Spectra ST802, DG813, RC803, SF803, DG613 User Manual

DG813 DG613

|

ST802 |

SF803 |

RC803 |

2

TABLE OF CONTENTS |

|

Introduction |

|

For Your Safety |

|

Laser |

|

How to Use the Laser System |

|

Powering the Laser |

|

Turning On/Off the laser |

|

Features and Functions |

|

Laser Setup |

|

Turning On/Off the laser |

|

Standard Display Laser and RC803 |

|

RC803 Radio/IR Remote Control |

|

Powering the RC803 |

|

Turning On/Off the Radio/IR Remote Control |

|

Pairing the RC803 with the DG813/DG613 |

|

Components SpotFinder SF803 |

|

Powering the SF803 |

|

SF803 - Features and Functions |

|

Pairing the Spot Finder SF803 with the DG813 |

|

Turning On/Off the Transporter ST802 |

|

Pairing the ST802 with the DG813/DG613 |

|

Menu Functions |

|

Entering Grade |

|

Automatic Spot Align (DG813) |

|

Automatic Spot Match (DG813) |

|

Automatic SpotLok (DG813) |

|

Manual Spot Search (DG813) |

|

Line Scan |

|

Line Set/Check |

|

Start Reference Check |

3 |

|

|

Standby Mode |

|

Settings

Info

Service

Setting menu details

Grade Entry

Grade Display

Sensitivity Selection

User Name

Set Password

Password On/Off

Radio Channel

Select Language

Position Info

Calibration

PROTECTING THE UNIT

CLEANING AND MAINTENANCE

PROTECTING THE ENVIRONMENT

TECHNICAL DATA

DECLARATION OF CONFORMITY

4

Introduction

Thank you for choosing one of the Spectra Precision Lasers from the Trimble family of precision pipe lasers. The pipe laser is an easy-to-use tool that provides underground contractors line, elevation, and grade control for installing storm, sanitary, or other gravity-flow pipe. This system can also be used for tunneling, boring, pipe alignment, or any other application requiring line, elevation, and grade control.

The pipe laser projects a highly visible laser beam in a direction at a predetermined (grade) for the alignment of gravity-flow pipe. The laser light is intercepted by a target. To align the pipe, you need to position it so that the pipe laser’s beam is centered at the target’s bullseye.

For Your Safety

For hazardless and safe operation, read all the user guide instructions.

-Use of this product by people other than those trained on this product may result in exposure to hazardous laser light.

-Do not remove warning labels from the unit.

-The DG813/DG613 are class 3A/3R laser (<5mW; 600 – 680nm) IEC 60825-1:2007). Class 2 version are also available.

-Never look into the laser beam or direct it to the eyes of other people.

-Always operate the unit in a way that prevents the beam from getting into people's eyes.

-If initial service is required, which results in the removal of the outer protective cover, removal must only be performed by factory-trained personnel.

Caution: Use of other than the described user and calibration tools or other procedures may result in exposure to hazardous laser light.

Caution: Using different than described at the pipe laser user guide, may result in unsafe |

|

operation. |

5 |

Features and Functions

Laser |

12 Power Button |

|||

1 Battery Compartment |

||||

13 M - Menu Button |

||||

2 |

Battery Door Latches |

|||

14 |

E - Enter Button |

|||

3 |

LCD Graphic Display |

|||

15 Escape/Lock Button |

||||

4 |

Grade Axis Pivot Marker |

|||

16 |

Left Line Control Button |

|||

5 |

Line-Axis Pivot Marker and LED |

|||

17 Plus Button |

||||

6 Handle |

||||

18 Minus Button |

||||

7 |

Axis Alignment Markers |

|||

19 |

Right Line Control Button |

|||

8 |

Mounts for scope adapter |

|||

|

|

|||

9 |

5/8”-11 Threaded Mount |

|

|

|

10 Remote Receiver Window |

|

|

||

11 Beam-Exit Window |

|

|

||

How to Use the Laser System Batteries

WARNING

Ni-MH batteries may contain small amounts of harmful substances.

Be sure to charge the battery before using it for the first time, and after not using it for an extended length of time.

Charge only with specified chargers according to device manufacturer‘s instructions.

Do not open the battery, dispose of in fire or short circuit; it may ignite, explode, leak or get hot causing personal injury.

Dispose in accordance with all applicable federal, state, and local regulations.

Keep the battery away from children. If swallowed, do not induce vomiting. Seek medical attention immediately.

6

Powering the Laser Recharging the Batteries

The laser is shipped with a rechargeable Ni-MH battery pack, it is keyed to prevent mis-insertion.

Note: The approximate charge of the batteries is shown at the top of the LCD when pressing the E button. The charger requires approx. 10 hours to charge completely discharged batteries.

For charging, connect the plug of the charger to the recharge jack of the battery pack.

New or long-time out-of-use rechargeable batteries reach their best performance after being charged and recharged five times. Alkaline batteries can be used as a backup. Insert 4 D-cell batteries noting the plus (+) and minus (-) diagrams inside the battery housing.

The batteries should only be charged when the laser is between 50°F and 104° F (10°C to 40°C). Charging at a higher temperature may damage the batteries. Charging at a lower temperature may increase the charge time and decrease the charge capacity, resulting in loss of performance and shortened life expectancy.

Installing Batteries

Open the battery door by pulling out the door latches. Insert batteries (or a rechargeable battery pack) into the housing so that the negative poles are on the bigger battery spiral springs.

Close the battery door and lock it by pushing the door latches back to the housing. Only the original rechargeable battery pack allows charging with the provided charger.

7

Features and Functions

1. Battery Compartment – holds the

|

NiMH battery pack. (D-Cell alkaline batteries |

|

|

|

|

|

|

|

|

|

|

|

||

|

can be used as a backup.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

Battery Door Latches – |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

locks/unlocks and holds the battery |

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

compartment in place. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. |

LCD Graphic Display - shows the |

|

|

|

|

|

|

|

|

|

|

|

||

|

power, grade, battery, out-of-level, beam |

|

|

|

|

|

|

|

|

|

|

|

||

|

position and status of the laser. |

|

|

|

|

|

|

|

|

|

|

|

|

|

4. |

Grade Axis Pivot Marker - |

identifies |

|

|

|

|

|

|

|

|

|

|

|

|

|

the pivot point for the grade |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

system |

|

|

|

|

|

|

|

|

|

|

|

|

|

5. |

Line-Axis Pivot Marker and LED – |

|

|

|

|

|

|

|

|

|

6 |

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

used to align a transit over the top of the |

|

|

|

|

|

|

|

|

|

|

|

||

|

laser; lights for 15 minutes after turning on |

|

4 |

|

3 |

|

2 |

|

1 |

|

|

|||

|

the laser or pressing one of the buttons. |

|

|

|

|

|

|

|||||||

6. |

Handle - to carry the laser easily |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

and to attach a safety rope in manholes |

|

|

|

|

|

|

|

|

|

|

|

||

|

with water. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

||

Features and Functions

7. Axis Alignment Markers - used to align

the laser when the line system is centered.

8. Mounts for scope adapter – to

attach the optional scope adapter for the

„Over the Top“ application

9. 5/8”-11 Threaded Mount – to attach the laser

to various setup accessories

7

8

8

10. Remote Receiver Window –

receives signals from the RC803 and SF803

11. Beam-Exit Window – provides a

clear window for the laser beam to exit the pipe laser.

9

10

11

9

Features and Functions

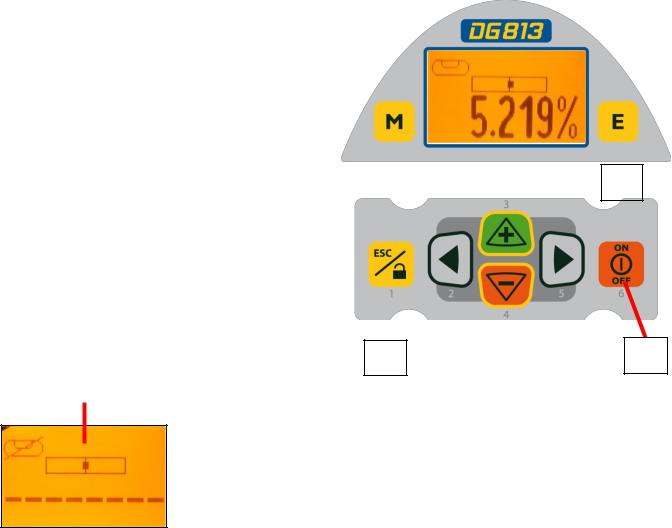

12. Power Button - turns the laser On/Off

(To turn off the laser, press and hold the button for 2 seconds).

13. M – Menu Button - Quickly press and release starts the menu entry. Use the 2 to 5

buttons to toggle through the menu.

14. E - Enter Button - Quickly press and release to activate a selected menu function and show the actual laser and remote control battery status.

15. Escape/Lock (ESC) Button - (If pressed

simultaneously with one of the left/right or +/- buttons, it locks/unlocks the +/- or the left/right buttons, so that the unit can’t be unintentionally changed. If pressed for 5 seconds, the unit switches to the manual mode (steep grade).

|

|

|

|

|

|

|

|

|

|

13 |

|

14 |

||

|

|

|

|

15 |

|

12 |

|

|

|

|

|

10

Features and Functions

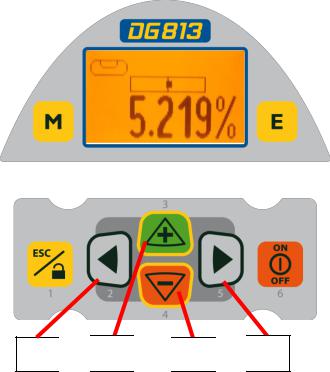

16. Left Line Control Button - moves the laser

beam to the left. (Simultaneously pressed with the Right Line Button, centers the line.)

17.Plus Button - increases the grade.

18.Minus Button - decreases the grade.

19.Right Line Control Button - moves the laser

beam to the right. (Simultaneously pressed with the Left Line Button, centers the line.)

16

17

17

18

18

19

19

11

Laser Setup

Position the laser at the manhole invert or on bottom of the trench at the desired elevation.

Turning On/Off the laser

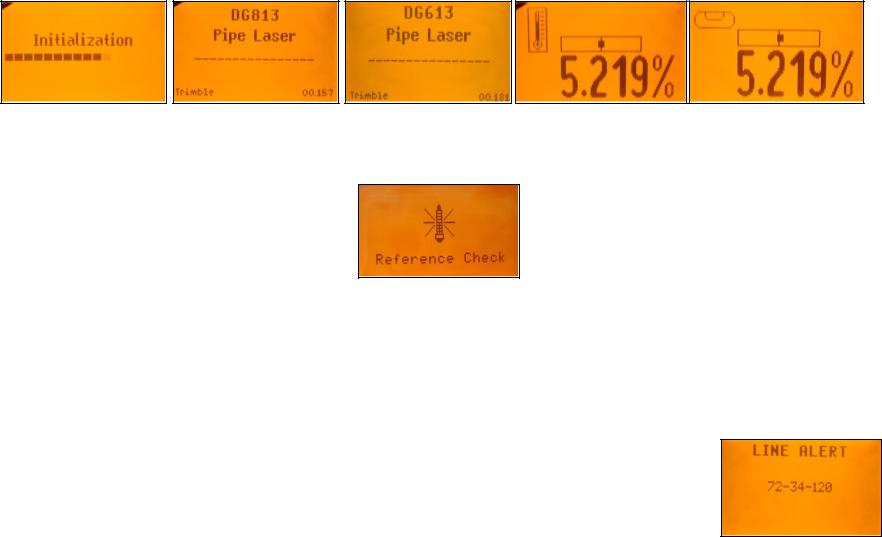

Press the power button to turn On the laser; the LCD shows Initialization for one second (red and green LEDs are on - diagnostic mode).

The unit starts the temperature/reference check while the thermometer symbol is flashing.

Don‘t start automatic functions at the menu before the reference check has been finished.

If an automatic function will be selected and then confirmed with the E button during the reference check, the display shows the reference check is still running.

The standard display turns on and the self-leveling will start at once.

The unit is leveled when the laser beam is no longer flashing (once every second). To turn Off the laser, press and hold the power button for two seconds.

If the laser is positioned beyond its self-leveling range of -12 to + 40%, the laser beam remains flashing. Reposition the laser within its self-leveling range. The laser’s cross axis is completely compensated over the entire roll range. Once leveled, the unit constantly monitors its level condition. Depending on the selection at settings, the setup control (Line alert) is activated 5 minutes or 30 seconds after self-leveling was performed. If Line Alert condition comes Off, the beam (+LEDs) flashes two times,

pauses for 2 seconds and flashes again two times. After deleting the Line Alert by pressing the E button, check the beam’s correct position using the target at the last pipe which was led before the Line alert came off.

12

Features and Functions

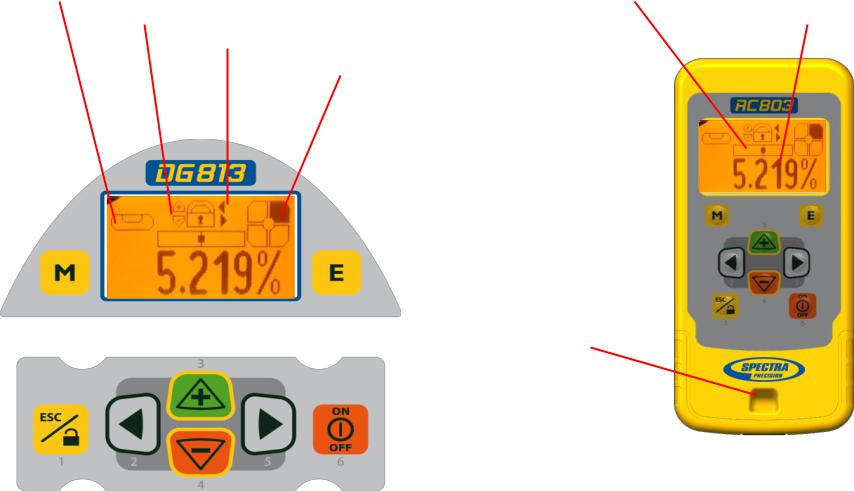

Standard Display Laser and RC803

The remote control mirrors the functionality of the pipe laser keypad

Automatic mode |

Beam line position related to the housing |

+/- buttons locked |

actual grade value |

line buttons locked |

|

Beam position at SF803 |

|

1 - Escape/Lock Button

2 - Left Line Control Button

3 - Plus Button

4 - Minus Button

5 - Right Line Control Button

6 - Power Button

M - Menu Button

E - Enter Button Hole for hand loop

9

13

RC803 Radio/IR Remote Control Powering the RC803

1. Open the battery door using a coin or similar pry device to release the battery door tab on the RC803.

RC803 will be shipped with alkaline batteries Rechargeable batteries can be used optional but need to be charged externally

2.Insert two AA batteries noting the plus (+) and minus (-) diagrams inside the battery housing.

3.Close the battery door. Push down until it “clicks” into the locked position.

Turning On/Off the Radio/IR Remote Control

The Radio/IR remote control is a hand-held device that allows you to send operational commands to the laser from a remote location.

Press the power button to turn on the radio/IR remote control.

If the RC803 is outside the radio operating range the remote switches automatically into the IR connection capability. Note: When the remote control is initially turned on, the standard display (model number and software version) appear for the first 3 seconds, then the grade value and line direction indications briefly appear in the LCD.

With every button press, the LCD backlight is activated and turns off automatically if no button is pressed for 8 seconds.

To turn off the radio remote control, press and hold the power button for two seconds. Note: 5 minutes after the last button press, the remote control turns off automatically.

Pairing the RC803 with the DG813/DG613 - First, make sure the transmitter and the remote control

are turned off. Then press and hold the Escape/Lock (ESC) button and turn on the transmitter. During the next 6 seconds (the red LED flashes fast while the display shows Pairing) repeat the same steps on the remote control. The remote’s display show Pairing OK for one second and then the same function as the laser is actually working to

indicate the transmitter has been matched with the remote control.

14

Loading...

Loading...