Southern Pride MLR-150 Installation Manual

Gas-Fired Wood-Burning

Rotisserie BBQ Smoker

OWNER’S MANUAL

MLR-150 SPX-300 SPK-500 SP-700 MLR-850 (Additional models supported by this manual not pictured: SPK-1000 and SPK-1400)

* Smokers shown on Southern Pride delivery casters

Southern Pride smokers have been tested and approved by Intertek Testing Services, and are ETL listed to ANSI Z83.11b - 2009, CSA 1.8b - 2009,

and to NSF/ANSI Standard 4. ETL File Number 4007026

401 South Mill Street , Alamo, Tennessee 38001 |

731-696-3175 http://www.southern-pride.com |

1 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

Southern Pride smokers are gas-fired, wood-burning, ETL listed, commercial cooking appliances whose installation, operation, and maintenance should comply with the instructions in this manual, NFPA® 96 and other codes and standards as called out in this manual. For more information on NFPA® 96, or to obtain a copy of the latest publication, please contact:

NFPA®

1 Batterymarch Park

PO Box 9101

Quincy, MA 02169-7471

www.nfpa.org

2 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

CONGRATULATIONS!

In selecting Southern Pride, you have chosen the finest, most advanced and most fully automatic wood burning barbecue smoker available.

With us, “ It’s Simply, a Matter of Pride”.

Please read this Manual carefully prior to installation, operation and maintenance of your Southern Pride smoker. Proper installation, operation, and maintenance are essential for your satisfaction and safe operation.

KEEP THIS MANUAL FOR REFERENCE

NOTE: An Electrical Diagram for this appliance can be found on the inside of the service access panel. This smoker may be operated outdoors.

3 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

TABLE OF CONTENTS |

|

Safety Information and Precautions................................................................... |

5 |

Diagram of Controls & Components.............................................................. |

6-7 |

INSTALLATION |

|

Receiving the Smoker........................................................................................... |

8 |

Delivery Location.................................................................................................. |

8 |

Unloading the Smoker.......................................................................................... |

9 |

Unpacking the Smoker......................................................................................... |

9 |

Site Instructions ........................................................................................... |

10-11 |

Electrical Instructions........................................................................................ |

12 |

Gas Piping Instructions................................................................................ |

13-15 |

Gas Connection Instructions ............................................................................. |

16 |

Burner Specification........................................................................................... |

17 |

Venting Instructions..................................................................................... |

18-19 |

OPERATION |

|

Product Loading Instructions ........................................................................... |

20 |

Firebox Loading Instructions............................................................................ |

21 |

Control Operating Instructions................................................................... |

21-22 |

Product Unloading Instructions........................................................................ |

23 |

Ash Removal Instructions.................................................................................. |

23 |

Grease Removal Instructions ............................................................................ |

24 |

Wood Storage Instructions ................................................................................ |

24 |

Mobile Smoker Operations................................................................................ |

25 |

Mobile Smoker Electrical Information ............................................................ |

25 |

Mobile Smoker Warnings............................................................................ |

25-27 |

Propane Tank Operations ........................................................................... |

28-30 |

MAINTENANCE |

|

Daily..................................................................................................................... |

31 |

Weekly ........................................................................................................... |

31-32 |

Monthly ......................................................................................................... |

33-34 |

Annually/Semi-Annually.................................................................................... |

35 |

As Needed...................................................................................................... |

36-37 |

Wiring Diagrams .......................................................................................... |

38-41 |

Replacement Parts List ................................................................................ |

42-43 |

Before You Call For Service.............................................................................. |

44 |

Troubleshooting the Gas Burner ...................................................................... |

45 |

Limited Warranty .............................................................................................. |

46 |

4 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

SAFETY INFORMATION AND PRECAUTIONS

This Manual should be considered a permanent part of this smoker. THE SMOKER MUST BE INSTALLED BY A QUALIFIED SERVICE TECHNICIAN. All troubleshooting guides, component views and parts lists included in this manual are for general reference only and are intended for use by qualified technical personnel.

DANGER:

Improper installation, alteration, adjustment, service, or maintenance could result in severe injury, death, or cause property damage. Read the installation, operating, and maintenance instructions thoroughly before installing or servicing this equipment.

DANGER:

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliances.

CAUTION:

Metal parts and surfaces of this smoker become extremely hot when in operation. To avoid burns, always use hand protection when operating the smoker.

WARNING:

ELECTRIC SHOCK HAZARD

Follow these rules to avoid electric shock.Use only a properly grounded circuit.

Do not spray water directly on electrical components.

Turn off power before servicing.

WARNING:

FOR YOUR SAFETY

IF YOU SMELL GAS…...

1.Open windows

2.Do not touch electrical switches

3.Extinguish any open flames

4.Immediately call your gas supplier

WARNING:

CARBON MONOXIDE

POISONING HAZARD

Carbon monoxide is a colorless, odorless gas that can kill. Follow these rules to control carbon monoxide.Do not use the smoker if in an unvented, enclosed

area. Carbon monoxide may accumulate.

Allow only qualified burner service persons to adjust the burner. Special instruments and training are required.

Read the owner’s manual before using.

1.IT IS EXTREMELY IMPORTANT TO FOLLOW THE PRESCRIBED CLEANING INSTRUCTIONS. GREASE OR SOLIDS BUILDUP INSIDE THE SMOKER COULD RESULT IN A FIRE HAZARD.

2.This smoker is intended for use in commercial facilities where all operators are familiar with the purpose, limitations, and associated hazards of this equipment. The operating instructions and warnings must be read and understood by all operators and users.

3.This manual and all supplied instructions, diagrams, schematics, parts lists, notices and labels must remain with the smoker even if the smoker is sold or moved to another location.

4.The area around the smoker MUST be kept clear and free of combustible materials, gasoline and other flammable vapors and liquids.

5.The flow of combustion and ventilating air MUST NOT be obstructed from reaching the smoker.

6.The frame of the smoker MUST be electrically grounded at all times. See “Electrical instructions”.

7.Caution should be used when opening and closing the firebox door. The door is HOT during operation.

8.DO NOT remove service compartment access panels when smoker is in operation or leave off during operation.

9.Gas burners require the services of a qualified service technician for proper setting and adjustment. If the burner does not appear to be operating properly, DO NOT ATTEMPT TO ADJUST THE BURNER YOURSELF.

10.DO NOT allow unqualified personnel to perform service work or adjustments on this smoker. Doing so, will VOID WARRANTY and could result in a hazardous condition.

11.Ensure new employees, who might operate the smoker, are properly instructed and supervised on the operation and safety information prior to operating the smoker.

12.Ashes removed from the firebox should be stored in a non-combustible container with a sealed lid only. Store ashes in a well ventilated area. FUMES COULD BE HAZARDOUS.

5 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

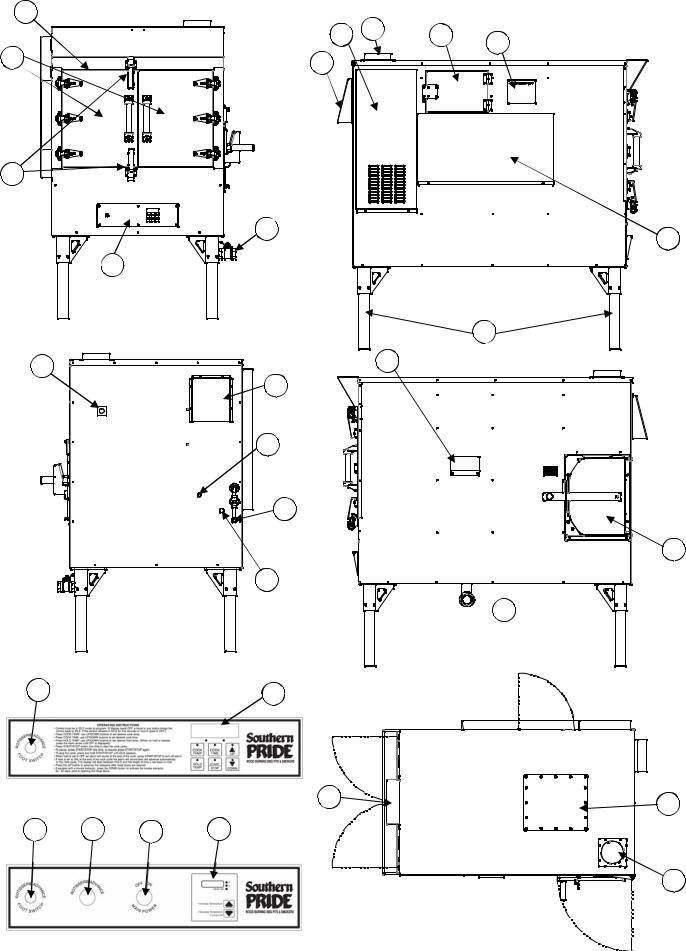

DIAGRAM OF CONTROLS AND COMPONENTS

18

19

20

21

Front View

22

Rear View

4

Optional Digital Cook & Hold Control

4 |

3 |

2 |

1 |

(Model SPX-300 Shown)

16 |

7 |

15 |

14 |

|

|||

|

|

|

17

9 |

13 |

|

|

12 |

11 |

Left Side View |

|

17

23

24

10

25

9

9

Right Side View

5

6 |

8 |

|

7

Top View

Standard Digital Control

6 of 46

Copyright 2015 by Southern Pride Distributing, LLC Volume 1

DIAGRAM OF CONTROL AND COMPONENTS

1.DIGITAL THERMOSTAT CONTROL - Digital thermostat control allows for cook temperature selection range between 140°F to 325°F, with OFF position. Maintains desired smoker temperature by controlling the gas burner. It also displays the actual temperature inside the smoker during the cook cycle.

2.MAIN POWER SWITCH - Activates the rotisserie, convection fan, thermostat, and red indicator lamp. (The red indicator lamp on the main power switch indicates when the switch is ON).

3.ROTISSERIE ADVANCE SWITCH - Momentarily activates rotisserie to advance the product racks for loading and unloading when the smoker door is open, or the main power switch is OFF.

4.ROTISSERIE ADVANCE FOOT SWITCH – Provides hands free operation to advance the rotisserie while loading or unloading product.

5.DIGITAL COOK & HOLD CONTROL (Optional) - Provides precise temperature control of the smoker along with control of the other functions of the smoker.

6.FRONT FLUE (Optional) - Designed for use with VSP Hood System or Type-1 Canopy hood.

7.REAR FLUE COLLAR (Optional) - For connection of 6” chimney pipe. Typically used for direct vent & mobile applications.

8.SMOKE EXTRACTOR DAMPER (Optional) - The smoke extractor damper enables the operator, through the use of a customer supplied exhaust fan, to evacuate the smoke from the smoker prior to fully opening the product loading door(s).

9.GREASE DRAIN VALVE – Open valve to drain grease from smoker after each cook. DO NOT connect the grease drain to the building drain system or any other drain connection.

10.FIREBOX DOOR - Provides access to the firebox chamber for loading wood and ash removal. Keep closed while cooking.

11.BEARING COVER - Provides access to rotisserie axle bearing.

12.CABINET LEGS - Provides adjustment for leveling of the smoker.

13.DRIVE SYSTEM COVER - Access to chain and driven sprocket on rotisserie axle.

14.DATA PLATE - Label containing smoker’s serial number, model number, manufactured date, etc.

15.CONVECTION FAN ACCESS DOOR– All models except the SP-700 and SPK-1400 where the fan access is on the rear of the smoker. Provides access to the fan blade for cleaning. Maintaining a CLEAN fan blade is critical to the overall performance of the smoker.

16.SERVICE COMPARTMENT COVER - Access to service bay where burner, convection fan motor, drive motor, and shock relay are located.

17.SERVICE COMPARTMENT VENT - Air vent to cool electrical components in service bay.

18.DOOR INTERLOCK SWITCH - When product loading door(s) are opened, the door interlock switch automatically turns OFF the rotisserie, convection fan and gas burner. On smokers with an optional smoke extractor the smoke extractor is automatically activated. On smokers with optional VSP vent hood systems the exhaust fan is automatically switched to high speed.

19.PRODUCT LOADING DOOR(S) – Provides access to load/unload product and for cleaning the interior of the smoker.

20.PRODUCT LOADING DOOR LATCHES - Latches apply positive pressure and seals doors.

21.CONTROL PANEL INTERFACE - Location of smoker control panel, where cooking parameters are set and monitored.

22.MOISTURE INFUSION SYSTEM PORT - Optional moisture system produces steam in the cooking chamber, primarily used with competition cooking (solid fuel cooking).

23.AUXILIARY POWER CONNECTION - Power supply access point used to power the smoke extractor exhaust fan or VSP eyebrow hood system.

24.GAS SUPPLY CONNECTION - Drip leg connection point for incoming gas supply to smoker.

25.POWER CORD CONNECTION - All models except the SPK-1400 where the cord connection is in the front of the smok-

er. Access point for supply power cord to smoker.

7 of 46

Copyright 2015 by Southern Pride Distributing, LLC Volume 1

INSTALLATION

RECEIVING THE SMOKER

Your smoker can be shipped via a contract hauler on a flatbed trailer (all models), or Common Carrier (all models except SPK-1400 and trailered smokers). Once the smoker arrives you will need a forklift to remove the crated smoker from the truck (Common Carrier deliveries) and install the permanent legs on the smoker (all deliveries).

Model |

Approx. Wt. |

Approx. Wt. |

|

Uncrated |

Crated |

||

|

|||

|

|

|

|

MLR-150 |

656 lb. |

875 lb. |

|

SPX-300 |

910 lb. |

1150 lb. |

|

SPK-500 |

1204 lb. |

1480 lb. |

|

SP-700 |

1512 lb. |

2000 lb. |

|

MLR-850 |

1576 lb. |

1875 lb. |

|

SPK-1000 |

2164 lb. |

2530 lb. |

|

SPK-1400 |

3098 lb. |

NA |

NOTE: The above weights are for the base model only.

WARNING:

If the forklift forks are not long enough to support the entire smoker/crate do not attempt to move the smoker; obtain another forklift or use fork extensions.

DELIVERY LOCATION

Commercial smokers are large and heavy. Before scheduling the delivery of your smoker have a plan and location in place to accept the delivery of the smoker and maneuver the smoker into the desired installation location. The trucker will require a flat, level surface that is safe from traffic to unload the smoker. A forklift will be required to unload the smoker and install the permanent legs on the smoker. The trucker is only responsible for delivery of the smoker. It is your responsibility to unpack the smoker, move it to its installation location, and install the smoker.

WARNING:

Only proper heavy lifting machinery and heavy lifting equipment should be used for unloading, moving and installing the smoker. This duty should only be performed by professionals trained in this kind of work. Improper handling of the equipment could result in damaging the smoker or personal injury and even death.

8 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

UNLOADING THE SMOKER

Smokers Shipped via Common Carrier

Remove the crated smoker from the truck using the appropriate forklift. Note any damage to the crate, smoker or accessories. Do not sign the delivery bill until the smoker has been inspected and any damage noted on the delivery bill.

The smoker is shipped bolted to a wooden pallet with an industrial cardboard carton. Once the smoker is in a level and safe place remove the cardboard carton and open the product loading doors. Plastic zip ties secure a cardboard box and permanent legs to one of the product racks of the smoker. Remove the cardboard box and permanent legs from the product rack. The smoker is secured to the wooden pallet with a bolt on each leg. After removing the 4 bolts securing the smoker to the wooden pallet use the appropriate forklift to lift the smoker off of the wooden pallet. With the wooden pallet removed from under the smoker, and the smoker still lifted by the forklift, install the permanent legs on the smoker. The permanent legs slide into the leg receivers on the bottom of the smoker and should be secured tightly using the provided set screws. After securing the permanent legs, slowly lower the smoker to the ground.

Smokers Shipped via Contract Hauler

The driver will unload the smoker from the trailer. Once the smoker is in a level and safe place remove the white protective wrap from the outside of the smoker and open the product loading doors. Plastic zip ties secure a cardboard box and permanent legs to one of the product racks of the smoker. Remove the cardboard box and permanent legs from the product rack. Using the appropriate forklift, lift the smoker and remove the delivery casters from the smoker and install the permanent legs. The permanent legs slide into the leg receivers on the bottom of the smoker and should be secured tightly using the provided set screws. After securing the permanent legs, slowly lower the smoker to the ground.

Leg receiver set screws

CAUTION:

Do not lift the smoker higher than necessary to remove it from the wooden pallet and install the permanent legs.

UNPACKING THE SMOKER

The cardboard box inside the smoker contains the following items:

Sample seasoning and sauces. Bulk sizes are available. Please contact your authorized Southern Pride distributor for additional information.

Pneumatic foot pedal. Connect to the control panel for hands-free operation of rotisserie. See pages 6 and 7 for connection location.

90 degree drain elbow. Connect to the grease drain ball valve to direct the draining grease towards the ground. See pages 6 and 7 for connection location.

The smoker is shipped with plastic zip ties holding the hanger racks to the rotisserie wheels. These zip ties should be removed prior to initial operation.

9 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

SITE INSTRUCTIONS

The Southern Pride smoker must be installed in a location that will permit the smoker to function for its intended purpose and to allow adequate clearance for ventilation, proper cleaning, and maintenance access.

Minimum Clearance Requirement from Combustible Material

Back…...18” (457mm) |

Firebox Door Side……...24” (610mm) |

Top…….18” (457mm) |

Service Bay Side……….18” (457mm) |

Front…...48” (1219mm) |

|

NOTE: If provision is made for service access, service bay side & back clearance can be reduced to 2” (51mm).

WARNING: Failure to maintain proper safety, storage, handling, and ash removal for solid fuel appliances on or around combustible materials may result in fire, property damage and/or death. Our product listing allows for the smoker to be installed on a combustible surface however, Southern Pride recommends the use of a noncombustible material for the floor surface area under the fire box, which should extend at least 6” beyond each side of the fire box, and outward from the smoker beyond the area needed for placement of the ash container.

During operation the smoker must be level to allow for smooth movement of the rotisserie wheels and drive system, to limit the movement of product on the product racks and to allow for proper grease drainage. If adjustment is necessary to level the smoker each of the legs can be adjusted up or down by loosening the 2 set screws on each leg and adjusting the legs.

CAUTION:

The appropriate sized forklift should be used to lift the smoker to adjust the leg height and the smoker should not be lifted any higher than necessary to perform the adjustment.

THROUGH THE WALL INSTALLATIONS

When installing a smoker through a wall made of combustible material an insulation kit must be used. The insulation board must be installed between the smoker and the combustible material. The following insulation

kits consist of 3 pieces of 1 inch thick, 8 inches wide insulation board that is installed on the top and each side |

|||||

of the smoker. |

|

|

|

|

|

Through the Wall Insula on Kits |

|

||||

|

|

||||

|

Model |

Kit Number |

Model |

Kit Number |

|

|

MLR 150 |

087002 |

MLR 850 |

087003 |

|

|

SPX 300 |

087003 |

SPK 1000 |

087004 |

|

|

SPK 500 |

087005 |

SPK 1400 |

087006 |

|

|

SP 700 |

087004 |

|

|

|

The wall cutout should be 2.5 inches wider than the smoker width and 1.25 inches taller than the smoker height to allow space for the insulation board between the wall and the smoker.

Also available is a stainless steel trim kit that will cover the gap between the smoker and the wall on all four sides of the smoker. The trim kit is only for one side of the building; two can be used for the interior and exterior of the building.

NOTE: When using a VSP hood system in a through the wall installation, a special insulation and stainless steel trim kit must be ordered. The special kits are designed with taller side pieces to extend beyond the height of the smoker to also account for the height of the VSP hood system. Please contact your authorized Southern Pride distributor for more details.

10 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

SITE INSTRUCTIONS (continued)

THROUGH THE WALL INSTALLATIONS (continued)

Illustrations of a through the wall installation.

11 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

INSTALLATION INSTRUCTIONS ELECTRICAL INSTRUCTIONS

Electrical Requirements:

120 volts AC, 60 Hz

2 wire, single phase

15 amp required, NEMA 5-15P plug

WARNING:

This appliance, when installed, must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable.

THE WARRANTY IS VOID IF THE SMOKER IS CONNECTED TO ANY VOLTAGE OTHER THAN SPECIFIED ABOVE AND ON THE SMOKER DATA PLATE.

Remove all packing material before connecting the electrical and gas supply to the smoker.

An electrician must provide the conduit and wire for electrical hookup.

The power is to be left OFF throughout the installation.

The electrical service is connected via the factory supplied power cord normally located to the rear of the smoker on the service bay side. Alternatively, the power cord can be removed and the smoker hard wired.

On models equipped with an optional smoke extractor, the electrician must provide conduit and wire hookup from the junction box, located on the rear of the smoker, to the exhaust fan. Make the electrical connections inside the junction box.

NOTE: 125 V.A.C., 1/4 hp maximum connected load, 1100 CFM fan rating recommended for smokers equipped with the optional smoke extractor damper.

5. If venting or gas connections are to be done at a later time, be sure that the power remains OFF.

Smoker extractor damper (Optional) |

|

|

|

||

|

|

Junction box |

|

Smoke extractor |

|

|

(Auxiliary power connection |

|

damper |

||

|

for smoke extractor exhaust fan) |

(Optional) |

|||

|

Power connection |

|

|

Rear flue |

|

|

|

|

|

|

(Optional) |

|

Gas supply |

|

|

|

|

|

connection |

|

|

WARNING: |

|

|

|

|

|

|

|

|

Shown |

configured |

with |

|

The junction box |

|

|

is not a power |

|||

|

right-hand firebox. Con- |

|

|||

Rear View of |

nections |

points are |

mir- |

supply connection. |

|

rored if |

configured |

with |

|

|

|

Smoker |

|

Junction box |

|||

left-hand firebox. |

|

|

|||

|

|

|

|||

|

|

|

|

|

(Auxiliary power connection) |

|

|

12 of 46 |

|

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

|

GAS PIPING INSTRUCTIONS

IMPORTANT NOTES TO THE INSTALLER

Read all instructions contained in this Owner’s Manual before making gas connections.

Ensure all packing material is removed from the smoker compartments before connecting the gas supply to the smoker.

Be sure your smoker is installed and grounded properly by a qualified service technician.Observe all governing codes and ordinances.

WARNING: IMPROPER GAS HOOKUP WILL VOID WARRANTY AND COULD RESULT IN A HAZARDOUS CONDITION.

1.All local and national codes and ordinances must be observed. Installation must conform with local codes or in the absence of codes, the National Fuel Gas Code ANSI Z223.1 / NFPA-54, latest edition available from The American Gas Association, Inc., 1515 Wilson Boulevard, Arlington, VA 22209.

2.The gas supply (service) line must be the same size or greater than the inlet line of the appliance. This smoker uses a 1/2” (1.3 cm) ID NPT (Sch40) inlet. Sealant on all pipe joints must be resistive to LP gas.

3.Manifold pressure should be checked with a manometer, natural gas requires a minimum of 4.5” W.C.P. and LP gas requires a minimum of 10.0” W.C.P. Incoming line pressure upstream from the regulator must be 1” W.C.P. higher than the manifold pressure in order to check the regulator. The regulator used on this smoker can withstand a maximum input pressure of 1/2” PSI (14.0” W.C.P.). Over pressuring the valve may cause damage to the valve. If the line pressure is in excess of that amount, a step down regulator will be required.

4.It is recommended new pipe be used and located so that a minimum amount of work will be required in future servicing. The piping should be so installed as to be durable, substantial, and gas tight. It should be free from cutting burrs and defects in structure and threading. Cast iron fittings or aluminum tubing should not be used for the main gas circuit. Joint compounds (pipe dope) should be used sparingly on male threads only and be approved for all gases.

NOTE: The building structure should not be weakened by installation of the gas piping. The piping should not be supported by other piping, but should be firmly supported by pipe hooks, straps, bands, or hangers. Butt or lap welded pipe should not be bent.

5.TEST PIPING FOR LEAKS. Before turning gas under pressure into piping, all openings from which gas can escape must be closed. Immediately after turning on gas, the system should be checked for leaks. This can be done by watching the 1/2 cubic foot test dial for 5 minutes to show any movement, or by soaping each pipe connection and watching for bubbles. If a leak is found, make the necessary repairs and repeat the above test.

NOTE: Defective pipes or fittings should be replaced and not repaired. Never use a flame or fire of any form to locate gas leaks, use a soap solution.

6.After the piping and meter have been checked completely, PURGE THE SYSTEM OF AIR. DO NOT bleed the air inside the smoker. Be sure to relight all the gas pilots on other appliances.

NOTE: The burner and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing in excess of 1/2 psig.

13 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

GAS PIPING INSTRUCTIONS

Pipe Sizing Chart for Natural Gas (0-0.5 psi) with Straight Schedule 40 Metal Pipe

The following chart is based on 0-0.5 psi inlet pressure, specific gravity of 0.6, and a pressure loss of 0.5” w.c.

Maximum Capacity of Pipe Size in Btu per Hour

Pipe Size |

1/2” |

3/4” |

1” |

1 1/4” |

1 1/2” |

|

|

|

|

|

|

Pipe Length |

|

Maximum Capacity in Btu/hr |

|

||

(ft) |

|

|

|||

|

|

|

|

|

|

10 |

175,000 |

360,000 |

680,000 |

1,400,000 |

2,100,000 |

|

|

|

|

|

|

20 |

120,000 |

250,000 |

465,000 |

950,000 |

1,460,000 |

|

|

|

|

|

|

30 |

97,000 |

200,000 |

375,000 |

770,000 |

1,180,000 |

|

|

|

|

|

|

40 |

82,000 |

170,000 |

320,000 |

660,000 |

990,000 |

|

|

|

|

|

|

50 |

73,000 |

151,000 |

285,000 |

580,000 |

900,000 |

|

|

|

|

|

|

60 |

66,000 |

138,000 |

260,000 |

530,000 |

810,000 |

|

|

|

|

|

|

70 |

61,000 |

125,000 |

240,000 |

490,000 |

750,000 |

|

|

|

|

|

|

80 |

57,000 |

118,000 |

220,000 |

460,000 |

690,000 |

|

|

|

|

|

|

90 |

53,000 |

110,000 |

205,000 |

430,000 |

650,000 |

|

|

|

|

|

|

100 |

50,000 |

103,000 |

195,000 |

400,000 |

620,000 |

|

|

|

|

|

|

150 |

40,000 |

84,000 |

160,000 |

325,000 |

500,000 |

|

|

|

|

|

|

200 |

35,000 |

72,000 |

135,000 |

280,000 |

430,000 |

|

|

|

|

|

|

Pipe Sizing Chart for Liquid Propane (11” w.c.) with Copper Tubing

The following chart is based on 11” w.c. inlet pressure and a pressure drop of 0.5” w.c. NOTE: Copper tubing shall comply with standard type K or L of ASTM B 88 or STM B 280.

Maximum Capacity of Tube Size in Btu per Hour

Pipe Size |

1/2” |

|

5/8” |

3/4” |

|

7/8” |

|

|

|

|

|

|

|

|

|

Pipe Length |

|

Maximum Capacity in Btu/hr |

|

|

|||

(ft) |

|

|

|

||||

|

|

|

|

|

|

|

|

10 |

110,000 |

|

206,000 |

348,000 |

|

536,000 |

|

|

|

|

|

|

|

|

|

20 |

76,000 |

|

141,000 |

239,000 |

|

368,000 |

|

|

|

|

|

|

|

|

|

30 |

61,000 |

|

114,000 |

192,000 |

|

296,000 |

|

|

|

|

|

|

|

|

|

40 |

52,000 |

|

97,000 |

164,000 |

|

253,000 |

|

|

|

|

|

|

|

|

|

50 |

46,000 |

|

86,000 |

146,000 |

|

224,000 |

|

|

|

|

|

|

|

|

|

60 |

42,000 |

|

78,000 |

132,000 |

|

203,000 |

|

|

|

|

|

|

|

|

|

70 |

38,000 |

|

71,000 |

120,000 |

|

185,000 |

|

|

|

|

|

|

|

|

|

80 |

36,000 |

|

67,000 |

113,000 |

|

174,000 |

|

|

|

|

|

|

|

|

|

90 |

33,000 |

|

62,000 |

105,000 |

|

161,000 |

|

|

|

|

|

|

|

|

|

100 |

32,000 |

|

59,000 |

100,000 |

|

154,000 |

|

|

|

|

|

|

|

|

|

|

|

|

14 of 46 |

Copyright 2015 by Southern Pride Distributing, LLC Volume 1 |

|||

Loading...

Loading...