Page 1

Spicer

®

CTIS

(

Central Tire Inflation System

Troubleshooting Guide

AXTS0015

)

July 2010

Page 2

General Information

General Information

The description and specifications contained in the service

publication are current at the time of printing.

Dana reserves the right to discontinue or modify its models

and/or procedures and to change specifications at any time

without notice.

IMPORTANT NOTICE

This symbol is used throughout this

manual to call attention to procedures

where carelessness or failure to follow

specific instructions may result in

personal injury and/or component

damage.

Departure from the instructions, choice

of tools, materials and recommended

parts mentioned in this publication

may jeopardize the personal safety

of the service technician or vehicle

operator.

Any reference to brand name in this publication is made as an

example of the types of tools and materials recommended for

use and should not be considered an endorsement. Equivalents may be used.

WARNING: Failure to follow indicated

procedures creates a high risk of personal

injury to the servicing technician.

CAUTION: Failure to follow indicated

procedures may cause component

damage or malfunction.

IMPORTANT: Highly recommended

procedures for proper service of this unit.

Note: Additional service information not

covered in the service procedures.

Always use genuine Spicer replacement parts.

Every effort has been made to endure the accuracy of all information in this guide. However, Dana Commercial Vehicle

Systems Division makes no expressed or implied warranty

or representation based on the enclosed information.

Any errors or omissions may be reported to:

Marketing Services

Dana Commercial Vehicle Systems Division

P.O. Box 4097

Kalamazoo, MI 49003

Tip: Helpful removal and installation

procedures to aid in the service of this unit.

Page 3

Table of Contents

Table of Contents

General Information

Central Tire Inflation System (CTIS) . . . . . . . . . . . . . . . 1

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Component Description . . . . . . . . . . . . . . . . . . . . . . . . 2

Central Tire Inflation System Components . . . . . . . . . . 3

Simplified System Schematic . . . . . . . . . . . . . . . . . . . . 4

Operator Instructions

Flange or Panel

Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Driver Display Module (DDM)

Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . 9

Warning Signals . . . . . . . . . . . . . . . . . . . . . . . . . 10

Diagnostics

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Service Codes Summary . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service Codes

No Code

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Service Guidelines

CTIS Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Joint Compounds and Fittings . . . . . . . . . . . . . . . . . . .59

Air Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Wire Harness

Connector Illustrations . . . . . . . . . . . . . . . . . . . . . . . .61

M939 Wiring Diagram (676422 and 676603) . . . . . . . . 62

Flange Mount Wiring Diagram . . . . . . . . . . . . . . . . . . .63

Panel Mount Wiring Diagram . . . . . . . . . . . . . . . . . . . .64

Chassis ECU with DDM Wiring Diagram

Separate Power and Switched Ignition . . . . . . . . .65

All Power Switched . . . . . . . . . . . . . . . . . . . . . . . .66

Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . .67

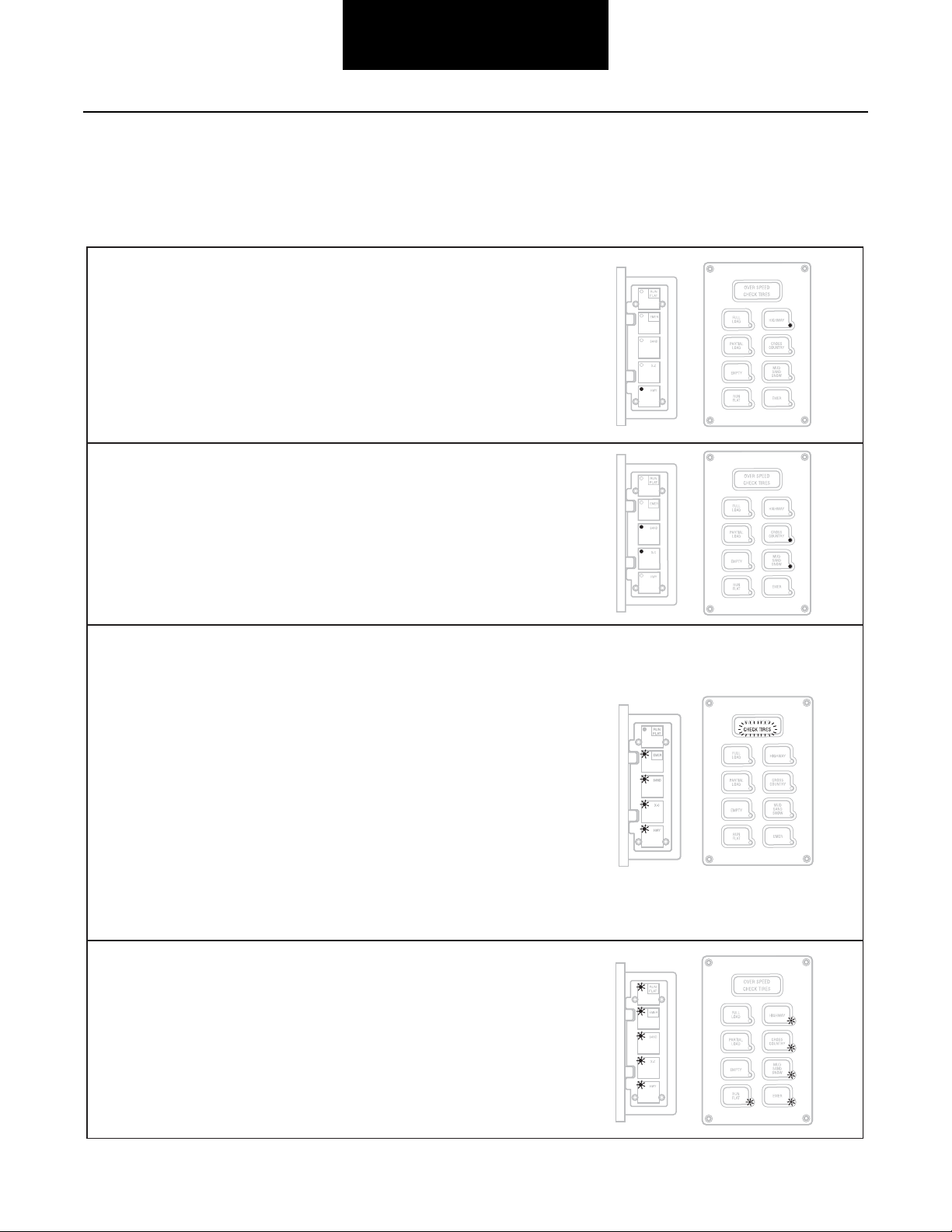

5 Flashing Lights or DDM – Dashes "--"

4 Flashing Lights or CHECK TIRES Flashing

2 Terrain Lights on Solid or DDM – Dashes "--"

No Terrain Lights or DDM – Dashes "--"

No Terrain Lights or DDM – Blank Display

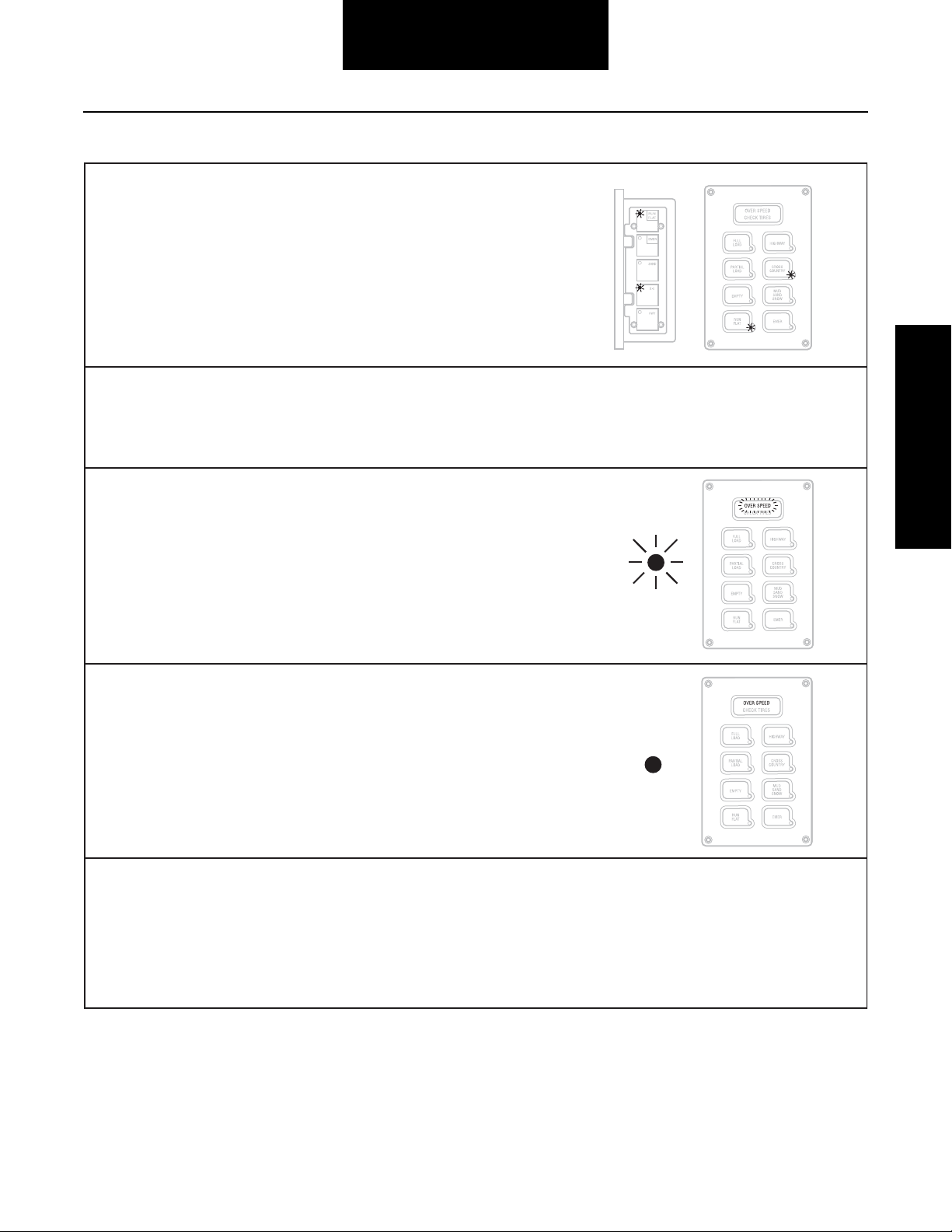

DDM – Dashes "--"

Lights Sequentially Flashing

Solid Warning Lamp or Solid OVER SPEED

No Indication or DDM – Dashes "--"

No Indication

Low Pressure (Codes 26, 27) . . . . . . . . . . . . . . . 21

Low Air Supply (Code 32) . . . . . . . . . . . . . . . . . . 23

Atmospheric (Code 35) . . . . . . . . . . . . . . . . . . . . 25

Inflate Trend (Codes 36, 37) . . . . . . . . . . . . . . . . 27

Deflate Trend (Code 14) . . . . . . . . . . . . . . . . . . . 29

PCU Sensor (Codes 33, 34) . . . . . . . . . . . . . . . . 31

Pressure Switch (Code 31) . . . . . . . . . . . . . . . . . 33

Tire Leak (Imbalance) (Codes 44, 45) . . . . . . . . . 35

Tire Leak (Confirm) (Codes 41, 42) . . . . . . . . . . 37

Between Modes (Codes 23, 24) . . . . . . . . . . . . . 39

Deflate Signal (Codes 11, 12, 16) . . . . . . . . . . . . 41

PCU Solenoid (Supply, Deflate, Control, Front,

or Rear) (Codes 51, 52, 54, 55, 56) . . . . . . . . . . 43

Power (Code 17) . . . . . . . . . . . . . . . . . . . . . . . . . 45

Display Control Communications (Code 75) . . . . 47

Configuration Error . . . . . . . . . . . . . . . . . . . . . . . 49

Speed Signal (Codes 18, 76, 77) . . . . . . . . . . . . 51

Miscellaneous Output (Codes 53, 57, 58, 67, 68) 53

Wheel Valve Shut Off (Codes 61, 62, 64, 65) . . . 55

i

Page 4

Central Tire Inflation System (CTIS)

General Information

Spicer’s Central Tire Inflation System features driver control of

tire air pressure through:

• Simple push button operation.

• Electronic braking priority for air system.

• Vehicle speed sensing and response capability.

• Self-diagnostics.

• Optional independent front and rear operation.

• Optional load selection.

Key Features

Depressurized Control Lines

The only time the system is pressurized is when changing tire

pressures or during pressure checks. Wheel valves isolate the

tires from the rest of the system.

Electronic Braking Priority

A pressure switch, installed in the supply tank, controls the

CTIS and use of air. This optimizes and protects the brake

system’s primary tank pressures during system operation.

Self-Diagnostic and Auto Shut-Down

The Spicer CTIS provides self-diagnosis during operation. If

the system detects a problem, it will display a series of flashing lights on the Electronic Control Unit (ECU) panel to alert

the

driver. If necessary, it will close the wheel valves and shut

down.

Diagnostic Capability

The Spicer CTIS provides for easy troubleshooting using

PC-based or industry standard tools. Personal computersupported diagnostics improve troubleshooting and reduce

maintenance time. The diagnostics provide for manual control

of CTIS test sequences and gives historical and active service

code data.

Speed/Pressure Control and Warning

If truck speed exceeds the maximum allowable speed for a

given setting, a panel-mounted light is activated by CTIS to

warn the driver. If speed is not reduced, the system

automatically inflates the tires to the appropriate pressure.

Manual Tire Inflation/Deflation

A valve stem has been included on each wheel valve, and may

be used for manual inflation, deflation, or measurement of tire

pressures.

Run Flat Operation

The CTIS normally checks tire pressures at intervals of 15

minutes. If possible tire damage is detected, the system will

activate Auto RUN FLA

check interval to 15 seconds, helping to assure that the tire

will remain inflated despite minor tire damage.

T. RUN FLAT reduces the pressure

1

Page 5

CTIS Key Features

Component Description

General Information

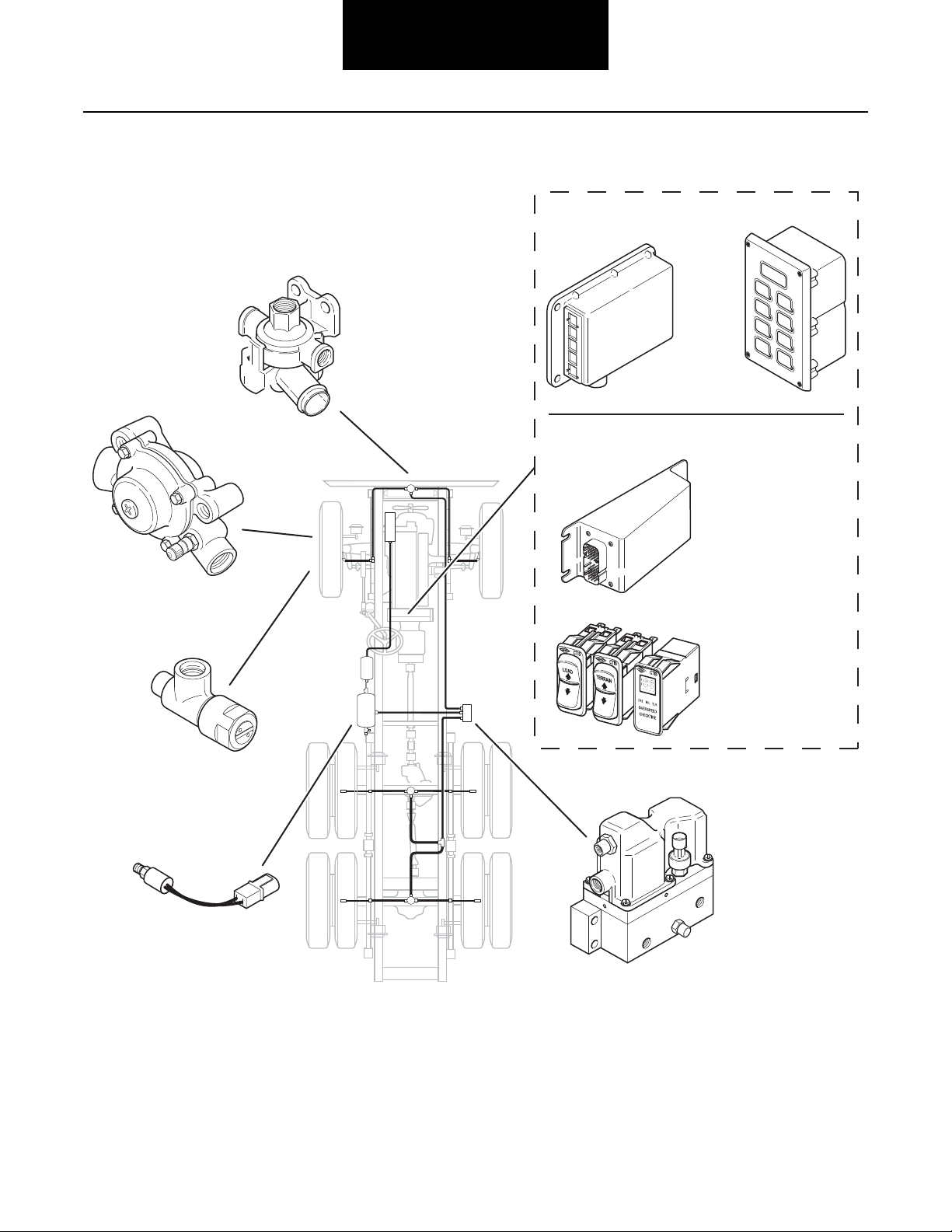

Wheel Valve (WV)

All axles use a Wheel Valve (WV) at each end. Dual wheels are

typically connected to one WV to provide tire pressure

balance between duals. When the system is idle, the WV

isolates the tire(s). A standard tank valve is included for

manual inflation.

Quick Release Valve (QRV)

The Quick Release Valve (one per axle) receives pneumatic

signals from the Pneumatic Control Unit (PCU) and either

inflates the tires, or vents air from the tires causing them to

deflate. The QRV can be vented through the air stack to

provide for vehicle deep water fording.

Air Transport Valve (ATV)—Optional

The Air Transport Valve (ATV) may be added in-line between

the Wheel Valve and the tire. Its purpose is to manually lower

the tire pressure significantly, decreasing the height of the

vehicle, to allow the vehicle to be loaded onto planes, etc. with

low clearances.

Load Selection/Sensing—Optional

Electronic Control Unit (ECU)

The Electronic Control Unit (ECU) is the control center for the

entire Central Tire Inflation System. The ECU receives commands from the driver through push buttons, and transmits

and monitors appropriate signals throughout the system.

Pneumatic Control Unit (PCU)

The Pneumatic Control Unit (PCU) is a solenoid controlled

manifold that controls the air system. It also contains the PCU

sensor (transducer) which reads tire pressures.

Speed Sensor or Speed Input

Speed is read from the vehicle data link or a separate speed

sensor.

Pressure Switch (PS)

The Pressure Switch (PS) acts as an electronic brake priority

switch. It prevents the Central Tire Inflation System from

using air from the supply tank until the brake system is fully

charged. The PS also ensures that enough pressure exists for

the system to operate properly.

Some CTI systems make use of either a user selectable load

setting or an automatic load setting, which adjusts pressure

targets based on the load of the vehicle.

Air Lines

The Central Tire Inflation System uses a dedicated pneumatic

system plumbed from the vehicles’ exiting supply tank. Air

lines between the Pneumatic Control Unit and the Quick

Release Valves (QRV) are called “Upper Control Lines”. Air

lines between the QRVs and the Wheel Valves are called

“Lower Control Lines”.

2

Page 6

General Information

RUN

FLAT

EM R

MPTY

MUD

SAND

S OW

PA T A L

L AD

CROSS

COUNTRY

FU L

LOAD

HIGHWAY

OVER SPEED

CHECK TIRES

Driver Display

Module

Chassis Mount

ECU

Electronic Control Unit (ECU)

• With separate operator controls

– or –

• With integrated operator controls

Pneumatic Control Unit

Pressure Switch

Air Transport Valve

(optional)

Wheel Valve

Quick Release Valve

Central Tire Inflation System Components

3

Page 7

CTIS Components

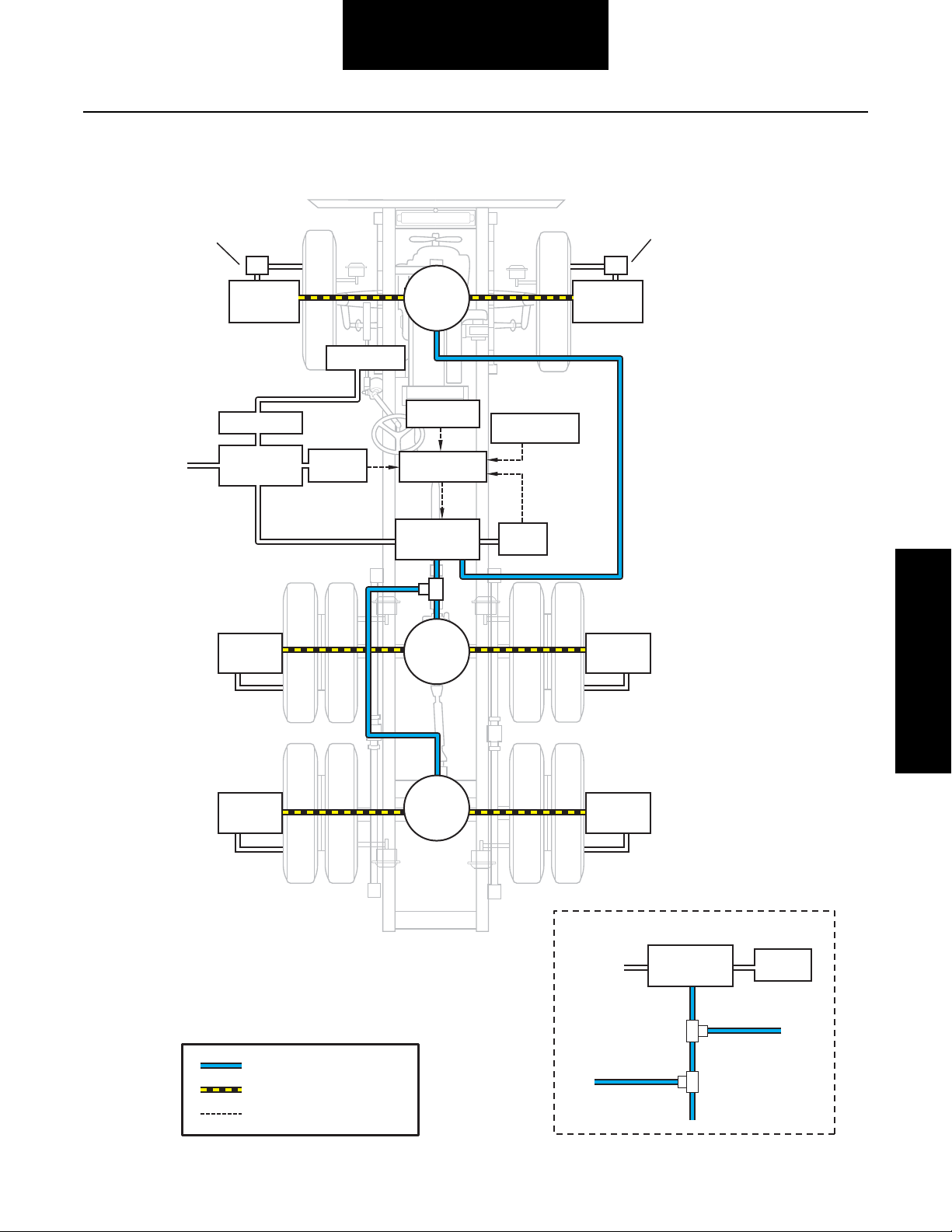

Simplified System Schematic

Tire

Hose

Tire

Hose

To Steers

Pressure

Sensor

To D rive Axle 2

To D rive Axle 1

Load Sensor

(Optional)

Electronic

Control Unit

Pressure

Switch

To P rimary and

Secondary

Tanks

Single Channel System

System Key

Pneumatic – Upper Control Lines

Electrical

Wheel

Valve

Wheel

Valve

Compressor

Speed Sensor

Air Transport

Valve (Optional)

Air Transport

Valve (Optional)

Tire

Hose

Supply Tank

Air Dryer

Tire

Hose

Tire

Hose

Tire

Hose

Supply Line

PCU

Sensor

Supply Line

Pneumatic – Lower Control Lines

Pneumatic

Control Unit

Quick

Release

Valve

Quick

Release

Valve

Wheel

Valve

Wheel

Valve

Quick

Release

Valve

Wheel

Valve

Wheel

Valve

PCU

General Information

4

Page 8

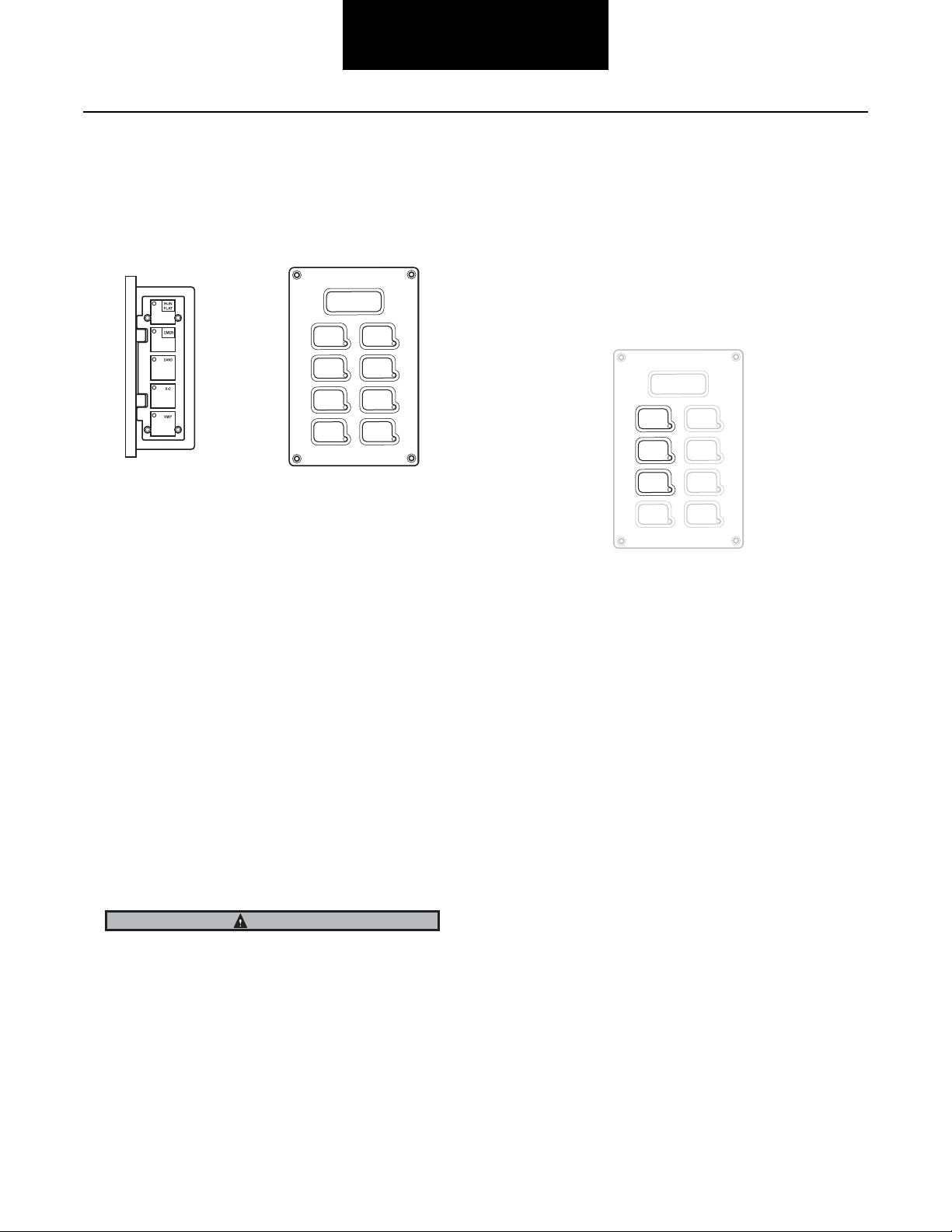

Flange or Panel—Operator Controls

RUN

FLAT

EMER

EMPTY

MUD

SAND

SNOW

PARTIAL

LOAD

CROSS

COUNTRY

FULL

LOAD

H GHWAY

OVER SPEED

CHECK TIRES

WARNING

RUN

FLAT

EMER

MUD

SAND

SNOW

CROSS

COUNTRY

HIGHWAY

OVER SPEED

CHECK TIRES

EMPTY

PART AL

LOAD

FULL

LOAD

Operator Instructions

The integrated push button/display is the primary interface for

display of system information and for push button entry of

system instructions. The following sections explain the

purpose and operation of the ECU controls and display.

Terrain Selection

These keys select pressures appropriate for different surface

conditions. Any mode may be selected at any time (within

built in speed limitations). Depressing the button for the

current mode will result in a pressure check.

HWY (Highway)—For operation on improved paved surfaces.

Load Selection (Optional)

This feature allows selection of pressures appropriate for

different vehicle load conditions (full load, partial-load,

empty). Switching the load setting will result in a pressure

check and subsequent changing of the pressures as

determined by the system.

Mode Annunciator Lights

The associated annunciator lights indicate the selected mode

and signal one of two states:

XC (Cross Country)—For operation on non-paved secondary

roads.

SAND (Sand)—For operation on trails and other unimproved

surfaces.

EMER (Emergency)—For selection of extremely low tire

pressures to help free a stuck vehicle, or to traverse a short

distance over a terrain known to require very low tire

pressures. Since this is an extremely low pressure, the

warning lamp will flash whenever this pressure is utilized.

The EMER key is for extreme conditions only and should not

be used for normal driving.

5

If the light is flashing:

The system is in the process of checking or changing pressures to attain the pressure(s) associated with that mode

light.

Some clicking may be heard from the PCU as the system

cycles to achieve the new pressure(s). A deflate will be

periodically interrupted as the system checks tire pressures to

determine how much further deflation is necessary.

Note: Adequate supply system pressure is required to begin

or continue any pressure changing sequence.

If the light is on steady:

The selected pressure has been achieved, the tires have been

isolated and the system is depressurized. The system will

cycle periodically to assure that tire pressure is maintained.

Note: The system is designed to allow tire pressure increase

due to heat buildup during vehicle use. This system will

not automatically deflate these pressure buildups—a

lower pressure mode must be selected to initiate a

deflate.

Page 9

Operator Instructions

Flange or Panel

EMER

EMPTY

MUD

SAND

SNOW

PART AL

LOAD

CROSS

COUNTRY

FULL

LOAD

H GHWAY

OVER SPEED

CHECK TIRES

RUN

FLAT

CAUTION

Run Flat Key and Annunciator Light

This key instructs the system to check tire pressures at more

frequent intervals. This key also allows the operator to

override the “4 flashing lights” (tire leak imbalance) codes and

reattempt 2 lights and some 5 lights codes. (See Warning

Signals in next section). While the system is in RUN FLAT

mode, the RUN FLAT light will flash on and off. The “RUN

FLAT” feature will automatically deselect after 10 minutes, or

may be shut off by pressing the button a second time.

Selecting RUN FLAT to enable the system to inflate a significantly low tire may cause other tires on that channel to

temporarily lose pressure. This condition will be corrected

once the low tires is inflated to the pressure of the other

tires.

6

Page 10

Operator Instructions

Single Terrain Light

• Flashing - System is working to achieve new pressures

associated with that mode light.

• Solid - Pressure is achieved, system is not active, and wheel

valves are closed.

2 Terrain Lights on Solid

System has shut off, closing wheel valves, with tire pressure

between two mode settings.

• Infl ating or defl ating tires is taking too long.

• CTIS is still operational.

• Select any mode button to re-attempt pressure change.

• On 2-channel systems, normal operation continues on

unaffected channel.

• Frequent occurrences may indicate need for service.

4 Terrain Lights Flashing or CHECK TIRES Flashing

Indicates low pressure in one or more tires. Stop vehicle and

identify damage.

• System shuts off, closing wheel valves, and waits for

operator instruction.

• T

ire damage i

s possible.

• CTIS should not be operated if major tire damage is found.

Repair tire before continuing to operate vehicle.

• On 2-channel systems, normal operation will continue on

the unaffected channel.

• If tire damage is minimal, operate CTIS by selecting RUN

FLAT.

Not

e: Repeated use of RUN FLAT to override mode light warnings

may result in tires infl ating higher than set point.

Note: Excessive air seal leakage on cold weather startup may

result in "4-5 Mode Lights" warning. If no tire damage exists, this

condition will self-correct as seals warm up with use.

5 Lights Flashing

System shuts off at least one channel due to fault detection on a

CTIS component.

• System closes wheel valves.

• System may periodically cycle PCU to determine if fault still

exists.

• On 2-channel systems, operation may be allowed on the

unaffected channel.

• Get service at next opportunity.

• No ability to override

system.

Several warning signals report operating problems. The Central Tire Infl ation System uses general sequences displayed

on the electronic control unit lights and an instrument panel-mounted warning lamp to identify the type and area of fault.

Flange or Panel—Warning Signals

7

Page 11

Flange or Panel

RUN FLAT Flashing (with a Terrain Light)

RUN FLAT is selected, and tire pressures are checked at more

frequent intervals.

• If RUN FLAT is pushed to clear a "4 Mode Lights" fl ashing

display, imbalance and confi rmation fault detection is

overridden for the duration of RUN FLAT.

• Turn off by depressing RUN FLAT again or it will "time-out"

after 10 minutes.

Warning: RUN FLAT sho

uld not be used to infl ate tires with

substantial damage/defects. Use of RUN FLAT can result in other

tires on channel losing pressure.

No Terrain Lights

CTIS senses either a low system voltage or an electrical fault with a

Pneumatic Control Unit solenoid.

• System shuts off, closing wheel valves.

• Vehicle power i

s inadequate.

Flashing Warning Lamp and/or Buzzer or OVER SPEED Flashing

Vehicle speed is too fast for pressure selected.

• Reduce speed or select higher pressure by pressing

appropriate key.

• Continued operation in this mode will result in automatic

selection of more appropriate pressure setting.

• Warni

ng lamp may fl ash while system is in EMERGENCY

mode.

Solid Warning Lamp or Solid OVER SPEED

ECU has seen 25-50 ignition cycles without seeing any speed

signal.

• If no problem exists with speed circuit wiring or sensor,

lamp will go off when vehicle is moved.

Lights Sequentially Flashing (one after another)

A confi g uration error has occurred and the CTIS memory has been

"reloaded" from the system defaults.

• System reloads default confi g uration values.

• Pressing HWY and RUN FLAT butto

ns together may clear

display.

• Any past changes of target pressure, etc. should be

updated.

Lamp on

Instrument

Panel

Lamp on

Instrument

Panel

Operator Instructions

8

Page 12

Operator Instructions

CAUTION

CAUTION

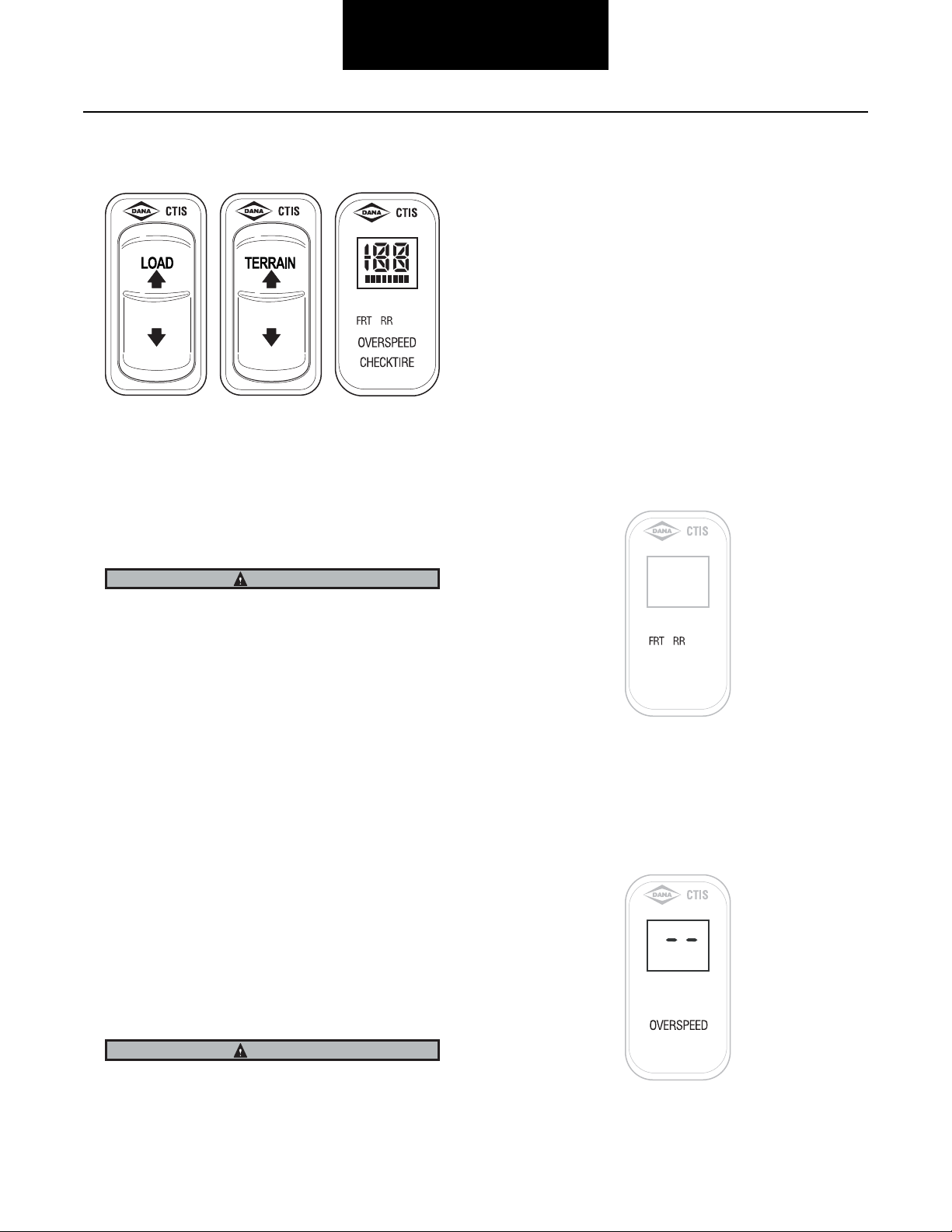

Driver Display Module—Operator Controls

Display

The Driver Display Module (DDM) uses a multi-function display to indicate the current selections. The display will show

HY for highway pressures, CC for cross-country pressures,

SS for mud-sand-snow pressures, and E for emergency pressures.

Note: The system is designed to allow tire pressure increase

due to heat buildup during vehicle use. It will not automatically deflate these pressure buildups.

Channel Indicators

Load Selection

Vehicle load selection is represented by a horizontal bar graph

under the mode display. Depress the load rocker switch to

change the selection, up for increasing load and down for

decreasing load.

Operating a loaded vehicle at unloaded tire pressures may

result in tire overheating and reduced tire life or blowout.

Terrain Selection

The terrain selection is changed by depressing the terrain

rocker switch, up to increase pressures and down to decrease

pressures. Any switch operation which does not change pressures will command the system to do a pressure check.

Tire pressures for the following terrains can be programmed

and may be selected by the operator:

• (HY) Highway - For travel on paved surfaces at

higher speeds.

The DDM indicates FRT or RR, respectively, for front or rear

axle groups. A flashing indicator identifies a group which is

changing or checking pressures. A solid indicator identifies a

group that has achieved target pressure.

Service Code Indication

The DDM will not display service codes directly but will display two dashes if service is required. (Accessing the service

codes requires a diagnostic tool). Also, a solid over speed

indicator identifies a loss of expected vehicle speed input.

• (CC) Cross Country - For reduced speed operation

on secondary roads.

• (SS) Mud Sand Snow - For reduced speed operation

on unpaved surfaces.

• (E) Emergency - For selection of extremely low tire

pressures to help free a stuck vehicle.

The Emergency selection is for extreme conditions only and

should not be used for normal driving.

9

Page 13

Operator Instructions

Driver Display Module

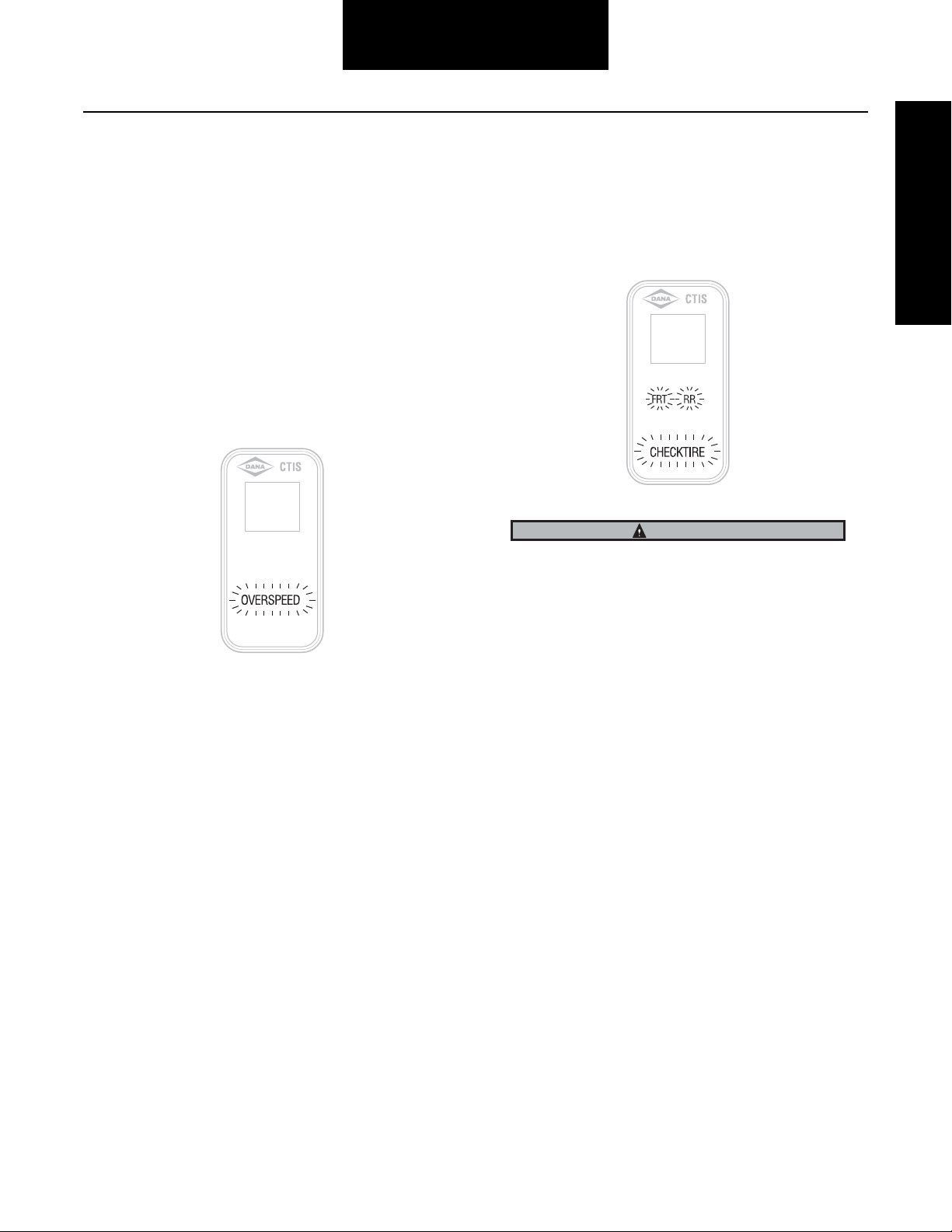

Driver Display Module (DDM)—Warning

Signals

CTIS includes two distinct warnings to report possible tire

problems and inappropriate vehicle operation. You must take

immediate action to either reduce vehicle speed or check tire

condition whenever these warnings are displayed.

Over Speed Flashing

This signal reports that the vehicle speed is too fast for the

pressure selected. You must either reduce speed or select a

higher pressure by pressing the appropriate key. Continued

operation in this mode will result in the system automatically

selecting a more appropriate pressure setting.

Check Tire Flashing

This signal reports that one or more tires may be at a significantly lower pressure than the others and could indicate that a

tire is not holding pressure. Blinking channel indicators (FRT

or RR) indicate the fault location. Stop the vehicle immediately in a safe place and identify the extent of tire damage.

IMPORTANT

Tires can still go flat! Although the Central Tire Inflation System is designed to identify under-inflated tires and fill these

tires to the desired operating pressure, you can still expect

that tires will occasionally be punctured or otherwise damaged during normal use and no longer retain air reliably. A

daily walk-around inspection of the vehicle at the start of the

day, including a manual check of the tires, is still an important

responsibility of the vehicle operator. Tire damage is more

apparent after the vehicle has been idle overnight and will be

more difficult to detect visually once the CTIS equipped vehicle is in operation. Although observation of excessive inflation

periods through the driver interface can help identify a tire

problem, you should have damaged tires replaced prior to

placing the vehicle in operation.

10

Page 14

Diagnostics

Diagnostics

This section covers the equipment and procedures used to

find and correct CTIS problems.

Test Equipment

CTIS troubleshooting can be performed at three levels:

1. PC diagnostics.

2. Handheld tester.

3. ECU warning signals (flashing light combinations).

Regardless of the testing equipment used, the

troubleshooting procedures will be based upon the diagnostic

service codes. Diagnostic tools offer the advantages of

computer-aided testing without interpreting service codes.

CTIS Diagnostics

The onboard system diagnostics are an important feature of

Spicer's CTIS. This section describes the use of service codes

to identify CTIS operating problems.

The CTIS uses a code to identify service issues. The codes

can be extracted from the ECU memory using a diagnostic

service tool equipped with the appropriate software. Refer to

the Service Codes Summary for more detailed information on

service codes.

Service Codes

Test Modes

Diagnostic tools allow the system to be placed in several

diagnostic modes:

Info—Display ECU information and configuration.

Codes—Active and historic codes are listed as reported by

the ECU.

Monitor (Normal)—CTIS operates normally, while status of

system components is observed.

Test—The following operations can be performed on each

channel (axle group):

• Check & Hold—System checks and

displays the pressures, then holds pressure in air

lines (quick test of control line and seal integrity).

• Deflate—System "manually" deflates (test the

deflation signal).

flate—System "manually" inflates (test for large

• In

leaks).

• Hold—Pressure is held in control lines (test for

small leaks).

Setup—Allows the technician to modify parameters such as

target tire pressures, etc.

Codes are described in the Service Codes Summary section.

Some service codes identify the component that is associated

with the problem. A list of possible causes is shown in order

of most likely occurrence.

In addition, the system stores service codes in the memory of

the ECU. These historical codes can only be accessed by a

diagnostic tool. Historical codes are automatically cleared

after 50 ECU resets with no active faults.

11

Page 15

Diagnostics

Download free Dana Diagnostic

T

Note:

Windows 98 or newe

Connect to diagnostic

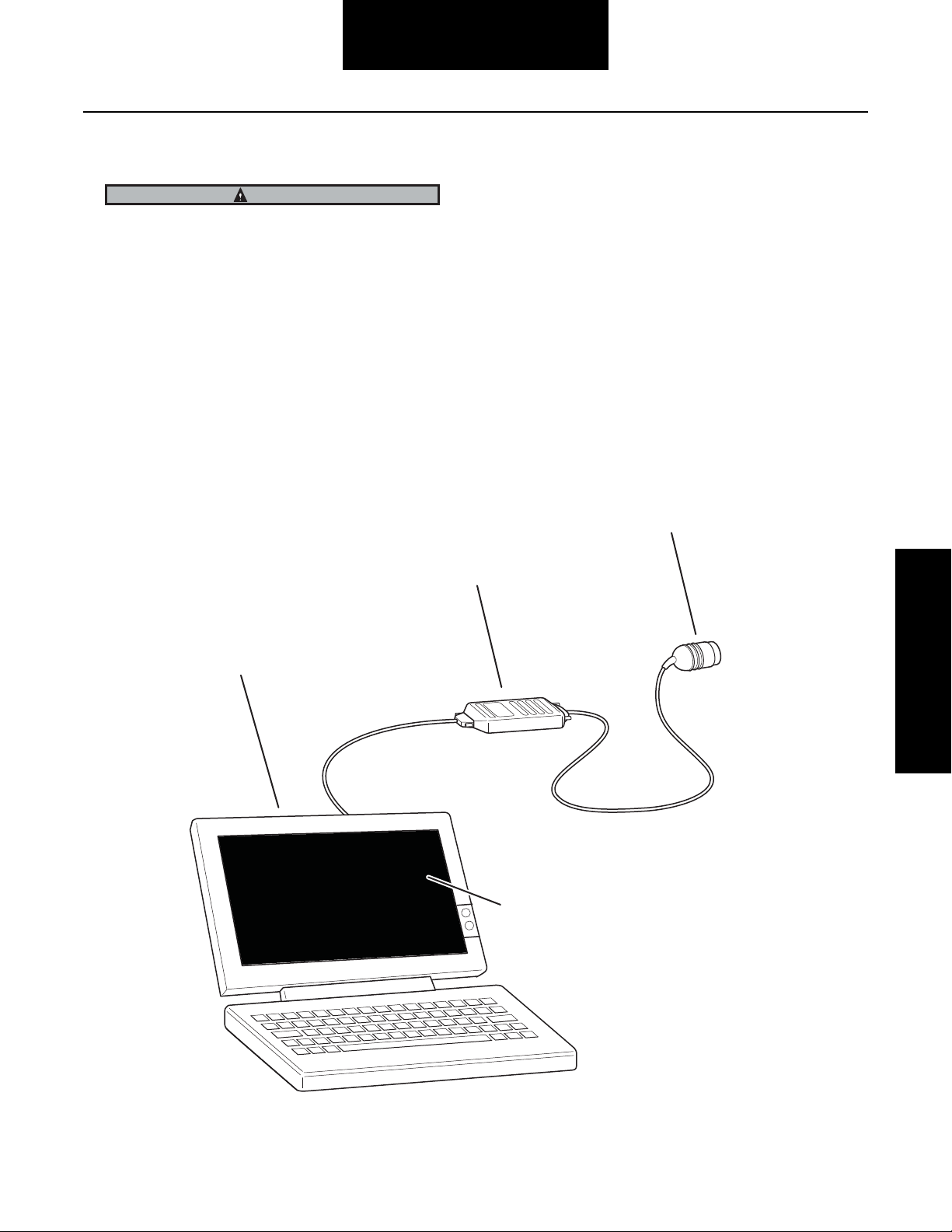

PC Diagnostics

CAUTION

A battery charger is not an adequate source of power.

Visit www.dana.com for free download of Dana Diagnostic

Tool (DDT).

PC diagnostics are easy to use and provide the quickest

diagnostic capabilities.

• Retrieve historical data, faults and tire pressures.

• Pressurize system to detect leaks.

• Access troubleshooting flowcharts and service

procedures.

Attach computer to RP1210A

communications box.

To use this program, an RP1210A compatible interface box

and cables are needed to connect the PC to the vehicle.

For these types of interface boxes to work with the Dana

Diagnostic Tool program, you must install a "RP1210 driver"

program provided by the manufacturer of the interface box.

If you do not have this program, it can normally be obtained

from the manufacturer's web site. Please contact the

manufacturer of your interface box if you have any questions

regarding this process.

connector.

ool from dana.com.

Program requires

r.

Diagnostics

Follow on-screen

instructions.

12

Page 16

Diagnostics

Handheld Tester

A Prolink handheld tester may be used to read and clear

service codes and to obtain a short description of failures. The

tester can initiate test sequences for controller outputs and

can also read system parameters when equipped with the

Dana program card.

KEN MOORE

M RO P O E SOR Y T MS NC

Pro-Link

9

7 8

6

4 5

2 3

1

ENTER

0

FUNC

Multimeter

Based upon system schematics and aided by component

specific service codes, a multimeter can be used to check

sensor and solenoid resistances and to find wiring harness

faults. The multimeter can be used to check the Tire Pressure

Control System wiring and components for:

• Continuity

• Ground

• Broken wires

• Open circuits

• Shorted circuits

• Incorrect battery voltage

13

Page 17

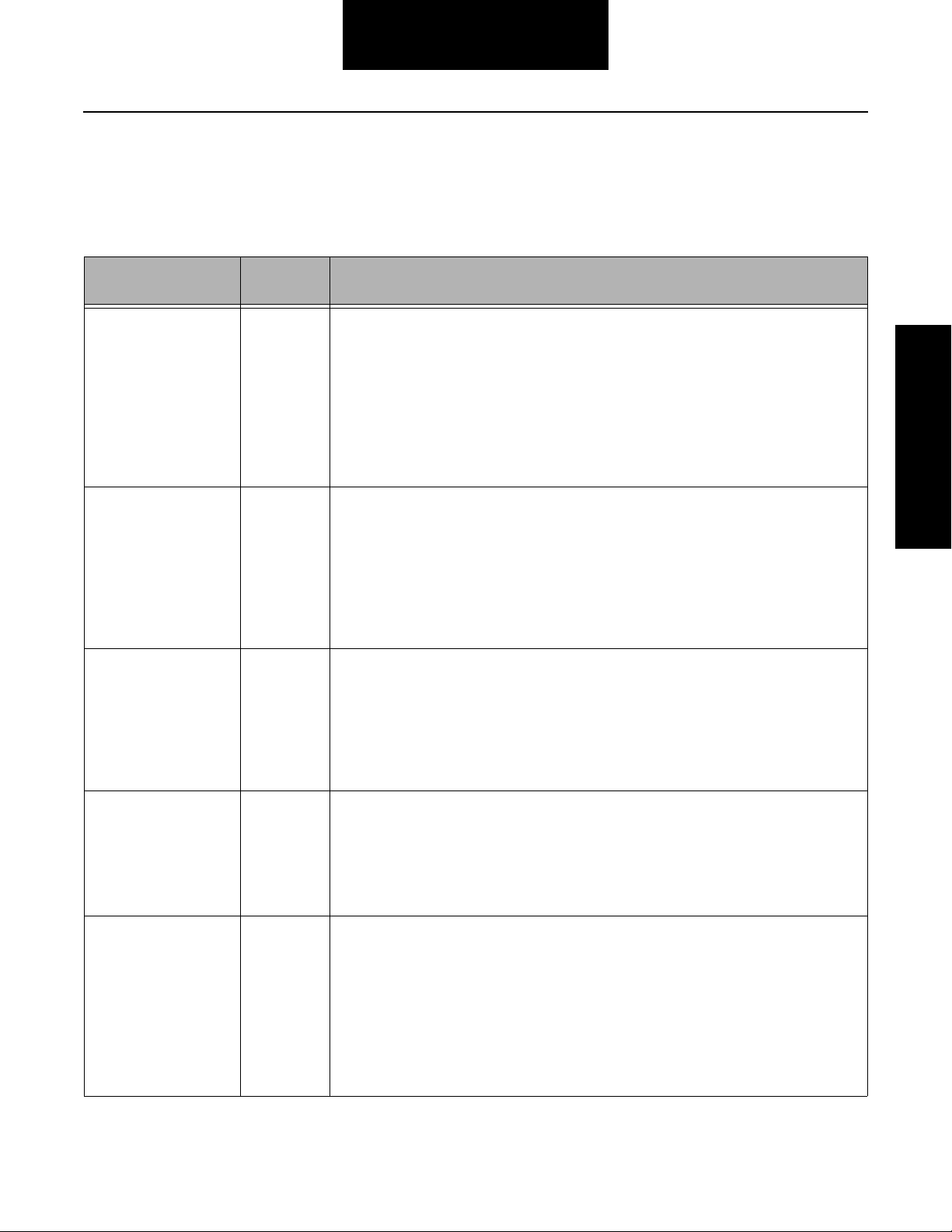

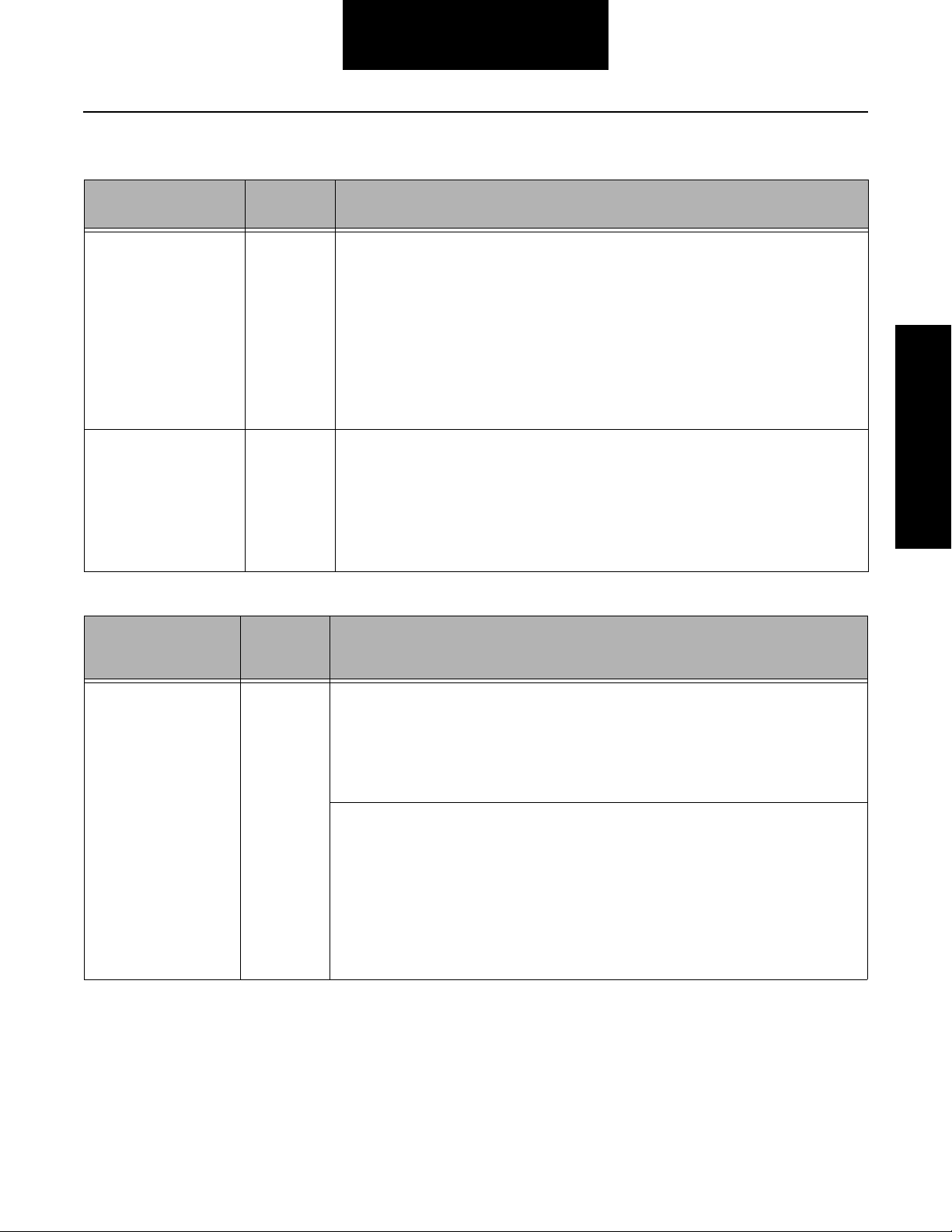

Service Codes Summary

Service Codes Summary

Diagnostics

The following chart provides a brief overview of the Central

Tire Inflation System (CTIS) service codes and the effect on

the system.

5 Flashing LIGHTs or

DDM – Dashes "--"

Low Pressure 26, 27 CHANNEL PRESSURE LOSS (Channel only checks pressures): Pressure check of

Low Air Supply 32 PRESSURE SWITCH REMAINS OPEN (System non-operative until switch closes):

Code No. Causes (numbered in order of likely occurrence)

given channel returns low reading (< 5 psig) indicating an extreme loss of pressure.

Repair and request pressure check to clear (press any mode button or run flat).

1) Open or broken line between PCU and wheel valve

2) Significant hub air seal leakage

3) Kinked or plugged line between supply tank and PCU

4) Faulty PCU sensor (ex. frozen water contamination)

5) PCU failure (supply off or control off)

6) Pressure switch failure (shorted closed)

For 4 minutes at vehicle speed > 20 mph pressure switch failed to close.

Repair and allow pressure switch to close to clear.

1) Compressor governor cutout set too low

2) Pressure switch unplugged, or open wire

3) Faulty pressure switch (failed open)

4) Faulty compressor

5) Broken, kinked, or plugged line from compressor to supply tank

Note: Any reference to a “channel” on a single-channel

system refers to all control lines and wheel ends.

Atmospheric 35 OUT OF RANGE ATMOSPHERIC READING (System waits to check pressures):

Atmospheric pressure check indicates vented PCU pressure is outside of valid

atmospheric range (5-20 psia).

Repair and request pressure check to clear (press any mode button or run flat).

1) Poor ground connection to PCU sensor

2) Faulty PCU sensor (ex, frozen water contamination)

3) Faulty PCU or blocked PCU exhaust vent

Inflate Trend 36, 37 INFLATE PRESSURE LOSS (System disables given channel): Given channel loses > 6

psi while inflating.

Repair and cycle ignition to clear.

1) Damaged tire or tire leakage

2) Leaking lines or seals

3) Faulty PCU (control solenoid off or additional channel stuck on)

Deflate Trend 14 FAILURE TO DEFLATE PROPERLY (System disables deflates): System gains >10 psi

pressure while attempting to deflate, or does not lower tires by even a small amount

of the intended change.

Repair and cycle ignition to clear.

1) Plugged or restricted PCU vent line

2) Faulty PCU relief valve

3) Poor ground connection to PCU sensor

4) Contaminated PCU

5) Faulty PCU

14

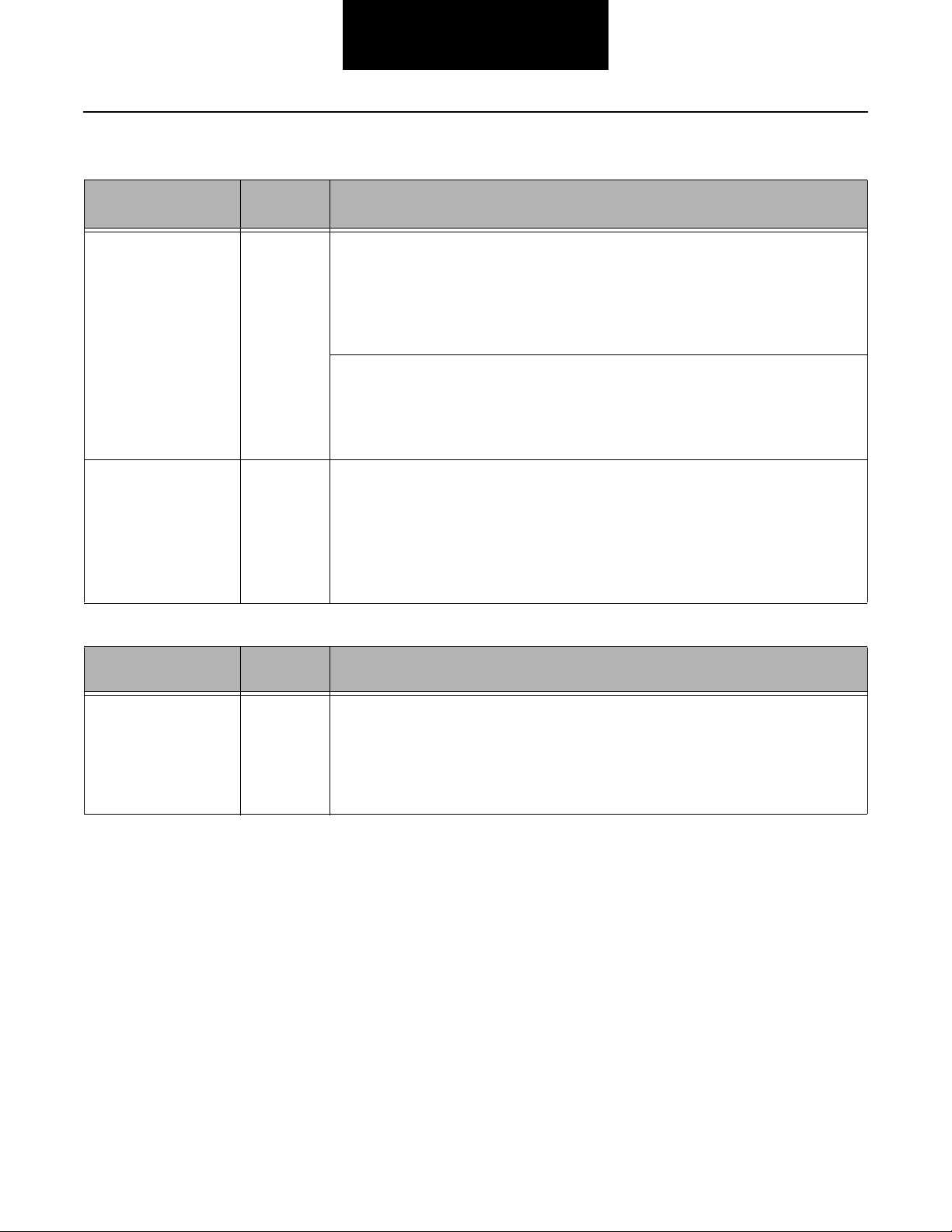

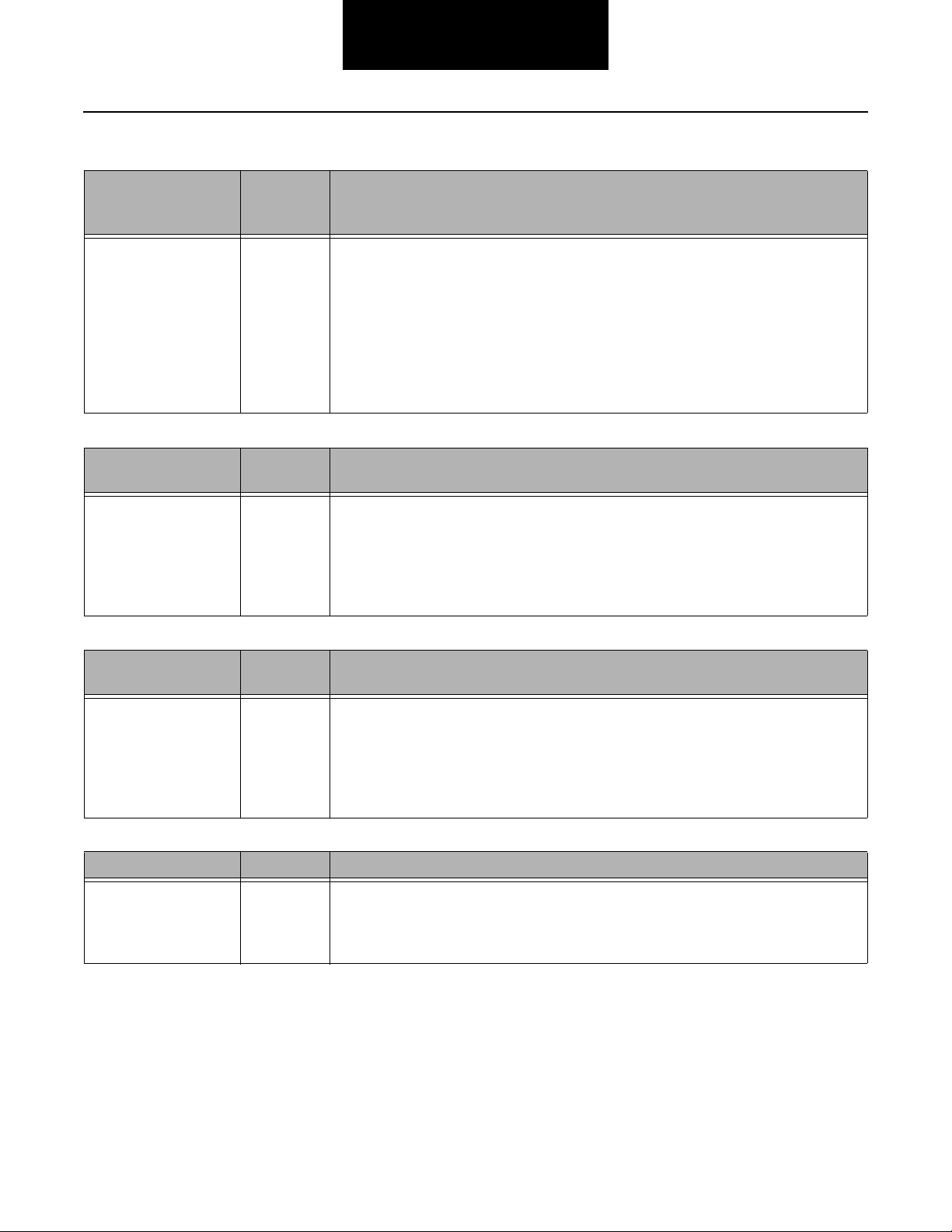

Page 18

Service Codes Summary (continued)

Diagnostics

5 Flashing LIGHTs or

DDM – Dashes "--"

PCU Sensor 33, 34 NO PCU SENSOR READING (System non-operative): No sensor voltage to ECU.

Pressure Switch 31 PRESSURE SWITCH SHORTED or FAILED CLOSED (System waits to check pres-

Code No. Causes (numbered in order of likely occurrence)

Clears 5 seconds following a valid reading.

1) Sensor is electrically disconnected

2) Pressure signal wire (XDCR SIGNAL) is shorted to ground, or open

3) PCU sensor VREF wire is shorted to ground, or open

4) Faulty sensor

PCU SENSOR READING TOO HIGH (System non-operative): Sensor voltage higher

than allowed.

Clears 5 seconds following a valid reading.

1) Pressure signal wire (XDCR SIGNAL) is shorted to power or XDCR VREF

2) Faulty sensor

sures): Pressure switch is read as closed, but pressure check of supply tank

indicates insufficient air pressure to continue.

Repair and request pressure check to clear (press any mode button or RUN FLAT).

1) Wire to pressure switch shorted to ground

2) Faulty pressure switch (failed closed)

3) Faulty PCU (leaks air during supply tank check)

5 Flashing LIGHTs and

CHECK TIRES Solid

Inflate Trend 36, 37 INFLATE PRESSURE LOSS (System disables given channel): Given channel loses > 6

Code No. Causes (numbered in order of likely occurrence)

psi while inflating.

Repair and cycle ignition to clear.

1) Damaged tire or tire leakage

2) Leaking lines or seals

3) Faulty PCU (control solenoid off or additional channel stuck on)

15

Page 19

Service Codes Summary

Service Codes Summary (continued)

Diagnostics

4 Flashing LIGHTs or

CHECK TIRES Flashing

Tire Leak (Imbalance) 44, 45 TIRES IMBALANCED (System only checks pressures on given channel): Pressure

Tire Leak (Confirm) 41, 42 CONFIRMATION FAILURE (System disables given channel): Given channel fails to

2 Terrain Lights on

Solid or DDM –

Dashes "--"

Code No. Causes (numbered in order of likely occurrence)

check indicates a tire on the given channel may be significantly lower than other tires

on same channel. RUN FLAT will override this fault.

1) Significant tire pressure loss (i.e. overnight leakdown)

2) Significant tire damage or leaks

3) Leaking lines or seals

4) Contaminated wheel valve filters

5) Restricted tire valve stem

6) Faulty wheel valve (leaking back through QRV)

7) Kinked or restricted control lines

confirm 10 times in a row.

RUN FLAT will override this fault.

1) Damaged tire or tire leakage

2) Leaking hose between wheel valve and tire

3) Faulty wheel valve (leaking back through QRV)

4) Restricted air passage between QRV and wheel valve

Code No. Causes (numbered in order of likely occurrence)

Between Modes 23, 24 SLOW INFLATE (Channel only checks pressures): Given channel takes too long(> 40

minutes) in active inflate (pressure switch closed) to achieve requested mode.

Repair and request pressure check to clear (any mode button or run flat).

1) Insufficient air supply

2) Contaminated wheel valve filters

3) Kinked, plugged, or leaking lines

SLOW DEFLATE (Channel only checks pressures): Given channel takes too long in

active deflate (> 20 minutes) to achieve requested mode.

Repair and request pressure check to clear (any mode button or run flat).

1) Contaminated wheel valve filters

2) Restricted tire valve stem

3) Leaking upper control lines

4) Faulty PCU relief valve

5) Restricted QRV exhaust

6) Restricted PCU vent line

16

Page 20

Service Codes Summary (continued)

Diagnostics

2 Terrain Lights on

Solid or DDM –

Dashes "--"

Deflate Signal 11, 12, 16 INCORRECT DEFLATE PRESSURE: Deflate signal reads outside of configured range

No Terrain Lights or

DDM – Dashes "--"

PCU Solenoid 51, 52, 54,

Code No. Causes (numbered in order of likely occurrence)

for 30 seconds. If occurs during multi-channel deflate, system will reattempt deflates

on individual channels.

Repair and request pressure check to clear. (any mode button or run flat).

1) Faulty PCU relief valve

2) Leaking upper control lines

3) PCU internal leaks

4) Deflate solenoid poppet stuck in non-energized position

5) Poor ground connection to PCU sensor or faulty sensor

Code No. Causes (numbered in order of likely occurrence)

ELECTRICAL SOLENOID FAILURE (System non-operative): Solenoid fails electrical

55, 56

diagnostics for approximately 2 seconds.

Repair & cycle ignition to clear.

1) Solenoid or harness wire is shorted to ground

2) Solenoid or harness wire is shorted to power

3) Faulty solenoid

No Terrain Lights or

DDM – Blank Display

Power 17 POWER (System non-operative): After initialization, voltage drops below 18V for > 15

DDM – Dashes "--" Code No. Causes (numbered in order of likely occurrence)

Display Control

Communications

Code No. Causes (numbered in order of likely occurrence)

seconds.

Clears immediately when voltage > = 18V.

1) Low battery voltage

2) Poor ground connection to ECU

3) Poor power connection to ECU

75 NO COMMUNICATION TO DDM: ECU not receiving data from DDM user interface.

Repair to clear.

1) No data link connection to DDM (damaged harness wiring)

2) Faulty DDM

17

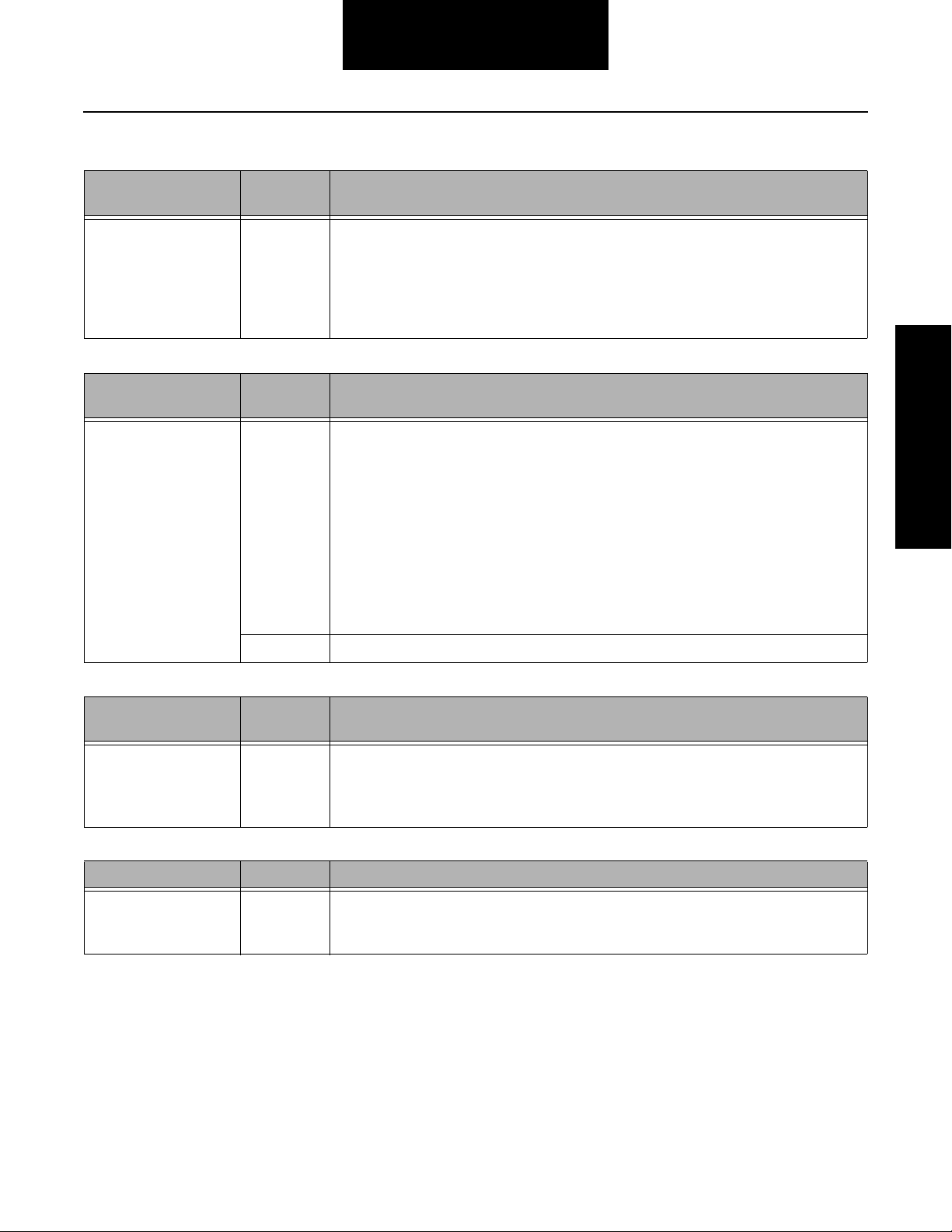

Page 21

Service Codes Summary

Service Codes Summary (continued)

Diagnostics

Lights Sequentially

Flashing

Configuration Error N/A CONFIGURATION ERROR (System is “Limp-Home”): System has reloaded the system

Solid Warning Lamp

or Solid OVER SPEED

Speed Signal 18 NO SPEED SIGNAL (System operation is normal): ECU has been reset 25-50 times

Code No. Causes (numbered in order of likely occurrence)

defaults, eliminating any changes (target pressures, etc.) previously programmed via

a diagnostic tool. Pressing HWY and RUN FLAT at the same time may clear the

display...updated config data should be reprogrammed.

1) Configuration connector loose or missing

2) Faulty ECU (if repeatedly occurs)

Code No. Causes (numbered in order of likely occurrence)

without any speed input to ECU. Note: Fault will be set immediately on power up.

Any speed input (driving vehicle with good speed sense operation) will clear fault.

1) Vehicle has been started approximately 25-50 times without being moved (no

speed input).

2) Sensor is electrically disconnected

3) Either speed sense wire is open or shorted to ground

4) Faulty speed sensor

5) Sensor actuation failure (Tang broken/disconnected on mechanical sensor, or

incorrect gap on pole sensor)

6) Both speed sense wires are shorted together

76, 77 Expected data link message not received

No Indication or DDM

– Dashes "--"

Miscellaneous Output 53, 57, 58,

No Indication Code No. Causes (numbered in order of likely occurrence)

Wheel Valve Shut Off 61, 62, 64, 65LOSS OF PRESSURE DURING SHUT OFF:

Code No. Causes (numbered in order of likely occurrence)

SPARE OUTPUT OR COMPONENT FAILURE:

67, 68

1) Harness wire is shorted to ground

2) Harness wire is shorted to power

3) Faulty component

1) Wheel valve shut off failure

2) Air passage restriction

18

Page 22

Diagnostics

Inaccurate Tire Pressures

May be caused by leaking control lines, clogged wheel valve

filters or valve stems, or closed Air Transport Valves.

Run Flat Definition

Pressing the RUN FLAT button once during normal system

operation puts the system in Run Flat Mode for 10 minutes

and causes several things to happen:

• The RUN FLAT light will flash along with the selected

mode light.

• A full pressure check (including atmospheric) is

requested.

• After 10 minutes Run Flat will automatically

deselect...OR... pushing RUN FLAT button again

will deselect it. It can be reselected by pressing the

button again after timeout.

• Tire pressures are checked at more frequent

intervals.

In addition, pressing the RUN FLAT button while the ECU is

displaying a “4 lights” flashing code will cause all “4 mode

lights” flashing codes (imbalance and confirmation) to be

overridden for the duration of RUN FLAT.

Note: ECU replacement—ECUs are NOT a typical cause of

problems. If an ECU is replaced, the system should be

carefully rechecked to make sure the problem has been

fixed, and does not reoccur.

19

Page 23

Diagnostics

Troubleshooting Tips

Troubleshooting Tips

This checklist outlines some general hints and guidelines that

will be helpful in tracking down and correcting operating

problems.

The ECU only displays one active code.

Only the most recent service code displays on the

ECU lights. In troubleshooting, be alert for related

codes. Use of a diagnostic tool offers the advantage of

spotting multiple active codes as well as retrieving

historical codes.

A cleared code alone does not indicate a corrected

problem.

A code is set by a specific fault condition and may be

cleared by switching the ignition off, and then on. It’s

possible to clear a code (i.e, clear the flashing lights)

only to have it display again when the fault condition

reoccurs. To ensure that a problem is fixed, you must

run the system through the same operating modes

that caused the problem and verify that the service

code does not reappear.

Electrical faults are often connection problems.

The most likely cause of electrical faults will be damaged wires or connections. As a first step in troubleshooting all electrical codes, switch off vehicle

ignition, then disconnect applicable connectors and

inspect for damage. (Switching off the ignition is

required before disconnecting the harness at the Electronic Control Unit, but is also a recommended practice before all other electrical system disconnections.)

Clean or repair all bad connections before proceeding.

Disconnect the Electronic Control Unit connector

with ignition off.

To avoid setting electrical fault codes, make sure that

the ignition is off before unplugging the wire harness

connection at the Electronic Control Unit module.

Reconnect the connector before switching on the ignition.

System is not continually pressurized.

When troubleshooting pneumatic faults, keep in mind

that the air system is only pressurized as needed (for

example, in the inflate mode). This means that such

procedures as checking for leaks require the system

to be in an active pressurized state. This can be

accomplished most easily by using a diagnostic tool.

Basic vehicle air and power systems are not covered in this guide.

The Central Tire Inflation System requires air pressure

and electrical power supply from the base vehicle systems. Diagnosis and service of these systems is outside the scope of this manual.

2-Channel (front/rear) systems may respond differently than single-channel systems.

If a fault can be isolated to a specific channel, a 2channel system may allow continued operation on the

unaffected channel. When troubleshooting, use a

diagnostic tool to determine which channel has the

fault.

20

Page 24

Service Codes

5 Flashing Lights or DDM – Dashes "--" (Codes 26, 27)

Type: Low Pressure

System Mode Condition Possible Causes (listed in order of likely occurrence)

System waits to

check pressures

Faulty pneumatic system,

or extremely low pressure

reading

• Open line between PCU and wheel valve

• Significant hub air seal leakage

• Open solenoid (PCU electrically or pneumatically disconnected)

• Crimped or plugged line between supply tank and PCU

• Faulty PCU sensor (ex. frozen water contamination)

• PCU failure, supply or control off

• Pressure switch failure, shorted closed

• Faulty ECU

Air Pressure Check

Note that the Central Tire Inflation System is not continuously

pressurized; pressure checks occur on a periodic basis. During tire pressure checks, the system delivers compressed air

to each channel for approximately two seconds while monitoring the pressure in that channel.

Code Description

A “Low Pressure” code indicates an extreme low pressure

reading. The most likely cause is an open line which would

have a clearly audible leak during a pressure check. A secondary cause could be a faulty air delivery system (i.e. Pneumatic

Control Unit [PCU]Low Pressure (Codes 26, 27) electrically or

pneumatically disconnected).

Other components that can cause a Low Pressure code are:

• Electrically or pneumatically disconnected PCU

• Faulty PCU

• Restricted line between the supply tank and PCU

21

• Faulty PCU sensor

• Open line from PCU to Quick Release Valve

• Open line from Quick Release Valve to Wheel Valve

To correctly diagnose the faulty component, connect the Diagnostic Tool (see "Diagnostics" for test equipment and descriptions) and follow the procedure in the Low Pressure

troubleshooting tree.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

Page 25

Low Pressure (Codes 26,

27)

Low Pressure (Codes 26, 27)

On 2-channel systems, use the diagnostic

tool to identify the faulty channel: front or rear.

Using the diagnostic tool, initiate inflate mode

for the faulty channel.

Service Codes

Is there

extreme audible

pressure loss?

No

Verify that the pressure switch opens

when the supply tank is below 80 psi.

Note: Primary and secondary air brake

gauges do not reflect actual pressure in

the supply tank.

Does the

pressure switch

open?

No

Replace pressure switch and

recheck system.

Repair faulty components

Yes

Yes

and recheck system.

Is there a restricted

line between the supply

tank and PCU?

No

After a pressure

check, is the pressure

reading <5 psi?

No

Check harness and PCU for open supply or

control solenoids. See Solenoid Fault flowchart.

Replace PCU and recheck system.

Note: While replacing the PCU, pay particular

attention to possible air line contamination (e.g.,

oil, water, particles) which may suggest further

air system maintenance needs.

Yes

Make repairs to faulty

components and recheck

Yes

Replace PCU sensor

and recheck system.

system.

Does fault

reoccur?

Yes

Replace ECU and recheck system.

Note: ECUs are not a typical cause of problems. If

an ECU is replaced, the system should be carefully

rechecked to make sure the problem has been

fixed and does not reoccur.

No

Complete

22

Page 26

Service Codes

5 Flashing Lights or DDM – Dashes "--" (Code 32)

Type: Low Air Supply

System Mode Condition Possible Causes (listed in order of likely occurrence)

System waits to

check pressures

Pressure switch won’t

close

• Compressor governor cutout set too low

• Air dryer needs service

• Pressure switch unplugged

• Faulty pressure switch

• Faulty compressor

• Open or broken line from supply tank to PCU

• Crimped or plugged line from supply tank to PCU

Air Pressure Check

Note that the Central Tire Inflation System is not continuously

pressurized; pressure checks occur on a periodic basis.

During tire pressure checks, the system delivers compressed

air to the tires for approximately two seconds while

monitoring the pressure.

Code Description

A “Low Air Supply” code displays if system air pressure is

inadequate to perform a tire pressure check.

This occurs when the pressure switch will not close. The

components that can cause the pressure switch to remain

open include:

Pressure Switch Harness Connector

B

A

– or –

ECU Harness Connector

A

R

B

C

D

E

F

P

S

T

a

U

V

G

N

b

Z

c

Y

W

X

K

H

J

– or –

M

L

ABCDE

ABCDE

ABCDE

A C

B

FGHJK

FGHJK

FGHJK

3

2

1

• Compressor governor cutout set too low

• Pressure switch unplugged

• Faulty pressure switch

• Faulty compressor

• Open or broken line from supply tank to Pneumatic

Control Unit (PCU)

• Crimped or plugged line from supply tank to PCU

To correctly diagnose the faulty component, connect the Diagnostic Tool (see "Diagnostics" for test equipment and descriptions) and follow the procedure in the Low Air Supply

troubleshooting tree.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

23

Page 27

Low Air Supply (Code 32)

Low Air Supply (Code 32)

When the

governor cuts out, is the

supply pressure greater than

value shown in table? (Use

calibrated pressure gauge

in tank.)

Reset governor cutout

pressure and retest system.

Is the pressure

switch plugged in?

Plug in pressure switch and

retest system.

Using the diagnostic tool, verify

pressure switch operation.

Does the

pressure switch

close above setting

shown in table?

Is

continuity

OK?

Repair harness

and retest.

Verify air system capacity by checking

supply tank pressure buildup time.

Does the

supply tank build

up pressure?

Service code is not active. Reverify

flowchart steps and wait for fault to reoccur.

Repair vehicle air supply

system and retest.

Replace pressure switch

and retest system.

No

Yes

Yes

Yes

No

No

Yes

Yes

No

No

Pressure Switch

Part Number

673345 (black)

676770 (blue)

Minimum Supply

Tank Pressure

120 psig

125 psig

Identify vehicle pressure switch:

Part #673345 (black)

Part #676770 (blue)

Switch off ignition.

Disconnect the ECU connector and

the pressure switch connector.

There are two wires used for the pressure switch (PS).

One is the signal wire. The other connects the pressure

switch to GROUND.

Verify continuity between:

PS Harness ECU Harness

Connector Pin Connector Pin

T (Round Connector)

PS signal or

(pin A or B) G3 (Rectangular Connector)

AND

ForNon-M939 Style Vehicle

PS GROUND Vehicle GROUND

(other pin A or B)

For M939 Style Vehicle

PS GROUND L (Round Connector)

(other pin A or B)

Start pressure build

up in supply tank.

Service Codes

24

Page 28

Service Codes

5 Flashing Lights or DDM – Dashes "--" (Code 35)

Type: Atmospheric

System Mode Condition Possible Causes (listed in order of likely occurrence)

System waits to

check pressures

PCU pressure out of range

when PCU is “vented”

• Frozen water or other contaminant in PCU sensor

• Plugged PCU vent

• Poor ground connection to PCU sensor

• Faulty PCU sensor

• Faulty PCU

Air Pressure Check

Note that the Central Tire Inflation System is not continuously

pressurized; pressure checks occur on a periodic basis.

During tire pressure checks, the system delivers compressed

air to the tires for approximately two seconds while

monitoring the pressure.

Code Description

An “Atmospheric” code is logged if the atmospheric pressure

reading is out of range. The atmospheric pressure reading can

be out of range as a result of a blocked or restricted Pneumatic Control Unit (PCU) or vent line, contaminated PCU sensor (i.e. frozen water), air bleeding back into the PCU or

because of a faulty PCU sensor.

The components that can cause this code to be set include:

PCU Sensor Harness Connector

AB

C

– or –

ECU Harness Connector

A

R

B

C

D

E

F

P

S

T

a

U

N

b

Z

V

c

Y

W

X

G

K

H

J

– or –

M

L

CAB

ABCDE

ABCDE

ABCDE

FGHJK

FGHJK

FGHJK

3

2

1

• Faulty or contaminated PCU sensor

• Faulty or contaminated PCU

• Faulty Electronic Control Unit (ECU)

To correctly diagnose the faulty component, connect the Diagnostic Tool (see "Diagnostics" for test equipment and descriptions) and follow the procedure in the Atmospheric

troubleshooting tree.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

25

Page 29

Atmospheric (Code 35)

Atmospheric (Code 35)

Service Codes

Disconnect ECU and

PCU sensor connectors.

Check for continuity between:

Using the diagnostic tool, read

the atmospheric pressure.

Is the reading

between 5 and 20

psia?

Yes

Service code is not active. Reverify flowchart steps and wait

for fault to reoccur.

Is any audible

No

air flowing through

the PCU?

Yes

Replace PCU and recheck system.

No

PCU Sensor Harness ECU Harness

A (round connector) J (round connector)

B (oval connector ) H3 (rectangular connector)

Disconnect harness from PCU sensor and plug new

PCU sensor onto harness (do not install new sensor

in PCU yet). Verify atmospheric reading.

or or

Is there

continuity?

Yes

Is the reading

within range?

Yes

No

niP rotcennoCniP rotcennoC

Inspect and repair faulty

harness or pins.

No

Complete

Note: While replacing the PCU, pay particular

attention to possible air line contamination (e.g.,

oil, water, particles) which may suggest further

air system maintenance needs.

Yes

Replace ECU and recheck system.

Note: ECUs are not a typical cause of problems. If

an ECU is replaced, the system should be carefully

rechecked to make sure the problem has been

Is the reading

within range?

No

fixed and does not reoccur.

Install new sensor in PCU.

Verify atmospheric reading.

No

Is the reading

within range?

Yes

Complete

26

Page 30

Service Codes

5 Flashing Lights or DDM – Dashes "--" or 5 Flashing Lights and Check Tires Solid (Codes 36, 37)

Type: Inflate Trend

System Mode Condition Possible Causes (listed in order of likely occurrence)

Channel

inoperative

Loss of channel pressure in

inflate mode

• Damaged or leaking tire

• Leaking lines

• Leaking seals

• Leaking QRV

• Leaking wheel valve

• Faulty PCU

Code Description

An “Inflate Trend” code displays when tire pressure readings

are dropping while in inflate mode. Tire damage, which the

compressor cannot keep up with, may have occurred after

starting an inflate sequence. When possible, a 2-channel system will isolate this fault to a given channel.

The air leak can be located either before or after the wheel

valve location. The components located before the wheel

valve that may cause this include:

• Leaking control lines

• Leaking Quick Release Valve (QRV) exhaust port

• Leaking wheel air seals

Components located after the wheel valve that may cause this

include:

•Tire damage

• Rim leaks

• Leaking air lines

• Faulty wheel valve

To correctly diagnose the faulty component, connect the Diagnostic Tool (see "Diagnostics" for test equipment and descriptions) and follow the procedure in the Inflate Trend

troubleshooting tree.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

27

Page 31

Inflate Trend (Codes 36,

37)

Inflate Trend (Codes 36, 37)

On 2-channel systems, use the

diagnostic tool to identify the

faulty channel: front or rear.

Using the diagnostic tool, initiate

inflate mode on the faulty channel.

Is there a

damaged tire?

Is there a leaking

hose between a tire

and wheel valve?

Repair tire and retest system.

Replace the hose and

retest the system.

Make sure all tires on the channel

are at the same pressures.

Is air leaking

through the QRV?

Replace the QRV and

retest the system.

Are there any

leaks in the control

lines or seals?

Is air leaking

out the PCU vent

port?

Fault code is not active.

Reverify flowchart steps and

wait for fault to reoccur.

Repair leaks and retest.

Replace PCU and retest.

Note: While replacing the PCU, pay particular

attention to possible air line contamination (e.g.,

oil, water, particles) which may suggest further

air system maintenance needs.

Yes

No

No

Yes

No

Yes

Yes

No

Yes

No

Service Codes

28

Page 32

Service Codes

5 Flashing Lights or DDM – Dashes "--" (Code 14)

Type: Deflate Trend

System Mode Condition Possible Causes (listed in order of likely occurrence)

Inflate only Improper deflate sequence • Upper control line leak

• Plugged or restricted PCU vent line

• Faulty PCU relief valve

• Poor ground connection to PCU sensor

• Contaminated PCU

• Faulty PCU

Code Description

A “Deflate Trend” code displays when the system has determined that a deflate sequence is not functioning correctly.

This is the result of either a pressure increase during a deflation, or the system failing to lower the tires even a small

amount of the desired pressure drop.

29

Page 33

Deflate Trend (Code 14)

Deflate Trend (Code 14)

Yes

Using the diagnostic tool, manually

deflate the tires on one channel.

While

deflating, is the

system (relief valve)

pressure within 1 psig

of nominal? *

Continue using diagnostic tool

to deflate the tires to 45 psi.

Use manual pressure gauge

to verify all tires at 45 psi.

Use diagnostic tool to select

Check & Hold.

Pressure

reading < 55

psi?

2-channel

system?

Test should

be repeated for both

channels. Both channels

tested?

Are the tires

deflating?

Use diagnostic tool to

manually deflate the tires on

the other channel.

Fault is not active.

Reverify flowchart

steps and wait for fault

to reoccur.

Check wheel valve filters, replace as

necessary and recheck system.

Will the tires

deflate now?

Vent wheel valve covers

and recheck system.

Repair PCU restriction and

recheck system.

Is the PCU

vent line or relief

valve plugged or

restricted?

Use diagnostic tool to place system

into “pressure check and hold” mode.

Check for upper control line leaks.

Make repairs to faulty components.

Use diagnostic tool to

manually deflate the tires.

Replace PCU relief valve

and recheck system.

Perform continuity check on

front and rear channel

solenoids. See Solenoid

Fault flowchart.

Complete

Yes

Yes

Yes

Yes

No

No

No

No

No

No

Yes

Yes

No

2-channel

system?

Are the tires

deflating?

PCU is contaminated or faulty.

Clean, repair and/or replace

PCU as necessary and recheck

system.

Note: While replacing the PCU,

pay particular attention to

possible air line contamination

(e.g., oil, water, particles) which

may suggest further air system

maintenance needs.

PCU is contaminated or faulty.

Clean, repair and/or replace

PCU as necessary and recheck

system.

Note: While replacing the PCU,

pay particular attention to

possible air line contamination

(e.g., oil, water, particles) which

may suggest further air system

maintenance needs.

* Reference vehicle build

information for nominal

relief valve pressure.

While

deflating, is the

system (relief valve)

pressure within 1

psig of

nominal? *

No

No

No

Yes

Yes

Yes

Service Codes

30

Page 34

Service Codes

5 Flashing Lights or DDM – Dashes "--" (Codes 33, 34)

Type: PCU Sensor

System Mode Condition Possible Causes (listed in order of likely occurrence)

No operation No PCU sensor reading • Sensor electrically disconnected

• Pressure signal wire open

• Pressure signal wire shorted to ground

• PCU sensor VREF wire open

• PCU sensor VREF wire shorted to ground

• PCU sensor ground wire open

• Faulty sensor

• Faulty ECU

No operation High PCU sensor reading • Pressure signal wire shorted to VBAT or VREF

• Faulty sensor

• Faulty ECU

Code Description

A "Pneumatic Control Unit (PCU) Sensor" code occurs when

the Electronic Control Unit (ECU) receives an unusually high

or low reading from the PCU sensor. A diagnostic tool will

specify which of the two conditions is responsible for setting

the code.

Initial troubleshooting steps involve checking for a shortedto-ground or an open PCU sensor circuit.

If the circuits check out OK, secondary causes could involve a

faulty sensor or a faulty ECU.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

PCU Sensor Harness Connector

AB

C

– or –

ECU Harness Connector

A

R

B

C

D

E

F

P

S

T

a

U

N

b

Z

V

c

Y

W

X

G

K

H

J

– or –

M

L

CAB

ABCDE

ABCDE

ABCDE

FGHJK

FGHJK

FGHJK

3

2

1

31

Page 35

PCU Sensor (Codes 33, 34)

PCU Sensor (Codes 33, 34)

No

With ignition off, inspect socket

connections at ECU connector

and at PCU sensor 3-way.

Are connections

mechanically and

electrically sound?

Repair connection

as necessary.

Disconnect the ECU connector

and the PCU sensor connector.

Is there

continuity?

Check for short circuits between each

pair of PCU sensor harness pins:

A and B

B and C

C and A

A

Are any

shorted?

With ignition switch on, check

voltage between PCU sensor

harness pin B (round

connector) or pin A (oval

connector) and ground.

Is voltage

between 4.9 and

5.1 V?

Is the active

fault cleared?

Complete

Replace ECU and recheck system.

Note: ECUs are not a typical cause of problems. If

an ECU is replaced, the system should be carefully

rechecked to make sure the problem has been

fixed and does not reoccur.

A

Replace PCU sensor.

Inspect and repair

faulty harness.

Inspect and repair

faulty harness.

No

Yes

Yes

No

Yes

Yes

Yes

No

No

Check for continuity between the following points:

PCU Sensor Harness Connector Pin ECU Harness Connector Pin

c (round connector)

C (all connectors) or

H1 (rectangular connector)

B (round connector) b (round connector)

or or

A (oval connector) H2 (rectangular connector)

A (round connector) J (round connector)

or or

B (oval connector) H3 (rectangular connector)

Service Codes

32

Page 36

Service Codes

5 Flashing Lights or DDM – Dashes "--" (Code 31)

Type: Pressure Switch

System Mode Condition Possible Causes (listed in order of likely occurrence)

Pressure check

only

Pressure switch shorted or

won’t open.

• Pressure switch wire shorted to ground

• Faulty pressure switch (failed closed)

• Faulty PCU (leaks air during supply tank check)

Air Pressure Check

Note that the Central Tire Inflation System is not continuously

pressurized; pressure checks occur on a periodic basis.

During tire pressure checks, the system delivers compressed

air to each channel for approximately two seconds while

monitoring the pressure in that channel.

Code Description

A “Pressure Switch” code displays if system air pressure is

inadequate to perform a tire pressure check, yet the pressure

switch status is “closed”.

This occurs when the pressure switch will not open. The components that can cause the pressure switch to remain closed

include:

• Pressure switch wire shorted to ground.

• Faulty pressure switch (failed closed).

ECU Harness Connector

A

R

B

C

D

E

F

P

S

T

a

U

N

b

Z

V

c

Y

W

X

G

K

H

J

– or –

M

L

ABCDE

ABCDE

ABCDE

FGHJK

FGHJK

FGHJK

3

2

1

To correctly diagnose the faulty component, connect the Diagnostic Tool (see "Diagnostics" for test equipment and descriptions) and follow the procedure in the Pressure Switch

troubleshooting tree.

Note: This feature is only available on 2-channel systems.

This fault could be logged as a result of a singlechannel system (with a single-channel Pneumatic Control Unit [PCU]) being configured as a two-channel system. See “Configuration Error” troubleshooting tree to

verify correct harness configuration selection.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

33

Page 37

Pressure Switch (Code 31)

Pressure Switch (Code 31)

Service Codes

Identify vehicle pressure switch:

Part #673345 (black)

Part #676770 (blue)

Using the diagnostic tool,

verify pressure switch

status is closed.

Is the pressure

switch plugged in?

Yes

Using the diagnostic tool, verify

pressure switch operation.

Does the

pressure switch open

below psi value shown

in table?

Yes

No

No

Plug in pressure switch

and retest system.

Switch off ignition.

Disconnect the ECU connector

and the pressure switch connector.

Verify NO continuity between:

ECU Harness Connector Pins

T and F (round connector)

or

G3 and K2 (rectangular connector)

Part Number

673345 (black)

676770 (blue)

Pressure Switch

Open Value

78 psi

87 psi

Verify correct vehicle configuration.

See Configuration Error flowchart.

Use diagnostic tool to

read supply pressure.

Is supply pressure

Service code is not active. Reverify

flowchart steps and wait for fault to reoccur.

accurate?

Yes

No

Is there

continuity?

Yes

Repair harness and retest.

Replace PCU and recheck system.

Note: While replacing the PCU, pay

particular attention to possible air line

contamination (e.g., oil, water,

particles) which may suggest further

air system maintenance needs.

Replace pressure

No

switch and retest

system.

Does fault

reoccur?

Yes

Replace ECU and recheck system.

Note: ECUs are not a typical cause

of problems. If an ECU is replaced,

the system should be carefully

rechecked to make sure the problem

has been fixed and does not reoccur.

No

Complete

34

Page 38

Service Codes

4 Flashing Lights or CHECK TIRES Flashing (Codes 44, 45)

Type: Tire Leak (Imbalance)

Note: RUN FLAT overrides this fault.

System Mode Condition Possible Causes (listed in order of likely occurrence)

Channel only

checks pressures.

Tire pressure lower on one

tire than others.

• Minor tire leakage at startup (leaked overnight)

• Severe tire damage or leaks

• Contaminated wheel valve filters

• Restricted tires valve stem

• Leaking lines

• Leaking seals

• Leaking wheel valve

• Crimped or restricted control lines

Air Pressure Check

Note that the Central Tire Inflation System is not continuously

pressurized; pressure checks occur on a periodic basis.

During tire pressure checks, the system delivers compressed

air to each channel for approximately two seconds while

monitoring the pressure in that channel.

Code Description

An “Imbalance” code indicates that either the tire pressure on

one tire or wheel end was read lower than the other tires, or

there is an air leak someplace in the system.

Low tire pressure can be caused by a damaged tire, plugged

wheel valve filter or leaking air lines. An air leak can be located

either before or after the wheel valve.

Note: When using a diagnostic tool to inflate or inflate-hold a

channel with one low tire, air may be heard leaking out

or the Quick Release Valves (QRV) by the higher pressure tires. This is normal and should stop once the low

tire is inflated to the pressure of the other tires.

The components located before the wheel valve that may

cause a “Tire Leak (Imbalance)” code include:

• Leaking wheel air seals

• Leaking control lines

Components located after the wheel valve that may cause an

imbalance include:

• Damaged tire

• Rim leaks

• Clogged or restricted Wheel Valve filter or valve stem

• Leaking air lines

• Wheel valve damage

To correctly diagnose the faulty component, connect the Diagnostic Tool (see "Diagnostics" for test equipment and descriptions) and follow the procedure in the Tire Leak (Imbalance)

troubleshooting tree.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

• Restricted QRV exhaust port

35

Page 39

Tire Leak (Imbalance)

(Codes 44, 45)

Tire Leak (Imbalance) (Codes 44, 45)

On 2-channel systems, use diagnostic tool to

identify faulty channel: front or rear.

Manually check the tire pressures on the faulty

channel at the wheel valves.

Check for a blocked QRV exhaust or

plugged wheel valve filter or valve

stem. Make repairs to faulty

components and recheck the system.

Yes

Are any wheel

readings low?

No

Are any wheel

readings high?

Service Codes

Yes

Check the following:

Tire damage

Wheel valve filter

Air line leaks

Wheel seal air leaks

Wheel valve leaks

Repair faulty components

and recheck the system.

Make repairs to faulty

components and recheck system.

No

Use diagnostic tool to place system into

inflate mode and check for audible leaks

(see note under Code Description on

Yes

Use diagnostic tool to place system into

“Pressure Check and Hold” mode and look

previous page).

Is there an

audible leak?

No

for steady hold pressure.

Was pressure

steady?

Yes

Use diagnostic tool to

vent system.

Is air leaking

from the QRV

exhaust port.

Yes

Locate the leaking wheel valve

associated with that QRV and

replace it. Recheck the system.

Check the system for

kinked lines. Repair faulty

No

components and recheck

the system.

No

Find leak and make repairs to faulty

components. Recheck system.

36

Page 40

Service Codes

4 Flashing Lights or CHECK TIRES Flashing (Codes 41, 42)

Type: Tire Leak (Confirm)

Note: RUN FLAT overrides this fault.

System Mode Condition Possible Causes (listed in order of likely occurrence)

Channel inoperative

Channel confirmation failure • Damaged or leaking tire

• Leaking line between wheel valve and tire

• Plugged or restricted QRV

• Leaking wheel valve

• Plugged or restricted PCU vent line

• Restricted air passage between QRV and wheel valve

Air Pressure Check

Note that the Central Tire Inflation System is not continuously

pressurized; pressure checks occur on a periodic basis.

During tire pressure checks, the system delivers compressed

air to each channel for approximately two seconds while

monitoring the pressure in that channel.

Code Description

A “Tire Leak” occurs if a channel fails to confirm tire pressure.

Following an inflate or deflate sequence, the Central Tire

Inflation System will return to confirm, or “double-check” the

new pressure. If the pressure has dropped, the system will reinflate, and then reconfirm the tires. After multiple failed

confirmation attempts, the system will log a Tire Leak

(Confirm) code and the system will become inoperative.

A confirmation failure can be caused by:

• Damaged or leaking tire

• Leaking air line between the wheel valve and tire

• Plugged or restricted Quick Release Valve (QRV)

• Leaking wheel valve

37

• Plugged or restricted Pneumatic Control Unit (PCU)

vent line

• Restricted air passage between QRV and wheel valve

To correctly diagnose the faulty component, connect the Diagnostic Tool (see "Diagnostics" for test equipment and descriptions) and follow the procedure in the Tire Leak

(Confirm) troubleshooting tree.

See “Troubleshooting Tips” for general guidelines on system

diagnostics.

Page 41

Tire Leak (Confirm) (Codes

41, 42)

Tire Leak (Confirm) (Codes 41, 42)

No

Using the diagnostic

tool, initiate inflate mode.

Is there a

damaged tire?

Is there a leaking

hose between a tire

and wheel valve?

Repair tire and

retest system.

Replace the hose and

retest the system.

Use diagnostic tool to

vent system.

Does air

continue to vent

out PCU vent

line?

Is air leaking

through the QRV

exhaust?

Service code is not active.

reverify flowchart steps and

wait for fault to reoccur.

Check vent line.

Identify axle where

tire pressure is low.

Replace QRV.

Locate the leaking wheel valve

associated with that QRV and

replace it. Recheck the system.

On 2-channel systems, use the diagnostic tool

to identify the faulty channel: front or rear.

Manually check the tire pressures on the faulty

channel at the wheel valves. A low tire(s)

indicates likely location of problem.

Yes

Yes

Yes

No

No

Yes

No

Check for restrictions

between QRV and

wheel valve.

Are restrictions

present?

Yes

No

Repair restrictions and

recheck system.

Service Codes

38

Page 42

Service Codes

2 Terrain Lights on Solid or DDM – Dashes "--" (Codes 23, 24)

Type: Between Modes

System Mode Condition Possible Causes (listed in order of likely occurrence)

Pressure check

only

Pressure check

only

Slow inflate • Faulty compressor

• Restricted flow at wheel valve air filters

• Crimped or plugged lines

Slow deflate • Restricted flow at wheel valve air filters or valve stem

• Leaking upper control lines