Southern Pride XLR-1400 Installation Manual

XLR-1400

XLR SERIES

XLR-600 & XLR-1400

INSTRUCTION MANUAL

XLR-600

Distributing, L.L.C.

472 South Mill Street, Alamo, TN 38001

Sales: 800-851-8180

www.southernpride.com - sales@soprid e.com - servic e@sopride.com

Service: 800-437-2679 - Service Fax: 618-993-0378 - parts@sopride.com

CONGRATULATIONS

In selecting Southern Pride, you have chosen the finest, most advanced

and most fully automatic wood burning barbecue pit available.

With us, “ It’s Simply, a Matter of Pride”.

Please read this Instruction Manual carefully prior to installation and operation

of your Southern Pride pit. Proper installation, operation, cleaning and maintenance

are essential for your satisfaction and safe operation.

KEEP THIS MANNUAL FOR REFERENCE

TABLE OF CONTENTS

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

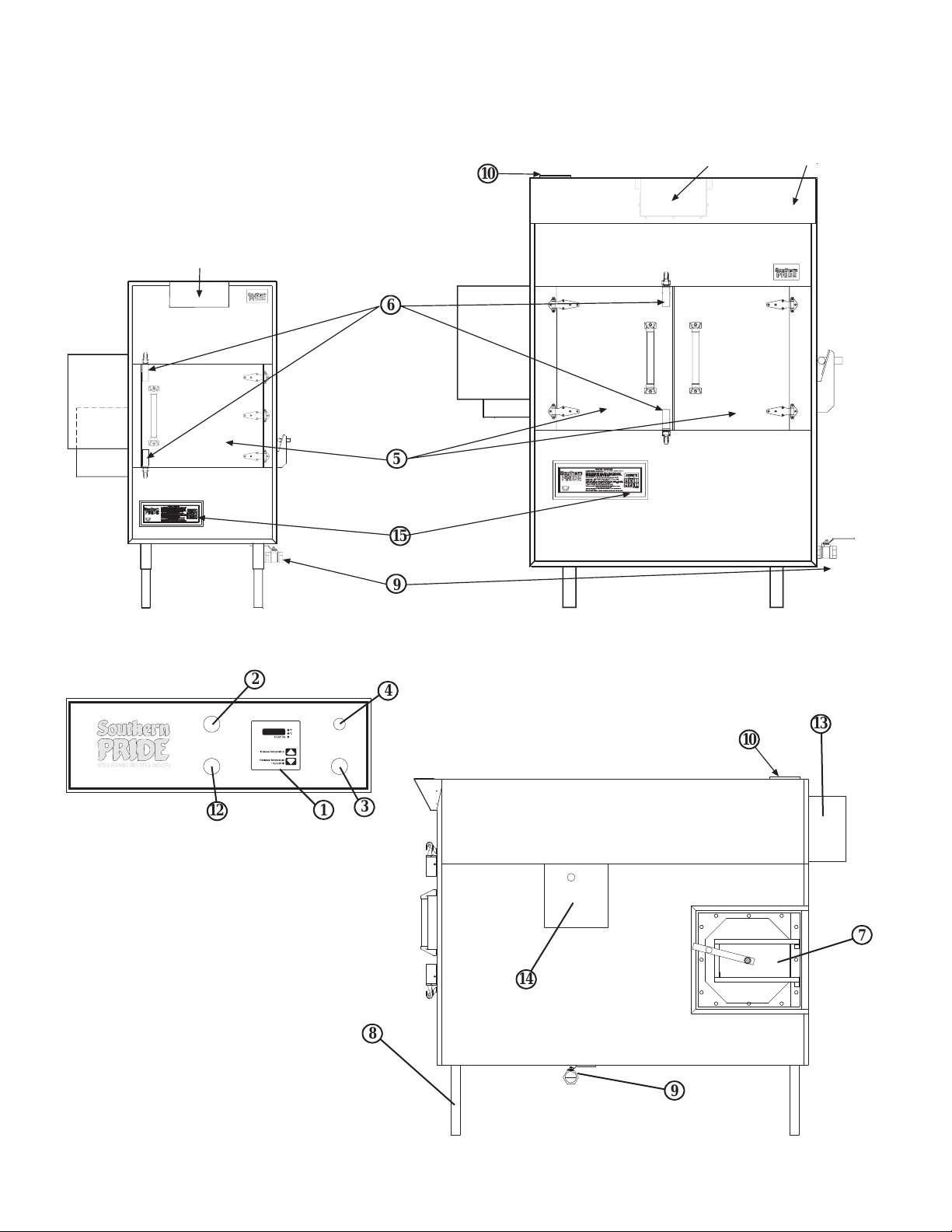

Diagram of Controls & Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Burner Specification & Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Piping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Venting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cold Weather Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

SAFETY INFORMATION

FOR YOUR SAFETY

IF YOU SMELL GAS . . .

1. Open windows.

2. Do not touch electrical switches.

3. Extinguish any open flames.

4. Immediately call your gas supplier.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCES.

1. The pit area MUST be kept clear and free of combustible materials, gasoline and

other flammable vapors and liquids.

2. The flow of combustion and ventilating air MUST NOT be obstructed from reaching

the pit.

3. The frame of the unit MUST be electrically grounded at all times. See “Electrical

Instructions”.

4. Caution should be used when opening and closing the Firebox Door. The door is HOT

during operation.

5. DO NOT remove service compartment access panels when unit is in operation or leave

off during operation.

6. Gas burners require the services of an experienced Service Technician for proper setting

and adjustment. If the burner does not appear to be operating properly, DO NOT

ATTEMPT TO ADJUST THE BURNER YOURSELF, but call in a competent

serviceman or contact Southern Pride.

7. DO NOT allow unqualified personnel to perform service work or adjustments on

this unit. To do so will VOID WARRANTY and could result in a hazardous condition.

8. Be sure any new employees, who might operate the unit, are instructed on operation and

safety information prior to operating the unit.

9. Caution: Ashes removed from the Firebox should be stored in a non-combustible

container with a sealed lid only. Store ashes in a well ventilated area. FUMES COULD

BE HAZARDOUS.

10. W ARNING : IT IS EXTREMELY IMPORTANT TO FOLLOW DAILY CLEANING

INSTRUCTIONS. BUILDUP OF GREASE OR SOLIDS INSIDE THE PIT COULD

RESULT IN A FIRE HAZARD.

11. KEEP THIS INSTRUCTION MANUAL FOR REFERENCE.

3

Optional Front Flue

SOUTHERN PRIDE’S

XLR-SERIES BBQ OVENS

10

6

5

15

Front Flue

Heat Shield

2

O

F

N

F

O

M

R

A

E

I

N

W

P

O

E

I

A

R

D

E

V

S

A

S

N

I

T

C

O

E

R

12

STANDARD CONTROLS

9

4

C

R

I

R

E

C

K

U

A

I

E

T

R

B

T

X

R

E

A

E

C

K

T

O

O

R

M

S

3

1

10

13

7

14

8

9

4

XLR Series

CONTROLS AND COMPONENTS

1 . CONTROL THERMOSTAT - Adjustable temperature setting (140-325° F) with OFF position.

Maintains desired Pit temperature by controlling the Gas Burner. Also displays the actual temperature

inside the oven during the cooking cycle.

2. MAIN POWER SWITCH - Activates the Rotisserie, Convection Fan, Thermostat, and Red

Indicator Lamp. (The Red Indicator Lamp on the Main Power Switch indicates when the switch

is ON.)

3. SMOKE EXTRACTOR SWITCH - Activates Smoke Extractor Damper, Exhaust

Fan, and Blue Indicator Lamp. (The Blue Indicator Lamp on the Smoke Extractor Switch indicates

when the switch is ON.) At the same time it de-activates the Burner and Red Indicator Lamp.

4. CIRCUIT BREAKER - Provides protection for the Rotisserie Drive Motor.

5. MEAT LOADING DOORS - For access to Racks and Pit interior.

6. MEAT LOADING DOOR LATCHES - Latches apply positive pressure and seal doors.

7. FIREBOX DOOR - Provides access for loading wood in the Firebox Chamber.

8. CABINET LEGS - Provide adjustment for leveling of the unit.

9. DRAIN VALVE - Is opened after each cooking to drain grease.

10. FLUE COLLAR - For connection of 6” Flue.

11. OPTIONAL SMOKE EXTRACTOR DAMPER - Closes to hold smoke inside pit while

cooking and opens for Exhaust Fan to remove smoke when Smoke Extractor Switch is ON or

when the Meat Loading Doors are Open.

12. ROTISSERIE ADVANCE SWITCH - Momentarily activates Rotisserie to advance the food

racks for loading and unloading when the Meat Door is open, or the Main Power switch is OFF.

13. CONVECTION FAN - Provides air flow inside the Oven for even cooking.

14. BEARING COVER - Provides access for greasing Bearing.

15. DIGITAL CONTROL (Optional) - Provides precise control of the oven and adds special

features, such as a Hold Mode, Automatic Cool Down prior to advancing into the Hold Mode

and an Audible Alarm that sounds when the Cook Cycle is complete or when the control

advances to the Hold Mode.

5

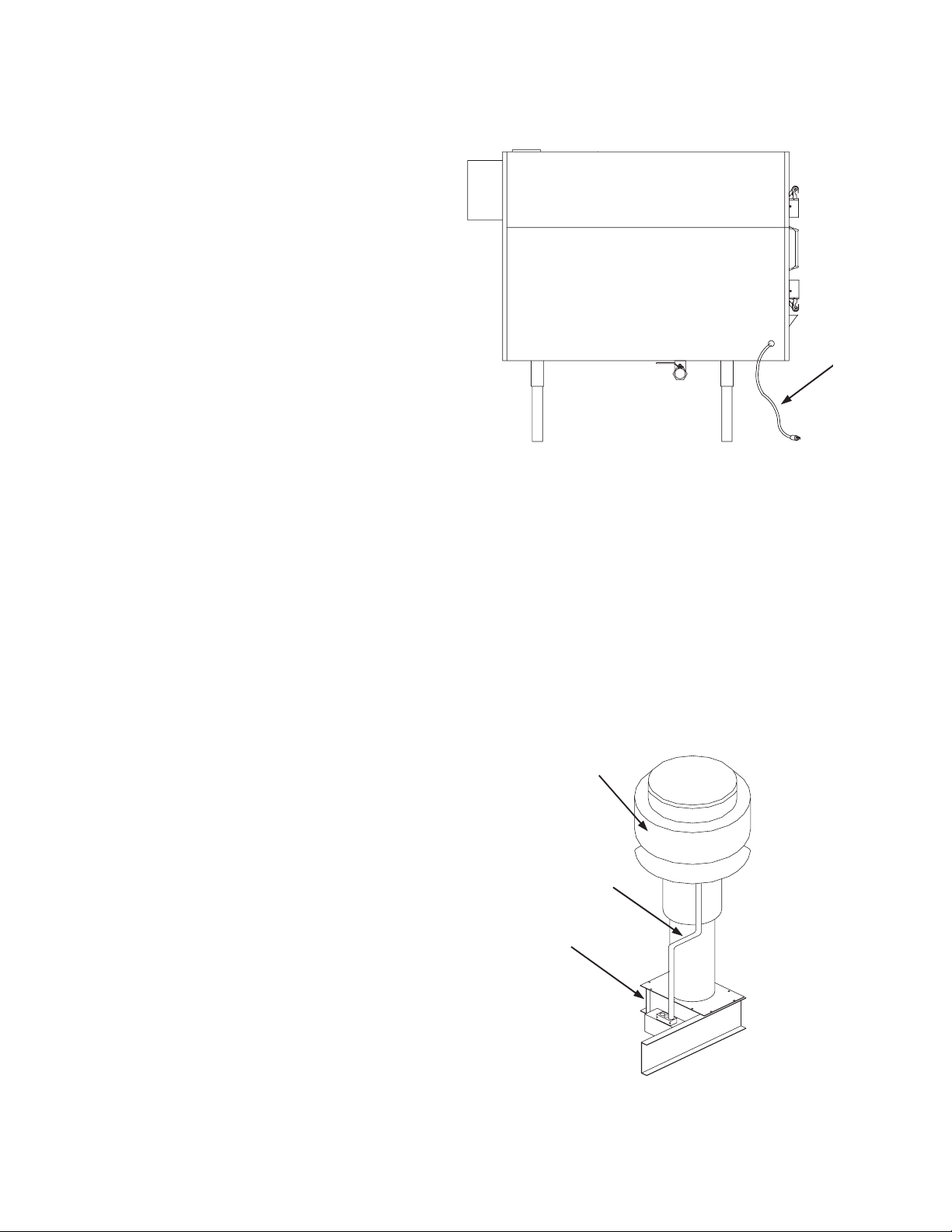

ELECTRICAL INSTRUCTIONS

ELECTRICAL REQUIREMENTS:

120 Volts A.C., 60 hz.,

2 wire, single phase,

15 amp wiring required.

WARNING:

CHASSIS MUST BE GROUNDED TO

PREVENT POSSIBLE SHOCK HAZARD.

DO NOT ASSUME A PLUMBING LINE

WILL PROVIDE SUCH A GROUND.

WARRANTY IS VOID IF UNIT IS CONNECTED TO ANY VOLTAGE OTHER THAN

SPECIFIED ABOVE AND ON NAMEPLATE.

Power

cord

1. Electrician must provide the conduit and wire for hookup.

2. Power is to be left OFF throughout installation.

3. Electrical Service is connected via the factory supplied power cord located on the left front

corner of the oven.

4. On models with optional Smoke Extractor,

electrician must provide conduit and wire

EXHAUST

FAN

for hookup from Junction Box above the

Smoke Extractor Motor on the top of the

pit to the Exhaust fan. Make electrical

connections inside the Junction box.

NOTE: THIS IS NOT A POWER SUPPLY

CONNECTION. IT IS FOR A FAN

CONNECTION ONLY.

CONDUIT

SMOKE

EXTRACTOR

NOTE: 125 V.A.C., 1/4 hp

maximum connected load,

1100 cfm fan rating recom mended.

5. If venting or gas connections are to be

done later, be sure that power is OFF.

6

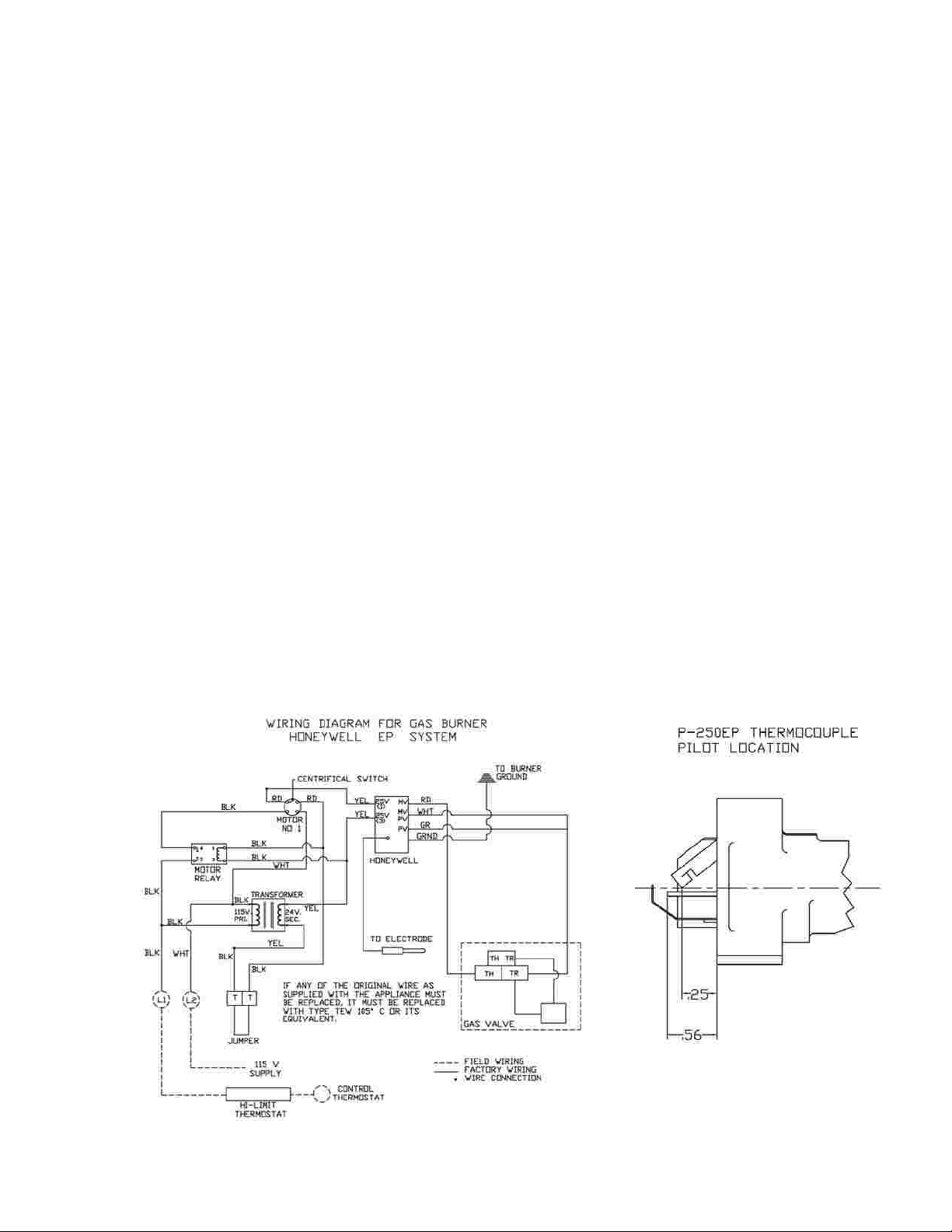

BURNER SPECIFICATIONS

Burner Model: Wayne P250-EP

Firing Capacity: Maximum Input

100,000 BTU/HR on Model XLR-600

125,000 BTU/HR on Model XLR-1400

150,000 BTU/HR on Model XLR-1400 with 18” Racks

Fuels: Natural and L.P. Gases

Electrical: 120 V.A.C., 60 hz, 1 ph

Orifice Sizes: XLR-600 XLR-1400

Natural Gas #5 #1 #5

L.P. Gas 1/8” #29 1/8”

NOTE: Orifice and valve setting must correlate with type of gas being supplied.

Gas Supply Line Pressure: Natural - 4.5” W.C. Minimum L.P. - 11.0” W.C. Minimum

10.0” W.C Maximum 13.0” W.C. Maximum

MANIFOLD PRESSURE: Natural - 3.5” W.C. L.P. - 10.0” W.C.

GAS VALVE: Control Knob must be ON.

(150,000 BTU)

XLR-1400

(125,000 BTU)

7

Loading...

Loading...