Page 1

FOR INDIVIDUAL

SLIDING DOORS

L O C K I N G S Y S T E M S

Maximum

security.

8065L PNEUMATIC

LOCKING

The 8065L series covers several

versions of a system designed for

locking, unlocking and propelling

sliding doors in safety vestibules,

in dayrooms or in high-traffic

corridors.

Each 8065L model utilizes

pneumatic

door. Doors are locked at top and

bottom in both the open and

closed positions by means of a

concealed vertical lock bar at the

rear jamb of the door. The vertical

lock bar is deadlocked at a third

locking point inside the horizontal

cover box above the door.

Standard clear door opening

widths available are 3'-0" to 4'-6".

SYSTEM

cylinders to operate the

8065L

PNEUMATIC LOCKING

SYSTEM

TECHNICAL DATA:

FUNCTION:

ELECTRIC - A remote switch

activates

which raise a vertical lock bar and

propel the door open or closed.

MECHANICAL - Manual

unlocking

device. After being manually

released, door movement is by

hand. The door automatically

deadlocks when moved to the fully

open or closed position.

Revised 3/09

pneumatic cylinders

is provided for each

• COVER BOX:

1' 0-3/4" H x 7-1/2" D

• COVER BOX MATERIAL:

7 gauge steel plate

• HINGED PANEL:

10 gauge steel

• DOOR ROLLERS:

3" diameter, with

sealed bearings

• VERTICAL LOCK BAR

DIMENSIONS:

5/8" SQ by full height

of door

• FINISH: Prime paint

• DOOR HANGER:

7 gauge steel plate

FOR MORE INFORMATION, PLEASE CALL 210-533-1231

• ELECTRICAL: 3.5 watts

• WIRE REQUIREMENTS:

Minimum of five 24 volt conductors

are required between the

control point and the door,

except for those models

having the letter “K”

(keyswitch) in the suffix.

Keyswitch models require

minimum six conductors.

• AIR REQUIREMENTS:

Air consumption varies with

door size at 80 PSIG.

C11

Page 2

FOR INDIVIDUAL

SLIDING DOORS

Maximum

STANDARD FEATURES:

• Bottom door guide

• Door hanger

• Local mechanical release at cover box

• Sloped-front cover box

• Hinged cover panel for maintenance access

• Vertical lock bar assembly

• ASTM F1643 Certified

Horizontal and Vertical Impact Test-Grade 1

• Prime paint finish

security.

L O C K I N G S Y S T E M S

8065L PNEUMATIC

LOCKING SYSTEM

8065LP– 2 PNEUMATIC SLIDING DOOR SYSTEM

OPTIONAL FEATURES:

PILASTER RELEASE - Hip-high

paracentric keyed mechanical release

mounted in a full-height pilaster adjacent

to the receiving jamb.

Specify “8065LP-1” keyed one side.

Specify “8065LP-2” keyed two sides.

ELECTRIC KEYSWITCH - Paracentric or mogul

keyed local electric control switch mounted below

mechanical release mechanism in pilaster.

Specify “8065LPK-1” paracentric keyed one side.

Specify “8065LPK-2” paracentric keyed two sides.

Specify “8065LPKM-1” for mogul keyed one side.

Specify “8065LPKM-2” for mogul keyed two sides.

HOT DIP GALVANIZED FINISH - Available for

external applications with lift-off cover panel only.

Not available with standard hinged cover panel.

Specify “G” when ordering. Example: 8065LP-1G

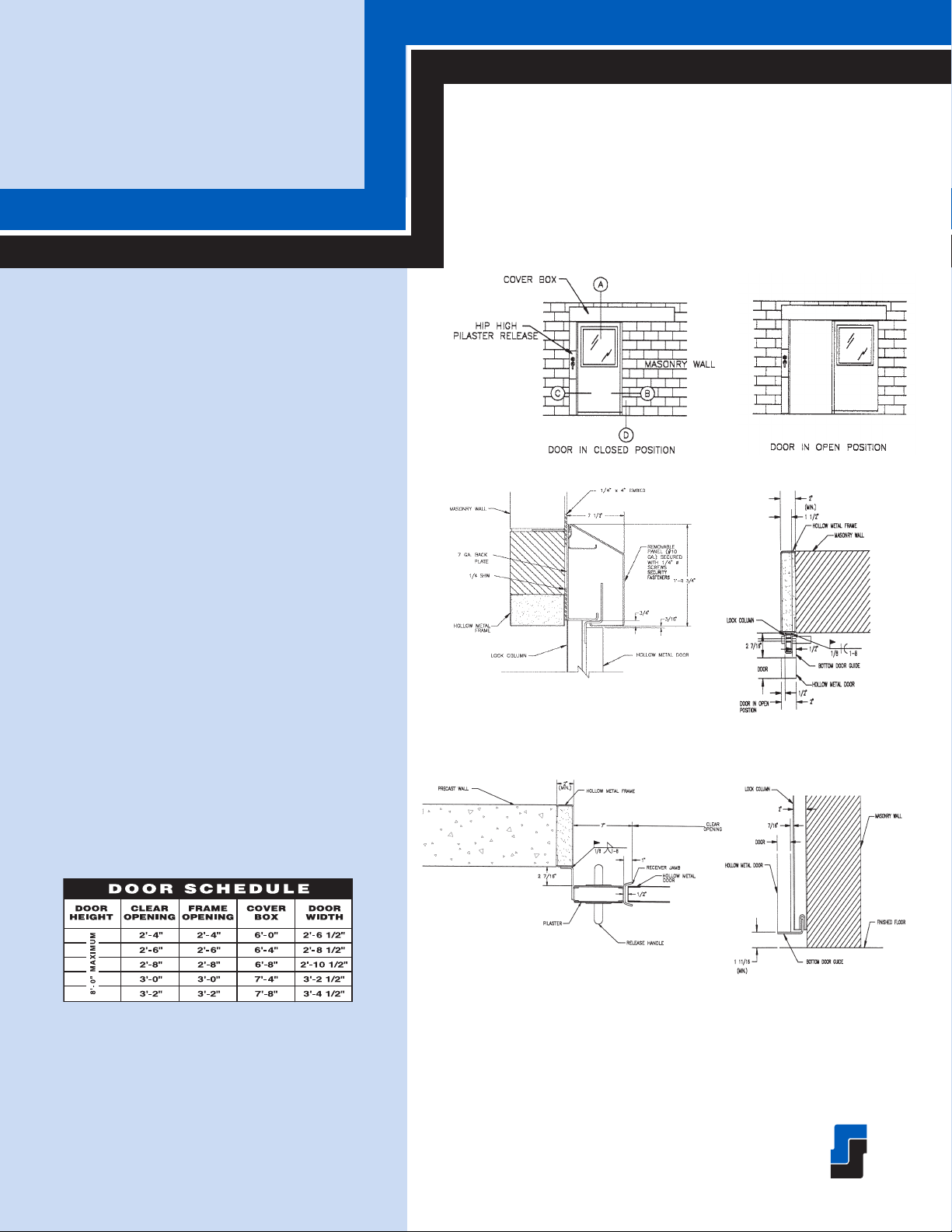

DETAIL A – SLOPED BOX

COVER BOX SECTION

7-1/ 2” de ep x 1’-0-3/ 4” ta ll cov er box

fiel d wel ded 1” on 6 ” top and b ottom

DETAIL C – PILASTER P2

DETAIL B – VERTICAL LOCK BAR JAMB

DETAIL D – BOTTOM DOOR GUIDE SECTION

NOTE: Cover box minimum length =

(7" overtravel) + (2 x clear opening) + 9".

For doors exceeding 450 lbs. and/or greater than

4’-6” clear opening, contact factory.

THREE HOUR FIRE DOOR RATING

AVAILABLE. Standard cover box calculation does

not apply to fire rated door.

C12

Revised 7/12

P-2 PILASTER JAMB SECTION

Pila ster and re ceiver jamb requir es fr ame op ening

to be 7” large r than clear open ing.

8065LP-2 Shown

Note: Other system configurations and details are available.

Call Customer Service for more information.

P.O. BOX 2021 • SAN ANTONIO, TX • 78297 • 210-533-1231 • FAX: 210-533-2211

Loading...

Loading...