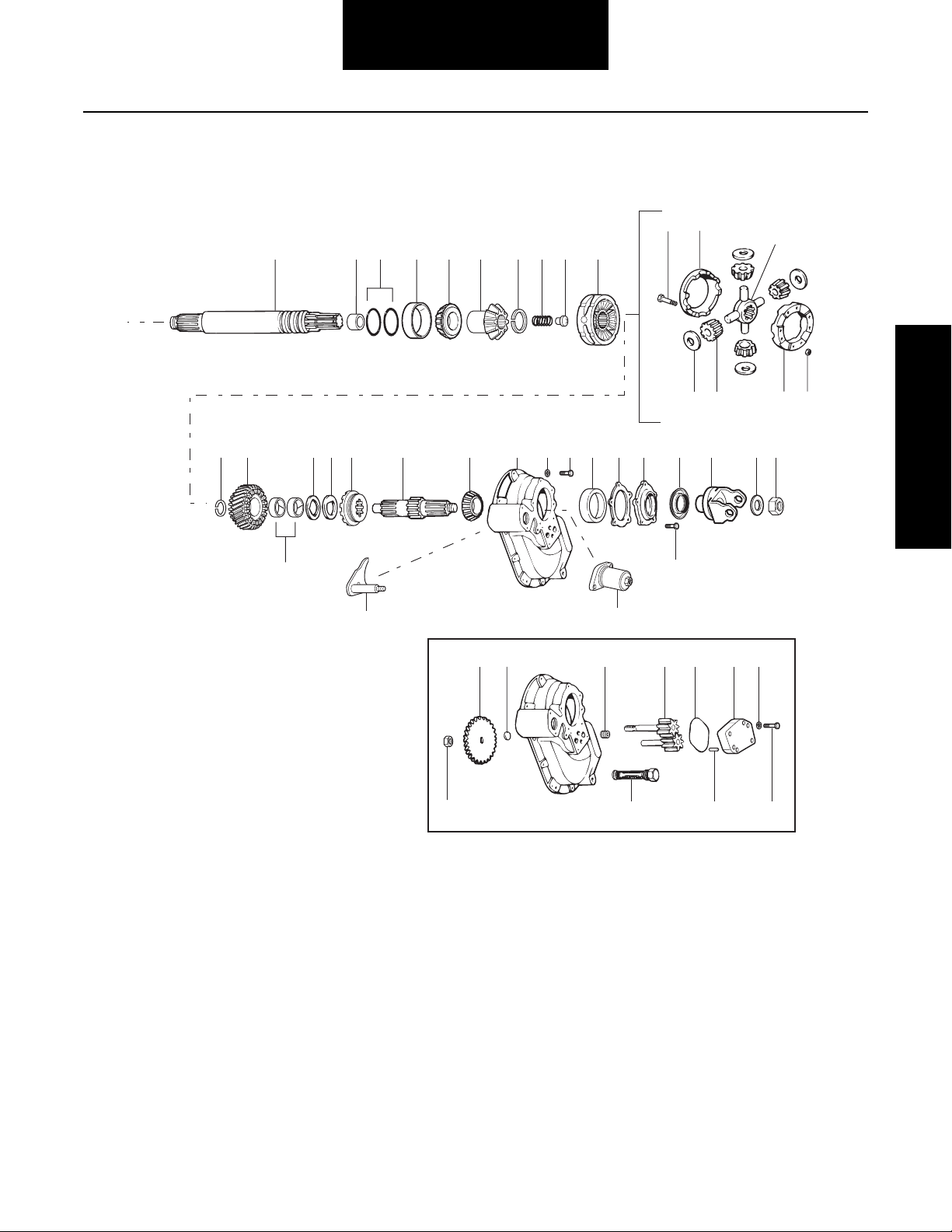

Power Divider - Parts Exploded View

1

2* 3 4 5

Inspection

678 910

11

12

13

19 21 22 23 24 25 27 28 29 31 32 33 35

18

20

26

39

40

41

30

42 44 45 47 48

34

36 37 38

4643

49

1517 16

14

Inspection

1 - Output shaft

2 - Bushings*

3 - O-rings

4 - Bearing cup

5 - Bearing cone

6 - Side gear

7 - Snap ring

8 - Spring

9 - Button

10 - Inter-axle differential assembly

11 - Capscrew

12 - Case half

13 - Spider

14 - Nut

* Removed in September 1994

15 - Case half

16 - Side pinion

17 - Thrust washer

18 - Snap ring

19 - Helical gear

20 - Bushings

21 - Thrust washer

22 - “D” washer

23 - Lockout sliding clutch

24 - Input shaft

25 - Bearing cone

25 - Shift fork and push rod

27 - Power divider cover

28 - Lock washer

29 - Capscrew

30 - Lockout unit

31 - Bearing cup

32 - Shim

33 - Bearing cover

34 - Capscrew

35 - Oil seal

36 - Yoke

37 - Flat washer

38 - Nut

Lube Pump Parts

39 - Lock nut

40 - Pump drive gear

41 - Expansion plug

42 - Pipe plug

43 - Magnetic screen

44 - Pump gears

45 - O-ring

46 - Dowel pin

47 - Pump cover

48 - Lock washer

49 - Capscrew

23

Page 28

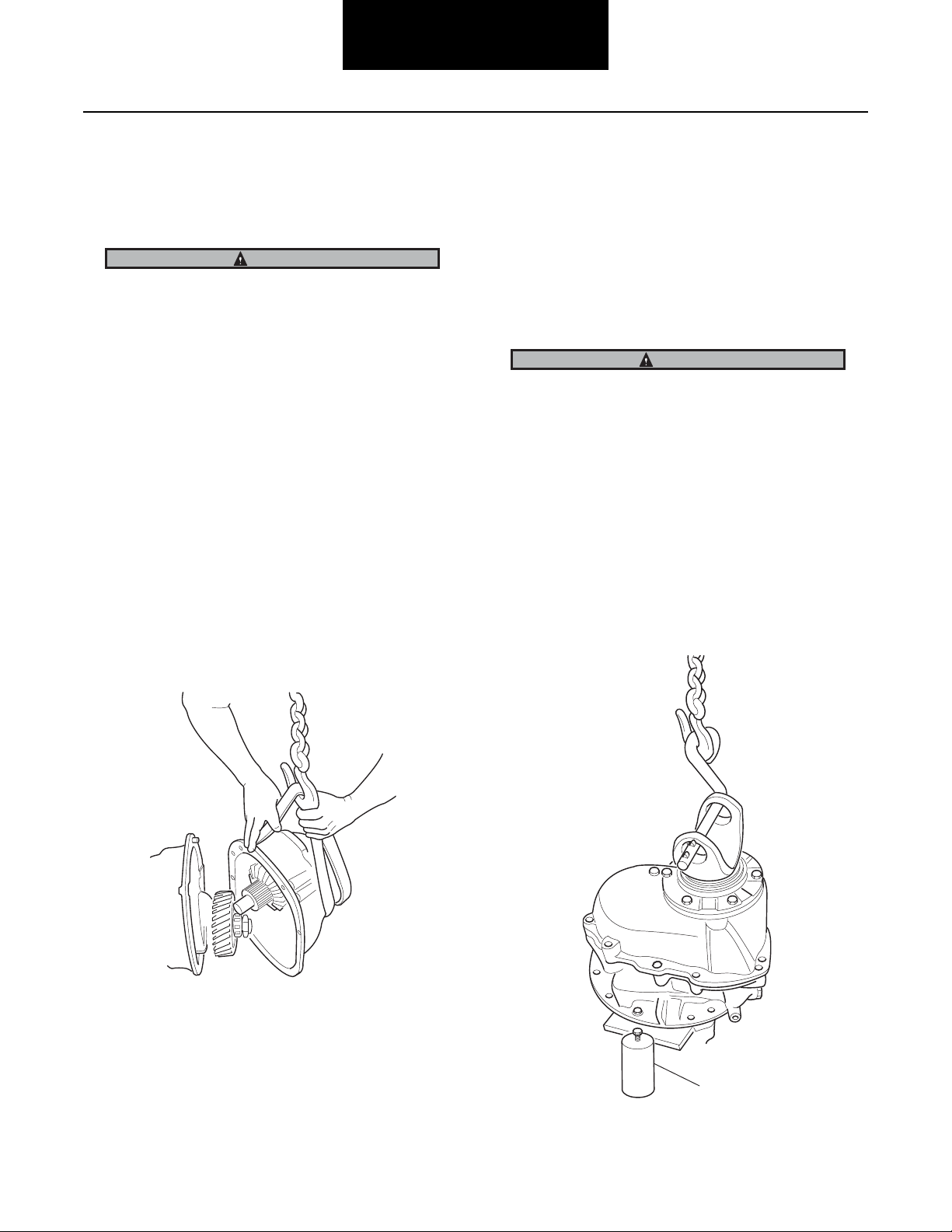

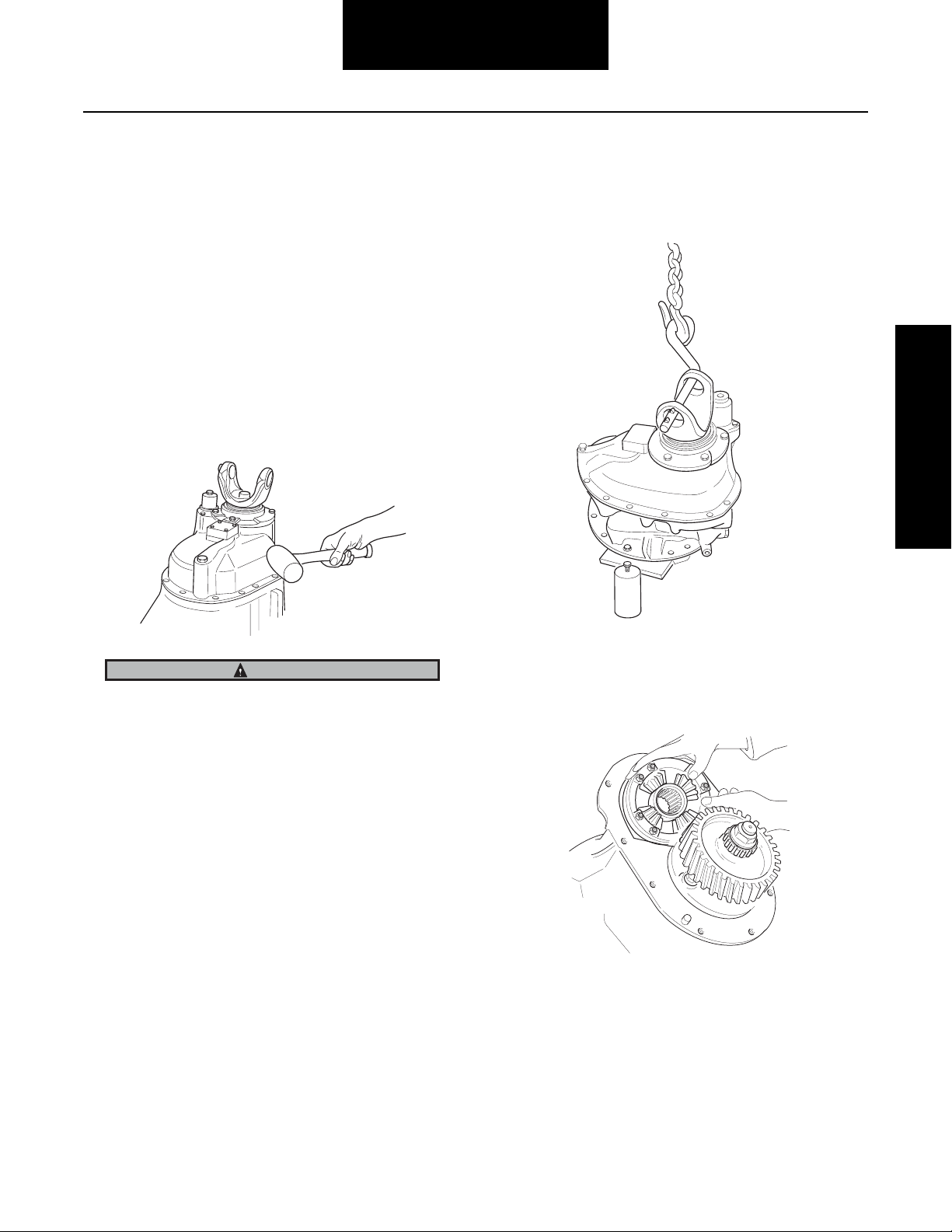

Remove Power Divider

Power Divider

The power divider can be replaced with the axle assembly both

in or out of the chassis and with the differential carrier assembled to the axle housing.

CAUTION

During removal of power divider cover, the inter-axle differential (IAD), input shaft assembly or IAD shift system parts

may fall from the carrier if not careful. Use caution to prevent injury or damage.

1. Disconnect the main driveline.

2. Disconnect the lockout air line.

3. If overhauling the power divider, loosen but do not remove input nut.

4. Position a drain pan under the unit.

5. Remove PDU capscrews.

Method A - With Carrier Installed in

Chassis

1. Use a transmission jack or a chain hoist and a sling.

Method B - With Carrier Out of Chassis

1. Use a chain hoist.

2. Mount carrier assembly in carrier assembly stand.

3. Remove PDU capscrews.

4. Fasten chain or strap to input yoke to remove power

divider.

CAUTION

During removal of power divider cover, the inter-axle differential (IAD), input shaft assembly or IAD shift system parts

may fall from the carrier if not careful. Use caution to prevent injury or damage.

Note: Lifting mechanism may create nicks and burrs on input

yoke. Remove nicks and burrs if present.

5. Tap the sides of the cover at the dowel pin location

with a mallet to loosen cover.

6. Remove PDU assembly.

7. Remove IAD assembly.

2. Wrap sling strap around power divider and attach to

chain hoist hook.

3. Tap on the sides of the cover at the dowel pins with a

mallet to create a space large enough to finish freeing

the cover from the dowel pins.

4. Pull the power divider forward until the input shaft

stub end is free of the output side gear, then remove

the assembly.

5. Remove IAD assembly.

1

1 - Carrier assembly stand

24

Page 29

Power Divider

Remove Power Divider from Differential Carrier (with carrier removed from axle housing)

Note: It is assumed that the differential carrier assembly has

been removed from axle housing prior to starting the following procedures:

1. Mount differential carrier in repair stand. Loosen input shaft nut.

2. Remove power divider cover capscrews and lock

washers.

3. Fasten chain or strap to input yoke to remove power

divider.

Note: Power divider may not separate easily, strike the cover

near the dowel pin location with a mallet.

CAUTION

During removal of power divider, the inter-axle differential

may fall off input shaft from differential carrier. Exert caution to prevent damage of injury.

5. With chain hoist attached to input yoke, lift power divider off carrier.

Power Divider

Note: Lifting mechanism may create nicks or burrs on input

yoke. Remove if present.

6. Lift inter-axle differential assembly out of carrier or

off of output shaft side gear.

4. Tap the sides of the cover at the dowel pin location

with a mallet to loosen cover.

Note: Late model axles may be equipped with a spring and

thrust button mounted between the input and output

shafts, remove these parts.

25

Page 30

Power Divider

7. Tilt carrier and remove the output shaft assembly.

8. If removal of the output shaft side gear bearing cup is

necessary, use puller to remove bearing cup from

carrier

26

Page 31

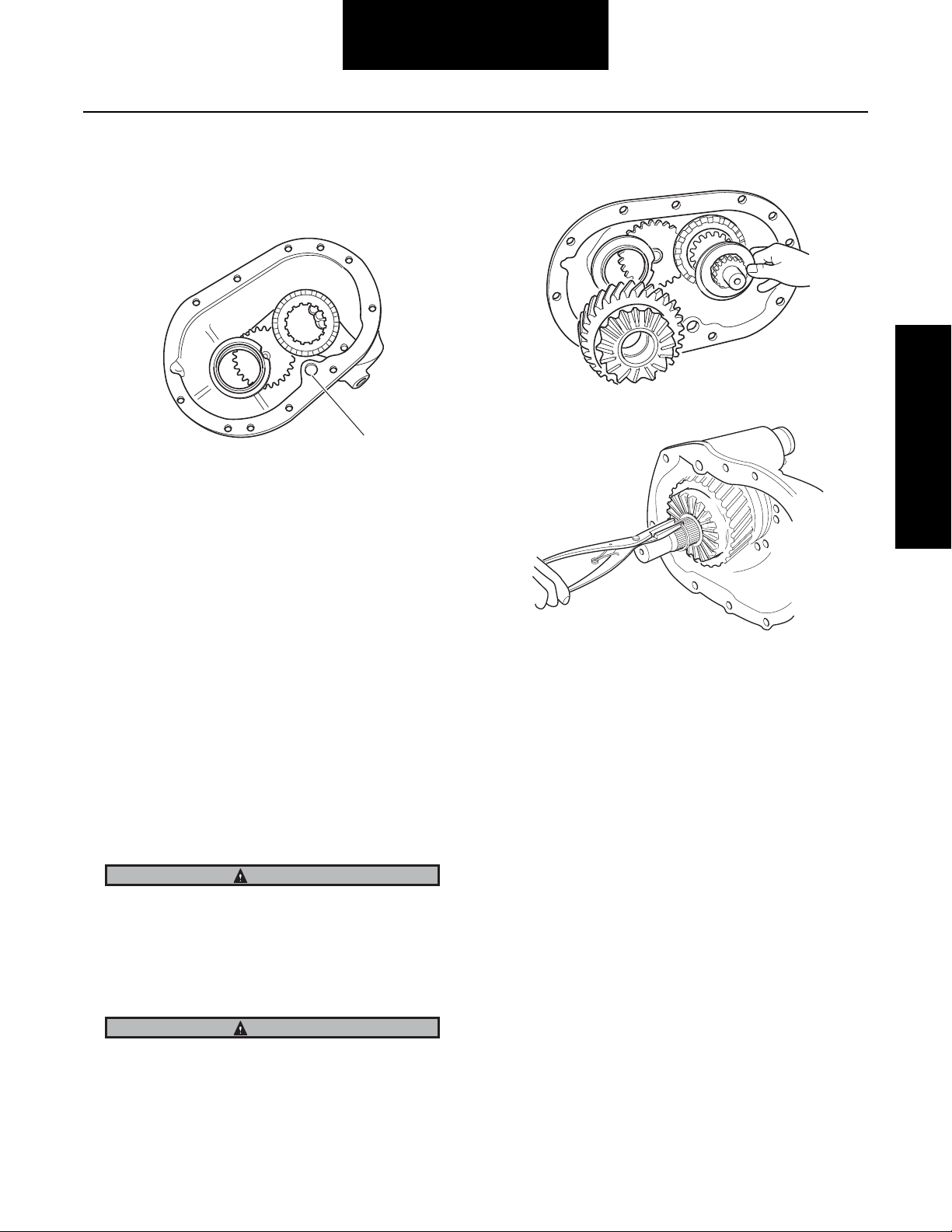

Power Divider

Disassemble, Assemble and Overhaul the Power Divider

The power divider may be serviced with the carrier assembly

in or out of the axle housing.

Note: The following procedure assumes that the differential

carrier has been removed from the axle housing and that

the power divider has been removed from the carrier assembly.

1. Late model axles may be equipped with a spring and

thrust button mounted between the input and output

shafts, remove these parts.

2. Remove output shaft and output side gear

Hammer: Use slipper to get under the cup and with a

hammer and drift from the back side of carrier tap out

bearing cup.

Power Divider

4. Remove snap ring from machined groove at rear of

input shaft.

3. If replacement of the output shaft side gear bearing

cup is necessary, use either of the following methods:

Weld: Place a weld bead around the inside of the cup,

when the weld cools the cup will fall out.

5. Slide helical side gear off input shaft.

6. Remove helical side gear thrust washer, and “D”

washer from shaft.

27

Page 32

Power Divider

7. At this point in disassembly, it is desirable to remove

lube pump drive gear nut. Hold input shaft yoke to secure drive gear, then loosen and remove drive gear

nut.

8. Remove input shaft nut and flat washer.

Note: Some models do not use flat washer as it is built into the

nut.

9. Remove yoke from input shaft using a puller tool.

TIP: A yoke puller tool may be made from the center

section of most gear puller tools, or may be purchased from your local tool distributor.

10. Remove input bearing cage, capscrews, input bearing cover and shim pack.

Note: Shift fork cannot be removed until lockout unit is disas-

sembled (see Differential Lockout Overhaul on page 20).

Shift fork push rod is secured to the lockout piston with

a nut.

12. Slide input shaft assembly out of cover.

13. Remove sliding clutch.

11. If input shaft bearing cup needs replacement, use either of the following recommended practices:

Weld: Place a weld bead around the cup, when the

weld cools the cup will fall out.

Drill: Drill a 1/4 inch size hole through the bearing

cover to the back side of the cup and use a punch to

remove the bearing cup.

1

1 - Sliding clutch

14. Remove input shaft bearing cone. Temporarily place

lockout sliding clutch over rear of input shaft, teeth

toward bearing cone. Place shaft in press and remove.

28

Page 33

Power Divider

Disassemble Power Divider Cover (For Axles with Input Shaft Tapered Roller Bearing)

Note: The drive on early pump models is equipped with a woo-

druff key. On late pump models the key is eliminated. The

drive shaft end has two machined flats and the drive gear

mounting hole is shaped to accommodate these flats.

1 - Lock nut

2 - Power divider cover

3 - Pipe plug

4 - Woodruff key

5 - O-ring

6 - Pump cover

7 - Capscrew

1

2

Power Divider

3

4*

13

12

11

10

8 - Lock washer

9 - Dowel pin

10 - Pump gears

11 - Magnetic strainer

12 - Expansion plug

13 - Pump drive gear

5

6

7

9

8

29

Page 34

Power Divider

1. With drive gear locknut previously removed and

working through input shaft bore, gently pry oil pump

drive gear from its shaft. See steps 5 and 6 for pump

disassembly.

2. For models built before February 1, 2000, remove

snap ring securing pinion outer support bearing race.

For models built after February 1, 2000, a design

change to a one piece roller bearing was implemented. Reference Dana Bulletin ABIB-0102 for more information.

WARNING

4. Unscrew and remove magnetic strainer from power

divider cover.

5. Remove oil pump cover capscrews and lock washers. Remove pump cover and o-ring.

Snap ring is spring steel and may pop out. Wear safety

glasses when removing.

3. Remove pinion outer support bearing race with suitable puller.

6. When woodruff key is used, remove key from gear

shaft. Remove pump gears from power divider cover.

30

Page 35

Power Divider

Assemble Power Divider Cover (For Axles with Input Shaft Tapered Roller Bearing)

1. Install pinion outer bearing race in power divider cover using a driver and a hammer.

2. For models built before February 1, 2000, install snap

ring to secure bearing race. For models built after

February 1, 2000, a design change to a one piece roller bearing was implemented. Reference Dana Bulletin

ABIB-0102 for more information.

WARNING

4. Install o-ring in pump cover, making sure o-ring is

seated firmly in body. If removed, install dowel pins.

Install pump cover on power divider cover and secure

with capscrews and lock washers. (See Torque Chart

on page 107).

Power Divider

5. Install pump drive gear. Install drive gear on pump

shaft end. Hand tighten drive gear nut.

Snap ring is spring steel and may pop out. Wear safety

glasses when installing.

3. Install pump gears in power divider cover (position

gear with long shaft in opening adjacent to input

shaft).

Note: Some pump drive shafts use a woodruff key. When key

is used, place key in shaft slot. Position gear on shaft engaging key. Then install gear with driver and hammer.

31

Page 36

Power Divider

6. Press input bearing cone on input shaft.

1 - Press

2 - Plate

3 - Drive Seal

4 - Input shaft bearing cone

5 - Input shaft

8. If bushing removal is needed, the bushings must exit

from the thrust washer side of the helical gear.

1

1

2

3

4

1 - Remove bearing from helical gear

9. Install bushings in helical side gear. Bushings must

5

be installed from thrust washer side of gear. See illustration for dimensional tolerances.

Note: Starting in March 1995, helical side gears are designed

with a shoulder step that helps prevent bushing walkout.

The inner bushing must be installed from the thrust

washer side of the helical gear against the shoulder step.

1 - Press

2 - Plate

3 - Drive sleeve

4 - Input shaft bearing cone

5 - Input shaft

7. Press bearing cup in input bearing cover.

1 - Input bearing cage

1

1 - Step added

1

2

3

4

1

1

5

1/32"

6

1 - Press

2 - Sleeve

3 - First bushing (press to shoulder step)

4 - Shoulder

5 - Sleeve

6 - Second bushing (recess 1/32”)

32

Page 37

Power Divider

10. Check expansion plug in power divider cover to make

sure it is in place and firmly seated. If loose, seat by

tapping with a hammer. Replace plug if necessary.

1

1 - Expansions plug

11. Install shift fork in power divider cover.

12. Install lockout cylinder assembly if removed. See Differential Lockout on page 20.

13. Place sliding clutch in power divider cover, engaging

clutch with shift fork. Position clutch teeth toward helical side gear.

14. Slide input shaft into power divider cover. Engage

shaft splines in lockout sliding clutch. Install bearing

spacer on input shaft. Use only on DS440-P, DS460P, DS480-P.

Snap ring is spring steel and may pop off. Wear safety glasses when installing.

Power Divider

16. Install magnetic strainer in power divider cover.

Torque to 40-60 lbs. ft. (54-81N•m).

15. Install input bearing cover and shims.

Note: Input shaft end-play must be adjusted after power divid-

er is assembled to differential carrier. For easier adjustment, temporally install input bearing cage cover and

tighten capscrews finger tight. See page 10 for End-play

Adjustment.

IMPORTANT

For axles with spring and thrust button between input shaft

and output shaft: For preliminary adjustment of input shaft

end play, install a 0.045" (0.024 mm) shim pack under bearing cover. See Axial Spring and Spring Button Adjustment

Section.

WARNING

Slide “D” washer over input shaft up to base of sliding clutch

splines. Install bronze thrust washer. Install helical side

gear. Secure with snap ring.

33

Page 38

Inter-axle Differential

Power Divider

1

2

3

6

8

4

5

7

1 - Case half

2 - Spider

3 - Bushing (use on models built before November 1, 1991)

4 - Side pinion

5 - Thrust washer

6 - Bolt

7 - Case half

8 - Lock nut

34

Page 39

Power Divider

Disassemble Inter-axle Differential

1. Punch mark differential case halves for correct position during reassembly.

2. Remove lock nuts and bolts. Separate case halves

and remove thrust washers, side pinions, bushings

and spider.

Note: Side pinion bushings are not used on tandem models

equipped with lube pumps built after November 1, 1991.

Use when originally equipped.

Assemble Inter-axle Differential

1. Install bushings, side pinions and thrust washers on

inter-axle differential spider. Pre-lube all components

at time of assembly.

Power Divider

1

1

1 - Punch marks

2. Install spider assembly in one differential case half,

align punch marks and install other case half. Secure

assembly with bolts and lock nuts. Torque to 17-23

lbs. ft. (23-31 N•m).

Note: Side pinion bushings are not used on tandem models

equipped with lube pumps built after November 1, 1991.

Use when originally equipped.

35

Page 40

Power Divider

Output Shaft Assembly

*Bushing removed from production axles in September 1994.

Output shafts with P/N 129016 do not use bushings.

1

1 - Output shaft

2 - Bushing

3 - O-rings

4 - Bearing cup (mounted in carrier)

5 - Bearing cone

2

3

6 - Side gear

7 - Axial spring

8 - Thrust button

9 - Snap ring

4

5

6

7

9

8

36

Page 41

Power Divider

Disassemble Output Shaft

WARNING

Snap ring is spring steel and may pop off. Wear safety glasses when removing.

1. Mount shaft assembly in vise, using brass vise jaw

protectors. Remove snap ring, side gear and bearing

cone assembly.

2. Remove output shaft o-rings. If replacement is necessary, remove bushing mounted in end of output

shaft.

Assemble Output Shaft

Note: Lubricate parts with gear lube during assembly.

1. Press bearing cone on output shaft side gear.

Power Divider

CAUTION

Provide protection against possible gear teeth damage during press operation.

2. Mount output shaft in a vise. Lubricate and install orings. If removed, install bushing in end of output

shaft.

Note: Output Shaft Bushings: In September 1994, a bushing-

less output shaft design change was implemented on

production 461, 521 and 581 model axles. Replace bushings only if originally equipped.

3. Remove bearing cone from side gear using press and

split-type puller.

Note: Tandem Axles built after September 1994 are equipped

with bushingless output shafts. Verify output shaft design before attempting to install a bushing.

WARNING

Snap ring is spring steel and may pop off. Wear safety glasses when installing.

3. Install side gear and bearing cone assembly. Install

snap ring, be careful not to over stretch the snap ring

when installing it into the shaft.

37

Page 42

Power Divider

Install Power Divider on Differential Carrier (with carrier assembled to axle housing)

Note: Lubricate all parts before installation.

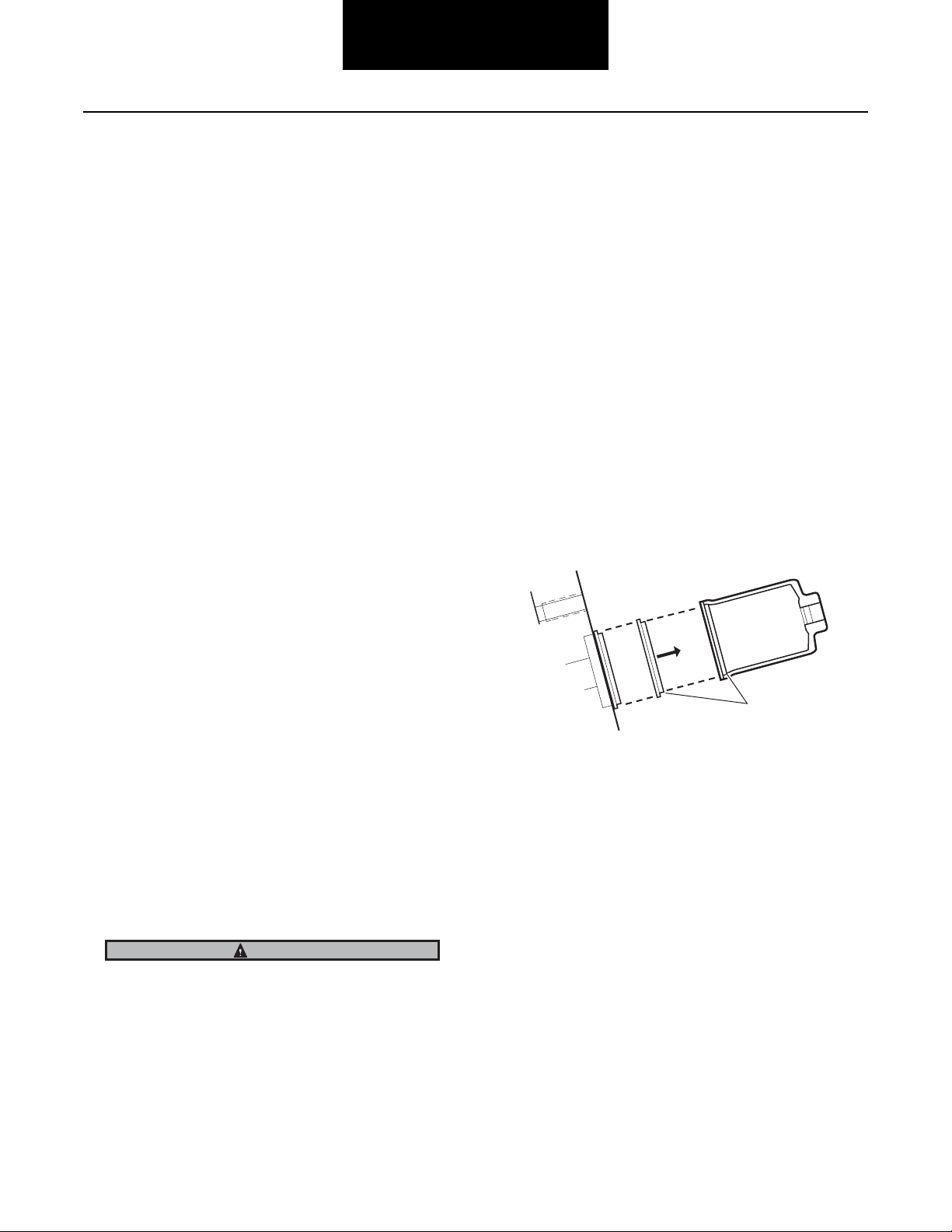

1. If removed, install axle housing cover and output

shaft bearing. For instructions, see Installation of Forward Axle Housing Cover and Output Shaft Bearing

Parts on page 14.

2. If output shaft was removed, lubricate o-rings, then

install shaft assembly in differential carrier and housing cover. Lubricate seal lip. Make sure yoke is clean

and dry, then install yoke and self-locking nut. Torque

nut to 840-1020 lbs. ft. (1139-1383 N•m).

3. Insert axial spring and thrust button in the end of the

output shaft

4. Install inter-axle differential on output shaft side gear

(with nuts facing away from side gear).

5. Use silicone rubber gasket compound on differential

carrier mating surface.

1

2

3

1

1 - Input shaft

2 - Thrust button (Part #51228)

3 - Axial spring (Part #51238)

4 - Output shaft

Note: Late model axles may be equipped with axial spring and

thrust button mounted between input and output shafts.

See page 43.

38

4

1

1 - Dowel pin

Note: Gasket compound will set in 20 minutes. Install power

divider before compound sets or reapply.

CAUTION

During installation of the power divider, the inter-axle differential may fall from the carrier. Exert caution to prevent

damage or injury.

Page 43

Power Divider

6. Make certain dowel pins are installed in carrier, then

install power divider assembly.

1

1 - Dowel pin

TIP: During installation, rotate input shaft to engage

input shaft splines with inter-axle differential. After

assembly output shaft should turn when input shaft

is rotated, and output shaft should turn independently from the input shaft.

8. Check and adjust input shaft end play. With power divider assembled to differential carrier, check end play

with dial indicator. End play should be 0.003" to

0.007". If necessary, adjust (see page 43). After end

play is within specifications, complete assembly procedures as follows:

Power Divider

9. Connect main driveline and inter-axle driveline.

10. Connect all applicable lines:

• IAD lockout

• Differential lock shift unit

11. Fill axle to proper lube level (see Lube Fill Capacities

on page 104).

IMPORTANT

TIP: The use of two guide pins in the carrier mating

surface will help align the PDU cover and aid in installation. Guide pins may be made from 9/16"-12 UNC

bolts approximately four inches long with the heads

removed.

7. Install power divider capscrews. Torque hex head

capscrew to 110-125 lbs. ft. (149-169 N•m) and

socket head capscrew to 115-125 lbs. ft. (155-169

N•m).

When the axle has been disassembled or the housing,

gears, axle shafts or wheel equipment replaced, check axle

assembly for proper differential action before operating vehicle. Wheels must rotate freely and independently.

39

Page 44

Power Divider

Install Power Divider on Differential Carrier (with carrier removed from axle housing)

The following instructions pertain to installation of power divider on differential carrier with carrier removed from axle

housing.

1. If output shaft side gear bearing cup was removed,

press bearing cup in carrier. Use a press and appropriate sleeve or use a brass drift and a mallet. Tap

bearing cup into its bore making certain cup is evenly

and firmly seated.

2. Lubricate o-rings, then install output shaft assembly

in carrier.

3. Insert axial spring and thrust button in the end of the

output shaft.

4. Install inter-axle differential assembly on output shaft

side gear (with nuts facing away from output shaft

side gear).

5. Apply silicone gasket compound on carrier mating

surface.

2

3

1

1 - Input Shaft

2 - Thrust button (Part #51228)

3 - Axial spring (Part #51238)

4 - Output shaft

Note: Early model axles may not be equipped with axial spring

and thrust button. If your axle was not equipped with

these parts, go to step 4.

40

4

Note: Gasket compound will set in 20 minutes. Install power

divider before compound sets or reapply.

6. Attach chain hoist to input yoke and install power divider assembly. During installation, rotate input shaft

to engage input shaft splines with inter-axle differential. After installation, rotate input shaft again. Output

shaft should turn when input shaft is rotated if assembly is correct.

Page 45

Power Divider

Note: Lifting mechanism may create nicks and burrs on input

yoke. Remove if present.

7. If removed, install dowel pins in carrier. Install power

divider cover capscrews and lock washers placing

sockethead capscrew at location shown on drawing.

Torque capscrews to appropriate specification. (See

Torque Chart on page 107).

2

1

2

1 - Socket head capscrew

2 - Dowel pin

Note: For power dividers equipped with an input shaft tapered

roller bearing, adjust shaft end play after power divider

cover is assembled to differential carrier. Refer to page

43.

Power Divider

41

Page 46

Power Divider

Measure and Adjust Input Shaft End-Play

Note: After power divider overhaul and installation on carrier,

check and adjust input shaft end-play.

Input Shaft End Play Chart

New or Rebuild

with new parts

0.003" to 0.007"

Acceptable End-Play Tolerances when measuring as a regular maintenance procedure with axle in truck.

Up to 0.060" with

over 100,000

miles or 1 year

service off-road

Up to 0.040" with

less than 100,000

miles or 1 year

service on-road

NOTE: Because of manufacturing variations in individual parts, correctly adjusted end-play could vary 0.010", after

the unit is rotated.

NOTE: If end-play exceeds limits, disassemble power divider and replace worn

parts.

Without Input Shaft Axial Spring Thrust

Button

CAUTION

In September 1988, a axial spring and thrust button were

added between the input and output shafts. End-play tolerances are the same for axles with or without this spring and

button. However, end-play measurement procedure is different than described here. Refer to page 44 of this manual

for procedure variances.

2. Reinstall bearing cover without shims. Hold in position with hand pressure and measure clearance between power divider cover and bearing cover, using a

feeler gauge.

3. The bearing cover clearance measured in Step 2 plus

0.005" will equal shim pack thickness required for desired end-play (rebuild with new parts). Add 0.015" to

shim pack for rebuild with used parts.

4. Install shim pack and bearing cover. Install capscrews. Torque screws to 75–85 lbs. ft. (101–115

N•m). Make sure shims are flat with no kinks or

bends.

5. Install yoke. Tighten nut snugly. Tap end of input

shaft lightly to seat bearings.

6. Check input shaft end-play with dial indicator positioned at yoke end of input shaft. Move input shaft axially and measure end-play. If end-play is correct, seal

shim pack with Dana approved RTV compound to

prevent lube leakage. Then torque input shaft nut.

The correct end-play when new parts are used in overhaul is

0.003" to 0.007", with reused parts the maximum is 0.14".

1. Remove input shaft nut, flat washer and yoke. Remove input bearing cover capscrews. Remove bearing cover (and shim pack if installed).

42

Page 47

Power Divider

With Input Shaft Axial Spring Thrust Button

In September 1988, Spicer added an axial spring and thrust

button between the input and output shafts. The addition of

these parts reduces shaft end play movement by loading the

shafts axially in the direction of the yoke. End play tolerances

are the same for axles with or with out the new spring and

thrust button. However, end play measurement procedure is

different as described below.

Note: As of September 1994, production and service output

shafts for the D461, 521 and 581 models are no longer

produced with a bushing in the end of the shaft. The

shafts can be identified by part number, see Output Shaft

Assembly on page 38 for more information.

1

2 3

3. Build up a 0.045" (0.024 mm) thick shim pack and

place shim pack and bearing cover on power divider

cover.

Power Divider

4. Install the U-bracket on bearing cover, using two

bearing cover capscrews. Install all other cover capscrews and torque to 75-85 lbs. ft. (101-115 N•m).

1

2

4

1 - Thrust button

2 - Axial spring

3 - Output shaft

4 - Input shaft

Input Shaft Axial Spring

1. Fabricate a U-bracket from 1 in. flat stock (minimum

thickness 0.125") as specified in the illustration.

2. If axle is assembled, first remove input shaft nut, flat

washer and yoke.

3

4

5

6

1 - Bearing cover capscrew

2 - Lock washer

3 - Fabricated U-bracket

4 - Inner bearing cover

5 - Input bearing cover shim(s)

6 - Input shaft

43

Page 48

Power Divider

5. Position a dial indicator on the end of the input shaft.

3

2

1

1 - Pry bar

2 - U-bracket

3 - Dial indicator

4 - Input shaft

Remove shim to decrease end-play

Measured end-play (Step 6) 0.015" – 0.015"

Desired end-play (New Parts) 0.003” to 0.007”

Remove shims to provide desired end-

0.012” to 0.008”

play

4

11. To add or remove shims, remove input shaft nut, flat

washer and yoke. Remove capscrews, lock washers

and bearing cover. Add or remove shims as required.

12. Install bearing cover and capscrews. Seal shim pack

with Dana approved RTV compound to prevent lube

leakage then torque input shaft capscrews 75–85

lbs. ft. (101–115 N•m).

13. Install yoke.

14. Install new yoke nut with the pre-applied thread adhesive compound. Tighten the nut to the specified

torque 840–1020 lbs. ft. (1148–1383 N•m).

6. Lift up on pry bar to compress input shaft.

7. Insert a pry bar through the U-bracket with the end of

the bar resting on the end of the input shaft.

8. Zero the dial indicator and lift up on the pry bar to

move the input shaft axially until it bottoms out within

the bearing cover. Measure the end-play.

9. If the end-play is acceptable, remove U-bracket and

bearing cover. Seal shim pack to prevent lube leakage. Reinstall bearing cover and capscrews. Torque

capscrews to 75-85 lbs. ft. (101-115 N•m). Continue

axle assembly as necessary.

10. If end-play is incorrect, change shim pack size as follows:

Add shims to increase end-play

Desired end-play (New Parts) 0.003" to 0.007"

Measured end-play (Step 6) 0.001” – 0.001”

Add shims to provide desired end-play 0.002" to 0.006"

44

Page 49

Carrier Assembly

Forward Axle Carrier Assembly (Single Speed) with Diff. Lock - Parts Exploded View

4

52 53 54 56 57 58 55 6 1 5

59

7

2

3

1

DIFFERENTIAL

& RING GEAR

14

8

9

10

11

19 15

13

1

12

16

17

18

20

Carrier Assembly

21

30

RH

22

23 24

33

29 31 32 35 34 38 36 37 34 35 28 27 26 25

LH

45

Page 50

Carrier Assembly

76 77

62

60

78

61

79 80 81 82 83

106

63

64 65

66

91

INTER-AXLE

DIFFERENTIAL

ASSEMBLY

68

67

92

93

84 85 86 88 8990

69

105

71

87

74

70

73

75

70

72

46

39 31 40

41

42

43 45

LUBE PUMP

104 103 95

444647

43

50

48

40

91

49

94 97 98 99

96

51

100

101

102

Page 51

Carrier Assembly

1 - Differential carrier & bearing caps

2 - Bearing capscrew

3 - Flat washer

4 - Lockwire

5 - Dowel bushing

6 - Bearing cap adjuster lock (RH)

7 - Capscrew

8 - Bearing cap adjuster lock (LH)

9 - Cotter pin (LH)

10 - Expansion plug (upper)

11 -Expansion plug (lower)

12 - Filler plug

13 - Shift fork shaft

14 - Carrier cover dowel pun

15 - Shift unit mounting stud

16 - Shift fork seal & spring assembly

17 - Flat washer

18 - Stud nut

19 - Shift fork & roller assembly

20 - Shift unit assembly

21 - Sliding clutch

22 - Differential bearing adjuster (RH)

23 - Differential bearing cup (RH)

24 - Differential bearing cone (RH)

25 - Differential bearing adjuster (LH)

26 - Differential bearing cup (LH)

27 - Differential bearing cone (LH)

28 - Differential case (plain half)

29 - Differential case (flanged half)

30 - Differential case capscrew

31 - Ring gear & drive pinion

32 - Bolt

33 - Nut

34 - Differential side gear

36 - Side pinion

37 - Side pinion thrust washer

38 - Spider

39 - Pinion pilot bearing

40 - Pinion bearing cone

41 - Pinion bearing spacer washer

42 - Pinion bearing spacer

43 - Pinion bearing cup

44 - Pinion bearing cage

45 - Pinion bearing cage shim

46 - Lock washer

47 - Bearing cage capscrew

48 - Pinion helical gear

49 - Outer pinion support bearing (one

piece)

50 - Pinion shaft end nut

51 - Pinion nut spring pin

52 - Output shaft nut

53 - Output shaft washer

54 - Rear bearing retaining washer

55 - Axle housing cover

56 - Output shaft oil seal

57 - Bearing snap ring

58 - Output shaft bearing

59 - Filler plug

60 - Output shaft

61 - Output shaft bushing

62 - Output shaft O-ring

63 - Output shaft bearing cup

64 - Output shaft bearing cone

65 - Output shaft side gear

66 - Side gear snap ring

67 - Output shaft compression spring

68 - Output shaft thrust bearing

69 - Inter-axle differential assemble

70 - Inter-axle differential case half

71 - Case bolt

72 - Case nut

73 - Side pinion

74 - Side pinion thrust washer

75 - Spider

76 - Helical side gear snap ring

77- Helical side gear

78 - Helical side gear bushing

79 - Helical side gear thrust washer

80 - Helical side gear “D” washer

81 - Lockout sliding clutch

82 - Input shaft

83 - Input shaft bearing cone

84 - Input shaft bearing cup

85 - Input cover shim

86 - Input bearing cover

87 - Bearing cover capscrew

88 - Input shaft oil seal

89 - Input shaft nut washer

90 - Input shaft nut

91 - PDU carrier cover

92 - Carrier cover capscrew

93 - Lock washer

94 - Pipe plug

95 - Expansion plug

96 - Magnetic filter screen

97 - Pump gear & shaft assembly

98 - Cover O-ring

99 - Lube pump cover

100 - Lock washer

101 - Cover capscrew