Page 1

18

18

Instruction Manual

Bedienungsanleitung

Manuel d’utilisation

Manuale di Istruzioni

®

®

Page 2

EN

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon Hobby, LLC. For up-to-date

product literature, visit horizonhobby.com and click on the support tab for this product.

Meaning of Special Language

The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND little or no possibility of injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage and serious injury

OR create a high probability of super cial injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating.

Failure to operate the product correctly can result in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product. It must be operated with caution and common sense and requires some basic mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury or damage to the product or other property.

This product is not intended for use by children without direct adult supervision. Do not attempt disassembly, use with incompatible

components or augment product in any way without the approval of Horizon Hobby, LLC. This manual contains instructions for safety,

operation and maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to assembly, setup or

use, in order to operate correctly and avoid damage or serious injury.

WARNING AGAINST COUNTERFEIT PRODUCTS

Always purchase from a Horizon Hobby, LLC. authorized dealer to ensure authentic high-quality Spektrum product. Horizon

Hobby, LLC. disclaims all support and warranty with regards, but not limited to, compatibility and performance of counterfeit products or

products claiming compatibility with DSM or Spektrum.

NOTICE: This product is only intended for use with unmanned, hobby-grade, remote-controlled vehicles and aircraft. Horizon Hobby

disclaims all liability outside of the intended purpose and will not provide warranty service related thereto.

Age Recommendation: Not for Children under 14 years. This is not a toy.

Warranty Registration

Visit spektrumrc.com today to register your product.

NOTICE:

While DSMX allows you to use more than 40 transmitters simultaneously, when using DSM2 receivers, DSMX receivers in

DSM2 mode or transmitters in DSM2 mode, do not use more than 40 transmitters simultaneously.

General Notes

• Models are hazardous when operated and maintained incorrectly.

• Always install and operate a radio control system correctly.

• Always pilot a model so the model is kept under control in all

conditions.

• Please seek help from an experienced pilot or your local hobby

store.

• Contact local or regional modeling organizations for guidance

and instructions about ying in your area.

• When working with a model, always power on the transmitter

rst and power off the transmitter last.

• After a model is bound to a transmitter and the model is set

up in the transmitter, always bind the model to the transmitter

again to establish failsafe settings.

Pilot Safety

• Always make sure all batteries are fully charged before ying.

• Time ights so you can y safely within the time allotted by

your battery.

• Perform a range check of the transmitter and the model

before ying the model.

• Make sure all control surfaces correctly respond to transmitter

controls before ying.

• Do NOT y a model near spectators, parking areas or any

other area that could result in injury to people or damage to

property.

• Do NOT y during adverse weather conditions. Poor visibility,

wind, moisture and ice can cause pilot disorientation and/or

loss of control of a model.

• When a ying model does not respond correctly to controls,

land the model and correct the cause of the problem.

2 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 3

BEFORE USING YOUR TRANSMITTER:

Before going any further, visit the Spektrum Community website at spektrumrc.com to register your transmitter and

download the latest AirWare™ rmware updates. A registration reminder screen occasionally appears until you register

your transmitter. When you register your transmitter, the reminder screen does not appear again.

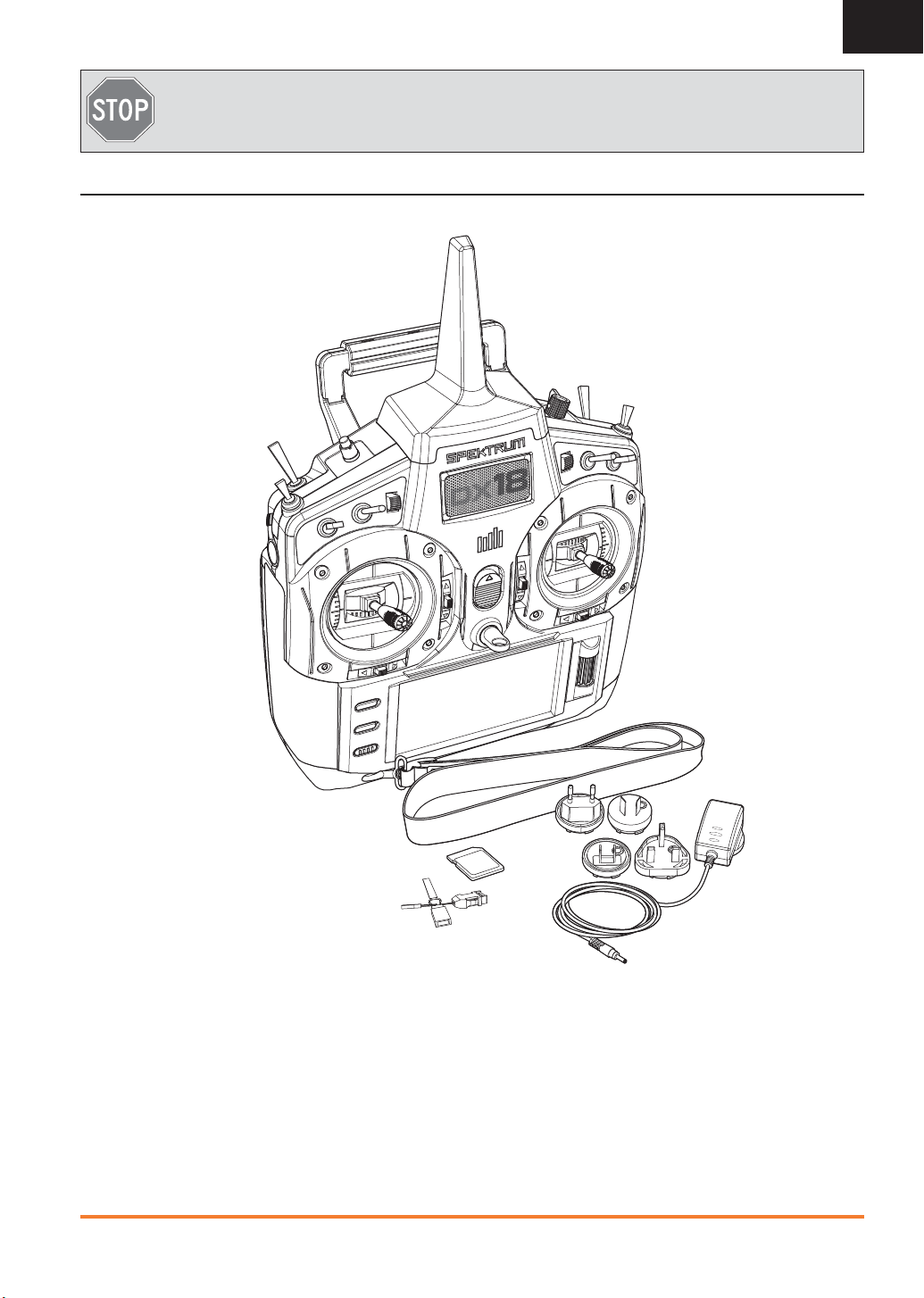

Box Contents

• DX18 Transmitter

• 2600mAh LiPo Transmitter Pack (Installed in transmitter)

• SPMAR9020 AR9020 9-Channel DSMX X-Plus Receiver

• SPM6803 Male/Female Bind plug

• Global Power Supply

• SD card

• Neck strap

• Manual

EN

3SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 4

EN

Table of Contents

System Overview ...................................................

Transmitter Batteries ............................................................. 5

Charging Your Transmitter ........................................................ 5

Transmitter Functions ........................................................... 6

Main Screen ........................................................................... 8

Navigation .............................................................................. 8

Volume Control .......................................................................8

Binding ................................................................................... 9

Programming Failsafe Positions ......................................... 10

SmartSafe Failsafe ................................................................ 10

Hold Last Command .............................................................. 10

Preset Failsafe ...................................................................... 10

™

X-Plus

................................................................................ 11

Installation ............................................................................ 11

X-Plus Channels and Failsafe ................................................. 12

SD Card ................................................................................12

Model Type Programming Guide ....................... 13

Common System Setup Functions .................... 14

Model Select ......................................................................... 14

Model Type ........................................................................... 14

Model Name ......................................................................... 14

F-Mode Setup ....................................................................... 15

Spoken Flight Mode .............................................................. 15

Channel Assign ..................................................................... 16

Channel Input Con guration ................................................... 16

X-Plus Input Con guration ..................................................... 16

Trim Setup ............................................................................ 16

Model Utilities ....................................................................... 17

Warnings .............................................................................. 18

Telemetry ............................................................................. 18

Pre ight Setup ......................................................................19

Frame Rate ........................................................................... 19

Bind ..................................................................................... 19

Trainer ..................................................................................20

Analog Switch Setup ............................................................. 22

System Settings .................................................................... 22

Transfer SD Card ................................................................... 24

Function List ...................................................... 26

Servo Setup .......................................................................... 26

D/R & Expo ........................................................................... 27

Differential (Air And Sail Types Only) ....................................... 27

V-Tail Differential (Air And Sail Types Only) .............................. 27

Throttle Cut .......................................................................... 28

Throttle Curve ....................................................................... 28

Mixing .................................................................................. 28

Sequencer ............................................................................ 29

Range Test ............................................................................ 30

Timer ................................................................................... 30

Telemetry ............................................................................. 31

Custom Voice Setup .............................................................. 31

System Setup ....................................................................... 31

Monitor................................................................................. 32

X-Plus Monitor ...................................................................... 32

ACRO (Airplane) ................................................. 33

Aircraft Type ......................................................................... 33

Recommended Servo Connections ......................................... 33

Elevon Servo Control ............................................................. 34

Flap System .......................................................................... 34

ACRO Mixing ........................................................................ 34

Acro Gyro Function ............................................................... 35

Pitch Curve Function ............................................................. 35

HELI (Helicopter) ................................................ 36

Swash Type .......................................................................... 36

Pitch Curve ........................................................................... 36

Swashplate ........................................................................... 36

Gyro ..................................................................................... 37

Governor .............................................................................. 37

Tail Curve ............................................................................ 37

Mixing ................................................................................. 37

SAIL (Sailplane) ................................................. 38

Sailplane Type ....................................................................... 38

Camber Preset ...................................................................... 38

Camber System .................................................................... 38

SAIL Mixing .......................................................................... 39

Receiver Installation And

Power System Requirements ............................ 40

Speci cations ....................................................................... 40

Receiver Installation .............................................................. 40

Power System Requirements ................................................. 40

Recommended Power System Guidelines ............................... 40

Physical Transmitter Adjustments .................... 41

Mode Conversion .................................................................. 41

Adjust Stick Tension ............................................................. 41

Control Stick Length Adjustment ...........................................41

Adjust Throttle Friction Straps ................................................ 41

Throttle Ratchet Strip Installation ............................................ 41

2.4GHz Troubleshooting Guide .......................... 42

Parts list ............................................................. 42

1-Year LIMITED WARRANTY .............................. 43

Warranty and Service Contact Information ........................ 44

FCC Information ................................................................... 44

Antenna Separation Distance ................................................. 44

IC Information ...................................................................... 44

FAA Information ................................................................... 44

AMA National Model Aircraft Safety Code .......................... 45

Compliance Information for the European Union ............... 46

4 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 5

Transmitter Batteries

Battery and Charging Precautions and Warnings

Failure to exercise caution while using this product and comply with the following warnings could result in product malfunction,

electrical issues, excessive heat, FIRE, and ultimately injury and property damage.

• Read all safety precautions and literature prior to use of this product

• Never allow minors to charge battery packs

• Never drop charger or batteries

• Never attempt to charge damaged batteries

• Never attempt to charge a battery pack containing different types of batteries

• Never charge a battery if the cable has been pinched or shorted

• Never allow batteries or battery packs to come into contact with moisture at any time

• Never charge batteries in extremely hot or cold places (recommended between 50–80 degrees F or 10–27 degrees C) or place

in direct sunlight

• Always disconnect the battery after charging, and let the charger cool between charges

• Always inspect a new battery before charging

• Always terminate all processes and contact Horizon Hobby if the product malfunctions

• Always keep batteries and charger away from any material that could be affected by heat (such as ceramic and tile), as they

can get hot

• Always end the charging process if the charger or battery becomes hot to the touch or starts to change form (swell) during the

charge process

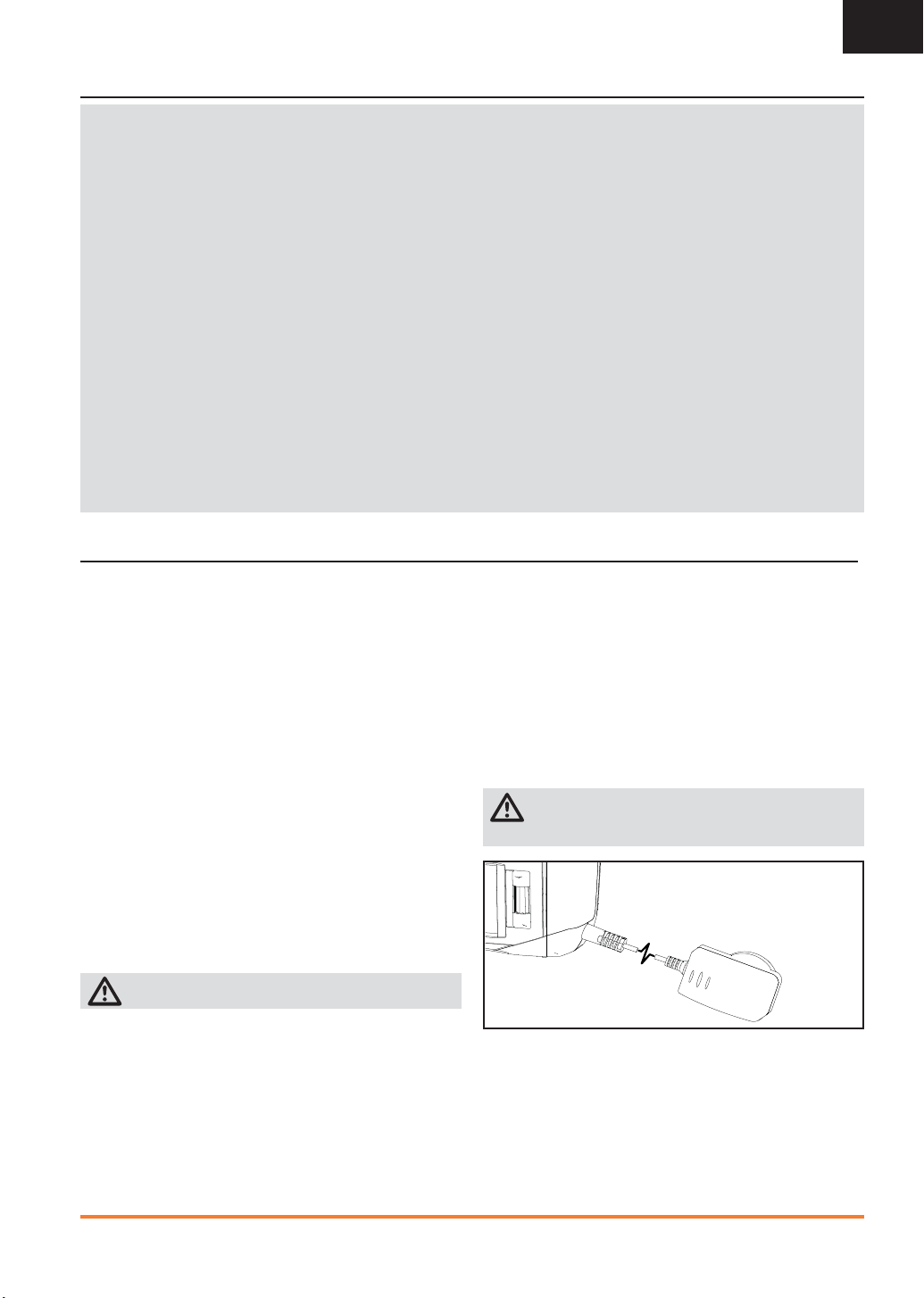

Charging Your Transmitter

EN

The DX18 has an internal charger designed to charge the included

2-cell LiPo battery at a charge rate of 200mAh. The charge port on

the right side of the transmitter is not polarity-dependent.

NOTICE: Never connect an external battery charger to your

DX18 transmitter. If you wish to charge the LiPo battery using a

LiPo charger, you must remove the battery from the transmitter

before charging.

The rst time you charge the transmitter battery, the charge time

may be 12–15 hours. Always charge the transmitter on a heatresistant surface.

1. Power off your transmitter.

2. Connect the power supply connector to the transmitter charge

port.

3. Connect the power supply to a power outlet using the appropriate adapter.

4. The blue LED on the front of the transmitter turns on during

charging and turns off when the battery is fully charged.

5. Disconnect the transmitter from the power supply once charging is complete and disconnect the power supply from the

power outlet.

CAUTION: Never leave a charging battery unattended.

LED indicators

The blue LED indicates the transmitter battery is charging. The

orange LED indicates the transmitter is powered on and there is

radio transmission.

Battery Alarm

The System Settings Screen allows you to change the battery

type and low alarm settings. See “System Settings” for more

information.

• An alarm will sound when the battery reaches the low voltage

limit (4.3V for NiMH, 6.4V for LiPo).

CAUTION: Never change the low voltage limit for LiPo

batteries from 6.4V. Doing so could over-discharge the

battery and damage both battery and transmitter.

5SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 6

EN

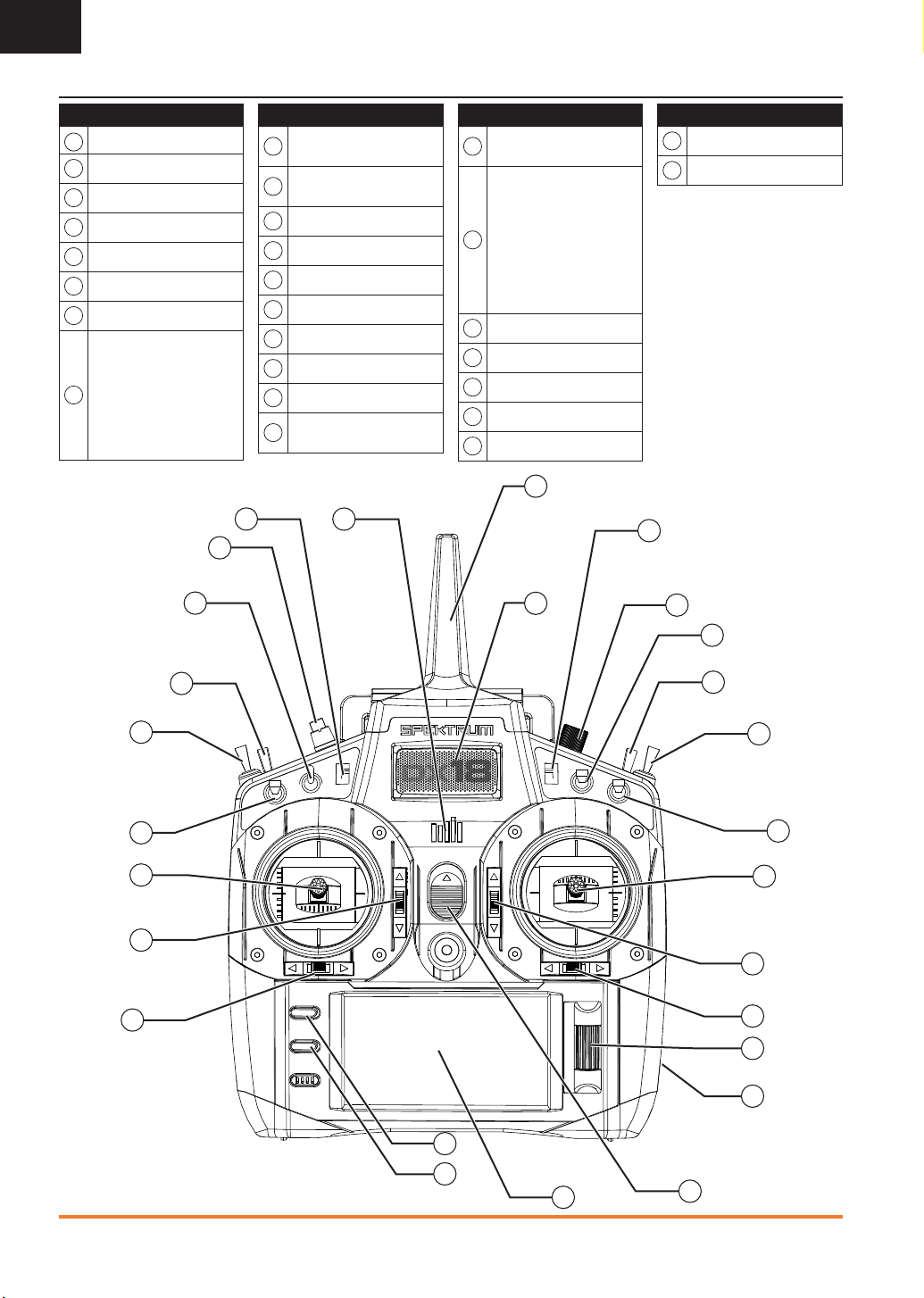

Transmitter Functions

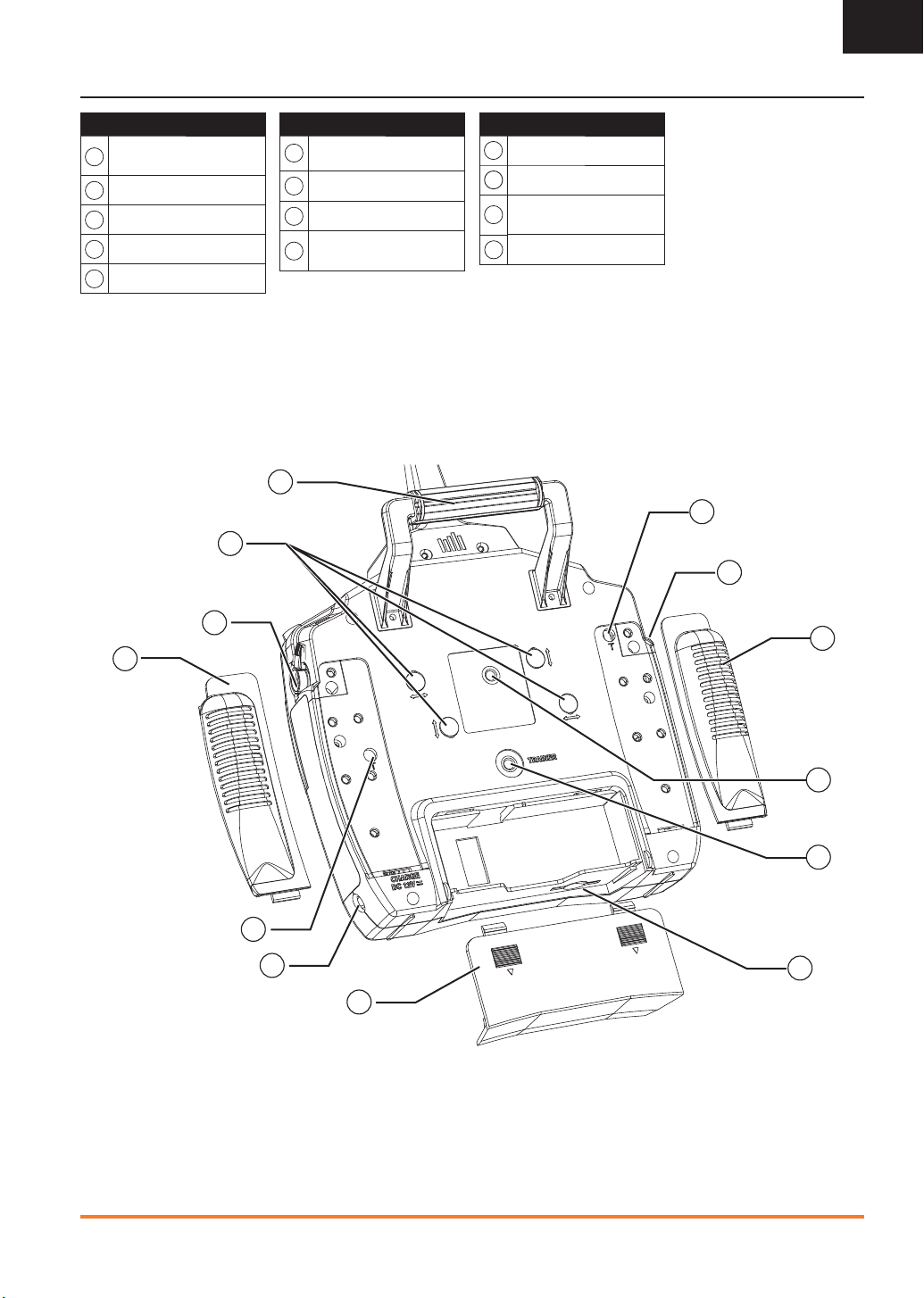

Function

Antenna 1

1

RIght Trim

2

3

Right Knob

Switch E

4

Switch H

5

6

Switch G

Switch F

7

Throttle/Aileron Stick

(Mode 1)

Elevator/Aileron Stick

(Mode 2) Throttle/Rudder

8

Stick (Mode 3)

Elevator/Rudder Stick

(Mode 4)

24

25

26

Function

Elevator Trim (Mode 2, 4)

9

Throttle Trim (Mode 1, 3)

Aileron Trim (Mode 1,2)

10

Rudder Trim (Mode 3,4)

Roller

11

12

Charge Port

On/Off Switch

13

14

LCD

Clear Button

15

Back Button

16

17

Speaker Grill

Rudder Trim (Mode 1,2)

18

Aileron Trim (Mode 3,4)

27

Function

Elevator Trim (Mode 1,3)

19

Throttle Trim (Mode 2,4)

Elevator/Rudder Stick

(Mode 1)

Throttle/Rudder Stick

(Mode 2)

20

Elevator/Aileron Stick

(Mode 3)

Throttle/AileronStick

(Mode 4)

21

Switch C

22

Switch B

23

Switch A

24

Switch D

25

Bind/Switch I

1

17

Function

26

Left Trim

LED

27

The transmitter comes with a thin,

clear plastic lm applied to some

front panels for protection during

shipping. Humidity and use may

cause this lm to come off.

Carefully remove this lm as

desired.

2

3

4

18

22

21

20

19

23

15

16

14

5

6

7

8

9

10

11

12

13

6 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 7

Transmitter Functions

EN

Function

Throttle Spring Tension

1

Adjustment (Mode 2,4)

2

Left Lever

3

Left Rear Grip

4

Audio Jack

5

Trainer Port

10

11

12

SD Card

6

7

Battery Cover

8

Charge Port

Throttle Spring Tension

9

Adjustment (Mode 1,3)

13

Function

Function

10

Right Rear Grip

Right Lever

11

Gimbal Stick Tension

12

Adjustment

13

Handle/Antenna 2

1

2

3

4

5

9

8

6

7

7SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 8

EN

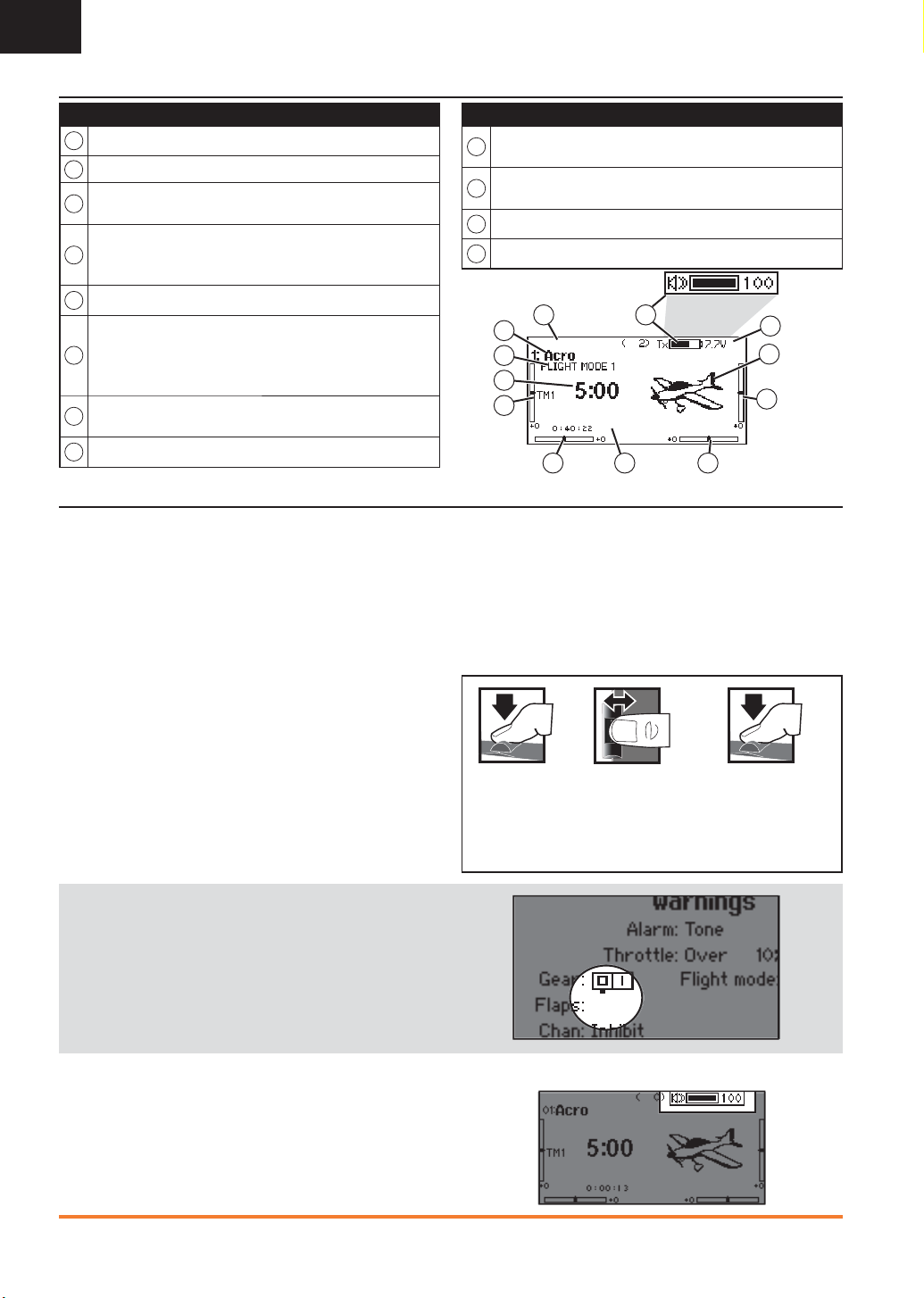

Main Screen

Function

A

Model Name

®

DSMX

B

C

D

E

F

G

H

/DSM2® If not shown, this indicates “not bound”

Transmitter Battery

Charge Level

Digital Battery Voltage (an alarm sounds and the screen

fl ashes when battery charge gets down to 4.3V when using an NiMH battery or 6.4V for a LiPo/Li Ion battery.)

Model Type

Elevator Trim

(Modes 2 and 4)

Throttle Trim

(Modes 1 and 3)

Aileron Trim (Modes 1 and 2)

Rudder Trim (Modes 3 and 4)

Model Memory Timer

Also displays the Volume Level

when the BACK button is pressed

Also displays R Trim values when

the Right Trim button is pressed

Navigation

• Turn the scroll wheel to move through the screen content or

change programming values. Press the scroll wheel to make

a selection.

• Use the Back button to go to the previous screen

(for example, to go from the Mixing Screen to the Function

List).

• Use the Clear button to return a selected value on a screen to

the default setting.

• Direct Model Access enables you to access the Model Select

screen without powering off the transmitter. Anytime the

transmitter power is on, press the Clear and Back buttons to

access the Model Select screen.

• Press and hold the roller while powering on the transmitter

to show the System Setup list. No radio transmission occurs

when a System Setup screen is displayed, preventing

accidental damage to linkages and servos during changes to

programming.

Function

Rudder Trim (Modes 1 and 2)

I

Aileron Trim (Modes 3 and 4)

Throttle Trim (Mode 2 and 4)

J

Elevator Trim (Mode 1 and 3)

K

Timer

L

Active Flight Mode

A

L

K

J

• At the main screen you can roll the roller to view the servo

monitor.

• The Main Screen appears when you power on the transmitter.

Press the scroll wheel once to display the Function List.

• When you want to change a value in a screen for a particular

control position, move the control to the desired position to

highlight the value you want to change, such as 0/1/2, up/

down or left/right.

Also displays L Trim values when

the Left Trim button is pressed

CB

E

F

GI H

D

Turn HoldPress

Enter, Choose

or Exit

Move between

options or change

value in an option

Hold for 3

seconds and

release to move to

the Main Screen

Tip: The tick mark below shows the current switch position.

Rolling and clicking the roller turns the selected box black,

indicating that the value or condition will act on that position.

Volume Control

Volume control is adjusted from the Main Screen.

To change the volume:

1. Press the BACK button.

2. Turn the scroll wheel left or right to adjust the volume level.

3. Press the scroll wheel to save the selection.

8 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 9

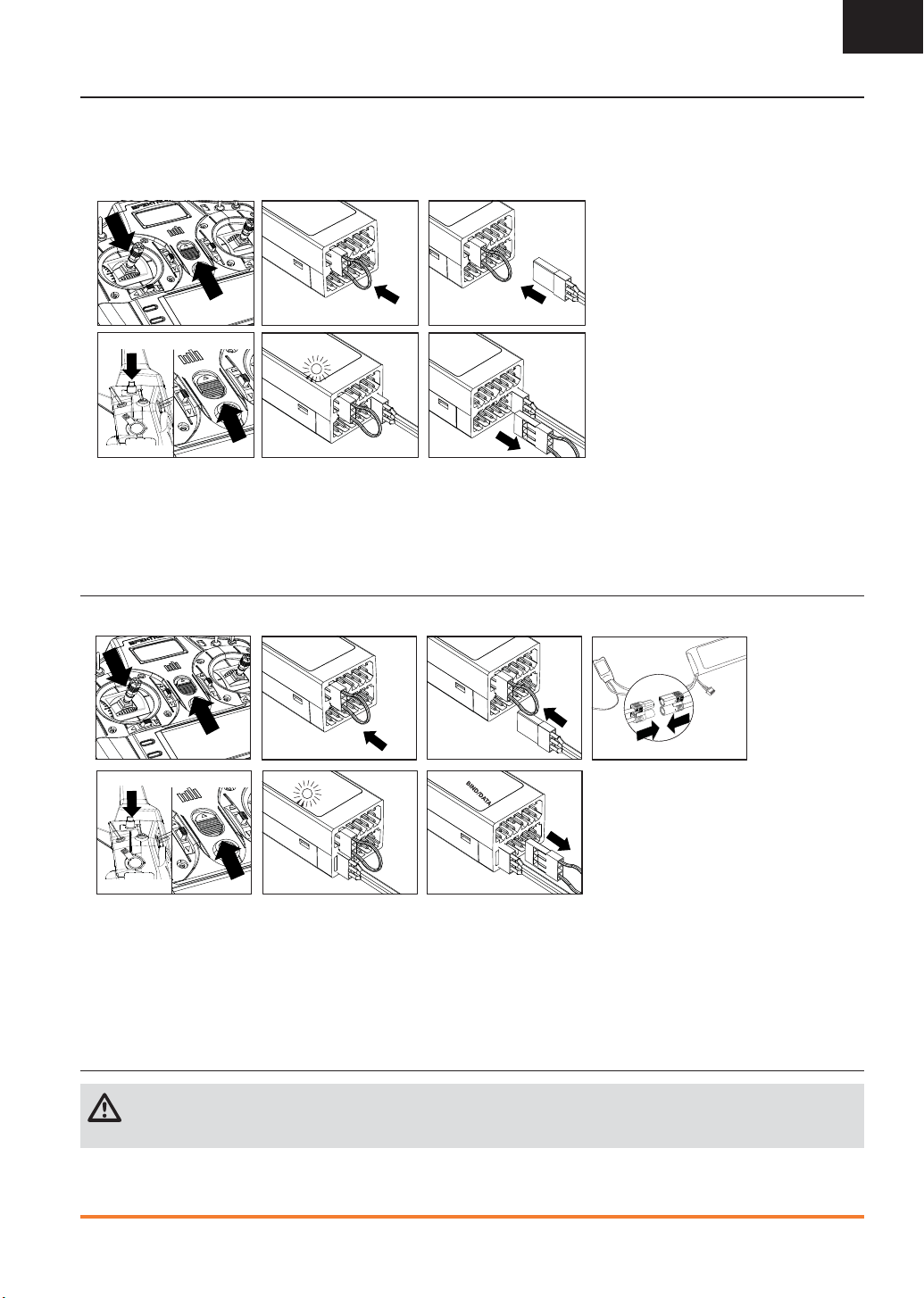

BINDING

Binding is the process of programming the receiver to recognize the GUID (Globally Unique Identi er) code of a single speci c

transmitter. The DX18 and AR9020 are pre-bound at the factory. You will need to rebind after the model programming is initially

set up to fully program the model’s failsafe positions.

Binding Using the Receiver and Receiver Battery

1.

2. 3.

EN

Hold button while powereing on

4.

Mode 2 shown

5.

1. Move the throttle stick to the lowest position and power off the

transmitter.

2. Insert the bind plug into the BIND/DATA port on the receiver.

3. Connect a fully charged receiver pack to any open port on the

receiver. The orange LED on the receiver rapidly ashes when

the receiver is in bind mode.

Binding Using the Receiver and ESC

1.

Hold button while powereing on

5.

2. 3.

6.

7.

6.

4. Press and hold the transmitter bind button while powering the

transmitter on.

5. Release the Bind button when the transmitter screen displays

“Binding”. Binding is complete when the orange transmitter

and receiver LEDs are on solid.

6. Power off the receiver and remove the bind plug.

4.

Mode 2 shown

1. Lower throttle to the lowest position and make sure the

transmitter is powered off.

2. Insert the bind plug into the BIND/DATA port.

3. Insert the ESC plug into the THRO port.

4. Connect battery to ESC and turn on ESC switch, if available.

The receiver’s LED will rapidly ash when the receiver is ready

5. While pressing the Bind button, power on the transmitter.

6. Release the Bind button after the receiver has stopped ashing

rapidly, once the receiver’s LED stays illuminated; this indicates the receiver is bound to the transmitter. The screen also

provides binding information.

7. Remove the bind plug from the receiver.

to bind.

CAUTION: When using the DX18 with park yer receivers, only use such receivers in park yer-type aircraft (small electric

airplanes or mini and micro helicopters). Installing park yer receivers in larger aircraft could cause signal blocking and

loss of connection.

9SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 10

EN

PROGRAMMING FAILSAFE POSITIONS

You establish failsafe positions when you bind your transmitter

and receiver. If the radio signal connection is lost between the

transmitter and receiver, the receiver immediately moves the

aircraft control surfaces to the failsafe positions. If you assign the

receiver THRO channel to a transmitter channel other than throttle,

we recommend using Preset failsafe with the throttle in the low

position.

SmartSafeTM Failsafe

SmartSafe failsafe is a technology that only acts on the throttle

channel and offers the following bene ts:

• Prevents electric motors from operating when the receiver

power is on and the transmitter power is off.

• Prevents the speed controller from arming until the throttle is

moved to the low throttle position.

• Powers off an electric motor and reduces gas/glow engines to

idle if signal is lost.

Hold Last Command

The Hold Last Command failsafe maintains the last command on

all channels except throttle. If the radio signal is lost, the aircraft

maintains the commanded heading until the receiver regains

signal.

To program Hold Last Command, follow the provided binding

instructions in this instruction manual.

To Test Hold Last Command:

1. Power on the transmitter and receiver.

2. Move one of the control sticks to the desired Hold Last

Command position and hold the input.

3. While holding the control input (for example, a small amount of

rudder) power off the transmitter. The rudder should maintain

the input command.

NOTICE: Failsafe features vary according to receiver. Always

consult the receiver instruction manual for failsafe features.

Before ight, ALWAYS con rm the failsafe functions as you would

expect.

To Program SmartSafe, move the throttle to the low or off position

before putting the transmitter into bind mode.

To Test the SmartSafe failsafe

1. Power the transmitter and receiver on.

2. Power off the transmitter. The throttle should immediately move

to the failsafe position.

CAUTION: Make sure the aircraft is fully restrained on

the ground. If the failsafe is not set correctly, your aircraft

might advance to mid or full throttle.

CAUTION: Make sure the aircraft is fully restrained on

the ground. If the failsafe is not set correctly, the aircraft

throttle might advance to mid or full throttle.

Preset Failsafe

The Preset failsafe moves all channels to their programmed

failsafe positions.

We recommend using Preset failsafe to deploy spoilers on sailplanes to prevent a yaway if the radio signal is lost.

To program Preset failsafe:

1. Insert the bind plug in the bind port on the receiver and power

on the receiver.

2. Remove the bind plug when the orange LED on the main

receiver and all attached remote receivers ash rapidly. The

orange receiver LEDs will continue ashing.

10 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

3. Move the transmitter control sticks and switches to the desired

Preset failsafe position. Power the transmitter on.

4. Failsafe programming is complete when the orange LEDs on

the transmitter and all receivers turn solid.

CAUTION: Make sure the aircraft is fully restrained on

the ground. If the failsafe is not set correctly, the aircraft

throttle might advance to mid or full throttle.

Page 11

X-PLUS™

EN

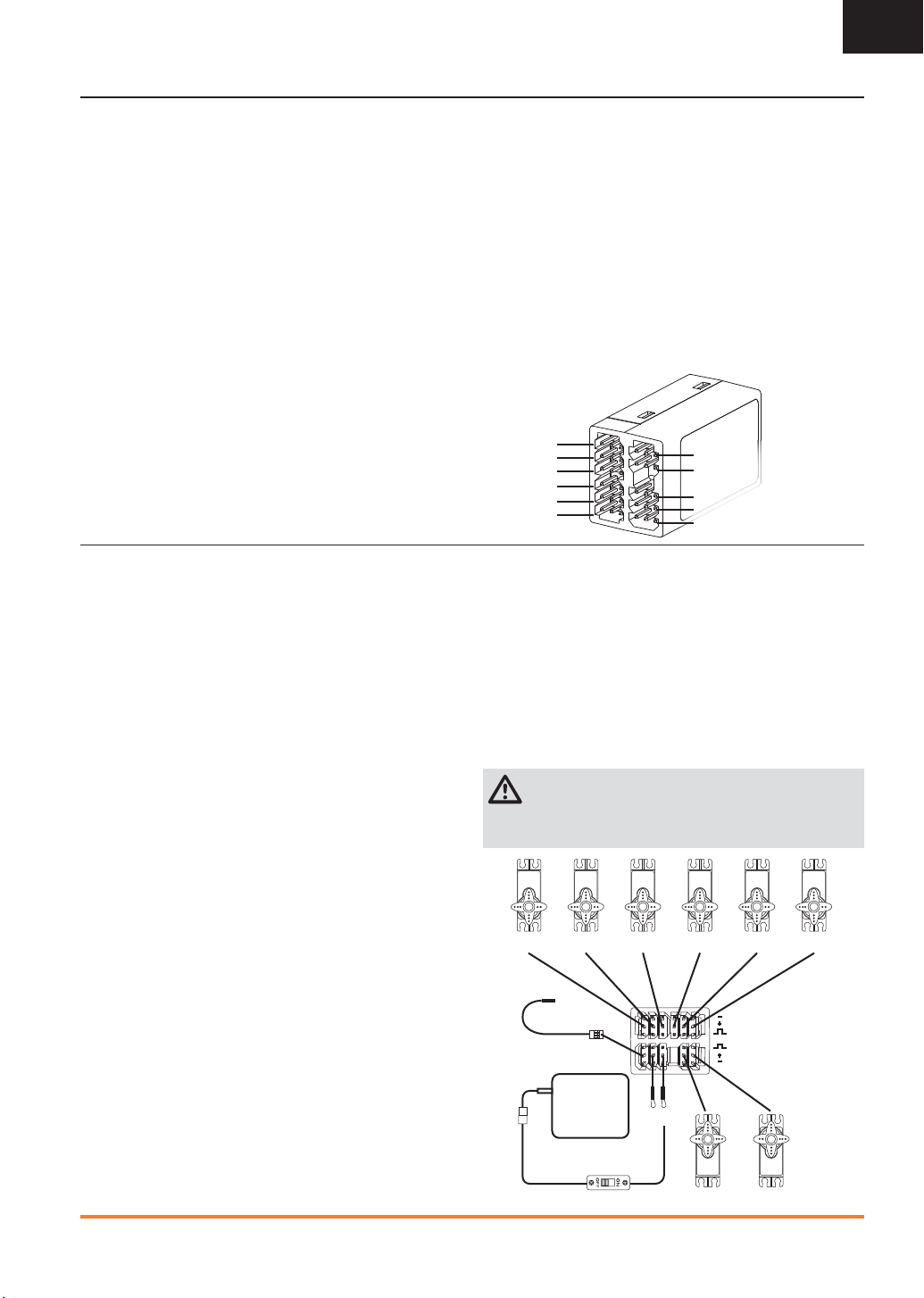

The X-Plus™ 8 module is designed to allow expansion of up to

8 servos for non-control surface functions such as bomb drops,

lights, winches, retractable landing gear, and many more. The

X-Plus 8 is compatible with Spektrum™ X-Plus transmitters and

receivers. The X-Plus 8 module offers the option to power the

connected servos via dual auxiliary battery ports with separate

batteries and switch harnesses (sold separately) independent of

the receiver. The X-Plus 8 module can also be powered inclusive

of the receiver by using the included jumper through either of the

dual BATT/JMPR ports.

Features:

• 8-channel expansion

• Dual battery ports

• Included Jumper offers option of using receiver power

• Allows ne tuning of 8 servos on non-critical controls (bomb

drops, lights, winches, gear, etc.)

Applications

Scale modelers with complex aircraft, ships, or surface applications will enjoy the easy programming and functions of the X-Plus

8 module using X-Plus compatible transmitter’s AirWare™

Installation

In gas and glow aircraft, install the X-Plus 8 module by wrapping it

in protective foam and fastening it in place using rubber bands or a

hook and loop strap. In electric airplanes or helicopters, you can use

thick double-sided foam tape to fasten the module in place.

When using an X-Plus receiver and module, it is recommended that

the X-Plus 8 module be mounted as near to the receiver as possible.

When using the jumper lead to power the module, mounting the

X-Plus 8 module near the receiver system will minimize the current

loss from the receiver. Servo extensions can be used with each

servo, but we recommend using heavy 22 gauge wire with goldplated connectors.

A power jumper plug must be installed in one of the BATT/JMPR

ports of the module if the module is powered from the receiver

through the SRXL port.

Always remove the power jumper when an auxiliary battery or auxiliary batteries are used. When the auxiliary battery option is used, the

X-Plus 8 module can be mounted as far away from the receiver as

needed to be near connected servos.

Power System Requirements

Inadequate power systems that do not provide the necessary minimum voltage to the receiver during ight are the number one cause

of in- ight failures. Some of the power system components that

affect the ability to properly deliver adequate power include:

• Receiver battery pack (number of cells, capacity, cell type, state

of charge)

• The ESC’s capability to deliver current to the receiver in electric

aircraft

• The switch harness, battery leads, servo leads, regulators, etc.

The X-Plus 8 module has a minimum operational voltage of 3.5

volts; it is highly recommended that the power system be tested per

the guidelines below.

software. Modelers will be able to select 2 position,

3 position or potentiometer adjustment through their transmitter.

After selecting the speci c switch or port, AirWare software will allow the individual servo adjustment of each X-Plus channel‘s travel

adjust, sub trim, reversing, and speed.

Specifi cations

Type: X-Plus Module

Channels: 8

Dimensions: 0.91x 1.61 x 0.79 in

(23 x 41 x 20mm)

Weight: .42 oz (11.9 g)

Voltage Range: 3.5 to 9.6V

Resolution: 512

Compatibility: All X-Plus transmitters and receivers

X+1

X+2

X+3

X+4

X+5

X+6

X+7

X+8

BATT/JMPR

BATT/JMPR

SRXL

Recommended Power System Test Guidelines

If a questionable power system is being used (e.g., a small or old

battery, an ESC that may not have a BEC that will support highcurrent draw, etc.), perform the following test with a voltmeter.

The Hangar 9

®

Digital Servo & Rx Current Meter (HAN172) or the

Spektrum Flight Log (SPM9540) work well for this test.

Plug the voltmeter into an open channel port in the receiver and, with

the system on, load the control surfaces (apply pressure with your

hand) while monitoring the voltage at the receiver. The voltage should

remain above 4.8 volts even when all servos are heavily loaded.

CAUTION: When charging Ni-MH batteries, make sure the

battery fully charges. Ni-MH batteries charged with peak

detection fast chargers have a tendency to false peak (i.e. not fully

charge), which could lead to a crash.

X+6 Servo

To SRXL Port

X+5 Servo

Auxiliary Battery

Pack

(optional)

X+4 Servo X+3 Servo X+2 Servo X+1 Servo

Jumper

On/Off Switch Harness (optional)

X+8 Servo X+9 Servo

11SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 12

EN

X-Plus Channels and Failsafe

Failsafe is not supported for servos connected to the X-Plus

Module. We recommend that no failsafe should be expected or

attempted for a servo connected through the X-Plus Module.

However, servos connected to the X-Plus Module will hold last

command in the event of a failsafe condition.

To Activate X-Plus

1. Open the Frame Rate Menu in System Setup.

2. Scroll to X-Plus

and press the scroll

wheel to activate.

The X-Plus Inputs

screen is now active

in the Channel Assign menu.

AUX6 and AUX7 channels are available on 12-channel receivers

when X-Plus is active. AUX6 and AUX7 are 2048 resolution and

22ms frame rate (12-channel receivers only).

Channels X+1 and X+2 are duplicate channels of channels 11

and 12 on a 12 channel receiver with X-Plus active. If channels 11

and 12 require any adjustment for travel adjust, servo reversing,

sub trim or any other function, adjust channels X+1 and X+2.

Note that channels 11 and 12 will also show on the X-Plus monitor

as channels X+1 and X+2.

If you select 11ms frame rate before you activate X-Plus, the

transmitter reverts to 22ms frame rate when X-Plus is active.

CAUTION: Do NOT connect throttle or any primary

control surface to the X-Plus Module. The X-Plus channels are intended to be used for auxiliary functions only. X-Plus

channels have a resolution of 512 and variable latency from

22ms to about 88ms. When X-Plus is active, the rst 10 channels default to 22ms.

from Channel Assign menu

Refer to community.spektrumrc.com for more information

about X-Plus options.

SD CARD

Installing the SD Card

The included SD Card enables you to:

• Import (copy) models from another

DX18 transmitter

• Export (transfer) models to another

DX18 transmitter

• Update AirWare™ software in the transmitter

To install the SD Card:

1. Power off the

transmitter.

2. Remove the

battery door.

3. Press the SD

Card into the

card slot with the

card label facing

upward.

4. Install the battery

door.

Exporting the Transmitter Serial Number to the

SD Card

Exporting the transmitter serial number to the SD Card allows you

to copy and paste the serial number into the registration screen at

community.spektrumrc.com.

To export the serial number:

1. Press and hold the scroll wheel while powering the transmitter

on until the System Setup list appears.

2. Scroll to the System Settings menu. Press the scroll wheel once

to open the menu.

3. Select NEXT on the System Settings and Extra Settings screens.

4. When the Serial Number screen appears, select EXPORT.

5. Power off the transmitter and remove the SD Card from the

transmitter.

6. Insert the SD Card in your computer and open the .txt le on the

card.

7. Copy and Paste the serial number into the Registration screen on

the Spektrum Community site (community.spektrumrc.com).

12 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 13

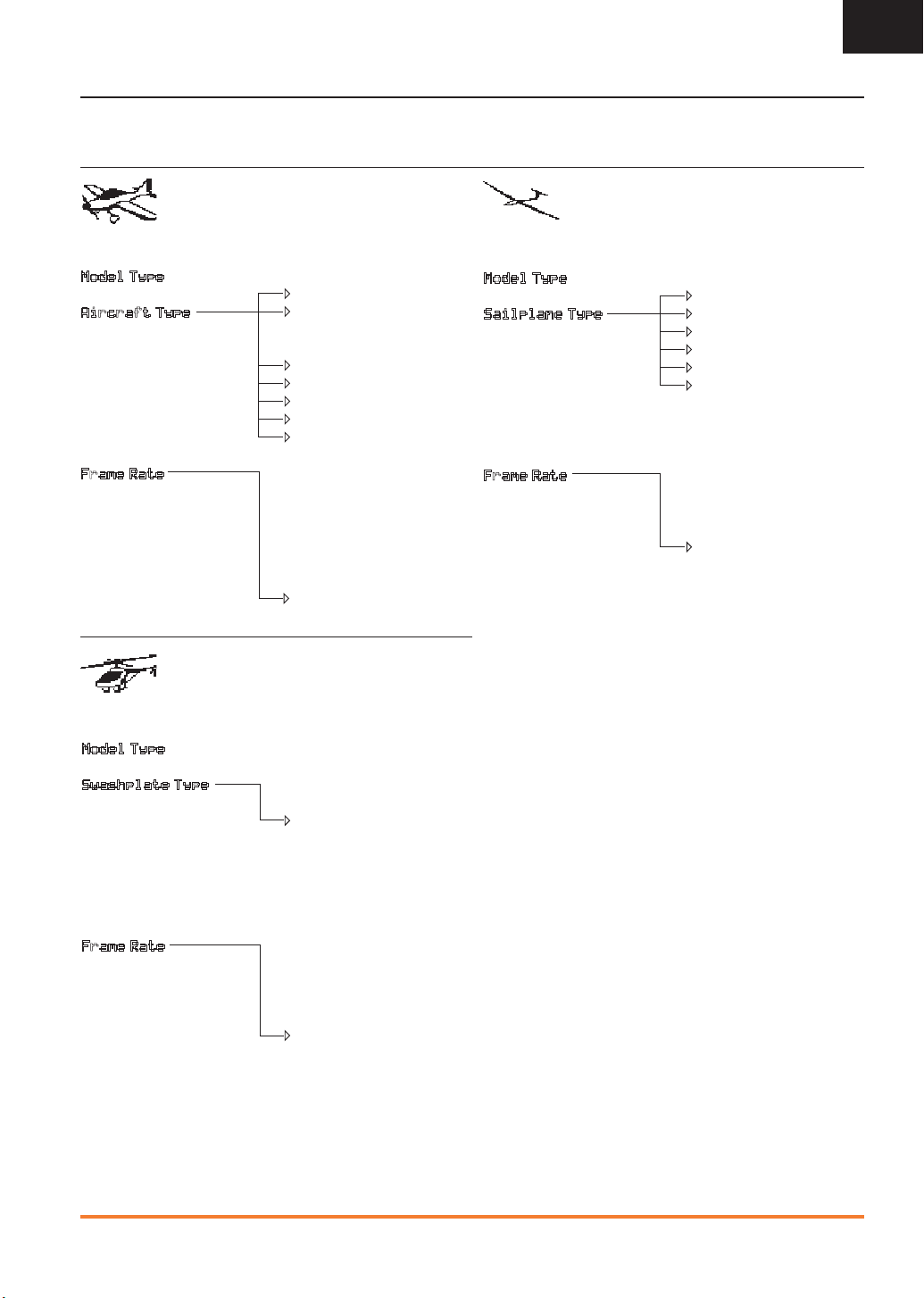

MODEL TYPE PROGRAMMING GUIDE

EN

Menu options show up on model type selection. These menu

options vary between Model Types (Airplane, Helicopter and

Sailplane), but are identical for all models in that type.

System Setup List:

Model Select

Model Type

Model Name

Aircraft Type

F-Mode Setup

Spoken Flight Mode

Channel Assign

Trim Setup

Model Utilities

Warnings

Telemetry

Preflight Setup

Frame Rate

Bind

Trainer

Analog Switch Setup

System Settings

Transfer SD Card

Function List:

Servo Setup

D/R and Expo

Differential

V-Tail Differential

Throttle Cut

Throttle Curve

Gyro1

Gyro2

Gyro3

Pitch Curve

Flap System

Mixing

Sequencer

Range Test

Timer

Telemetry

Custom Voice Setup

System Setup

Monitor

XPlus Monitor

Subsequent aircraft type (Aircraft, Swashplate or Sailplane) selections make other menu options appear.

System Setup List:

Model Select

Model Type

Model Name

Sailplane Type

F-Mode Setup

Spoken Flight Mode

Channel Assign

Trim Setup

Model Utilities

Warnings

Telemetry

Preflight Setup

Frame Rate

Bind

Trainer

Analog Switch Setup

System Settings

Model Utilities

Transfer SD Card

Function List:

Servo Setup

D/R and Expo

Differential

V-Tail Differential

Throttle Cut

Motor Curve

Camber Presets

Camber System

Mixing

Sequencer

Range Test

Timer

Telemetry

Custom Voice Setup

System Setup

Monitor

XPlus Monitor

System Setup List:

Model Select

Model Type

Model Name

Swashplate Type

F-Mode Setup

Spoken Flight Mode

Channel Assign

Trim Setup

Model Utilities

Warnings

Telemetry

Preflight Setup

Frame Rate

Bind

Trainer

Analog Switch Setup

System Settings

Model Utilities

Transfer SD Card

Function List:

Servo Setup

D/R and Expo

Throttle Cut

Throttle Curve

Pitch Curve

Swashplate

Gyro

Governor

Tail Curve

Mixing

Sequencer

Range Test

Timer

Telemetry

Custom Voice Setup

System Setup

Monitor

XPlus Monitor

13SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 14

EN

COMMON SYSTEM SETUP FUNCTIONS

Model Select

Model Select enables you to access any of the 250 internal model

memory locations in the Model Select list.

1. Scroll to the desired model memory in the Model Select list.

2. When the desired model memory is highlighted, press the

scroll wheel once to select the model. The transmitter returns

to the System Setup List.

3. Add a new model by rolling to the bottom of the list. You will

then be prompted with the Create New Model screen, with the

option to create a new model or cancel. If you select Cancel

the system will return to the Model Select function. If you

select Create, the new model will be created and now be available in the model select list.

Direct Model Access

Press the Clear and Back buttons from the Main Screen or a

telemetry screen to access Model Select.

Model Type

Select from Airplane, Helicopter or Sailplane model types.

IMPORTANT: When you select a new model type, you will delete

any programming data in the current model memory. Always

con rm the desired model memory before changing model types. It

will be necessary to re-bind after resetting the model type.

To change the model type:

1. Scroll to the desired model type and press the scroll wheel.

The Con rm Model Type screen appears.

2. Select Yes and press the scroll wheel to con rm the model

type. All data will be reset. Selecting No will exit the Con rm

Model Type screen and return to the Model Type screen.

Model Name

Model Name enables you to assign a custom name to the current

model memory. Model names can include up to 20 characters

including spaces.

To add letters to a Model Name:

1. Scroll to the desired letter position and press the scroll wheel

once. A ashing box appears.

2. Scroll left or right until the desired character appears. Press

the scroll wheel once to save the character.

3. Scroll to the next desired letter position. Repeat Steps 1 and 2

until the Model Name is complete.

4. Select BACK to return to the System Setup list.

To erase a character:

1. Press CLEAR while the character is selected.

2. Press CLEAR a second time to erase all characters to the right

of the cursor.

14 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 15

EN

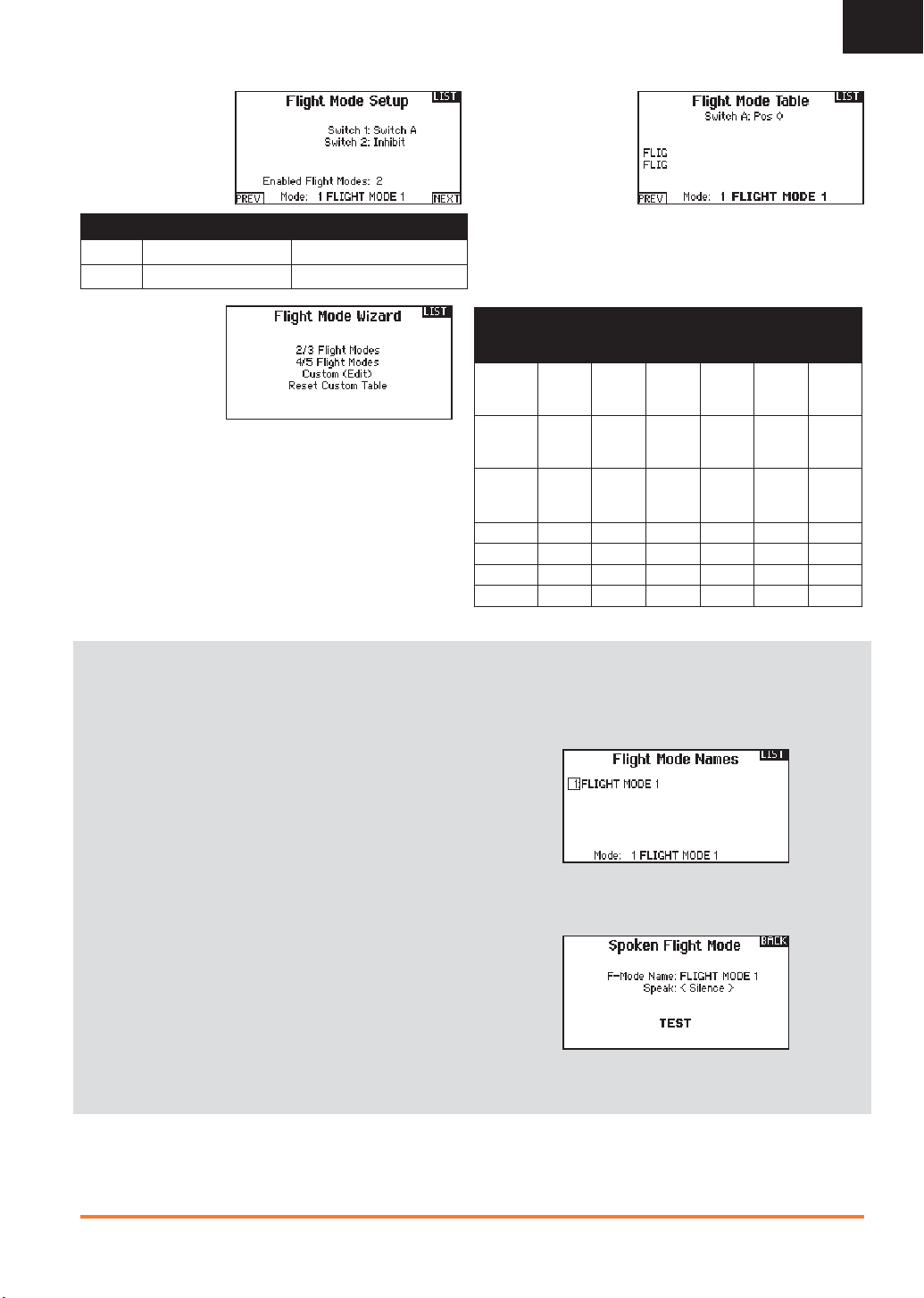

F-Mode Setup

Use the Flight Mode

Setup menu to assign

switches to ight modes.

Mode Number of Switches Number of Flight Modes

Aircraft 2 5

Heli 3 (including Throttle Hold) 5 (including Throttle Hold)

Flight Mode Wizard

The Flight Mode Wizard

resets the Flight Mode

Table to the default

settings without affecting

the ight mode switch

assignments.

To reset the Flight Mode Table:

1. Select PREVIOUS until you reach the Flight Mode Wizard.

2. Select the desired option, based on the number of active ight

modes. The Flight Mode Table is now reset.

Sailplane Flight Mode Setup

You can assign up to ten ight modes using any combination of

up to three switches. You can also assign a priority switch. When

the priority switch position is active, only the current ight mode is

active, regardless of other switch positions.

Aircraft and Sailplane Flight Mode Table

You can assign the

available ight modes (up

to 5 for Air, up to 10 for

Sail) to each of the switch

positions (up to 3 switches

can be used for sailplane

and up to 2 switches

can be used for aircraft). Press NEXT from the Flight Mode Name

page to access the ight mode table assignment page when Custom

ight mode has been selected in the Flight Mode Setup page. The

combination of up to 2 or 3 switches can be used to access all of the

ight modes available.

Number

of Flight

Modes

Switch 1

(number of

positions)

Switch 2

(number of

positions)

Flight

Mode

1

2 Cruise Cruise Cruise Cruise Cruise Cruise

3 Land Land Land

4 Thermal Thermal Thermal Thermal

5 Speed Speed

*Must be set up in a 4/5 fl ight mode

2 3 3* 4 4 5

2P 3P 2P 2P 3P 3P

2P 3P 2P 3P

Launch Launch Launch Launch Launch Launch

.

Spoken Flight Mode Setup

Enables you to assign custom names to the Flight Mode positions.

Flight Mode names can include up to 20 characters including

spaces.

To change the Flight Mode name:

1. Scroll to the Flight Mode name you wish to change and press

the scroll wheel.

2. Scroll to the character position you wish to change and press

the scroll wheel once. A ashing box appears.

3. Scroll left or right until the desired character appears. Press

the scroll wheel once to save the character.

4. Repeat Steps 2 and 3 until the Model Name is complete.

5. Select BACK to return to the Flight Mode Names list.

Spoken Flight Mode:

The Spoken Flight Mode option enables you to activate audio ight

mode alerts. As you change between ight modes, the transmitter

will “speak”, informing you of the active ight mode. You can select

a word or phrase for each ight mode.

To activate Spoken Flight Mode:

1. Enter the Spoken Flight Mode menu option.

2. Scroll to <Silence> (default), then press the scroll wheel.

3. Scroll left or right to view the options.

4. Press the scroll wheel again to save the selection.

15SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 16

EN

Channel Assign

The Channel Assignment function allows you to reassign almost

any receiver channel to a different transmitter channel. For

example, the receiver gear channel could be re-assigned to the

transmitter throttle channel.

1. Scroll to the receiver channel you wish to change.

2. Press the scroll wheel once and scroll left or right to change

the receiver input selection.

3. Press the scroll wheel a second time to save the selection.

Channel Input Confi guration

The Channel Input Con guration screen enables you to assign a

transmitter channel to a different control stick or switch.

1. Select NEXT on the RX Port Assignments screen to access the

Channel Input Con guration screen.

2. Scroll to the transmitter channel you wish to re-assign and

press the scroll wheel. The box around the current input

selection ashes.

3. Scroll left or right to select the desired control stick or switch.

4. Press the scroll wheel to save the selection.

X-Plus Input Confi guration

The X-Plus Input Con guration screen enables you to assign any

X-Plus channel to any transmitter input.

1. Select NEXT on the Channel Input Con g screen to access the

X-Plus Input Con g screen.

2. Scroll to the X-Plus channel you wish to change.

3. Press the scroll wheel once and scroll left or right to change

the X-Plus Input for that X-Plus channel.

IMPORTANT: You cannot assign a mix to a channel that has been

moved. Create the mix rst, then move the channel.

Trim Setup

Use the Trim Setup screen to change the size of the trim step and

the trim type.

Trim Step

Adjusting the trim step value determines how many “clicks” of trim

you input each time you press the trim button. Changing the trim

step value to 0 disables the trim for the channel.

To change the trim step value:

1. Scroll to the trim step channel you wish to change.

2. Select the trim step value and scroll left or right to change the

value.

3. Press the scroll wheel to save the selection.

Trim Type

The two Trim Type options are Common and F Mode.

Common trim type maintains the same trim values for all ight

modes.

F Mode trim type enables you to save trim values for individual

ight modes if you nd, for example, the aircraft requires aileron

trim in Flight Mode 1 but not in Flight Mode 2.

Trim Assignment

In a few instances, you can reassign a trim to a different location.

Aircraft Model Type

Throttle

• Throttle Digital trim button (default)

• Left Analog lever

• Right Analog lever

Throttle Trim Type

• Common

• Flight Mode

• 3-Pos

Tip: With throttle trim set to 3-Pos, the throttle trim will function as

a 3-position throttle trim where the throttle trim can be set to low,

middle, and high. This can be helpful for turbine set up.

Helicopter Model Type

Throttle and Pitch Hover Trim —Used to trim the throttle and pitch

setting for precision hovering. This does not affect normal throttle

trim operation.

• Right Knob

• Left Analog Lever

• Right Analog Lever

• L Trim

• R Trim

16 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 17

EN

Active Gyro and Governor Trim—Used to trim the gyro and

governor settings in fl ight.

• L Trim

• R Trim

Trim Location

Normal and Cross trim types are available. Normal trims align with

the control stick; for example, the throttle trim is next to the throttle

stick.

Cross trims reverse the position of the trims; for example, the throttle

trim is next to the elevator stick and vice versa.

To change the Trim Position from Normal to Crossed, select Normal

at the bottom of the Trim Setup screen and press the scroll wheel.

IMPORTANT: Crossed trims will cross both sets of trims for both

gimbals.

Model Utilities

In the Model Utilities function you can create a new model, delete a model, copy a model, reset a model to default settings and sort the

model list.

Create New Model

Use this selection to create a new model in the model select list.

1. Select Create New Model. Within this screen, you will have the

option to create a new model or cancel.

2. If you select Cancel, the system will return to the Model Select

function.

3. If you select Create, the new model will be created and now be

available in the model select list.

Delete Model

Use this selection to permanently delete a model from the model

select list. If you do not wish to delete a model, select Cancel to

exit the page.

1. To delete a model, highlight the model listed. Press to select

then roll to the model name. Press the roller to select.

2. Select DELETE to delete the model.

Copy Model

The Model Copy menu enables you to duplicate model

programming from one Model List location to another.

Use Model Copy to:

• Save a default model copy before experimenting with

programming values

• Expedite programming for a model using a similar

programming setup

IMPORTANT: Copying a model program from one model

memory to another will erase any programming in the “To”

model memory.

Reset Model

Use the Model Reset menu to delete all model programming in

the active model memory. Reset returns all model settings to the

default settings and erases all programming in the selected model.

After a model reset, it is necessary to re-bind.

To copy model programming:

1. Make sure the model program you wish to copy is active. If the

desired model program is not active, select Cancel and change

the active model in the Model Select menu.

2. Select the model memory next to “To” and scroll to the desired

model memory. Press the scroll wheel once to save the selection.

3. Select Copy and the Con rm Copy screen appears.

4. Select Copy to con rm. Selecting Cancel will return to the

System Setup screen.

5. Select the “To” model as the current model, then bind the

transmitter and receiver. Copying a model does not copy the

bind from the original model.

You cannot use the Model Copy screen to copy model

programming to an SD Card. To copy model programming to the

SD Card, please see “Transfer SD Card”.

17SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 18

EN

Sort Model List

With this function you can sort the model order in the model select

function. This is helpful to group similar models together to make

them easy to nd. To move a model, highlight the model that you

wish to move with the roller, then press the roller to highlight it.

Then roll with the roller to move the selected model to the position

desired. Press the roller when you have the model in the position

desired.

Warnings

The Warnings menu enables you to program a tone or vibration

alert during power on of the transmitter for any selected switch or

channel position.

The alarm activates and an alert message appears on the screen if

a speci c switch or control stick is in an unsafe position when you

power the transmitter on.

Return the switch or control stick to the safe position to silence the

alarm.

For safety reasons, the default throttle alarm activates if the throttle

position is above 10%.

Telemetry

Installing the optional

telemetry module

and sensors enables

the display of aircraft

performance data on the

transmitter screen. You

can also enable Data

Logging to save a telemetry le on the SD Card and view the data

in the Spektrum STi

Settings

Display

Telemetry display

options include:

Tele: When you press

the scroll wheel,

the Telemetry

screens appear and the Main Screen is disabled.

Main: Telemetry alerts appear on the Main screen, but all

Telemetry screens are disabled.

Roller (Default): Allows you to toggle between the Telemetry

Auto: The Telemetry screen automatically appears as soon as

the transmitter receives data from the telemetry module.

Units

Scroll to Units and press the scroll wheel to change between US

and Metric.

Auto-Confi guration

IMPORTANT: The

Auto-Con g option is

not available from the

System Setup>Telemetry

menu. RF signal must

be transmitting when

you use the Auto-Con g

option. When the System Setup menu is active, RF signal is off.

TM

mobile application.

screens and the main screen by pressing the

scroll wheel.

The DX18 transmitter features telemetry Auto-Con guration,

allowing the transmitter to detect new telemetry sensors.

To use Telemetry Auto-Con g:

1. Make sure all telemetry components are bound to the

transmitter and receiver.

2. Power on the transmitter, then power on the receiver.

3. Select Telemetry from the Function List, then select Auto

Con g. “Con guring” ashes for 5 seconds and any new

sensors appear in the list.

4. Adjust the sensor alert values as necessary.

Status Reports:

Status Reports

determines how often the

transmitter refreshes the

data on the screen. Each

telemetry sensor can be

adjusted independently.

For example, the RPM

status report can refresh every 10 seconds while the altimeter

sensor refreshes every 15 seconds.

Warning Reports:

Warning Reports determines how often a telemetry alert occurs,

if an alert is active.

Alarm

Select Inh under Alarm to select the type of alarm desired. Options

include Inh, Tone, Vibe, Tone/Vibe, Voice, Voice/Vibe.

Status Reports (Spoken Telemetry)

1. Select Inh next to Status Reports in each telemetry setting to

add spoken telemetry feedback as desired.

2. Scroll to select how often you want to hear the status report.

Warning Reports (Spoken Telemetry)

1. Select Inh next to Warning Reports in each telemetry setting

to add spoken telemetry feedback for telemetry warnings as

desired.

2. Scroll to select how often you want to hear the telemetry

warning.

18 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 19

File Settings

This is used to select the

data logging settings.

File Name

1. Select File Name to

assign a custom le

name.

2. The File Name screen appears, allowing you to name the le

as you would for a Model Name or Flight Mode Name. The le

name can include a maximum of 8 characters.

3. Press BACK to save the name.

Start

1. Select Start to assign a speci c switch position or stick

position that activates Data Logging.

2. Press the scroll wheel once to save the selection.

Prefl ight Setup

The Pre ight Setup menu option enables you to program a pre- ight

checklist that appears each time you power on the transmitter or

when you select a new model memory. Each item on the list must be

con rmed before you can access the Main Screen.

EN

Enabled

When Enabled is set to NO, Data Logging is turned off.

Select YES to save Telemetry data to the SD Card. The SD Card

must be installed in the transmitter to select YES.

CAUTION: If you access the Telemetry menu from the

Function List, you may see a Frame Loss appear when you

exit the menu. The Frame Loss is not an error, but there will be a

momentary loss of radio signal when exiting the Telemetry screen.

DO NOT access the Telemetry menu during ight.

Frame Rate

The Frame Rate menu

enables you to change

the frame rate and

modulation mode. Select

the option you wish to

change and press the

scroll wheel.

You must use digital servos if you select 11ms frame rate. Analog

and digital servos can be used with a 22ms frame rate.

Modulation Mode

We recommend using DSMX (default) modulation mode. When

DSMX is active, the transmitter operates in DSMX with DSMX

receivers and DSM2 with DSM2 receivers. The transmitter

automatically detects DSM2 or DSMX during binding and changes

the mode accordingly to match the receiver type you are using.

If you select DSM2, the transmitter operates in DSM2 regardless of

whether it is bound to a DSM2 or DSMX receiver.

NOTICE: While DSMX allows you to use more than 40

transmitters simultaneously, do not use more than 40

transmitters simultaneously when using a DSM2 receiver

or a transmitter in DSM2 mode.

Bind

The Bind menu enables you to bind a transmitter and receiver

without powering off the transmitter. This menu is helpful if you are

programming a model and need to bind the receiver for failsafe

positions.

See “Programming Failsafe Positions” for more information.

Bind Progress

The Bind Progress menu

enables you to activate

or inhibit voice alerts for

the binding process. The

alerts are set to Voice by

default.

This menu is accessed by selecting NEXT in the Frame Rate menu.

To activate or inhibit bind voice alerts:

1. Select the alert you wish to change.

2. Press the scroll wheel to change the value.

3. Select BACK to save the selections.

19SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 20

EN

Trainer

The DX18 features a programmable trainer function with 4 wired trainer modes and 2 wireless trainer modes. The transmitter assigns

the trainer function to Switch I.

Wired Trainer

The 4 wired trainer modes include:

Inhibit

In Inhibit, the slave

transmitter must have

the same programming

as the master transmitter

(e.g., servo reversing,

travel adjust, sub-trim,

trims).

Programmable Master

Programmable mode

enables you to program

the master transmitter

to transfer any or all

individual channels

when you activate the

trainer switch. This mode

is ideal for beginners

learning to control individual channels while the master transmitter

maintains control of all other channels.

The slave transmitter should be in Inhibit mode, if available. The

Master and Slave transmitters MUST have the same programming.

Pilot Link Master

Pilot Link Master

enables you to program

the master transmitter

to transfer any or all

individual channels

when you activate the

trainer switch. Pilot

Link Master is ideal for

complex models, as the master transmitter can maintain control

of all secondary functions—for example ight modes, retracts,

aps and brakes. Secondary functions can be individually assigned

to the Slave transmitter as necessary. It is not necessary to have

model programming in the slave transmitter.

It may be necessary for the slave transmitter to be in Inhibit mode

to allow trim changes to transfer over from the master transmitter.

Slave

Use Slave mode when

using the DX18 as a

slave transmitter and

Pilot Link is active in the

master transmitter.

Wired Trainer Operation

1. Bind the master transmitter to the model.

2. Connect the trainer cord (SPM6805) to the back of the master

transmitter.

3. Make sure the master and slave transmitter battery packs are

fully charged.

4. Make sure the slave transmitter is powered off. The slave

transmitter receives power when you connect the trainer cord.

5. Connect the trainer cord to the slave transmitter.

6. The slave transmitter screen displays information but does not

send a signal to the model.

7. Press the trainer button on the master transmitter to transfer

model control from the master to the slave.

8. While moving the trainer switch between the off and on

positions, watch for movement on the control surfaces. Adjust

the trims as necessary before ying.

9. Release the trainer button and the master transmitter regains

control of the model.

Master Override

The Master Override feature enables the instructor to immediately

regain control of the model by moving the control sticks. After you

activate Master Override, the slave transmitter cannot control the

model until you reset the trainer switch. To reset the trainer switch:

1. Move the trainer switch to the OFF position.

2. Move the trainer switch to the ON position to activate the slave

transmitter.

20 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 21

EN

Wireless Trainer

Wireless Trainer works just like the Wired Trainer, without the

wire. Select Wireless Trainer to bind a DSM2 or DSMX slave

transmitter to the master transmitter. With this option, when the

master presses the trainer button or switch, control is given to

the currently bound slave transmitter. After binding, the slave

transmitter will remain bound to the master transmitter until a

different transmitter is bound to the master, or the slave transmitter

is bound to another receiver or a wireless master transmitter.

ModelMatch™ technology applies to the wireless trainer system;

the master transmitter will be bound to the slave in the bound

model used. Also if the slave transmitter has ModelMatch

technology, it will only be bound to the master transmitter in the

selected model during binding.

Inhibit

In Inhibit, the wireless

trainer function will be

inhibited and will not

function.

CAUTION: Select Inhibit in the Trainer menu when you are

not using the wireless trainer function. Failure to select Inhibit

may result in loss of control of the aircraft.

Programmable Master

Programmable mode

enables you to program

the master transmitter

to transfer any or all

individual channels

when you activate the

trainer switch. This mode

is ideal for beginners

learning to control individual channels while the master transmitter

maintains control of all other channels. The slave transmitter

should be in Inhibit mode, if available. The Master and Slave

transmitters MUST have the same programming.

Pilot Link Master

Pilot Link Master

enables you to program

the master transmitter

to transfer any or all

individual channels when

you activate the trainer

switch. Pilot Link Master

is ideal for complex models, as the master transmitter maintains

control of all secondary functions, such as ight modes, retracts,

aps and brakes.

Secondary functions can be individually assigned to the Slave

transmitter as necessary. It is not necessary to have model

programming in the slave transmitter.

Wireless Trainer Operation

1. Enter an unused model on the slave transmitter (computer

transmitter only).

2. Bind the master transmitter to the model.

3. Make sure the master and slave transmitter battery packs are

fully charged.

4. Make sure the slave transmitter is powered off.

5. Either in the Wireless Programmable Master setup page or the

Wireless Pilot Link Master setup page, select BIND. This will

put the master transmitter’s wireless trainer receiver into bind

mode. You should see the following screen:

6. Enter bind mode on the slave transmitter following the

instructions provided with that transmitter.

7. After a successful bind, the following screen should appear.

8. Press the trainer button on the master transmitter to transfer

model control from the master to the slave.

9. Release the trainer button and the master transmitter regains

control of the model.

Master Override

The Master Override feature enables the instructor to immediately

regain control of the model by moving the control sticks. After you

activate Master Override, the slave transmitter cannot control the

model until you reset the trainer switch.

To reset the trainer switch:

1. Move the trainer switch to the OFF position.

2. Move the trainer switch to the ON position to activate the slave

transmitter.

Trainer Alerts

The Trainer Alerts menu

allows you to select

Voice, Tone or Inhibit for

the alerts given while

training. You are also able

to change the voice alerts

given to any selection

from the pre-loaded list of voice alerts.

To change the trainer alert:

1. Scroll to the alert you wish to change and press the scroll

wheel.

2. Scroll to the alert you wish to use: Voice (default), Tone, or Inh.

3. Press the scroll wheel to save your selection.

To change a voice alert:

1. Set the alert to Voice.

2. Scroll to the voice alert you wish to change and press the

scroll wheel.

3. Scroll through the provided list to the voice alert you wish to

use.

4. Press the scroll wheel to save your selection.

21SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 22

EN

EN

Analog Switch Setup

Allows all sticks and pots to be used as a kick point to turn on

functions like mixes. To add a kick point:

1. Move the control stick, lever or knob to the desired kick point

position.

2. Scroll to the desired kick point and press the scroll wheel once

to save the selection.

To delete a kick point, scroll to the desired kick point and press the

Clear button.

System Settings

The System Settings menu consists of four screens:

System Settings, Extra Settings, Serial Number and Calibrate. Select NEXT or PREV to move between screens.

System Settings

User Name

The User Name eld

displays your name in the

lower right corner of the

main screen.

To Program a User Name:

1. Scroll to User Name

and press the scroll wheel. The User Name screen appears.

2. Scroll to the desired character position and press the scroll

wheel. Scroll left or right to change the character and press

the scroll wheel to save the selection. The User Name can

contain a maximum of 20 characters, including spaces.

3. Press the Back button to save the User Name and return to the

System Settings screen.

Contrast

To adjust the screen contrast:

1. Scroll to Contrast and press the scroll wheel.

2. Scroll left or right to adjust the contrast value. Lower numbers

lighten the contrast, higher numbers darken it.

3. Press the scroll wheel once to save the selection.

Backlight

The Backlight eld adjusts the backlight appearance time and

brightness. You have the option to turn the backlight off for models

you y during the day and turn the backlight on for night ying

models.

The backlight time options are:

Off: Appears for a short time when you power on the transmitter.

On: The backlight is always on.

Set Time: The backlight is on for 3, 10, 20, 30, 45 or 60

seconds before automatically turning off. Press the scroll

wheel once to turn the backlight on.

The backlight percentage adjusts the backlight intensity and it

is adjustable in 10% increments from 10% (darker) to 100%

(brighter).

Mode

You can change the control stick mode from

Mode 2 to Mode 4 or Mode 1 to Mode 3.

Mode changes that require movement of complete gimbal

assemblies must be performed by a Horizon Hobby service center.

To change the gimbal stick mode:

1. Scroll to Mode and press the scroll wheel.

2. Scroll left or right to change the gimbal stick mode. Press the

scroll wheel to save the selection.

3. Select NEXT in the lower left corner until the Calibration screen

appears.

4. Move all transmitter controls to the center position and

complete the calibration process before exiting the System

Settings menu. See “Calibrating Your Transmitter” for more

information.

Battery Alarm

Battery Alarm enables you to change the transmitter battery type

and the alarm voltage limit. The alarm activates when the battery

reaches the low voltage limit.

To change the battery alarm:

1. Scroll to the battery type and press the scroll wheel once to

change the type to LiPo/Li-Ion or NiMH.

2. Scroll to the battery voltage and press the scroll wheel. Turn

the scroll wheel left or right to change the voltage level. Press

the scroll wheel again to save the selection.

CAUTION: Never select NiMH when a LiPo/Li-Ion

battery is installed in the transmitter. Doing so may overdischarge the LiPo battery and damage the battery, transmitter

or both.

CAUTION: Never adjust the low voltage limit for the LiPo/

Li-Ion battery pack below 6.4V. Doing so could overdischarge the battery pack and damage both battery pack and

transmitter.

Selecting a Language

In the Systems Settings screen, rotate the roller to highlight

Language, then press the roller to select the Language function.

Rotate the roller to select the desired Language. When the desired

Language is selected, press the roller to accept that Language.

Names you input will not be affected by language change. After

changing the language for the text, you may also want to change

the language for the spoken alerts. See the “Spoken” and “SD

Card” sections for more information.

Inactive Alarm

An alarm activates if the transmitter sees a period of inactivity for

a certain amount of time. The alarm is helpful in reminding you

to power off the transmitter and avoiding a situation where the

transmitter battery completely discharges.

The Inactive Alarm options are:

• Inh (No alarm sounds)

• 5 min

• 10 min (Default)

• 30 min

• 60 min

To change the Inactive alarm time:

1. Scroll to the current alarm time and press the scroll wheel.

2. Scroll left or right to change the alarm time. Press the scroll

wheel to save the selection.

22 SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 23

EN

Extra Settings

The Extra Settings screen

enables you to:

• Turn sounds off or on

• Turn vibration off

or on

• Change the

appearance of the

trim indicators.

System Sounds

Scrolling to System

Sounds and pressing the

scroll wheel turns sounds

on (Active) or off (Inhibit).

You may disable all

sounds by changing the

volume to 0.

Vibrator

The Vibrator value determines how many times the vibration alert

pulses each second. A value of “1” = 1 pulse/second. The value can

be adjusted from 1-10. Use the Warnings menu to turn the vibration

alert off.

Trim Display

Trim display changes the shape of the trim indicators on the Main

Screen. Display options include:

• Boxed Boxes (Default)– The indicators appear as an outlined box

when you adjust the trim.

• Boxed Arrows– The indicators appear as outlined arrows when

you adjust the trim.

• INH– The indicators appear as arrows on lines when you adjust

the trim.

Inhibit removes all trim bars and indicators from the Main Screen.

To change the Trim Display:

1. Scroll to Trim Display and press the scroll wheel once.

2. Scroll left or right to change the Trim Display option. Press the

scroll wheel to save the selection.

Voice Volume Control

The Volume Voice Control

menu enables you to

adjust the default volume

levels for voice alerts in

the transmitter. All values

are set to 50% from the

factory.

To change the default volume level:

1. Scroll to the voice alert you wish to change, then press the roller.

2. Turn the roller left or right to adjust the value in 10% increments.

3. Press the roller to save the value.

System Warnings

The System Warnings

screen enables you to

assign either a voice/

vibe or a tone/vibe to the

Inactivity and the Low

Voltage warnings.

Serial Number

The Serial Number

screen displays the

transmitter serial number

and AirWare software

version.

Reference the Serial

Number screen any time

you need to register your transmitter or update the AirWare software

from the Spektrum Community website.

Exporting the Serial Number to the SD Card

You may nd it helpful to export the transmitter serial number to a

text le for your personal records or when you are registering the

transmitter on the Spektrum Community.

To export the transmitter serial number:

1. Insert an SD Card in the card slot on the transmitter.

2. Scroll to EXPORT and

press the scroll wheel.

The SD Status screen

appears and should

display MY_DX18.xml

in the middle of the

screen.

3. Press the scroll wheel again to return to the Serial Number screen.

4. Power off the transmitter and remove the SD Card from the

transmitter.

5. Install the SD Card in a card reader connected to your computer.

6. Open the MY_DX18.xml le from the SD Card location. You can

then copy and paste the serial number into your personal records

or to the Spektrum Community website.

Locating the Transmitter AirWare Software Version

The transmitter AirWare software version appears between PREV

and NEXT at the bottom of the Serial Number screen. Register

your DX18 to get AirWare software updates and other news at

spektrumrc.com

IMPORTANT: AirWare les are speci c to the transmitter serial

number and you cannot transfer AirWare les between transmitters,

ie., downloading an AirWare software update once and attempting to

install it on multiple transmitters.

Calibrate

The Calibration screen

stores the potentiometer

endpoints for all

proportional controls. It is

mandatory to complete

the calibration after

changing the stick mode

selection.

Calibrating the Transmitter

1. Carefully move the gimbal sticks in a + shape moving from left

to right, then up and down. Press gently on the gimbals at the

stops to achieve an accurate calibration. Return both gimbal

sticks to the center position.

2. Move the Left and Right Side Levers to the top and bottom

positions, then move the side levers to the center position.

IMPORTANT: Only move one side lever at a time during

calibration.

3. Move the Knob to the full clockwise and counterclockwise

positions, then return the Knob to the center position.

4. Select SAVE to store the calibration.

23SPEKTRUM DX18 • TRANSMITTER INSTRUCTION MANUAL

Page 24

EN

Transfer SD Card

Import Model

This function overwrites

all model memories.

Ensure that the models

currently in your

transmitter are saved

on an SD card separate

from the transmitter

before performing this

function.

To import an individual model le from the SD Card:

1. Save the model le to the SD Card.

2. Select the Model List location where you wish to import the

new model le.

3. In the SD Card menu, scroll to Select Option and press the

scroll button once.

4. Scroll to Import Model and press the scroll button again to save

the selection. The Select File screen appears.

5. Select the model le you wish to import. The Overwrite screen

appears.

IMPORTANT: When you select Import, the transmitter leaves the

System Setup List.

6. Select the model that you would like to import the model to.

7. Select Import to con rm overwriting the current model le. The

transmitter activates the new model le and the Main Screen

appears.

A Pre ight Checklist may appear prior to the Main Screen if the