Page 1

BleaseSirius

Anesthetic Machine

Technical Manual

073-0227-00/REV. D

1

Page 2

2

Page 3

BleaseSirius

Anesthetic Machine

With 700/900 Series Ventilators

Technical

Manual

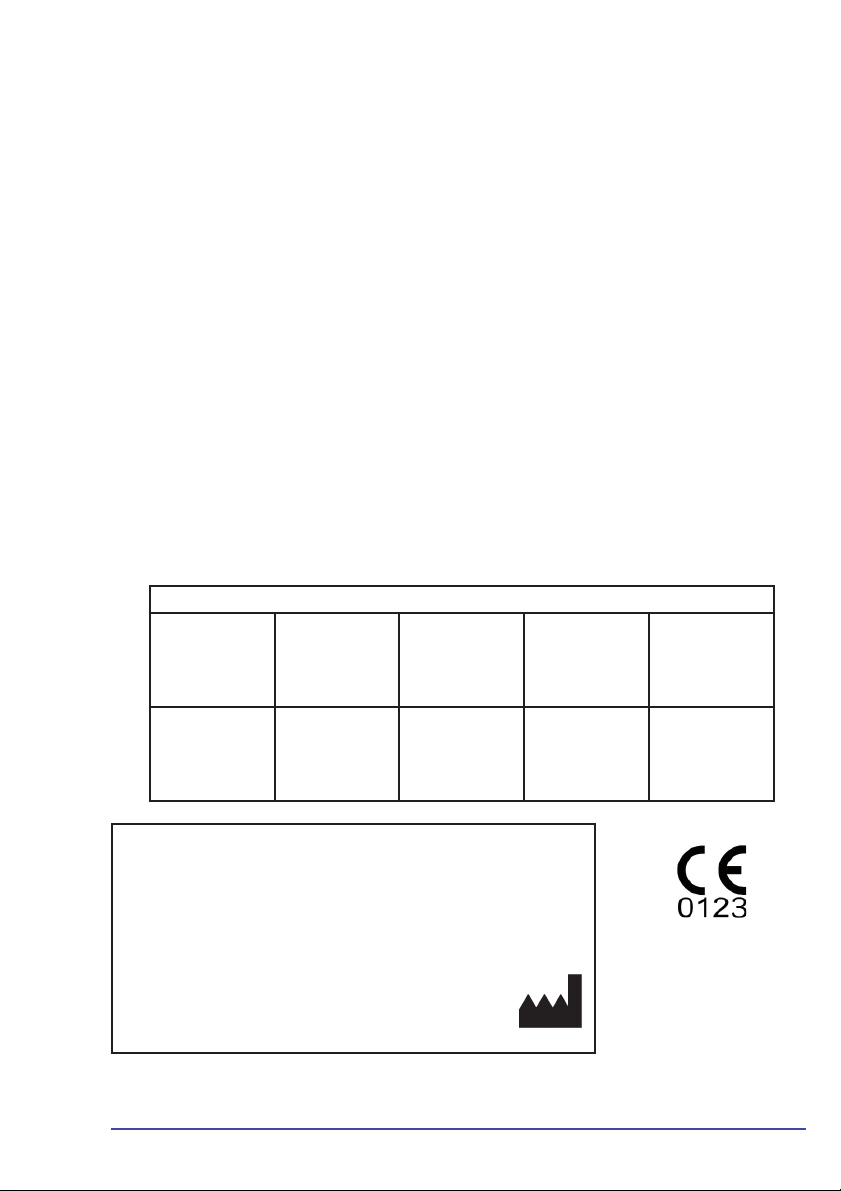

MODIFICATIONS LABEL

ECO A

REV B

REV C

REV D

REV E

PR023288

REV F REV G REV H REV I REV J

Spacelabs Healthcare Ltd.

1 Harforde Court • John Tate Road • Hertford

SG13 7NW • United Kingdom

Tel: +44 (0)1992 507700

Fax: +44 (0)1992 501213

e-mail (enquiries): advsales@spacelabs.com

e-mail (technical): advsupport@spacelabs.com

www.spacelabshealthcare.com

PR032030

PR033225

PR034475

Part Number: 073-227-00

Rev. D/ July 2013

3

Page 4

4

Page 5

Important

Read this manual before operating or servicing the machine.

For all users and Service Personnel, refer to the User Manual before operating

the machine.

© Copyright 2013, Spacelabs Healthcare Limited.

All rights reserved. The information contained in this publication may not be

used for any other purpose than that for which it was originally supplied.

This publication may not be reproduced in part or in whole without the written

consent of Spacelabs Healthcare.

5

Page 6

This page is intentionally left blank

6

Page 7

Contents

Chapter 1-Technical Description ............................................................... 19

1.1 Description .........................................................................................................21

1.1.1 General ................................................................................................21

1.1.2 The Frame ............................................................................................21

1.1.3 Pneumatic Assembly ............................................................................21

1.1.4 The Monitor Shelf .................................................................................21

1.2 Specifi cation ......................................................................................................24

1.2.1 Machine Dimension..............................................................................24

1.2.2 Work Surface Dimensions ....................................................................24

1.2.3 Monitor Shelf Dimensions ....................................................................24

1.2.4 Maximum Loading ................................................................................24

1.3 Pneumatics ........................................................................................................25

1.3.1 Gas-Specifi c Color Specifi cations ........................................................25

1.3.2 Gas Supply Combinations....................................................................25

1.3.3 Common Gas Outlet ............................................................................25

1.4 Technical/Performance Specifi cation ..............................................................26

1.4.1 Controls ................................................................................................26

1.4.2 Ventilator ..............................................................................................26

1.4.3 Alarms / Indicators ...............................................................................26

1.4.4 Regulator Safety Valve Settings ...........................................................26

1.4.5 Electrical ...............................................................................................27

1.4.6 Supplies ...............................................................................................28

1.4.7 Environmental ......................................................................................28

Chapter 2-Overview .................................................................................... 29

2.1 Description of the Ventilator ...........................................................................31

2.1.1 Overview ..............................................................................................31

2.1.1.1 PEEP ...................................................................................................31

2.1.1.2 Trigger .................................................................................................32

2.1.1.3 Support Pressure .................................................................................32

2.1.1.4 Fresh Gas Compensation ....................................................................32

7

Page 8

Contents

2.1.1.5 Oxygen ................................................................................................32

2.1.1.6 Tidal Volume ........................................................................................32

2.1.1.7 Minute Volume .....................................................................................32

2.1.1.8 Expired Tidal volume ...........................................................................32

2.1.1.9 BPM (Frequency Control) ....................................................................32

2.1.1.10 I:E Ratio ...............................................................................................33

2.1.1.11 Pressure Limit ......................................................................................33

2.1.1.12 Peak Pressure .....................................................................................33

2.1.1.13 Mean Pressure ....................................................................................33

2.1.1.14 Compliance ..........................................................................................33

2.1.1.15 Volume Measurement ..........................................................................33

2.1.1.16 Oxygen Measurement .........................................................................33

2.2 Pre-use Test .......................................................................................................34

2.2.1 Fresh Gas ............................................................................................34

2.2.2 Compliance ..........................................................................................34

2.2.3 Compensation ......................................................................................36

2.2.4 Mode Dependant Features ..................................................................37

2.3 Principles of Operation .....................................................................................41

Chapter 3-Planned Maintenance ............................................................... 43

3.1 Planned Maintenance ........................................................................................45

3.2 Routine Maintenance and Service Check. ......................................................48

3.2.1 Fitting Planned Maintenance Kit PN 14000511 ....................................48

3.2.2 Bodoc Seals .........................................................................................48

3.2.3 Backbar Seals ......................................................................................48

3.2.4 Backbar Dzus Springs..........................................................................48

3.2.5 Absorber Stop/’O’ Ring ........................................................................48

3.2.6 Pipeline Fitting and ‘O’ Ring .................................................................48

3.3 AGSS Probe and Float for Spacelabs AGSS

PN 14200018, (if Fitted) ......................................................................50

3.4 Bellows Base/Canister ......................................................................................51

3.5 Pop-off Valve ......................................................................................................51

8

Page 9

Contents

3.6 Absorber .............................................................................................................53

3.6.1 Valve Covers ........................................................................................53

3.6.2 Manometer ...........................................................................................53

3.6.3 Canister Seals ......................................................................................53

3.6.4 Fitting 4 Year Planned Maintenance Kit, PN 14000512 .......................54

3.6.5 Ventilator Filter ....................................................................................54

3.6.5.1 Two Valve Version Only (on units before Feb 2009) ............................54

3.6.5.1 Valve Block on units after Feb 2009 ........................................................54

3.6.6 Cylinder Regulator Pressure Relief Valve, PN 019-0831-00 ................55

3.7 CLEANING ......................................................................................................56

Chapter 4-System Checks ......................................................................... 59

4.1 Overview.............................................................................................................61

4.2 Tools and Test Equipment Required ...............................................................61

Parts Required........................................................................................................62

4.3 Visual Inspection ...............................................................................................65

4.4 Pipeline Leak Test .............................................................................................66

4.5 Cylinder Leak Test .............................................................................................68

4.6 Regulator Output Test .......................................................................................68

4.7 On/Off Switch Gas Cut Off Test .......................................................................70

4.8 Oxygen Supply Failure Test .............................................................................70

4.9 High Pressure Outlet Test .................................................................................71

4.9.1 Parts required ...............................................................................................71

4.10 Hypoxic Guard and Flow Control Accuracy Tests .......................................72

4.11 Backbar Tests ..................................................................................................74

4.11.1 Pressure Build-up Test ................................................................................74

4.11.2 T1 Backbar Test ..........................................................................................75

4.11.3 T2 Backbar test ............................................................................................76

4.12 Common Gas Outlet (CGO) Test ....................................................................77

4.12.1 Oxygen Flush Test ......................................................................................77

4.12.2 Pressure Relief Valve Test ..........................................................................77

9

Page 10

Contents

4.13 Suction System Test .......................................................................................78

4.14 Absorber Tests.................................................................................................79

4.14.1 Expiratory Valve Leak Test .........................................................................79

4.14.2 Inspiratory Valve Leak Test .........................................................................80

4.14.3 APL Valve Check ........................................................................................81

4.15 Ventilator Test ..................................................................................................83

4.16 Vaporizer Output Concentration Check ........................................................89

4.17 Electrical Safety Test .......................................................................................91

4.18 Complete the BleaseSirius Checkout Sheet .................................................92

Chapter 5-Detailed Repair Procedures ..................................................... 93

5.1 Removal/Replacement Instructions.................................................................95

5.1.1 Removal of Outer Cases (on units up to Jan 2009) .............................95

5.1.2 Removal of Outer Cases (on units after Jan 2009) .............................97

5.2 Mechanical Hypoxic Guard Block ..................................................................103

5.2.1 Introduction ........................................................................................103

5.2.2 Flow Meter Removal...................................................................................104

5.2.3 Replacement of Hypoxic Guard Block (FR135025) ...........................107

5.2.4 Calibration of Hypoxic Guard System ................................................108

5.2.5 Calibration procedure .........................................................................109

5.3 Setting Oxygen Basal Flow ............................................................................110

5.4 Nitrous Oxide and Air Flow Valve Leak Test ................................................. 111

5.5 Mechanical Hypoxic Guard Regulators, Adjustment and Output Check ... 115

5.5.1 Hypoxic Regulator Replacement (for units manufactured before Feb

2009) .................................................................................................. 117

5.6 Cylinder Regulator Pressure Relief Valve Replacement ...............................122

Replace the Cylinder Regulators.......................................................................123

5.7 Backbar Valve Replacement ...........................................................................129

5.8 Common Gas Outlet (CGO) Removal/Replacement (up to Feb 2009) ........130

5.9 Alarm Block Removal/Replacement ..............................................................131

5.9.1 On units Manufactured Before Feb 2009 ...........................................131

10

Page 11

Contents

5.9.2 On units Manufactured After Feb 2009Feb 2009 onwards) ...............132

5.10 Oxygen Flush & Common Gas Outlet Safety Valve Adjustment

(up to Feb 2009) ................................................................................133

5.10.1 Oxygen Flush Adjustment on units sold before July 2010

(Units sold after July 2010 are not adjustable.) ..................................134

5.10.2 Common Gas Outlet (CGO) Removal/ Replacement

(From Feb 2009 onward) ...................................................................135

5.11 ON/OFF Switch (PN FR142028) ...................................................................140

5.10.1 Test Procedure for Microswitches .............................................................145

5.12 Absorber .........................................................................................................146

5.12.1 General ..............................................................................................146

5.12.2 Absorber Interface Manifold Assembly...............................................150

5.12.3 Absorber Alignment ............................................................................151

5.12.4 Standby / Run ....................................................................................151

5.12.5 Absorber Docking...............................................................................152

5.12.6 Setting Ball Catch...............................................................................153

5.13 Internal Absorber ...........................................................................................155

5.13.1 Bellows Interface Gasket ...................................................................158

5.14 Servicing the Bag Arm ..................................................................................159

5.15 Drawer Removal/Replacement .....................................................................164

5.16 Braking System Maintenance.......................................................................167

5.17 Castors Maintenance ....................................................................................168

5.18 Suction Controller Removal/Replacement ..................................................169

5.19 Ventilator ........................................................................................................172

5.19.1 Inspiratory Block Assembly ................................................................172

5.198.2 Ventilator Internal System ..................................................................173

5.19.2.1 Replacement of Major Components .................................................173

5.19.3 Removal of Inspiratory Block (FR137025) .........................................174

5.19.4 Removal of BAV Controller (FR101027) ............................................177

5.19.5 Removal of BAV Power Supply (FR136029) ......................................178

5.19.6 Removal of Front Panel (FR101026) .................................................179

5.19.7 Removal of the Screen (FR812025) ..................................................181

11

Page 12

Contents

5.19.8 Removal of Switch Mode Power Supply (FR136025) ........................182

5.19.9 Removal of Flow Control Valves (up to March 2009) .........................183

5.19.10 Removal of Gas Inlet Module (FR 140026) (up to March 2009) ........184

5.19.11 Replacement of Battery (80300025) ..................................................185

5.19.12 Exchanging of Fuses (EF533789)......................................................186

5.20 Major Component Installation ......................................................................187

5.21 Set up Options ...............................................................................................188

5.22 Fresh Gas Calibration (2) ..............................................................................189

5.23 Absorber fi tted (3) .........................................................................................189

5.24 Sigh (4) 189

5.25 Gas Exhaust (5) .............................................................................................190

5.26 Enable Pre-use Test (6) .................................................................................190

5.27 Touch Calibration (7) .....................................................................................190

5.28 Ventilator Service Mode Passwords ............................................................191

5.28.1 Passwords used in the Service Mode ................................................191

Test Procedure ..................................................................................................199

5.29 Reprogramming .............................................................................................200

5.29.1 Software Upgrade Procedure.............................................................200

5.29.2 To use VentFlash................................................................................201

5.29.3 To upgrade the Language File ...........................................................202

5.29.4 To Upgrade the Ventilator Model ........................................................203

Chapter 6-EFM Option .............................................................................. 205

Chapter 7

Error Codes ................................................................................................ 237

7.1 Error Codes ......................................................................................................239

7.1.1 Error codes on the Blease700/900 series Ventilators ........................239

Chapter 8-Spare Parts .............................................................................. 241

8.1 Parts List ..........................................................................................................243

12

Page 13

Contents

Chapter 9-Notices and Important Information ....................................... 253

9.1 Product Improvement .....................................................................................255

9.2 Responsibilities of the User ...........................................................................255

9.3 Responsibilities of the Manufacturer ............................................................255

9.4 Disclaimer ........................................................................................................256

9.5 Technology Disclaimer / Tamper Proof Seal ................................................256

9.6 Note to Service Personnel ..............................................................................256

9.7 CE Mark 257

9.8 Trademarks and Acknowledgements ............................................................258

9.9 Hazard Notices.................................................................................................259

9.9.1 BleaseSirius Warnings .......................................................................260

9.9.2 Electrostatic Sensitive Devices (ESD) Warnings and Cautions .....262

9.9.3 Cautions .............................................................................................263

9.9.4 Ventilator Warnings ...........................................................................264

9.9.5 Hazard Information.............................................................................265

9.9.6 Cautionary Notices .............................................................................268

9.9.7 Vaporizer Warnings ...........................................................................270

9.9.8 Absorber Warnings ...........................................................................271

9.9.9 Cautionary Notices .............................................................................272

Chapter 10-Schematics ............................................................................ 273

13

Page 14

Figures

Figure 1 - BleaseSirius Anesthetic Machine .............................................................22

Figure 2 - Electrical Labeling ......................................................................................27

Figure 3 - PEEP Diagram ...........................................................................................31

Figure 4 - Ventilator Schematic ..................................................................................38

Figure 5 - Absorber Pneumatic Schematic .................................................................39

Figure 6 - Pneumatic Circuit .......................................................................................40

Figure 7 - BleaseSirius Annual Planned Maintenance Kit

PN 14000511 ......................................................................................46

Figure 8 - BleaseSirius Four Year Planned Maintenance Kit PN 14000512 ..............47

Figure 9 - Pipeline Fitting & ‘O’ Ring...........................................................................49

Figure 10 - AGSS .....................................................................................................50

Figure 11 - Pop-off Valve ............................................................................................51

Figure 12 - Bellows Assembly ....................................................................................52

Figure 13 - Pneumatic Module ...................................................................................54

Figure 14 - Primary Regulator ....................................................................................57

Figure 15 - BleaseSirius Checkout Sheet (PN 073-0301-00 Rev. C) .........................64

Figure 16 - Connect the Pipeline Test Shut-off Valve .................................................66

Figure 17 - N2O Pipeline Gauge .................................................................................67

Figure 18 - Connect Pressure

Measuring Device ...............................................................................69

Figure 19 - Regulator Nut and Set Crew Locations ....................................................69

Figure 20 - Test Hose Assembly .................................................................................71

Figure 21 - Test Hose Connections ............................................................................72

Figure 22 - Connect O2 Analyzer (L) and Tubing to AGSS (R) ...................................73

Figure 23 - Pressure Build-up Test .............................................................................74

Figure 24 - Fit 6 mm Plug ...........................................................................................75

Figure 25 - Steps 5 and 8 ...........................................................................................75

Figure 26 - Step 4: Plug the CGO Taper ....................................................................76

Figure 27 - Steps 6 and 8 ...........................................................................................76

Figure 28 - O2 Flush Test ............................................................................................77

Figure 29 - Connect Pressure Measuring Device.......................................................77

Figure 30 - Suction Gauge and Bowl..........................................................................78

Figure 31 - Expiratory Valve Test Setup .....................................................................79

Figure 32 - Setup for Inspiratory Valve Test ...............................................................80

Figure 33 - Steps 3 & 4 of the Inspiratory Valve Test .................................................81

Figure 34 - Connect a Pressure Measuring Device....................................................81

Figure 35 - Connect the Pressure Sampling Tee .......................................................82

Figure 36 - Step 5: Occlude the Bag Port...................................................................82

Figure 37 - Exhaust Port Location ..............................................................................83

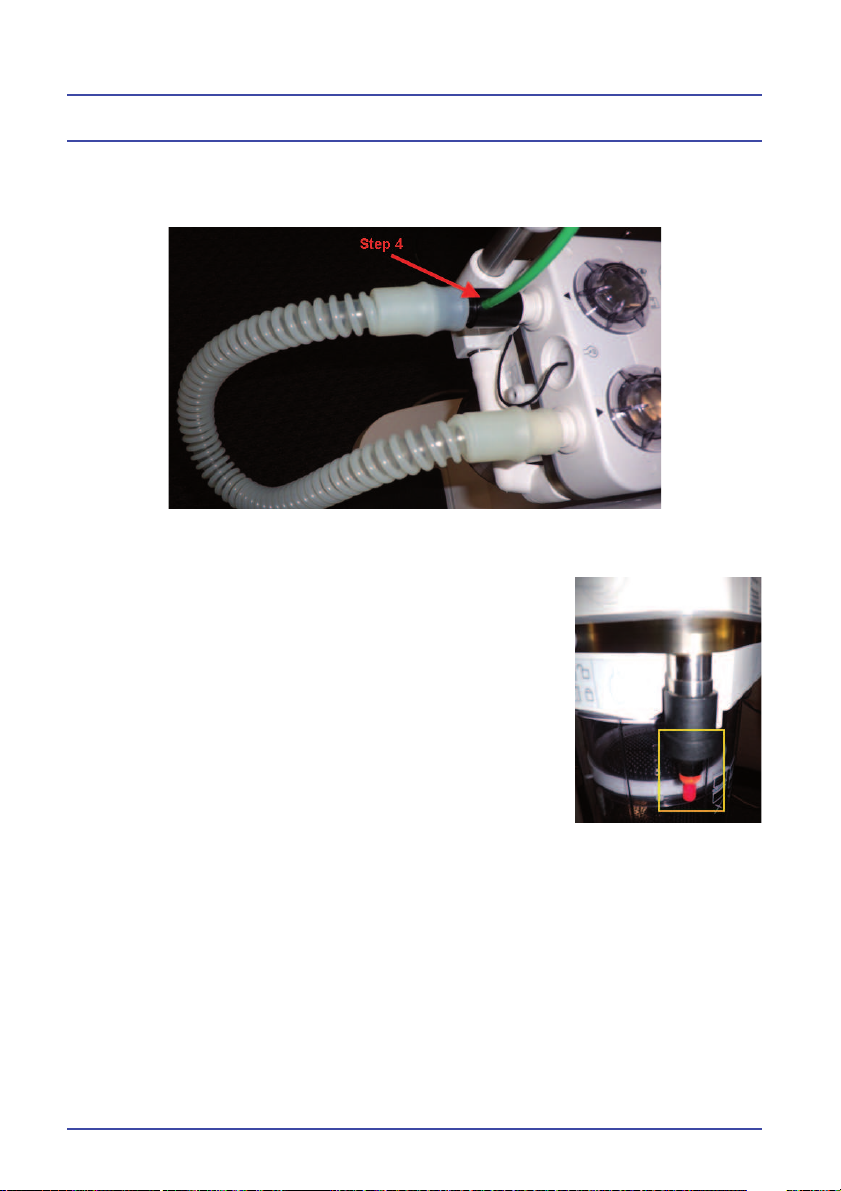

Figure 38 - Step 11: Disconnect Patient Hose ............................................................84

14

Page 15

Figures

Figure 39 - Connect a Flow Measuring Device ..........................................................84

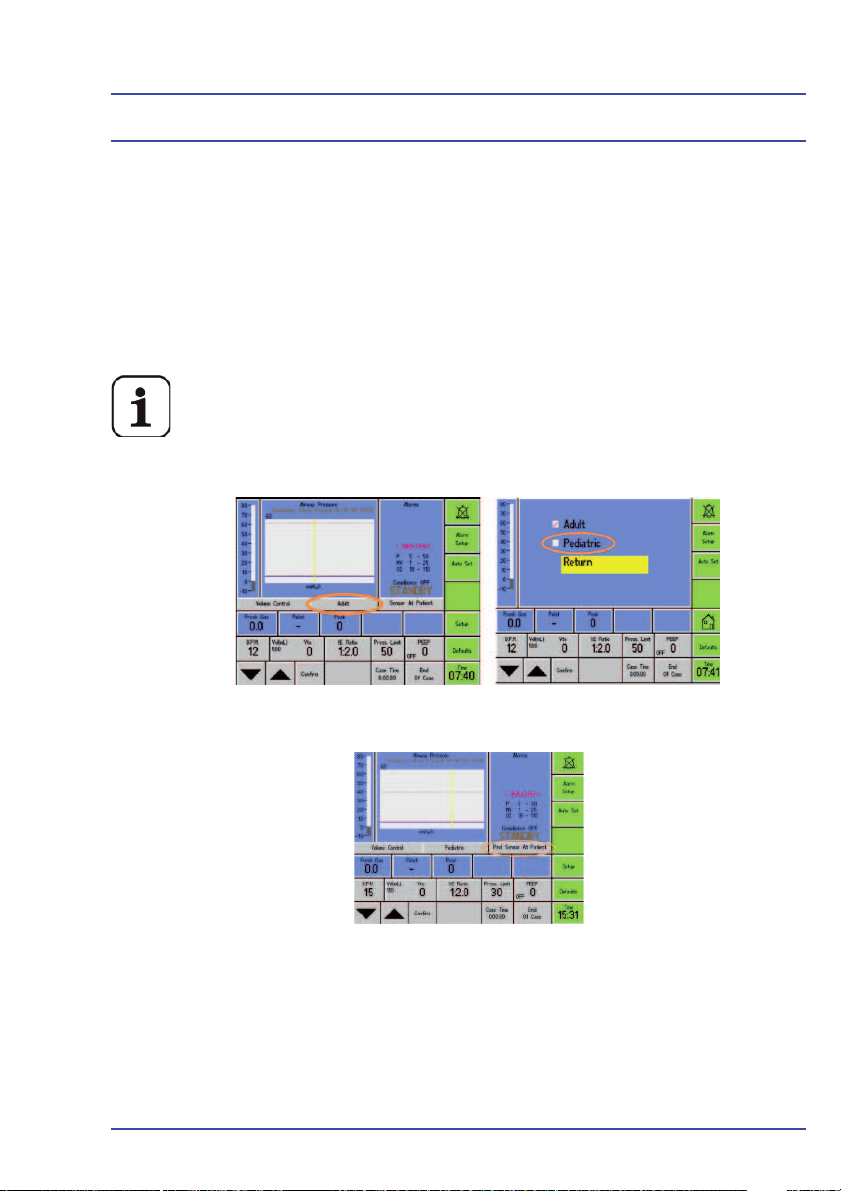

Figure 40A - Change the Flow Sensor Settings .........................................................85

Figure 40B - Pedi Sensor Placement setting..............................................................85

Figure 41 - Connect a Pressure Measuring Device....................................................86

Figure 42 - Step 5: Connect a Reusable Tube ...........................................................89

Figure 43 - Connect a Pressure Sample Tee .............................................................90

Figure 44 - Gas Analyzer Connection ........................................................................90

Figure 45 - Removal of Top Surface ...........................................................................95

Figure 46 - Removal of Screw as Shown ...................................................................96

Figure 47 - Removal of Top Screws as Shown ..........................................................96

Figure 48 - Removal of Front Cover ...........................................................................97

Figure 49 - Front Cover Fixing Screws (on units after Jan 2009) ...............................97

Figure 50 - Front of Machine With Front Cover Removed (Close-up) ........................99

Figure 51 - Rear of Machine .....................................................................................100

Figure 52 - Rear Panels ...........................................................................................101

Figure 53 - Removal of Large Rear Panel ................................................................102

Figure 54 - Flow Meter Removal ..............................................................................104

Figure 55 - BL1 Connector Location.........................................................................105

Figure 56 - Flow Tube Removal ...............................................................................106

Figure 57 - Removal of Screws on Flow Meter Assembly ........................................107

Figure 58 - Rear of Flow Meter Assembly ................................................................107

Figure 59 - Hypoxic Guard fi xing screws ..................................................................108

Figure 60 - Assembled Hypoxic Guard Unit ............................................................. 111

Figure 61 - Exploded View of Hypoxic Guard Components .....................................112

Figure 62 - Flow Block Showing Flow Tube Filters and Tube Lower Inserts ............113

Figure 63 - View of Assembled Hypoxic Guard From Below ....................................114

Figure 64 - Test Points .............................................................................................116

Figure 65 - Pre Feb 2009 Regulator Adjustment ......................................................117

Figure 66 - Rear Panel Screw Locations (8) ............................................................118

Figure 67 - Secondary Gas Test Point Locations .................................................... 118

Figure 68 - Secondary Gas Regulator Locations ....................................................119

Figure 69 - Adjust the Regulator Set Screw ............................................................120

Figure 70 - Primary Regulator Assembly ..................................................................122

Figure 71 - Cylinder Regulator Locations .................................................................123

Figure 72 - Location of Bonnet .................................................................................123

Figure 73 - Diaphragm and Actuator Assemblies .....................................................124

Figure 74 - Valve Cartridge and Relief Valve ...........................................................124

Figure 75 - Regulator Service Kit .............................................................................125

Figure 76 - Valve cartridge and Seal Ring ................................................................125

15

Page 16

Figures

Figure 77 - Assemble the Spring, Spring Rest and Bonnet ......................................126

Figure 78 - Slip Ring Location ..................................................................................126

Figure 79 - Diaphragm Assembly .............................................................................126

Figure 80 - Fit the Actuator Assembly ......................................................................127

Figure 81 - Attach the Bonnet to the Regulator ........................................................127

Figure 82 - Fit the Relief Valve to the Regulator ......................................................128

Figure 83 - Location of Valve Retaining Screws .......................................................129

Figure 84- Backbar Valve .........................................................................................129

Figure 85 - CGO Block (up to Feb 2009)..................................................................130

Figure 86 - Alarm Block Removal (up to Feb 2009) .................................................131

Figure 87 - Alarm Block Removal (Feb 2009 onwards) ............................................132

Figure 88 - CGO Adjustment (up to Feb 2009) ........................................................133

Figure 89 - Valve Adjuster and Disc Removed (up to Feb 2009) .............................134

Figure 90 - CGO Block (Feb 2009 onwards) ............................................................135

Figure 91 - Location of (4) Suction Plate Screws .....................................................136

Figure 92 - Location of (3) ACGO Assembly Screws ...............................................136

Figure 93 - Location of 6 mm Tubing ........................................................................136

Figure 94 - Location of 8 mm Tubing ........................................................................137

Figure 95 - Location of 6 mm Tubing ........................................................................137

Figure 96 - Location of 8 mm Stem ..........................................................................137

Figure 97 - Location of Microswitch ..........................................................................138

Figure 98 - ACGO Tubing Orientation ......................................................................138

Figure 99 - ACGO Switch Set to Absorber ...............................................................139

Figure 100 - A.C.G.O Ventilator Screen Display ......................................................139

Figure 101 - Microswitch Components .....................................................................140

Figure 102 - Ventilator Wire Orientation ...................................................................141

Figure 103 - NC Valves (PN 214-1089-00) ..............................................................142

Figure 104 - 4-6 mm Increaser (PN 54200184) and

6-5 mm Reducer (PN 54200110) ......................................................142

Figure 105 - 5 mm Tubing (1) and 6 mm Tubing (2) .................................................143

Figure 106 - Tubing Diagram ....................................................................................144

Figure 107 - Tighten Two Screws .............................................................................145

Figure 108 - Absorber Interface Manifold Assembly .................................................150

Figure 109 - ‘P’ Clip ..................................................................................................151

Figure 110- Absorber Prongs....................................................................................152

Figure 111 - Micro Switch .........................................................................................152

Figure 112 - Setting Ball Catch .................................................................................153

Figure 113 - Lock Screw Insertion ............................................................................154

Figure 114 - Absorber Molding 01 ............................................................................155

Figure 115 - Absorber Molding 02 ............................................................................155

16

Page 17

Figures

Figure 116 - Absorber Molding 03 ............................................................................156

Figure 117 - Absorber Molding 04 ............................................................................156

Figure 118 - Internal view of Absorber Moldings ......................................................157

Figure 119 -Valve Arc ...............................................................................................157

Figure 120 - Bellows Interface Gasket Fixing Screws ..............................................158

Figure 121 - Gasket Removed .................................................................................158

Figure 122 - Drawer Mechanism ..............................................................................164

Figure 123 - Location of Drawer Mechanism and Removal .....................................165

Figure 124 - Drawer Mechanism ..............................................................................166

Figure 125 - Drawer Re-Assembly ...........................................................................166

Figure 126 - Pedal Screw Location ..........................................................................167

Figure 127 - Hex Bar ................................................................................................167

Figure 128 - Hex Bar Removal .................................................................................167

Figure 129 - Location of Caster Retaining Screw .....................................................168

Figure 130 - Caster Removal ...................................................................................168

Figure 131 - Suction Controller Removal / Replacement .........................................169

Figure 132 - Suction Controller in Place ...................................................................170

Figure 133 - Electrical Fuses ....................................................................................171

Figure 134 - Ventilator Case Top ..............................................................................172

Figure 135 - Inside the Ventilator (Top View) ...........................................................173

Figure 136 - View of Removed Inspiratory Block .....................................................176

Figure 137 - View of BAV Controller .........................................................................177

Figure 138 ..........................................................................................................178

Figure 139 ..........................................................................................................178

Figure 140 - Ventilator Control Knob ........................................................................179

Figure 141 - Front Panel Retaining Screws..............................................................180

Figure 142 - Front Panel (Rear View) .......................................................................180

Figure 143 - Gas Inlet Module ..................................................................................184

Figure 144 - Replace the Battery..............................................................................185

Figure 145 - Replace the Fuses ...............................................................................186

Figure 146 - VentFlash Screen .................................................................................201

Figure 147 - VentFlash Sync Screen ........................................................................201

Figure 148 - VentFlash Check Language Screen ....................................................202

Figure 149 - EFM Components ................................................................................205

Figure 150 - System Information, Page 2 .................................................................209

Figure 151 - EFM Hypoxic Guard Block Assembly ..................................................210

Figure 152 - EFM-Machine Retaining Screws ........................................................211

Figure 153 - Ribbon Cable, Power Connector and Light Pipe Locations ...............211

Figure 154 - Flow Tube Locations ..........................................................................212

Figure 155 - Flow Sensor Screw Locations ............................................................212

17

Page 18

List of Schematics

Figure 156 - Banjo Fitting .........................................................................................212

Figure 157 - Hypoxic Guard Retaining Screws ........................................................213

Figure 158 - Screen Retaining Screws .....................................................................214

Figure 159 - Screen-Circuit Board Connectors (3) ...................................................215

Figure 160 - Circuit Board Screws (6) ......................................................................217

Figure 161 - Flow Sensor .........................................................................................218

Figure 162 - Software Update Panel ........................................................................220

Figure 164 - Exit Panel .............................................................................................222

Figure 163 - Confi guration Panel..............................................................................222

Figure 165 - Diagnostics Panel ................................................................................223

Figure 166 - Detect Sensors Display ........................................................................224

Figure 167 - Touch-Screen Panel .............................................................................226

Figure 168 - Exit Panel .............................................................................................227

Schematic 1 - Title Block ...........................................................................................................218

Schematic 2 - SOM Interface ....................................................................................................219

Schematic 3 - Power .................................................................................................................220

Schematic 4 - I2C Sensors ........................................................................................................221

Schematic 5 - Sensors ..............................................................................................................222

Schematic 6 - LCD Digital .........................................................................................................223

Schematic 7 - LCD/LCD Power .................................................................................................224

Schematic 8 - SD Card ..............................................................................................................225

Schematic 9 - Development Circuits .........................................................................................226

Schematic 10 - 10110326 Pressure Interface Board - Master .................................................265

Schematic 11 - 10110326 Pressure Interface Board - Transducers ..........................................266

Schematic 12 - 10110326 Pressure Interface Board - Patient Flow ..........................................267

Schematic 13 - 10110326 Pressure Interface Board - Fresh Gas ..........................................268

Schematic 14 - 10110375 Blease LVDS Display Interface sht. 1 of 4 ......................................269

Schematic 15 - 10110375 Blease LVDS Display Interface sht. 2 of 4 ......................................270

Schematic 16 - 10110375 Blease LVDS Display Interface sht. 3 of 4 ......................................271

Schematic 17 - 10110375 Blease LVDS Display Interface sht. 4 of 4 ......................................272

Schematic 18 - 10110376SCH Power Supply Board ...............................................................273

Schematic 19 - 10110377SCH Controller Board, CPU .............................................................274

Schematic 20 - 10110377SCH Controller Board, Alarms ..........................................................275

Schematic 21 - 10110377SCH Controller Board, Connect ........................................................276

Schematic 22 - 10110377SCH Controller Board, Analogue ......................................................277

Schematic 23 - 10110377SCH Controller Board, I/O Circuits ...................................................278

Schematic 24 - 10110377SCH Controller Board, PWM ............................................................279

Schematic 25 - 10110377SCH Controller Board, Xilinx PWM and I/O ......................................280

Schematic 26 - 13600381 Cable Assy Sirius Vent Interface sht 1of 2 ......................................281

Schematic 27 - 13600381 Cable Assy Sirius Vent Interface sht 2of 2 ......................................282

Schematic 28 - 13600379SCH Sirius Power Distribution 110VA...............................................283

Schematic 29 - 13600379SCH Transformer Interconnections & Soft-Start PCB - 110V ...........284

Schematic 30 - 13600379SCH Transformer Interconnections & Soft-Start PCB - 230V ...........285

18

Page 19

BleaseSirius

Anesthetic Machine

Chapter 1

Technical Description

19

Page 20

Technical Description

20

Page 21

Technical Description

1.1 Description

1.1.1 General

The BleaseSirius anesthetic machines contain all the pneumatic circuitry,

controls, monitoring, ancillaries and storage required to control, distribute and

mix medical gases and anesthetic agents in order to deliver them to a patient

system.

The BleaseSirius anesthetic machine is based on the Frontline machines. The

BleaseSirius has enhanced components and new features and improvements.

The BleaseSirius anesthetic machine is designed to comply with the following:

ASTM F-1850, UL 60601-1, ISO 5358, IEC 60601-1, IEC 60601-2-13, BS EN

740 and other International Standards.

The BleaseSirius machine consists of the major components described below

(See Figure 1).

1.1.2 The Frame

The frame is made of steel supported on a cast aluminum base with four castors,

there is a brake pedal at the bottom of the trolley. The steel frame is covered by

moldings with a painted fi nish.

1.1.3 Pneumatic Assembly

The frame contains the pneumatic assembly. The pneumatic unit contains the

gas supply inputs, the pneumatics that regulate the supply pressures to a usable

pressure, the oxygen failure alarm and its logic circuitry, the common gas outlet,

the user controls and the pneumatic power outlets. Above the work surface are

the cylinder contents and pipeline pressure gauges, fl ow control valves, hypoxic

guard and fl owblock assemblies, the vaporizer back bar and the uprights which

support the monitor shelf.

1.1.4 The Monitor Shelf

The monitor shelf A in Figure 1, is mounted on top of the machine. Loading

should not exceed 25Kg/55.1lbs.

In US markets, use a cord fi tted with a NEMA 5-15 hospital grade plug to connect

the BleaseSirius to the mains supply. Connection of equipment to the auxiliary

mains socket outlets may increase leakage currents to values exceeding the

allowable limits.

21

Page 22

R

Technical Description

S

Q

P

O

N

M

L

K

A

B

C

D

E

F

G

H

I

J

22

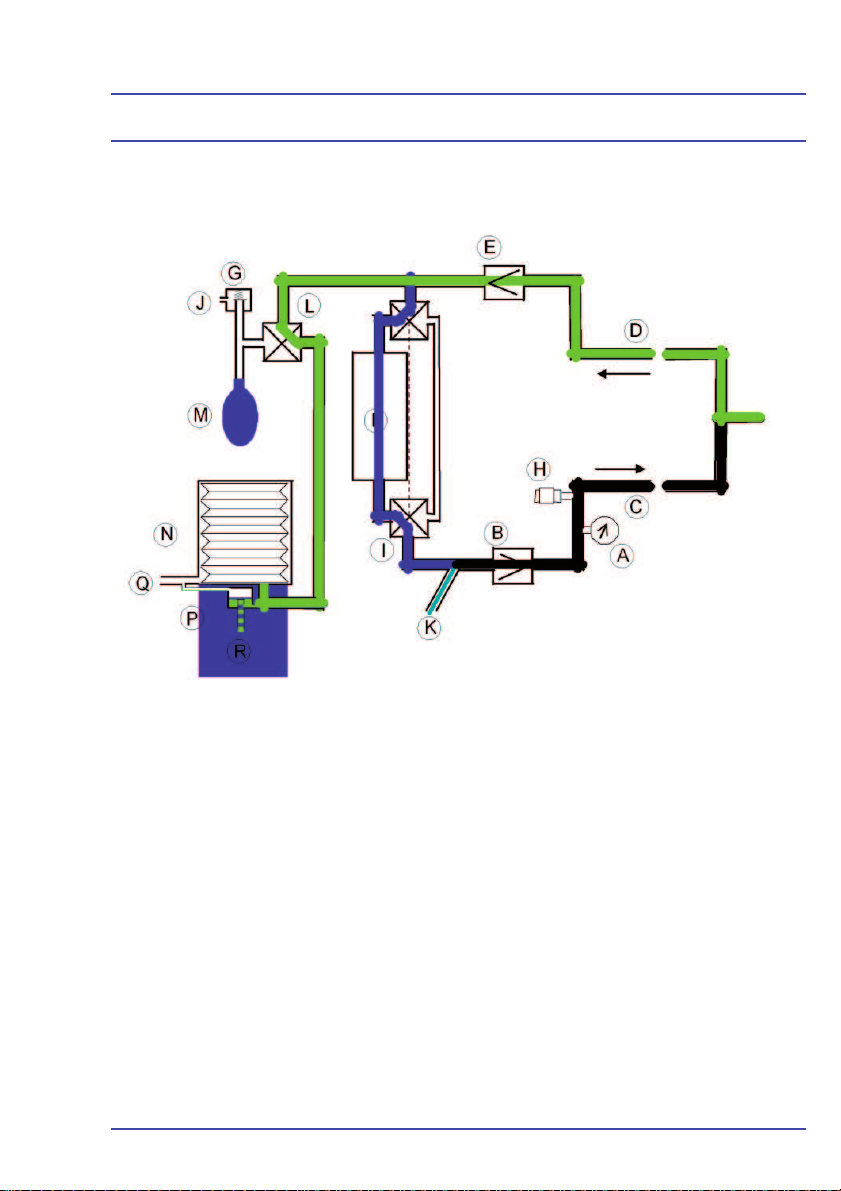

Figure 1 - BleaseSirius Anesthetic Machine

Page 23

Technical Description

Figure 1 Key

A Monitor shelf

B Ventilator

C Vaporizer

D Cylinder/pipeline gauges

E Pneumatic unit - (behind gauge panel)

F Handle

G Oxygen fl ush

H Common gas outlet (or option A.C.G.O.)

I Drawer

J Frame

K Brake Pedal

L Absorber

M Bag Arm Link Pipe

N Adjustable Bag Arm

O Main On/Off Switch

P Suction Controller

Q Flow Control Valves with Hypoxic Guard

R Flowblock Assembly

S Auxiliary Flowmeter

23

Page 24

Technical Description

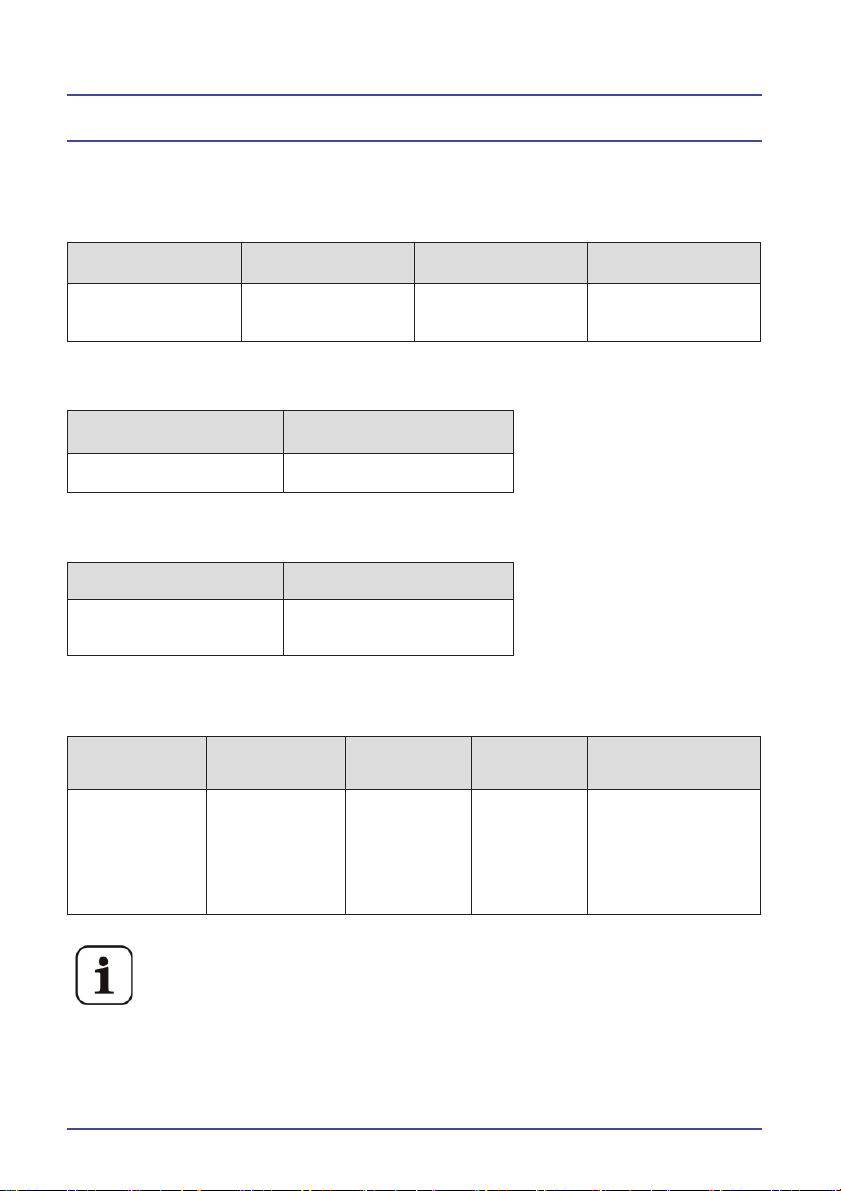

1.2 Specifi cation

1.2.1 Machine Dimension

Height Max. Width Depth Average Weight

1486mm / 158.5” 705mm / 27.7” 747mm / 29” 110kg / 242.5lbs

1.2.2 Work Surface Dimensions

Height Area

854mm / 33.6” 98612.2mm2 / 152.8”

1.2.3 Monitor Shelf Dimensions

Height Area

1486mm/58.5” 175833mm2 / 272.54”

2

2

1.2.4 Maximum Loading

Monitor

Shelf

25kg/55.1lbs

evenly

distributed

Work

Surface

25kg/55.1lbs

evenly

distributed

Gross Loading = 250kg/551.1lbs

24

Bottom

Shelf

8kg/17.6lbs

evenly

distributed

Drawers

5kg/11.0lbs

evenly

distributed

Extended Work

Surface

15kg/33.0lbs

evenly distributed

(intermittent or

occasional loading

only).

Page 25

Technical Description

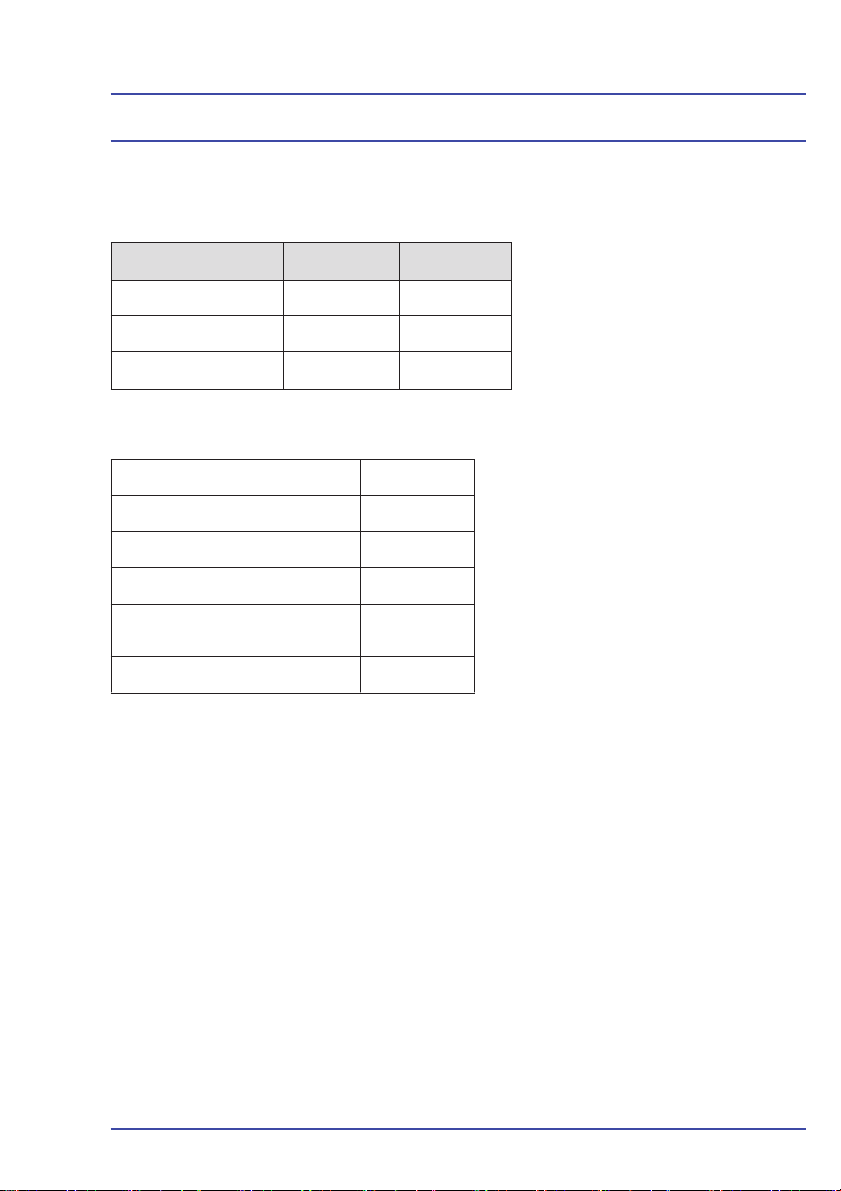

1.3 Pneumatics

1.3.1 Gas-Specifi c Color Specifi cations

Gas ISO ANSI

Oxygen White Green

Nitrous Oxide Blue Blue

MED AIR Black Yellow

1.3.2 Gas Supply Combinations

Max No. of Gases 3

Max No. of Cylinders 4

Max No. of Pipelines 3

Max No. of Gauges 7

Max Cylinder Size

(using PIV Index)

Large Cylinder Kit Max. 2

E

1.3.3 Common Gas Outlet

The common gas outlet is fi tted onto the front of the machine below the work

surface. It will accept a 22mm female or a 15mm male taper coupling.

25

Page 26

Technical Description

1.4 Technical/Performance Specifi cation

1.4.1 Controls

Oxygen fl ow 150ml/m to 10 l/m Simplex/ Cascade

Nitrous oxide fl ow 0ml/m to 12 l/m Simplex/Cascade

MED AIR fl ow 0ml/m to 15 l/m

Flowblock assembly accuracy ±5% measured value at 20ºC and

101.3 kPa/14.6 psi

Oxygen fl ush Non-locking 35 to 55 l/m

Vaporizers Accepts Selectatec

Hypoxic gases Minimum 21% oxygen/nitrous oxide

mixture allowed

1.4.2 Ventilator

A Blease700/900 ventilator is built

into the BleaseSirius.

1.4.3 Alarms / Indicators

Oxygen failure Audible alarm sounds for minimum

of 8 secs when oxygen pressure falls

below 30 psi.

1.4.4 Regulator Safety Valve Settings

Cylinder regulator 43 psi - 47 psi

Cylinder regulator relief valve > 75 psi

Machine gas piping design

rating

Secondary hypoxic regulators

Common gas outlet relief valve 3.25 psi - 3.95 psi

26

700 kPa/max. 101.5 psi/max

25-32 psi

25-35 psi

O

N

2

O2 0.5 Lpm fl ow

}

Page 27

Technical Description

1.4.5 Electrical

Voltage 100 / 230 V

Frequency 60 / 50 Hz

Power 1.2 / 1.0 kVa

The auxiliary sockets are numbered 1 through 4, top to bottom and are rated

as in the following tables. If the machine has the switching sockets option,

sockets 3 and 4 will switch On and Off when the Main On/Off (Figure 1, Key

O) is switched On and Off, rather than with the Mains On/Off switch (Figure 2).

230V 110V

Socket

1 2A 3A 5A 1 - 4 2A 3A 4A

2 - 4 1A 2A 3.15A

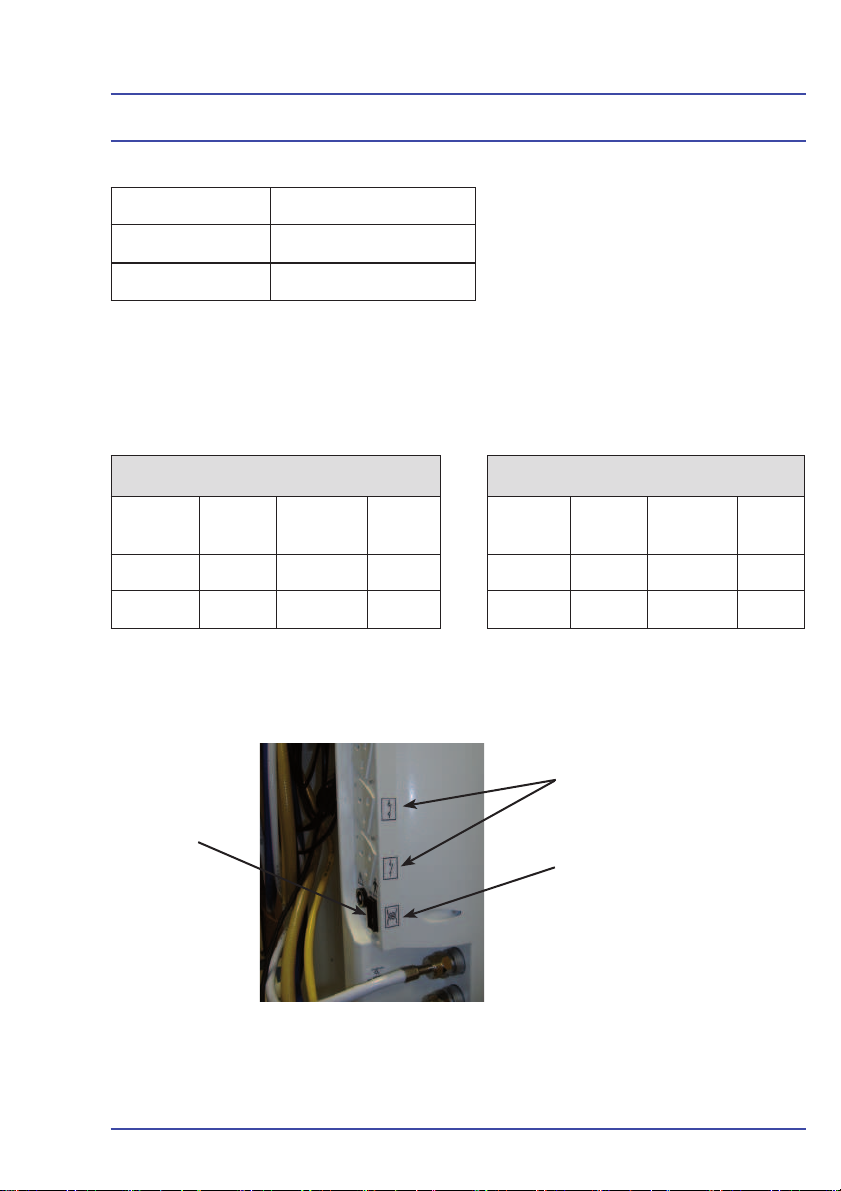

1.4.5.1 Electrical Labeling

Mains ON/OFF

Outlet

Rating

switch

Breaker Fuse Socket

Figure 2 - Electrical Labeling

Outlet

Rating

Switched outlet label

Isolation transformer label

Breaker Fuse

27

Page 28

1.4.6 Supplies

O2, MED AIR, N2O pipeline Nominal pressure 400 kPa/58.0 psi,

Technical Description

minimum 275 kPa/39.8 psi, maximum

482 kPa/69.9 psi

Auxiliary pneumatic outlets MED AIR or O

zero fl ow. 80 l/m max. fl ow

Auxiliary Oxygen Outlet 0-15 lpm

1.4.7 Environmental

Operating Temperature 5ºC-40ºC (41ºF-104ºF)

oxygen cell operates to specifi cation

10ºC-40ºC (50ºF-104ºF)

Storage Temperature -20

cell removed

0ºC-50ºC (32ºF-122ºF) with oxygen

cell in place

Humidity 15-95% Non-condensing

- 400 kPa/58.0 psi at

2

o

C-60ºC (-4ºF-140ºF) with oxygen

28

Page 29

BleaseSirius

Anesthetic Machine

Chapter 2

Overview

29

Page 30

Overview

30

Page 31

Overview

2.1 Description of the Ventilator

2.1.1 Overview

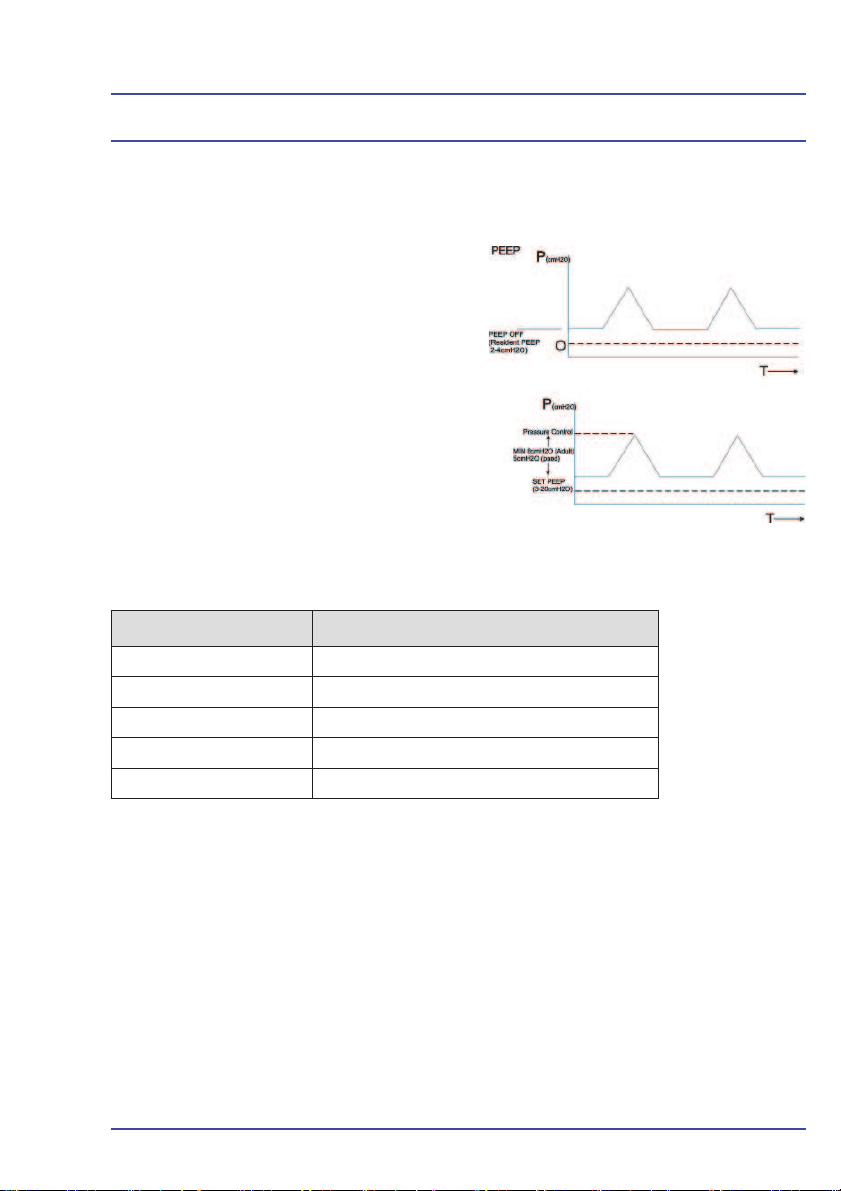

2.1.1.1 PEEP

The Blease700/900 series ventilator

continuously monitors and displays

the Positive End Expiratory Pressure

(PEEP). By default, a PEEP of

2 - 4 cmH

caused by the bellows assembly,

which is shown as OFF. A PEEP value

between 3 and 20 cmH2O can be set

from the panel, with an automatic alarm

of more than 25% above the set value.

A minimum difference of 8 cmH2O

in adult and 5 cmH2O in pediatric is

enforced between the set PEEP level

and the pressure controls shown below.

Mode Pressure Control

Volume Control Pressure Limit

Pressure Control Set Pressure

Pressure Support Support Pressure

SIMV-VC + PSV Support Pressure + Set Volume

SIMV-PC + PSV Support Pressure + Set Pressure

O is introduced to the circuit,

2

Figure 3 - PEEP Diagram

When the user changes a value such that it does not comply with the required

difference, the box surrounding the feature being adjusted and the value of

the feature causing limiting to be enforced is highlighted red. The value being

adjusted could either be the PEEP level or the relevant pressure control.

The user can then:

• Accept the value being adjusted, in which case, it will be set to the

nearest acceptable value.

• Adjust the value to a non-confl icting value.

If the user does not make the change before end of time allowed for adjustment,

the value will set to the nearest acceptable value.

31

Page 32

Overview

2.1.1.2 Trigger

The level of negative fl ow caused by the patient’s attempt to breathe before the

ventilator initiates fl ow to assist the patient with the spontaneous breath.

Range: 1 to 15 l/m all modes (SIMV + PSV and Pressure Support).

2.1.1.3 Support Pressure

Breathing circuit pressure level for assistance with patient’s spontaneous breath.

Range: 5 cmH

referenced).

O to 30 cmH2O SIMV-PC + PSV and Pressure Support (PEEP

2

2.1.1.4 Fresh Gas Compensation

Fresh gas can be compensated for and displayed on screen.

2.1.1.5 Oxygen

A fuel cell sensor can be connected to allow monitoring of 0% to 110% O

alarms of 18% to 110%. The sensor can be calibrated.

, with

2

2.1.1.6 Tidal Volume

Volume to be delivered by the ventilator in each breath.

Range: 20 ml to 1500 ml all modes.

2.1.1.7 Minute Volume

Measured volume delivered by the ventilator per minute.

Range: 0.3 l/m to 25 l/m all modes.

2.1.1.8 Expired Tidal volume

Expired tidal volume is measured by the sensor in the breathing circuit, in either

mechanical ventilator spontaneous breathing mode. The measured value is

displayed in the tidal volume window.

2.1.1.9 BPM (Frequency Control)

The mechanical frequency of the ventilator in breaths per minute (BPM).

Range: 2 bpm to 99 bpm all modes.

32

Page 33

Overview

2.1.1.10 I:E Ratio

The ratio of the inspiratory time to the expiratory time.

Range: 2.0:1 to 1:5.0, all modes in steps of 0.1.

2.1.1.11 Pressure Limit

The breathing system maximum pressure limit.

Range: 10 cmH

10 cmH2O to 50 cmH2O Adult.

O to 50 cmH2O Pediatric.

2

2.1.1.12 Peak Pressure

Range: 0 cmH

O to 100 cmH2O

2

2.1.1.13 Mean Pressure

Range: 0 cmH

O to 100 cmH2O

2

2.1.1.14 Compliance

System compliance in ml/cmH

Patient compliance in ml/cmH2O

O

2

2.1.1.15 Volume Measurement

Accuracy of delivered gas at 25ºC 101.3 kPa/14.6 psi (volume mode)

= ±10% or ± 10 ml from 50 ml to 1 liter

(whichever is greater)

Volume monitoring accuracy = ± 10% or ± 10 ml (whichever is greater)

Controlled Patient Pressure = ± 10% or ± 2 cmH

Monitored Patient Pressure = ± 5% or 1 cmH2O (whichever is greater)

O (whichever is greater)

2

Delivered PEEP = ±1.5 cmH2O from 4 to 20 cmH2O (whichever is greater)

Fresh Gas Flow = ± 10% or ± 200 ml from 300 ml to 15 liters (whichever is

greater)

2.1.1.16 Oxygen Measurement

Oxygen Concentration accuracy = 3%.

Drift < 1% over 8 hours at constant temperature.

Response time < 30 seconds for 90% change.

33

Page 34

Overview

2.2 Pre-use Test

2.2.1 Fresh Gas

Fresh gas (FG) fl ow adds to the delivered Tidal Volume (TV) during the

inspiratory period. To compensate, the delivered volume must be reduced.

The formula for this reduction is:

Effective TV = TV - TV due to FG

TVE =TV - ((FG fl ow rate (mL)/60)* Inspired time (sec))

TVE = TV - TV

For example, let

FG fl ow rate = 5LPM, TV = 600mL, Frequency = 10BPM, I:E = 1:20

Inspired time = * = 2 Sec

TVfg = * 2 = 83 1/3 = 167ml

Therefore,

Effective TV = 600 - 167 = 433mL

5000

60

FG

1

60

10

3

2.2.2 Compliance

Compression of gas in the dead space within the breathing system reduces the

tidal volume delivered to the patient. In an ideal ventilator, the Set TV would

be the volume of gas that is delivered to the patient’s lungs. This cannot be

achieved because the anatomy of the patient is unknown. However, the Set

TV can be accurately delivered from the catheter mount, thus reducing Set TV

errors to a minimum.

To calculate the effect of breathing system compliance on

the delivered TV, it is necessary to measure the capacity or

compliance (Cs) of the system. This can only be done as part

of a pre-use check procedure.

34

Page 35

Overview

1. Switch the unit ON. The compliance menu will be displayed.

The patient airway fl ow sensor head must be in the patient circuit

in order to carry out compliance compensation.

2. Select Yes to Compliance Compensation and follow the instructions

on screen instructions

The ventilator delivers a breath of known volume to the breathing circuit, records

the pressure (cmH

O) achieved and verifi es that a leak is not present.

2

3. The dead space is calculated as follows:

Volume (mL)

= dead space compliance (C

Pressure (cmH20)

)

3

This value is retained in memory until the ventilator is switched off or retested.

4. When the ventilator is set to use on a patient and when the

ventilation is stable, the total compliance of system and patient

(Ct) is measured. The TV can then be increased to compensate for

the volume lost due to compression within the breathing system.

The increase in tidal volume is calculated by the formula:

C

Set TV * (

1 + ) = new TV (mL)

s

C

C

-

t

s

For example:

A system test measurement at a TV of 200 ml gave a pressure rise of 25 cmH

C

200mL

=

s

25cmH2O

= 8

O.

2

Running the ventilator on a patient with a set 500ml TV gave a peak pressure

of 20cmH

O.

2

35

Page 36

Overview

To calculate the increase in TV:

C

The 735ml is the actual ventilator output into the breathing circuit to give

500ml at the catheter mount. The value must be recalculated every time volume

controlled ventilation starts.

500mL

=

t

20cmH2O

= 25

new TV = 500 * (

2.2.3 Compensation

Mode Compliance Fresh Gas

Volume Control

Pressure Support

SIMV-VC + PSV

SIMV-PC + PSV

Pressure Control

1 + ) = 735mL

25 88-

P P

O P

P P

O P

O P

36

Page 37

Overview

2.2.4 Mode Dependant Features

PRESSURE

V O L U M E

CONTROL

SIGH PAUSE

P P O O

SUPPORT

TRIGGER

PRESSURE

SUPPORT

PRESSURE

BPM

Set

VOL/

FLOW

Meas/

Set

I:E

Set

PRESSURE

LIMIT

Pressure

Limit

PR ESS U RE

SUPPORT

SIMV-VC +

PSV

SIMV-PC +

PSV

PR ESS U RE

CONTROL

O O

O P

O O

ALWAYS ALWAYS Meas Meas Meas

ALWAYS ALWAYS

ALWAYS ALWAYS

O O O O

Meas/

Set

Meas/

Set

Set

Meas/

Set

O

IINSP

FLOW

Meas/

Set

Meas/

Set

Set

Pressure

Limit

Pressure

Limit

Ptot

Set

Pressure

37

Page 38

Overview

38

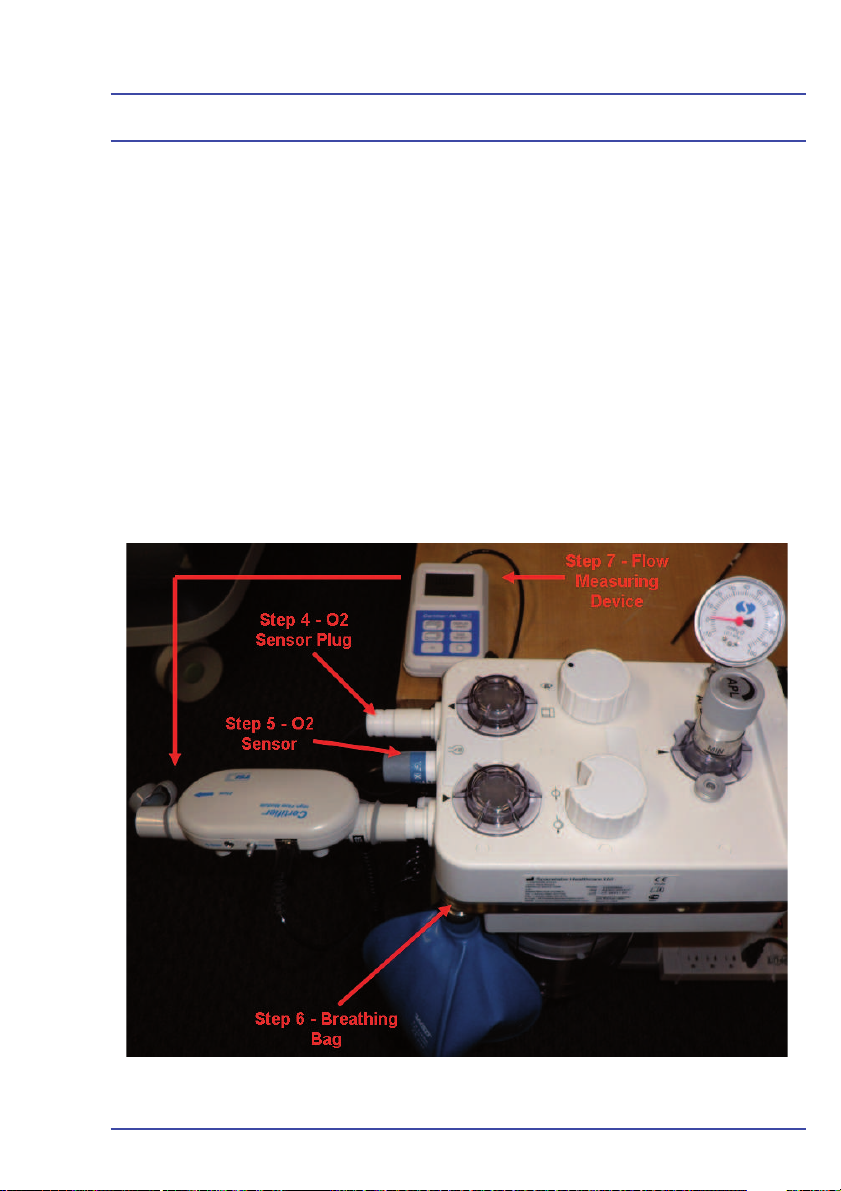

Figure 4 - Ventilator Schematic

Page 39

Overview

A Manometer

B Inspiratory Non-return Valve

C Patient Inspiratory Connector

D Patient Expiratory Connector

E Expiratory Non-return Valve

F Canister(s)

G APL Valve

H Oxygen Sensor Port

I Bypass Switch

Figure 5 - Absorber Pneumatic Schematic

J APL Exhaust Valve

K Fresh Gas Port

L Bag/Vent Valve

M Bag Port

N Bellows

P Pop-Off Valve

Q Ventilator Drive Gas

R Pop-Off Exhaust

39

Page 40

Overview

M

S

O

J

A B

T

U

P

Q

C

D

A Air Pipeline

B Air Cylinder Yoke

C N

D N

E O

F O

O Pipeline

2

O Cylinder Yoke

2

Pipeline

2

Cylinder Yoke

2

G Reservoir

H Auxiliary Flowmeter

I O2 High Pressure Outlet

J Air Takeover Valve

K O

Failure Alarm Whistle

2

L O2 Failure Alarm Valve

M On/Off Switch

V

M

K

L

FE

Y

Z

W

R

G

H

I

X

N

N Vent Supply

O Air Secondary Regulator

P N

O Secondary Regulator

2

Q Oxygen Secondary Regulator

R Oxygen Flush

S Air Flowmeter

T N

O Flowmeter

2

U Hypoxic Protection Link System

V Oxygen Flowmeter

W Pressure Relief Valve

X CGO

Y Seletatec Back Bar

Z Fresh Gas Flow Sensor

40

Figure 6 - Pneumatic Circuit

Page 41

Overview

2.3 Principles of Operation

For active inspiration, the fl ow control valve is opened to provide a specifi c gas

fl ow into the bellows assembly. Simultaneously, the expiratory solenoid closes

and pressure is generated in the bellows assembly producing an inspiratory

fl ow to the patient.

The fl ow and pressure are measured and monitored by the microprocessor

feedback system.

Expiration occurs when the fl ow control valve is closed and the expiratory

solenoid opens and releases the gas from the bellows assembly.

In Pressure Control Mode, the set pressure is achieved during inspiration

and maintained at that level by allowing a controlled bypass through the

expiratory valve. This allows the required pressure level to be maintained while

compensating for any fresh gas fl ow into the patient circuit.

For expiration, the expiratory solenoid is opened which releases the gas from

the bellows assembly.

During all modes of ventilation, an autozero is periodically applied to the fl ow

sensors just prior to a breath being delivered. At this point, there is no fl ow

through the sensors, which ensures that the measured values are maintained

as accurately as possible regardless of environmental variations.

A safety valve is present in the drive pressure exhaust

75 cmH2O. Its function is to protect the patient against pressures exceeding 75 cmH2O ± 2 cmH2O by relieving the drive

pressure on the bellows.

NEEP is not supported by this machine but patient generated pressures may be measured to - 10 cmH2O, at which

point an alarm will sound.

41

Page 42

Notes

42

Page 43

BleaseSirius

Anesthetic Machine

Chapter 3

Planned Maintenance

43

Page 44

Planned Maintenance

44

Page 45

Planned Maintenance

3.1 Planned Maintenance

Only authorized technical engineers should service the machine, since they

have the appropriate training and qualifi cations in the use of high-pressure

medical devices. Servicing should take place in a clean and controlled

environment taking particular care to prevent contaminants entering the unit

while disassembled.

Service Kits Part Number

Annual Service Kit 14000511

*Four-Year Service Kit 14000512

* Includes all parts required for units with four cylinder yokes installed.

All parts included in PN 14000512 are not required for all

BleaseSirius machines. You can order idividual parts instead of

ordering PN 14000512.

Four-Year PM Kit Contents Part Number

*Annual PM Kit 14000511

*Battery 80300025

**Regulator Pressure Relief Valve 019-0831-00

***Filter 53700027

***O-ring 51150283

* Required for every machine

**One kit required for each cylinder yoke installed on the machine.

***Required for machines sold before February 2009.

45

Page 46

Planned Maintenance

• Bodocs Seals

• Backbar Seals

• Absorber Stop

+ O2 Blanking

Plug

• Backbar Dzus

Springs

• AGSS Probe

Seal

• AGSS Float

Seal

• Pipeline Filter

• Pipeline ‘O’ Ring

• Bellows Base/

Cover

• Ped Bellows

• Bellows Base/

Pop off

• Absorber Upper

Seal

• Absorber ‘O’

Rings for Insp/

Exp + APL

• Pop off Valve

• Absorber Gauge

• Absorber

Control Seal

• Absorber

Bottom Canister

Figure 7 - BleaseSirius Annual Planned Maintenance Kit

PN 14000511

46

Page 47

Planned Maintenance

• Cylinder

Regulator

Service Kit

• ‘O’ Ring for

Filter

• Battery

Figure 8 - BleaseSirius Four Year Planned Maintenance Kit

PN 14000512

Note:

Includes annual

kit, PN 14000511

47

Page 48

Planned Maintenance

3.2 Routine Maintenance and Service Check.

3.2.1 Fitting Planned Maintenance Kit PN 14000511

Bodoc Seals (1), Backbar Seals (2) and O2 Probe ‘O’ Ring (3)

are duplicated. The duplicated set is to be placed in one of the

drawers for the user to replace if one is damaged or fails test

during use.

3.2.2 Bodoc Seals

1. Remove cylinders from the yokes, then remove the old Bodoc Seal

and replace with new ones.

2. Refi t the cylinder.

3.2.3 Backbar Seals

1. Remove vaporizers from the Selectatec backbar then remove all

four seals.

2. Replace with new ones.

3.2.4 Backbar Dzus Springs

1. Remove the two Dzus Spring assemblies by undoing the two

screws (in the diagonal corners of the plate). Lift the place up,

taking care not to drop the index pin. The index pin must be fi tted

to the new Dzus Spring assembly before fi tting new item.

2. Refi t the vaporizers and check that they locate and lock on the

backbar currently.

3.2.5 Absorber Stop/’O’ Ring

1. Remove the ‘O’ Ring from the absorber blanking plugs and

absorber stop, then replace them. (The new cell is supplied with

‘O’ ring fi tted.)

3.2.6 Pipeline Fitting and ‘O’ Ring

1. Disconnect pipelines from their supply. Disconnect the pipeline

connection from the BleaseSirius.

2. Unscrew the two small grub screws until the main body of the

connection is free to rotate.

3. Unscrew the connector, the fi lter and ‘O’ Ring can now be changed.

48

Page 49

Planned Maintenance

4. Refi t the outer part of the connector and tighten the two small grub

screws.

5. Repeat for all three pipelines.

6. Note each gas type has a unique fi tting and can not be incorrectly

mixed.

7. Refi t the pipeline and check for leaks.

Figure 9 - Pipeline Fitting & ‘O’ Ring

49

Page 50

Planned Maintenance

3.3 AGSS Probe and Float for Spacelabs AGSS

PN 14200018, (if Fitted)

The AGSS is not available in the U. S.)

1. Disconnect electrical supply to BleaseSirius

2. Remove the bellows assembly by sliding the absorber forward until

the bellows connections become free, then

remove the two thumb wheels at the front of

the bellows. The bellows assembly can now

be lifted clear of the locating pins at the rear of

the bellows assembly.

3. Working through the apparatus below the

bellows assembly.

4. The AGSS probe can be pulled out of the top of

the AGSS unit.

5. Remove the ‘O’ Ring and replace with the new

part.

6. Disconnect the 30mm connector from the

side of the AGSS unit, (located approximately

100mm down the AGSS unit).

7. The AGSS unit will now pull off its V mounting

bracket and can be removed through the

apparatus.

8. Hold the lower black part of the body (where

the 30mm connector is) and unscrew the top

black part (with the windows).

9. Clean the fi lter.

10. Remove the top ‘O’ Ring slide the green fl oat

off the central stem and remove the bottom

‘O’ Ring.

11. Replace the bottom ‘O’ Ring.

12. Refi t the fl oat (make sure it is the correct way

up) then replace the top ‘O’ Ring.

13. Reassemble the fi tted/window on top, screw

onto the lower sections.

14. Place the AGSS unit back onto its V bracket.

15. Refi t the 30mm connector and the AGSS probe.

“O’ Ring

“O’ Ring

Figure 10 - AGSS

50

Page 51

Planned Maintenance

3.4 Bellows Base/Canister

1. Remove the bellows cover (bayonet fi tting), then replace the

bellows base/canister ‘O’ Ring.

2. Remove the bellows by gently pulling the lower convolution of the

retaining ring.

3. Remove the pop-off valve.

4. Replace the bellows base pop-off valve “O” ring.

3.5 Pop-off Valve

Figure 11 - Pop-off Valve

1. Replace Pop-off valve in bellows base.

2. Refi t bellows by gently pulling the lower convolution over the ring

in the bellows base.

3. Replace the bellows outer cover.

51

Page 52

Planned Maintenance

A

B

C

A - Cover

B - Bellows

C - Pop-off valve

D - Valve seat

E - Fixing screws

F - Bellows base

G - O-ring

52

G

D

E

F

Figure 12 - Bellows Assembly

Page 53

Planned Maintenance

3.6 Absorber

3.6.1 Valve Covers

When removing or refi tting any of these valves, it is important to

ensure the metal valve disk and seat are not damaged.

1. Remove the expiratory valve by twisting the clear plastic valve cover.

2. Replace the ‘O’ Ring seal on the valve cover.

3. Replace the expiratory valve on the absorber.

4. Remove the inspiratory valve cover.

5. Replace the ‘O’ ring seal.

6. Replace the valve cover.

7. Remove the APL valve.

8. Replace the ‘O’ ring seal.

9. Replace the APL valve.

3.6.2 Manometer

1. Remove the manometer gauge by pressing the quick release lever at the

base of the gauge.

2. Replace the ‘O’ ring seal.

3. Refi t the gauge.

3.6.3 Canister Seals

The outer canister seal is a bayonet fi tting.

1. Remove the soda lime canister.

2. The outer canister seal is located on the base of the absorber in the

groove.

3. Replace the outer canister seal.

4. The upper canister seal is fi tted to a lip inside the bottom absorber

molding.

5. Replace the upper seal.

6. The central seal is laid on top of the lower inner canister before the upper

canister is fi tted.

7. Install the canister assembly onto the bottom of the Absorber.

53

Page 54

Planned Maintenance

3.6.4 Fitting 4 Year Planned Maintenance Kit, PN 14000512

The recommended service intervals for the following are every 4 years. The

following procedure outlines the steps taken to replace the parts included in the

service kit 14200512.

3.6.5 Ventilator Filter

3.6.5.1 Two Valve Version Only (on units before Feb 2009)

1. Ensure all gas supplies are disconnected.

2. See Section 5.1 for removal of top surface and front cover.

3. Once the front cover is removed, you can access the 6 screws that secure

the top of the ventilator casing.

4. The front display panel will hinge forward a little. This will allow the top

cover to be hinged back.

5. The fi ller cover is in the inlet manifold which can be seen from the front

of the unit.

6. Remove the cover.

7. The fi lter can then be

unscrewed.

8. Replace the fi lter and cover

and make sure the new ‘O’

ring is fi tted.

9. Replace the screws in the

top cover and front display

panel.

10. Reconnect the O

pipeline

2

only and turn on the system.

11. Check that there are no

Figure 13 - Pneumatic Module

leaks.

12. Turn the systems OFF.

13. Fit the front cover and top surface.

3.6.5.1 Valve Block on units after Feb 2009

Due to major enhancements in the inlet fi ltration methods, a valve block fi lter is

no longer required and, therefore, is not fi tted.

54

Page 55

Planned Maintenance

3.6.6 Cylinder Regulator Pressure Relief Valve, PN 019-0831-00

1. Remove all cylinders.

2. Remove the large back panel.

3. Fit a service kit to each of the regulators.

Disassembly

1. Remove and discard relief valve by turning counter-clockwise using a

15/16” spanner or socket.

Assembly

1. Fit new relief valve and ‘O’ ring.

2. Reset the pressure as required. See ‘ADJUSTMENT’ below.

Adjustment

Turn the adjusting screw clockwise to increase and counterclockwise to

decrease outlet pressure setting. To reduce pressure, fi rst reduce to a

pressure less than that desired, then increase to the desired outlet pressure.

Turn the adjusting screw using a 1/8-inch hex key.

Once 45 psi setting has been achieved, secure the locknut.

55

Page 56

Planned Maintenance

3.7 CLEANING

Cleaning of external surfaces is possible using water or isopropyl alcohol.

Cleaning of internal surfaces and parts should not be required and is not

recommended.

This product is intended for use in medical compressed gas

systems only. Do not use this product where pressures and

temperatures can exceed those listed under Technical Data.

DO NOT use any lubricants that are not compatible with oxygen or medical gases. The use of lubricants not compatible

with oxygen may pose a risk of fi re or explosion.

Open the cylinder valve slowly to prevent the risk of fi re or explosion due to

oxygen pressure shocks. The relief valve is a safety device and must only be

removed for servicing. When servicing is complete, a new relief valve must be

fi tted. Do not attempt to adjust or tamper with the relief valve.

56

Page 57

Adjusting Screw

Spring

Planned Maintenance

Locknut

Bonnet

Slip Ring

Seal Ring

Body

Mounting Spacer

Upper Spring Rest

Diaphragm Assembly

Actuator Assembly

Valve Cartridge

‘O’ Ring

Relief Valve

Figure 14 - Primary Regulator

57

Page 58

Notes

58

Page 59

BleaseSirius

Anesthetic Machine

Chapter 4

System Checks

59

Page 60

System Checks

60

Page 61

System Checks

4.1 Overview

This chapter explains the systems checks that must be used on all BleaseSirius

anesthetic machines whenever any of the following procedures has been

performed:

• Installation

• Planned Maintenance (should be performed annually)

• Service

• Repair

Use the service check sheet, shown on page 64, to record the results.

4.2 Tools and Test Equipment Required