Page 1

Ambulatory Blood Pressure

Monitor

90207/90207Q

Service Manual

070-0189-02 Rev. F

more time to care

Page 2

© 2004 Spacelabs Medical, Inc.

All rights reserved. Contents of this publication may not be reproduced in any form without the written permission of Spacelabs

Medical. Products of Spacelabs Medical are covered by U.S. and foreign patents and/or pending patents. Printed in U.S.A.

Specifications and price change privileges are reserved.

Spacelabs Medical considers itself responsible for the effects on safety, reliability and performance of the equipment only if:

• assembly operations, re-adjustments, modifications or repairs are carried out by persons authorized by Spacelabs

Medical, and

• the electrical installation of the relevant room complies with the requirements of the standard in force, and

• the equipment is used in accordance with the operations manual.

Spacelabs Medical will make available, on request, such circuit diagrams, component part lists, descriptions, calibration instructions

or other information which will assist appropriately qualified technical personnel to repair those parts of the equipment which are

classified by Spacelabs Medical as field repairable.

Spacelabs Medical is committed to providing comprehensive customer support beginning with your initial inquiry through purchase,

training, and service for the life of your Spacelabs Medical equipment.

CORPORATE OFFICES

U.S.A.

Spacelabs Medical, Inc.

5150 220th Ave SE

Issaquah, WA 98029

Telephone: 425-657-7200

Telephone: 800-522-7025

Fax: 425-657-7212

Authorized EC Representative

UNITED KINGDOM

Spacelabs Limited

71 Great North Road, Hatfield

Herts AL9 5EN

Telephone: 44-1707-263-570

Fax: 44-1707-260-065

BirthNet, Data Shuttle, Flexport, Intesys Clinical Suite, Maternal Obstetrical Monitor, MOM, Mermaid, Multiview, PCIS, PCMS,

PrintMaster, Quicknet, Sensorwatch, TRU-CAP, TRU-CUFF, TRU-LINK, UCW, Ultralite, Ultraview, Ultraview Clinical Messenger,

Ultraview SL, Uni-Pouch, Universal Flexport, Varitrend and WinDNA are trademarks of Spacelabs Medical, Inc.

Other brands and product names are trademarks of their respective owners.

CAUTION:

US Federal law restricts the devices documented herein to sale by, or on the order

Rx

Only

of, a physician.

Page 3

Table of Contents

Contents

Introduction

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Rear and Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

ABP System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Installation

Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Setup Instructions for the 90121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Setup Instructions for the 90219 and 92506. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Theory

Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Other Power Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

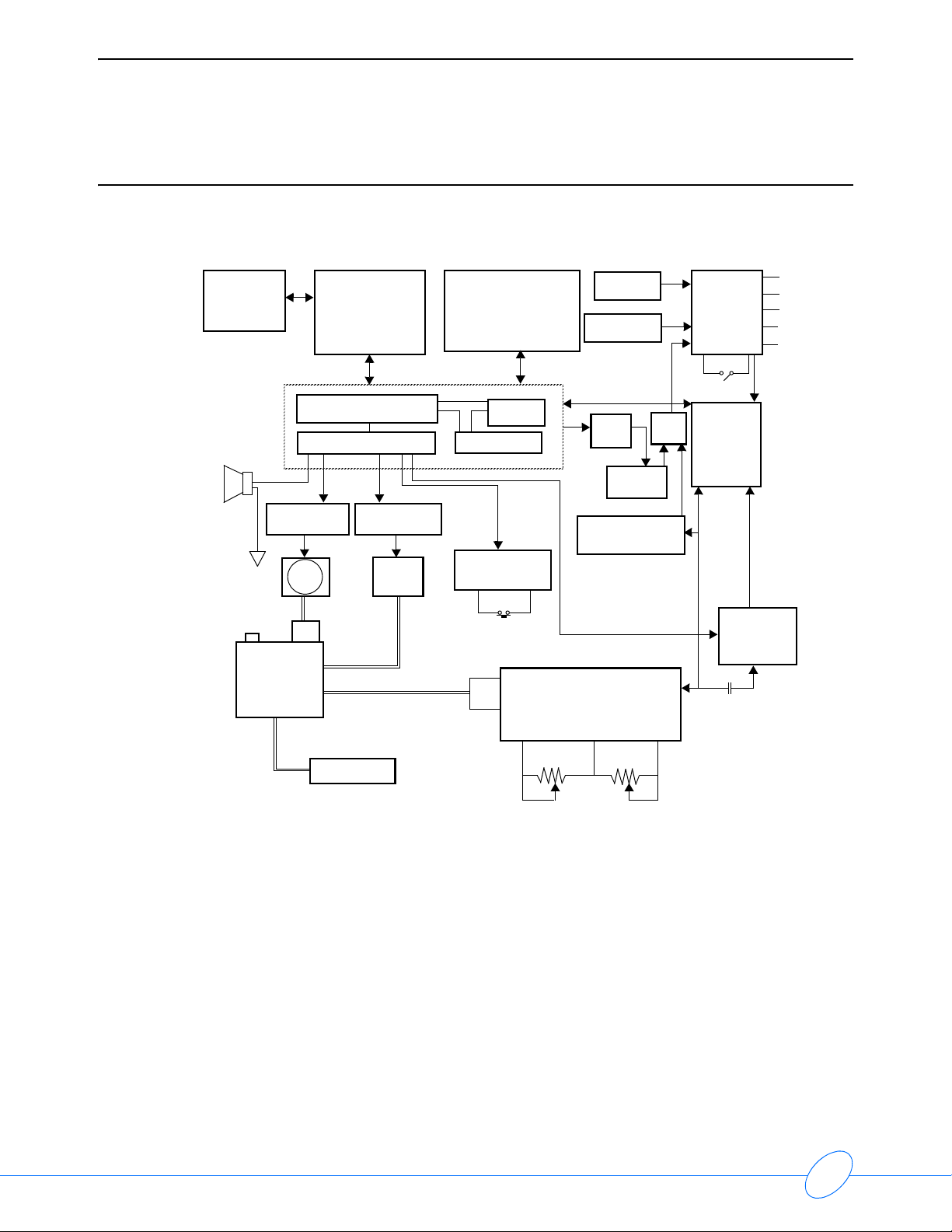

90207 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wake Up and Power Up Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

START/STOP Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Minute Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Second Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Watch Dog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Fault Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Overpressure Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Pressure Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Offset Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Gain Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Pressure Amplifier Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Oscillometric Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Gain Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Offset and Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Digital Circuitry Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Addressing and Control Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Communications RS-232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

AA Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Lithium Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Battery Clip Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

90207 Disassembly Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Accuracy Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

i

Page 4

90207 Ambulatory Blood Pressure Monitor Service Manual

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Solvents/Compounds Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

90207 Main Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Computer System Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Power Supply Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Amplifier Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

CuffLink Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

CuffLink Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Troubleshooting

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Monitor Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Base Station Report Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Problem Solving Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Parts

90207 Field Replaceable Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

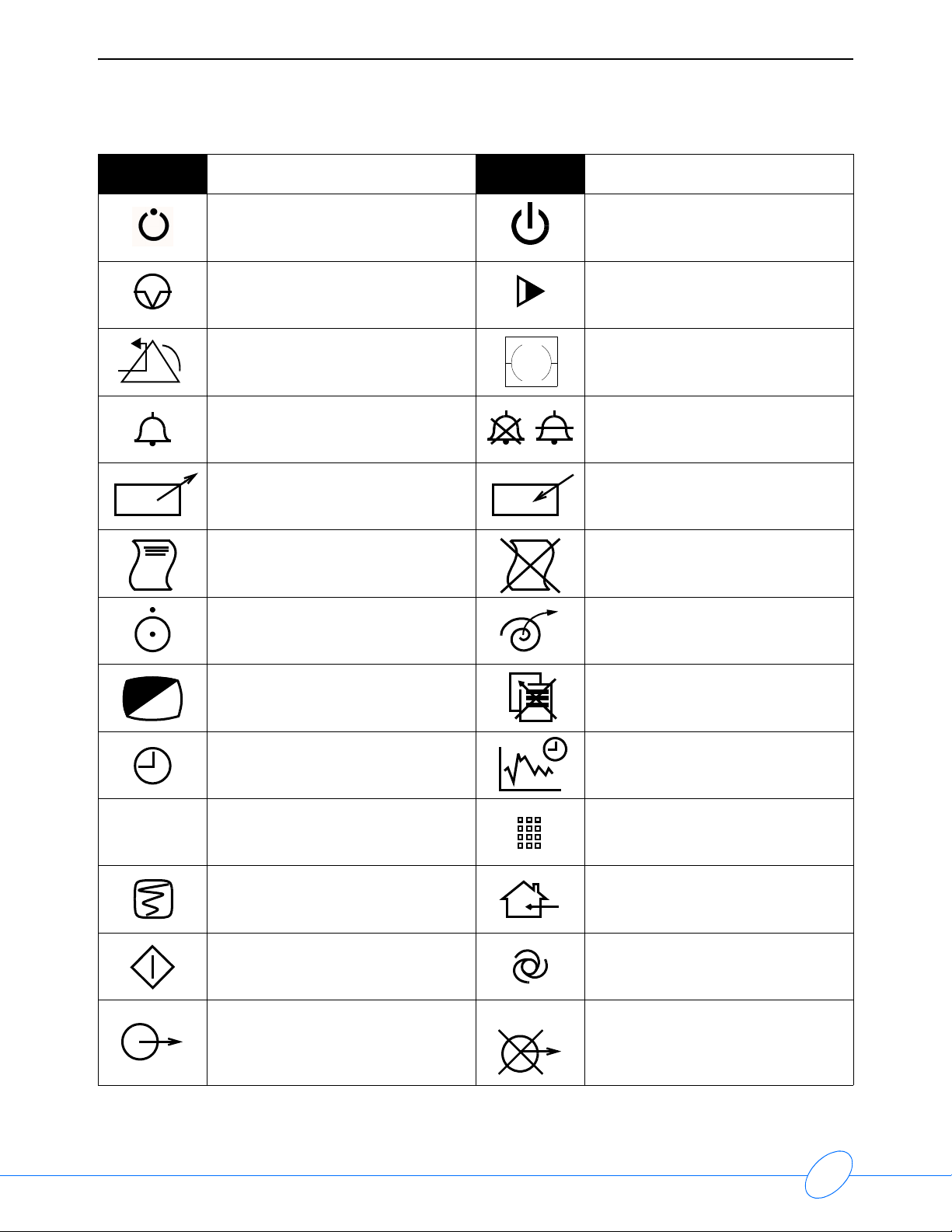

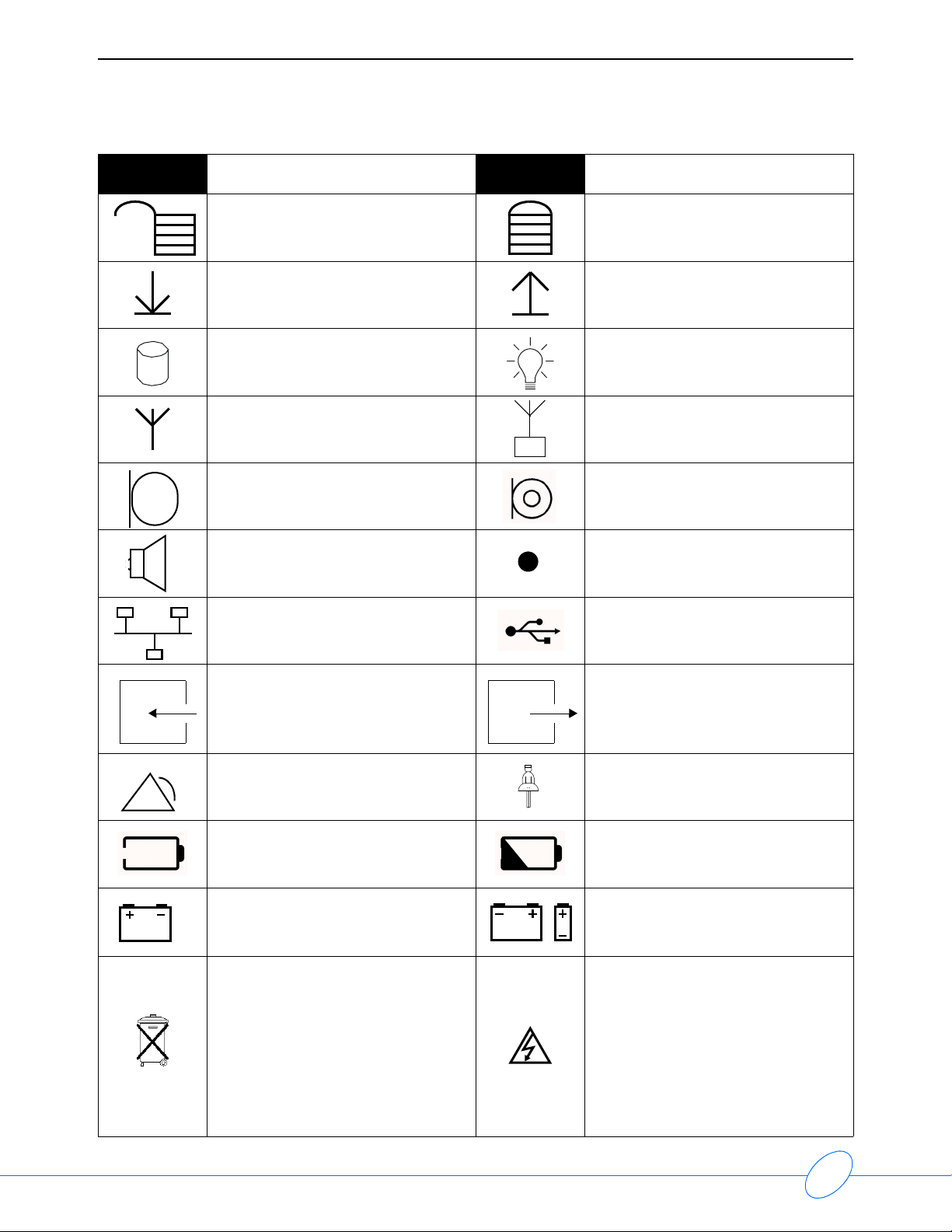

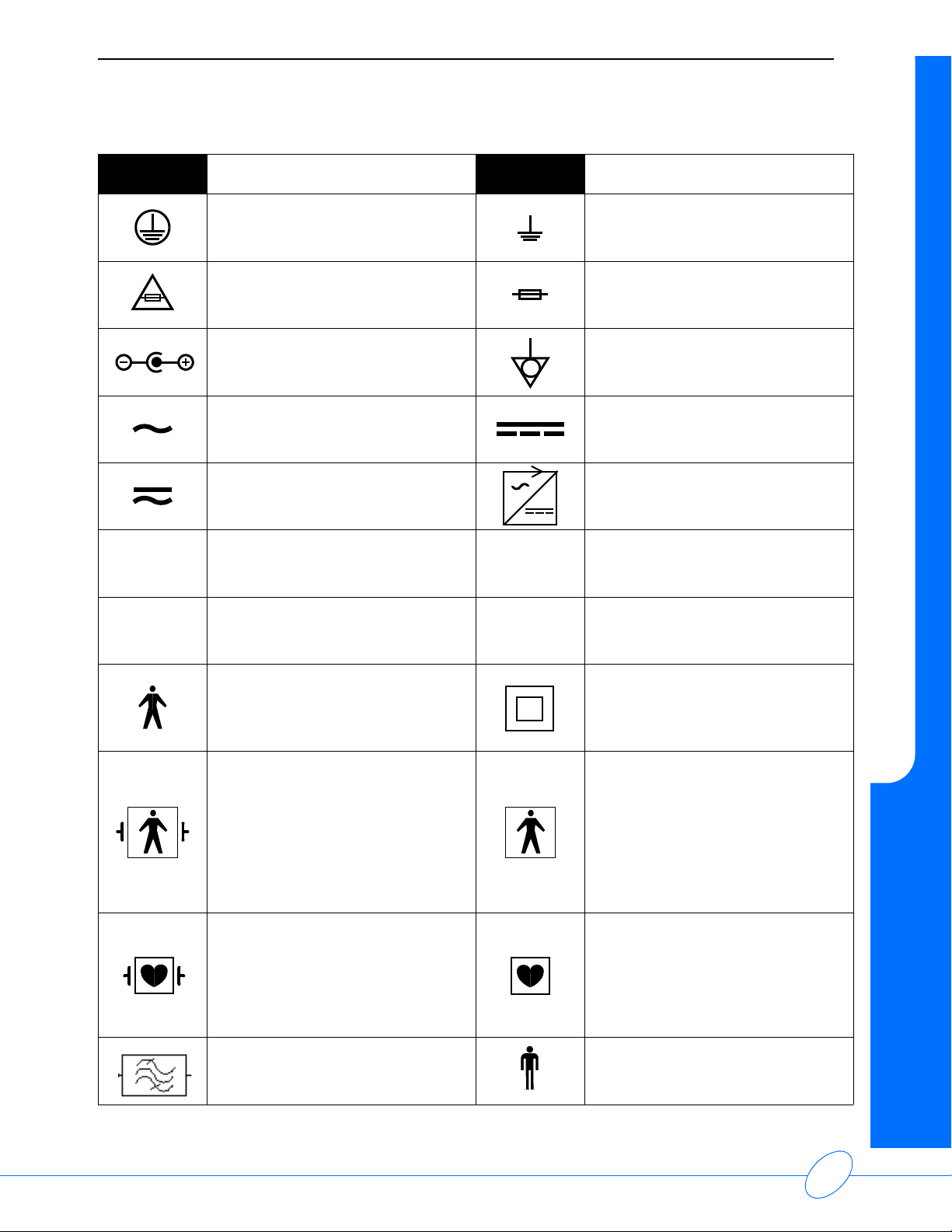

Symbols

Appendix A — Electromagnetic Compatibility

Electromagnetic Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Electromagnetic Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Frequency Separation Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

ii

Page 5

Contents

Overview

The Spacelabs Medical Model 90207 Ambulatory Blood Pressure (ABP) Monitor is a small,

lightweight unit designed to take blood pressure and heart rate measurements for a 24- or 48-hour

period. These measurements are recorded in the monitor and transmitted to a Spacelabs Medical

ABP analysis system for report generation. Several analysis systems are available. Refer to your

specific analysis system manual for more information.

Note:

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ABP System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Beginning with August 2004 shipments, all 90207 models have a “Q” suffix indicating a quick

disconnect fitting for patient cuffs. Prior versions had a luer fitting. This manual includes

information relating to both fittings.

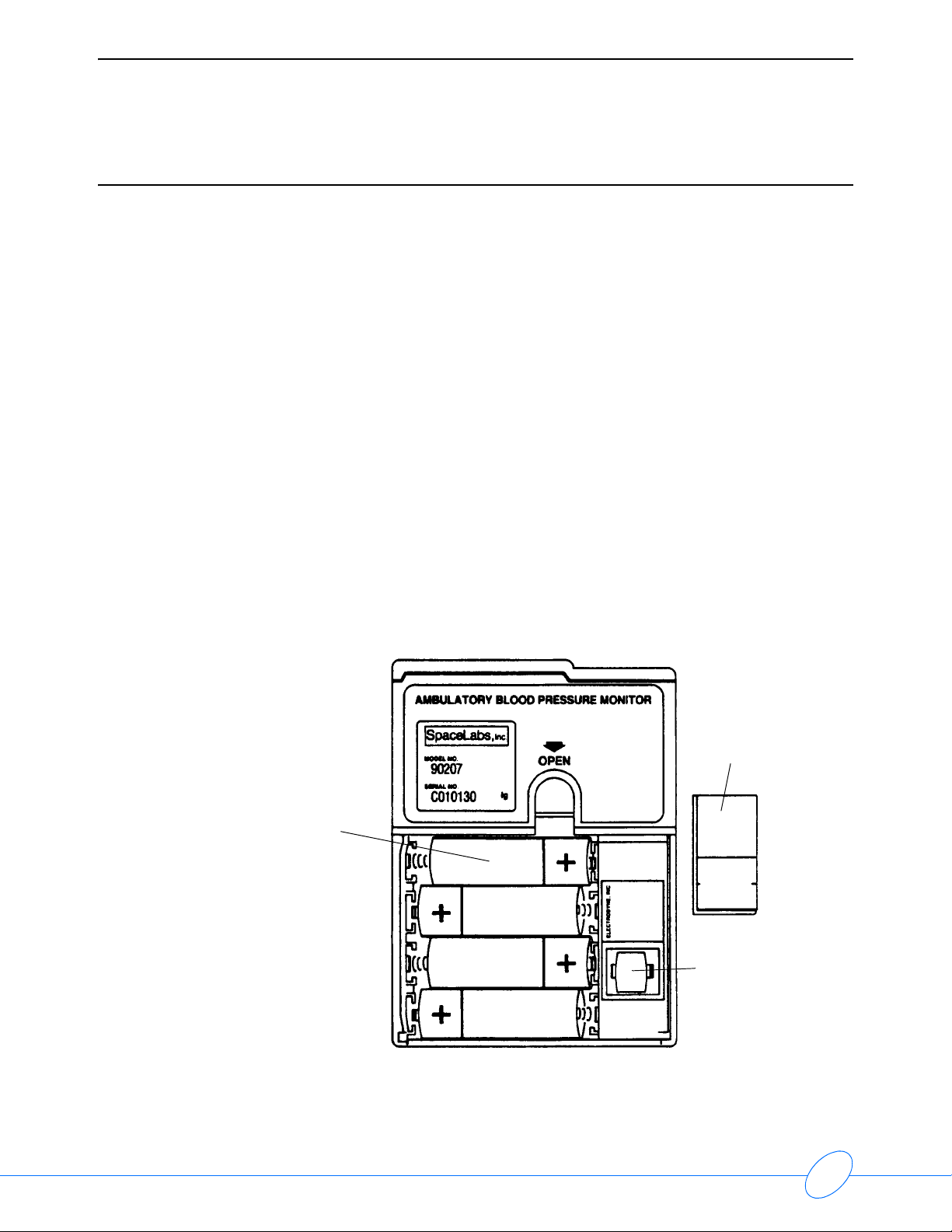

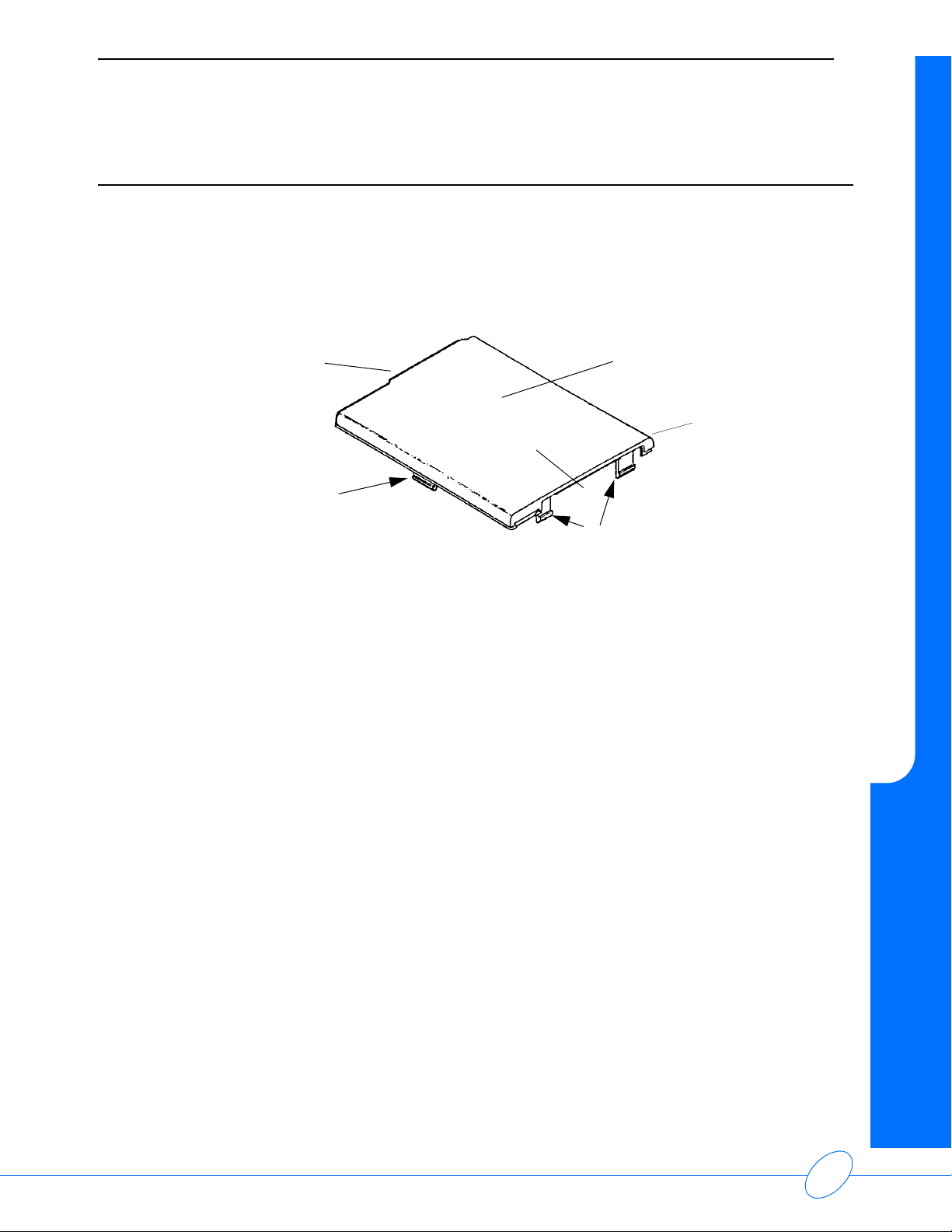

patient cuff

Figure 1-1: 90207 ABP monitor

The 90207 ABP monitor includes the following features:

• four-digit LCD display

• battery powered operation

• serial communications port (infrared)

• front panel START/STOP button

• blood pressure cuff

• carrying pouch with shoulder strap

model 90207 ABP monitor

1-1

Page 6

Description

This ABP monitor is carried in a pouch that is strapped and/or belted at the patient’s side. Blood

pressure and heart rate measurements are taken using a pressure cuff attached around the

patient’s arm. An ABP analysis system programs the monitor and specifies the monitoring period,

patient information, time format, measurement interval, monitor tone ON/OFF during selected

periods, event code display, and whether or not to display readings. Information is transferred

either over a modem link or over a cable connection between the monitor and the ABP analysis

system.

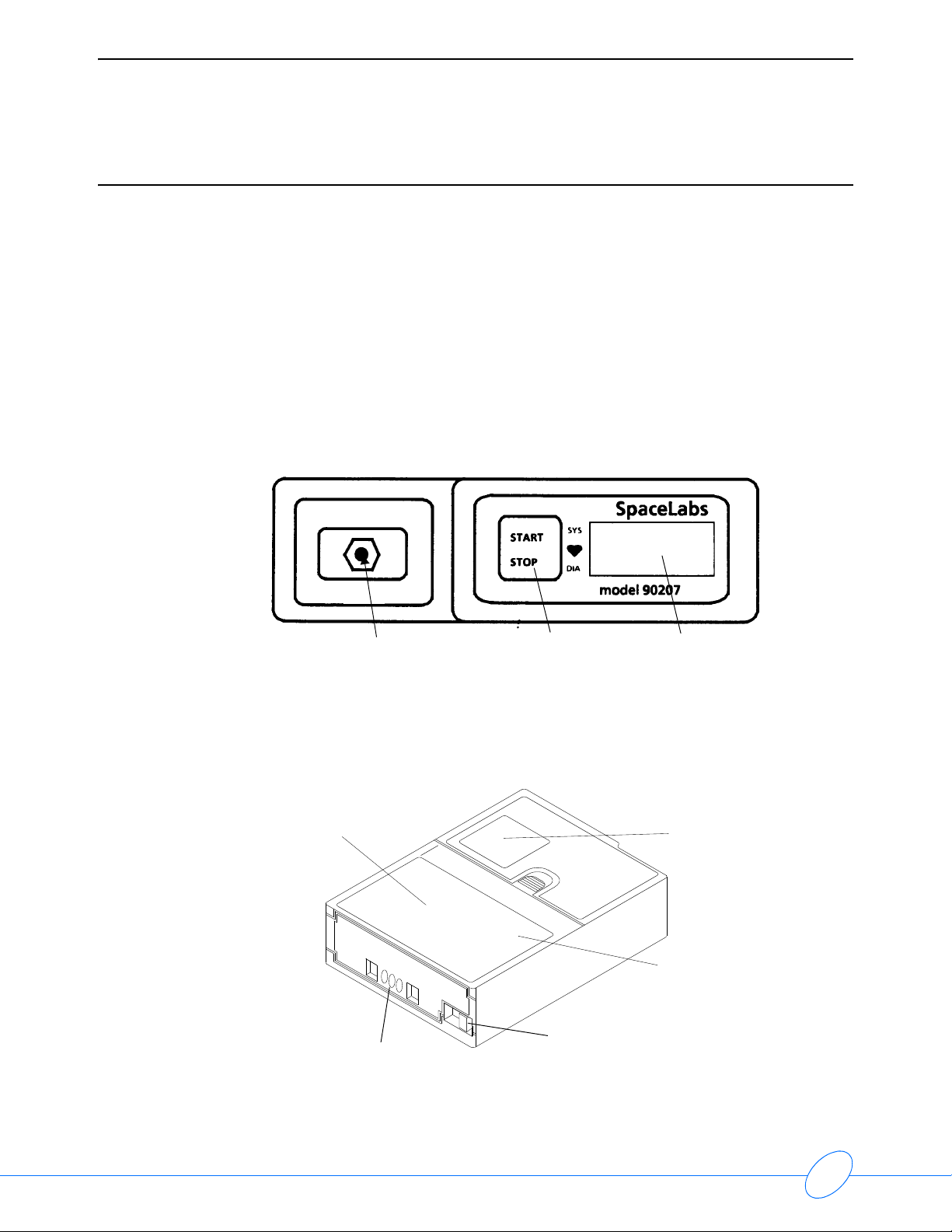

Front Panel

The front panel of the monitor includes the LCD display, the cuff hose connector, and the

START/STOP button. The figure below illustrates the ABP front panel.

90207 Ambulatory Blood Pressure Monitor Service Manual

cuff hose connector START/STOP button 4-digit LCD

Figure 1-2: Front panel

Rear and Top View

The rear panel of the monitor contains the communications port and the power ON/OFF switch.

operating instructions

communications port

unit ON/OFF switch

Figure 1-3: Rear panel and top panel

identification label

(serial number)

battery compartment

The top panel provides the unit’s model number, serial numbers, and abbreviated operation

instructions.

1-2

Page 7

90207 Ambulatory Blood Pressure Monitor Service Manual

ABP System Options

ABP analysis systems are used to program the ABP monitor, retrieve collected patient data, and

generate blood pressure reports from the acquired data. Current analysis systems available are:

• Model 90121 Ambulatory Blood Pressure Report Management System

• Model 90219-02 Personal Computer Direct Interface software for IBM PC XT or AT

compatible (5.25-inch diskettes)

• Model 90219-03 Base Station Interface software for connection by modem

• Model 90219-05 PC Direct Interface software for FT Holter Analysis Workstations

• Model 90229 Local Report Generator

• Model 90239A Report Generator with thermal printer

• Model 92506 Ambulatory Blood Pressure Management System

Spacelabs Medical software is available for both direct and remote ABP monitoring and reporting.

Refer to Spacelabs Medical Model 90219 ABP PC Interface/Base Station Interface Operations

Manual (P/N 070-0238-xx) for descriptions of the available options and operation configurations.

Introduction

1-3

Page 8

Page 9

Contents

Caution

Note:

Installation

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Setup Instructions for the 90121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Setup Instructions for the 90219 and 92506 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Observe precautions for handling electrostatic-sensitive devices!

• Never touch electrostatic-sensitive electronic components without following proper anti-

static procedures, including the use of an ESD wrist band and mat. An electrostatic

discharge from your fingers can permanently damage electronic components.

• All static-sensitive electronic components are packaged in static-shielding bags. Retain the

bag for repackaging the component should you need to store it or return it to Spacelabs

Medical for any reason.

Hardware Requirements

For analysis systems using an IBM PC XT or AT compatible computer, the following hardware is

required to run the ABP analysis systems (except for the 90229 and 90239A).

An IBM PC XT or AT compatible computer with the following features:

One floppy disk and one hard disk drive with a minimum of 512 KB available random access

memory (RAM).

IBM color graphics card with a color monitor, or a composite (black and white) monitor, or a

Hercules monochrome graphics card with a monochrome monitor.

At least one available serial port for the Model 90219-02, 03.

Setup Instructions for the 90121

1 Start Microsoft Windows.

2 Insert the ABP Report Management System Setup disk in drive A.

3 From the File menu, choose Run.

4 Type A:SETUP and press Enter.

5 When prompted, choose the desired operating language.

6 When prompted, enter the desired directory location of the ABP Report Management System.

7 When prompted, remove the Setup disk and insert Program Disk #1 into drive A.

8 When prompted, remove the Program Disk #1 and insert Program Disk #2 into drive A.

9 When prompted, restart the Windows operating system and remove the Program Disk #2.

2-1

Page 10

90207 Ambulatory Blood Pressure Monitor Service Manual

Setup Instructions for the 90219 and 92506

Note:

Refer to the 90219 Ambulatory Blood Pressure PC Base Station Interface (P/N 070-0238-xx)

or the 92506 Ambulatory Blood Pressure Report Management System Client Application (P/N

070-0932-00) for setup and operating instructions.

Installation

Data collected by the Model 90207 ABP monitor may either be transferred to a standalone report

generator or to an ABP analysis system running on an IBM PC XT/AT/PS2 or equivalent computer

for data analysis, report printing, and archiving.

Five modes of data interface operation are possible:

• Standalone Report Generator (a 90229 or 90239A Report Generator)

• PC Interface (direct connect using a 90219-02 or 90219-05 PCI for FT1000/FT2000/FT3000)

• ABP Base Station (modem connection using a 90219-03).

• ABP Report Management System 92506

• ABP Report Management System 90121

Caution

Refer to the appropriate operations manuals for setup configurations and initialization instructions.

Prior to patient monitoring, the ABP analysis system must initialize the ABP monitor.

The monitor should be disconnected from the patient during initialization. Be sure that

power to all hardware is OFF when connecting the ABP monitor for initialization. If

power switches are left ON during the connections, improper operation can result.

2-2

Page 11

Contents

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

90207 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Wake Up and Power Up Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Oscillometric Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Digital Circuitry Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Addressing and Control Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Communications RS-232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Supplies

Theory

All power required for operation of the Model 90207 ABP Monitor is derived from the four userinstalled AA cells. A 3-volt lithium battery provides memory (CMOS) backup.

Power Converter

A MAXIM “MAX631” step-up converter develops a +5 unregulated voltage whenever battery

potential drops below approximately +5.7 volts. This converter also provides an additional 45 kHz

square wave output to develop the +10 and -5.0 volt unregulated supplies.

+5 Unregulated Supply

The +5 volt unregulated supply is powered directly from +VPS (main battery voltage) through a

diode when the voltage is above +5.7 volts, and is powered by the step-up convertor when the

voltage drops below approximately +5.7 volts. The step-up convertor prevents the +5 unregulated

supply from dropping below +5.0 volts.

If the +5 unregulated power supply drops below 5.0 volts, the RAM protect circuit asserts a reset

signal to the processor that protects unit memory from a data loss during a power collapse. A startup processor reset signal with a 40 msec time constant is provided when power is initially applied.

The +5 unregulated supply needs approximately 30 msec to reach its full potential. This requires

that the processor be held in a reset condition for approximately 70 msec after unit power is first

applied.

Battery OK Status

The 90207 main battery voltage is monitored by reading the BAT VOLTS with an A/D convertor. A

low lithium battery is detected by reading a sample of the lithium battery BB VOLTS with an A/D

convertor.

3-1

Page 12

90207 Ambulatory Blood Pressure Monitor Service Manual

Power Enable

The power converter is activated when main battery voltage (+VPS) is first applied to the

converter’s step-up inductor. Three control lines determine if the +VPS supply is turned ON:

•PWR_ENABLE

•C_CON

• SHUTDOWN

PWR_ENABLE activates the various power supplies during a measurement or clock update.

The C_CON line (cable connected) keeps the power supplies active whenever the

communications cable is connected to the unit.

SHUTDOWN overrides both the PWR_ENABLE and C_CON lines to cause a power shutdown in

the event of a detected fault condition.

A/D Voltage References

The A/D converter uses two voltage references:

+ADR (+3.672 volts adjustable)

+ADR LOW (+1.022 volts)

Both are developed from a precision source (an LM358-1.2) that establishes a voltage reference

(+ADR), which is adjusted to +3.672 volts.

+4.7 Volts

The +4.7 volt regulator circuit compares a divided-down sample of the +4.7 volt supply output

against the +ADR reference and adjusts the drive for the two pass transistors (FETs) to

compensate for differences between the reference and the output voltages.

Two FETs are used as pass transistors to reduce the voltage drop across them. The +4.7 volt

supply provides most of the secondary power and sources approximately 25 mA.

+8.6 VREF Volts

The +8.6 VREF is developed from the +10 volt unregulated supply. The +8.6 VREF regulator is

similar to the +4.7 regulator, except that only one FET is needed, and there are two resistors in the

output drive of the circuit’s operational amplifier. These resistors ensure that the FET can be

turned ON or OFF at the minimum specified output voltage extremes of the OP Amp.

The +8.6 VREF sources approximately 1.6 mA to the pressure transducer and smaller amounts of

current to other circuits to produce a total current drain of about 2 mA.

3-2

Page 13

90207 Ambulatory Blood Pressure Monitor Service Manual

Other Power Sources

In addition to the regulated power supplies, there are five other power sources in the 90207:

+VSW, +VPS, +VSB, +VAA, and +VBB

+VSW is the voltage coming directly from the unit’s main batteries through the power ON/OFF

switch. This supply becomes active as soon as the power switch is ON.

+VPS is the power converter supply. When enabled, it is at about the same potential as +VSW,

and it is enabled to awaken the microprocessor.

+VSB is activated when +VSW is up and is a diode drop less than +VSW or +4.7 volts, depending

on which supply happens to be at the higher voltage.

+VAA supplies the main battery voltage to the 90207 clock and RAM chips when the power switch

is OFF and main batteries are present. This design prevents any unnecessary power drain from

the unit’s lithium battery.

+VBB is the backup battery supply. Its potential is always a diode drop down from the voltage at

+VSB or the backup battery potential, whichever happens to be at the higher voltage.

There are two conditions when the +VBB supply will operate from the backup battery:

• the main batteries have been removed

• the main batteries are discharged below 3.0 volts

Theory

3-3

Page 14

90207 Ambulatory Blood Pressure Monitor Service Manual

90207 Block Diagram

IR

serial

I/O

comm. port

speaker

internal

overpressure

relief valve

assembly

motor speed

control circuit

pump

manifold

IR

transmitter/

receiver

CPU / internal ROM

device latch

air

internal

check

valve

central processing

valve ON

control circuit

air

valve

LCD screen

address logic

hold

start up logic

Star t/ Stop

button

pressure

transducer

RAM

4 AA cells

3 volt lithium

backup battery

data/control

real

time

clock

watch dog

timer

over pressure

detector

gain and DC restore

pressure amplifier

fault

detect

power

supply

ON/OFF

switch

oscillometric

amplifier

oscillometric

amplifier

AC coupling

+8.6 Ref

+4.7 V

+5 UR

+10 UR

-5 UR

low

batteries

pressure cuff

gain adjust offset adjust

Figure 3-1: 90207 block diagram

3-4

Page 15

90207 Ambulatory Blood Pressure Monitor Service Manual

Wake Up and Power Up Logic

The 90207 power up sequence can be initiated by any of the following actions:

• Power START/STOP switch turned ON

• START/STOP switch depressed

• REAL TIME CLOCK generates minute change pulse

• IR serial RS-232 cable connected to communications port

The first three of the above actions trigger a wake-up pulse from a one-shot generator to assert the

PWR_ENABLE line and to enable the converter supply. When asserted, the PWR_ENABLE line

applies power to the microprocessor and generates a restart condition, causing the 90207 circuits

to awaken. The microprocessor then sets the HOLD line high to keep the converter supply up,

even after the wake-up one-shot pulse has timed out (the wake-up one-shot pulse has a duration

of approximately 120 msec).

After a wake-up, the microprocessor determines which event initiated the wake-up:

• It checks the C_CON (cable connected) line to determine if the IR RS-232 serial cable

activated the supplies.

• It checks the START/STOP line to see if this button is being pressed.

• It checks the PWR_SW line to see if the unit was just powered ON.

Theory

If none of these three conditions was responsible for waking up the unit, the minute timer is

assumed to have generated the wake-up pulse.

START/STOP Button

Pressing the START/STOP button triggers the wake-up one-shot generator and also generates an

interrupt to the microprocessor that is processed after the converter supplies are activated. The

microprocessor has a restart time of about 70 msec. After the restart time, the microprocessor

asserts the HOLD line and processes the interrupt (if the IR RS-232 cable is not connected), which

initiates the restart.

Power Switch

When the main power switch contacts are closed, power (+VSB) is applied to a power switch flipflop circuit. This flip-flop is then cleared and the PWR_SW line to the processor goes high (since

the processor is not yet powered ON, a resistor is used to protect the microprocessor input).

At the same time, the wake-up one-shot generator is triggered. This in turn activates the converter

supplies and awakens the microprocessor. The microprocessor now checks for conditions

START/STOP and C_CON. The PWR_SW line is read to determine if the power-up condition was

initiated by the power switch being ON. If ON, the HOLD line is asserted to clear the PWR_SW

line.

3-5

Page 16

90207 Ambulatory Blood Pressure Monitor Service Manual

Minute Pulse

The clock produces a pulse with a duration of 30 seconds every minute. The leading edge of this

pulse causes the minute timer flip-flop to change states. A narrow pulse (about 500 nsec) is

generated that also resets the flip-flop. This pulse triggers the wake-up one-shot, which in turn

powers up the converter and activates the microprocessor.

After waking up, the microprocessor first checks to see if any of the three possible wake-up

conditions has awakened it (C_CON, START/STOP LINE, or PWR_SW). If none of these three

have awakened the microprocessor, the microprocessor then asserts the HOLD line and

determines if it is time for a pressure reading. If it is time for pressure reading, the reading is

initiated; if it is not time for a pressure reading, the display time is updated, the HOLD line is

removed, and the microprocessor returns to its sleep state.

Cable Connection

If a cable is connected to the 90207 RS-232 communications connector and the power switch is in

the ON position, the power converter will be activated, bringing up the microprocessor. When

receiving a C_CON wake-up, the microprocessor gives it priority over the other three wake-up

conditions. A C_CON wake-up also prevents the power convertor from being deactivated as a

result of a shutdown fault, which might be generated by the watch dog timer or overpressure

detector.

After wake-up, the microprocessor goes into a listening mode and waits for instructions from the

attached computer. These instructions adhere to the ABP communications protocol.

Second Pulse

The SECONDS line from the unit’s real-time clock is monitored by the watch dog timer to

determine how long a pressure reading takes. When the unit wakes up, a reset signal is sent to the

watch dog timer, setting it to zero time. When the watch dog counts 256 second pulses, it

generates a pulse to activate the fault shutdown flip-flop circuit. The SECONDS line also goes to

the display circuit where it is used to blink the display colon and change polarity to the LCD

display.

Watch Dog Timer

The watch dog timer ensures that the cuff cannot remain inflated if the 90207 software crashes.

This timer begins counting second pulses from the real-time clock at converter power up. When it

counts up to 256-second pulses, the diode-connected outputs of the counter go high, causing a

transistor to pull low on the trigger input of the fault shutdown one-shot generator. This triggers a

25-second pulse, which asserts the shutdown line.

3-6

Page 17

90207 Ambulatory Blood Pressure Monitor Service Manual

Fault Shutdown

The fault shutdown circuitry causes the power converter to shut down. It also disables the

pressure pump and opens the pressure release valve until the shutdown circuit times out in

approximately 25 seconds. Shutdown can be caused by two conditions:

• There is an overpressure situation that is not detected by software.

• The pressure reading takes longer than 256 seconds. This duration indicates a software

crash, because there is also a 180-second software time-out that should have already stopped

the reading.

Overpressure Detector

In addition to software overpressure detecting, there is also a hardware overpressure detector

(at approximately 310 mmHg) that detects an overpressure situation that lasts longer than one-half

of a second. This small delay prevents motion artifacts from causing false overpressure detection.

Pressure Amplifier

The pressure amplifier circuitry amplifies voltage produced across the pressure transducer. This

voltage is proportional to the pressure in the arm cuff. The pressure transducer requires

compensation to make the voltage output linear with pressure. This compensation is

accomplished with a reference voltage and a current source. The current source provides an

output that increases as the voltage across the bridge decreases. This linearizes the transducer’s

output voltage.

Theory

Voltage across the transducer is amplified differentially and converted into single-ended voltage.

This voltage is amplified and sent to the A/D converter (ADC0848), the oscillometric amplifier, and

the overpressure detector.

Offset Adjust

Transducer offset is nulled out using a pressure offset adjustment. Minor variations in the offset

are tracked and compensated for through software.

Gain Adjust

Variations in gain can be compensated for with gain adjustment. The voltage gain to the A/D

converter is +14.4 mv/mmHg. This voltage is offset by about 0.2 volts. The 0.2 volts is inserted into

the last stage to prevent the signal to the A/D converter from going negative. The 0.2-volt offset is

subtracted with software.

Pressure Amplifier Filters

Some filtering is done in the pressure channel to reduce the effect of the pumping action, which

adds pulses to the pressure in the cuff. A 23-Hz low pass filter serves this purpose. The R-C

combination at the pressure output prevents the A/D converter loading from affecting the

oscillometric waveform.

3-7

Page 18

90207 Ambulatory Blood Pressure Monitor Service Manual

Oscillometric Amplifier

The first two stages of the oscillometric amplifier are a 2-pole low-pass filter and a 2-pole highpass filter. Together, these filters produce an insertion loss of 30%. The center frequency of the

pass band is 2 Hz; the 3-db points are at about 0.9 Hz and 5.5 Hz. During cuff bleeds and cuff

inflation, the high-pass filter is restored to charge the coupling capacitor up to the new pressure

level voltage. This helps reduce filter settling time.

Filtering has the effect of narrowing the oscillometric pulse width and generating a pulse with an

amplitude that is proportional to the rising edge of the oscillometric input waveform and its original

amplitude. The oscillometric pulse is similar to a half-sine wave with an extended trailing edge.

Gain Switching

Gain switching is provided by the oscillometric amplifier to account for varying amplitudes of the

oscillometric pulse. Switching is done by using switching gain resistors with analog switches

(DG211) selected by the GAIN_0 and GAIN_1 lines. Gain can be selected at 2, 4, 8, or 16.

Offset and Limiting

The offset stage offsets the voltage to the A/D converter to prevent negative voltages from going to

the converter. The input offset of the amplifiers can cause as much as 0.6 volts of unwanted offset

at the oscillometric output. Offset is subtracted out with software.

The last stage in the oscillometric amplifier limits the output swing from 0 to +4.7 volts to prevent

over-driving the A/D converter input.

Digital Circuitry Display Board

Information is sent from the microprocessor to the LCD controller by a serial bus (CBUS). The

LCD controller activates the necessary segments separately to display information on the 4segment LCD. The microprocessor determines what segments are to be turned on, sending this

information to the controller.

An exclusive OR gate blinks the colons once each second when in the clock mode, and it also

changes polarity of the drive.

Real-Time Clock

The real-time clock uses a serial data bus to send and receive information. This bidirectional bus is

divided into two lines (transmit and receive) that go to the microprocessor. If the main batteries are

removed, the clock will be backed up for approximately 2 minutes by the 3-volt lithium cell.

RAM

RAM is a 32 KB x 8 bit device for storing both patient collected information and programmed

information. RAM data is backed up during main battery removal by the 3-volt lithium cell.

3-8

Page 19

90207 Ambulatory Blood Pressure Monitor Service Manual

Addressing and Control Lines

Unit addressing and control is accomplished with a combination of microprocessor ports, two

latches, and one-half of a multiplexer circuit. The 74HC174 latch controls the motor, valve, alert,

gain switching, and hold line. A 74HC373 provides address latching for the RAM.

Communications RS-232 Connector

The 90207 communications connector is a modified RS-232 interface. When the communications

cable (IR cable) is connected to the back of the 90207, a reed relay is activated, causing power to

be applied to the ABP unit.

The microprocessor checks and determines that the C_CON line is asserted. It then goes into

communication mode. The microprocessor must then determine whether the cable is

communicating with a modem, a PC direct interface, or a local report generator. It then responds

accordingly.

Communications are accomplished by means of a transmit and a receive line. The data is

converted into IR signals.

Theory

Microprocessor

The 90207 uses a 80C51 microprocessor with a 7.272-MHz crystal. This chip contains on board

RAM and ROM. Four 8-bit ports provide the data lines, the addressing, and the control and serial

bus lines.

The on-board ROM provides routines for communications and start up. The majority of the

program is loaded into RAM using the IR RS-232 port.

One interrupt is used, and it is initiated by these following conditions:

• The START/STOP line goes low

• The PWR_SW line and the ADC INT lines go low (lowest-priority interrupt)

3-9

Page 20

Page 21

Contents

Caution

Note:

Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery Clip Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

90207 Disassembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Observe precautions for handling electrostatic-sensitive devices!

• Never touch electrostatic-sensitive electronic components without following proper anti-

static procedures, including the use of an ESD wrist band and mat. An electrostatic

discharge from your fingers can permanently damage electronic components.

• All static-sensitive electronic components are packaged in static-shielding bags. Retain the

bag for repackaging the component should you need to store it or return it to Spacelabs

Medical for any reason.

Periodic maintenance consists of cleaning the exterior of the unit, replacing or recharging the

monitor batteries, and calibrating the unit for accurate operation.

Cleaning

Use a soft, damp cloth and mild detergent mixed with water to wipe the exterior of the monitor.

Clean the carrying pouch and air hose with isopropyl alcohol.

The cuff wrap may be sterilized only by ethylene oxide (ETO) sterilization methods, using standard

hospital procedures. Use standard aeration techniques after sterilization. Small soiled or stained

areas may be cleaned by gentle scrubbing with a sponge or cloth soaked in a mild soap and water

solution.

The cuff wrap (with the air bladder removed) is machine washable on “delicate” cycle only. Do not

wash with bed linens and gowns or in large commercial-type washers.

To remove the bladder for cleaning, refer to the figures on the next page and follow these

steps:

1 Using your fingers only, fold or roll up the bladder inside the cuff. Do not use pencils, pens, or

2 Remove the bladder through the hose exit opening. After the bladder has been removed, be

3 After washing and drying the cuff, reinstall the bladder in the reverse order, as previously

other hard objects, because damage to the bladder could easily occur.

sure to again mate the hook-and-loop surfaces on the cuff before washing.

described. Make certain that any folds in the bladder are removed before inserting it back inside

the cuff.

Note:

The bladder may be installed with the hose exiting the second cuff opening. However, the

bladder must be positioned with its long side toward the center of the cuff.

4-1

Page 22

90207 Ambulatory Blood Pressure Monitor Service Manual

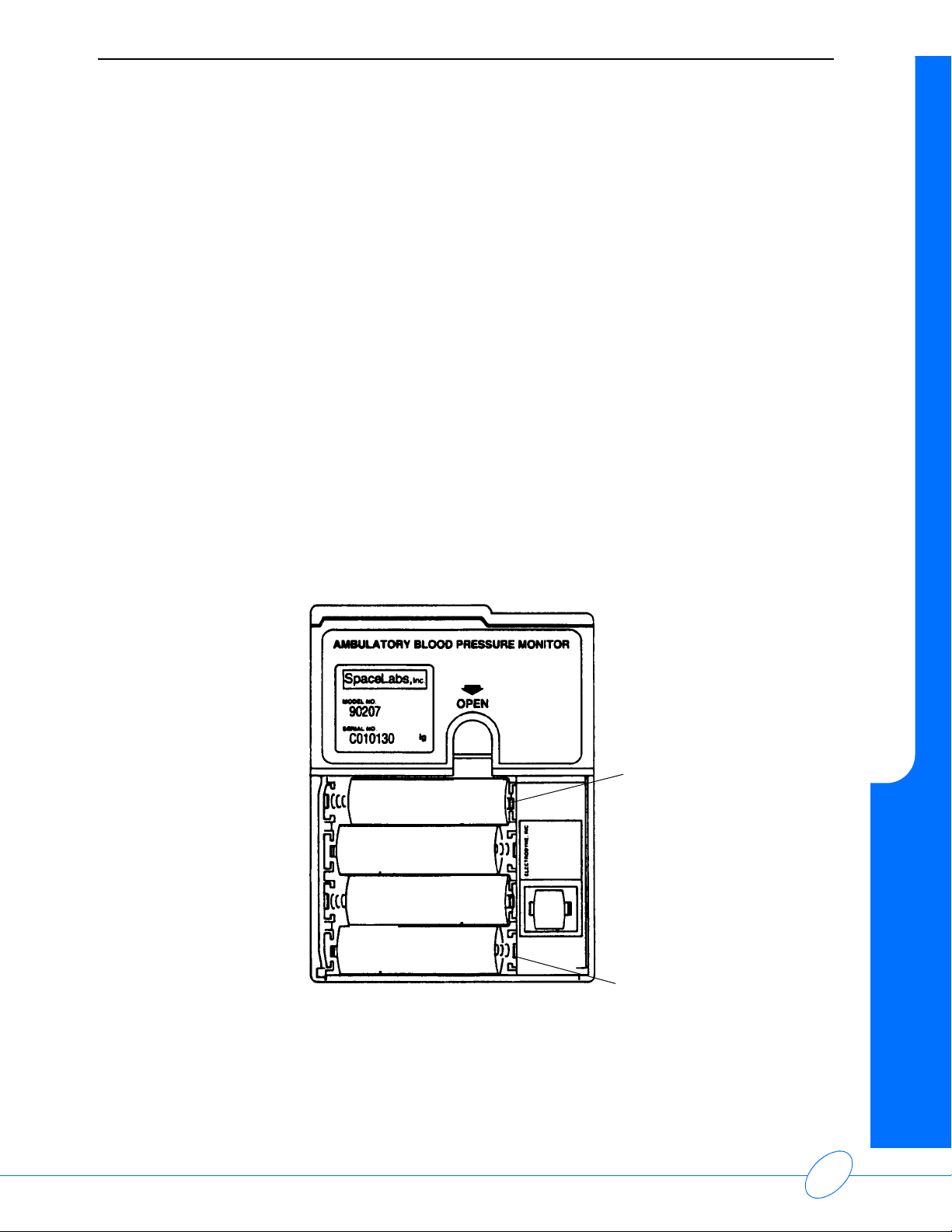

Battery Replacement

Two types of replaceable batteries are used in the 90207 ABP Monitor: four AA batteries

(Spacelabs Medical part number 146-5011-00) that power the cuff air pump, and one lithium

battery (3 volts, Spacelabs Medical P/N 146-0008-00) that preserves the information held in the

monitor’s memory circuits.

If alkaline batteries are used for the AA batteries, they must be replaced after each patient use.

Nickel cadmium batteries require a full recharge after each use. The lithium battery should be

replaced with a fresh battery every three years.

AA Batteries

Note:

If batteries are being replaced during patient testing, their replacement must be completed

within 1 minute to guarantee successful resumption of the test.

To replace the four monitor AA batteries:

1 Power the monitor OFF using its rear panel ON/OFF switch.

2 Remove the battery compartment cover plate by pulling back and up on the provided latch.

3 If present, remove the old AA batteries from the monitor and replace each with a fresh alkaline

(or fully charged nickel cadmium) battery, being careful to observe the voltage polarity (+ or -)

as identified in

4 AA batteries

Figure 4-1.

Lithium

battery cover.

Note shape of

cover. It will

insert in one

position only.

lithium battery

Figure 4-1: Battery compartment

4-2

Page 23

90207 Ambulatory Blood Pressure Monitor Service Manual

Note:

• The monitor will not operate if either the alkaline or the lithium batteries are incorrectly

installed.

• If the monitor is going to be stored for over two weeks, remove the batteries to prevent the

possibility of leakage or discharge. Spacelabs Medical is not responsible for product

damage incurred as a result of battery leakage. In the event that your unit has been

damaged from a leaky battery, contact the battery manufacturer for any recoverable repair

or replacement costs.

4 After replacing the batteries, gently replace the battery cover and secure the latch.

5 Turn ON the monitor. Check that the display is ON. If there is no display, power the monitor

OFF and refer to

Maintenance on page 4-1.

Lithium Battery

The expected life for the 3V lithium battery is 10 years; however, Spacelabs Medical recommends

that it be replaced before three years of use.

To replace the lithium battery:

1 Power OFF the monitor using the rear panel ON/OFF switch.

2 Remove the battery compartment cover plate by pulling back and up on the provided latch.

3 Remove the protective cover from the lithium battery, taking note of the battery position (polarity

of cell and socket indicators).

Maintenance

4 Remove the old lithium battery by carefully prying it out (curved forceps are recommended).

5 Install the new lithium battery, observing the correct polarity.

6 Replace the battery’s protective cover (step #3).

7 Replace the battery compartment cover plate (step #2).

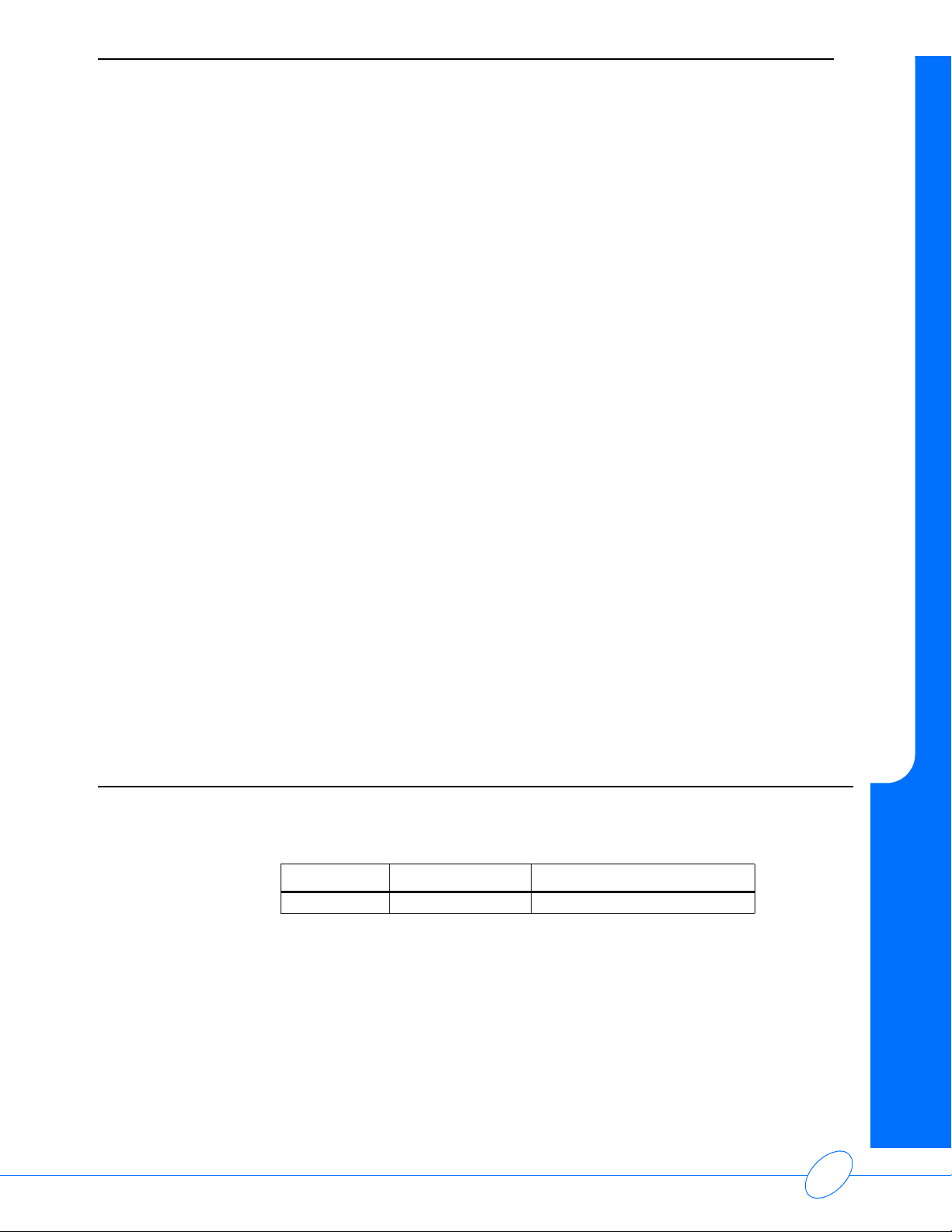

Battery Clip Upgrade

Please verify that you have the part before beginning:

Quantity Part Number Description

3 131-1218-01 Battery clip, 90207

Tools Required

• Needle-nose pliers

• Fine-tipped flat screwdriver

4-3

Page 24

90207 Ambulatory Blood Pressure Monitor Service Manual

Installation Instructions

1 Remove the battery cover from the 90207. Refer to Figure 4-2: Battery contact clip installation.

2 Using a fine-tipped flat screwdriver, remove the three twin-spring contacts () by gently prying

the contacts out from under the molded retaining hooks (

Note:

Use extreme care not to break the retaining hooks.

3 Insert each new battery contact clip () over the short spring () (+ terminals) (refer to Battery

contact clip installation on page 4-4).

).

Figure 4-2: Battery contact clip installation

4 Orienting the metal bump on the contact toward the battery with all coils under the contact tab,

slide the contact and spring assembly back down into the case slots. Ensure that the contact is

inserted into the case slot (

5 Carefully press down and position the center part of the spring assembly under the plastic

retaining hook.

6 Ensure that each battery clip is securely in place and makes good contact with an installed

battery.

Note:

The last battery in the center of the unit does not require the installation of a battery clip.

) facing the battery slot.

4-4

Page 25

90207 Ambulatory Blood Pressure Monitor Service Manual

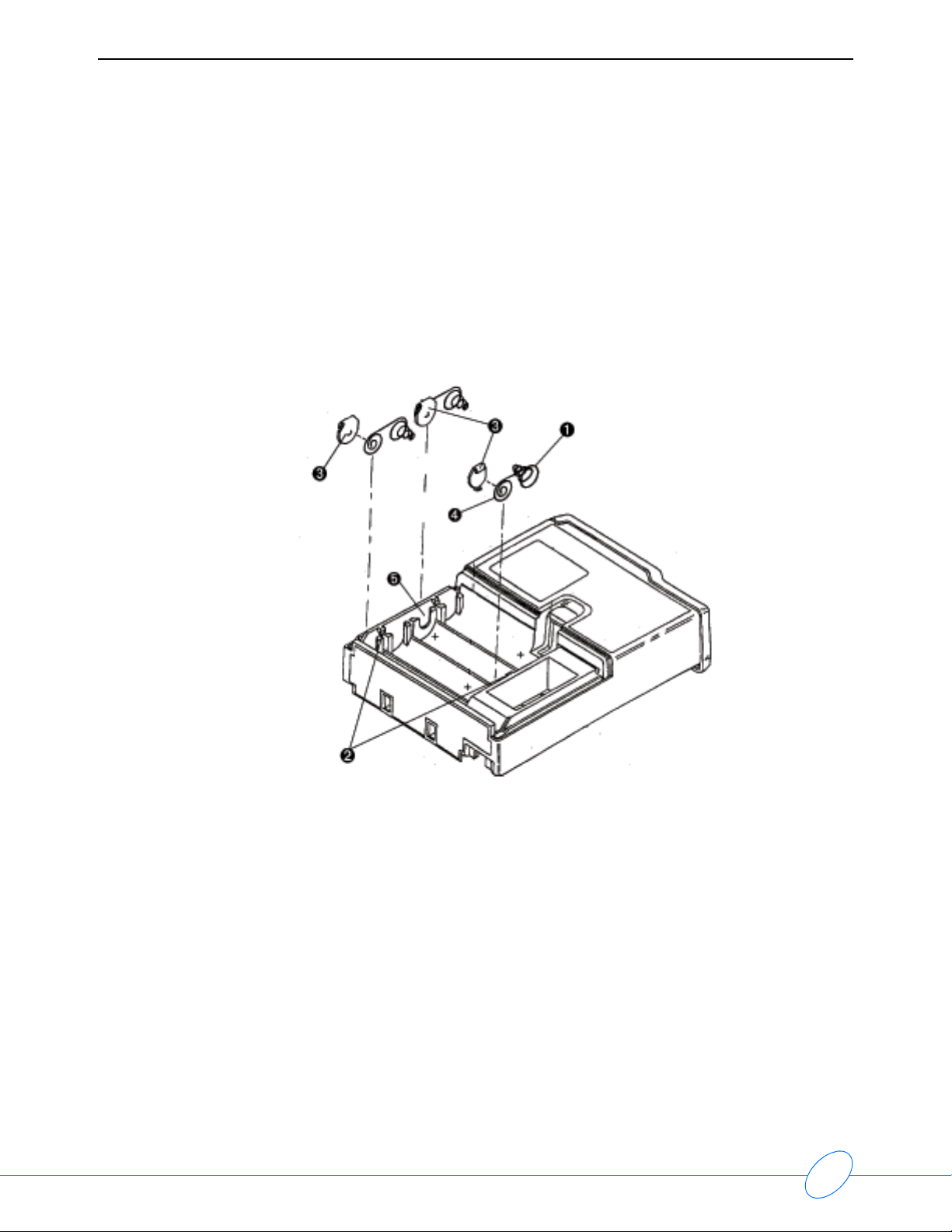

90207 Disassembly Procedure

To remove the top case cover and gain access to the internal components:

1 At the rear of unit, use two small screwdrivers (or similar tools) to press in on the cover’s two

locking tabs until the tabs both clear contact with the rear panel (the tabs are located on each

side of the infrared connector, refer to

Maintenance

Figure 4-3: Top cover removal).

front

infrared connector

location

side tabs

Figure 4-3: Top cover removal

Aplly sufficient pressure to lift the cover and pull the two side tabs free. Be sure to pull from the

rear of the cover. The front of the cover is tucked under the front panel and it cannot be pulled

out until the locking tabs are free from the case.

2 When the locking tabs are pulled out of the case, pull the cover away from the front panel to

free it from the unit.

top case cover

rear

push in these two tabs

and pull cover up when

tabs clear rear panel

4-5

Page 26

90207 Ambulatory Blood Pressure Monitor Service Manual

Accuracy Procedure

To check the accuracy of the monitor:

1 Disconnect the cuff hose from the monitor. Connect the T-tube splitter to the monitor pneumatic

connector and the sphygmomanometer.

2 Wrap the pressure cuff around the rigid cylinder, and then fasten the cuff. Connect the cuff hose

to the remaining connection on the T-tube splitter. The test setup should appear as shown

below.

016-0040-xx

712-0039-01 CALIBRATION KIT

TO SPHYGMOMONOMETER

TO CUFF/CYLINDER

Figure 4-4: T-Tube connection

TO MONITOR

4-6

Page 27

90207 Ambulatory Blood Pressure Monitor Service Manual

)RUXVHZLWK40RQLWRU4XLFN'LVFRQQHFW&XII&DQ

&RQQHFW

WR

6SK\JPRPRQRPHWHU

&RQQHFW

WR

4XLFN'LVFRQQHFW

)LWWLQJ&XII

&RQQHFW

WR

4

$%30RQLWRU

Maintenance

)RUXVHZLWK0RQLWRU/XHU)LWWLQJ&XII&DQ

&RQQHFW

WR

6SK\JPRPRQRPHWHU

5HPRYH/XHU%DUE7XELQJ

5HPRYH4XLFN

'LVFRQQHFW)LWWLQJ

3 Press START/STOP on the monitor; the monitor should read approximately 165. Compare the

readings on the monitor and the manometer as the pressure bleeds down. The monitor reading

should be within three millimeters or 2% of the manometer reading, whichever is greater

(± the accuracy of the manometer).

Note:

If the monitor pressure values fall outside the allowed tolerance, call your local Customer

Service Representative or Spacelabs Medical for servicing.

4 At the end of the procedure, the monitor displays an event code indicating that no dynamic

blood pressure measurements were obtained.

5 Disconnect the T-tube splitter from the monitor. Disconnect the air hose and

sphygmomanometer.

4-7

Page 28

90207 Ambulatory Blood Pressure Monitor Service Manual

Calibration Procedures

Complete the following procedures to calibrate the Model 90207 ABP Monitor.

Test Equipment Required

Note:

Any test equipment listed below can be replaced with equivalent models.

• 1 Tektronix 7603 or TDS420 oscilloscope

• 7A22 or AM502 Differential Amplifiers

• 7B53A Dual Time Base

• DM501A Digital Multimeter

• FG501A Function Generator

• PS503A Dual Power Supply

• BK 1630 DC Power Supply

• Fluke 8052A Digital Multimeter

• IBM PC-AT (or compatible) loaded with 90207 manometer mode software (P/N 063-0165-00)

and 90209 to PC cable assembly or 90219 software

• 90209 Data Interface Unit or 90219-02, -03

• IR Direct Connect Cable Assembly (P/N 012-0097-xx)

• Temperature-controlled soldering station

• Analog or digital sphygmomanometer

• Two-hole pressure can (made from empty pint paint can with lid and two 1/8-inch outer

diameter brass fittings soldered on)

• Squeeze bulb with tubing and T-fittings

• 1000 µF or greater capacitor

•1 µF capacitor

Tools Required

• Needle nose pliers

• Hemostats

• Diagonal cutters

• Small Phillips screwdriver

• Small flat-tip screwdriver

• Anti-static equipment

•Tweezers

• Small cleaning brush (acid brush)

• Small gauge wire strippers

• Utility knife

• Soldering iron with small tip

4-8

Page 29

90207 Ambulatory Blood Pressure Monitor Service Manual

Solvents/Compounds Required

• Isopropyl alcohol

• Rosin core solder

90207 Main Board Components

Refer to Figure 4-5 to identify test points and other components when conducting calibration and

verification procedures for PCBAs P/N 670-0303-10 (and earlier versions).

SW910 SW860

TP731

P710

Maintenance

TP730

TP631

TP630

L530

C533

U440

C432

C431

C330

R330

C250

R130

TP110

Figure 4-5: Main board components for P/N 670-0303-10 (and earlier versions)

4-9

Page 30

90207 Ambulatory Blood Pressure Monitor Service Manual

Figure 4-6: Main board components (front view) for P/N 670-0303-11 (and later versions)

4-10

Page 31

90207 Ambulatory Blood Pressure Monitor Service Manual

N1

Maintenance

N26

N10

N23

N18

N19

N9

N20

N17

N57

D534

N24

N11

N8

Figure 4-7: Main board components, back view, for P/N 670-0303-11 (and later versions)

Computer System Setup

The following equipment is required to set up the test computer required for 90207 calibration:

• IBM PC (or compatible) loaded with manometer mode software (P/N 063-0165-00)

• 90209 Data Interface Unit or 90219 PCDI software

• 90209 to PC Cable Assembly

• IR Direct Connect Cable Assembly

4-11

Page 32

90207 Ambulatory Blood Pressure Monitor Service Manual

To set up the computer system (refer to Figure 4-8):

computer system block diagram

90219

IBM PC

with 90219

software

IR cable

012-0097-xx

Figure 4-8: Computer system block diagram

1 Connect power to the 90209 Data Interface Unit.

2 Connect the 90209 to PC cable between the 90209 and the IBM PC. Use the proper cable for

either a PC AT or XT, depending on the computer being used.

90207

3 Connect the IR Direct Connect Cable Assembly to the 90209 at the 90207 connection.

Note:

• Refer to the 90219 operations manual if not using a 90209 for these procedures.

• The test equipment settings specified in these procedures are for reference only.

• The power supply must have a 1000 µf or greater capacitor connected between the plus

(+) and minus (-) terminals and must be

within three inches of where the power is applied

to the flex board.

• The calibration adjustment on the dual time base must remain in the CAL position (fully

clockwise) when making timing measurements. The SOURCE selection should remain in

the INT position.

• The ground wire of the test lead must be connected to the power ground of the circuit

board under test whenever measurements are made using the differential amplifier.

4-12

Page 33

90207 Ambulatory Blood Pressure Monitor Service Manual

Power Supply Check

To check the Model 90207 power supply:

1 Set your oscilloscope as shown below.

Time/Div 5 ms

Volts/Div 10 mV

Mode AUTO

+ Input AC

Coupling AC

HF -3 dB Point 10kHz

LF -3 dB point DC

2 Set the power supply output to 5.7 VDC ±0.1 VDC.

3 Connect the power supply to the 90207 monitor at the positive (+) and negative (-) AA battery

terminals:

Maintenance

+ lead of power supply

- lead of power supply

Figure 4-9: Power supply

4 Ensure that the ON/OFF switch (SW910) is in the OFF position. Verify a voltage reading of

0.0

V at +VSW (P710, pin 2). For P/N 670-0303-11 assemblies (and later versions), verify the

voltage at N9. Use N17 (AGND) as ground reference. Refer to

pad location.

Figure 4-7 on page 4-11 to verify

4-13

Page 34

90207 Ambulatory Blood Pressure Monitor Service Manual

5 Slide the ON/OFF switch to the ON position and verify the following:

a The LCD shows the current ROM version number followed by the time.

b A sleeping current draw of less than 300 µADC (monitor is in sleep state when LCD shows

time).

c A voltage reading of +5.7 VDC at +VSW.

6 Connect a jumper lead across the reed switch (SW860). The LCD will show “9999”.

7 Verify a current flow of less than 30 mA.

8 Verify a voltage reading of greater than +5.65 VDC at + VPS (L530) for P/N 670-0303-10 and

earlier versions. For P/N 670-0303-11 and later versions, verify the voltage reading at the

cathode side of D534. Refer to figure

9 For main board assemblies P/N 670-0303-10 (and earlier versions) set the ADR reference

voltage, measured at +C330, to 3.672

refer to

Main board assemblies of P/N 670-0303-11 (and later versions) require a board test fixture to

calibrate ADR. If ADR is out of specification, recalibrate on an ABP board test fixture. ADR can

be measured at N10. To locate this point, refer to

as ground reference.

Figure 4-5 on page 4-9.

Figure 4-7 on page 4-11.

V ± 0.001 V by adjusting point R330. To locate this point,

Figure 4-7 on page 4-11. Use N17 (AGND)

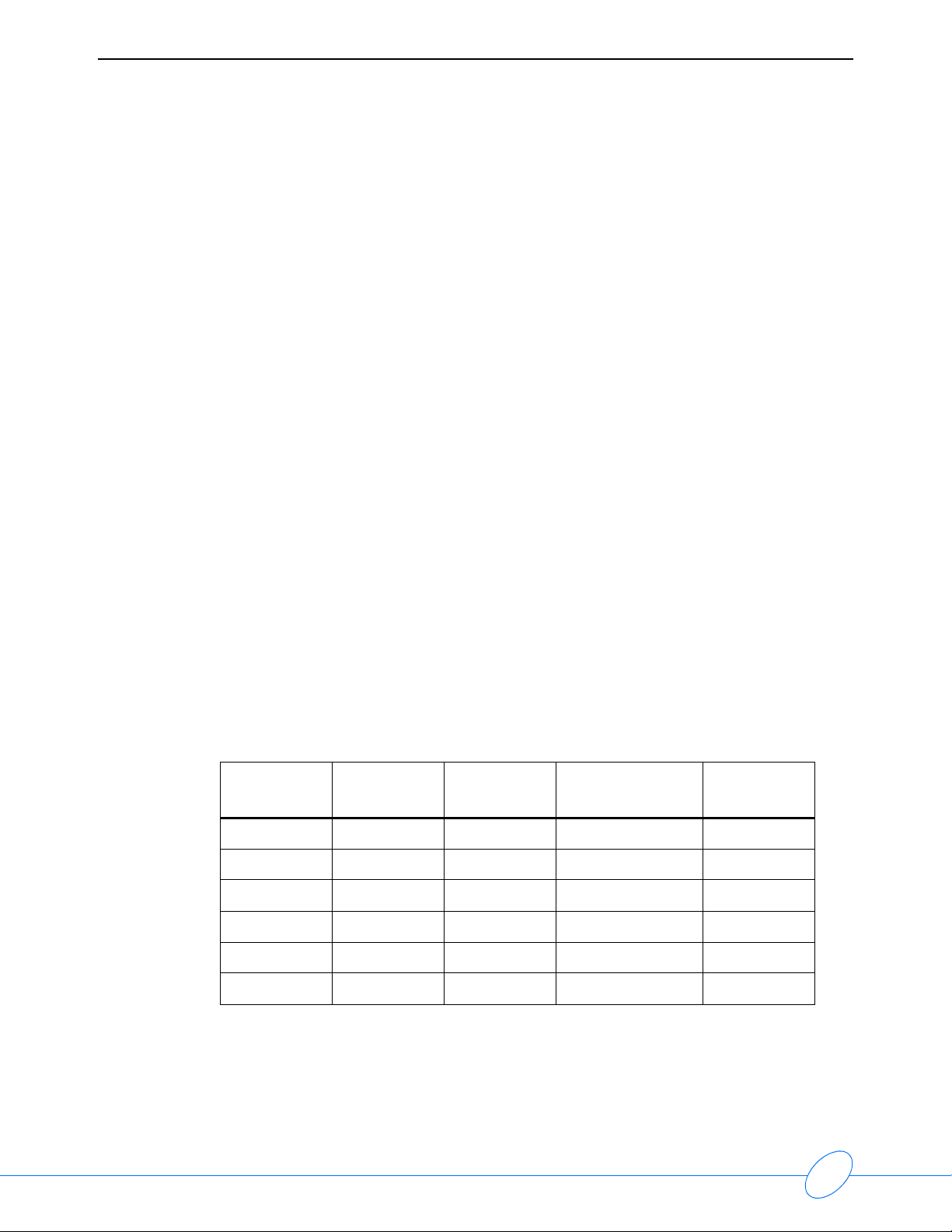

10 Refer to the table below and verify each voltage specification.

Note:

In the following checks and adjustments, TP730 must be used as a ground test point for board

assemblies P/N 670-0303-10 (and earlier versions). For board assemblies P/N 670-0303-11

(and later versions), use N17 (AGND) as ground reference. Refer to

to verify pin location.

Figure 4-7 on page 4-11

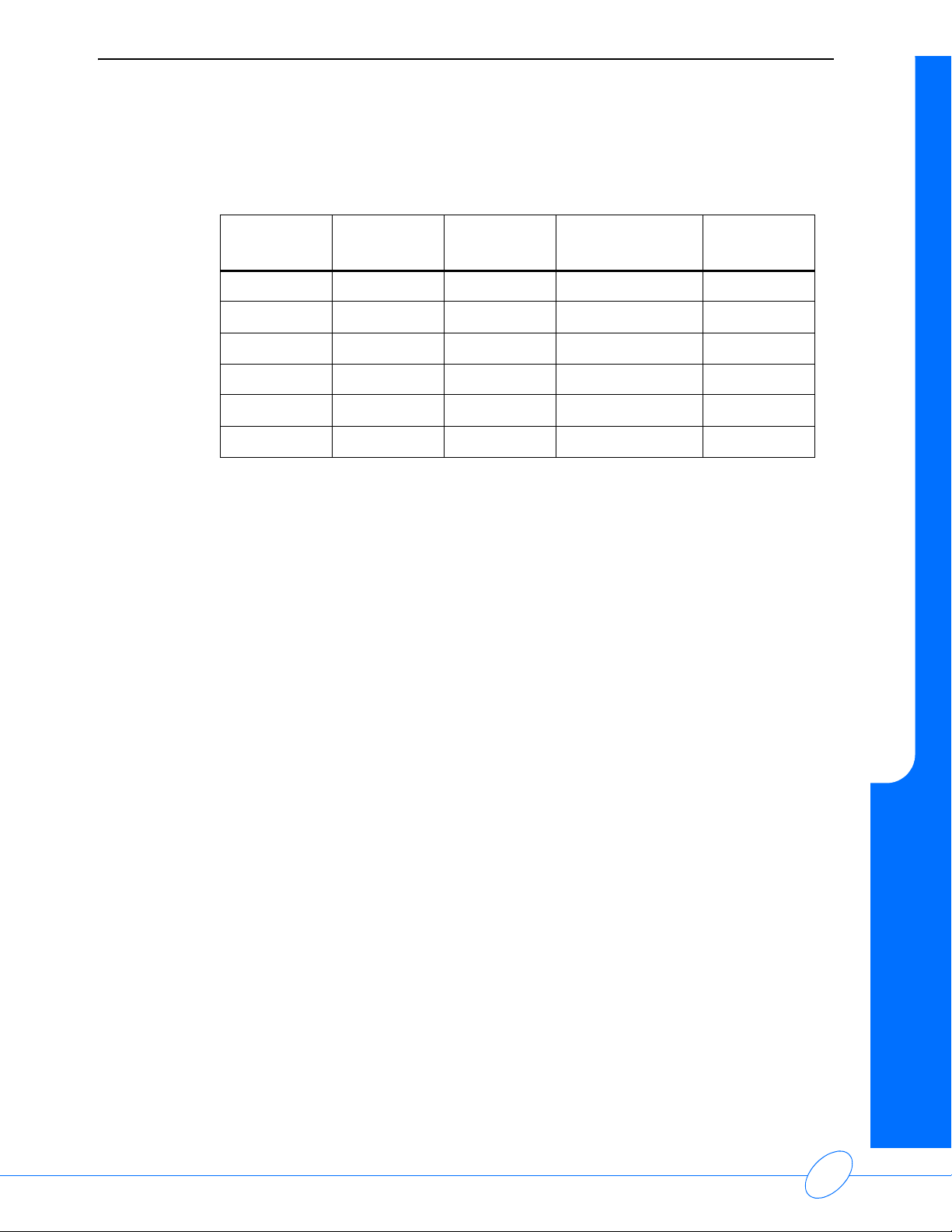

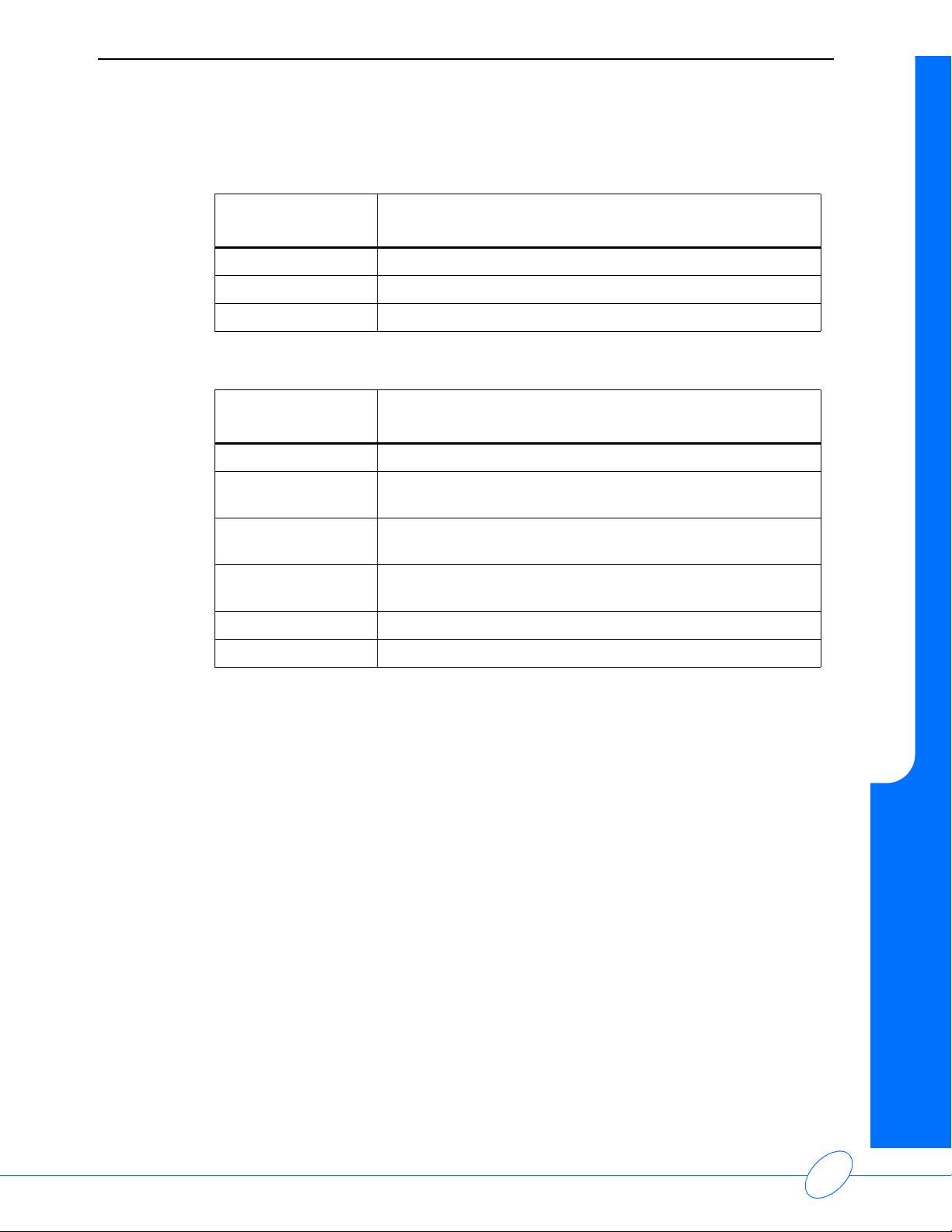

Power Supply Voltage Specifications

Table 1: Specifications for Board Assemblies 670-0303-10 and earlier versions

Supply Location

ADR Low TP731 1.022 1.009 to 1.035 <10

+4.7 V +C431 4.7 4.69 to 4.71 <50

+5 V UR +C432 5.45 5.1 to 5.65 <100

-5 V UR -C430 -4.45 -4.0 to -4.7 <50

+10 V UR +C533 9.75 9.0 to 10.5 <50

+8.6 V Ref +C250 8.6 8.575 to 8.625 <20

Voltage

(VDC)

Range (VDC)

Ripple

(mVPP)

4-14

Page 35

90207 Ambulatory Blood Pressure Monitor Service Manual

Table 2: Specifications for Board Assemblies P/N 670-0303-11 and later versions

Maintenance

Supply Location

ADR Low N8 1.022 1.009 to 1.035 <10

+4.7 V N11 4.7 4.69 to 4.71 <50

+5 V UR N18 5.45 5.1 to 5.65 <100

-5 V UR N23 -4.45 -4.0 to -4.7 <50

+10 V UR N19 9.75 9.0 to 10.5 <50

+8.6 V Ref N20 8.6 8.575 to 8.625 <20

Voltage

(VDC)

Range (VDC)

Ripple

(mVPP)

Amplifier Calibration

Pressure Amplifier

1 Monitor TP731, ADR_LOW, with a DVM. For P/N 670-0303-11 (and later versions), monitor N8.

Refer to

2 Check for 1.0224 V ±0.0144 V.

3 Monitor TP630, PRESS, with a DVM. Monitor N24, PRES_OUT, for P/N 670-0303-11

assemblies (and later versions). Refer to

Figure 4-7 on page 4-11.

Figure 4-7 on page 4-11.

4 For main board assemblies of P/N 670-0303-10 (and earlier versions), adjust R130 to

0.1872 V ± 0.005 V.

For main board assemblies of P/N 670-0303-11 (and later versions), the ABP system test

fixture is required to adjust pressure offset.

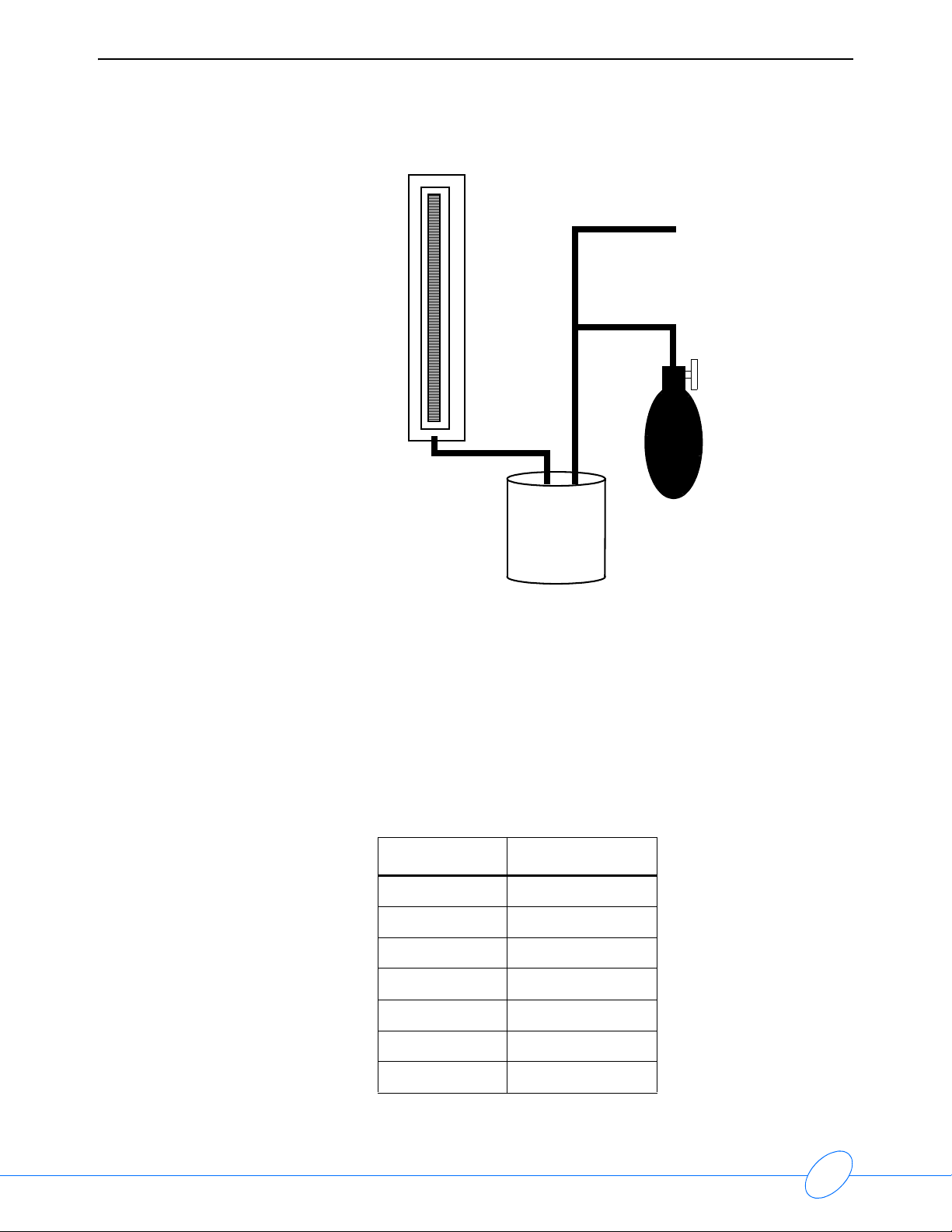

5 Connect the pressure bulb manometer and standard two-hole can to the input (refer to

Figure 4-10 on page 4-16). Clamp the hose to the bleed valve using the hemostats.

4-15

Page 36

90207 Ambulatory Blood Pressure Monitor Service Manual

to 90207

sphygmomanometer

two-hole can

squeeze bulb

Figure 4-10: Sphygmomanometer test configuration

6 Connect the 90207 monitor to the PC and run the manometer mode software.

7 Manually pump the bulb to apply 200 mmHg pressure to the system.

8 Verify a voltage reading of between 3.060 VDC and 3.070 VDC at TP630 (sphygmomanometer

and display must read 200

(and later versions). Refer to

mmHg). Monitor N24, PRES_OUT, for P/N 670-0303-11 assemblies

Figure 4-7 on page 4-11.

9 Check the following voltages for each given pressure reading (if any adjustment is made,

all pressure and voltages must be verified again).

Pressure Voltage

300 mmHg 4.507, ±0.02

250 mmHg 3.787, ±0.01

200 mmHg 3.067, ±0.01

150 mmHg 2.347, ±0.01

100 mmHg 1.627, ±0.02

50 mmHg 0.907, ±0.02

0 mmHg 0.187, ± 0.01

4-16

Page 37

90207 Ambulatory Blood Pressure Monitor Service Manual

Overpressure Detector

1 Monitor U440 pin 7 with an oscilloscope for main board assemblies P/N 670-0303-10 (and

earlier versions). Monitor N57 for main board assemblies P/N 670-0303-11 (and later versions).

Refer to Figure 4-7 on page 4-11.

2 Slowly increase the pressure while observing the manometer.

3 For P/N 670-0303-10 assemblies (and earlier versions), verify that U440 pin 7 goes low

between 305 mmHg and 320 mmHg. For P/N 670-0303-11 (and later versions), verify this

measurement at N57.

4 Relieve the pressure in the system.

Noise

1 Configure the oscilloscope as follows:

Model 7A22

Window: DC - 3 kHz

Volts/Div: 50 mV/Div

Input: AC +

Maintenance

2 Check TP630, PRESS, for <10 mV of noise. Monitor N24, PRES_OUT, for P/N 670-0303-11

assemblies (and later versions). Refer to

Figure 4-7 on page 4-11.

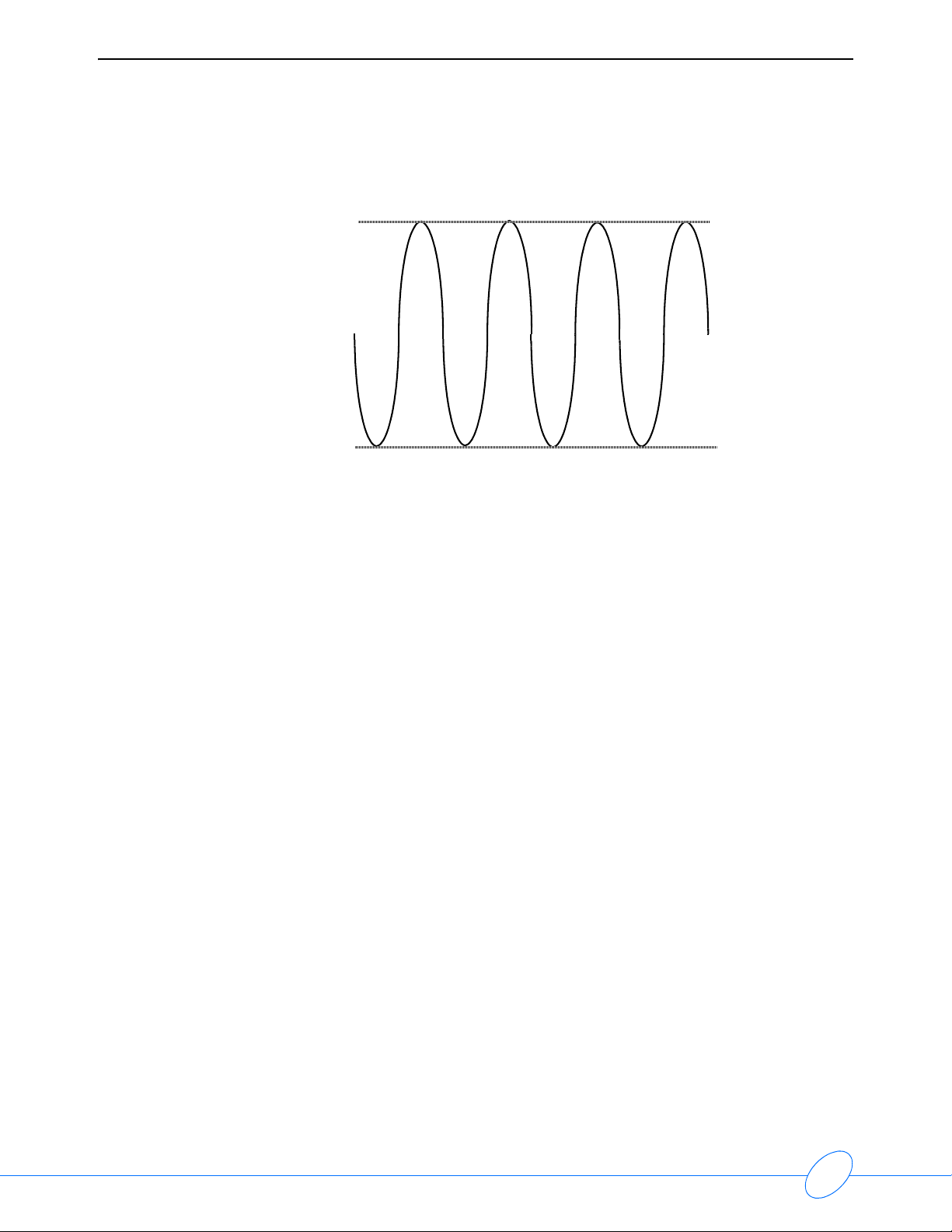

Oscillometric Bandpass

1 Connect a 1µF capacitor between the scope probe and TP631 (OSC_OUT) for P/N 670-0303-

10 assemblies (and earlier versions). For 670-0303-11 assemblies (and later versions),

connect the probe to N26 (OSC_OUT). Refer to

2 Set the oscilloscope (7A22) to AC, 20 mV/division.

3 For P/N 670-0303-10 assemblies (and earlier versions):

Set the function generator for sine wave, a frequency of 2.5 Hz, free run mode, -60 db (minimum

amplitude), and connect it to TP110.

For 670-0303-11 assemblies (and later versions):

Repeat the previous steps, but disregard the connection to TP110. Instead, connect to point

N1. Refer to

4 Adjust the amplitude of the function generator until the OSC_OUT pressure output signal is 100

millivolts, peak-to-peak.

Figure 4-7 on page 4-11 to verify the location of this point.

Figure 4-7 on page 4-11.

4-17

Page 38

90207 Ambulatory Blood Pressure Monitor Service Manual

2.5-Hz Signal on Percentage Scale

100%

0%

Figure 4-11: Signal on percentage scale

5 Decrease the frequency until the amplitude is 70%.

6 Verify that the frequency is 0.9 to 1.1 Hz.

7 Increase the frequency until the amplitude is at 70%.

8 Verify that the frequency is from 5 to 7 Hz.

9 Remove the capacitor and hemostats.

Backup Battery Check

To test the lithium battery current:

1 With a primary power supply connected across the main battery terminals, set a secondary

power supply for a 2.6 ±0.1 VDC output. Connect a current meter in series with the power

supply.

2 Remove the lithium battery from its holder.

3 With the 90207 power switched OFF, connect the power source to the 90207 at the lithium

battery holder terminals (pay attention to terminal polarity).

4 Turn the unit ON and start a reading by pressing the START/STOP button, and then verify that

an “Lbb” indication does not occur.

5 Decrease the lithium battery input voltage to 2.25 ±0.05 VDC.

6 Start a reading and verify that an “Lbb” indication does occur.

7 Reinstall the lithium battery removed in step 2 above.

8 Initialize the ABP monitor using one of the ABP systems. Set it to view pressure steps.

Functional Test

To test the operation of the Model 90207:

1 Set the primary power supply for a 5.7 VDC output.

2 Connect a current meter in series with the supply.

4-18

Page 39

90207 Ambulatory Blood Pressure Monitor Service Manual

3 Remove the four AA batteries from the main battery compartment of the 90207.

4 Connect the 5.7 VDC power source to the 90207 at the main battery terminals.

5 Turn ON the 90207. The display shows the current ROM version and then the current time; the

colon will be flashing.

6 Connect the sphygmomanometer test configuration (page 4-11) to the 90207.

7 Press the START/STOP button and verify the occurrence of two audible tones.

8 Verify that the display begins the countdown sequence; “5555”, “4444”, “3333”, “2222”, “1111”.

9 Verify that the pump starts, the current draw is less than 350 mA, and that the pump reaches

its target pressure of 175 mmHg, +/-8 mmHg.

10 Verify that the pressure bleeds down in increments of between 7 and 9 mmHg.

11 Verify a current drain of less than 55 mA during bleed down. Current spikes of approximately

70 mA are acceptable.

12 Verify a rapid succession of tones and a display reading of “EC 08”.

13 Verify that the display changes from showing the event code to showing the current time.

14 Verify that the monitor goes to a sleep mode with a current drain of less than 250 µA. Lower the

main battery input voltage to 4.8 ±0.03 VDC.

15 Attempt a reading by depressing the START/STOP button.

16 Verify that the display shows “LLL”, indicating a low main battery.

Maintenance

17 Increase the main battery input voltage to 5.0 ±0.03 VDC and attempt a reading.

18 Verify that the 90207 performs a normal reading.

19 Start another reading. Decrease the main battery input voltage to 4.1 VDC when the 90207

begins to pump.

20 Verify that an “LLL” indication does NOT occur.

21 Decrease the main battery input voltage to 3.9 VDC while the 90207 is still pumping.

22 Verify that an “LLL” indication occurs immediately.

23 Increase the main battery input voltage to 5.7 VDC.

24 Disconnect the primary power source and reinstall the four AA batteries (observe correct

polarity).

25 Assemble the 90207 module into the main body case. Make sure that the display board fits

completely into the window of the case.

26 Fit the case cover over the 90207 module and snap it into place.

27 Fit the tabs on the case battery cover into the hinges on the main body case; snap the cover in

place.

28 Reinitialize the 90207 monitor using the ABP program.

4-19

Page 40

90207 Ambulatory Blood Pressure Monitor Service Manual

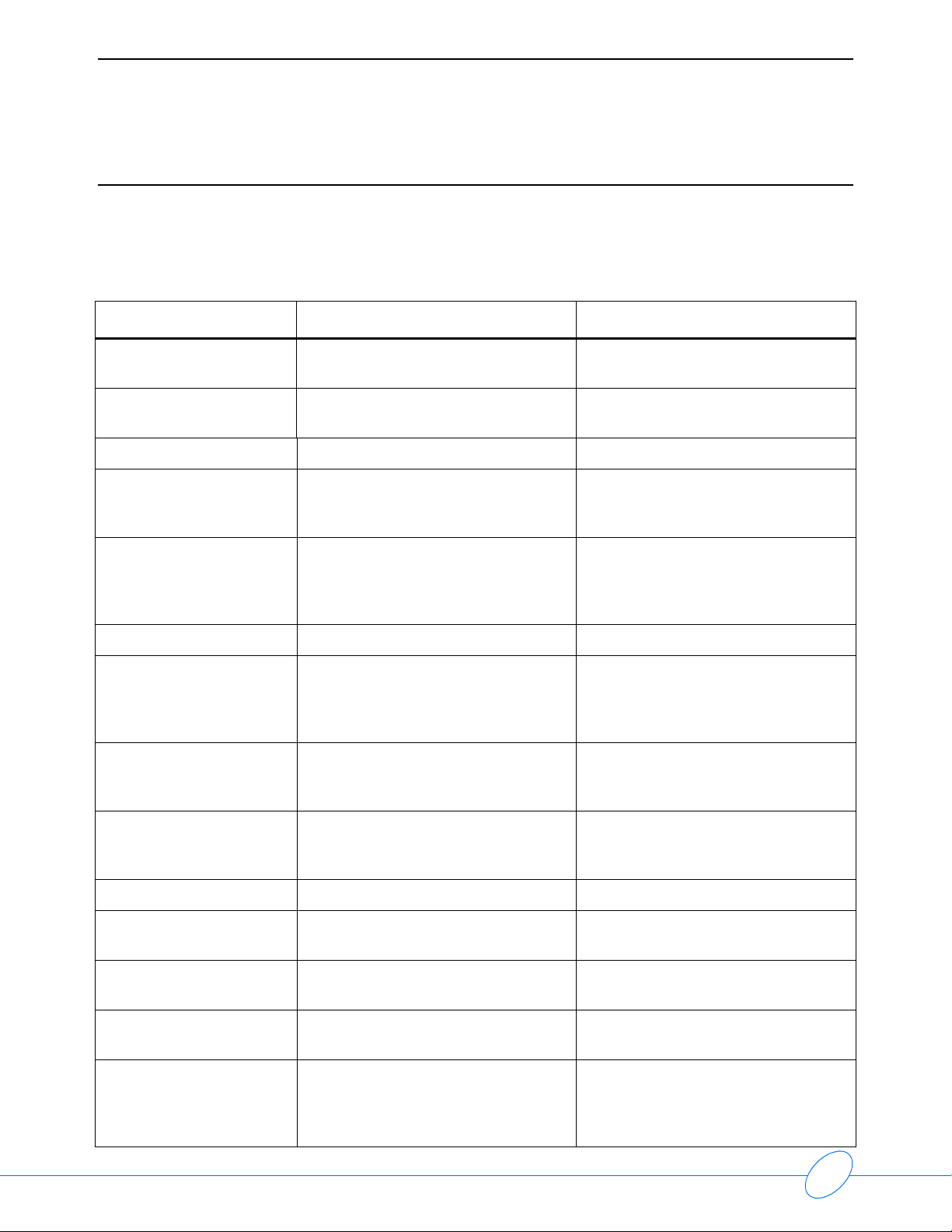

Operation Verification

The following procedures verify that the 90207 ABP monitor’s blood pressure readings are

consistent with design standards.

Note:

These procedures refer to use of the DynaTech Nevada CuffLink Blood Pressure Simulator. If

you are using a different simulator, refer to its operator’s manual to determine equivalent tests.

Refer to the end of this Maintenance chapter for instructions on using the CuffLink simulator in

automatic or manual modes.

Equipment Required

• DynaTech Nevada CuffLink Noninvasive Blood Pressure Analyzer and associated tubing,

manuals, luer fittings (software version 2.0 or higher is required)

• 1/8 inch I. D. tubing (P/N 162-0019-00 or equivalent)

• Adult cuff

• Luer connector (P/N 103-0008-00)

Blood Pressure Simulator Preparation

1 Verify that the calibration sticker on the simulator is current. If it is not, the simulator will need

to be calibrated by the manufacturer or the authorized service facility.

2 Turn ON the CuffLink simulator and allow it to warm up for a minimum of 15 minutes.

3 Check the zero pressure by selecting ADAMS Adult from SelectBp in the Main menu.

4 Press ENT.

5 Press F5 to zero the pressure.

6 Press Esc to return to the Main menu.

7 Perform a leak rate check on the blood pressure simulator and associated tubing as follows:

a While in the Main menu, move the cursor to Press and select Leak Test by pressing ENT.

b Connect a squeeze bulb to the hose which will connect directly to the unit under test.

c Pump up the system pressure to approximately 170 mmHg.

d Wait 10 seconds for the pressure to stabilize.

e Press the START (F1) key on the CuffLink simulator and wait one minute while the leak

rate is measured.

f At the end of the minute, the leak rate will be displayed on the CuffLink display.

g If the leak rate is greater than 10 mmHg per minute, retighten all external hose connections

and repeat the test. If the system continues to fail, isolate each length of tubing to locate

the source of the leak. Repair the leak.

h Press the Esc key to return to the Main menu.

4-20

Page 41

90207 Ambulatory Blood Pressure Monitor Service Manual

90207 Preparation

1 Set up the ABP monitor by connecting it to the CuffLink.

2 Refer to the table below for a list of systolic/diastolic/heart rate settings to perform on the unit

under test.

Pressure Setting Range

Systolic 60 57 to 64

Diastolic 30 26 to 33

Heart Rate 40

Systolic 100 95 to 106

Diastolic 65 60 to 70

Heart Rate 60

Systolic 120 113 to 125

Maintenance

Diastolic 80 74 to 88

Heart Rate 80

Systolic 150 142 to 158

Diastolic 100 92 to 108

Heart Rate 120

Systolic 200 190 to 210

Diastolic 150 142 to 158

Heart Rate 120

Systolic 255 243 to 267

Diastolic 195 185 to 205

Heart Rate 120

4-21

Page 42

90207 Ambulatory Blood Pressure Monitor Service Manual

3 Connect the unit under test to the simulator, as illustrated in Figure 4-12.

Adult Cuff

CuffLink

Simulator

1/8” ID x 12”

1/8” ID x 6”

T-connector

90207 ABP

Monitor

1/8” ID x 108”

Figure 4-12: Test connection

4 Move the CuffLink cursor to SelectBp and press the ENT key to select ADAMS Adult.

5 Press the F2 key (AdjEnv) and verify that the gain is at 100%. If it i s n ot, adjust it u s i ng the arrow

keys. At the same time, verify that OFFSET and/or SHIFT are at 0.

6 Press the ENT key.

7 Press the Esc key to return to the Main menu.

8 Move the cursor to AUTO using the arrow keys and select Execute using the ENT key.

9 Press the F1 key to select ADULT readings.

10 Zero the pressure by pressing the F5 key.

11 Press the Esc key until the first pressure simulation reading is displayed on the CuffLink.

12 Press the START/STOP button on the ABP monitor to start the reading.

Note:

The CuffLink simulator may automatically change to the next blood pressure setting when the

current reading is complete. If it is required to repeat a reading, press the Esc key repeatedly

until the ADULT INFANT menu is shown at the bottom of the screen. Press the F1 key to

select ADULT readings and then use the Esc key to increment to the reading desired.

13 Repeatedly press the START/STOP button on the 90207 to sequence through the list of blood

pressures simulated by the CuffLink.

14 At the end of the readings, verify that the systolic and diastolic readings are within given ranges

provided in step #2.

Note:

If the readings are out of range, retest the ABP monitor at the same setting. If it still fails, check

all hose connections, perform the leak test again, and check the gain settings on the simulator.

If all this fails, refer to

Troubleshooting on page 5-1.

4-22

Page 43

90207 Ambulatory Blood Pressure Monitor Service Manual

CuffLink Manual Operation

The following steps outline the manual selection of simulated blood pressures and heart rates.

These may be used to repeat a reading which was out of range or produced no reading.

1 When the CuffLink is warmed up, move the cursor to the SelectBp option of the Main menu and

ADAMS Adult. Press the ENT key to make a selection.

2 Press the F2 key and verify that the gain is set to 100%. At the same time, verify that the SHIFT

and/or OFFSET are at 0. Press the ENT key.

3 Press the F1 key to move to the Heart Rate menu. Use the arrow keys to move the cursor to

the desired heart rate. Press the ENT key to make a selection.

4 Use the arrow keys to move the cursor to the desired blood pressure and then press the ENT

key.

5 The CuffLink is ready to simulate the selected heart rate and pressure. Press the appropriate

key on the unit under test to begin.

CuffLink Automatic Operation

Use the following procedure to set or change the automatic sequences stored in the

CuffLink:

1 Move the cursor to the Auto option of the main menu and select Utility by pressing the ENT key.

Maintenance

2 Use the arrow keys to move the cursor to the EDIT box. Select sequences to edit and press the

appropriate button (F1, F2, F3, etc.).

F1 is assigned to ADULT. In the first screen, answer YES to the Pop-Off test and NO for the

remaining. The second and third screens list the sequence of blood pressures and heart rates.

Use the arrow keys to move around the list, and use the F4 and F5 keys to change the

settings. Set CYCLES for each blood pressure reading.

Note:

When complete with changes, press F3 (STORE) to end the edit session.

3 Use the arrow keys to move the cursor to the NAME box. Select the sequence to be named and

press the appropriate button (F1, F2, F3, etc.). Use the arrow keys to move to each character

and use the UP and DOWN arrow keys to change the character. When complete, press ENT

to end the edit.

4-23

Page 44

Page 45

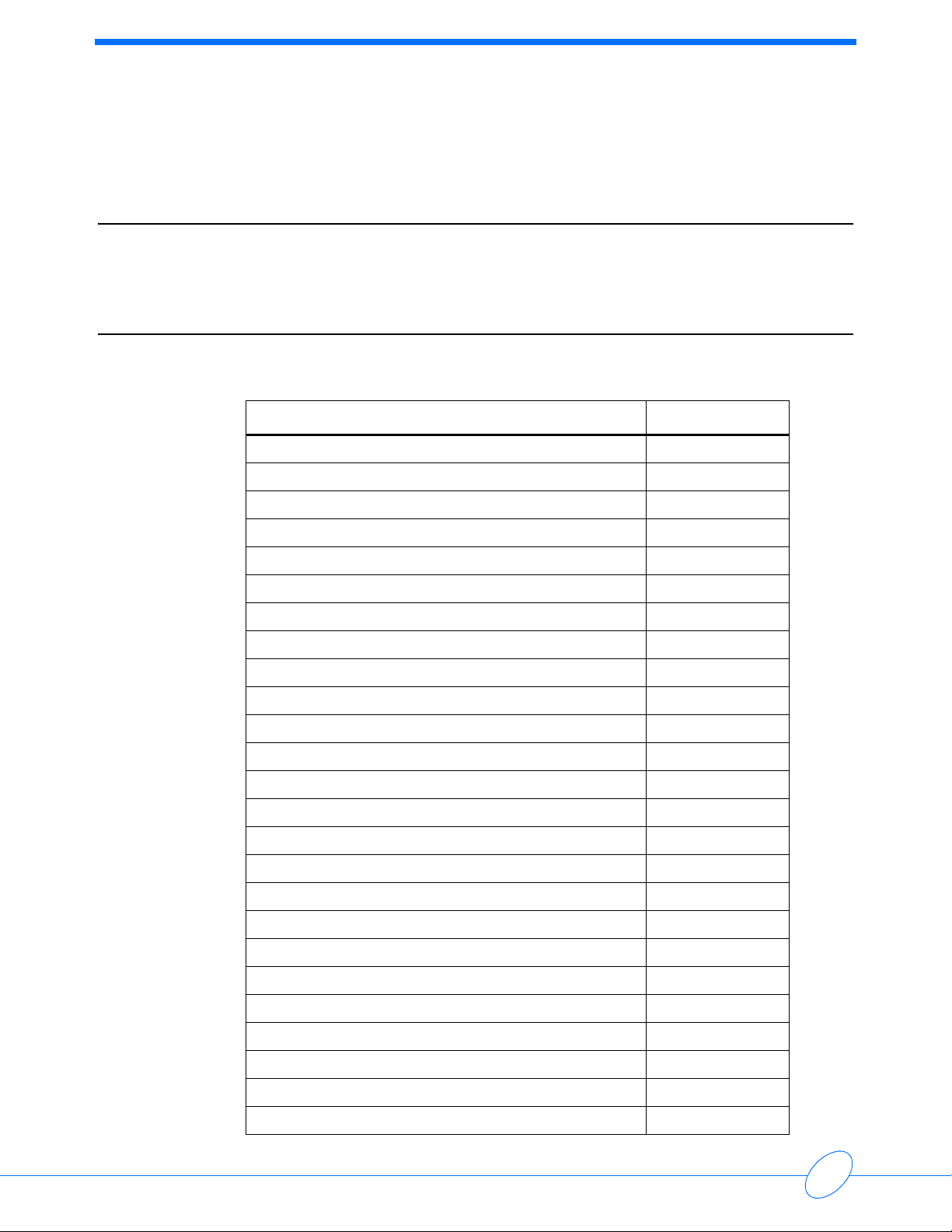

Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Monitor Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Base Station Report Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Problem Solving Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview

The Model 90207 ABP Monitor has been designed for easy maintenance. If problems develop,

use the following information as a problem solving guide.

Monitor Event Codes

The 90207 ABP Monitor displays a two-digit event code whenever it is unable to successfully

complete a blood pressure measurement. This event code appears as the last digit on the monitor

display and is preceded by the letters EC (for example, in EC01, 01 is the event code).

Troubleshooting

The following list contains a brief description of the event codes that can appear on the monitor

display:

EC00 A) Too much patient movement

B) Heart rate arrhythmia

EC01 Cuff not inflated above systole. The monitor will automatically inflate the cuff to a

higher pressure on the next attempt.

EC02 A) Cuff not properly applied

B) Kinked air hose

C) Air leak

EC03 Patient canceled readings by pressing STOP key. No retry attempt is made after an

EC03 code.

EC04 Blood pressure measurement not completed in the maximum time allowed. An

occasional EC04 is generally the result of excessive patient movement. Numerous

EC04 messages indicate an improperly applied cuff.

EC05 An occasional EC05 message indicates the monitor’s internal safety mechanisms

aborted the measurement. If these messages appear frequently, the monitor requires

servicing.

EC07 Clogged input filter.

EC08 Usually, no data. The cuff may have been taken off.

EC09 Blood pressure result unreasonable.

5-1

Page 46

90207 Ambulatory Blood Pressure Monitor Service Manual

The following codes may also appear on the monitor display.

LLL Low battery. The battery did not have sufficient power to operate the pump and

complete a measurement. No retry attempt is made following an LLL message.

Lbb Low backup battery. The blood pressure report will be lost if the lithium battery gets

too low.

FULL The monitor contains 240 readings and cannot store any additional data.

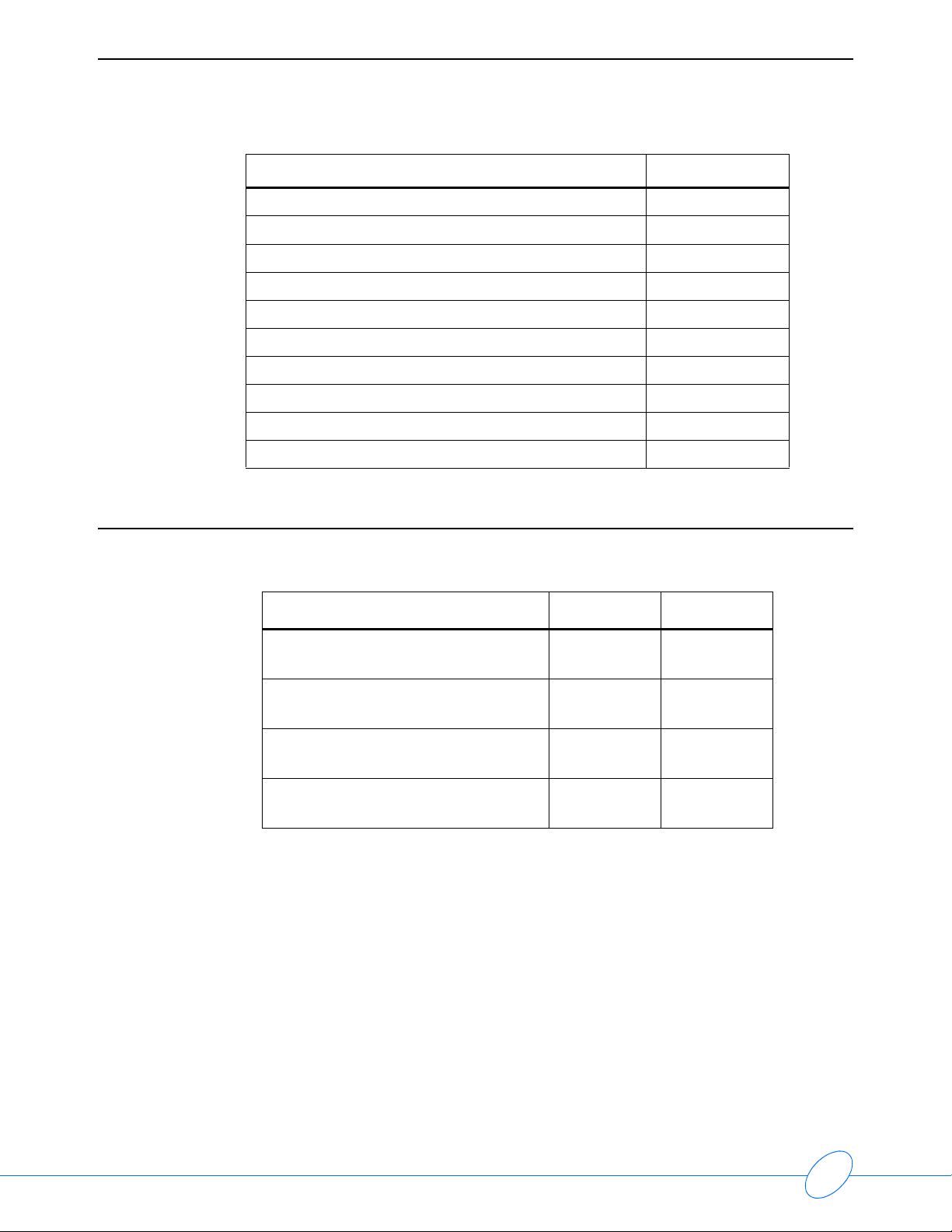

Base Station Report Event Codes

The following list contains the extended event codes that may appear in a blood pressure report.

The extended event code digit appears in the first (tens) digit position, for example, 11. The list is