Page 1

91390

070-2451-01 Rev. F | www.spacelabshealthcare.com October 2014

SERVICE MANUAL

Page 2

91390 QUBE

©2014 Spacelabs Healthcare

All rights reserved. Contents of this publication may not be reproduced in any form without the

written permission of Spacelabs Healthcare. Products of Spacelabs Healthcare are covered by U.S.

and foreign patents and/or pending patents. Printed in U.S.A. Specifications and price change

privileges are reserved.

Spacelabs Healthcare considers itself responsible for the effects on safety, reliability and performance

of the equipment only if:

• assembly operations, re-adjustments, modifications or repairs are carried out by persons

authorized by Spacelabs Healthcare, and

• the electrical installation of the relevant room complies with the requirements of the standard in

force, and

• the equipment is used in accordance with the operations manual.

Spacelabs Healthcare will make available, on request, such circuit diagrams, component part lists,

descriptions, calibration instructions or other information which will assist appropriately qualified

technical personnel to repair those parts of the equipment which are classified by Spacelabs

Healthcare as field repairable.

Spacelabs Healthcare is committed to providing comprehensive customer support beginning with

your initial inquiry through purchase, training, and service for the life of your Spacelabs Healthcare

equipment.

CORPORATE OFFICES

Corporate Headquarters

Spacelabs Healthcare, Inc.

35301 SE Center Street

Snoqualmie, WA 98065

U.S.A.

Telephone: (1) 800-287-7108

Telephone: (1) 425-396-3300

Authorized EC Representative

Spacelabs Healthcare, Ltd.

43 Moray Place

Edinburgh, EH3 6BT

Scotland

Telephone: 44 (0) 131 240 6481

Fax: 44 (0) 131 240 6459

Please refer to http://www.spacelabshealthcare.com/en/company/trademarks for a full listing of

Spacelabs Healthcare trademarks.Other brands and product names used herein are trademarks of

their respective owners.

• Rx Only U.S. Federal law restricts the devices documented herein to sale by or on

the order of a physician.

• Before use, carefully read the instructions, including all warnings and cautions.

www.spacelabshealthcare.com

Page 3

Table of Contents

1Introduction

Overview.............................................................................................................................. 1-1

Warnings, Cautions, and Notes.................................................................................. 1-2

Product Specifications .................................................................................................. 1-3

Electrical Specifications................................................................................................ 1-5

Classification ............................................................................................................. 1-5

Environmental Requirements ..................................................................................... 1-6

Transport and Storage ........................................................................................... 1-6

Operating ................................................................................................................... 1-6

Expected Service Life.................................................................................................... 1-6

Monitor Options............................................................................................................... 1-7

Product Overview ........................................................................................................... 1-7

Monitor Assembly and Module Housing ........................................................... 1-7

External AC Power Supply ................................................................................... 1-8

Batteries ...................................................................................................................... 1-8

Display ................................................................................................................................. 1-8

LCD Display ............................................................................................................... 1-8

Video Subsystem ..................................................................................................... 1-8

Basic Components .......................................................................................................... 1-9

Battery Indicators ................................................................................................... 1-10

Energy Saving Mode (Battery) .......................................................................... 1-13

Signal Strength Indicator ..................................................................................... 1-13

Batteries and Recharging Batteries ........................................................................1-14

To change batteries without interruptions while operating on battery

power ...........................................................................................................................1-15

Battery Power Level .................................................................................................1-15

Architecture......................................................................................................................1-16

Directory of Keys............................................................................................................1-17

2Setup

Unpack the Monitor........................................................................................................ 2-1

Display Assembly ........................................................................................................... 2-2

Input/Output Connections (Internal and External) .......................................... 2-3

Power LED ................................................................................................................ 2-9

Battery Status LED ................................................................................................. 2-9

Alarms ......................................................................................................................... 2-9

Cables ................................................................................................................................. 2-9

Maximum Cable Lengths ...................................................................................... 2-9

SDLC External Devices ......................................................................................... 2-9

SDLC Cable Interconnection ............................................................................... 2-15

SDLC Bus Termination ................................................................................................ 2-15

Alarm Relay for option A .................................................................................... 2-15

Power-ON Test............................................................................................................... 2-17

Configure the Monitor ................................................................................................. 2-17

Privileged Access Menus ..................................................................................... 2-17

www.spacelabshealthcare.com

I-I

Page 4

91390 QUBE

3Theory

CPU PCB ............................................................................................................................. 3-1

Battery Charger and Power Supply Subsection (on CPU PCB) ..................3-4

Li-Ion Batteries................................................................................................................3-5

Battery Switch PCBA for Options B and C .......................................................... 3-7

Monitor Docking PCBA and Connector PCBA.................................................... 3-8

Front Bezel Assembly .................................................................................................. 3-9

Pod Interface PCB........................................................................................................ 3-10

Interconnect PCB ......................................................................................................... 3-10

4 Maintenance

Overview............................................................................................................................. 4-1

Required Test Equipment .................................................................................... 4-2

Mechanical Inspection .................................................................................................. 4-2

Tests for Electrical Safety ........................................................................................... 4-2

Definitions ................................................................................................................. 4-2

Equipment Required ................................................................................................4-3

Ground Resistance ................................................................................................. 4-3

Chassis Leakage Current Tests .......................................................................... 4-4

Patient Lead Leakage Current Tests (Patient Modules) ........................... 4-4

Preventive Maintenance ..............................................................................................4-4

Touchscreen Calibration ...................................................................................... 4-4

To perform touchscreen calibration.................................................................4-4

Functional Tests.............................................................................................................. 4-5

Monitor Self-Test .................................................................................................... 4-5

Monitor Functional Tests ..................................................................................... 4-5

Verification of Monitor Functions ....................................................................... 4-5

Optional Recorder Assembly for Options A and B ......................................4-6

External Alarm Relay Output for Option A ..................................................... 4-6

Ethernet (Wired) ....................................................................................................... 4-7

Assembly/Disassembly Procedures........................................................................ 4-7

Required Tools and Parts .................................................................................... 4-7

Setup for Disassembly .......................................................................................... 4-7

For Option A.............................................................................................................. 4-8

For Options B and C............................................................................................... 4-8

Remove the Bezel Assembly .............................................................................. 4-8

Reassembly ................................................................................................................ 4-10

CPU PCB .................................................................................................................... 4-11

Restore Data to the Monitor .............................................................................. 4-14

Option 1: Exchange the USB Drive PCBAs .................................................... 4-14

Option 2: Format the USB Drive ....................................................................... 4-14

Complete Main Chassis Removal ..................................................................... 4-17

Reinstall the Chassis ............................................................................................. 4-18

SDLC Interface PCB .............................................................................................. 4-19

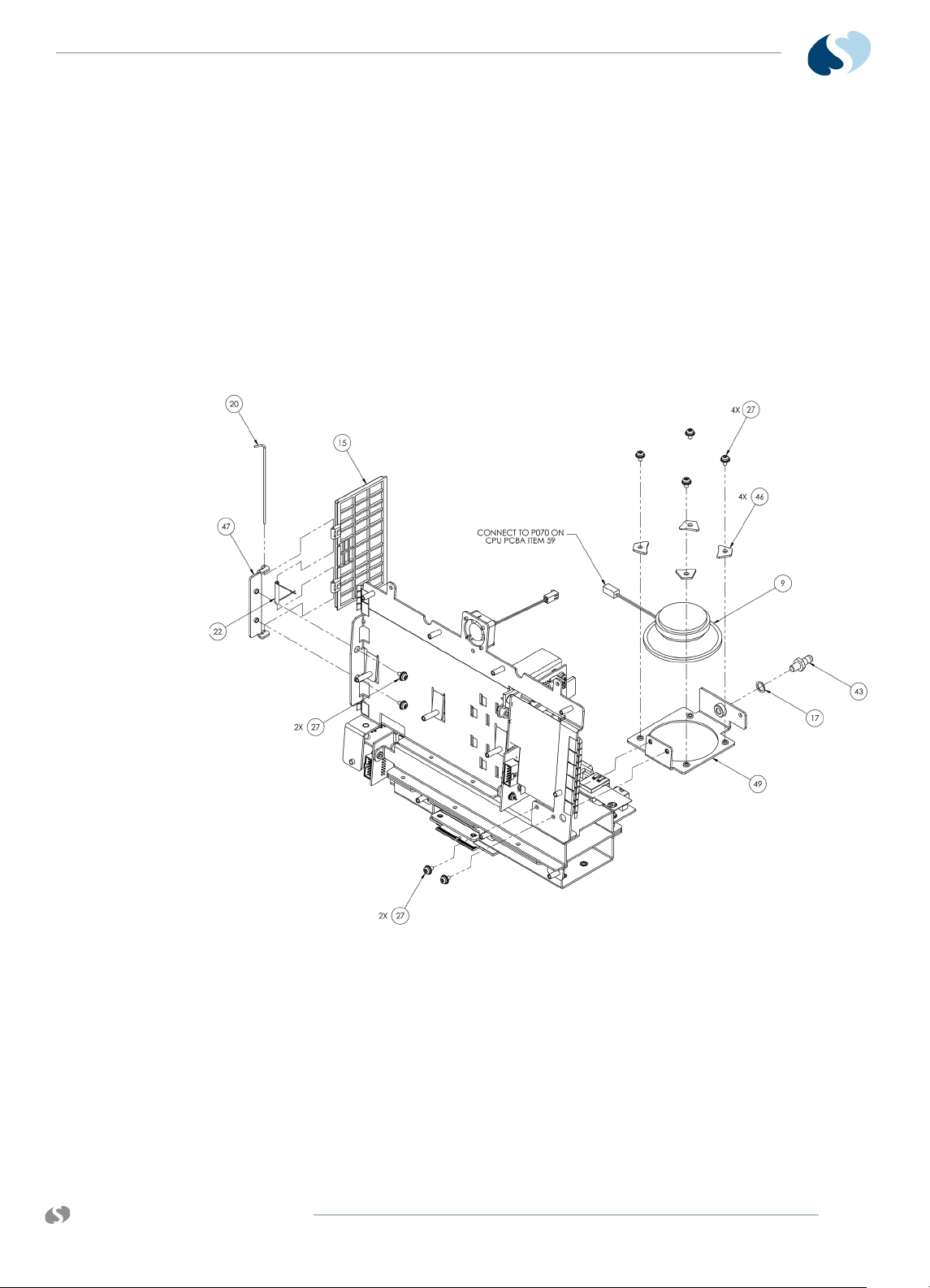

Speaker ................................................................................................................... 4-20

Mon-Dock PCB ........................................................................................................ 4-21

Battery Door for Option A ................................................................................ 4-22

Connector Board PCB ......................................................................................... 4-23

Replace the Battery Contact PCB .................................................................. 4-24

Replace and Align the Module Door .............................................................. 4-25

Handle ....................................................................................................................... 4-26

Reinstall the Rear Handle Assembly .............................................................. 4-26

Fan ............................................................................................................................. 4-27

Install or Replace the Optional Recorder Assembly ................................ 4-28

To install the recorder......................................................................................... 4-28

To replace the recorder ..................................................................................... 4-29

I-II

www.spacelabshealthcare.com

Page 5

91390 QUBE

Insert Recorder Paper ......................................................................................... 4-29

To insert a roll of paper...................................................................................... 4-29

Dock Connector Covers for Option A ........................................................... 4-29

Removal of Pod Interface PCBA for Options A and B ........................... 4-30

Reinstallation of the Pod Interface PCBA ................................................... 4-30

Docking Station PCBA Replacement Procedures for Option A ................ 4-31

Required Tools and Parts ................................................................................... 4-31

Docking Station ...................................................................................................... 4-31

Replace the Docking Station Latch ................................................................ 4-33

Replace the Docking Station Push Button .................................................. 4-34

Cleaning .......................................................................................................................... 4-35

5Troubleshooting

Overview............................................................................................................................. 5-1

Required Tools and Parts ..................................................................................... 5-2

System Startup................................................................................................................ 5-2

System ........................................................................................................................ 5-3

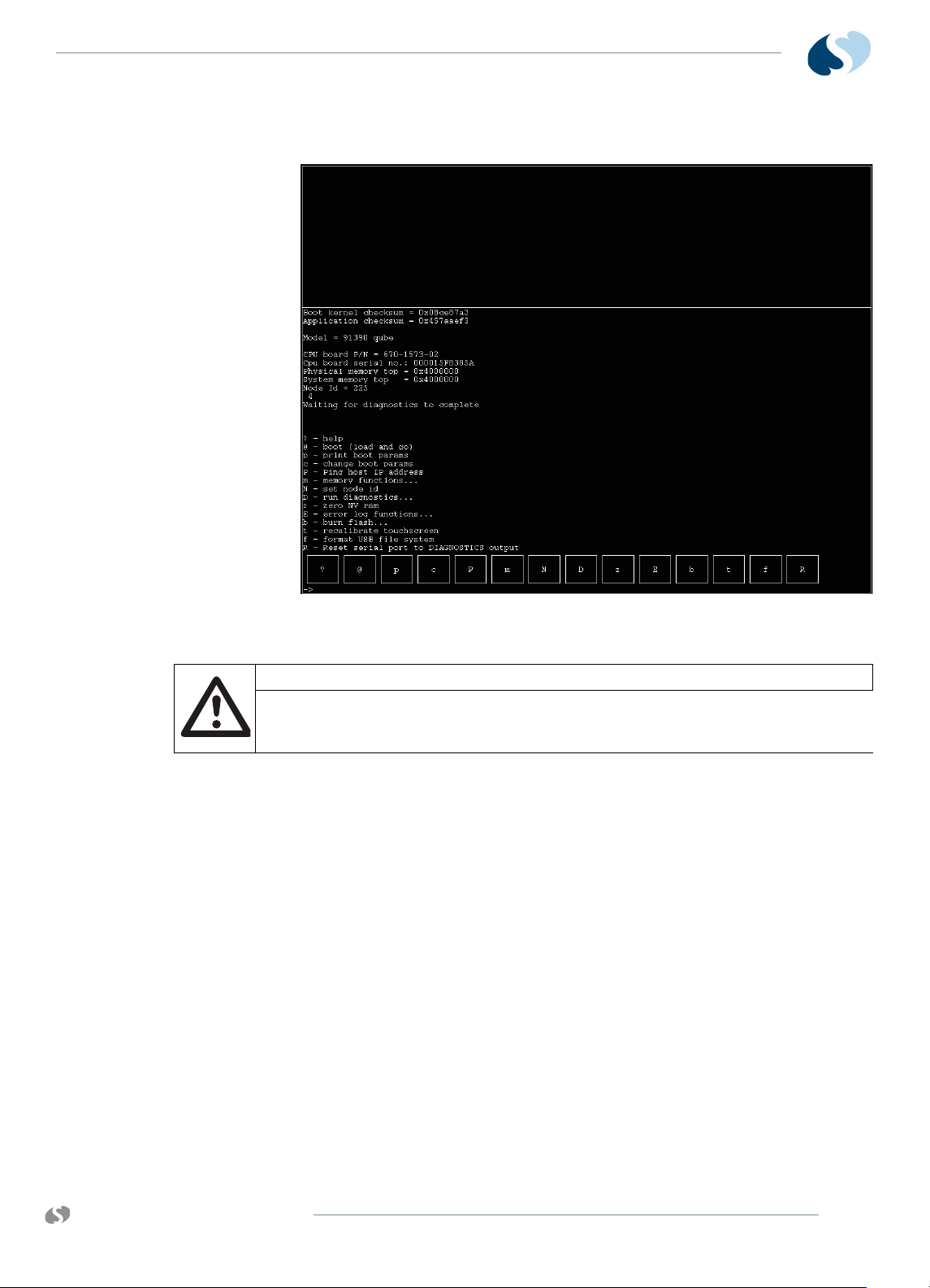

Power-ON Diagnostics................................................................................................. 5-3

Boot Menu......................................................................................................................... 5-4

To access the Boot menu if the display is functional ................................5-4

Boot Parameters ..................................................................................................... 5-6

Extended Diagnostics................................................................................................... 5-7

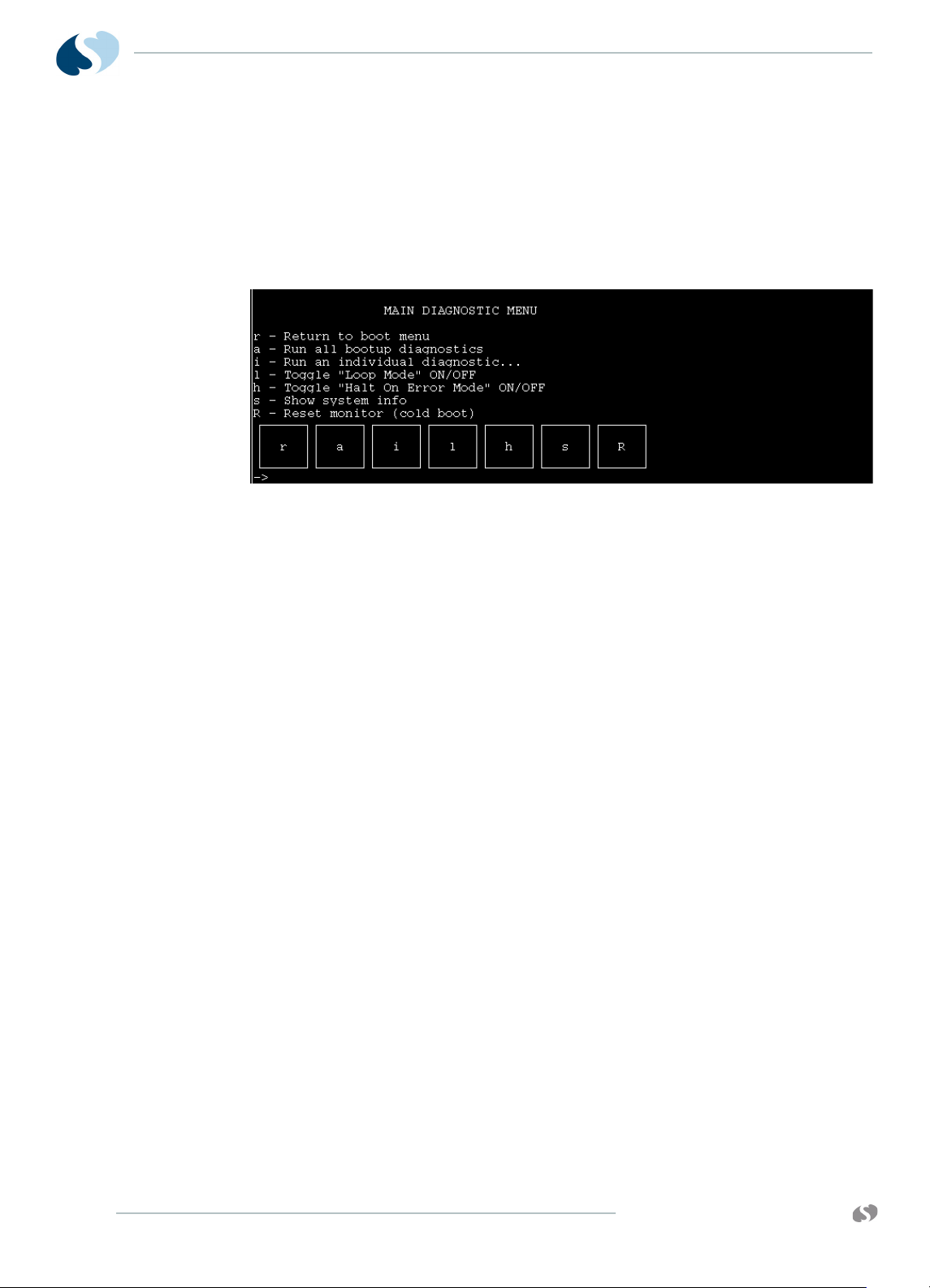

Diagnostic Menus ........................................................................................................... 5-8

Main Diagnostic Menu ........................................................................................... 5-8

Individual Diagnostic Menu ................................................................................. 5-9

Memory Menu ......................................................................................................... 5-10

Video Menu ............................................................................................................... 5-11

Error Log............................................................................................................................5-11

View the Error Log ................................................................................................ 5-12

Diagnostics Failure Messages and Error Codes ............................................... 5-14

System Troubleshooting ............................................................................................5-16

Suggested Tools/Test Equipment ................................................................... 5-16

Qube Monitor Does Not Power ON ................................................................. 5-17

Qube Monitor Powers ON, But Fails System Startup ............................... 5-19

High-pitched Tones Heard from the qube Monitor and

No Display is Present ............................................................................................ 5-21

System Software Failure Window Shown

Immediately After System Startup ................................................................. 5-22

Monitor Fails Power-ON Diagnostics ............................................................. 5-23

Troubleshooting Method 1: Use the Touchscreen or Mouse ..................5-23

Troubleshooting Method 2: Use the Remote Terminal—Use When

No Display is Present ............................................................................................. 5-23

Monitor Fails System Functions ...................................................................... 5-24

Batteries/ Battery Charger ..................................................................................5-24

Touchscreen .............................................................................................................5-24

Module does not sign on when installed in an

external module housing .....................................................................................5-24

Module does not sign on when installed

in the monitor for options A and B ..................................................................5-25

Pod does not sign on ......................................................................................... 5-26

Module signs on but parameters do not function ................................... 5-26

Ethernet ................................................................................................................... 5-26

External Alarm Relay for Option A ................................................................. 5-27

Keyboard, Mouse, or Barcode Scanner ......................................................... 5-27

Touchscreen ........................................................................................................... 5-27

Ethernet/Network ................................................................................................ 5-28

External Alarm Relay/Nurse Alert for Option A ........................................ 5-28

www.spacelabshealthcare.com

I-III

Page 6

91390 QUBE

Keyboard, Mouse, or Barcode Scanner ......................................................... 5-29

6Parts

Overview............................................................................................................................. 6-1

Parts List ............................................................................................................................ 6-2

Option A .................................................................................................................... 6-2

Option B ..................................................................................................................... 6-4

Option C ..................................................................................................................... 6-7

Assembly Drawings and Schematics.................................................................... 6-10

7 Glossary

A Appendix A — Electromagnetic Compatibility

Electromagnetic Emissions .........................................................................................A-1

Electromagnetic Immunity .........................................................................................A-2

Separation Distances ................................................................................................... A-3

Mitigation ................................................................................................................... A-4

B Appendix B — Symbols

I-IV

www.spacelabshealthcare.com

Page 7

91390 QUBE

Introduction

Overview

Spacelabs Healthcare designs and manufacturers its products under

good manufacturing practices and in compliance with all applicable

regulatory requirements. To make sure that the product operates

correctly in accordance with these guidelines, trained technicians

using Spacelabs Healthcare authorized replacement parts maintain

this product.

The expected service life of the monitor is seven years from the date

of installation, but its service life can be extended. Many of the

monitor parts are replaceable. Calibration is not required, but

routine safety checks are required. Install a functional battery in the

unit for normal operation. Check the battery periodically and replace

it when necessary.

The qube™ monitor has a 26.2 cm (12.1 inches) LCD display with 1024

x 768 resolution. It has an intuitive user interface and a stylish,

compact design. The monitor includes a single module slot and

supports up to three Flexports® and four USB devices (a mouse,

keyboard, barcode scanner, etc.). Available options include an

integrated recorder and 802.11a/b/g wireless. Dual-battery slots

allow for its use as a transport monitor, as well as at the bedside.

The system has an improved performance and high-resolution LCD

display system. The touchscreen has built-in alarm lights, LED status

indicators (to show the power and battery state), and a power ON/

OFF switch.

www.spacelabshealthcare.com

1-1

Page 8

91390

A

B

C

QUBE

I NTRODUCTION

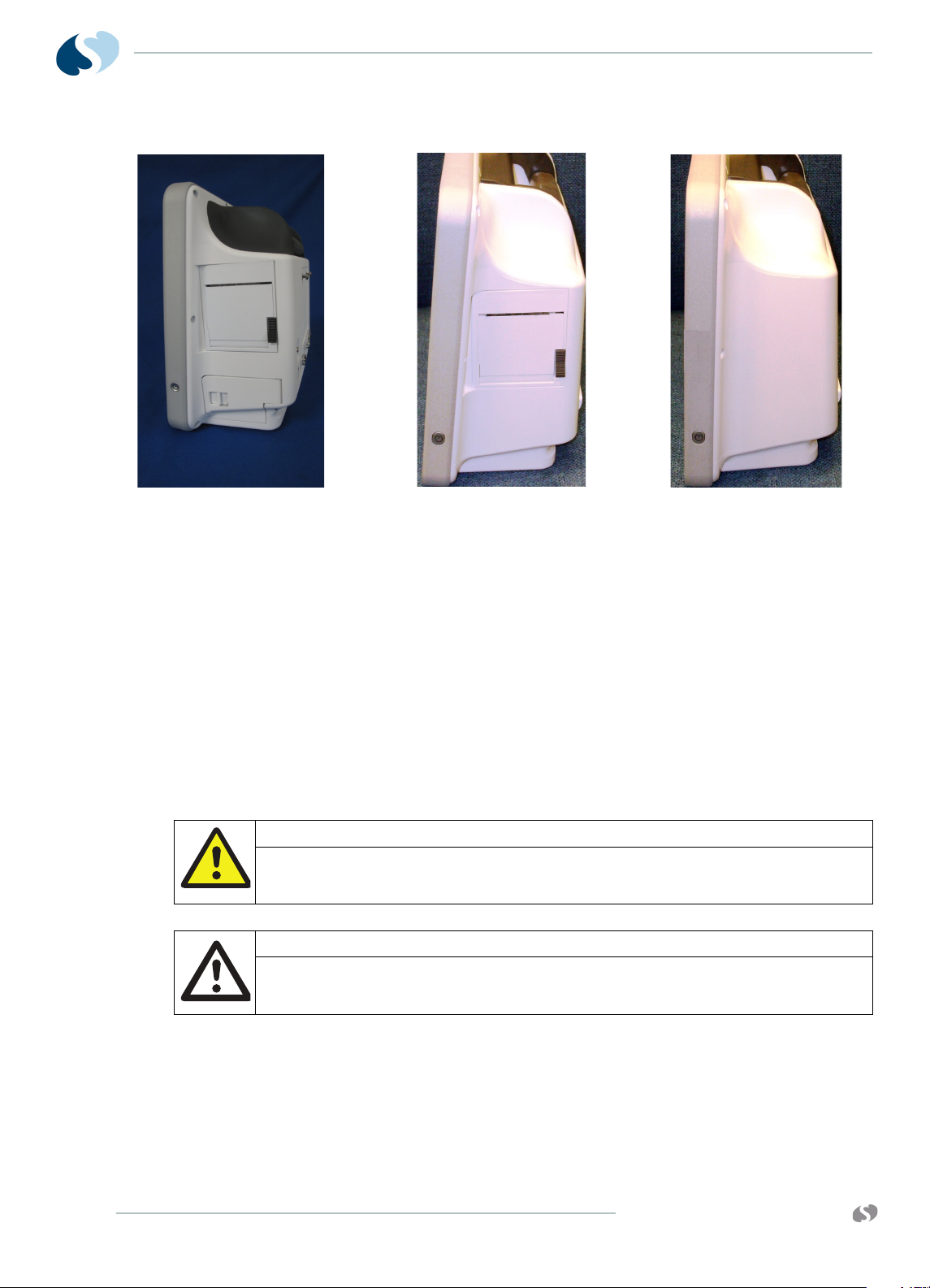

Figure 1-1 91390 qube monitor configuration options

a qube with both printer and battery slots (option A)

b qube with only printer slot (option B)

c qube with no printer or battery slots (option C)

Note:

For more details refer to Table 1-1 on page 4.

Warnings, Cautions, and Notes

Warnings, cautions, and notes are used throughout this manual. The

formats below show how warning, cautions, and notes are identified.

Warning:

Alerts the user to potentially serious outcomes (death, injury, or serious

adverse events) to the patient or user.

Caution:

Alerts the user to actions to be taken to avoid non-serious injury to the

patient or user, or to adverse effects to the device.

1-2

Note:

Failure to observe notifications can result in unexpected

outcomes.

www.spacelabshealthcare.com

Page 9

91390 QUBE

Product Specifications

Refer to Basic Components on page 1-9 for more information.

Product Specifications

Height 26.2 cm 10.3 inches

Width 31.5 cm 12.4 inches

Depth 13.2 cm 5.2 inches

Weight 4.1 kg 9 lbs

Color thin film transistor (TFT) liquid crystal display (LCD), resistive touchscreen

Resolution 1024 x 768 pixels

I NTRODUCTION

Physical Dimensions

Display

Size- wide

- high

24.6 cm

18.4 cm

9.7 inches

7.3 i nc he s

Printer

Printing Method* Thermal array print head

Paper Heat-sensitive paper roll, 50 mm wide x 30 m long

Resolution Eight dots per mm (vertical) and 32 dots per mm

(horizontal) at 25 mm per second sweep speed

Prints Manual and automatic alarm recordings for waveforms,

vital sign data, trends, calculations, and full annotations

are included

Controls Continuous, Stop Recording, Compressed, Paper Advance

Indicators Paper out, Unit off

Sweep Speed Various speeds are available under module control.

* May not be included in the qube configuration option package.

For more details on configuration options, refer to Qube

Configuration Options on page 1-4.

www.spacelabshealthcare.com

1-3

Page 10

91390

AB C

QUBE

I NTRODUCTION

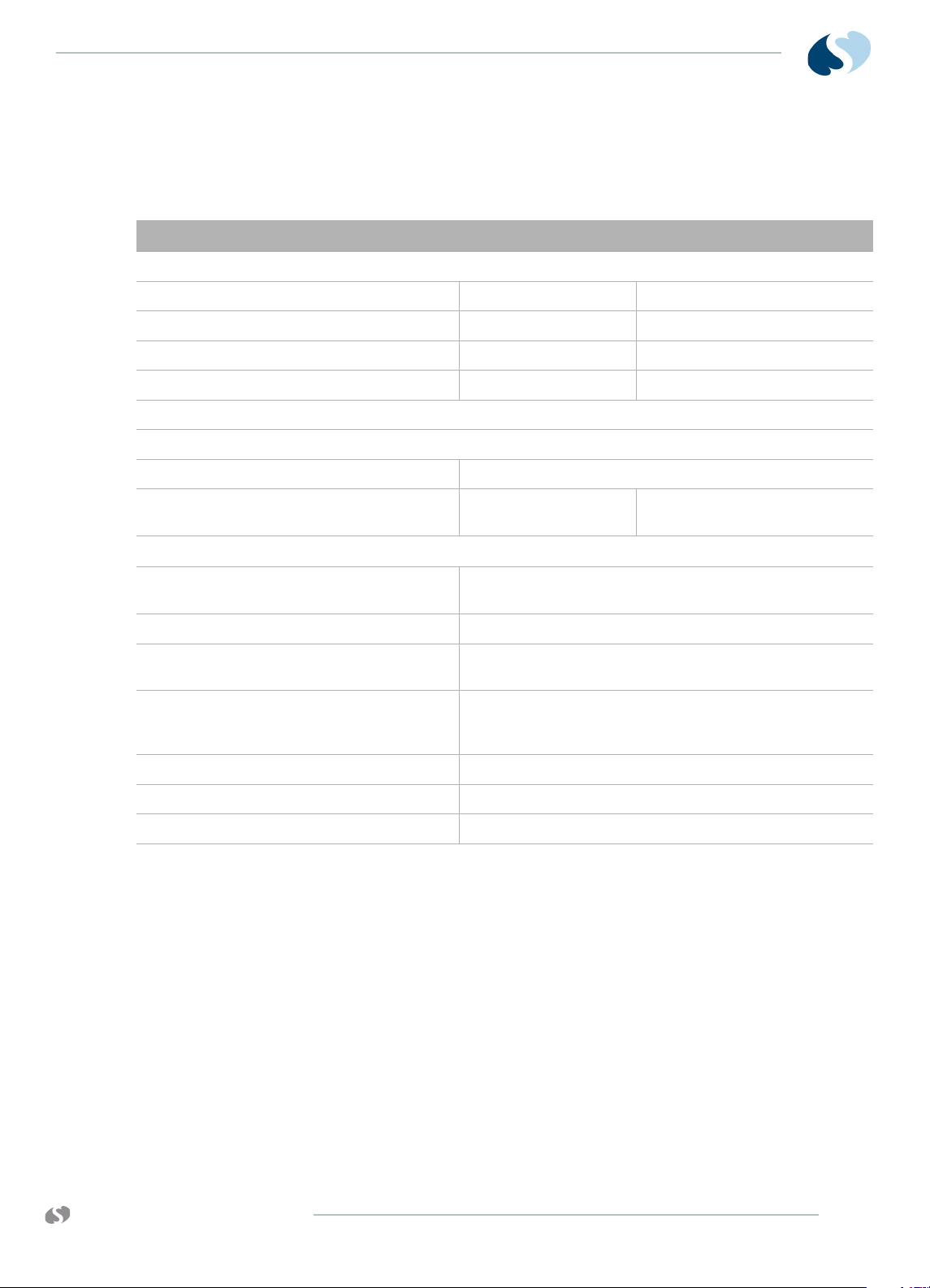

Table 1-1 Qube Configuration Options

Connectors

Internal Recorder Slot 1 on right panel 1 on right panel not included

Front Integrated Alarm Light 1 on top, front, and back of

Docking Station connection included not included not included

Integrated or Hot Swappable

Battery Slot

Equipotential Terminal 1 on rear panel not included not included

DC Power Input 1 on rear panel 1 on rear panel 1 on rear panel

Ethernet 10/100 Base T

Connection

Serial Port 1 on rear panel 1 on rear panel 1 on rear panel

USB Ports 4 on rear panel 2 on rear panel 2 on rear panel

Video Output, DVI-D 1 on rear panel 1 on rear panel 1 on rear panel

SDLC Port 1 on rear panel 1 on rear panel 1 on rear panel

Remote Alarm Output-Nurse

Alert

Module Slot 1 on left panel 1 on left panel 1 on left panel

POD Connection 1 on rear panel 1 on rear panel not included

Power On/Off Button on right side of display on right side of display on right side of display

2 Lithium-Ion (Li-Ion), right

side below printer slot

display

1 on rear panel 1 on rear panel 1 on rear panel

1 on rear panel not included not included

1 on front of display not included

2 Lithium-Ion (Li-Ion), fixed

non-removable

1 Lithium-Ion (Li-Ion), fixed

non-removable

1-4

www.spacelabshealthcare.com

Page 11

91390 QUBE

Electrical Specifications

Classification

Warning:

• Use designated power supply only.

• Do not modify this equipment without the authorization of the

manufacturer.

• To avoid electric shock, connect this equipment only to a supply mains

with a protective earth conductor.

• Class I - Requires outlet with Protective Earth (safety ground)

conductor

• Mains Power: 100 - 240 VAC, 50 - 60 Hz, 3 - 1.5 A

• Rated for continuous operation

• Isolation: Leakage currents meet ANSI/AAMI ES 60601-1, CSA

C22.2 No. 60601-1, and IEC 60601-1.

I NTRODUCTION

• Batteries: (For configuration options, refer to Qube

Configuration Options on page 1-4).

1 10.8 Volt (7.2-Ah Li-ion) smart battery. One battery

provides approximately 4 hours of operation. Two

batteries allow up to approximately 8 hours of operation.

There are approximately 300 charge/discharge cycles of

operation for each battery.

2 10.8 Volt (4.8-Ah Li-ion) smart battery. One battery

provides approximately 2 hours of operation. Two

batteries allow up to approximately 4 hours of operation.

There are approximately 300 charge/discharge cycles of

operation for each battery.

3 10.8 Volt (4.8-Ah Li-ion) smart battery. One battery

provides approximately 2 hours of operation. There are

approximately 300 charge/discharge cycles of operation

for each battery.

Note:

One battery charges in approximately two hours. Two batteries

charge in approximately four hours.

www.spacelabshealthcare.com

1-5

Page 12

91390

QUBE

Environmental Requirements

Transport and Storage

Temperature: -25º to 60º C (-13º to 140º F)

Humidity: 95% (non-condensing)

Altitude: 0 to 12,192 meters (0 to 40,000 feet)

Operating

Operating Temperature: 0º to 40º C (32º to 104º F)

Humidity: 95% (non-condensing)

Altitude: 0 to 4,572 meters (0 to 15,000 feet)

Expected Service Life

I NTRODUCTION

The expected service life is seven years from the date of first use.

Spacelabs Healthcare recommends regular replacement of the

following parts to extend service life:

•LCD

• LCD backlights

• batteries

•fan

Replace the listed items especially if you use them beyond the

service life range. Perform safety checks and maintenance of the

monitor on regular schedules. Spacelabs Healthcare offers a

refurbishment program for equipment that has passed its expected

service life. Contact your local service representative for more

information.

To protect the environment, properly dispose of all

batteries, electronic assemblies, plastics, and metals.

Follow your internal procedures or local (provincial)

laws regarding disposal or recycling.

1-6

www.spacelabshealthcare.com

Page 13

91390 QUBE

Monitor Options

I NTRODUCTION

Table 1-2 91390 Monitor Options

Option Definition

D Perioperative: provides customizable, user-specific display

setups and start case and end case functions

N Vital Signs Calculations (Hemodynamics, Oxygenation,

Ventilation, and Renal)

Q Data Shuttle

information

R Patient Data Logger (PDL); presents an ASCII data stream of

patient name and vital sign data to the serial port in a predefined format

S Dynamic Network Access (DNA); Spacelabs Healthcare

proprietary version of the Citrix ICA Client connects and

interacts with remote applications hosted on Citrix servers.

Citrix server software and other associated licenses and

applications must be purchased separately.

®

supports the transfer for up to 96 hours of trend

U Printer; one printer slot, refer to the product specifications

section for details

V Full View; supports simultaneous display of 12 ECG leads

W Full Bed Review; provides a multi-parameter view for any

monitored patient on the network (up to seven waveforms)

X Wireless; 802.11a/b/g

Product Overview

Monitor Assembly and Module Housing

The monitor is a portable product that provides physical mounting,

electrical connection, and power for a plug-in module. It also

provides power and SDLC I/O for externally connected flexports

and other devices. The monitor provides interfaces for:

• internal and optional external displays

• connections for a mouse, keyboard, barcode reader using USB

• remote control through IR remote control: option A

(SL number 90360-01)

www.spacelabshealthcare.com

• the required video signals for an external display

A separate external power supply powers the monitor. All voltage

conversion that is required to support the modules and the internal

electronics is provided inside the product. Provisions are provided

for detection of an AC line failure to provide for an orderly power

off.

1-7

Page 14

91390

QUBE

External AC Power Supply

The external AC supply that powers the monitor meets worldwide

safety and EMC requirements. The external AC supply provides

20 VDC. The external AC supply provides 20 VDC at 4.5 Amps. The

external power supply (an AC/DC converter) has a 6pin rectangular

connector (P/N 119-0552-00).

Batteries

The option A monitor accommodates the use of two removable

internal batteries. At least one battery must be installed for normal

operation.

The option B monitor has two fixed (non-removable) batteries. The

option C monitor has one fixed (non-removable) battery.

For more information, refer to Batteries and Recharging Batteries on

page 1-14.

Display

I NTRODUCTION

LCD Display

Video Subsystem

For options A and B, the LCD display assembly provides multicolor

visual alarm notification based on the severity of the alarm. The

software controls the operation of the alarm lights. There is a red

light for high priority, a yellow light for medium priority, and a cyan

light for low priority and technical alarms.

The alarm lights are visible directly above the display screen on

options A and B, and on the rear of the monitor above the handle on

option A.

The primary display is a 12.1-inch color TFT LCD. The video interface

is 24-bit Flat Panel Display Link (FPD-Link) using LVDS.

The display has an LED backlight supplied with 12-volt power. A

PWM control signal controls the brightness of the LED backlight.

The power supply microcontroller generates the PWM control signal

under the direction of the host application.

The secondary display is an external monitor compatible with

standard Digital Visual Interface (DVI) signaling. The interface is

DVI-D which supports digital-only, single-link.

The secondary display has the same image and resolution as the

primary display.

1-8

www.spacelabshealthcare.com

Page 15

91390 QUBE

1

2b

2a

3

3

4

Parameter Minimum Typical Maximum Unit Remarks

Video Clock Rate 60.0 15.385 68.0 nS 65-MHz typ.

Horizontal Rate 19.67 20.676 22.4 uS 48.363-KHz typ.

Vertical Rate 13.3 16.666 18.5 mS 60-Hz typ.

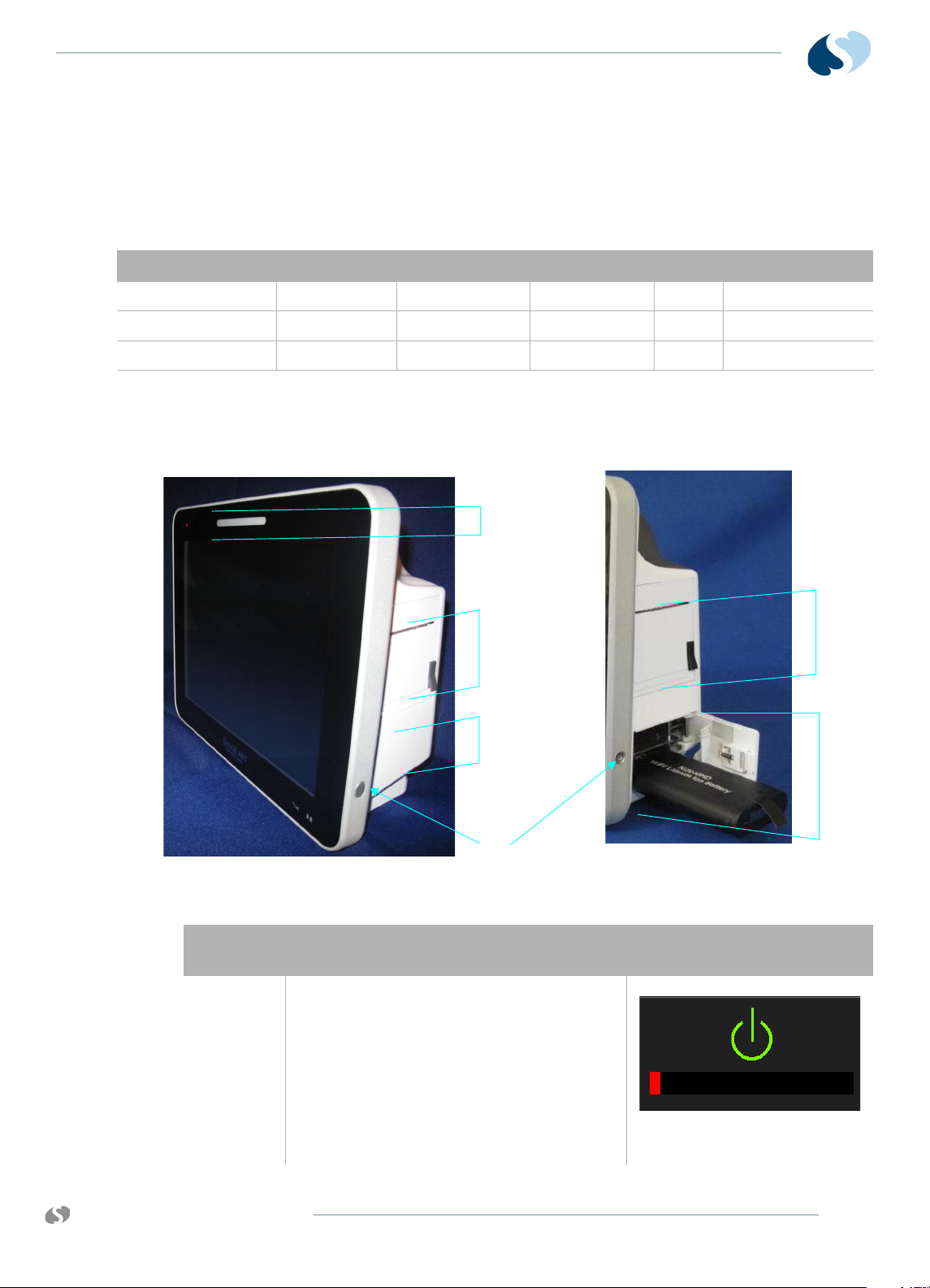

Basic Components

I NTRODUCTION

• Resolution 1024 x 768

• Active Lines 768

• Active Pixels 1024

Table 1-3 Display Specifications

Callout

Number

1 Power On/Off Button- Press and hold the

www.spacelabshealthcare.com

Figure 1-2 Front and Right Side of the Qube Option A

Description Symbol

power button for at least three seconds to turn

the monitor off. System shutdown progress is

shown below the green power symbol.

Note:

Hold the power On/Off for 3 seconds,

or the monitor will not power off.

Figure 1-3 System shutdown

progress

1-9

Page 16

91390

QUBE

I NTRODUCTION

Callout

Number

2a Integrated Battery Slot closed* Refer to To change batteries

2b Hot Swappable Battery Slot open with battery

3 Internal Recorder Slot* N/A

4 Front Integrated Alarm Light* N/A

Description Symbol

partially pulled out.*

Battery Indicators

Warning:

At least one battery should always be installed in the monitor. The

battery is a critical component of the electrical system. It improves EMC

immunity performance when the monitor is connected to the AC power.

without interruptions while

operating on battery power on

page 1-15 for details.

Refer to To change batteries

without interruptions while

operating on battery power on

page 1-15 for details.

* Not all of the qube configuration options include these items.

For more details, refer to Qube Configuration Options on

page 1-4.

Notes:

• The battery provides power to the monitor when it is

separated from the AC power.

• Batteries charge when the monitor is connected to the AC

power.

• The monitor auto-switches to battery operation when

separated from the AC power.

• Remove batteries if the monitor is not likely to be used for

some time.

• Remove batteries from the monitor before storage or

shipment.

1-10

www.spacelabshealthcare.com

Page 17

91390 QUBE

2

1

I NTRODUCTION

Figure 1-4 Battery charger and AC/DC power indicators

Table 1-4 Power Indicators (only shown when AC is connected)

Description Symbol on panel

1 AC/DC Power Indicator - External power supply is connected

to the monitor and the AC mains. When the AC power

indicator comes on, the connection is good.

Refer to Figure 1-4.

2 Battery Charge Status Indicator-

Shown if a battery is present. The left light shows if the top

battery is installed. The right light shows if the bottom

battery is installed.

Flashing (rate of 1 second on and 1 second off) shows the

battery is charging.

Steady ON shows the battery is charged.

Flashing, rapid or erratic shows the battery is faulty and must

be replaced.

Refer to Figure 1-4.

Note:

The option C monitor has one battery, so only one

battery charge indicator shows.

www.spacelabshealthcare.com

1-11

Page 18

91390

1

12

11

2

10

98 7 66 5 4 3

QUBE

I NTRODUCTION

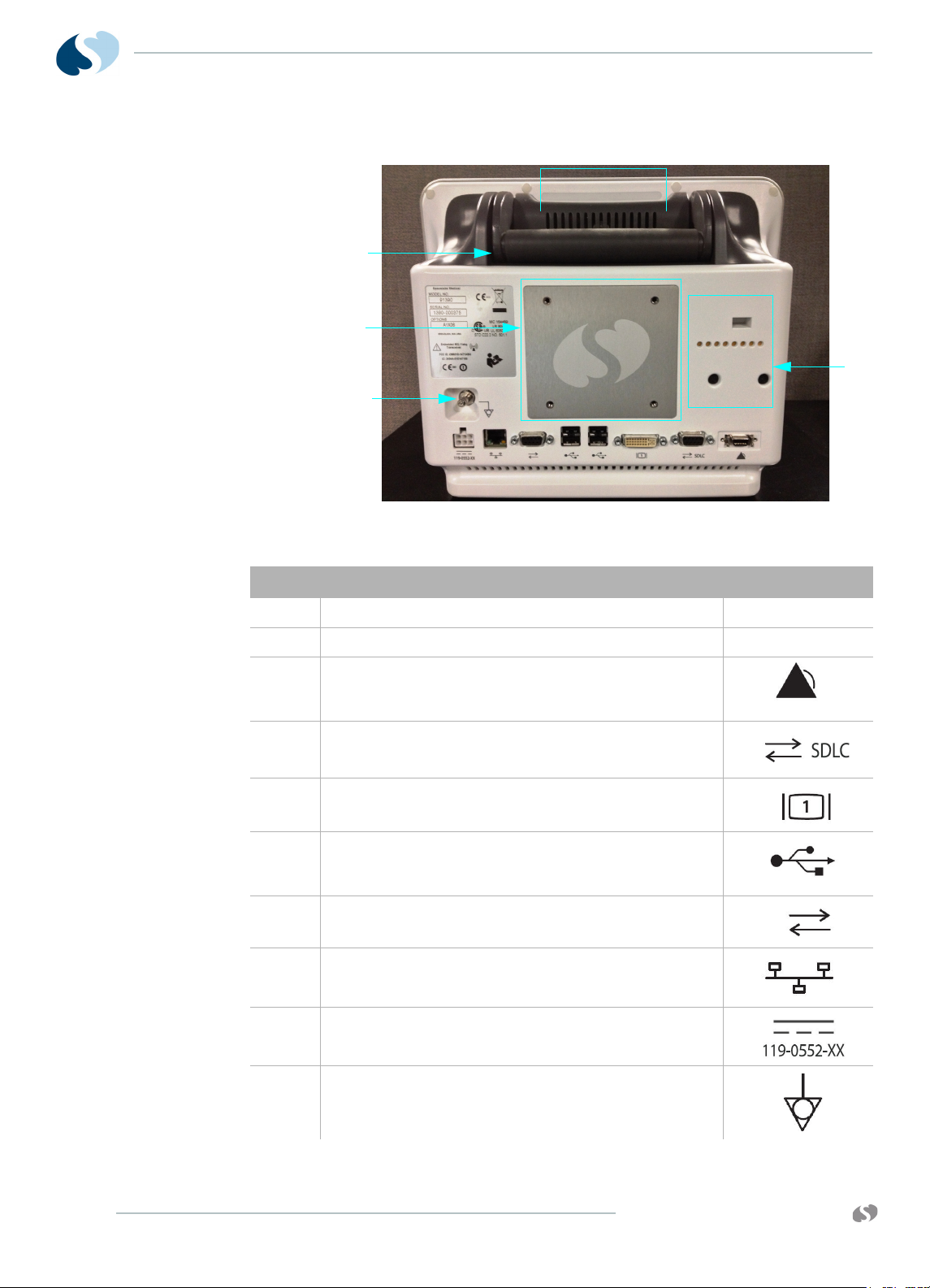

Figure 1-5 Back Panel of Qube*

Description Symbol on panel

1 Integrated Alarm Light*N/A

2 POD Connection such as Capnography Pod.* N/A

3 Remote Alarm Output - Nurse Alert*

Refer to Alarm Relay for option A on page 2-15 for

details.

4 SDLC Ports

Refer to SDLC Bus Termination on page 2-15 for details.

5 Video Output, DVI-D

Digital only

6 USB Ports

qty= 4 for option A

qty= 2 for options B and C

7 Serial Port

8 Ethernet 10/100 Base T Connection

9 DC Power Input

119-0552-00

1-12

10 Equipotential Terminal*

used for grounding the monitor

www.spacelabshealthcare.com

Page 19

91390 QUBE

Description Symbol on panel

11 75 mm VESA Mounting Pattern N/A

12 Handle N/A

* Not all of the qube configuration options include these items.

For more details, refer to Qube Configuration Options on

page 1-4.

Energy Saving Mode (Battery)

The qube has an energy saving mode. Energy saving mode lets the

monitor dim after 30 seconds of no interaction. If you enable this

mode, do not touch the monitor for 30 seconds to see it dim. The

monitor does not dim if you use a mouse with the monitor or an

alarm event occurs. Refer to the XPREZZON and qube System

Administration Manual (P/N 070-2380-xx) for more details.

I NTRODUCTION

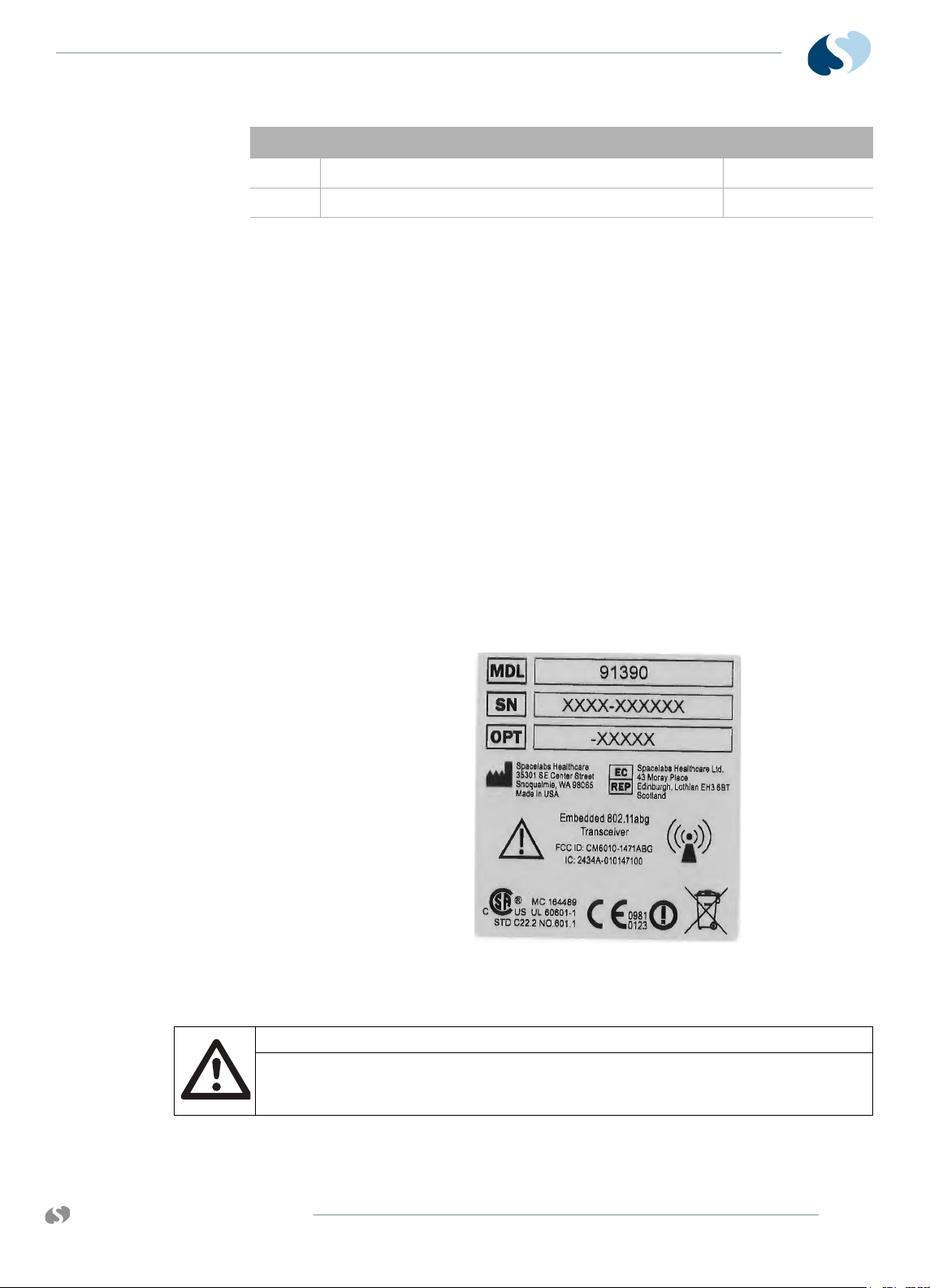

Signal Strength Indicator

Monitors equipped with option X (an embedded 802.11a/b/g

transceiver) are labeled at the factory. A separate label is provided

with the option X kit for field installation (Refer to Figure 1-6).

Figure 1-6 P/N 334-6134-01, LABEL,MOD,S/

N,OPT,REG,WIRELESS,91390

Caution:

www.spacelabshealthcare.com

The only other indication for the presence of option X is the wireless field

strength icon that shows when the ethernet cable is removed and the

wireless option is enabled (Refer to Figure 1-7).

1-13

Page 20

91390

QUBE

I NTRODUCTION

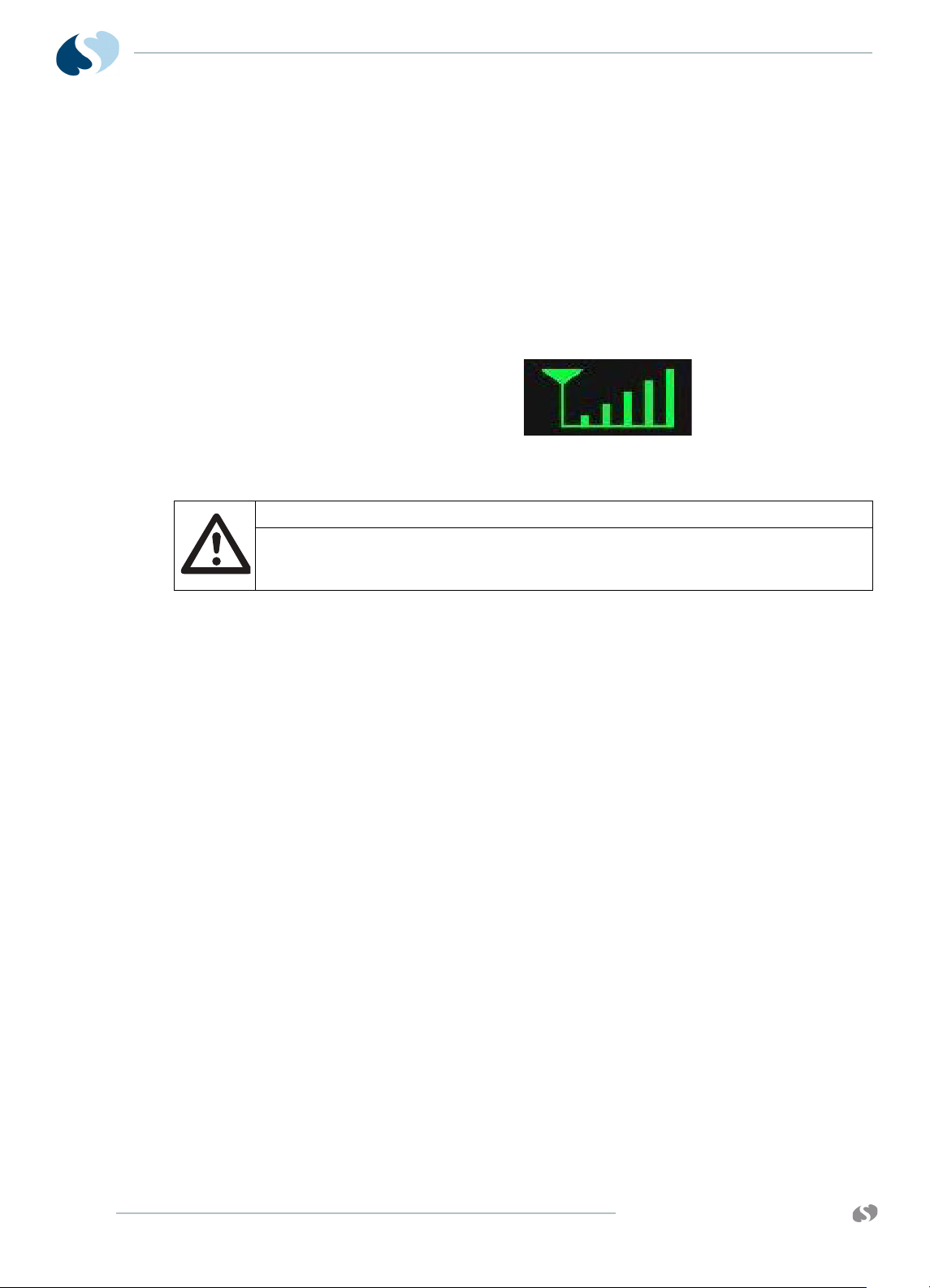

Monitors with wireless network communication show a wireless

signal strength indicator while they communicate over the wireless

network. To use the wireless feature, disconnect the wired network

connector. Not all qube monitors include the wireless option.

The wireless signal strength shows between the Admit Patient

button and alarm buttons. The signal strength shows a green

antenna with vertical bars on a black background. The number of

bars show the strength level. One bar is low strength. The strongest

signal is five bars. The signal changes to yellow when the network

connection is lost. For more information, refer to the XPREZZON and

qube System Administration Manual (P/N 070-2380-xx).

Figure 1-7 Wireless signal strength indication

Caution:

Signal strength and radio system congestion can contribute to waveform

gaps over the wireless network. Should this be a persistent issue, consult

with a Spacelabs Healthcare field service representative.

Batteries and Recharging Batteries

For option A, the monitor uses smart batteries, and at least one

battery must be installed for normal operations. If it uses two fully

charged batteries in a standard configuration, the monitor operates

up to eight (8) hours. With one fully-charged battery in a standard

configuration, the monitor operates up to four (4) hours.

The battery icon shows if the batteries are inserted. This icon shows

how much charge the batteries have. The icon updates every six

seconds and is to the left of the audio icon on the lower-right

section of the monitor. Refer to Table 1-5 on page 1-15.

Charge temperature limits are ≤80% RH.

The battery must be capable of continuous charge at 12.6 V. To

charge the battery, only use a dedicated level II or level III smart

battery charger. When you use a level II or level III smart battery

charger, the battery requests the appropriate charging voltage and

current.

The FULLY_CHARGED bit in the Battery Status is set when the

charging current tapers down to under 240 µA, while charging at

12.6 V.

Notes:

• The battery life greatly depends on usage, age, and the

environment. The battery operating life decreases over time.

1-14

www.spacelabshealthcare.com

Page 21

91390 QUBE

I NTRODUCTION

• One battery charges in approximately two hours, and two

batteries charge in approximately four hours.

The option B monitor operates for up to four hours with two fully

charged batteries and standard configuration. With a single fully

charged battery and standard configuration, the monitor operates

for up to two hours. The battery is not removable from the monitor.

The option C monitor operates for up to two hours with a single

fully-charged batteries and standard configuration. The battery is

not removable from the monitor.

Note:

For options B and C monitors, only one battery icon shows on the

main screen.

Caution:

The qube monitor and smart rechargeable Li-Ion batteries and cells do

not overheat, they have internal protection devices. Overexposure to heat

will activate one of these devices and may permanently disable the

battery. If this happens, contact Spacelabs Healthcare to purchase a

replacement battery.

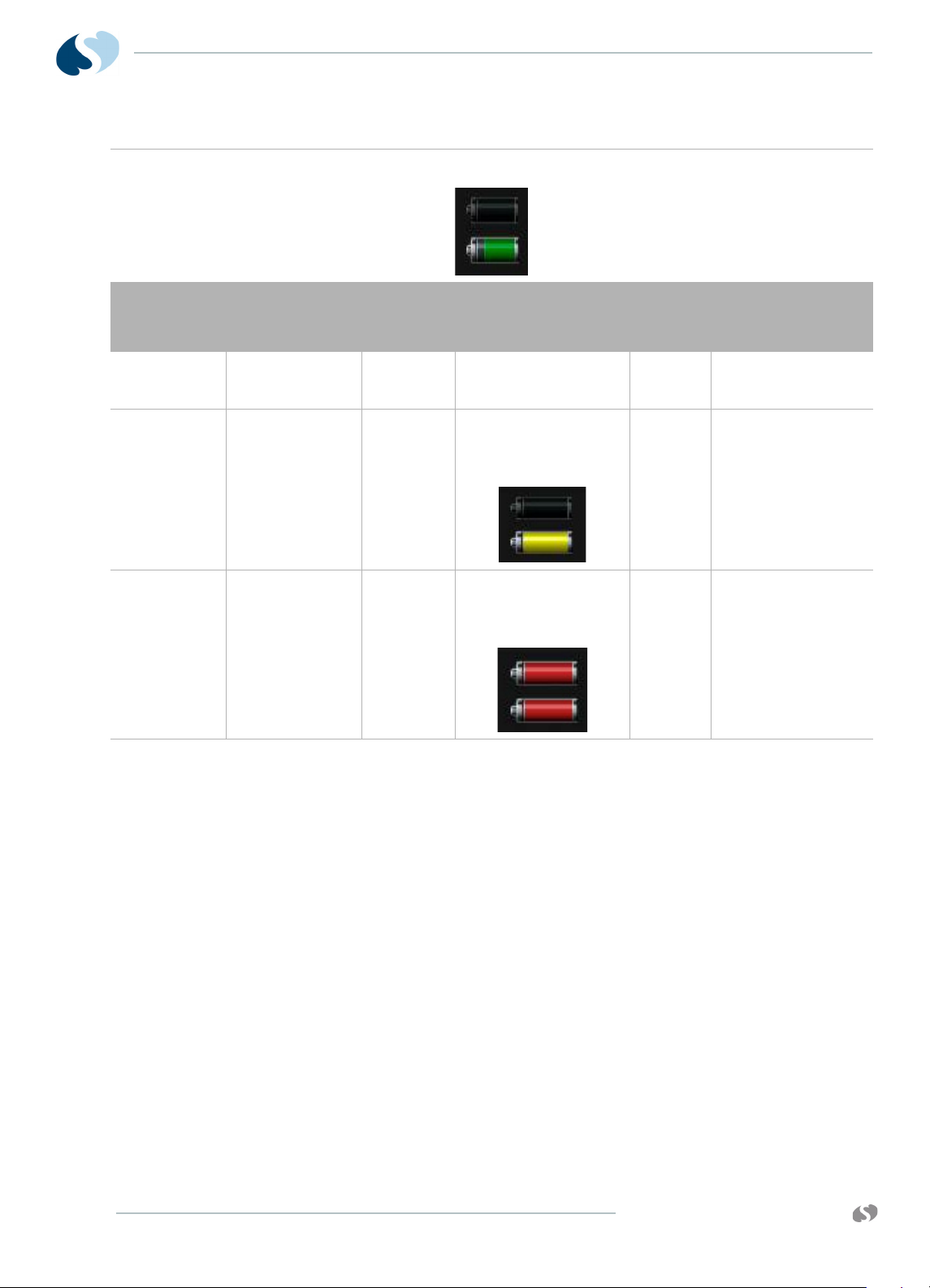

Battery Power Level

A green color on the battery icon shows the current charge level of the battery.

A yellow or red color shows that the battery power is at a critically low level. If the battery power is critically

To change batteries without interruptions while operating on battery power

1 If operating on top battery (battery A), remove lower battery

(battery B).

2 Install new battery (battery C) into the lower battery slot.

3 To make sure that the operation of the new battery is correct,

look at the battery indicator lights (Refer to Table 1-5 on page 1-

15).

4 Remove battery A. Replace it with another new battery.

Extended use of the batteries depletes the battery power. To

prevent patient data loss, the qube monitor watches the battery

power level that remains. As power gets low, the monitor warns the

user about low battery power and inhibits the use of the internal

recorder to extend run time.

Table 1-5 Battery power level messages and tones

low, recharge the battery.

www.spacelabshealthcare.com

1-15

Page 22

91390

QUBE

I NTRODUCTION

Table 1-5 Battery power level messages and tones

A dark gray outline around a solid black battery icon shows that a battery slot is empty. After you install a

battery into the slot, the battery icon shows a white outline and the current charge level of the battery..

Power level

(one battery)

11% 6% Yes The message shown

6% 3% Yes Yellow flashing battery

4% 2% With or

Power level

(two batteries)

Recorder

attached

without

recorder

** Time can be shorter or longer depending on the battery performance.

Warning description

lets you know that the

recordings stop.

icon is shown. Message

shown lets you know

the recordings are

stopped.

Red flashing battery

icon is shown. Message

shows that the battery

power level is critically

low.

Audible

tones

soft 30 minutes

soft 15 minutes

loud 10 minutes

**Approximate

time before device

shuts down

Architecture

1-16

The basic internal architecture, or Printed Circuit Board Assembly

(PCBA), of the qube monitor, is shown in the System Block Diagram

(Drawing 1, Sheet 1). Refer to the drawings section of this manual for

more information.

The hardware for the monitor has the following features built around

the Microprocessor Controller (MPC) MPC8270:

•10/100BaseT Ethernet

• 266-MHz maximum CPU speed

• 66-MHz system bus for memories

• 32 MB Flash, 64 MB of SDRAM, and 2 MB SRAM

• 3.3-V logic design

• PCI2.2 at 33 MHz

www.spacelabshealthcare.com

Page 23

91390 QUBE

Directory of Keys

I NTRODUCTION

• USB support (USB2)

• Optional mini-PCI Wireless interface for 802.11a/b/g devices

• External Video (Digital DVI)

• 5-wire resistive touchscreen

• Barcode Reader support (through USB port)

• Optional Remote IR Keypad support: option A

• Multilevel/Multicolor alarm indicator: option A

For a comprehensive directory of keys and explanations, refer to the

XPREZZON and qube System Administration Manual.

www.spacelabshealthcare.com

1-17

Page 24

91390

QUBE

I NTRODUCTION

1-18

www.spacelabshealthcare.com

Page 25

91390 QUBE

Setup

Unpack the Monitor

Standard contents in the box includes:

•91390 monitor

• Country-specific power cord

• Battery (option A: one, second is optional)

• External DC power supply

Make sure that there is a packing list for optional accessories. Keep

at least one shipping box and its packing materials in case you must

return items, or if the monitor requires factory service.

Notes:

• When you remove items from the shipping containers, make

sure that you remove ALL components from each container.

• To determine the contents, refer to the packing list for your

individual order.

• When you receive the equipment, complete a detailed

inventory to make sure that the equipment you received

matches your order. This inventory must include serial

numbers, model numbers, and all options and cables received.

Carefully examine these items for shipping damage. If you find

any damage, immediately notify the freight company and

Spacelabs Healthcare.

www.spacelabshealthcare.com

2-1

Page 26

91390

QUBE

S ETUP

Warning:

• The qube monitor and smart rechargeable Li-Ion batteries and cells do

not overheat, they have internal protection devices. Overexposure to

heat will activate one of these devices and may permanently disable

the battery. If this happens, contact Spacelabs Healthcare to purchase

a replacement battery.

• Failure to properly configure this device prior to network connection

may alter network time or corrupt patient data.

• Do not mount the monitor or docking station directly above the

patient.

Caution:

• If liquid spills onto the docking station, make sure that the docking

station is checked by service staff before you use it again.

• Observe precautions for handling electrostatic-sensitive devices!

Notes:

• Before you touch electrostatic-sensitive electronic

components, follow proper anti-static procedures, including

the use of an ESD wrist band and mat. An electrostatic

discharge from your fingers can permanently damage

electronic components and cause latent failures.

• All static-sensitive electronic components are packaged in

static-shielding bags. Keep the bag in case you must

repackage the component to store it or return it to Spacelabs

Healthcare for any reason.

• For options B and C, the battery switch must be set to ON

prior to use.

Display Assembly

2-2

Display features:

• LCD TFT Display, 12.1" with backlight control

• 5 Wire Resistive Touch screen

• RED, YELLOW, and CYAN LED bars: options A and B

• Remote control IR receiver: option A

• Power and Battery status indicators (LEDs)

•Power switch

www.spacelabshealthcare.com

Page 27

91390 QUBE

S ETUP

Input/Output Connections (Internal and External)

This section defines the I/O connections.

The back panel includes:

•DC Input Power connector

• SDLC (Flexport) connector

• Pod interface connector (SDLC protocol): options A and B

• Remote Nurse Alert connector: option A

• Second display connector (DVI-D)

• RS232 serial connector

• USB ports: Four for option A. Two for options B and C.Ethernet

10/100 base T, RJ45 connector.

Warning:

Data interface connectors on this device are Ground (Earth) referenced!

- Only connect this device to other medical equipment suitable for

use in the Patient Vicinity.

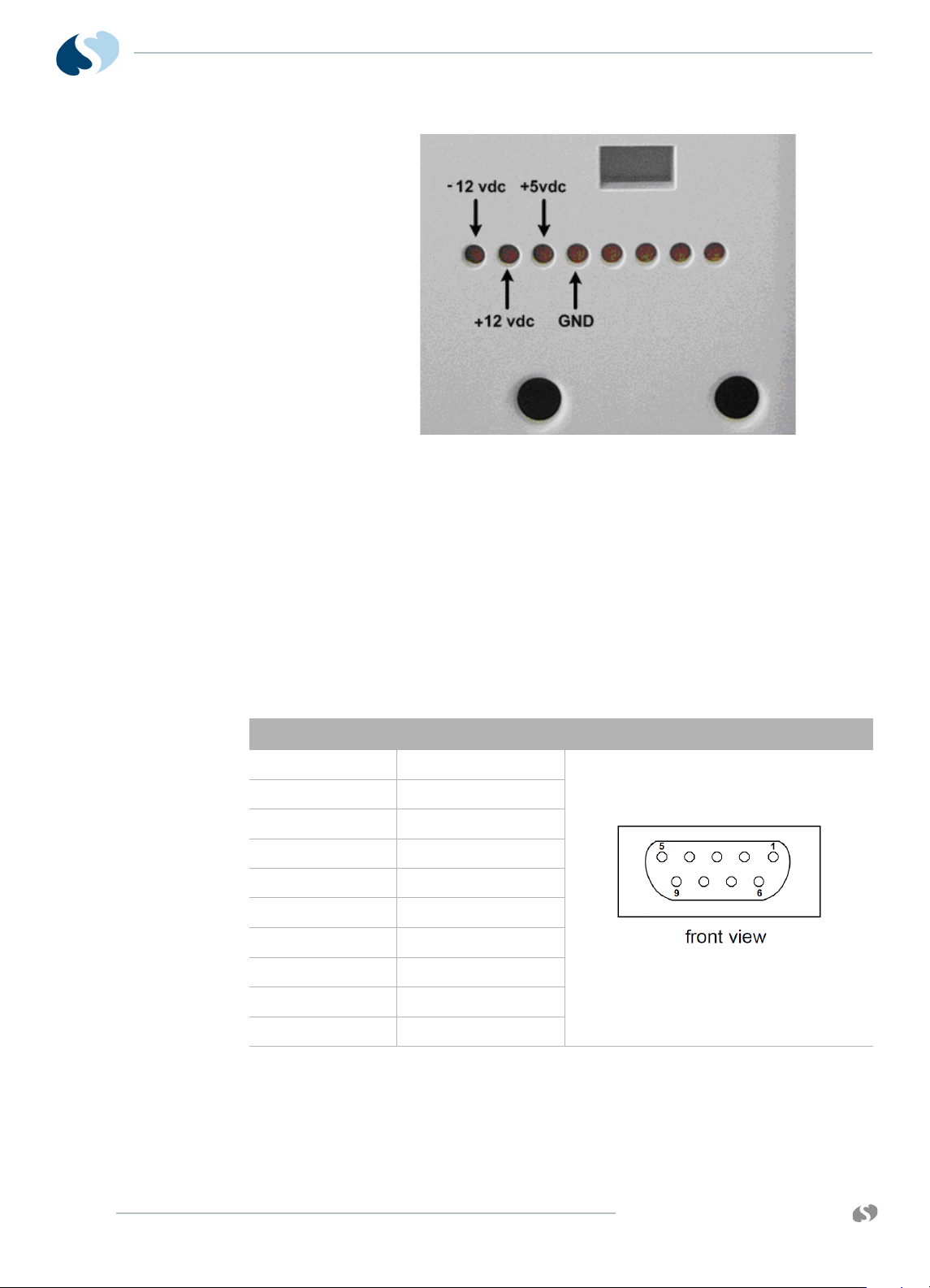

Pod Interface Connector - 8

CONTACT PADS for options A

and B

- Check Ground (Earth) Leakage after connecting data interface

cables.

The left side supports the module slot. The right side accommodates

two lithium batteries and the recorder.

The pod interface SDLC I/O connector (P300) is on the back panel

of the monitor. The pinout for this connector is designed as follows:

Table 2-1 Pinout for Pod Interface Connectors

Pin # Function

PIN 1 SDLC_DAT+

PIN 2 SDLC_DAT-

PIN 3 SDLC_CLK+

PIN 4 SDLC_ CLK +

PIN 5 GROUND

PIN 6 +5 VDC

PIN 7 +12 VDC

PIN 8 -12 VDC

www.spacelabshealthcare.com

2-3

Page 28

91390

QUBE

S ETUP

Figure 2-1 Voltage test points on pod connector

SDLC I/O Connector - DB9

Female

Pin # Function Image

The Flexport SDLC I/O connector is on the back panel. The SDLC

clock frequency is approximately 2 MHz. Docked, (P506) becomes

the SDLC I/O. This interface is electrically compatible with the EIARS485/RS422 standard. The communications protocol is derived

from the IBM Synchronous Data Link Control specification, and uses

its Non-Switched Multipoint Half-Duplex configuration. This

interface is compatible with all of Spacelabs Healthcare Flexports.

The CPU board always provides the SDLC clock. The SDLC clock

frequency is 3.7847 MHz ±100 ppm. The pinout for this connector is

as follows:

Table 2-2 Pinout for external SDLC connector

PIN 1 RTN

PIN 2 SDLC DATA +

PIN 3 SDLC DATA -

PIN 4 + 5V

PIN 5 + 12V

PIN 6 SDLC CLK +

PIN 7 SDLC CLK -

2-4

PIN 8 -12V

PIN 9 RTN

www.spacelabshealthcare.com

Page 29

91390 QUBE

S ETUP

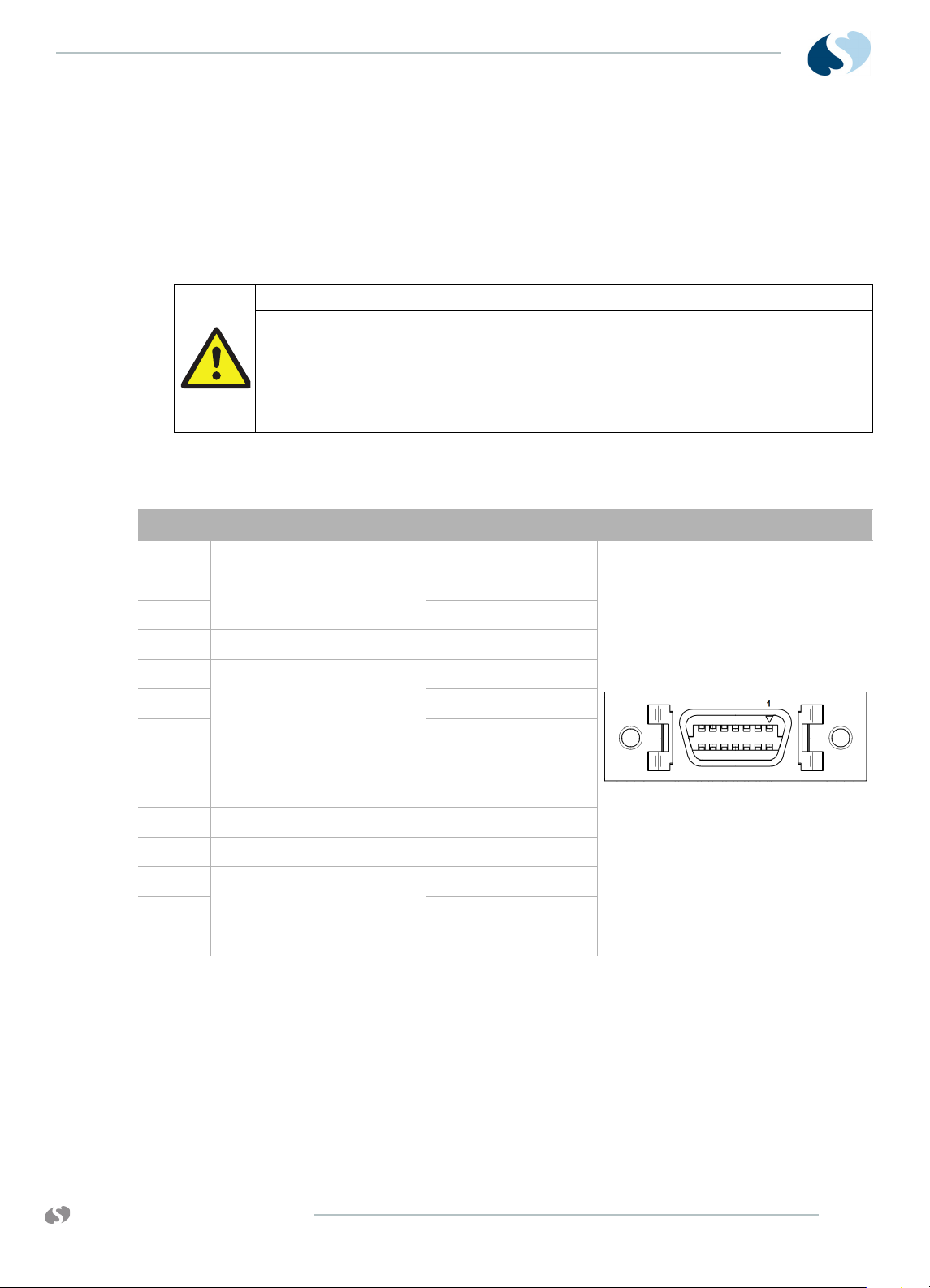

Remote Nurse Alert Connector 14 Pin for option A

Warning:

Data interface connectors on this device are Ground (Earth) referenced!

Pin

1 Alarm 0 (high priority) Common

2 Normally Closed

Alarm Circuit Meaning Image

The Remote Nurse Alert connector is primarily designed to provide

a contact closure to the outside world to indicate an alarm

condition. The nurse alert output provides +12V, return and three

sets of relay contacts. There is one set of relay contacts for each of

the three alarm levels. Each set of relay contacts consists of a

common normally open (NO) and normally closed (NC). Each

contact is able to carry at least 150 mA continuous.

- Only connect this device to other medical equipment suitable for

use in the Patient Vicinity.

- Check Ground (Earth) Leakage after connecting data interface

cables.

The pinout for this connector is as follows:

Table 2-3 Connector Pinouts

3Normally Open

4GND

5 Alarm 1 (medium priority) Normally Closed

6Normally Open

7 Common

8GND

9 +12 V, 140 μA

10 GND

11 GND

12 Alarm 2 (low priority) Normally Open

13 Common

14 Normally Closed

www.spacelabshealthcare.com

2-5

Page 30

91390

QUBE

S ETUP

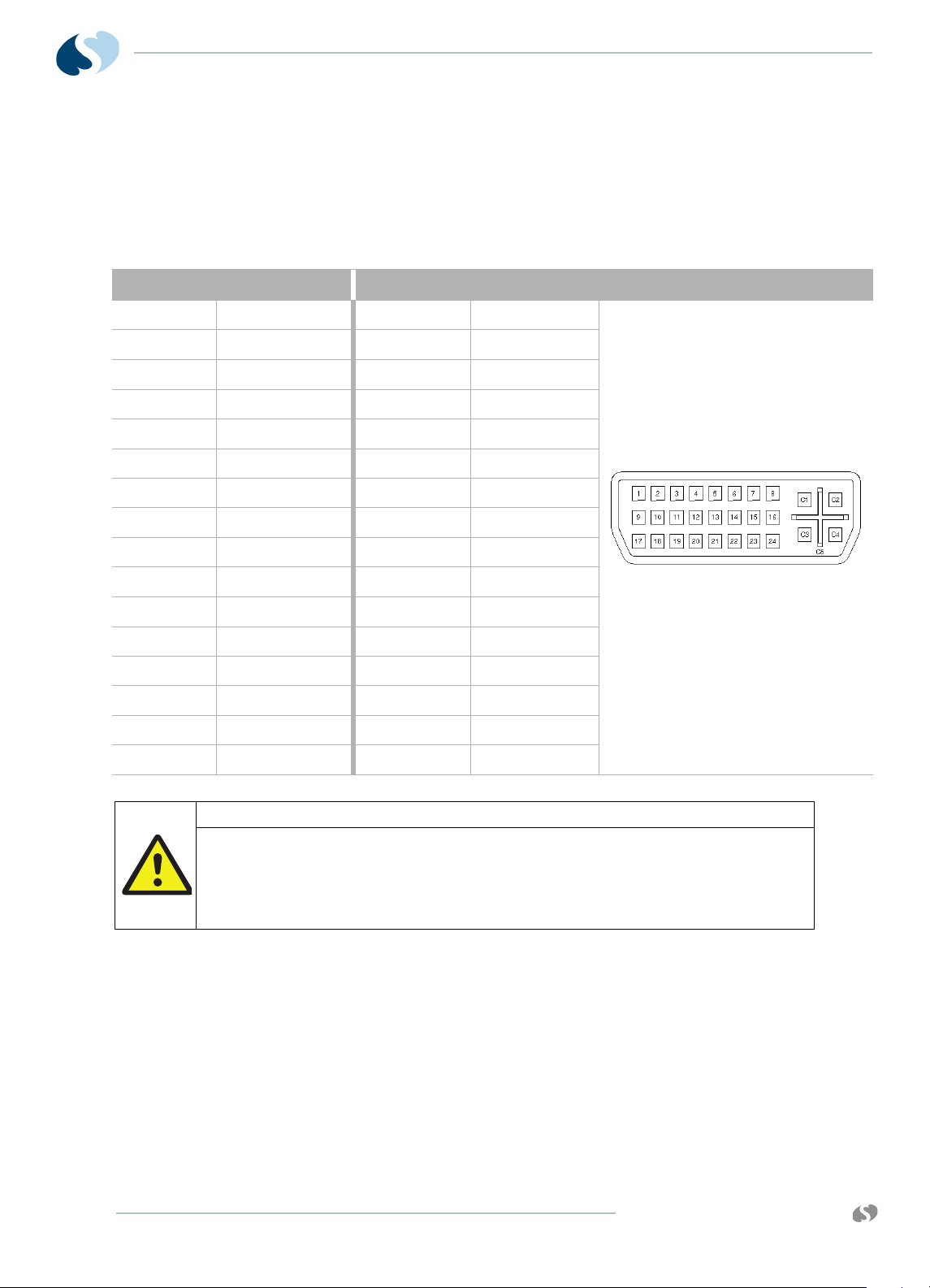

DVI Digital Video Output

Connector - 29 PIN DVI-D

Pin # Function Pin # Function Image

PIN 1 TX2N PIN 17 TX0N

PIN 2 TX2P

PIN 3 RTN

PIN 4 NC

PIN 5 NC PIN 21 NC

PIN 6 DDC_CLK

PIN 7 DDC_DAT

PIN 8 NC

PIN 9 TX1N

PIN 10 TX1P

This DVI-D video connector (P207) is an output to an optional

secondary display. The voltage levels on these connectors are

compatible with the EIA-RS343A standard. The video timing

supports the qube monitor itself. The pinout for this connector is as

follows:

Table 2-4 Pinout for External DVI Connector

PIN 18 TX0P

PIN 19 RTN

PIN 20 NC

PIN 22 RTN

PIN 23 TXCP

PIN 24 TXCN

PIN C1 NC

PIN C2 NC

PIN 11 RTN

PIN 12 NC

PIN 13 NC

PIN 14 +5VDC

PIN 15 RTN

PIN 16 NC

Warning:

Only connect to an approved medical device.

- Common computer equipment may exceed safe leakage current

limits in the patient vicinity.

- Check leakage currents after equipment is interconnected.

PIN C3 NC

PIN C4 NC

PIN C5A RTN

PIN C5B RTN

PIN 31 SHIELD

PIN 32 SHIELD

2-6

www.spacelabshealthcare.com

Page 31

91390 QUBE

S ETUP

DC Power Input Connector There is one DC Power input connector (P204). on the back of the

unit. The DC Power Input connector mates to an external AC/DC

converter supply. The pinouts for this connector are as follows:

Table 2-5 Pinout for the DC Power Input Connector

Pin # Function Image

PIN 1 Ground

PIN 2 + V

PIN 3 + V

PIN 4 RTN

PIN 5 RTN

PIN 6 Ground

Serial I/O Connector - DB9

Female

The Serial I/O connector is on the back of the unit and provides RS232 access to the CPU Board. This interface conforms to the EIARS232 standard. The baud rate and the number of start, stop, and

parity bits are software programmable.

This connector is also used to support the Sysgen Data Key function,

which controls access to menus to enable and disable qube options.

The pinouts for this connector are as follows:

Table 2-6 Pinout for Serial Port

Pin # Function Image

PIN 1 CD

PIN 2 RXD

PIN 3 TXD

PIN 4 DTR

PIN 5 RTN

PIN 6 DSR

PIN 7 RTS

PIN 8 CTS

PIN 9 NC

www.spacelabshealthcare.com

2-7

Page 32

91390

QUBE

S ETUP

USB Connectors (4 for option A,

2 for options B and C)

Port A Top PIN A1 A: VBUS (+5V)

Port B Bottom PIN B1 B: VBUS (+5V)

10/100BASE-T Ethernet

Connector - RJ 45

There are two dual USB type-A connectors which allow connection

of up to 4 USB devices. The type of USB devices supported are

limited to keyboards, mice, barcode readers, and USB flash drives.

Ports are compatible with USB 2.0. The pinouts for these connectors

are as follows:

Table 2-7 Pinout USB Connectors

Pin # Function Image

PIN A2 A: DATA-

PIN A3 A: DATA+

PIN A4 A: RTN

PIN B2 B: DATA-

PIN B3 B: DATA+

PIN B4 B: RTN

The 10/100 Base-T Ethernet connector is on the back of the unit. The

Ethernet interface is designed to conform to the IEEE802.3

standard. The monitor is designed to auto-detect and switch

between 10 Base-T and 100 Base-Tx. Pinouts for this connector are

as follows:

Table 2-8 Pinout 10/100 Base-T Ethernet Connector

Pin # Function Image

PIN 1 TD +

PIN 2 TD -

PIN 3 RD+

PIN 4 TCT (+3.3 VDC)

PIN 5 RCT

PIN 6 RD-

PIN 7 N/C

PIN 8 CHS

2-8

www.spacelabshealthcare.com

Page 33

91390 QUBE

Power LED

Battery Status LED

Alarms

S ETUP

The monitor has a recessed momentary push-button switch on the

right side to toggle the unit between ON and OFF. To turn OFF the

monitor, hold the On/Off switch for three seconds. When you power

off the monitor, it also turns the power off to all devices drawing

power from the monitor, such as keyboards, mice, barcode readers,

Flexports, Pod interfaces, and printers.

If you switch the power off, it does not stop the charging of

batteries when connected to mains. Refer to Battery charger and

AC/DC power indicators on page 1-11 for details.

Refer to To change batteries without interruptions while operating

on battery power on page 1-15 for details.

For information on alarms configuration and alarm tones, refer to

the XPREZZON™ and qube™ System Administration Manual.

Cables

Maximum Cable Lengths

The list of cables that follow are limited to the indicated maximum

length:

• SDLC Cable — 40 feet (12.2 m) maximum (total length from the

monitor to the last device on the bus). For longer SDLC cable

runs, contact your local customer service representative.

• DVI-D Video Cable — 16 feet without a repeater. For distances

greater than 16 feet, a repeater may be required in order to

guarantee signal quality.

• Ethernet cable (10/100BaseT) — 328 feet (100 m) maximum.

SDLC External Devices

External devices (for example, Flexport® system interfaces) can be

connected to the SDLC bus. In this context, the term external means

connected to the SDLC bus by cable through an external connector.

This is in contrast to modules, which are connected by inserting

them into a module housing.

www.spacelabshealthcare.com

2-9

Page 34

91390

QUBE

S ETUP

Warning:

Unreliable system operation will occur if the SDLC bus is not correctly

terminated or the maximum cable length is exceeded. Flexport interfaces

must be attached to the most distal module housing on the SDLC bus.

Figure 2-2 Qube Option A Connected to the 90499 Module Housing

Figure 2-3 Qube Option B Connected to the 90499 Module Housing

2-10

www.spacelabshealthcare.com

Page 35

91390 QUBE

S ETUP

Figure 2-4 Qube Option C Connected to the 90499 Module Housing

If no supplementary module housings are present (not including the

module slot on the monitor), then directly connect external devices

to the SDLC connector on the monitor (refer to Figure 2-5, Figure 2-

6, or Figure 2-7 depending on your monitor option).

www.spacelabshealthcare.com

Figure 2-5 Qube Option A Connected Directly to Flexports

2-11

Page 36

91390

QUBE

S ETUP

Figure 2-6 Qube Option B Connected Directly to Flexports

2-12

Figure 2-7 Qube Option C Connected Directly to Flexports

If one or more supplementary module housings are present, Flexport

devices are connected to connector J2 on the 90499

supplementary module housings. Refer to the

Module Housing Service Manual (P/N 070-0680-xx) for more

information.

www.spacelabshealthcare.com

Page 37

91390 QUBE

S ETUP

If multiple module housings are present, external devices must be

connected to the last module housing in the daisy-chain (the

housing electrically farthest from the monitor on the SDLC bus).

Even though multiple connectors can be available, only the SDLC

connector on the most distal module housing can be used for

connecting external devices. Do not use more than a single Flexport

connector, regardless of how many module housings are present

(refer to Figure 2-8, Figure 2-9, or Figure 2-10 depending on your

monitor option).

If you install multiple Flexport interfaces, they must be daisychained using the T-cable supplied with those devices. Up to three

Flexport interfaces can be connected in this way (refer to Figure 2-

8, Figure 2-9, or Figure 2-10 depending on your monitor option).

www.spacelabshealthcare.com

Figure 2-8 qube option A connected to 90499 module housing and

Flexports

2-13

Page 38

91390

QUBE

S ETUP

Figure 2-9 Qube Option B Connected to 90499 Module Housing and

Flexports

2-14

Figure 2-10 Qube Option C Connected to 90499 Module Housing

and Flexports

www.spacelabshealthcare.com

Page 39

91390 QUBE

Non-terminated Terminate

SDLC Cable Interconnection

To ensure Electromagnetic interference (EMI) compliance, the

appropriate Spacelabs Healthcare 9-pin connector must be used.

Refer to the Module Housing Service Manual (P/N 070-0680-xx).

SDLC Bus Termination

The SDLC bus must be properly terminated for correct operation. If

no external devices (for example, Flexports or multigas analyzers)

are connected, proper termination of the SDLC bus is accomplished

automatically. If external devices are connected, the switch on the

module housing farthest from the monitor must be set to the

terminated ( ) position. All others must be set to the nonterminated ( ) position. The SDLC clock and data signals are

switched by the terminator switches and are not present

“downstream” of any switch set to the position.

S ETUP

Because bus termination is handled by setting the switches

appropriately, an external terminator is only required when external

devices are connected.

If external devices are connected, an external cable terminator is

required to terminate the SDLC bus. This must be installed at the

end of the SDLC bus (following the last external device). In this case,

all module housings must have their switches in the position.

Note:

Flexports require a powered Flexport cable (P/N 012-0555-00)

when used with the 90499 module housing. SDLC data is only

passed along to the external device or devices when the

terminator switch (SW2) is in the position.

Alarm Relay for option A

Alarm output signals are available at the Nurse Alert ( )

connector instantaneously when an alarm occurs. Table 2-3

describes the connector pinouts for remote alarms. Figure 2-12 on

page 2-16, Figure 2-13 on page 2-16, and Figure 2-14 on page 2-17

illustrate the circuits for each alarm function.

Figure 2-11 Terminator switch settings

www.spacelabshealthcare.com

2-15

Page 40

91390

ALMON

+12 V

+5 V

relay

1

2

3

4

8

10

9

common

NC

NO

140

μA

Relay maximum ratings:

28 V AC/DC

0.25 A

11

GND

GND

GND

GND

ALMON

+12 V

+5 V

relay

7

5

6

4

8

10

9

common

NC

NO

140

μA

Relay maximum ratings:

28 V AC/DC

0.25 A

11

GND

GND

GND

GND

QUBE

S ETUP

Warning:

Data interface connectors on this device are Ground (Earth) referenced!

• Only connect this device to other medical equipment suitable for use

in the Patient Vicinity.

• Check Ground (Earth) Leakage after connecting data interface cables.

Warning:

For operational safety and reliability, the following relay contact ratings

MUST NOT BE EXCEEDED:

•Current = 250ma

• Voltage = 28 V AC/DC

2-16

Figure 2-12 Alarm 0 (High Priority) Relay Schematic

Figure 2-13 Alarm 1 (Medium Priority) Relay Schematic

www.spacelabshealthcare.com

Page 41

91390 QUBE

ALMON

+12 V

+5 V

relay

13

14

12

4

8

10

9

common

NC

NO

140

μA

Relay maximum ratings:

28 V AC/DC

0.25 A

11

GND

GND

GND

GND

Power-ON Test

S ETUP

Figure 2-14 Alarm 2 (Low Priority) Relay Schematic

Each time the monitor is powered ON:

• Diagnostic information displays for approximately 17 seconds.

• Monitor keys display on the right side of the screen.

The monitor is now ready for normal operation.

Configure the Monitor

Privileged Access Menus

The Privileged Access button in the Monitor Setup window

provides access to several levels of configuration. These

configuration levels are described in the sections of the XPREZZON

and qube System Administration Manual.

Refer to XPREZZON and qube System Administration Manual (P/N

070-2380-xx) for the Clinical and Biomed Level menu structure.

www.spacelabshealthcare.com

2-17

Page 42

91390

QUBE

S ETUP

2-18

www.spacelabshealthcare.com

Page 43

91390 QUBE

MPC8270 CPU

SCC2

SDLC

PFAIL

CPU PCBA

670-1573-xx

E-NET

Controller/

Transceiver

E-NET

SMC1

SCC3

5-WIRE RESISTIVE

TOUCHSCREEN

CONTROLLER

DRIVERS

+3V

TOUCHSCREEN

P341

ALARM

CONTROL

EXT. ALARM RELAYS

F440 (0.35A)

PCI

ALARM 2

ALARM 1

ALARM 0

SERIAL PORT

SMC2

PCI SUBSYSTEM

32-BIT

I2C

I2C BUS

I/O

LOGIC-LEVEL

DRIVERS

J941

YELLOW

RED

CYAN

RS232 XCVR

ETHERNET

PWR_RX_TX

TO LCD/ BEZZEL ASSY

RC RX/TX

INTERNAL NURSE ALERT

+12V

GND

ENB

+3.3V

SPI

MISC I/O

J1

EXT NURSE

ALERT

I2C BUS

DOCKED*

64-BIT

32 MB

FLASH ROM

64 MB

SDRAM

2 MB SRAM

(GDS)

SUPERCAP

BATTERY

BACKUP

+3V

CPU CORE

VOLTAGE REG

+3.3V

+1.2V

Local Bus

Local

Bus

128 x 8 MB

NV RAM / RTC

ETHERNET

USB (7-PORT HUB)

I2C BUS

I2C BUS

FPGA PGM

SPI BUS

TO LCD/ BEZZEL ASSY

DOCKED*

SDLC

+1.5V

+1.8V

SDLC TO INTERCONNECT PCBA

-12V

+3.3V

+5V

+12V

+18V

FROM POWER SUPPLY

“ALWAYS ON” CPU

TO SYSTEM

FAILURE ALARM

WD_MAIN

TO/FROM

MON-DOCK PCBA

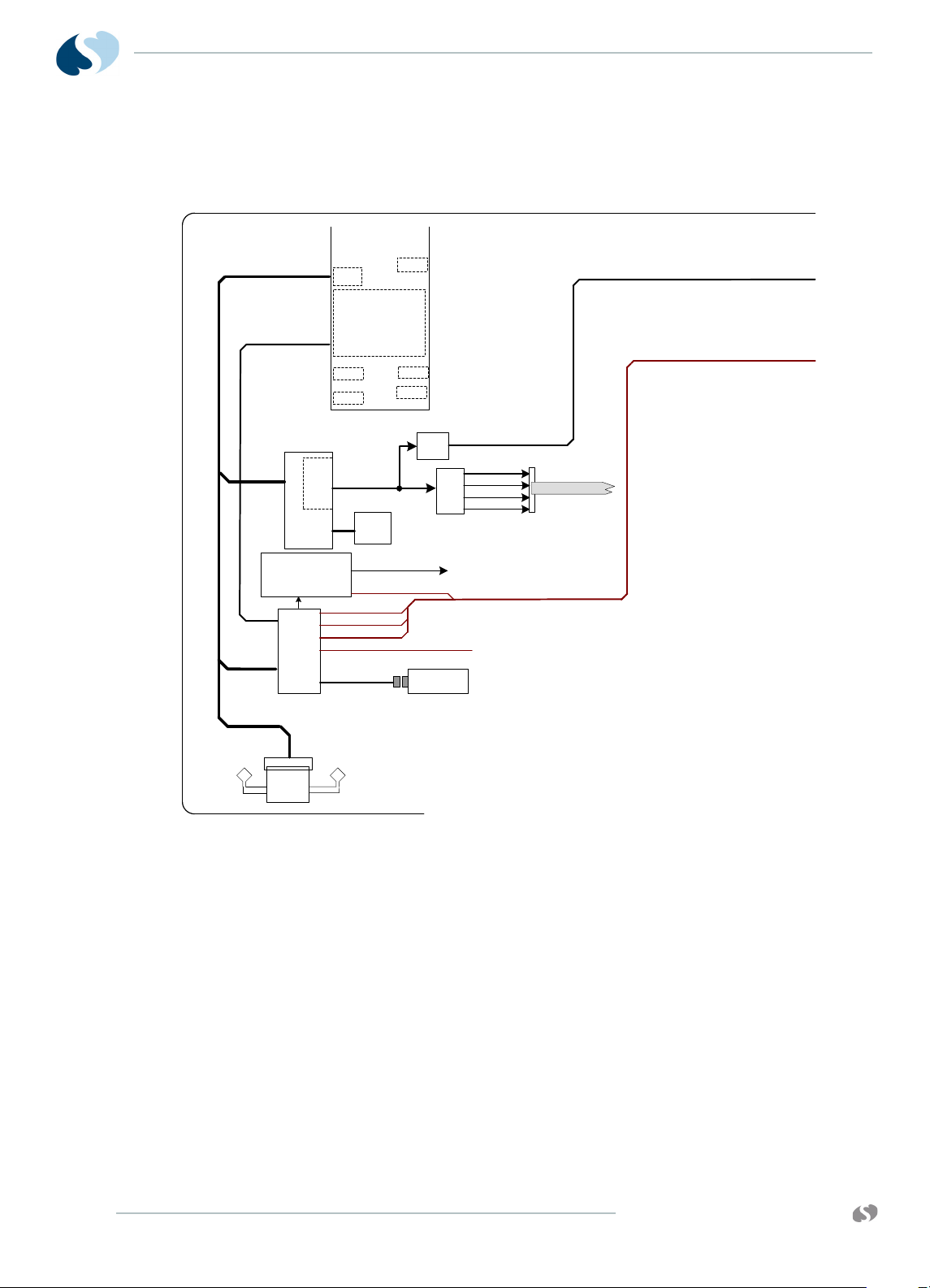

Theory

CPU PCB

The CPU PCB combines the CPU core, power supplies, Li-Ion battery

charger, touchscreen interface, USB subsystem, ATI ES1000

graphics processor and all other I/O interfaces (refer to Figure 3-1

on page 3-1). The Freescale MPC8270 running vxWorks Real Time

Operating System (RTOS) interfaces via 64-bit local bus to Flash,

SDRAM, SRAM, and Non-Volatile Memory (NVRAM). The application

code is stored in FLASH and loaded into SDRAM at run time.

NVRAM is used to store monitor configuration data and backed up

by an internal battery in the IC and also provides a real-time clock

function.

www.spacelabshealthcare.com

Figure 3-1 CPU Core Processing

3-1

Page 44

91390

P/O CPU

PCBA

670-1573-xx

SMC1

SCC3

PCI

SMC2

PCI SUBSYSTEM

32-BIT

I2C

I/O

PCI BUS

IEEE

802.11a/b/g

WIRELESS

J641

SPI

MISC I/O

Antenna

Antenna

USB FLASH

DRIVE PCBA

USB Host

Controller

P1

USB 1-2 VBUS

USB (FLASH DRIVE)

USB 2

USB (RECORDER)

USB (TO 7-PORT HUB)

USB 1

MISC I/O

USB POWER

ON/OFF &

OVER- CURRENT SENSE

USB RECODER VBUS

J261

12" TFT LCD DISPLAY

ATI ES1000

GRAPHICS

PROCESSOR

24-BIT DIGITAL

VIDEO OUT

64MB

VIDEO

SDRAM

VIDEO SIGNALS

DVI

TMDS

24-BIT DIGITAL VIDEO

LVDS

EXTERNAL VIDEO (DIGITAL)

PCI BUS

PCI BUS

USB 1-2, USB 1-2 VBUS, USB (TO 7-PORT HUB)

RED SERIAL

BLUE SERIAL

GREEN SERIAL

CONTROL

TO LCD/ BEZZEL ASSY

TO J5 (INTERCONNECT PCBA)

TO J5 (INTERCONNECT PCBA)

TO/FROM

MON-DOCK PCBA

USB 1-2, USB 1-2 VBUS, USB (TO 7-PORT HUB)

EXTERNAL VIDEO (DIGITAL)

P/O CPU

QUBE

T HEORY

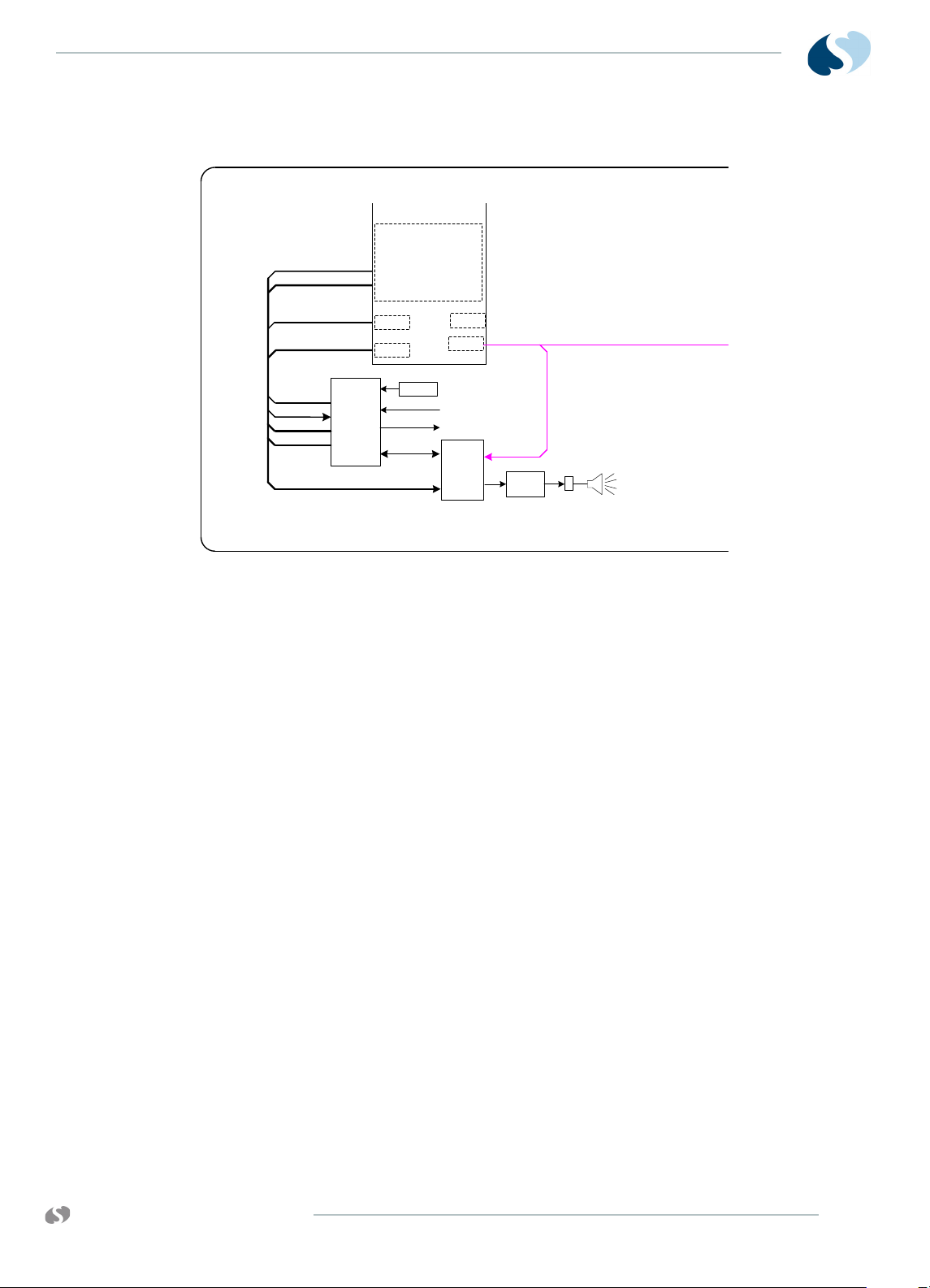

A PCI bus is used to communicate to the ATI / ES1000 GPU, USB

host controller, and optional wireless card (refer to Figure 3-2 on

page 3-2).

The USB host controller has 5 USB ports and interfaces to:

• USB port 1 - USB Flash Drive

• USB port 2.3 - becomes external USB1, USB2

• USB port 4 - drives USB Hub on Mon-Dock PCBA

• USB port 5 - drives recorder.

If replacement is ever required, an internal flash drive provides bulk

memory and has special formatting requirements.

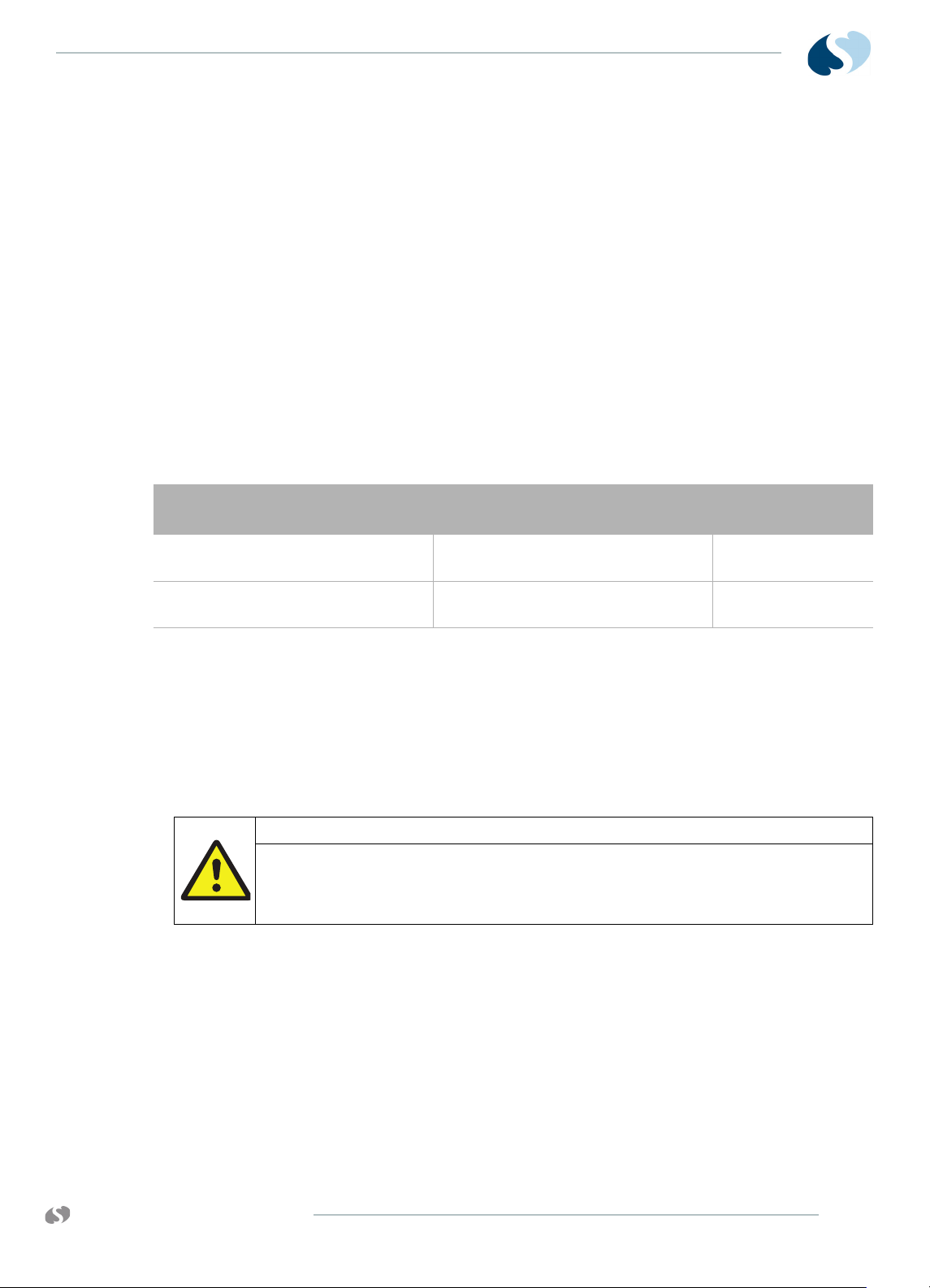

An on-board FPGA is used for SDLC Clock generation, and audio

clocks 11.3541 MHz (+/-1%). It is also used for SPI to I2S serial bus

conversion to interface the MPC8270 to the audio codec. The FPGA

is also responsible for decoding the IR remote control signals when

used with the 90360-01 remote control.

Figure 3-2 PCI Subsystem

3-2

www.spacelabshealthcare.com

Page 45

91390 QUBE

P/O CPU

PCBA

670-1573-xx

SMC1

SMC2

I2C

I2C BUS

I/O

RC RX/TX

SPI

MISC I/O

AUDIO

CODEC

AUDIO

AMP

P070

FPGA

PLD

SPI BUS

11.4MHz

Clock

RKEY

CONTROL

I2C BUS

FPGA PGM

RC RX/TX

MISC I/O

MISC I/O

FPGA PGM

SPI BUS

FROM J50

SDLC CLOCK

TO SDLC SECTION OF CPU

MAIN

SPKR

TO/FROM

MON-DOCK PCBA

P/O CPU

T HEORY

Figure 3-3 FPGA Subsystem

www.spacelabshealthcare.com

3-3

Page 46

91390

P/O CPU

PCBA

670-1573-xx

BACKLIGHT

J40

J9

INPUT

SELECT

DC_IN

BATT A

BATT B

3.3VAO

“ALWAYS

ON”

BATTERY

CHARGER

CPU

“ALWAYS ON”

CPU

CONTROL

BAT1_CH_LED

MAINS_LED

PWR_ON_LED

SW_PWR

RKEY

FP LEDs & IR

J50

BAT2_CH_LED

+3.3VAO

FET

SWITCHES

CH_LED2

CH_LED1

+3.3V

DC_IN

+18V BOOST

+5V / +3.3V

BUCK

-12V INVERT

+12V/+12V_REC

BUCK-BOOST

+5V

EN_3V

EN_5V

EN_18V

EN_12V

VCOM

EN_INV

+18V

+3.3V

-12V

+12VREC

+12V

EN_18V

EN_5V

EN_3V

EN_INV

EN_12V

VCOM

FAN

VCOM

FAN_CTL

VCOM

VCOM

VCOM

VCOM

+12V

+3.3VAO

J8

FAN_CTL

BL_PWM

+12V

BL_PWM

+5V

TO LCD/ BEZZEL A SSY

TO FPGA PLD

TO LCD/ BEZZEL A SSY

+3.3VAO

+3.3VAO

DC_IN

DC_IN

PWR_RX_TX

TO

MAIN

CPU

ANY_PWR_IN

TO SYSTEM

FAILURE ALARM

PFAIL

WD_PWR

TO SYSTEM

FAILURE ALARM

TO/FROM

MON-DOCK PCBA

BATTERY BBATTERY A

J9

P401 P402

BATTERY CONNECTOR PCB A

670-1555-xx

WD_PWR

WD_MAIN

SYSTEM FAILURE ALARM

ANY_PWR_IN

FROM MAIN CPU

FROM P.S. “ALWAYS ON” CPU

PIEZOELECTRIC

BUZZER

FET

+5v

REG

ONE-

SHOT

ONE-

SHOT

SUPERCAP

V_ALARM

DUALFREQUENCY

OSCILLATOR

670-1573-03 and later

CPU PCBA only

QUBE

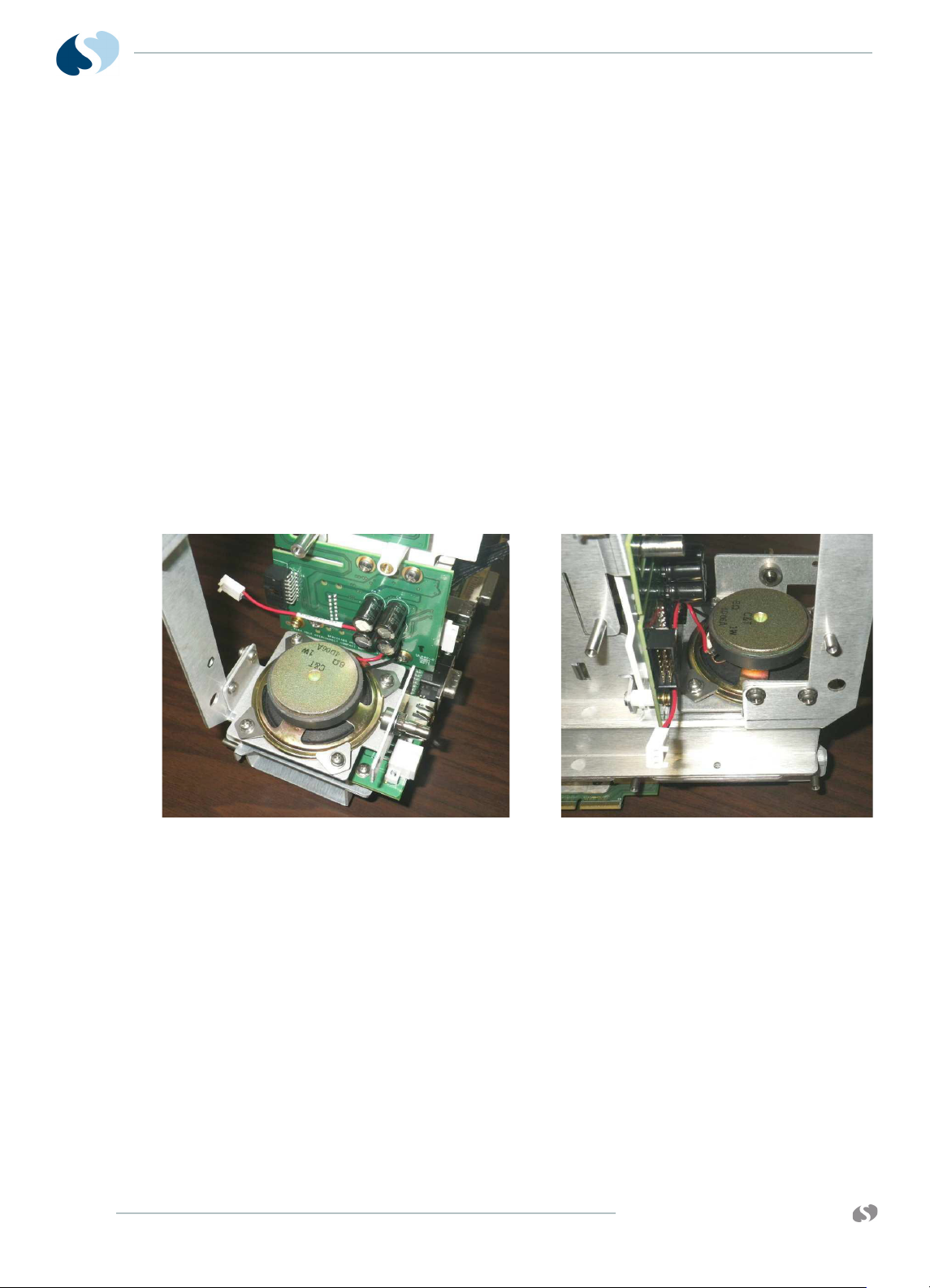

Battery Charger and Power Supply Subsection (on CPU PCB)

T HEORY

3-4

Figure 3-4 Power Supply Subsystem

The Power Supply and Battery Charger subsystem (refer to

Figure 3-4) consists of several subsystems:

• Always On (AO) MCU that provides ON/OFF control

• Battery management / charging control

• Voltage monitoring

• PWM for backlight

• Power sequencing

• Unit shutdown warning (PFAIL)

• Internal temperature monitoring

• Control of +12V, +5V, +3.3V, -12V power supplies

To show and monitor the supply voltages, open the Biomed menu,

click the System Info tab, then select the Analog key. If out of range

conditions are presented, voltages are checked at power-on, and

during run time and events are logged.

www.spacelabshealthcare.com

Page 47

91390 QUBE

T HEORY

The LTC1960 battery charger IC interfaces with the AO MCU. It is

responsible for load switching between AC and battery or batteries,

and direct communication via SMBUS protocol to the Li-Ion smart

batteries. The IC is also responsible for charging the batteries. Refer

to the battery section for more information on batteries.

For 670-1573-03 CPU PCBAs and higher, a high priority technical

alarm has been added. The AO MCU triggers a technical alarm in the

following events:

• Out of tolerance voltages on the +3.3V, +5V, +12V, and -12V

supplies

• No host CPU MPC8270 response

• If the AO MCU also fails to update the watchdog circuit

The technical alarm is a redundant alarming circuit that does not use

the main CPU audio. This circuit can derive power from the external

power supply, battery, or supercap incorporated in the circuit. The

safety circuit sounds if: the unit is unplugged from AC and no

battery is present, or if the unit is operating on battery and the

battery is depleted.

Li-Ion Batteries

If either the charger or host device fails to function correctly,

electronic circuitry is permanently connected within the battery

pack to prevent damage. If an illegal current source is placed across

the battery terminals or an illegal load is connected, the circuitry

also protects the battery. Redundant levels of protection have been

implemented (the primary protection levels are auto-resettable and

the secondary are non-resettable).

If any cell voltage >=4300 µV, the primary protection circuit

prevents the battery from charging. It allows charging again once all

cell voltages are <=4150 µV. If any cell voltage >=4.45 V +/-0.05 V

by blowing a power path logic fuse, the secondary protection circuit

prevents the battery from charging. The fuse is non-resettable,

which renders the battery pack nonfunctional.

The primary protection circuit also provides over-temperature

protection and prevents the battery from charging at temperatures

=>54º C. Then, once the battery temperature has cooled to <=45º C,

it again allows charging.

The primary protection circuit also provides continuous over-current

protection and prevents the battery from charging at Current()

=>4.25 A. Then, once the Average Current() <= 200 µA for 70 sec,

the battery will retest the overcurrent condition, and again allow

charging.

www.spacelabshealthcare.com

The primary protection circuit prevents the battery from being

further discharged once any cell voltage reaches <=2500 µV. Then,

once all cell voltages are >= 3000 µV, it allows discharge again.

3-5

Page 48

91390

QUBE

T HEORY

The primary protection circuit also provides over-temperature

protection and prevents the battery from discharging at

temperatures =>75º C. Then, once the battery temperature has

cooled to <=65º C, it allows discharging again. If the battery reaches

85º C for any reason, the secondary protection circuit blows the

in-line power path logic fuse. The fuse is non-resettable, which

renders the battery pack nonfunctional.

The primary protection circuit also provides continuous over-current

protection and prevents the battery from discharging at Current()

<= -6.25 A. Then, Once the Average Current() >= -200 µA for 70 sec,

the battery will retest the overcurrent condition, and again allow

discharging.

If a short-circuit is placed across the battery + / - terminals, the