Page 1

Multigas Analyzer

91518

Service Manual

070-1328-00 Rev. E

Page 2

©2008 Spacelabs Medical, Inc.

Rx Only

!

All rights reserved. Contents of this publication may not be reproduced in any form without the written permission of

Spacelabs Medical. Products of Spacelabs Medical are covered by U.S. and foreign patents and/or pending patents.

Printed in U.S.A. Specifications and price change privileges are reserved.

Spacelabs Medical considers itself responsible for the effects on safety, reliability and performance of the equipment

only if:

• assembly operations, re-adjustments, modifications or repairs are carried out by persons authorized by

Spacelabs Medical, and

• the electrical installation of the relevant room complies with the requirements of the standard in force, and

• the equipment is used in accordance with the operations manual.

Spacelabs Medical will make available, on request, such circuit diagrams, component part lists, descriptions,

calibration instructions or other information which will assist appropriately qualified technical personnel to repair those

parts of the equipment which are classified by Spacelabs Medical as field repairable.

Spacelabs Medical is committed to providing comprehensive customer support beginning with your initial inquiry

through purchase, training, and service for the life of your Spacelabs Medical equipment.

CORPORATE OFFICES

U.S.A.

Spacelabs Medical, Inc.

5150 220th Ave SE

Issaquah, WA 98029

Telephone: 425-657-7200

Telephone: 800-522-7025

Fax: 425-657-7212

Authorized EC Representative UNITED KINGDOM

Spacelabs Healthcare, Ltd.

Beech House, Chiltern Court

Asheridge Road, Chesham

Buckinghamshire HP5 2PX

Telephone: 44 (0) 1494 784422

Fax: 44 (0) 1494 794414

BirthNet, Clinical Browser, Data Shuttle, Flexport, Intesys, Mermaid, MOM, Multiview, PCIS, PCMS, PrintMaster,

Quicknet, Sensorwatch, TRU-CAP, TRU-CUFF, TruLink, Ultralite, Ultraview, Ultraview Care Network, Ultraview Clinical

Messenger, Ultraview Digital Telemetry, Ultraview SL, Uni-Pouch, UCW, Varitrend and WinDNA are trademarks of

Spacelabs Medical, Inc.

Other brands and product names are trademarks of their respective owners.

Caution:

US Federal law restricts the devices documented herein to sale by, or on the order of, a

physician.

Before use, carefully read the instructions, including all warnings and cautions.

Page 3

Table of Contents

Contents Page

Introduction

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Setup

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Multigas Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Power Up Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Theory

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Interface PCBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Gas Analyzer Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Maintenance

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Corrective Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Disassembly and FRU Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Troubleshooting

Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Problem Solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Parts

Field Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Appendix A — Electromagnetic Compatibility

Electromagnetic Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Frequency Separation Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Appendix B — Symbols

90518 Multigas Analyzer Service Manual i

Page 4

Page 5

Introduction

Contents

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

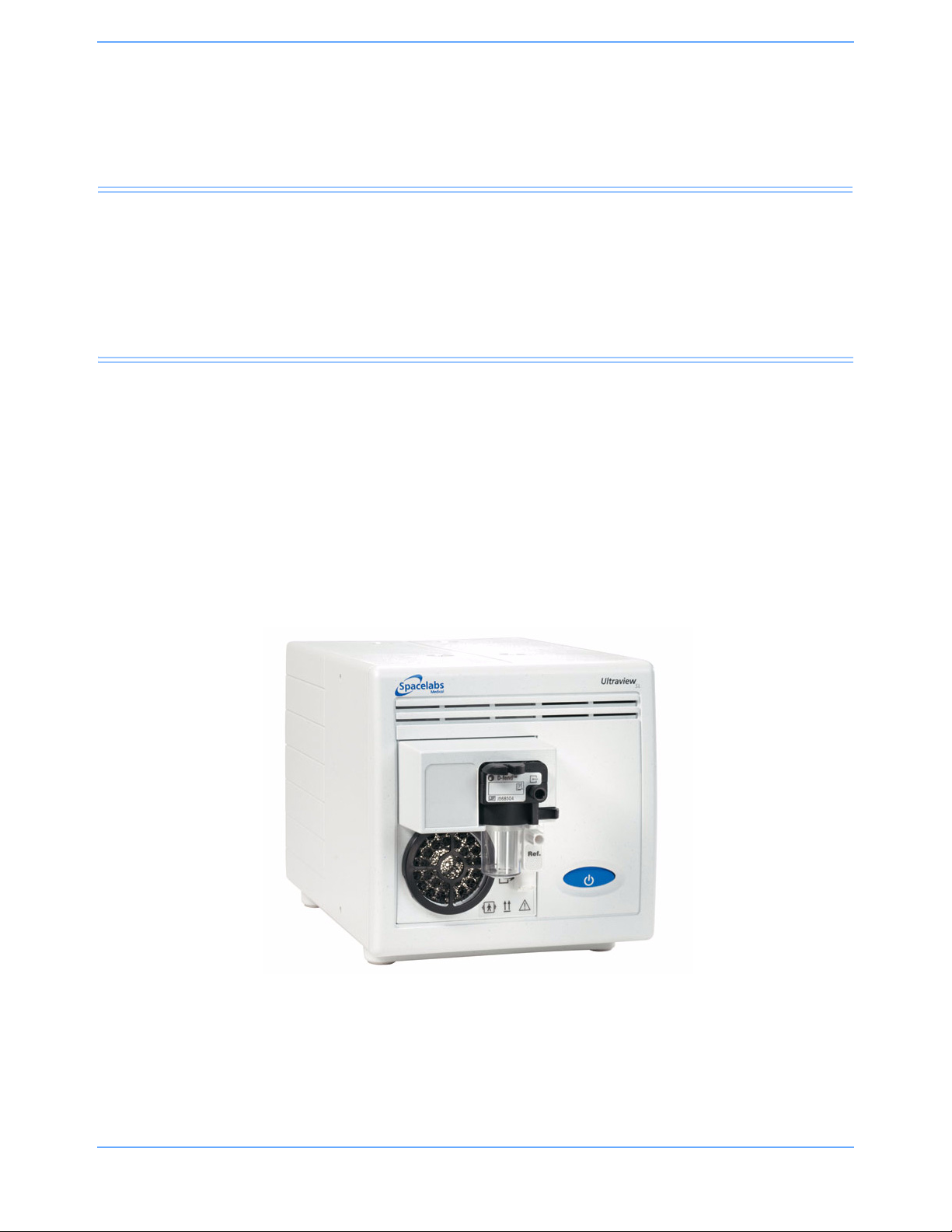

Overview

The 91518 is a multigas analyzer used primarily in an operating room environment to measure the CO2

produced by a patient and the O

are monitored are halothane, isoflurane, enflurane, sevoflurane, and desflurane.

The 91518 Multigas Analyzer interfaces to a Spacelabs Healthcare monitor through an SDLC connection. The

Spacelabs Healthcare monitor provides the numeric display for gas concentrations, a respiratory rate, and a

capnograph waveform for CO

, N2O, and anesthetic agents being administered. The anesthetic agents that

2

.

2

Multigas Analyzer

Figure 1-1: 91518 Multigas Analyzer

Spacelabs Healthcare products are designed and manufactured under good manufacturing practices and in

compliance with all applicable regulatory requirements. To ensure proper operation in accordance with these

guidelines, this product must be maintained by trained technicians using Spacelabs Healthcare authorized

replacement parts.

91518 Multigas Analyzer Service Manual 1-1

Page 6

Introduction

Compatibility

The 91518 Multigas Analyzer is designed for use with Ultraview SL, Ultraview, and UCW® monitors.

Ultraview SL

• Ultraview SL2400 (91369), SL2600 (91370), SL2700 (91387-27), SL2800 (91387-28)

Ultraview

• UCW (90385)*, Ultraview 1700 (90387)*, Ultraview 1500 (90363), Ultraview 1600 (90364), Ultraview 1050

(90369), Ultraview

* Some UCW (S/N below 385-3xxxxx) and Ultraview monitors (S/N below 387-1xxxxx) do not support all

waveforms and display options, such as colors.

™

®

1030 (90367)

Dimensions

Height 17.15 cm (6.75 inches) (enclosure: 14.605 cm [5.75 inches]); feet: 1.27 cm

(0.5 inches)

Width 15.24 cm (6 inches)

Depth 28.45 cm (11.2 inches) (enclosure: 21.59 cm [8.5 inches]); gas module protrudes

from front 4.572 cm (1.8 inches); handle in back of enclosure protrudes 2.286 cm

(0.9 inches)

Weight 3.714 kg (8.19 lbs)

91518 Multigas Analyzer Service Manual 1-2

Page 7

Introduction

Environmental Requirements

Table 1 lists the environmental requirements, including temperature, for operating and storing the 91518

Multigas Analyzer.

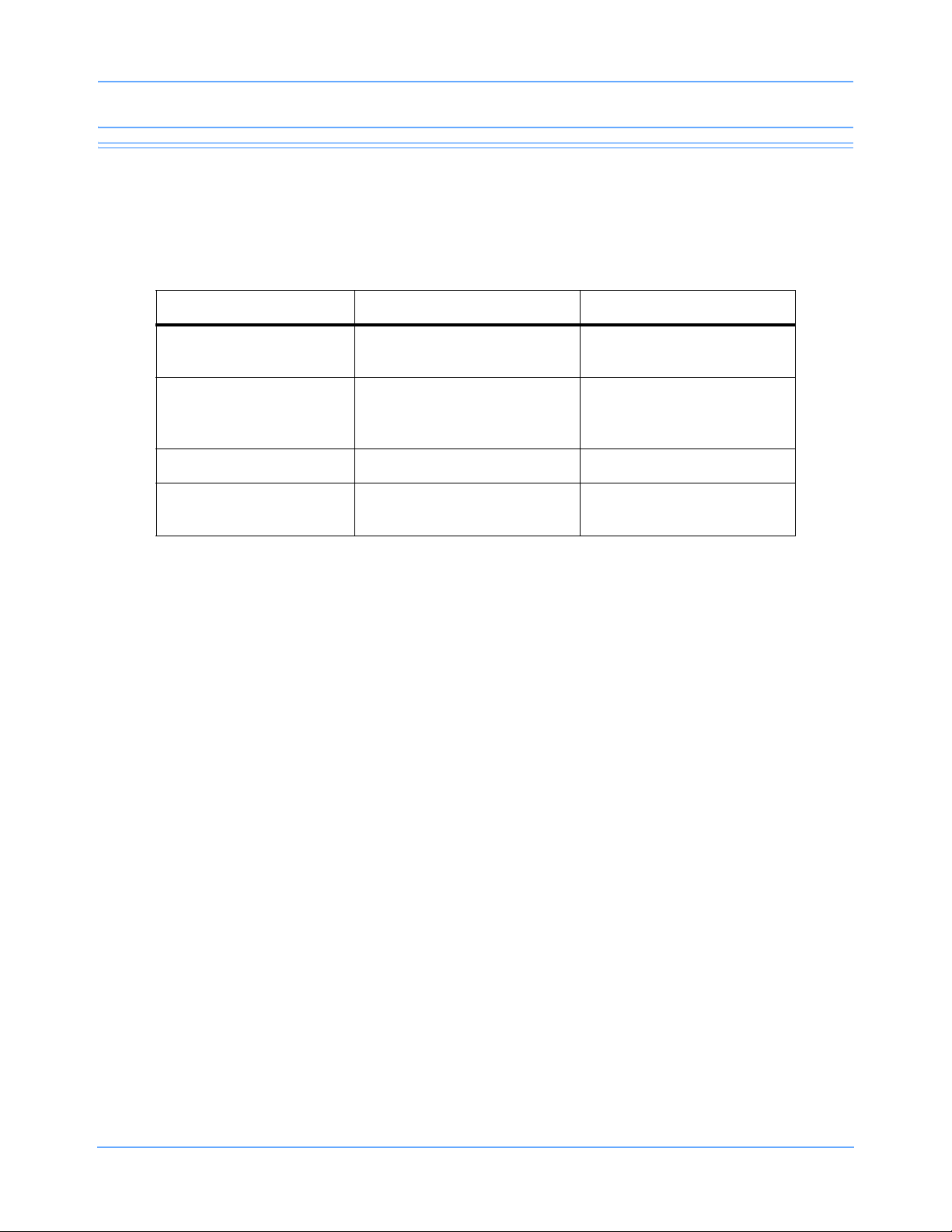

Table 1: Environmental Requirements

Operating Storage

Temperature

Humidity

Altitude N/A 12,192 m (40,000 feet)

Atmospheric Pressure

18° to 28° C (64.4° to 82.4° F),

±5° C of calibration

20 to 80% (non-condensing)

relative humidity (RH), ±20%

RH of calibration

500 to 800 mmHg, ±50mmHg

of calibration

-25° to 70° C (-13° to 158° F)

10 to 95% (non-condensing)

N/A

91518 Multigas Analyzer Service Manual 1-3

Page 8

Introduction

Controls and Connectors

The blue power ON/OFF switch is located on the front of the analyzer.

All other multigas analyzer functions are controlled using the touch keys on Spacelabs Healthcare monitors.

Front View

Figure 1-2: Front view of the 91518 Multigas Analyzer

Gas sampling line inlet connector

Replaceable D-fend water trap

Reference gas port (no connection)

Power ON/OFF switch

Gas outlet port

Fan and filter

91518 Multigas Analyzer Service Manual 1-4

Page 9

Rear View

Introduction

Figure 1-3: Rear of 91518 Multigas Analyzer

9 pin SDLC connector (J2)

RS-232 connector (J1)

SDLC terminator

Equipotential ground terminal

26-pin SDLC connector (J3)

Power connection

91518 Multigas Analyzer Service Manual 1-5

Page 10

Page 11

Setup

Contents

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Multigas Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Power Up Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Unpacking

Before unpacking the 91518 Multigas Analyzer, inspect its shipping container for visible damage. Unpack and

remove the multigas analyzer from its container. Check the multigas analyzer's exterior for signs of physical

damage. Be sure to check the SDLC connectors (refer to Figure 1-3 on page 1-5) on the back of the multigas

analyzer for bent pins. If any damage is apparent, notify the carrier and Spacelabs Healthcare immediately.

Please follow your hospital’s procedure regarding the disposal or recycling of packaging waste.

Equipment Inventory

The following items are included with the 91518 Multigas Analyzer:

• Gas sampling input line

Safety Checks

Physical Inspection

Visually inspect the unit to verify that it is physically sound (no loose hardware, no damaged fittings, clean fan

filter, etc.).

Table 1: Summary of Standards for Medical Monitoring Equipment

International Mains to

Chassis Leakage

100 μA - normal condition, ground

attached (AC connector to chassis)

500 μA - single fault condition, open

ground or reverse polarity

300 μA - normal condition, ground

attached (AC connector to chassis)

300 μA - single fault condition, open

ground or reverse polarity

U.S. (120 V) Mains to

Chassis Leakage

Mains Resistance

500 milliohms*

200 milliohms*

* Measured from the AC Power cord third wire ground to the most distant ground attachment

91518 Multigas Analyzer Service Manual 2-1

Page 12

Setup

Non-terminated Terminated

Multigas Setup

Sampling Lines

The sampling lines used with a 91518 Multigas Analyzer must be constructed of a material that will not absorb

anesthetic agents and cause erroneous readings. The correct sample lines are available from Spacelabs

Healthcare. Refer to Parts on page 6-1.

Power Supply

The 91518 can be powered from the J3 SDLC connector from the patient monitor or module housing, or it can

be powered from an external power supply, P/N 119-0479-xx.

SDLC Bus Termination

The SDLC bus must be properly terminated for correct operation. Termination of the SDLC bus is

accomplished by means of terminator switches on the rear of the monitor and the multigas analyzer, or by a

terminator plug P/N 012-0507-02, when connected to a portable monitor.

Figure 2-1: Terminator switch settings

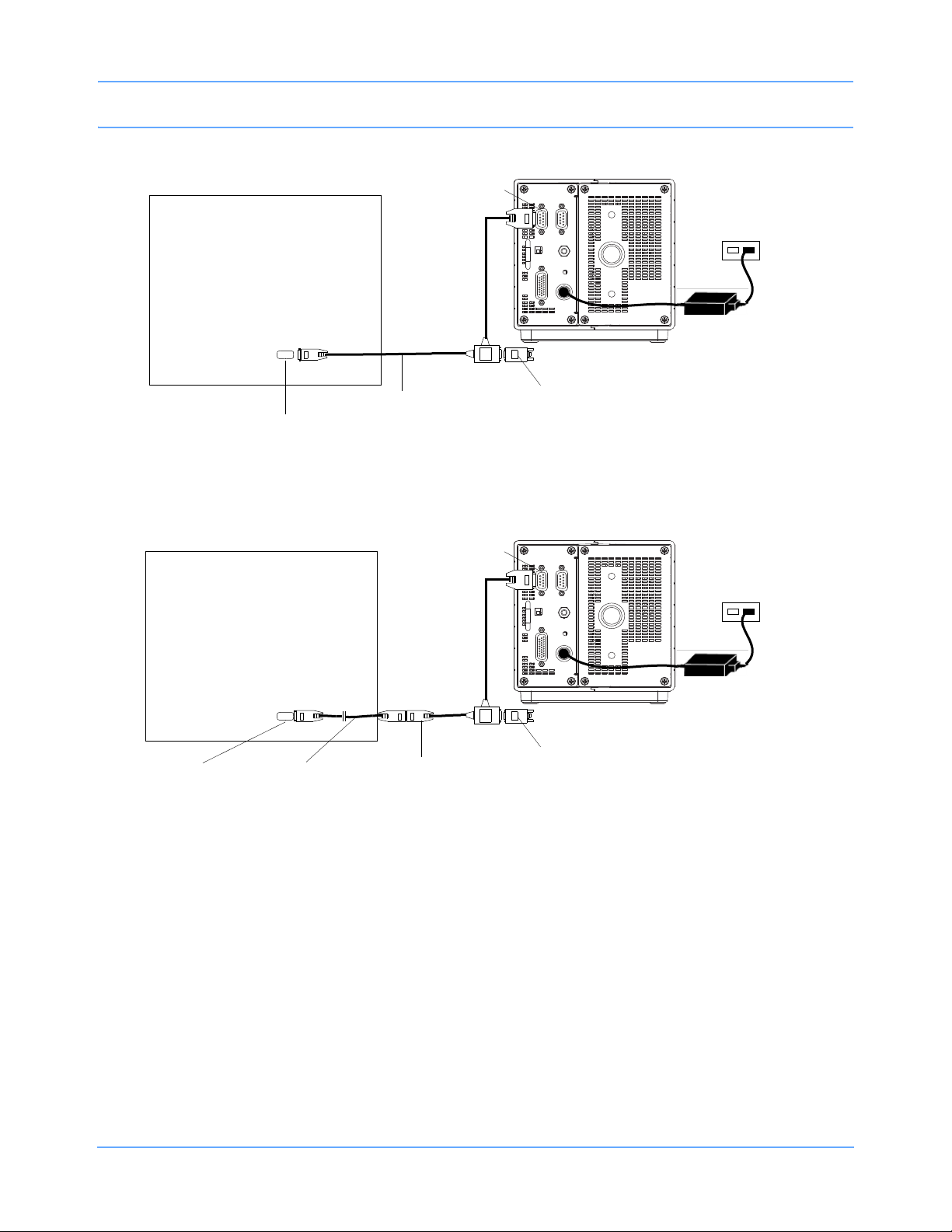

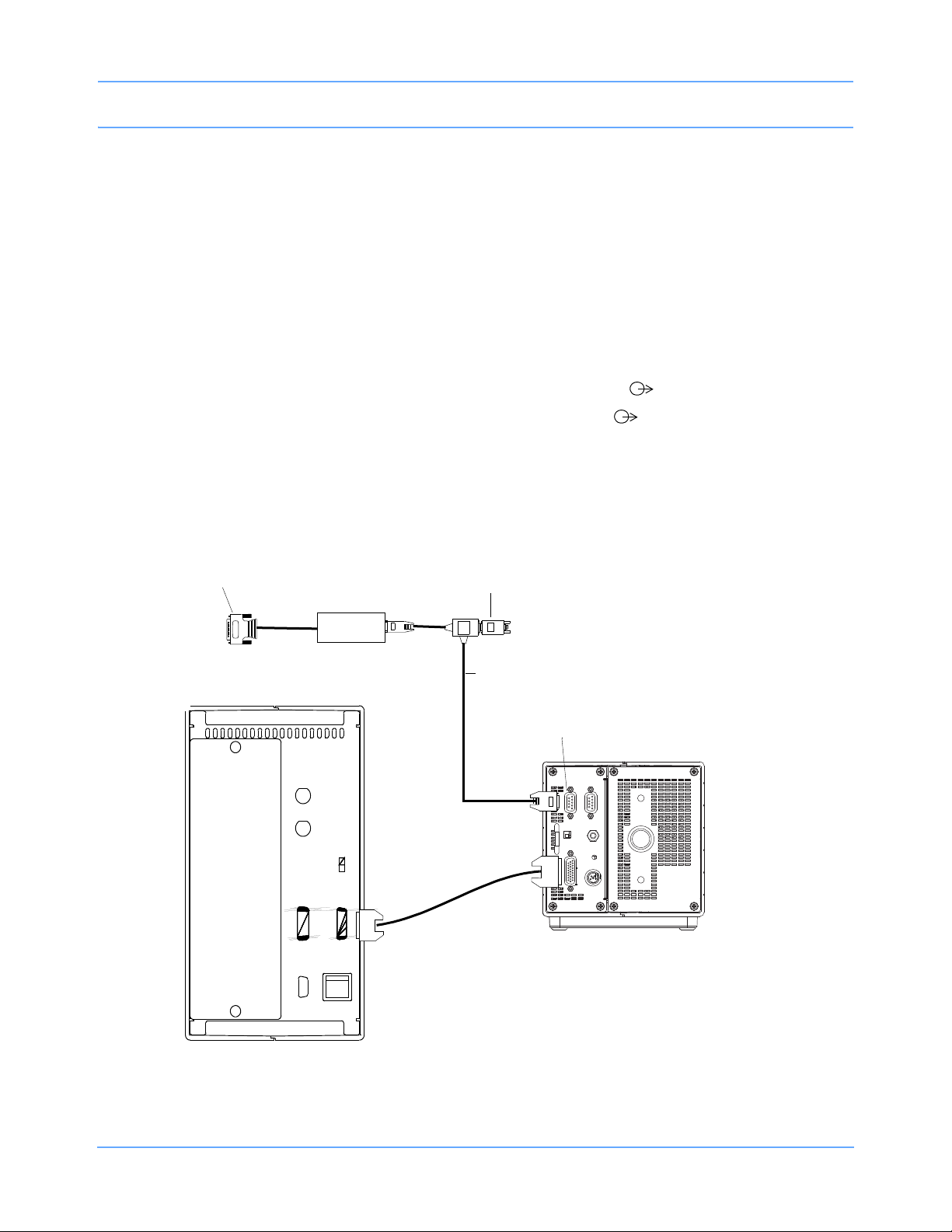

90367/69, 91369, 91370 Monitor Installations

To install the 91518 with 90367/69, 91369, 91370 monitors:

1 Verify that AC power is connected as required by local standards. An external power supply

(P/N

119-0480-00 or 119-0251-00) is required for use with the 91518 Multigas Analyzer.

2 Ensure that the monitor and multigas analyzer are powered OFF.

3 Assemble the required cables and terminators for your system configuration (refer to Figure 2-2 for part

numbers).

4 Connect the P1 connector of the tee cable (P/N 012-0175-01) to the SDLC jack (J2) on the 91518 rear panel

(refer to

Note:

An extension cable (6-foot SDLC extension cable [P/N 012-0619-00] or 3-foot SDLC extension cable

[P/N

(refer to

5 Connect the SDLC terminator to the P2 connector of the tee cable.

6 Connect the SDLC cable to the monitor.

7 Set the SDLC switch on the 91518 Multigas Analyzer to terminated ( ).

Figure 1-3 on page 1-5 for rear panel information).

012-0242-00]) can be connected to the tee cable to extend the distance of the 91518 from the monitor

Figure 2-3 on page 2-3).

91518 Multigas Analyzer Service Manual 2-2

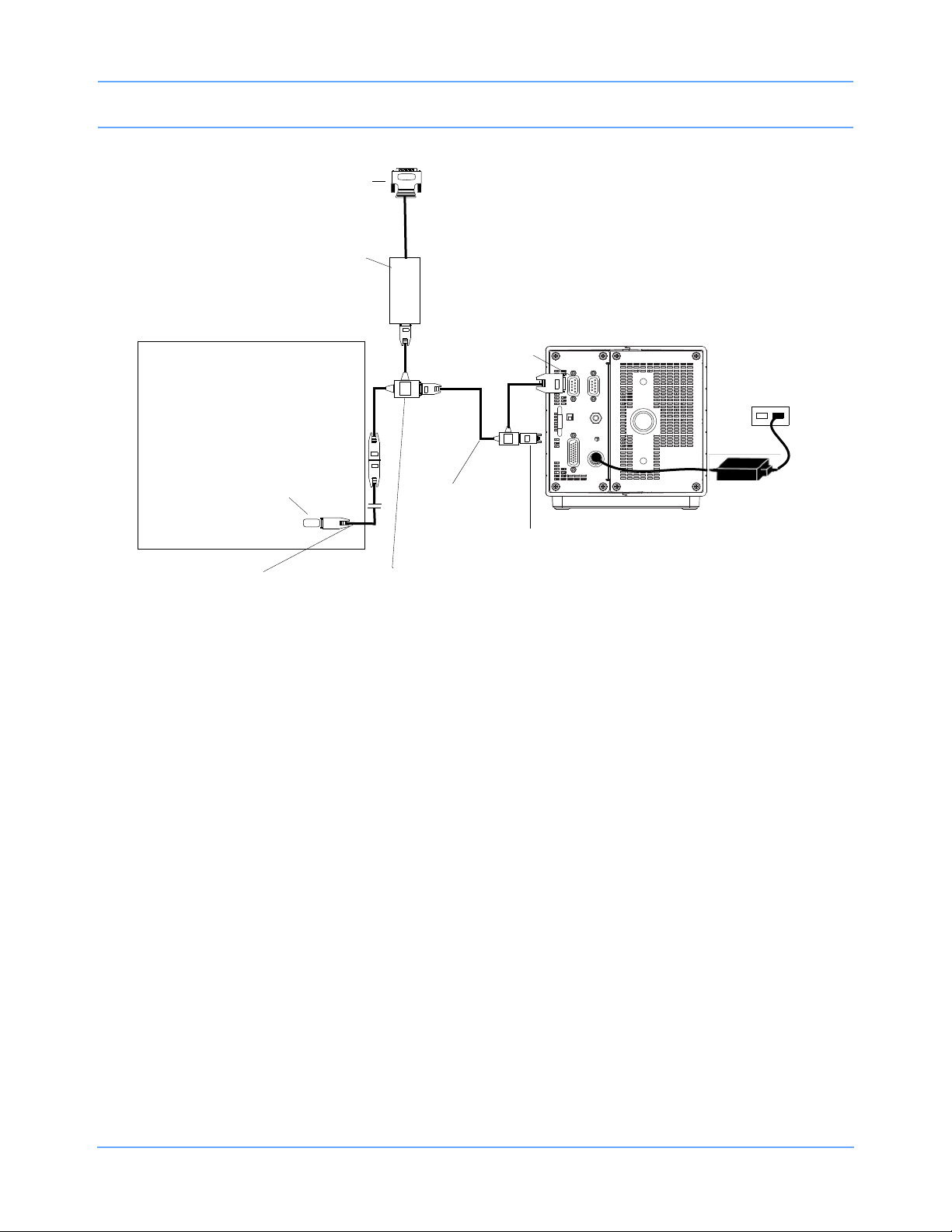

Page 13

Setup

jack (J2)

P/N 012-0175-01

SDLC

terminator

P/N 012-0507-02

SDLC

SDLC

....

.....

tee cable

91518

90367/69/91369/91370

monitor

jack

AC power

source

Power supply

P/N 119-0480-00

jack (J2)

P/N 012-0175-01

SDLC

terminator

P/N 012-0507-02

SDLC

SDLC

....

.....

tee cable

91518

90367/69/91369/91370

monitor

jack

AC power

source

Power supply

P/N 119-0480-00

extension cable

P/N 012-0619-00

or 012-0242-00

Figure 2-2: 91518 connections to 90367/69, 91369, 91370 monitors

91518 Multigas Analyzer Service Manual 2-3

Figure 2-3: 91518 connections to 90367/69, 91369, 91370 monitors, using extension cable

Page 14

Setup

jack (J2)

P/N 012-0175-01

SDLC

terminator

P/N 012-0507-02

SDLC

SDLC

....

.....

tee cable

91518

90367/69/91369/91370

monitor

jack

AC power

source

Power supply

P/N 119-0480-00

P/N 012-0152-00

tee cable

To peripheral device

Flexport interface

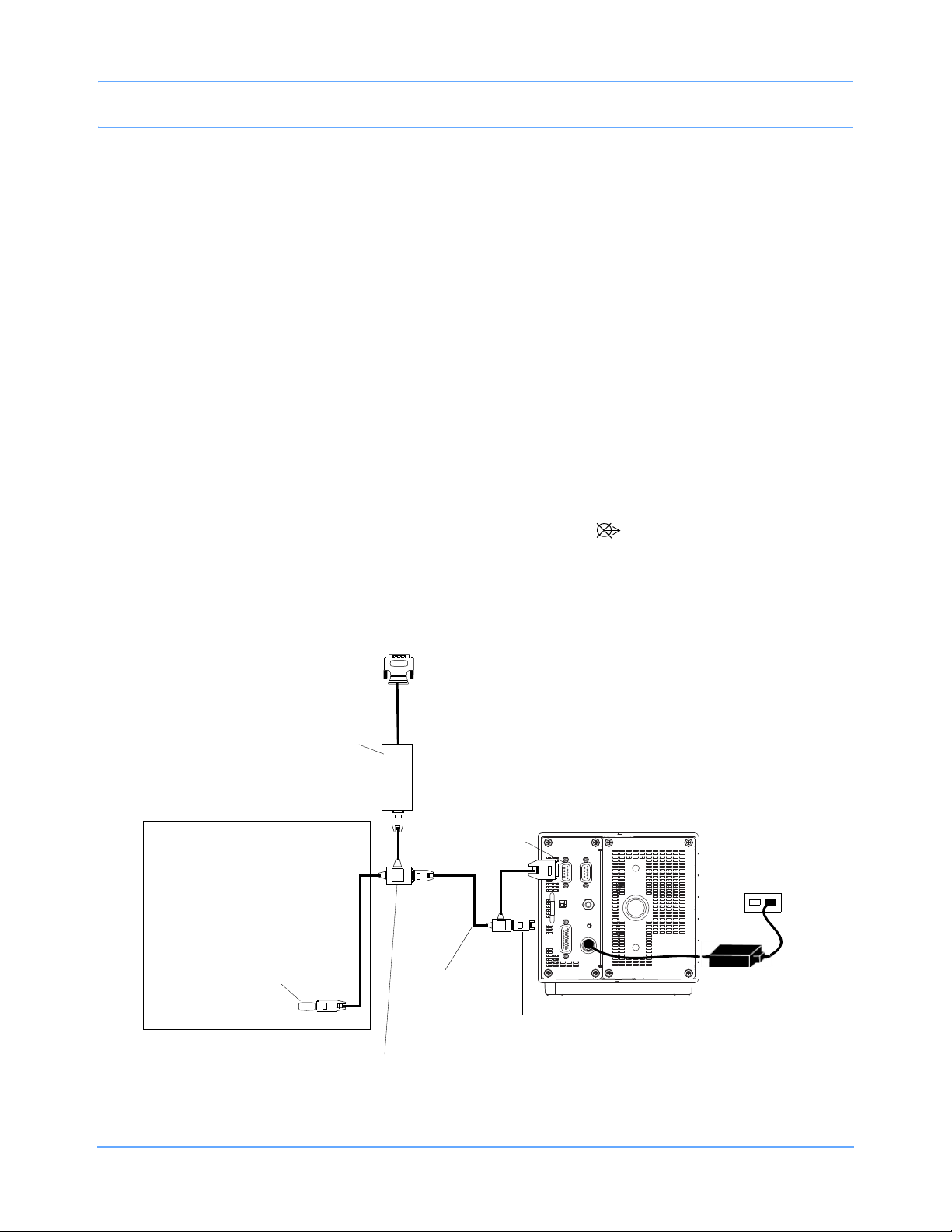

90367/69, 91369, 91370 Monitor Installations with Flexport

To install the 91518 with 90367/69, 91369, 91370 monitors:

1 Verify that AC power is connected as required by local standards. An external power supply

(P/N

119-0480-00 or 119-0251-00) is required for use with the 91518 Multigas Analyzer.

2 Ensure that the monitor and multigas analyzer are powered OFF.

3 Assemble the required cables and terminators or your system configuration (refer to Figure 2-4 for part

numbers).

4 Connect the P1 connector of the tee cable (P/N 012-0175-01) to the SDLC jack (J2) on the 91518 rear panel

(refer to

Note:

An extension cable (6-foot SDLC extension cable [P/N 012-0619-00] or 3-foot SDLC extension cable

[P/N

(refer to

5 Connect P3 of the Flexport tee cable (P/N 012-0152-00) to P2 of the tee cable (P/N 012-0175-01).

6 Connect P1 of the Flexport cable to the monitor.

7 Set the SDLC switch on the 91518 Multigas Analyzer to terminated ( ).

Figure 1-3 on page 1-5 for rear panel information).

012-0242-00]) can be connected to the tee cable to extend the distance of the 91518 from the monitor

Figure 2-5 on page 2-5).

Note:

If using more than one Flexport, Spacelabs Healthcare recommends the use of the Flexport Holder

(P/N

650-0201-00).

91518 Multigas Analyzer Service Manual 2-4

Figure 2-4: 91518 connections to 90367/69, 91369, 91370 monitors, with Flexport

Page 15

Setup

jack (J2)

P/N 012-0175-01

SDLC

terminator

P/N 012-0507-02

SDLC

SDLC

....

.....

tee cable

91518

90367/69/91369/91370

monitor

jack

AC power

source

Power supply

P/N 119-0480-00

P/N 012-0152-00

tee cable

To peripheral device

Flexport interface

extension cable

P/N 012-0619-00

or 012-0242-00

91518 Multigas Analyzer Service Manual 2-5

Figure 2-5: 91518 connections to 90367/69, 91369, 91370 monitors,

using Flexport and extension cable

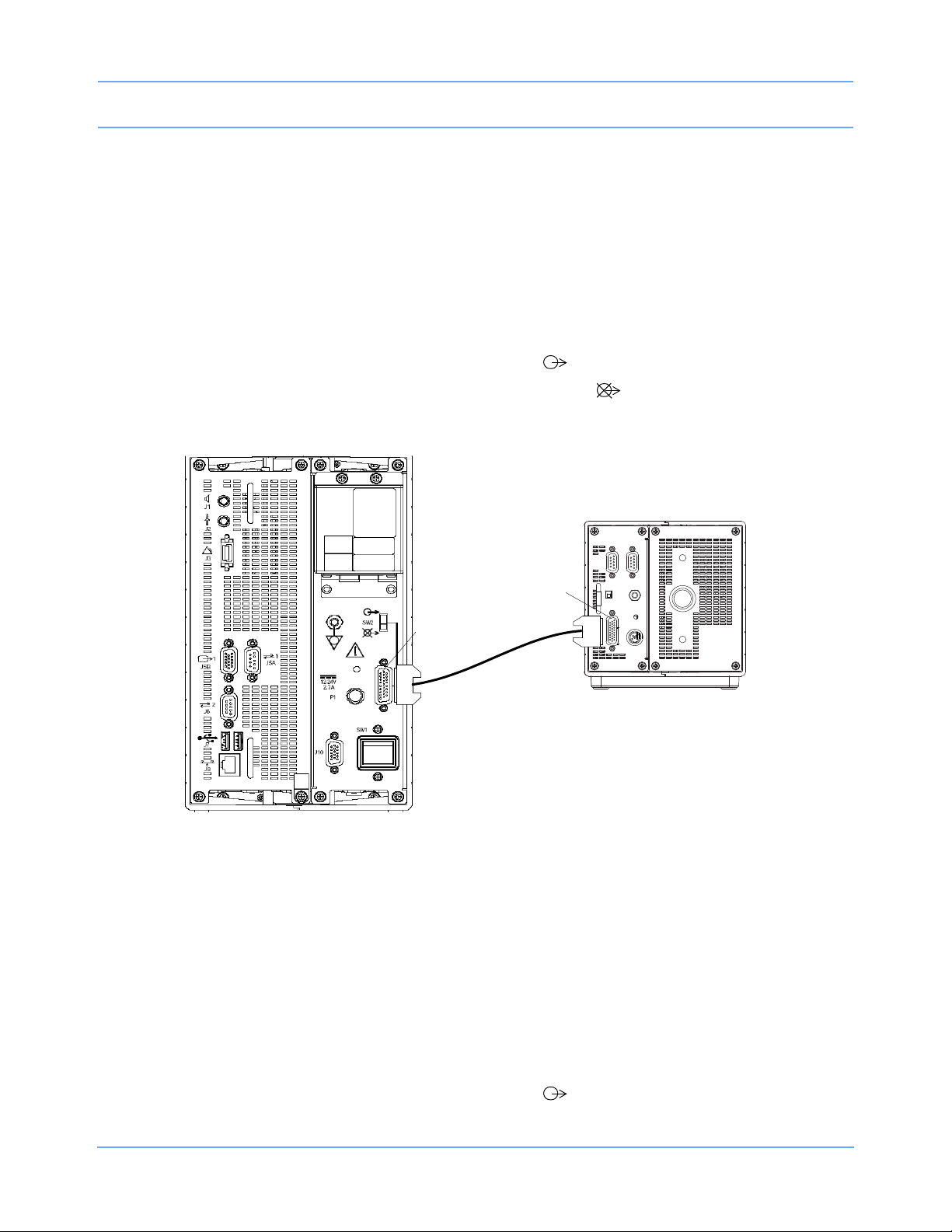

Page 16

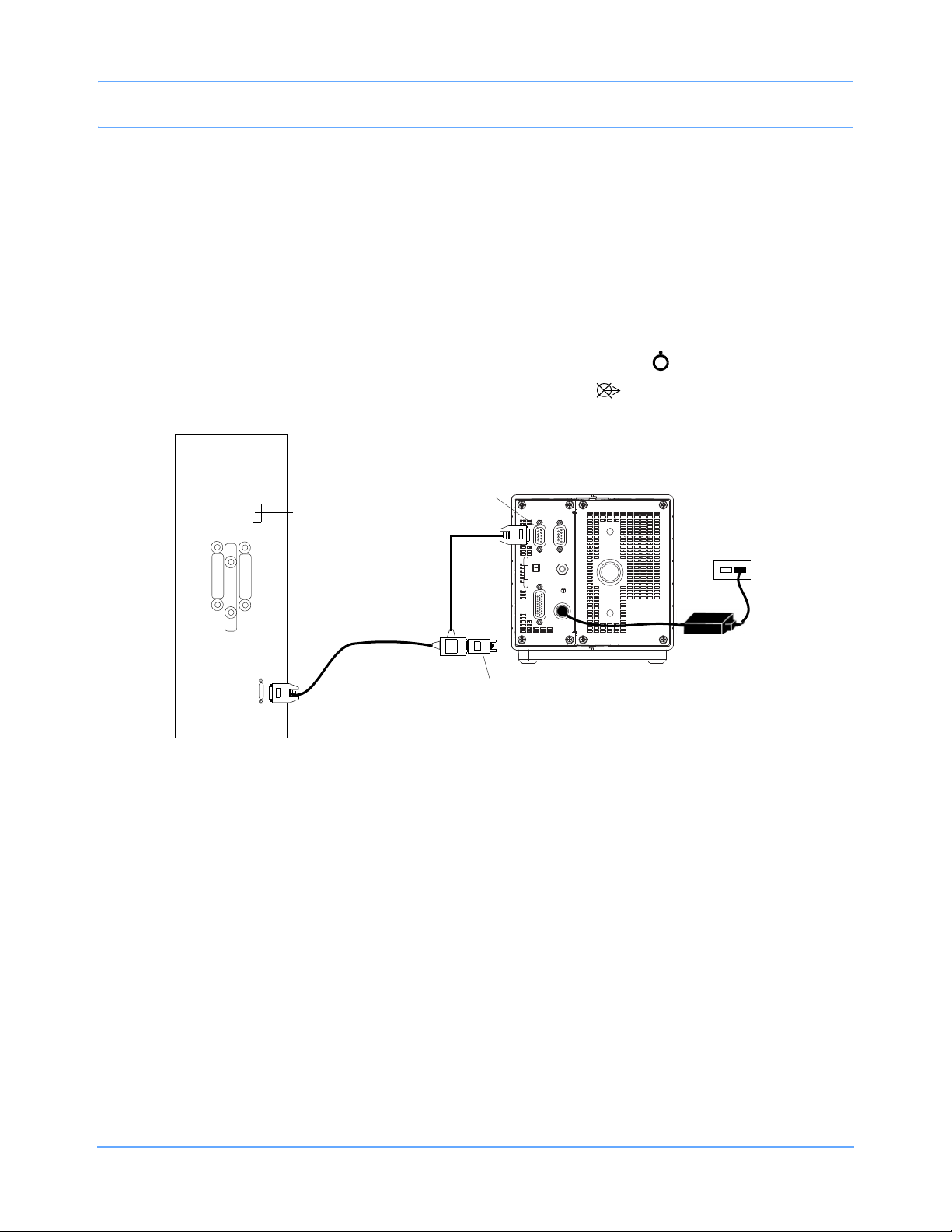

Setup

P/N 012-0601-xx

SDLC

jack (J3)

cable

91387

SDLC

jack (J9)

91518

91387 Monitor Installation

To install the 91518 with the 91387 monitor:

1 Verify that the AC power is connected as required by local standards. The 91518 Multigas Analyzer will not

require the use of an external power supply.

2 Ensure that the monitor and multigas analyzer are powered OFF.

3 Assemble the required cables for your system configuration (refer to Figure 2-6 for part numbers).

4 Connect the SDLC cable (P/N 012-0601-xx) to the SDLC jack (J3) on the 91518 rear panel (refer to

Figure 1-3 on page 1-5 for rear panel information) and to the SDLC (J9) of the monitor.

5 Set the SDLC switch on the 91387 monitor to unterminated ( ).

6 Set the SDLC switch on the 91518 Multigas Analyzer to terminated ( ).

Figure 2-6: 91518 connections to 91387 monitor, using power from monitor

91387 Monitor Installation with Flexport

To install the 91518 with the 91387 monitor:

1 Verify that the AC power is connected as required by local standards. The 91518 Multigas Analyzer will not

require the use of an external power supply.

2 Ensure that the monitor and multigas analyzer are powered OFF.

3 Assemble the required cables for your system configuration (refer to Figure 2-7 for part numbers).

4 Connect the SDLC cable (P/N 012-0601-xx) to the SDLC jack (J3) on the 91518 rear panel (refer to

Figure 1-3 on page 1-5 for rear panel information) and to the SDLC (J9) of the monitor.

5 Set the SDLC switch on the 91387 monitor to unterminated ( ).

91518 Multigas Analyzer Service Manual 2-6

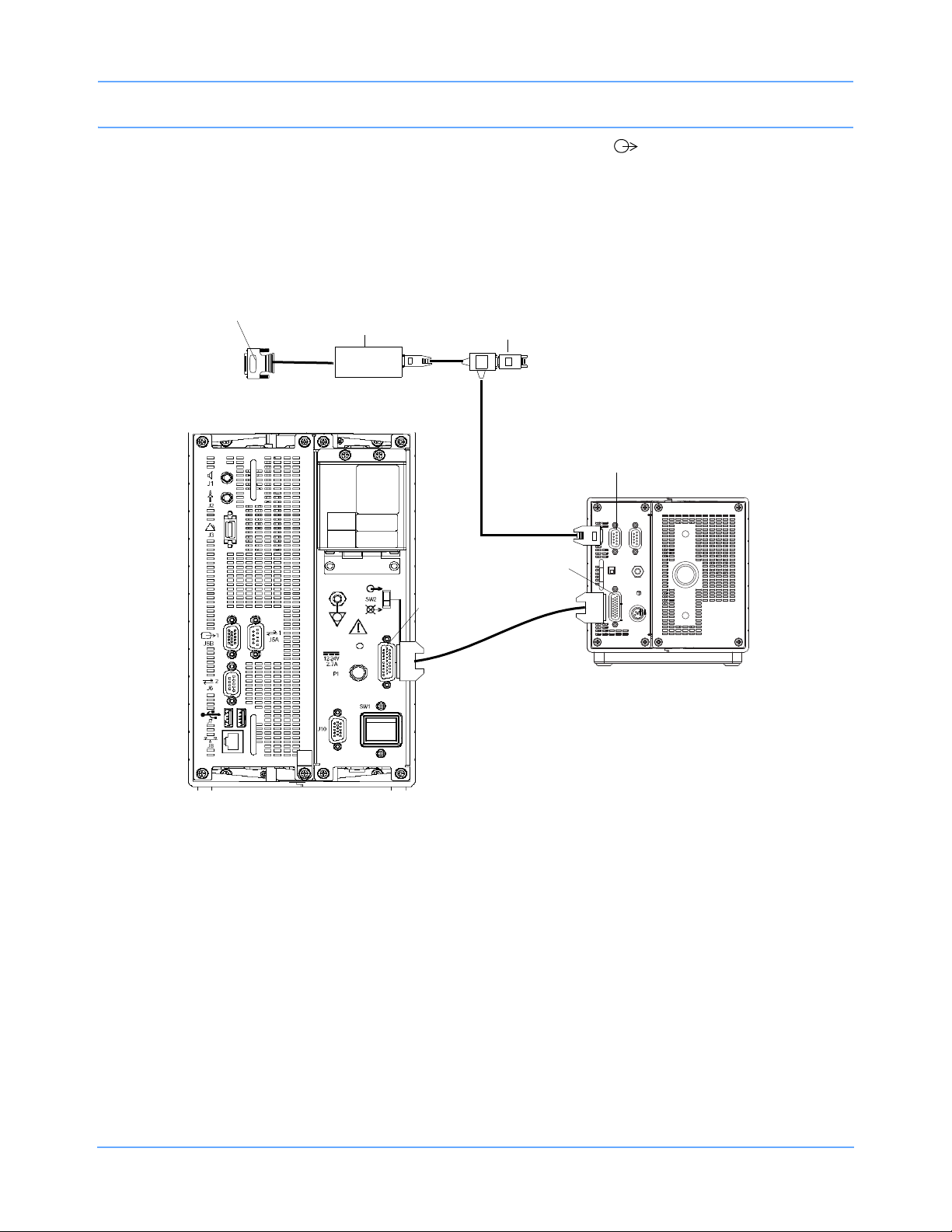

Page 17

Setup

P/N 012-0601-xx

SDLC

jack (J3)

cable

91387

SDLC

jack (J9)

91518

P/N 012-0152-00

cable

Flexport

To peripheral

device

interface

SDLC

jack (J2)

SDLC terminator

P/N 012-0507-02

6 Set the SDLC switch on the 91518 Multigas Analyzer to unterminated ( ).

7 Connect the Flexport cable (012-0152-00) to J2 of the multigas analyzer.

Note:

If using more than one Flexport, Spacelabs Healthcare recommends the use of the Flexport Holder

(P/N

650-0201-00).

Figure 2-7: 91518 connections to 91387 monitor, with Flexport

91518 Multigas Analyzer Service Manual 2-7

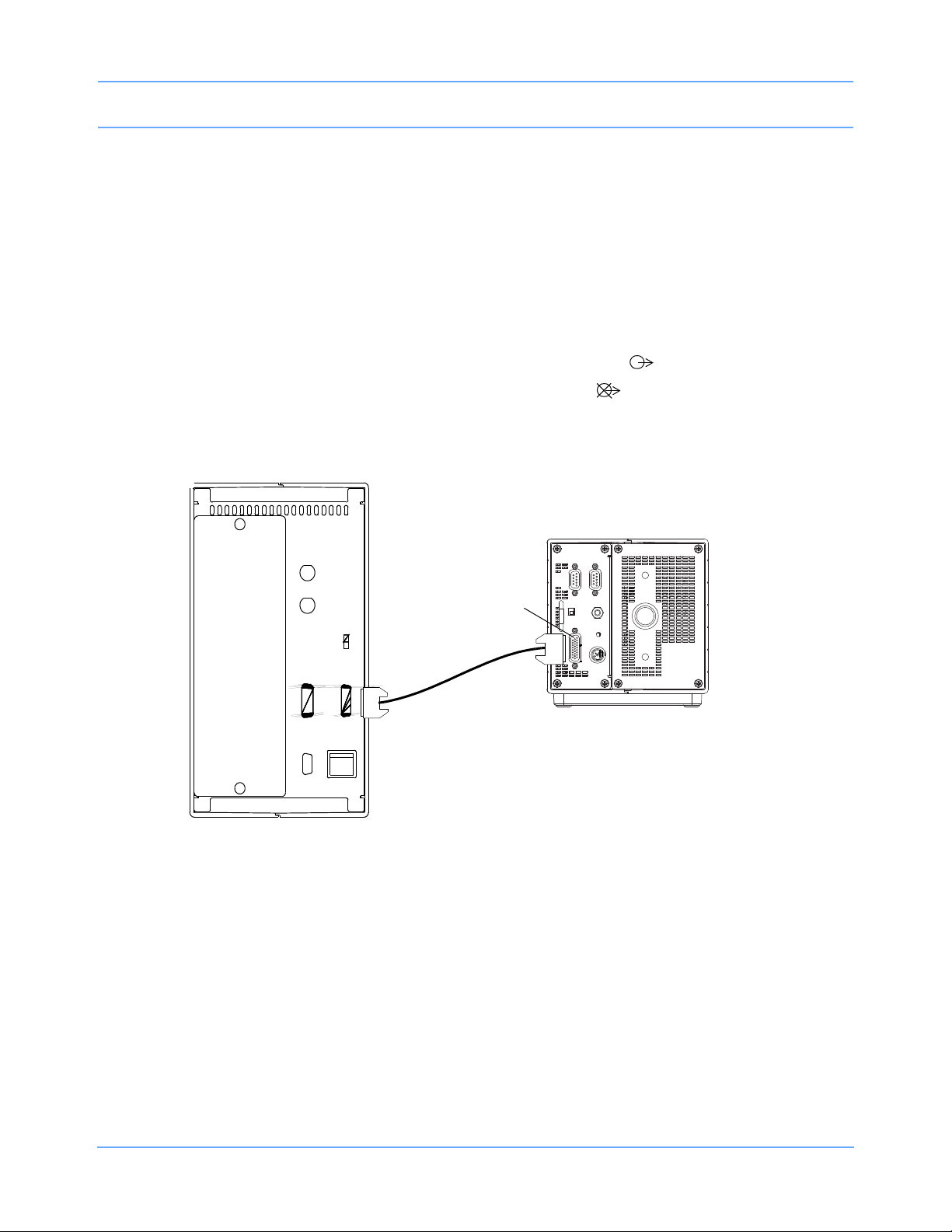

Page 18

Setup

J2

J3

P/N 012-0601-xx

SDLC

jack (J3)

cable

90364/90491/

90499/90387

91518

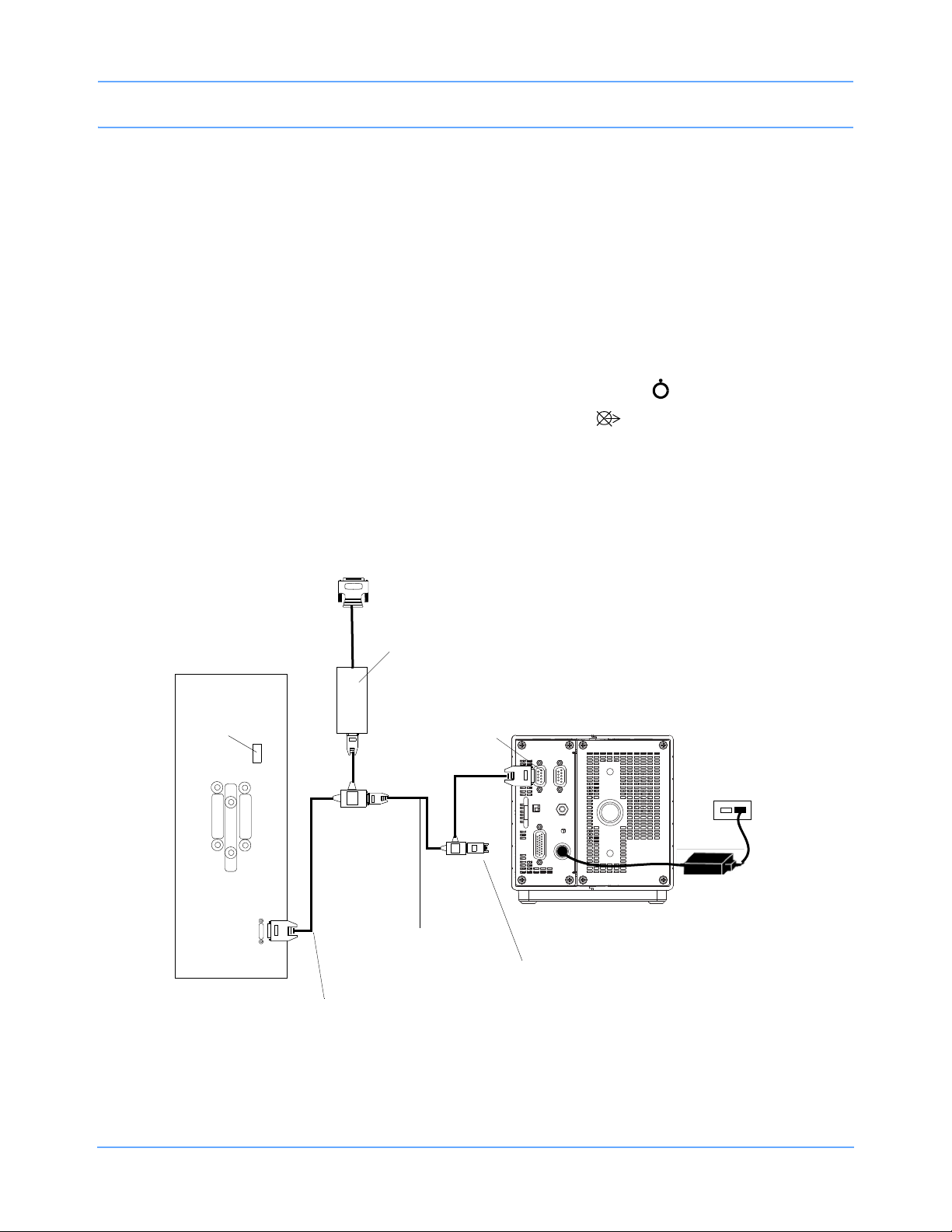

90364, 90491, 90499, and 90387 Module Housing or Monitor Installations

To install the 91518 with 90364, 90491, 90499, and 90387 module housings or monitors:

1 Verify that the AC power is connected as required by local standards. The 91518 Multigas Analyzer will not

require the use of an external power supply.

2 Ensure that the monitor or module housing and multigas analyzer are powered OFF.

3 Assemble the required cables for your system configuration (refer to Figure 2-8 for part numbers).

4 Connect the SDLC cable (P/N 012-0601-xx) to the SDLC jack (J3) on the 91518 rear panel (refer to

Figure 1-3 on page 1-5 for rear panel information) and to the SDLC (J2) of the monitor or module housing.

5 Set the SDLC switch on the 90364/90491/90499/90387 to unterminated ( ).

6 Set the SDLC switch on the 91518 Multigas Analyzer to terminated ( ).

Figure 2-8: 91518 connections to 90364, 90491, 90499, and 90387 monitors or housings

91518 Multigas Analyzer Service Manual 2-8

Page 19

Setup

J2

J3

P/N 012-0601-xx

SDLC

jack (J3)

cable

90364/90491/

90499/90387

91518

SDLC

jack (J2)

To peripheral

Flexport

SDLC terminator P/N 012-0507-02

interface

P/N 012-0152-00

cable

device

90364, 90491, 90499, and 90387 Module Housing or Monitor Installations with Flexport

To install the 91518 with 90364, 90491, 90499, and 90387 module housings or monitors:

1 Verify that the and AC power is connected as required by local standards. The 91518 Multigas Analyzer will

not require the use of an external power supply.

2 Ensure that the monitor or module housing and multigas analyzer are powered OFF.

3 Assemble the required cables for your system configuration (refer to Figure 2-9 for part numbers).

4 Connect the SDLC cable (P/N 012-0601-xx) to the SDLC jack (J3) on the 91518 rear panel (refer to

Figure 1-3 on page 1-5 for rear panel information) and to the SDLC (J2) of the monitor or module housing.

5 Set the SDLC switch on the 90364/90491/90499/90387 to unterminated ( ).

6 Set the SDLC switch on the 91518 Multigas Analyzer to unterminated ( ).

7 Connect the Flexport cable (012-0152-00) to J2 of the multigas analyzer.

Note:

If using more than one Flexport, Spacelabs Healthcare recommends the use of the Flexport Holder

(P/N

650-0201-00).

Figure 2-9: 91518 connections to 90364, 90491, 90499, and 90387 monitors or housings,

91518 Multigas Analyzer Service Manual 2-9

with Flexport

Page 20

Setup

J6

90485 Remote

P/N 012-0175-01

SDLC

terminator

P/N 012-0507-02

SDLC

jack (J2)

91518

SDLC termination

switch

Module Housing

tee cable

AC power

Power supply

P/N 119-0480-00

90485 Remote Module Housing Installation

1 Verify that AC power is connected as required by local standards. An external power supply

(P/N

119-0480-00 or 119-0251-00) is required for use with the 91518 Multigas Analyzer.

2 Ensure that the module housing and multigas analyzer are powered OFF.

3 Assemble the required cables for your system configuration (refer to Figure 2-10 for part numbers).

4 Connect the P1 connector of the tee cable (P/N 012-0175-01) to the SDLC jack (J2) on the 91518 rear panel

(refer to

5 Connect P2 of the tee cable (P/N 012-0175-01) to the remote module housing.

6 Set the SDLC switch on the 90485 remote module housing to unterminated ( ).

7 Set the SDLC switch on the 91518 Multigas Analyzer to terminated ( ).

Figure 1-3 on page 1-5 for rear panel information).

91518 Multigas Analyzer Service Manual 2-10

Figure 2-10: 91518 connections to a remote module housing

Page 21

Setup

J6

90485 Remote

SDLC

jack (J2)

91518

Module Housing

AC power

Power supply

P/N 119-0480-xx

P/N 012-0175-01

tee cable

P/N 012-0152-00

tee cable

SDLC

termination

switch

To peripheral device

Flexport interface

SDLC

terminator

P/N 012-0507-02

90485 Remote Module Housing Installation with Flexport

1 Verify that AC power is connected as required by local standards. An external power supply

(P/N

119-0480-00 or 119-0251-00) is required for use with the 91518 Multigas Analyzer.

2 Ensure that the module housing and multigas analyzer are powered OFF.

3 Assemble the required cables for your system configuration (refer to Figure 2-11 for part numbers).

4 Connect the P1 connector of the tee cable (P/N 012-0175-01) to the SDLC jack (J2) on the 91518 rear panel

(refer to

5 Connect P3 of the Flexport cable (P/N 012-0152-00) to P2 of the tee cable (P/N 012-0175-01).

6 Connect P1 of the Flexport cable to the remote module housing.

7 Set the SDLC switch on the 90485 remote module housing to unterminated ( ).

8 Set the SDLC switch on the 91518 Multigas Analyzer to terminated ( ).

Note:

If using more than one Flexport, Spacelabs Healthcare recommends the use of the Flexport Holder

(P/N

Figure 1-3 on page 1-5 for rear panel information).

650-0201-00).

91518 Multigas Analyzer Service Manual 2-11

Figure 2-11: 91518 connections to a remote module housing

Page 22

Setup

Room air

Hospital

scavenging

system

Gas

outlet

port

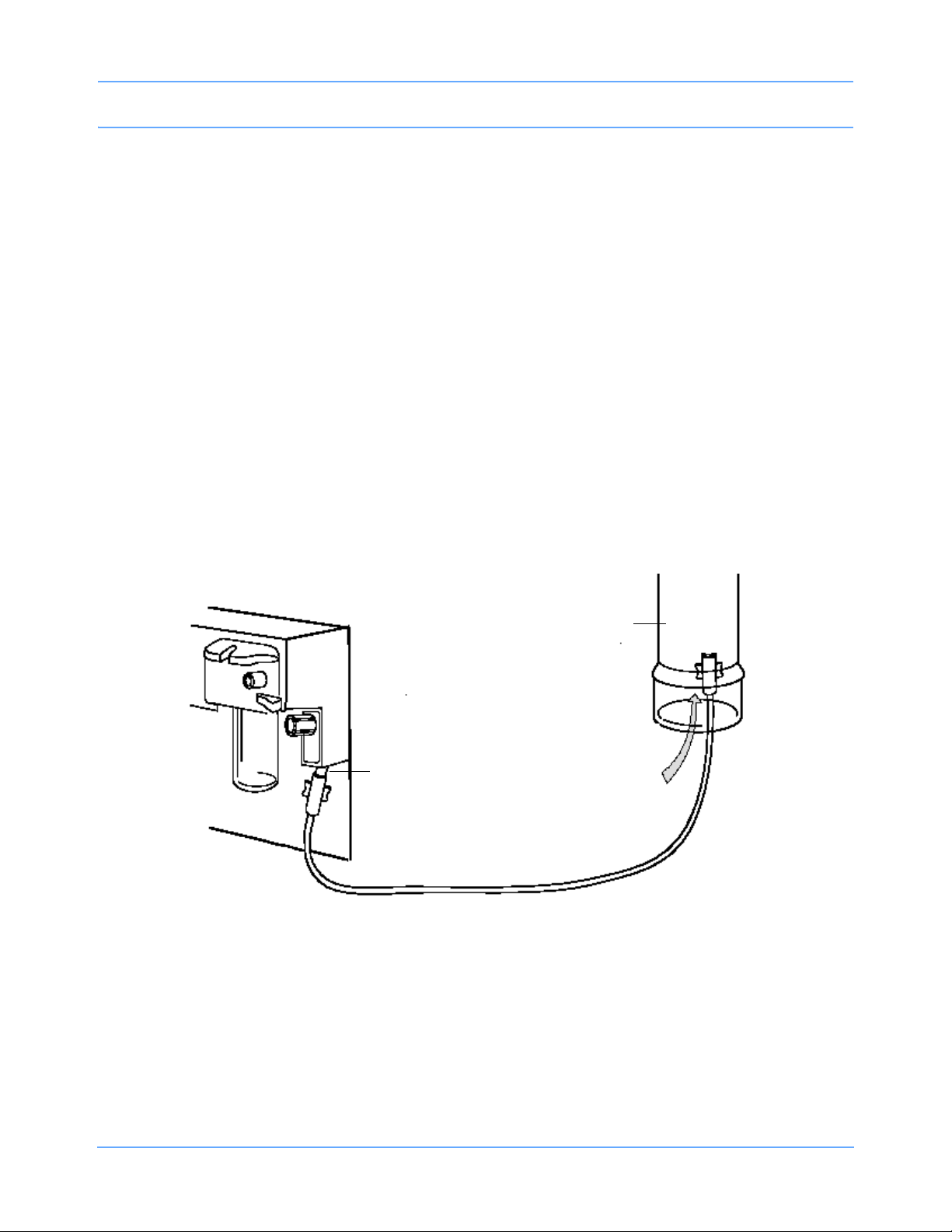

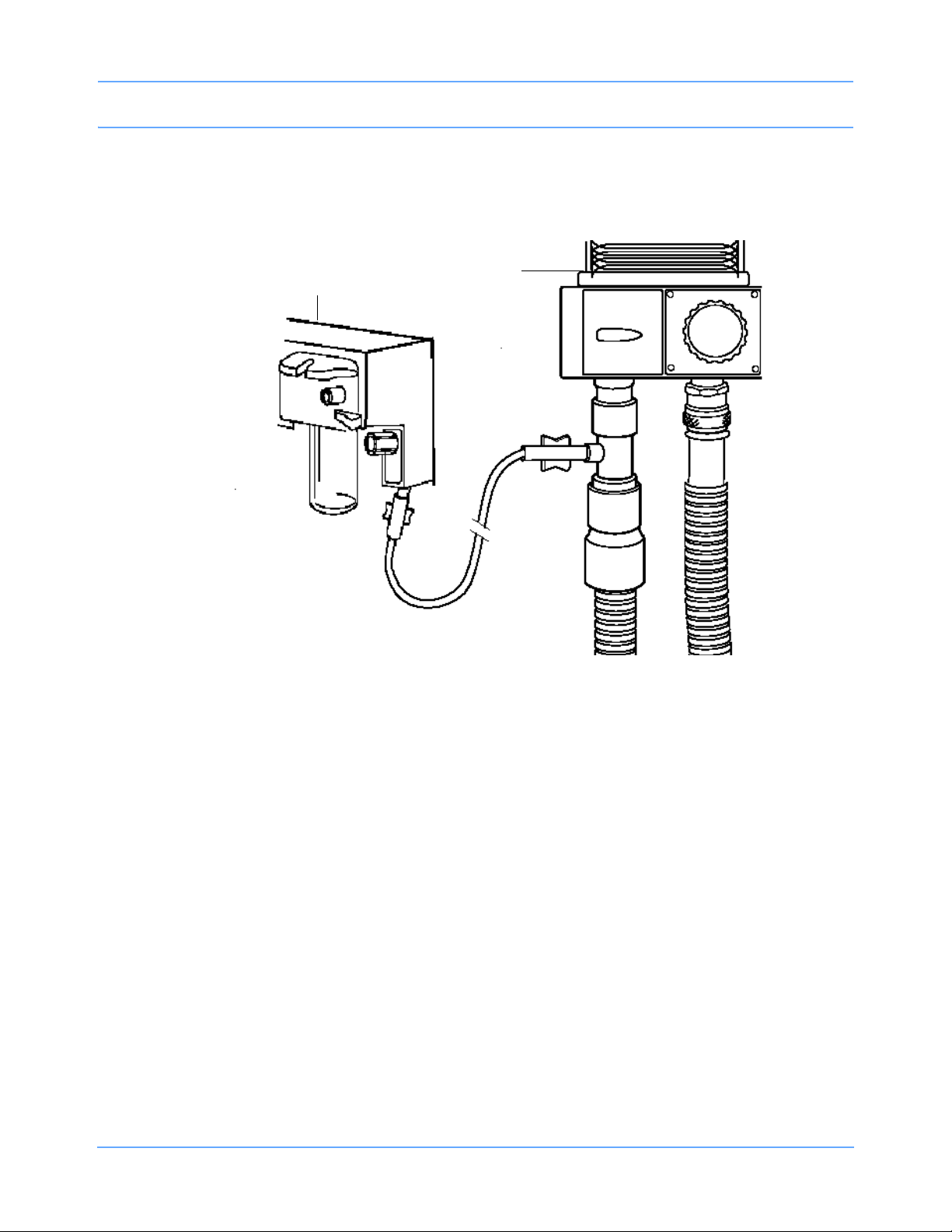

Connecting the Multigas Analyzer to a Scavenging System

To prevent pollution of the operating room, the gas sample should be vented from the operating room. Connect

the gas outlet port of the multigas analyzer (refer to Figure 1-2 on page 1-4) to the hospital scavenging system

(or anesthesia machine), or return the gas to the patient circuit.

Caution:

Do not connect the multigas analyzer directly to a vacuum scavenging system. Strong scavenging

suction can change the operating pressure of the multigas analyzer and can cause inaccurate

readings or damage to the analyzer.

Scavenging Through the Hospital Scavenging System

• Connect an exhaust line to the gas outlet port on the module’s front panel

• Insert the other end of the line into the hospital scavenging system. Ensure that the ventilation tube

diameter is at least two to three times larger than the exhaust line.

Caution:

Only connect the scavenging line to an open scavenging system, where the gas is removed at

room pressure. Do not connect the multigas analyzer directly to a vacuum scavenging system.

Figure 2-12: Scavenging through hospital ventilation

Scavenging Through the Anesthesia Machine Gas Scavenging System

Some anesthesia machines are equipped with an anesthesia gas scavenging system (AGSS). You may be

able to connect the multigas analyzer scavenging line directly to the AGSS. Refer to the documentation that

came with your anesthesia machine to determine if the scavenging line can be connected to the AGSS.

91518 Multigas Analyzer Service Manual 2-12

Page 23

Setup

Anesthesia

machine

Multigas Analyzer

Returning the Sample Gas to the Patient Circuit

The sample gas can also be returned to the patient breathing circuit. You may need an adapter to connect to

the patient breathing tubes.

Figure 2-13: Returning the sample gas to the patient circuit

91518 Multigas Analyzer Service Manual 2-13

Page 24

Setup

Power Up Verification

Prior to the initial use of a new analyzer (or a one that has just been serviced), verify the analyzer basic

performance using the following procedure. For equipment calibration, refer to Maintenance on page 4-1.

Note:

The 91518 Multigas Analyzer must be calibrated onsite prior to use and immediately after servicing.

Equipment Required

• Spacelabs Healthcare monitor

• SDLC cable

• Water trap

• Gas sampling line

Standalone Test

1 Insert a water trap (if one is not already present) into the analyzer front panel holder (ensure that the water

trap is not cracked.)

2 Verify that the monitor and analyzer are connected according to Multigas Setup on page 2-2.

3 Power OFF the multigas analyzer if the power is ON.

4 Power ON the monitor.

5 Power ON the analyzer.

6 Verify that the front panel ON/OFF button illuminates.

7 Verify that the pump starts within approximately 30 seconds.

8 Verify that the fan is operating.

9 Power OFF the analyzer.

System Test

1 Verify that the unit has passed the standalone test.

2 Connect the 91518 to a patient monitor as detailed in Multigas Setup on page 2-2.

3 Power ON the patient monitor.

4 Power ON the 91518.

Note:

The monitor must be powered on before the multigas analyzer.

5 Verify that the GAS parameter key and memory message appear on the monitor screen.

91518 Multigas Analyzer Service Manual 2-14

Page 25

Setup

6 Wait for at least two minutes for the gas sensors to warm up.

Note:

During warm up, other status messages may appear.

7 Connect the sampling line to the sampling line connector on the front of the water trap (refer to Figure 1-2

on page 1-4).

8 Breathe at least five breaths into the sample line.

9 Verify that a CO2 waveform and EtCO2 numerics appear on the monitor screen.

10 Verify that an O2 level of 16 to 23% appears.

Note:

The CO2 waveform and the EtCO2 and O2 numerics will take approximately 5 seconds before appearing

on the screen.

11 Remove the water trap. Verify that the LEAK DETECTED - Check System message appears on the monitor

screen within 20

12 Reinstall the water trap.

13 Verify that the leak detected message disappears.

If the water trap is not reinstalled within 40 seconds, the pump will shut off. To restart the sequence:

seconds.

a Touch GAS.

b Touch RESUME SAMPLING

c Touch YES.

14 Hold a finger over the water trap input (or pinch shut the sample line) to block air flow. Verify that the

message OCCLUSION - Check System appears on the monitor screen within 30

seconds.

91518 Multigas Analyzer Service Manual 2-15

Page 26

Page 27

Theory

Interface

& Power PCBA

Multigas Module

Rear

SDLC_26-pin

SDLC_9-pin

PD Dev.

Ports

AC

BRICK

DC in

I/O

I/O

Serial / USB

Debug

DC

Serial / Pwr / cntl

Switch

Switch

/LED

AC

Input

Power

On

Gas

Sampling

Front

SDLC Termination

Switch

Contents

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Interface PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Gas Analyzer Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oxygen Measuring Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

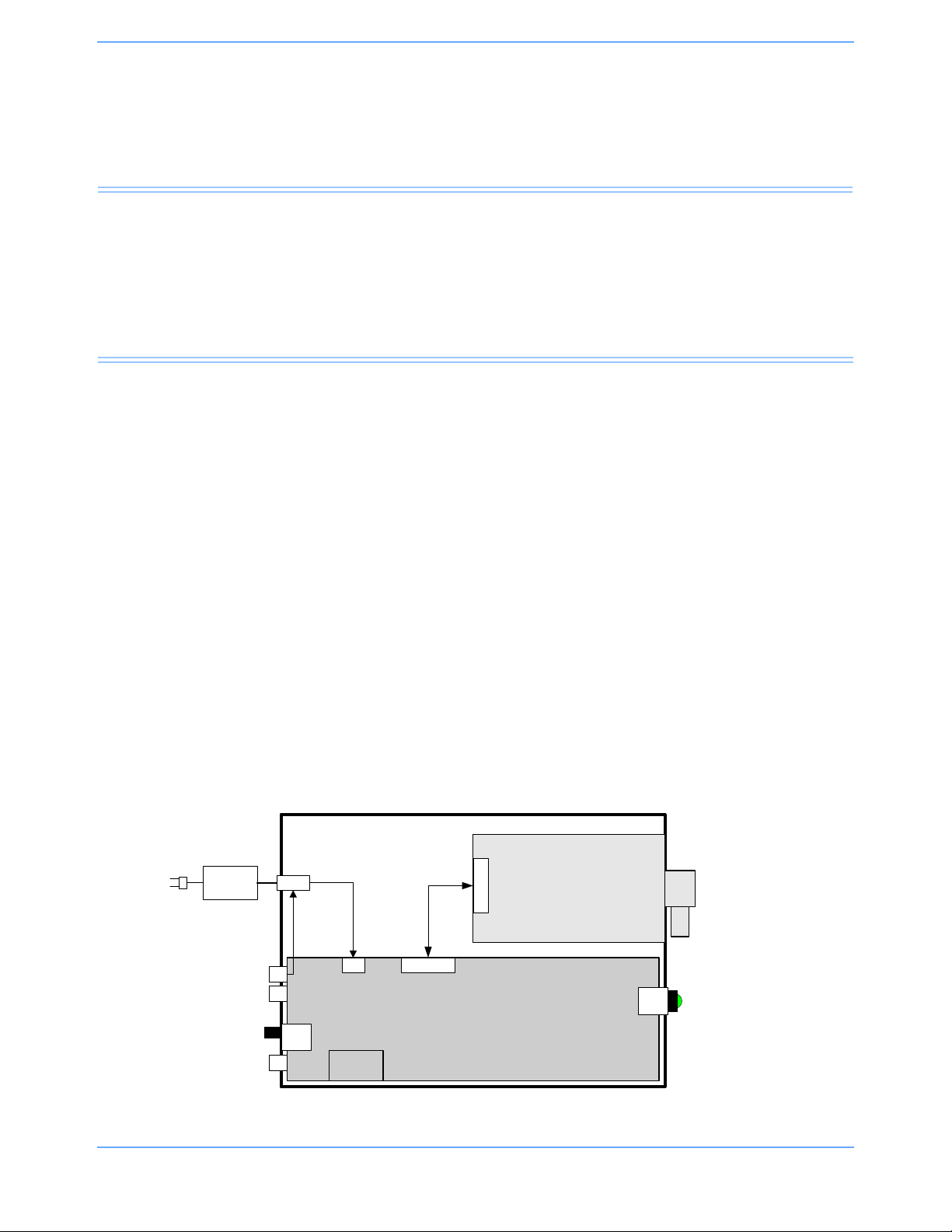

Overview

The 91518 Multigas Analyzer is a side stream gas analyzer, measuring real time concentrations of O2, CO2,

N

O and anesthetic agents (halothane, enflurane, isoflurane, desflurane and sevoflurane).

2

The interface PCBA communicates through a two-way SDLC connection to the Spacelabs Healthcare monitor.

Warning:

If any halogenated anesthetic agent other than halothane, isoflurane, enflurane, desflurane, or

sevoflurane is present, it will be misidentified and/or will interfere with the reported anesthetic

agent concentrations.

Caution:

• When administering anesthetic agents, incorrect agent identification may occur when a mixture

of sevoflurane and enflurane occur in the sample circuit.

• When administering anesthetic agents, always verify your anesthetic vaporizer setting.

Note:

The 91518 Multigas Analyzer automatically identifies which agent is detected, but it cannot measure more

than one agent at a time.

91518 Multigas Analyzer Service Manual 3-1

Figure 3-1: 91518 Product overview block diagram

Page 28

Multigas

Module

91518 Interface/Power PCBA

RS485

Xcvr

SDLC_9-pin

Serial / USB

Debug

BDM

Sniff1

Sniff 2

Ethernet

USB

Power

Switch

& LED

AC

input

DC-DC

Conv.

Power Path

Control

+9-18V to

+5V DC-

DC conv.

+18V

+18V

SDLC_26-pin

+5VDC

+/-15VDC

+5VDC

RS485

Ethernet

Controller

RS232

Xcvr

LED

indicators

Test

Switches

USB Xcvr

SDLC

Xcvr

Reset

MCU

RAM

Flash

eeprom

S/N rom

pcb ID

config

UART

Test /

Debug

Brick

supply

100-250VAC /

18.6 - 21V

(40W)

Interface

Core

Gas

Sampling

SW

SDLC

Termination

Switch

Power

On/Off

Power

On/Off

REAR FRONT

Regulators

PO_+5V

PO_+12V

PO_-12V

PO_+5V

PO_+12V

PO_-12V

SDLC

Theory

91518 Multigas Analyzer Service Manual 3-2

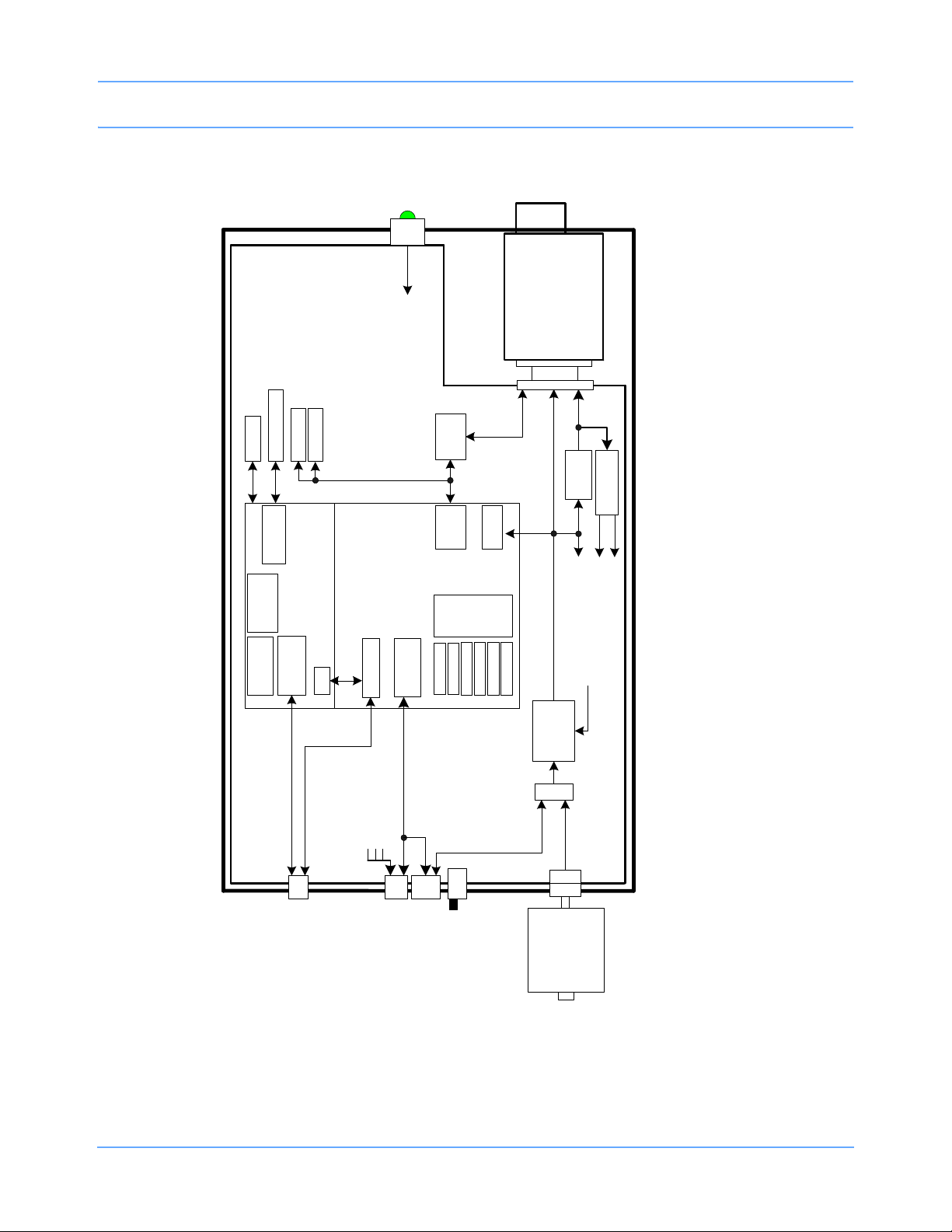

Figure 3-2: 91518 Detailed block diagram

Page 29

Theory

Interface PCBA

The interface PCBA (P/N 670-1319-xx) provides power to and controls the gas analyzer unit. The interface

PCBA is responsible for the two-way SDLC communication link with the Spacelabs Healthcare monitor. The

interface PCBA transmits processed data from the gas module to the monitor for display and recording.

Main CPU (MCU)

A Motorola MPC850 is the main CPU on the board.

EEPROM Circuit

The EEPROM stores configuration and setup information.

Serial Number IC Circuit

A serial number is available to be read by the MCU and then passed onto the host monitor upon demand. The

one-wire interface provides power through the pull-up resistor to the S/N IC. Data is bi-directional over this line.

This has no significance when replacing the PCBAs.

PCB Version Detection

The PCB codes the board version by selectively connecting each of the six lines either Hi or Lo, to form an ID

code. This is read and used by the software and passed to the host monitor upon demand.

Reset Circuit

A power-ON reset circuit provides a reset while the ISO_3.3V_CPU is coming up. The reset continues for an

additional 180 msec after the supply has reached the 3.0 V level or higher. If the supply drops below this level,

the circuit will again reset and reinitialize the 180 msec timer. Power Fail is implemented by monitoring the

+5 V supply and issuing a non-maskable interrupt (NMI) to the processor when the power supply goes low.

Data Lines - Power-Up Reset Configuration

During /HRESET, the MCU configuration is set by reading the data lines. /HRESET occurs at analyzer power

ON or reset.

Power Fault Detection

A low voltage fault on incoming ±12 V power supplies is determined by a pair of comparator circuits that

compare a divided-down sample of each supply to the reference voltage. When a fault occurs, an interrupt is

sent to the MCU.

91518 Multigas Analyzer Service Manual 3-3

Page 30

Theory

Memory Circuits (RAM and Flash ROM)

The memory circuits provide program memory for the MCU. The RAM is used for loading the software program

and data. The flash ROM is used for storing the software program.

SDLC Interface

The 91518 Multigas Analyzer communicates with the Spacelabs Healthcare monitor using a SDLC interface

that is common between all current Spacelabs Healthcare monitors and modules. The Multigas Analyzer can

use both 9-pin and 26-pin SDLC cables, depending on the Spacelabs monitor that is used. Refer to Multigas

Setup on page 2-2.

Test Indicator LEDs Circuit (Factory-Use Only)

The LED indicators are used for testing. Refer to Troubleshooting on page 5-1.

Gas Analyzer Unit

The OEM gas analyzer unit (P/N 010-1651-00) is a discrete device that measures the concentrations of gases.

Anesthetic agents or mixtures of two anesthetic agents are automatically identified and concentrations of the

identified agents are measured. The analyzer also detects mixtures of more than two agents and issues a

AGENT MIX message.

The gas analyzer unit consists of:

• Gas sampling system

• Gas measuring unit

• OM measuring unit

• CPU board

• OM board

Gas Sampling System

The sampling system takes care of drawing a gas sample into the analyzers at a fixed rate. The gas sampling

system samples the measured air to the analyzer and removes water and impurities from it. A sampling line is

connected to the water trap. The pump draws gas through the sampling line into the gas measuring unit. After

the gas measurements, the gas is exhausted through the sample gas out connector.

A larger pressure difference makes the deformations of the gas concentration curves less sensitive to high

variations of the airway pressures.

91518 Multigas Analyzer Service Manual 3-4

Page 31

Theory

D-fend Water Trap

The gas sample is drawn through a sampling line. The gas then enters the analyzer through the water trap,

where it is divided into two flows, a main flow and a side flow.

The main flow enters the analyzers and is separated from the patient side by a hydrophobic filter. The side flow

creates a slight subatmospheric pressure within the D-fend water trap, which causes fluid removed by the

hydrophobic filter to collect in the bottle.

Zero Valve and Absorber

The main flow passes through a magnetic valve before proceeding to the analyzers. This valve is activated to

establish the zero points for the gas measuring unit and the oxygen measuring unit. When the valve is

activated, room air is drawn through the absorber into the internal system and the gas sensors. Paralyme is

used as an absorbent.

Nafion Tube s

A nafion tube is used between the water trap and the zero valve to balance the sample gas humidity with that

of ambient air. The tube will prevent errors caused by the effect of water vapor on gas partial pressure when

humid gases are measured after calibration with dry gases.

Another nafion tube is used between the absorber and the pneumatic unit to prevent humidity caused by

absorption of CO

.

2

Gas Analyzers

After flowing through the zero valve and nafion tube, the gas flows through the gas measurement and oxygen

measurement (OM) units. The oxygen sensor has two inputs. One input accepts the main flow, and the other

draws in room air for reference, from the Ref port. Both gas flows exit from a single port.

Sample Flow Differential Pressure Transducer

The sample flow differential pressure transducer measures pressure drops across the OM inlet restrictor and

calculates the sample flow from the pressure difference.

Working Pressure Transducer

The working pressure transducer measures absolute working pressure between the gas measurement unit

and OM unit.

Pneumatic Unit

The pneumatic unit contains a zeroing valve, an occlusion valve, and tubing connections. A series of restrictors

and chambers forms a pneumatic filter that prevents pressure oscillations from the pump from reaching the

measuring units. The occlusion valve connection to room air includes a dust filter, and the zero valve

connection to room air includes an absorber.

Connection Block

The connection block contains a sample gas outlet connector and OM unit reference gas inlet (Ref). The inlet

is equipped with a dust filter.

91518 Multigas Analyzer Service Manual 3-5

Page 32

Theory

To Ref gas port

Occlusion Valve

The occlusion valve is activated when the sampling becomes occluded. The main flow is then diverted to the

side flow of the D-fend water trap, to remove the occlusion.

Sampling Pump and Damping Chamber

The gas sampling pump is a membrane pump that is run by a brushless DC motor. The sample flow is

measured with a differential pressure transducer across a known restriction. The motor is automatically

controlled to maintain a constant flow, even when the D-fend water starts to become occluded. The pump also

enables use of sampling lines of varying lengths and diameters. The damping chamber is used to even out the

pulsating flow and to silence the exhaust flow.

Note:

The flow is never reversed toward the patient.

Figure 3-3: Gas sampling system

91518 Multigas Analyzer Service Manual 3-6

Page 33

Theory

Figure 3-4: Gas tubing layout

Gas Measuring Unit

The gas measuring unit is a nondispersive infrared analyzer, measuring absorption of the gas sample (CO2,

N

O, halothane, enflurane, isoflurane, desflurane, and sevoflurane) at seven infrared wavelengths, which are

2

selected using optical narrow band filters. The infrared radiation detectors are thermopiles.

Figure 3-5: Gas analyzer in principle

Concentrations of CO2 and N2O are calculated from absorption measured at 3 to 5 µm (refer to Figure 3-6 on

page 3-8).

91518 Multigas Analyzer Service Manual 3-7

Page 34

Theory

Figure 3-6: CO2 and N2O absorbance

Identification of anesthetic agents and the calculation of their concentrations is performed by measuring

absorptions at five wavelengths in the 8 to 9 µm band (Figure 3-7) and solving the concentrations from a set of

five equations.

The measuring accuracy is achieved using numerous software compensations. The compensation parameters

are determined individually for each gas measuring unit during the factory calibration.

Figure 3-7: Infrared absorbance of anesthetic agents

The infrared radiation source is a 4-W filament, surrounded by thermal isolation. The lamp unit is gas tight. A

hole in the isolation allows the radiation to pass into to a 4-mm conical measuring chamber.

From the measuring chamber, the infrared radiation passes into seven tubular light guides with a reflective

inner surface. A thermopile detector with an optical filter is located at the other end of each light guide.

91518 Multigas Analyzer Service Manual 3-8

Page 35

Theory

The isothermal analyzer bench contains a temperature sensor that measures the temperature of the gas

sample, the optical filters, and the detectors. A pressure sensor measures the pressure of the gas sample.

The temperature sensor measures the gas measuring units’ temperature. It is used for temperature

compensation.

The gas measuring unit includes a TPX board located at the end of the unit. Its function is to connect the seven

thermopile signals and the temperature sensor signal to the CPU board.

Figure 3-8: Gas analyzing unit

Oxygen Measuring Unit

Oxygen concentration is measured with a paramagnetic oxygen sensor.

The sensor uses a differential pressure transducer to compare the pressure gradient produced when reference

and sample input gases are exposed to an oscillating magnetic field.

The oxygen measurement is based on paramagnetic susceptibility. The gas and the reference gas, which

usually is room air, are conducted into a gap with an electromagnet. A strong magnetic field switched on and

off at a frequency of approximately 165 Hz.

An alternating differential pressure is generated between the sample and reference inputs, due to magnetic

forces acting on the oxygen molecules in a magnetic field gradient.

The pressure is measured with a sensitive differential transducer. The transducer is rectified with a

synchronous detector and amplified to produce a DC voltage proportional to the oxygen partial pressure

difference of the two gases.

CPU board

The CPU board contains the processor and memories and analog-digital converters that are common to the

whole multigas analyzer. The CPU board also contains the preamplifiers for the TPX sensor and the drivers for

valves, fan, pump, and lamp. The multigas analyzer is connected to the analyzer bus through a RS-485 serial

channel.

91518 Multigas Analyzer Service Manual 3-9

Page 36

Theory

Figure 3-9: Signal processing

Figure 3-10: Control logic

91518 Multigas Analyzer Service Manual 3-10

Page 37

OM board

Theory

Figure 3-11: Calibration data stored in EEPROM

The oxygen measuring board contains the specific electronics for the oxygen sensor. The sample flow

measurement system and sampling system pressure sensors are on this board. It also contains EEPROMs

that store the calibration data for both the gas measuring and OM sensors.

91518 Multigas Analyzer Service Manual 3-11

Page 38

Page 39

Maintenance

Contents

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Corrective Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Disassembly and FRU Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Overview

Field service of this unit is limited to functional checks, cleaning, updating the interface software, replacement

of certain items during preventive maintenance, and replacement of the interface PCBA, the gas unit (OEM

gas module), and power switch.

Only trained personnel with appropriate equipment should perform the tests and repairs outlined in this

chapter.

Perform a functional check before starting preventive maintenance, to identify any issues requiring corrective

maintenance. A functional check should also be performed after the preventive maintenance procedure.

Perform a functional check after replacing any item during the corrective maintenance procedure.

Caution:

• Observe precautions for handling electrostatic-sensitive devices!

• Cleaning, preventive maintenance, and safety checks should be performed annually and

following any product disassembly/assembly. Preventive maintenance and safety checks must

be performed by trained personnel only.

Note:

• Never touch electrostatic-sensitive electronic components without following proper anti-static

procedures, including the use of an ESD wrist band and mat. An electrostatic discharge from your

fingers can permanently damage electronic components.

• All static-sensitive electronic components are packaged in static-shielding bags. Retain the bag for

repackaging the component, should you need to store it or return it to Spacelabs Healthcare for any

reason.

91518 Multigas Analyzer Service Manual 4-1

Page 40

Maintenance

Preventive Maintenance

If the multigas analyzer has been damaged in any way, check it for proper operation, and verify the accuracy of

its measurements.

A field service engineer should inspect the 91518 for acceptable performance at 12-month intervals, or at an

interval determined to be appropriate by an effective risk-based equipment management program established

by the hospital.

Hardware/Mechanical Check

Verify the following:

• The unit is clean.

• All screws are tight.

• The connector pins are not damaged.

• The case is not damaged.

Functional Performance Check

Note:

When the Multigas analyzer is initially connected to the power source, the analyzer will power ON. If the

analyzer does not power ON, press and hold the blue power button until the analyzer powers ON.

Before powering the multigas analyzer ON, make sure it is connected to a bedside monitor. The bedside

monitor must be powered ON prior to powering ON the multigas analyzer. Press the blue power ON/OFF

button located on the front of the multigas analyzer.

When you first power ON a properly installed multigas analyzer, the center of the power-ON button illuminates.

Within 30 seconds, the bedside monitor displays the GAS parameter key to the right of a flat waveform.

If this does not occur, verify that the power ON/OFF button is pressed and illuminated. The multigas analyzer

must be connected to an AC power outlet. Check that the SDLC switch on the back panel of the multigas

analyzer is in the correct position. Verify that the appropriate SDLC cable and terminator are connected to the

monitor. If the monitor or the module housing has an SDLC switch, check that the switch is in the correct

position. If the GAS parameter key does not display on the monitor, power OFF the multigas analyzer, and

then power OFF the monitor. Power ON the monitor again, and then power ON the multigas analyzer again.

Caution:

• The warm-up period for the multigas analyzer is less than two minutes for CO2, O2, and N2O,

and up to five minutes for anesthetic agents. The multigas analyzer reaches full accuracy after

30

minutes. You may use the multigas analyzer prior to full warm-up, but be aware of possible

inaccuracies in gas analysis.

• When the multigas analyzer is powered ON, all default settings will be re-established. Any

modifications made to the default settings (alarm limits, text display, etc.) prior to interruption

of power will be lost.

Check and verify that the D-fend water trap is empty. Spacelabs Healthcare recommends the disposal of the

water trap when full and between patients.

91518 Multigas Analyzer Service Manual 4-2

Page 41

Maintenance

If the water trap is not empty, follow the hospital safety procedures for handling possibly contaminated

material, and replace the water trap (refer to D-fend Water Trap Replacement on page 4-4).

Warning:

The used water trap may contain hazardous fluids and should be disposed of in accordance with

hospital procedures.

Initialization

When the multigas analyzer is powered ON, the message SENSOR WARMING UP will display for up to two

minutes, depending on the temperature of the multigas analyzer bench. Within two minutes, the SENSOR

WARMING UP message is replaced by the AGENT WARMING UP message on the prompt line. The AGENT

WARMING UP message will remain on the prompt line for up to three minutes.

The CO

waveform will be available only when the SENSOR WARMING UP message has disappeared.

2

After the warm-up periods, the GAS - SENSOR STABILIZING message displays on the prompt line for

approximately 30 minutes.

After the gas sensor has warmed up, the SENSOR WARMING UP message disappears, and the message

AUTO ZERO IN PROGRESS displays. A flat waveform displays at the zero baseline during zero calibrations.

During the warm-up periods or stabilization period, the multigas analyzer may perform one or more zero

calibrations.

Figure 4-1: Gas sampling line and gas sampling tee

1 After the SENSOR WARMING UP message has disappeared, and zeroing is not in progress, breathe

through the sampling tee for five slow breaths. If you don’t want to make contact with the sampling tee, cup

the tee in curled fingers, and breathe through your fist.

2 Verify that the waveform rises and falls accordingly. The numerics should display FiO2, FeO2, I CO2, and

ETCO

values. For the rest of the parameters question marks will display.

2

This completes the functional performance check. If the check passes, proceed with the preventive

maintenance. If the check fails, corrective maintenance is necessary.

91518 Multigas Analyzer Service Manual 4-3

Page 42

Maintenance

Replacing the Fan Air Filter

Note:

Depending upon the hospital environment, the air filter may need to be cleaned more frequently than

specified. It is recommended that, initially, hospitals inspect the air filter at monthly intervals until an

appropriate cleaning cycle can be established.

To replace the fan air filter:

1 Remove the filter cover from the front of the 91518 (refer to Figure 4-2 on page 4-4) using a small, flat

screwdriver.

2 Replace the filter with a new one, or clean the existing one by washing it with water and mild soap.

3 After the cleaned filter has dried, reinstall it.

4 Reinstall the fan filter cover.

5 Verify that fan is working properly and is drawing air into the unit.

Figure 4-2: Fan air filter

D-fend Water Trap Replacement

Warning:

The used water trap may contain hazardous fluids and should be disposed of in accordance with

hospital procedures.

To replace the D-fend Water Trap:

1 Twist the gas sampling line counter-clockwise at the input port to remove the sampling line from the D-fend

water trap.

2 Check and verify that the D-fend water trap is empty. Dispose of the water trap when full and between

patients.

3 If the water trap is not empty, follow the hospital safety procedures for handling possible contaminated

material.

91518 Multigas Analyzer Service Manual 4-4

Page 43

Maintenance

4 Remove the water trap by pressing the release lever on the right side of the water trap. Pull the water trap

away from its recess.

5 Discard the water trap according to hospital policies.

6 Open the D-fend package and remove the water container by pulling it away from the D-fend body with a

slight twisting motion.

7 Examine the water container’s O-rings to verify that there are no cracks or cuts.

8 Examine the D-fend ports that slip over the front panel connection posts, and verify that the front panel

chambers are smooth and have no slivers or burrs.

9 Press the water container into the D-fend, and press the D-fend into its recessed area on the front panel

until it is latched.

D-fend Connection O-Ring Replacement

An O-ring on each side of the connection post mates with the D-fend water trap. The O-rings can be removed.

To remove the O-rings:

1 Use a hooked dental pick or similar instrument (refer to Figure 4-3) to remove the O-rings from the posts.

Figure 4-3: Removing O-rings

To replace the O-rings:

1 Position the gas analyzer face up.

2 Lay the replacement O-ring on top of the connection post, and press the O-ring onto the post using finger

pressure. Or, position one edge of the O-ring onto the post groove using small, curved needle nose pliers

or tweezers, place a finger over the edge to keep it in the groove, then use you finger to roll the O-ring over

the top of the post.

3 Visually inspect the installation to make sure the O-ring is in the groove, and is not distorted (refer to

Figure 4-4).

91518 Multigas Analyzer Service Manual 4-5

Page 44

Maintenance

Figure 4-4: O-rings correctly seated in post grooves

Reference Gas Block Replacement

The reference gas connection block and filter is located to the right of the water trap.

To replace the reference gas connection block:

1 Peel off the label (; refer to Figure 4-5) that covers the screw, and then remove the screw.

Figure 4-5: Reference gas block label

Note:

A small O-ring is located between the filter unit and the front panel.

The filter element is sealed inside the block. Replacing the filter requires replacement of the entire block. There

is no replaceable filter in the block.

2 Install the new O-ring in the recess of the block, and carefully align the replacement block with the front

panel.

91518 Multigas Analyzer Service Manual 4-6

Page 45

Maintenance

3 Tighten the screw.

4 Apply the new Ref. Gas label.

Figure 4-6: Reference gas block assembly

Gas Unit Disassembly

The disassembly of the gas unit is necessary for the replacement of the pneumatic block filter, the nafion

tubing, and the absorber.

Caution:

Observe precautions for handling electrostatic-sensitive devices!

Note:

• Never touch electrostatic-sensitive electronic components without following proper anti-static

procedures, including the use of an ESD wrist band and mat. An electrostatic discharge from your

fingers can permanently damage electronic components.

• All static-sensitive electronic components are packaged in static-shielding bags. Retain the bag for

repackaging the component, should you need to store it or return it to Spacelabs Healthcare for any

reason.

To disassemble the gas unit:

1 Remove any cables from the back of the enclosure.

2 Unfasten the captive fastener (; Figure 4-7) in the middle of the right side rear panel. Remove the screws

(; Figure 4-7) securing the rear panel to the chassis enclosure. Retain the screws.

91518 Multigas Analyzer Service Manual 4-7

Page 46

Maintenance

Figure 4-7: Rear panel fastener and screws

3 Remove the rear panel from the chassis by pulling from the captive fastener straight back until the guide

pins clear both holes in the back of the unit handle.

4 Disconnect the gas unit connector cable by unfastening the cable’s captive screws

(Figure 4-8). Unplug the connector and route the cable to the left, away from the unit’s cavity in the chassis.

Figure 4-8: Connector cable

5 Remove the gas unit from the chassis by pulling straight back on the handle until the gas unit clears the

enclosure.

6 Remove the handle from the gas bench.

91518 Multigas Analyzer Service Manual 4-8

Page 47

Maintenance

7 Unfasten and remove the screws that secure the handle to the gas bench. Retain the screws.

Figure 4-9: Removing the handle from the gas bench

8 Grasp the front of the gas unit, and with the other hand, pull the metal case straight back and off. Set aside

the case, handle, and screws.

Figure 4-10: Separating the gas unit from the case

Assembly is the reverse of disassembly.

A functional check should be performed after the completion of the preventive maintenance procedure.

91518 Multigas Analyzer Service Manual 4-9

Page 48

Maintenance

Note:

There is a two-position dip switch located on the board edge near the end of the CPU board used with the

EEPROMs. It is shown in the normal operating position in

maintenance to ensure that the switch positions are not changed.

Figure 4-11: Dip switches, normal operating position

Figure 4-11. Be careful during preventive

Pneumatic Block Filter Replacement

To replace the pneumatic block filter:

1 Disassemble the gas unit according to Gas Unit Disassembly on page 4-7. Place the gas unit on an

anti-static mat with the pneumatic block and nafion tubing side facing up.

2 Remove the small Phillips head screw holding the filter restraint (refer to Figure 4-12). Use a needle nosed

pliers or tweezers to lift the filter restraint away from the block.

91518 Multigas Analyzer Service Manual 4-10

Page 49

Maintenance

Figure 4-12: Removing the filter restraint

3 Turn the gas unit over. The filter element should fall out. If it does not fall out, lightly tap on the side of the

pneumatic block to dislodge it. There is an O-ring on the bottom side of the filter element that may also fall

out.

4 Turn the gas unit over again.

5 Examine the O-ring. Unless it is severely damaged, place it back in the pneumatic block. The O-ring is used

as a spacer, and provides no seal.

6 Place the new filter element in the pneumatic block. Insert the filter element restraint in the recessed area,

and replace the screw. Do not overtighten the screw.

91518 Multigas Analyzer Service Manual 4-11

Page 50

Maintenance

Nafion Tubing Replacement

Follow the hospital safety procedures for handling possibly contaminated material.

1 Place the gas unit on an anti-static mat with the nafion tubing facing up. Refer to Figure 4-13, and examine

the routing of the Nafion tubing. There are two pieces of the nafion tubing of the same length arranged with

one oval loop laying inside another oval loop.

Figure 4-13: Nafion tubing routing

2 With your fingers or with needle-nosed pliers, lift the inside tubing loop away from the metal bracket fingers

and gently pull the end barb out of the short tube attached to the absorber (refer

page 4-13). Gently pull the other end barb out of the short tube attached to the pneumatic block G port.

91518 Multigas Analyzer Service Manual 4-12

to Figure 4-14 on

Page 51

Maintenance

Figure 4-14: Disconnecting the nafion tubing

3 Lift the remaining tubing loop away from the metal bracket fingers and gently pull the end barb from the short

tube on the pneumatic block port E.

4 Pull the other end barb from the short tube that connects to the small diameter tubing running to the front

panel water trap container.

5 Discard the two lengths of nafion tubing according to hospital policy.

Note:

• If the nafion tubing replacement is being performed as part of the preventive maintenance procedure,

proceed to

• If the nafion tubing replacement is being performed as part of the corrective maintenance procedure,

and the absorber is at least six months from replacement, install the new pieces of Nafion tubing.

Absorber Replacement on page 4-13.

Absorber Replacement

The absorber is marked with an expiration date. Before proceeding, verify that the new absorber from the

preventive maintenance or corrective maintenance kit has a minimum of one year to the expiration date.

To replace the absorber:

1 Follow the hospital safety procedures for handling possibly contaminated material.

2 Pull the end barb out of the short tube attached to the absorber (if not already disconnected as part of the

nafion tubing replacement procedure).

3 Remove the two bracket screws (; Figure 4-15 on page 4-14) near the ends of the absorber. Lift the

bracket slightly and pull out the free end of the absorber.

91518 Multigas Analyzer Service Manual 4-13

Page 52

Maintenance

4 With your fingers or with needle-nosed pliers, gently pull the short tubing off the captive end of the absorber,

being careful not to stress the inner small diameter tubing.

5 Lift the bracket and slip the absorber in position. Install the two bracket screws.

6 Install the nafion tubing barb into the short tube (; Figure 4-15) on the absorber.

Figure 4-15: Nafion tubing connected

Cleaning

Warning:

• Use only recommended cleaning solutions, or you may void the manufacturer’s warranty.

• Harsh chemical agents degrade plastics and will compromise the safety of the device.

• Disconnect the equipment from the patient and the electrical supply before cleaning.

• Do not allow liquid to enter the interior of the multigas analyzer or monitoring equipment.

• Do not immerse the equipment or cables in water or cleaning solutions.

• Do not autoclave.

To clean the exterior of monitoring equipment and cables:

• Prepare the cleaning solution according to the manufacturer’s instructions.

• Wet a clean cloth with the selected cleaning solution.

• Remove excess liquid from the cloth and squeeze dry.

91518 Multigas Analyzer Service Manual 4-14

Page 53

Maintenance

• Wipe exposed surfaces of the equipment and cables.

• Remove any soap residue by gently wiping with a clean damp cloth.

• Wipe dry with a clean dry cloth.

Use only the following recommended cleaning solutions:

• Mild soap and water solution

• U.S. Pharmacopoeia (USP) green soap

• Sodium hypochlorite solution (1:10 dilution of household chlorine bleach in water)

• Phenolic germicidal detergent (1% aqueous solution)

• Glutaraldehyde (2.4%) (Cidex)

• Isopropyl alcohol (70% solution

Note:

Over time, repeated use of a chlorine bleach solution may cause some colors to fade.

Tape adhesive can be removed with Spacelabs Healthcare adhesive tape remover pads (P/N 392196-001).

Questions and concerns about cleaning issues should be directed to a Spacelabs Healthcare field service

engineer.

Caution:

Do not allow liquid to enter the interior of the 91518 Multigas Analyzer. If this should occur, check

the unit for proper operation and verify its performance accuracy prior to reuse.

Disposable and reusable patient accessories are available for the 91518 Multigas Analyzer. Disposable

accessories are for single-patient use only and must not be sterilized or cleaned for reuse on other patients.

Refer to the instructions provided with each patient accessory to determine if the accessory may be cleaned

and reused on the same patient.

Reusable accessories can be used on multiple patients after cleaning and/or sterilizing. Refer to the

instructions provided with these accessories for details.

Instructions provided with patient accessories may contain warnings regarding their use. Read these

instructions carefully prior to use.

Note:

The Spacelabs Healthcare sampling lines are for single-patient use only. Cleaning deteriorates the

properties of the sampling line, resulting in slower response time and more frequent occlusions.

Software Updates

Software updates can only be performed by a Spacelabs Healthcare field service engineer. The 91518

Multigas Analyzer must be calibrated when it is installed at the site (refer to Power Up Verification on

page 2-14). Refer to Service Calibration Mode on page 4-16.

Caution:

The 91518 MUST BE CALIBRATED at a location within 50 mmHg (6.67 kPa) atmospheric pressure

of where the device will be used.

91518 Multigas Analyzer Service Manual 4-15

Page 54

Maintenance

Firmware Updates

When necessary, firmware updates to the 91518 Multigas Analyzer are made by PCBA replacement.

Corrective Maintenance

Corrective maintenance begins with initiating actions to determine the equipment’s state of functionality. This

usually begins with questioning the clinical user in the degree of equipment functionality and the type of

problem encountered.

Functional Performance Check

Part of the examination is a functional performance check.

Refer to Functional Performance Check on page 4-2, and perform the procedure. The functional performance

check is always performed before and after the preventive maintenance procedure, and before and after the

corrective maintenance procedure.

Service Calibration Mode

Warning:

The calibration gas used in these procedures contains an anesthetic agent that must be vented

away from users. You must either complete these procedures in a well-ventilated space or connect

the scavenge port and excess flow lines to an exhaust

hood or gas-scavenging system.

Gas Calibration

The calibration process utilizes a very specific and accurately proportioned mixture of anesthetic agent, N2O,

CO

, and either O2 or N2 against which the 91518 is standardized. The calibration gas is supplied in a canister

2

with a limited amount of gas.

When the calibration sequence begins, a detailed analysis of the incoming gas is performed. The 91518

software contains the exact numeric values for the various gases that are documented on the sample bottle.

Initially, the 91518 examines the contents of the measurement chamber for the specific signature of each gas

and compensates for any difference between the measured value and the expected value. These correction

factors are stored in non volatile memory for subsequent use.

Note:

The numeric values that are displayed following a successful calibration do not need to exactly match the

nominal values listed on the sample bottle. This is due to small ongoing variations in flow, pressure, and

temperature for both the source gas and the measurement chamber. However, if the initial error is larger

than 20%, a second calibration may be necessary to reduce the remaining error to insignificance.

When calibrating, it is recommended that you use a full bottle that has stabilized at a temperature of 21° to

32° C (70° to 90° F) for at least 24 hours.

Note:

Bottles that have been exposed to and have attained a temperature below 0° C (32° F) should never be

used for calibration due to the destructive nature of extremely cold temperatures on the gas mixture.

91518 Multigas Analyzer Service Manual 4-16

Page 55

Maintenance

Gas calibration uses the tee connector and gas flow meter configuration that is illustrated in

Figure 4-16 on page 4-18. The pressure regulator is set to provide a stable flow of calibration gases that is

greater than required by the 91518.

The excess calibration gas flow is directed through the side port of the tee. It is critical that the excess gas flow

be maintained through the flow meter at 20-50 ml/min to ensure that the gas flowing into the 91518 is not being

diluted by room air and preventing accurate calibration.

Equipment and Supplies Needed for Calibration

• Calibration Adapter Kit: P/N 025-0047-00

• Calibration Gas Mixture (5% Desflurane, 5.5% CO2, 43% N2O, 46.5% O2) (P/N 025-0047-00)

• 37" (94 cm) Polyurethane Tubing (used to cut 1" (2.54 cm) and 36" (91.4 cm)* tubing)

(P/N

166-0011-00)

• Tee Connector (P/N 214-0486-00)

• Male Luer Fitting* (P/N 214-0261-00) (used if the flow meter is equipped with 1/8 inch barb fittings. If

the flow meter has 1/16

and 1/16

• 7-foot (213 cm) Sample Line (P/N 162-0047-01)

• Gas Pressure Regulator (P/N 369009-002)

inch male luer fitting.)

inch barb fittings installed, substitute 36 inches 1/16" I.D. polyurethane tubing

• SDLC Cable, Tee (P/N 012-0175-xx)

• SDLC Terminator (P/N 012-0507-xx)

• Flow Meter, Brooks Model 1355 or equivalent (provide locally)

91518 Multigas Analyzer Service Manual 4-17

Page 56

Maintenance

gas pressure

1" (2.54 cm) polyurethane

flow meter

Brooks Model 1355 or

equivalent

91518 Multigas Analyzer

CAL gas cylinder

7' (2.13 m) blue tinted

to scavenging system

36" (91.4 cm) polyurethane

male luer fitting

sample line to

91518 water trap

input

regulator

or exhaust hood

tubing

from

scavenging port

tubing

To perform a gas calibration:

1 Perform the setup procedure and performance verification procedure.

2 Verify that the stabilization message has disappeared from the prompt line (the analyzer may take up to 30

minutes to fully warm up and stabilize).

3 Press the GAS key, then press the CAL key to open the Calibration Menu. Refer to

Figure 4-17 on page 4-20.

4 Press ZERO / YES to perform a zero calibration.

5 Connect the gas analyzer to the gas cylinder using the setup shown in Figure 4-16.

6 Touch the hidden SERVICE CAL key (one inch to the right of the ZERO key) five times.

7 Establish a gas flow which includes a gas overflow of 20 to 50 ml/min from the side port of the tee as read

on the flow meter (the pump rate should already be at the default value of 175

Note:

The 91518 must be powered on for 30 minutes to allow the internal temperatures to stabilize.

91518 Multigas Analyzer Service Manual 4-18

Figure 4-16: Gas calibration setup

ml/min).

Page 57

Maintenance

8 Watch the CO2 waveform line and all numeric values. When everything appears to be stable and the agent

is identified as DES, verify that the gas readings are as follows:

Table 1: Gas Readings

Calibration Gas

Bottle

Concentration

Required 91518 Indication

N2O 43% 39 – 47%

DES 5.0% 4.8 – 5.2%

O

CO

2

2

46.5%* 44 – 49%

5.5% 5.3 – 5.7%

* Although the gas bottle contains 46.5% O2, the 91518 reads O2 in whole number percentages.

9 If the displayed values of FiO2 do not fall within the range listed above after the completion of the gas

calibration, return to

step 3.

10 If the display values of N2O, DES, and CO2 do not fall within the ranges listed above, recalibration is

required. Touch CAL GAS. Recheck to ensure that the gas flow rate is correct and stable, then touch YES.

Wait for the span operation to complete. If the span is successful, the numeric values will reappear.

11 Verify that the gas values displayed are within the ranges provided in Table 1. If they are not correct, verify

that the excess gas flow rate is still within 20 to 50 ml/min. If the flow rate has diminished below the required

20 to 50

and read the values again. If the values are still outside the specified values as noted in

ml/min and the regulator valve is fully opened, replace the gas bottle, re-establish proper gas flow,

Table 1, repeat the

span procedures.

12 If the CAL GAS FAILED message appears, verify that the excess gas flow rate is still between 20 to

50 ml/min, then touch the monitor’s NORMAL SCREEN key and repeat the gas calibration procedures.

Note:

If the calibration fails, check the unit for leaks and/or a cracked water trap or a kinked hose.

13 Shut off the gas flow as soon as calibration is finished.

91518 Multigas Analyzer Service Manual 4-19

Page 58

Maintenance

GAS - SERVICE CAL ***WARNING*** The patient is not being monitored

LIMITS

ALARM

FREEZE

ON OFF

SETUP

PRINT

SERVICE

GAS - MAIN MENU

SUSPEND

SAMPLING

CAL

YES

NO

CAL

NEXT

PAG E

PRINT

PAG E

PREV

YES

NO

ZERO

CAL

Hidden key:

Touch five times

to display

SERVICE CAL menu

GAS - CALIBRATION MENU

GAS PAGE

SERVICE CAL Menu Keys

ZERO — touching this key leads to the ZERO confirmation menu. Pressing the YES key performs a zero.

CAL GAS — Touching this key leads to the CAL GAS confirmation menu. Pressing the YES key performs a

calibration of the agent, N

Spacelabs Healthcare calibration gas supply must be present throughout the entire procedure. After the gas

calibration is complete, compensation values will be stored in the nonvolatile memory (NVRAM). Pressing the

NO key will return to the Service Cal Mode menu.

If the gas calibration fails, the analyzer will display the CAL GAS FAILED message and will remain in this mode

until a successful calibration is completed or until the bench is turned OFF. When the calibration failed

message is displayed, touching the GAS key and then the NORMAL SCREEN key removes the message from

the waveform zone and stops the alarm tone. However, the message will continue to display on the monitor’s

prompt line. Whenever a span failure occurs, the previous calibration factors are not lost. The analyzer

continues to function and report the gas values, but the full accuracy of the values is not guaranteed. If the cal