Spectrex 40-40M User Manual

Model 40/40M

Multi IR Hydrocarbon and Hydrogen

Flame Detector

User Guide

FM, CSA Approved

Class I Div. 1 Groups B, C, D

Class II/III Div. 1 Groups E, F, G

ATEX, IECEx Approved

Ex II 2 GD, Exde IIC T5 (75°C)

Document ref: TM 40/40M, Rev (6) July 2013

218 Little Falls Rd., Cedar Grove, NJ 07009, USA

Phone: +1 (973) 239 8398 Fax: +1 (973) 239 761

Web-Site: www.spectrex.net; Email: spectrex@spectrex.net

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

ii

Legal Notice iii

Legal Notice

The SharpEye Optical Flame Detector described in this document is the property of Spectrex,

Inc.

No part of the hardware, software or documentation may be reproduced, transmitted,

transcribed, stored in a retrieval system or translated into any language or computer language,

in any form or by any means, without prior written permission of Spectrex, Inc.

While great efforts have been made to assure the accuracy and clarity of this document,

Spectrex, Inc. assumes no liability resulting from any omissions in this document, or from

misuse of the information obtained herein. The information in this document has been carefully

checked and is believed to be entirely reliable with all of the necessary information included.

Spectrex Inc. reserves the right to make changes to any products described herein to improve

reliability, function, or design, and reserves the right to revise this document and make

changes from time to time in content hereof with no obligation to notify any persons of

revisions or changes. Spectrex, Inc. does not assume any liability arising out of the application

or any use of any product or circuit described herein; neither does it convey license under its

patent rights or the rights of others

Warning: This manual should be read carefully by all individuals

who have or will have responsibility for using, maintaining or

servicing the product.

The Detector is not field-repairable due to the meticulous

alignment and calibration of the sensors and the respective

circuits. Do not attempt to modify or repair the internal circuits

or change their settings, as this will impair the system's

performance and void the Spectrex, Inc. Product warranty.

Warranty

SPECTREX INC. Agrees to extend to Purchaser/Distributor a warranty on the SPECTREX

supplied components of the SharpEye products. SPECTREX warrants to Purchaser/Distributor

that the products are free from defects in materials and workmanship for a period of five (5)

years, commencing with the date of delivery to Purchaser/Distributor. SPECTREX expressly

excludes damage incurred in transit from the factory or other damage due to abuse, misuse,

improper installation, or lack of maintenance or “Act of God” which are above and beyond its

control. SPECTREX will, upon receipt of any defective product, transportation prepaid, repair or

replace it at its sole discretion if found to have been defective when shipped. Said repair or

replacement is SPECTREX’S sole liability under this warranty and SPECTREX’S liability shall be

limited to repair or replacement of the component found defective and shall not include any

liability for consequential or other damages. The customer is responsible for all freight charges

and taxes due on shipments both ways. This warranty is exclusive of all other warranties

express or implied.

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

iv

Release History

Rev

Date

Revision History

Prepared by

Approved by

0

July 15,2008

First Release

Ian Buchanan

Eric Zinn

1

September 23, 2008

Second Release

Ian Buchanan

Eric Zinn

2

July, 2010

Third Release

Ian Buchanan

Eric Zinn

3

August 2010

Fourth Release

Ian Buchanan

Eric Zinn

4

November 2010

Fifth Release

Ian Buchanan

Eric Zinn

5

February 2013

Sixth Release

Ian Buchanan

Eric Zinn

6

July 2013

Seventh Release

Ian Buchanan

Eric Zinn

About this Guide v

About this Guide

This guide describes the SharpEye Model 40/40M Multi IR Flame Detector

and its features and provides instructions on how to install, operate and

maintain the detector.

This guide includes the following chapters and appendixes:

Chapter 1, Introduction, provides a general overview of the product,

principles of operation, and performance considerations.

Chapter 2, Installing the Detector, describes how to install the

detector including preparations before installation, wiring and mode

settings.

Chapter 3, Operating the Detector, describes how to power-up and

test the detector. The chapter also lists safety precautions you should

take when operating the detector.

Chapter 4, Maintenance and troubleshooting, describes basic

maintenance procedures, and troubleshooting and support procedures.

Appendix A, Technical Specifications: Lists the detectors technical

and other specifications.

Appendix B, Wiring Instructions, lists the wiring instructions for

connecting the detector and also provides examples of typical wiring

configurations.

Appendix C, RS-485 Communication Network, provides an overview

of the RS-485 communications network.

Appendix D, Accessories, describes the accessories available for the

detector.

Appendix E, SIL-2 Features, describes the special conditions to

comply with the requirements of EN 61508 for SIL 2 according to TUV.

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

vi Abbreviations and Acronyms

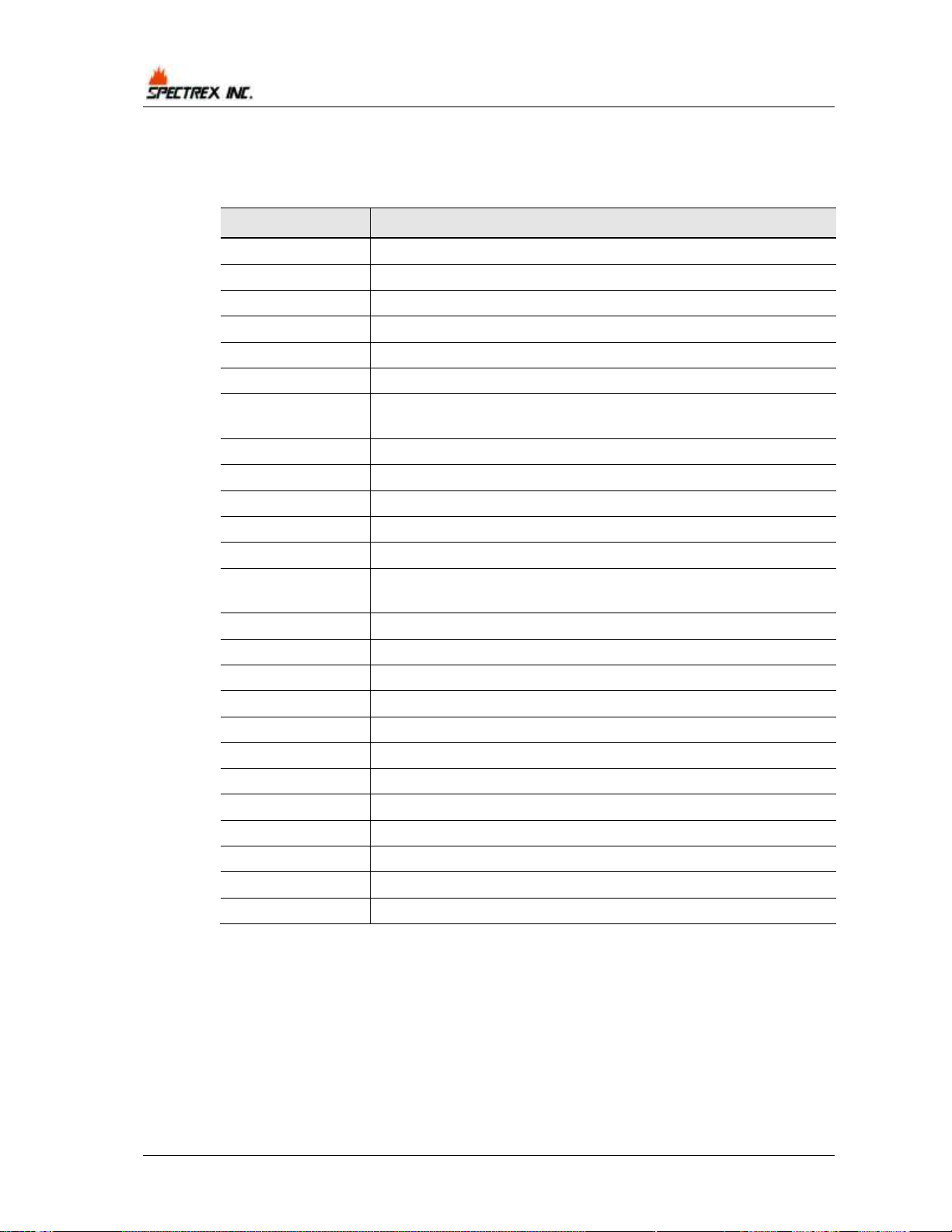

Abbreviations and Acronyms

Abbreviation

Meaning

ATEX

Atmosphere Explosives

AWG

American Wire Gauge

BIT

Built In Test

EMC

Electromagnetic Compatibility

EOL

End of Line

FOV

Field of View

HART

Highway Addressable Remote Transducer-

communication protocol

IAD

Immune at Any Distance

IECEx

International Electrotechnical Commission Explosion

IPA

Isopropyl Alcohol

IR

Infrared

JP5

Jet Fuel

Latching

Refers to relays remaining in the ON state even after the

ON condition has been removed

LED

Light Emitting Diode

LPG

Liquefied Petroleum Gas

mA

MilliAmps (0.001 amps)

MODBUS

Master-slave messaging structure

N.C.

Normally Closed

N.O.

Normally Open

N/A

Not Applicable

NFPA

National Fire Protection Association

NPT

National Pipe Thread

SIL

Safety Integrity Level

UNC

Unified Coarse Thread

VAC

Volts Alternating Current

Table of Contents vii

Table of Contents

Model 40/40M Multi IR Hydrocarbon and

Hydrogen Flame Detector User Guide ............................................................... i

Legal Notice .................................................................................................... iii

Warranty ........................................................................................................ iii

Release History ............................................................................................... iv

About this Guide .............................................................................................. v

Abbreviations and Acronyms ............................................................................. vi

1 Introduction .............................................................................................. 1

1.1 Overview .............................................................................................. 1

1.2 Model and Types .................................................................................... 2

1.3 Features and Benefits ............................................................................. 4

1.4 Principles of Operation ............................................................................ 4

1.4.1 Fire Detection Principle ..................................................................... 4

1.4.2 Heated Optics .................................................................................. 5

1.4.3 HART Protocol ................................................................................. 5

1.4.4 RS-485 Modbus ............................................................................... 6

1.4.5 Product Certification ......................................................................... 6

1.5 Performance Considerations .................................................................... 7

1.5.1 Detection Sensitivity ........................................................................ 7

1.5.2 Cone of Vision ................................................................................. 9

1.5.3 False Alarms Prevention ................................................................... 11

1.5.4 Visual Indicators ............................................................................. 12

1.5.5 Output Signals ................................................................................ 13

1.5.6 Detector Status .............................................................................. 14

1.5.7 Auxiliary Relay as End-of-Line Resistor .............................................. 15

1.6 Internal Detector Tests .......................................................................... 15

1.6.1 Continuous Feature Test .................................................................. 15

1.6.2 Built-In-Test (BIT) .......................................................................... 16

2 Installing the Detector ............................................................................ 19

2.1 General Guidelines ................................................................................ 19

2.2 Unpacking the Product ........................................................................... 20

2.2.1 Checking the Product Type ............................................................... 20

2.3 Required Tools ...................................................................................... 21

2.4 Certification Instructions ........................................................................ 22

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

viii Table of Contents

2.5 Installation Cables ................................................................................ 23

2.5.1 Conduit Installation ......................................................................... 23

2.6 Installing the Tilt Mount (part no. 40/40-001) .......................................... 24

2.6.1 Tilt Mount Assembly ........................................................................ 25

2.7 Connecting the Detector ........................................................................ 26

2.7.1 Verifying the Detector Wiring ........................................................... 28

2.8 Configuring your Detector ...................................................................... 29

2.8.1 Sensitivity ...................................................................................... 30

2.8.2 Alarm Delay ................................................................................... 30

2.8.3 Address Set-up ............................................................................... 30

2.8.4 Function Set-up .............................................................................. 31

2.8.5 Heated Optics ................................................................................. 31

3 Operating the Detector ............................................................................ 33

3.1 Powering Up ......................................................................................... 33

3.2 Safety Precautions ................................................................................ 34

3.2.1 Default Functions Settings ............................................................... 34

3.3 Testing Procedures ................................................................................ 35

3.3.1 Automatic BIT Test ......................................................................... 35

3.3.2 Manual BIT Test .............................................................................. 35

3.3.3 Testing with Fire Simulator Model 20/20-313 ..................................... 35

4 Maintenance and Troubleshooting ........................................................... 37

4.1 Maintenance ......................................................................................... 37

4.1.1 General Procedures ......................................................................... 37

4.1.2 Periodic Procedures ......................................................................... 38

4.1.3 Keeping Maintenance Records .......................................................... 38

4.2 Troubleshooting .................................................................................... 39

Appendices .................................................................................................... 41

A Specifications .......................................................................................... 43

A.1 Technical Specifications ......................................................................... 43

A.2 Electrical Specifications .......................................................................... 44

A.3 Outputs ............................................................................................... 44

A.4 Approvals............................................................................................. 46

A.5 Mechanical Specifications ....................................................................... 47

A.6 Environmental Specifications .................................................................. 47

TM 40/40M, Rev (6) July 2013

Table of Contents ix

B Wiring Instructions.................................................................................. 49

B.1 General Instructions for Electrical Wiring .................................................. 49

B.2 Typical Wiring Configurations ................................................................. 51

C RS-485 Communication Network ............................................................. 55

C.1 RS-485 Overview .................................................................................. 55

D Accessories .............................................................................................. 57

D.1 Long Range Multi IR Fire Simulator ......................................................... 57

D.1.1 Unpacking ...................................................................................... 58

D.1.2 Operating Instructions ..................................................................... 58

D.1.3 Range ........................................................................................... 59

D.1.4 Charging the Battery ....................................................................... 59

D.1.5 Technical Specifications ................................................................... 60

D.2 Tilt Mount - P/N 40/40-001 .................................................................... 60

D.3 Duct Mount P/N 777670 ......................................................................... 61

D.4 Weather Protection - P/N 777163 ............................................................ 62

D.5 Laser Detection Coverage Pointer - P/N 777166 ........................................ 63

E SIL-2 Features ......................................................................................... 65

E.1 40/40M Flame Detector ......................................................................... 65

E.1.1 Safety Relevant Parameters ............................................................. 65

E.1.2 Guidelines for Configuring, Installing, Operating and Service ................ 65

Technical Support ......................................................................................... 68

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

x List of Figures

List of Figures

Figure 1: Vertical Field of View for Gasoline ........................................................... 9

Figure 2: Horizontal Field of View for Gasoline ...................................................... 10

Figure 3: Fields of View for Hydrogen (Horizontal and Vertical) ............................... 10

Figure 4: Indication LED ..................................................................................... 12

Figure 5: Detector with Tilt Mount ....................................................................... 24

Figure 6: Tilt Mount Assembly ............................................................................. 25

Figure 7: Tilt Mount Assembly (dimensions in mm and inches) ................................ 25

Figure 8: Detector with Cover Removed ............................................................... 27

Figure 9: Wiring Terminals ................................................................................. 51

Figure 10: Typical Wiring for 4 Wire Controllers (Using Option 1 or 2 Wiring) ............ 52

Figure 11: 0-20mA Wiring Option 1 (Sink 4-Wire) - Default .................................... 53

Figure 12: 0-20mA Wiring Option 1 (Converted to Source 3-Wire) .......................... 53

Figure 13: 0-20mA Wiring Option 1 (Non-isolated Sink 3-Wire) ............................... 54

Figure 14: 0-20mA Wiring Option 2 and 3 (Source 3-Wire

available with the HART Protocol) ........................................................................ 54

Figure 15: RS-485 Networking ............................................................................ 55

Figure 16: SharpEye Multi IR Long Range Fire Simulator 20/20-313 ........................ 57

Figure 17: 40/40M Multi IR Detector Target Point .................................................. 58

Figure 18: Tilt Mount ......................................................................................... 60

Figure 19: Duct Mount ....................................................................................... 61

Figure 20: Weather Protection ............................................................................ 62

Figure 21: Laser Detection Coverage Pointer ........................................................ 63

TM 40/40M, Rev (6) July 2013

List of Tables xi

List of Tables

Table 1: Wiring Options ...................................................................................... 3

Table 2: Sensitivity Range Levels ......................................................................... 8

Table 3: Fuel Sensitivity Ranges ........................................................................... 8

Table 4: Immunity to False Alarm Sources ........................................................... 11

Table 5: Welding Immunity Distance ................................................................... 12

Table 6: LED Indications .................................................................................... 12

Table 7: Available Output Types .......................................................................... 13

Table 8: Detector Status .................................................................................... 14

Table 9: Output Signals versus Detector State ...................................................... 14

Table 10: Results of a Successful BIT................................................................... 17

Table 11: Results of an Unsuccessful BIT ............................................................. 17

Table 12: Results of a Successful Manual BIT ........................................................ 18

Table 13: Results of an Unsuccessful Manual BIT .................................................. 18

Table 14: Tools ................................................................................................. 21

Table 15: Model 40/40M Wiring Options ............................................................... 28

Table 16: Sensitivity Settings ............................................................................. 30

Table 17: Functions ........................................................................................... 31

Table 18: Default Function Values ....................................................................... 34

Table 19: Results of Successful Fire Simulator Test ............................................... 36

Table 20: Troubleshooting Table ......................................................................... 39

Table 21: Electrical Specifications ........................................................................ 44

Table 22: Contact Ratings .................................................................................. 45

Table 23: 20 mA Current Output ......................................................................... 45

Table 24: Electromagnetic Compatibility (EMC) ..................................................... 48

Table 25: Maximum DC resistance at 68°F (20ºC) for copper wire ........................... 49

Table 26: Wiring length in feet (meter) ................................................................ 50

Table 27: Wiring Connections ............................................................................. 52

Table 28: Sensitivity Ranges ............................................................................... 59

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

xii List of Tables

Overview 1

1 Introduction

➣ In this chapter…

Overview

page 1

Model and Types

page 2

Features and Benefits

page 4

Principles of Operation

page 4

Performance Considerations

page 7

Internal Detector Tests

page 15

1.1 Overview

The 40/40M Multi IR Flame Detector is specifically designed for detection of

hydrocarbon and hydrogen flames. It detects hydrocarbon-based fuel and

gas fires at long distances with the highest immunity to false alarms. The

40/40M can detect a gasoline pan fire at 215 ft. (65m) or a hydrogen flame

at 100 ft. (30m) in less than 5 seconds.

All 40/40 series detectors include a heated optical window for improved

performance in icing, snow and condensation conditions.

Detection performance can be easily adapted to all environments,

applications and requirements, by changing the detector’s configuration

parameters. Adjusting these parameters, as well and performing other

maintenance and monitoring tasks, is possible by means of RS485-based

Modbus communication or HART communication (in models with 0-20mA

output).

The detector enclosure is ATEX certified Exd flameproof with an integral,

segregated, rear, Exe terminal compartment (avoiding exposure of the

sensors and electronics to surrounding environment). Hence the combined

approval:

Ex II 2 G D

Ex de IIC T5 Ta -55°C to +75°C

Ex tD A21 IP66/X7 T95°C

or

Ex de IIC T4 Ta -55°C to +85°C

Ex tD A21 IP66/X7 T105°C

The SharpEye 40/40 detectors are designed to operate as a stand-alone unit

directly connected to an alarm system or an automatic fire extinguishing

system. The detector can also be a part of a more complex system, where

many detectors and other devices are integrated through a common control

unit.

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

2 Model and Types

1.2 Model and Types

The 40/40M is provided in various configurations depending on:

Wiring options

Temperature ranges

Type of cable entries

Housing type

Required approval

The configuration detail is included in the product part number on the

product label and takes the form: 40/40M XXXXX, where XXXXX defines the

model according to the above requirements.

To modify the default or pre-ordered configuration and perform

maintenance tasks, please refer to the HART Protocol TM777030, the

RS-485 Manual TM 777050 or TM777070.

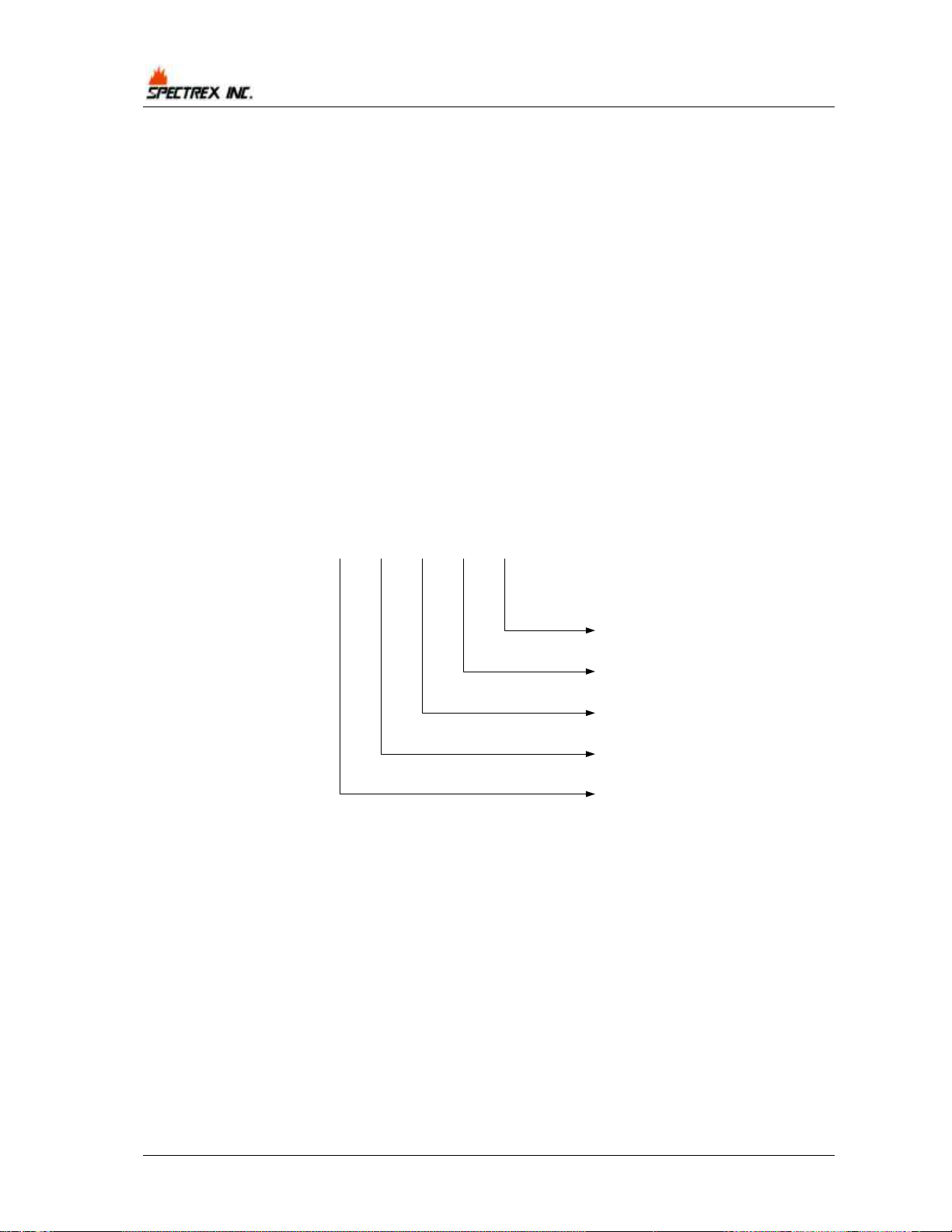

The Part Numbers are defined as:

Note: *Aluminum housing is available in ATEX/IECEx version only.

Table 1 describes the wiring options in detail.

*

40/40M X XX X X

Ex Approval

Wiring

Configuration

Temperature

Electrical

Entries

Housing

F – FM / CSA

C - ATEX / IECEx

1 - 75°C

2 - 85°C

1 - M25

2 - ¾" NPT

See Table 1

S - Stainless Steel

A - Aluminum

TM 40/40M, Rev (6) July 2013

Model and Types 3

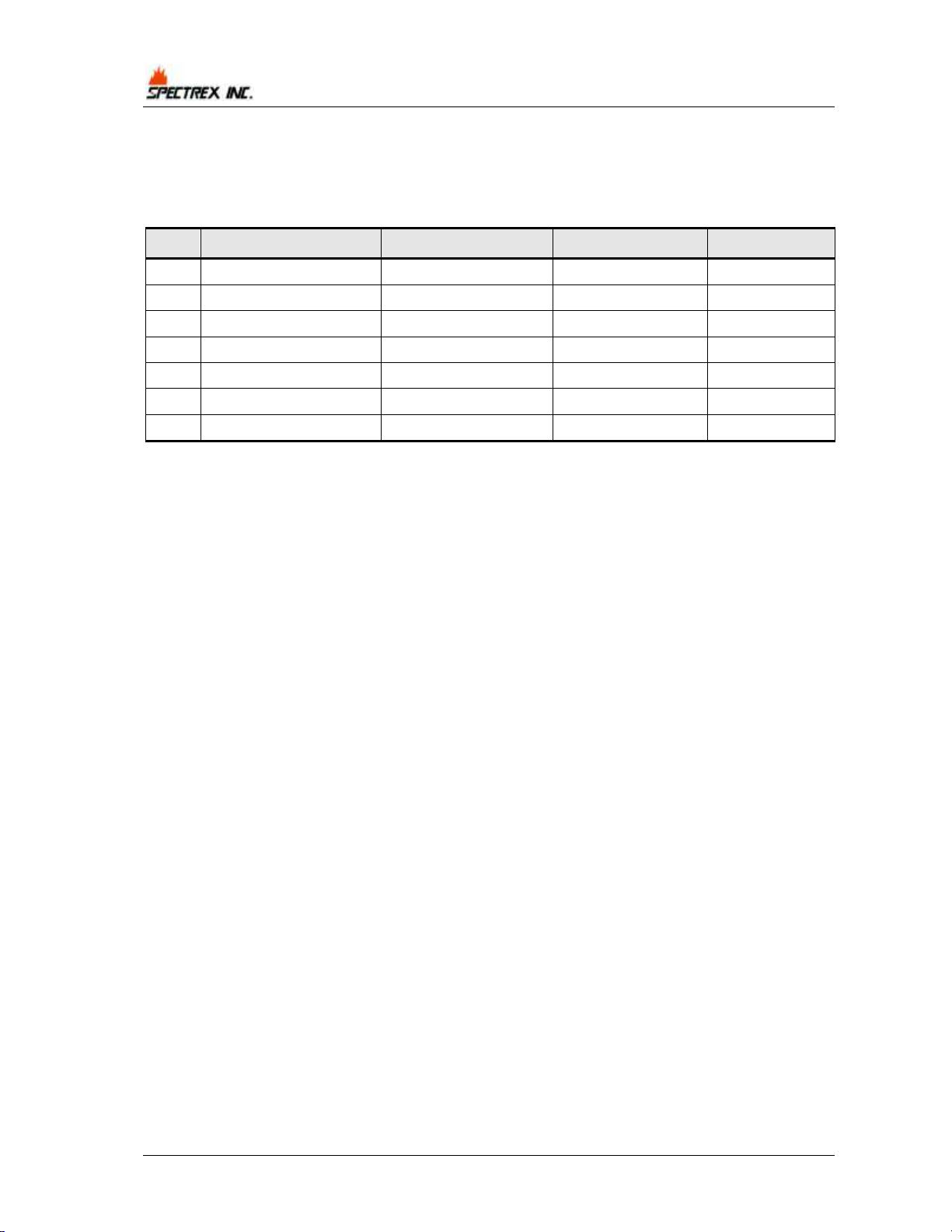

Table 1: Wiring Options

Wiring

Option

Connections Provided

1

Power

Manual

BIT

Fault

Relay

N.C.

Alarm

Relay

N.O.

0-20mA

Sink

RS-485

-

2

Power

Manual

BIT

Fault

Relay

N.C.

Alarm

Relay

N.O.,

N.C.

0-20mA

Source

RS-485

HART

3

Power

Manual

BIT

Fault

Relay

N.O.

Alarm

Relay

N.O.,

N.C.

0-20mA

Source

RS-485

HART

4

Power

Manual

BIT

Fault

Relay

N.C.

Alarm

Relay

N.O.

Auxiliary

N.O.

RS-485

-

5

Power

Manual

BIT

Fault

Relay

N.O.

Alarm

Relay

N.O.

Auxiliary

N.O.

RS-485

-

Note: Wiring option 1 is default. The mA 'Sink' output can be altered to

'Source' type, with a link between terminals 1 and 8. No other wiring options

can be changed on site.

For example, product number 40/40M-321SC has the following options:

Wiring Option: 3 (Power, Manual BIT, RS-485, 0-20mA (Source) with

the HART protocol, Fault Relay (N.O.), Alarm Relay (N.O., N.C.))

Temperature Range: 2 (85°C)

Cable Entry: 1 (M25)

Housing : S (Stainless Steel)

Approval: C (ATEX, IECEx)

Note: Check your specific part numbers against the information in Checking

the Product Type on page 20.

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

4 Features and Benefits

1.3 Features and Benefits

Detects Hydrocarbons and Hydrogen Flames.

Detection Range: Up to 215 ft. (65m) for a 1 ft

2

(0.1m

2

) n-heptane fire.

Ultra High Immunity to False Alarms: See Table 4 on page 11.

Advanced Digital Processing of the Dynamic Characteristics of Fire:

Flickering, threshold correlation and ratio.

Multi IR Channels: Between 2-5 microns.

Field Programmable Sensitivity: Four ranges to avoid zone crossover.

Built In Test (BIT): Manual and Automatic (see Built-In-Test (BIT) on

page 16).

Heated Window: Prevents effects of icing, snow, condensation.

Electrical Interface:

Dry contact relays

Communication network RS-485

0-20mA output

HART Protocol: Communication protocol (see HART Protocol on page 5).

Exde: Integral junction box for easy wiring.

SIL-2: TÜV approved.

Hazardous Area Certification: ATEX, IECEx, FM, CSA.

Functionality Approval:

EN54-10 approved by VdS

FM approved per FM3260

1.4 Principles of Operation

This section describes the 40/40M principles of operation and includes:

Fire Detection Principle, page 4

Heated Optics, page 5

HART Protocol, page 5

RS-485 Modbus, page 6

Product Certification, page 6

1.4.1 Fire Detection Principle

The SharpEye 40/40M detector is designed to detect hydrocarbon flames

that produce CO

2

in their combustion process and non-hydrocarbon flames

that produce mainly water vapor (H

2

O) from inorganic fuels, for example,

hydrogen, ammonia, hydrofluoric acid, hydrochloric acid and so on.

TM 40/40M, Rev (6) July 2013

Principles of Operation 5

The detector's principle of operation is based on the patented spectral

analysis technology that identifies the IR spectral signature of fire products,

namely the hot CO

2

spectral emission band at 4.2-4.7 microns and the hot

water (H

2

O) spectral emission band at 2.7-3.0 microns. Additional spectral

bands (above and below these bands) are analyzed for background

interferences.

The spectral analysis incorporates several detection algorithms, according to

several types of fire events, taking into account simultaneous detection of

both CO

2

and H

2

O peaks, or only one of them, as well as flickering analysis

at frequencies typical to these flames. Only when all the parameters of the

spectral analysis and the flickering analysis meet the predetermined values,

is a fire condition identified and the fire alarm is issued.

When exposed to non-fire radiation sources, these parameters do not

identify a fire condition and the detector does not react.

1.4.2 Heated Optics

The SharpEye 40/40 Flame Detectors use heated optics. The heater

increases the temperature of the optical surface by 5-8°F (~3-5°C) above

the ambient temperature to improve performance in icing, condensation and

snow conditions.

The heated optics can be set to one of the following:

Not operated

On continuously

Automatic, per temperature change (default): you can define the start

temperature below which the window is heated. (The default is 41°F

(5°C).) This temperature can be defined between 32°F (0°C) to 122°F

(50°C). The heating stops when the temperature is 27°F (15°C) above

the start temperature.

For more information, see Configuring your Detector on page 29.

1.4.3 HART Protocol

The SharpEye40/40 Flame Detectors use the HART protocol.

HART Communication is a bi-directional industrial field communication

protocol used to communicate between intelligent field instruments and host

systems. HART is the global standard for smart process instrumentation and

the majority of smart field devices installed in plants worldwide are HART-

enabled. HART is available in wiring options 2 and 3, see Table 1, page 3.

HART technology is easy to use and very reliable.

Through the HART connection, you are able to perform:

Detector set-up

Detector troubleshooting

Detector health and status

For more details, refer to the HART Manual TM 777030.

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

6 Principles of Operation

1.4.4 RS-485 Modbus

For more advanced communications, the 40/40M detector has an RS 485

Modbus-compatible output that provides data communication from a

network (up to 247 detectors) to a host computer or universal controller for

central monitoring. This feature allows for reduced installation costs, easy

maintenance and local or remote diagnostic tools.

1.4.5 Product Certification

The 40/40M Flame Detectors have the following certifications:

ATEX, IECEx, page 6

FM, CSA, page 6

SIL-2 Approved (TÜV), page 6

EN54-10, page 7

1.4.5.1 ATEX, IECEx

The 40/40M Flame Detector is certified to:

ATEX Ex II 2 GD per SIRA 07ATEX1250 and IECEx SIR. 07.0085.

Ex de IIC T5 Ta -55°C to +75°C

Ex tD A21 IP66/X7 T95°C

Ex de IIC T4 Ta -55°C to +85°C

Ex tD A21 IP66/X7 T105°C

This product is suitable to use in hazardous zones 1 and 2 with IIC gas

group vapors present.

1.4.5.2 FM, CSA

The 40/40M Flame Detector is certified to FM and CSA Explosion Proof and

Functionality per FM3260:

Class I, Division 1, Groups B, C and D, T5 Ta = 85°C.

Dust Ignition Proof – Class II/III Division 1, Groups E, F and G.

Ingress Protection – IP67, IP66, NEMA 250 Type 6P.

For more details see FM Report Project ID3029553 and CSA Report No.

2451134..

1.4.5.3 SIL-2 Approved (TÜV)

The 40/40M Flame Detector is certified to SIL-2 requirement per IEC

61508.4, Chapter 3.5.12.

The alert condition according to SIL-2 can be implemented by:

Alert signal via 0-20mA current loop.

or

Alert signal via alarm relay and fault relay.

TM 40/40M, Rev (6) July 2013

Performance Considerations 7

For more details and guidelines for configuring, installing, operating and

service – see SIL-2 Features on page 65 and TÜV Report No.

968/EZ348.00/009.

1.4.5.4 EN54-10

The 40/40M Flame Detector is certified to EN54-10 and CPD.

The detector has been tested and approved per EN54-10 by VdS.

This test includes functional test, environmental test, EMI/EMC test and

software check.

For more details see VdS Reports No’s. BMA 12117 and BMA 12118.

1.5 Performance Considerations

This section describes performance aspects of the 40/40M and includes:

Detection Sensitivity, page 7

Cone of Vision, page 9

False Alarms Prevention, page 11

Visual Indicators, page 12

Output Signals, page 13

Detector Status, page 14

Auxiliary Relay as End-of-Line Resistor, page 15

1.5.1 Detection Sensitivity

Detection sensitivity is the maximum distance at which the detector reliably

detects a specific size of fire and typical type of fuel (standard fire).

1.5.1.1 Standard Fire

Defined as a 1ft

2

/ 0.1m

2

n-heptane pan fire, with maximum wind speed of

6.5 ft./sec (2 m/sec).

1.5.1.2 Sensitivity Ranges

The detector has four user-selectable sensitivity ranges. For each range

there are two response levels.

WARNING (Pre-alarm)

ALARM

The detection distance, for the WARNING level, is approximately 10% higher

than the ALARM distance.

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

8 Performance Considerations

Alarm response times for a standard fire at a specified range are shown

Table 2.

Table 2: Sensitivity Range Levels

Level

Response Time (sec)

Sensitivity Range- ft. (m)

1

3

50 (15)

2 Default

5

100 (30)

3

8

150 (45)

4

10

215 (65)

For some typical ambient conditions the Zeta parameter as defined in NFPA

72 for the detector is 0.005 (1/meter).

Note: Zeta parameters may vary significantly with changes in temperature,

air pressure, humidity, visibility conditions, and so on.

1.5.1.3 Other Fuels

The detector reacts to other types of fire as follows:

The baseline fire refers to n-heptane 1ft

2

(0.1m

2

) and is defined as

100% sensitivity.

For fuel fire – standard pan fire size: 1 ft

2

(0.1 m

2

).

For gas flame - 20 inch (0.5m) high, 8 inch (0.2m) width plume fire.

Maximum Response Time: 10 sec.

Table 3: Fuel Sensitivity Ranges

Type Of Fuel

Percent of Max. Distance

at each Sensitivity Range

Max. Distance

(ft./m)

Gasoline

100%

215 / 65

N-Heptane

100%

215 / 65

JP5

70%

150 / 45

Kerosene

70%

150 / 45

Diesel Fuel

70%

150 / 45

Ethanol 95%

60%

135 / 40

IPA

60%

135 / 40

Methanol

55%

115 / 35

Methane

45%

100 / 30

LPG

45%

100 / 30

Paper

35%

33 / 10

Polypropylene

15%

16 / 5

Hydrogen

50%

100 / 30

Silane

8%

16 / 5

Ammonia

20%

40 / 12

TM 40/40M, Rev (6) July 2013

Performance Considerations 9

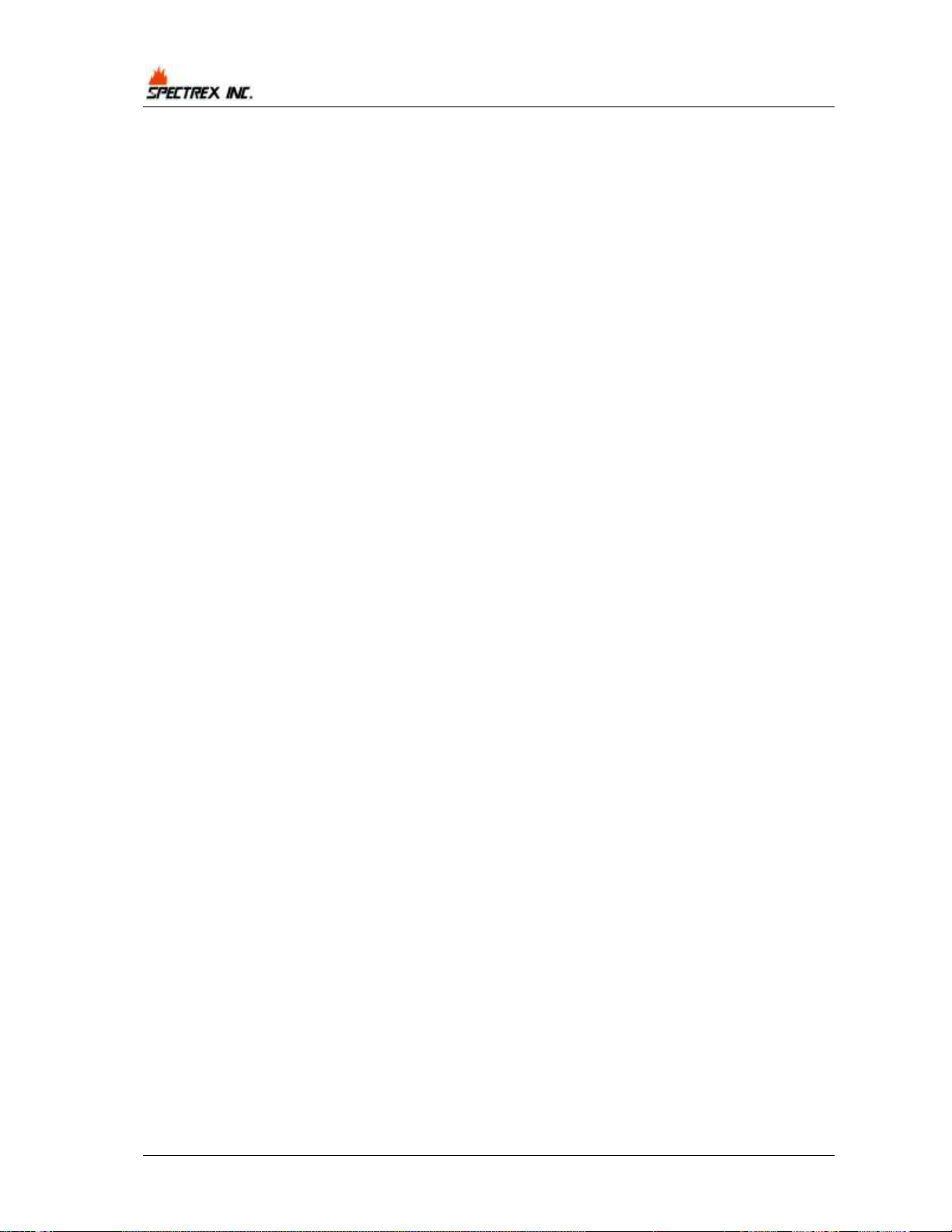

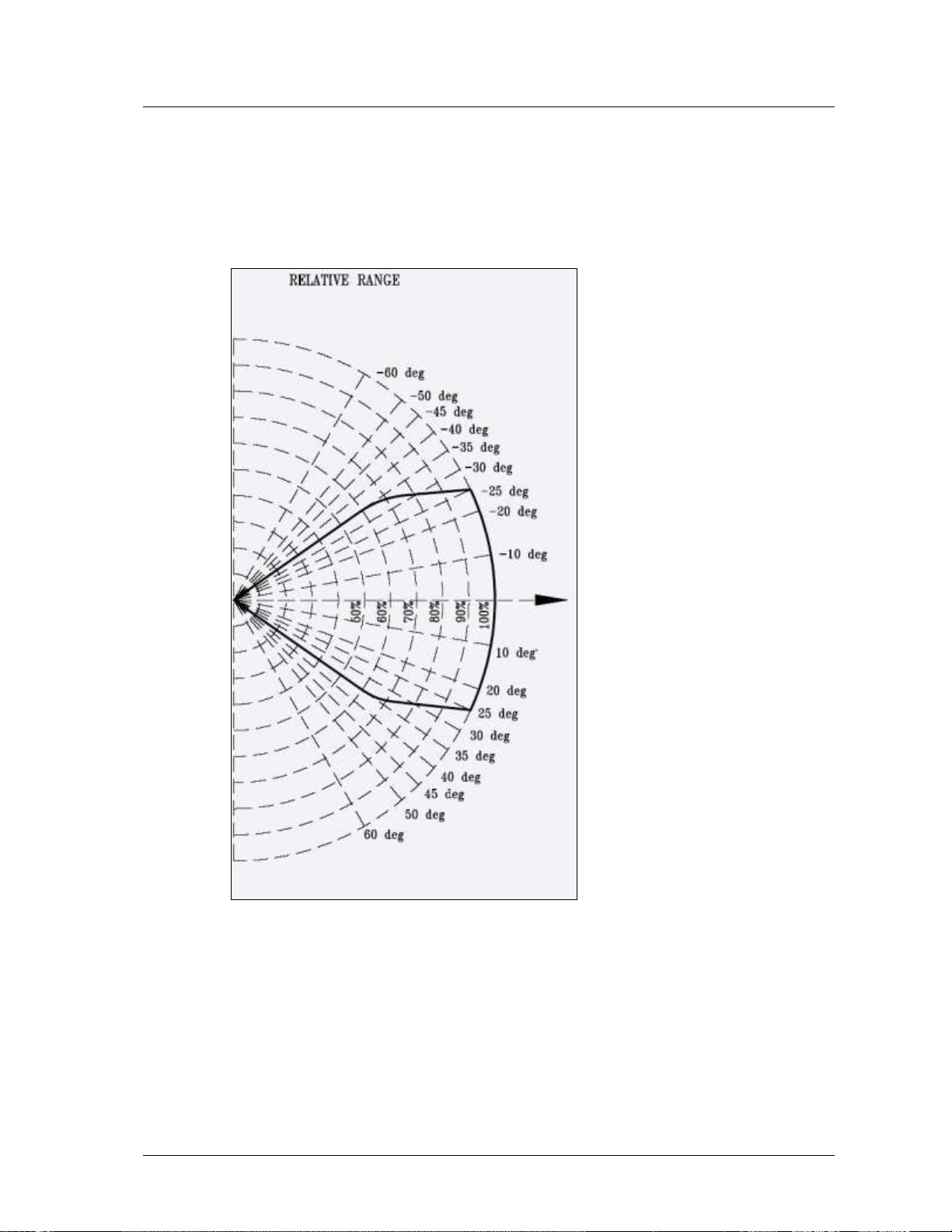

1.5.2 Cone of Vision

1.5.2.1 Gasoline

Horizontal: 67°

Vertical: 70°

Figure 1: Vertical Field of View for Gasoline

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

10 Performance Considerations

Figure 2: Horizontal Field of View for Gasoline

1.5.2.2 Hydrogen

Horizontal: 80°

Vertical: 80°

Figure 3: Fields of View for Hydrogen (Horizontal and Vertical)

TM 40/40M, Rev (6) July 2013

Performance Considerations 11

1.5.3 False Alarms Prevention

To prevent false alarms, the detector will not alarm or react to the radiation

sources specified in Table 4.

Table 4: Immunity to False Alarm Sources

Radiation Source

Immunity

Distance ft. (m)

Indirect or reflected sunlight

IAD

Vehicle headlights (low beam) conforming to

MS53023-1

IAD

Incandescent frosted glass light, 300 W

IAD

Fluorescent light with white enamel reflector, standard

office or shop, 70 W (or two 35 W)

IAD

Electric arc [12mm (

15

/

32

") gap at 4000 V alternating

current, 60 Hz]

IAD

Arc welding [6 mm (

5

/

16

") rod; 210 A]

See Table 5

Ambient light extremes (darkness to bright light with

snow, water, rain, desert glare and fog)

IAD

Bright colored clothing, including red and safety

orange

IAD

Electronic flash (180 watt-seconds minimum output)

IAD

Movie light, 625 W quartz DWY lamp (Sylvania S.G.-55

or equivalent)

>6.5 (2)

Blue-green dome light conforming to M251073-1

IAD

Flashlight (MX 991/U)

IAD

Radiation heater, 3000 W

>3 (1)

Radiation heater, 1000 W with fan

IAD

Quartz lamp (1000 W)

>3 (1)

Mercury vapor lamp

IAD

Grinding metal

IAD

Lit cigar

>1 (0.3)

Lit cigarette

>1 (0.3)

Match, wood, stick including flare up

>13 (4)

Notes:

IAD = Immune at Any Distance.

All sources are chopped from 0 to 20 Hz.

Multi IR Hydrocarbon and Hydrogen Flame Detector User Guide

12 Performance Considerations

Table 5: Welding Immunity Distance

Sensitivity Setting

Detection Range

Immunity Distance

1

50 ft. (15m)

>6 ft. (2m)

2

100 ft. (30m)

>12 ft. (4m)

3

150 ft. (45m)

>17 ft. (6m)

4

215 ft. (65m)

>25 ft. (7.5m)

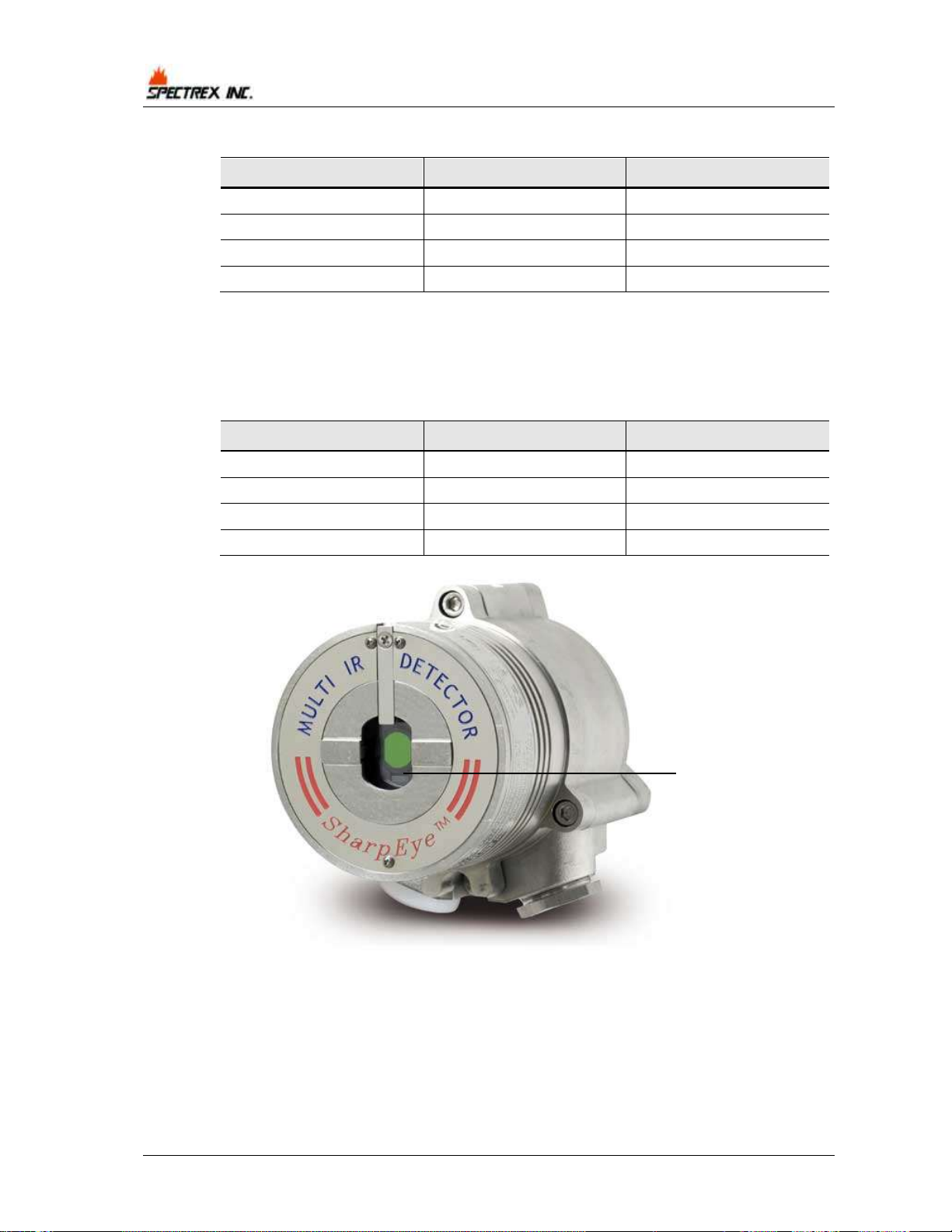

1.5.4 Visual Indicators

One 3-color LED indicator is located inside the detector window, as shown in

Figure 4. The detector statuses are listed in Table 6.

Table 6: LED Indications

Detector Status

LED color

LED mode

Fault, BIT Fault

Yellow

4 Hz - flashing

Normal

Green

1 Hz - flashing

Warning

Red

2 Hz - flashing

Alarm

Red

Steady

Figure 4: Indication LED

Indicator LED

Loading...

Loading...