Page 1

JAMB MOUNTED FOR

SWINGING DOORS

Minimum and medium security.

P N E U M A T I C L O C K S

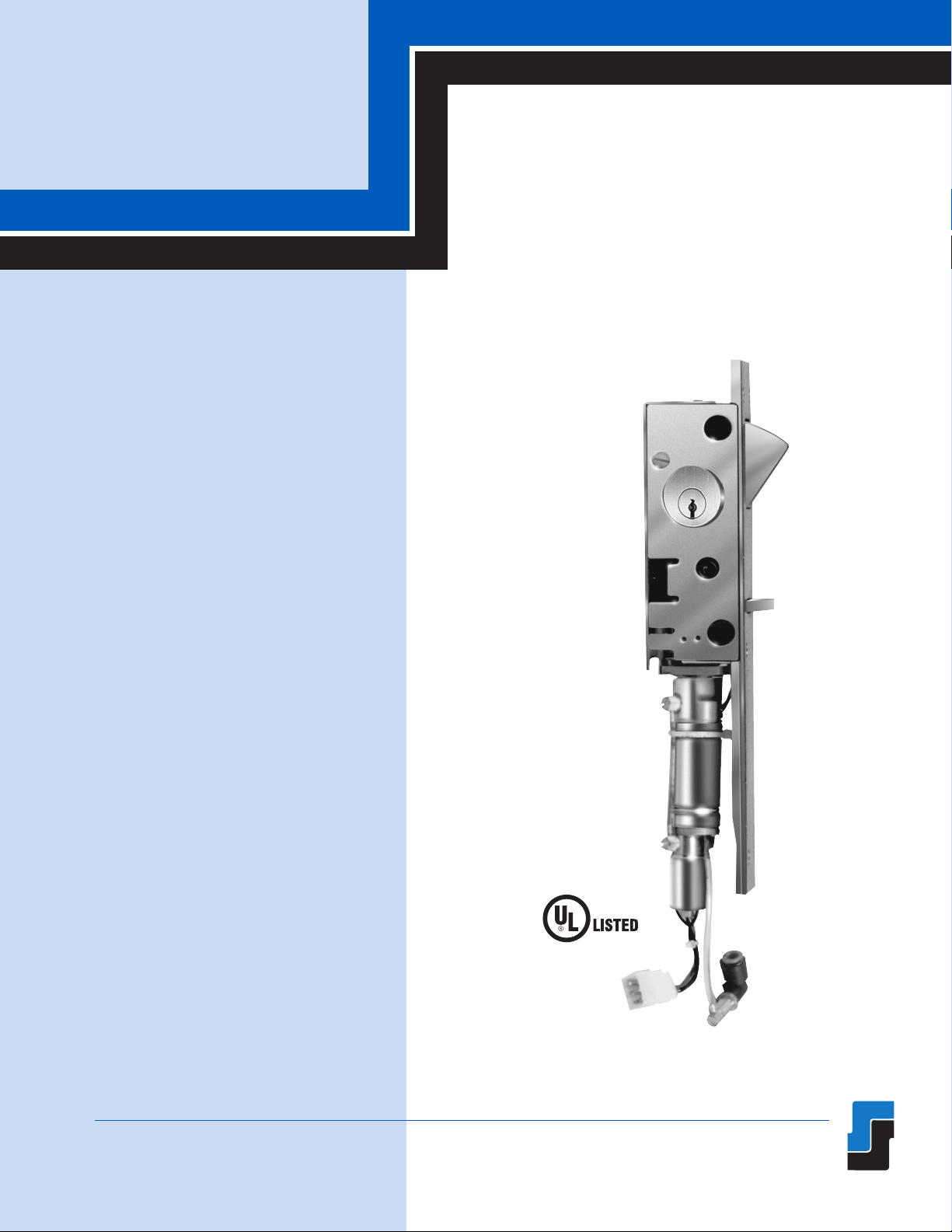

10300P

PNEUMATICALLY

OPERATED

10300P-1: KEYED ONE SIDE

10300P-2: KEYED BOTH SIDES

APPLICATION:

Minimum to medium security

swinging doors that are to be

unlocked from a remote

location. Jamb mounted.

Door position indicator switch,

door closer and heavy duty

door pull are recommended.

FUNCTION:

ELECTRIC - Remote switch

activates a pneumatic air

cylinder which retracts the

latchbolt. Latchbolt remains

retracted until door is opened

approximately 2", then it

releases, automatically latches

and deadlocks when the door is

closed.

DEADLATCH

MECHANICAL - Latchbolt is

retracted with a builder’s

hardware key at the door, and

remains retracted until door is

opened approximately 2", then

it releases, automatically

latches and deadlocks when the

door is closed.

For more information, please call 210.533.1231.

SS Rev. 04-14 C5

Page 2

JAMB MOUNTED FOR

SWINGING DOORS

Minimum and medium security.

STANDARD FEATURES:

• Deadlock indication switch

• Mechanical latchback

• Strike with security fasteners

• Faceplate with security fasteners

• Plug connector

• Solenoid valve

• Fail secure

• Mounting fasteners

Note #1: 1-11/16" O.D. x 1/8" wall cold drawn

tubes furnished by hollow metal manufacturer.

OPTIONAL FEATURES:

NO LATCHBACK - Latchbolt remains retracted

as long as control switch is activated. Latchbolt

extends when power is removed. Specify “NL.”

LOCAL ELECTRIC KEYSWITCH - Day key

provides local electric operation and may be

disabled from remote control point. Master key

provides both electric and mechanical

operation. Specify “LEK.”

EMERGENCY EXIT RELEASE - From remote

location latchbolt can be retracted and held

retracted until released from remote station.

Requires a second pneumatic tube to the lock

and an emergency reserve air system. Specify

“EER.” UL listing for fire door (GYQS) not

available with this function.

BUILDER’S HARDWARE CYLINDERS Specify:

• “10300P-1” keyed one side.

• “10300P-2” keyed both sides.

KEY CYLINDER EXTENDER Required whenever lock is keyed on stop side.

Overall frame depth 4" minimum. Specify “KCE.”

Full body rim cylinder required on stop side.

Full body mortise cylinder required on hinge side.

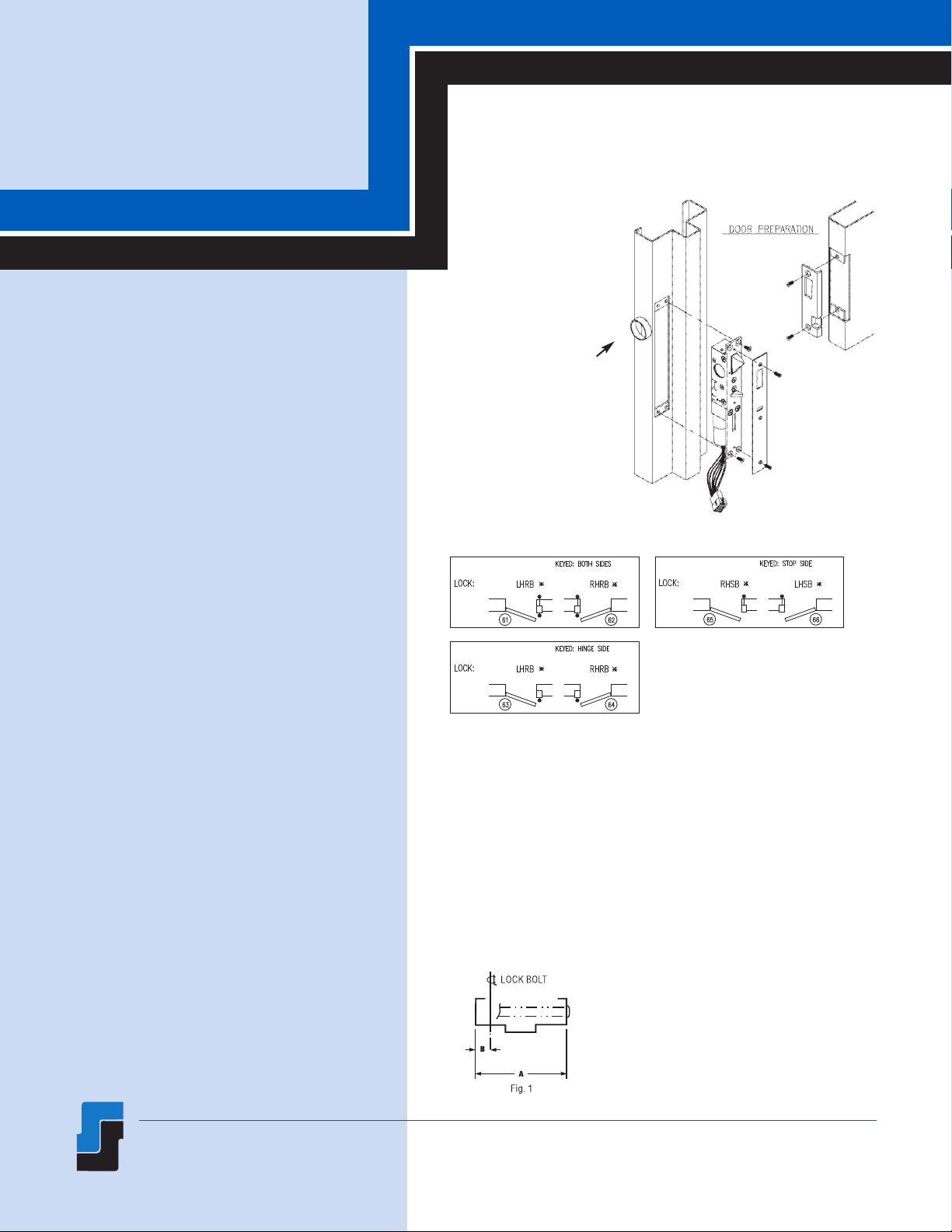

PROVIDE: (See Fig. 1)

1. Dimension “A” (overall frame width)

2. Dimension “B” (edge of frame to centerline

of lockbolt)

P N E U M A T I C L O C K S

10300P PNEUMATICALLY

OPERATED DEADLATCH

1-11/16" O.D. x 1/8"

wall cold drawn tubes

are required.

ee Note 1

S

NOTE: Drawing for illustration only. Reference template

Swing Chart: Specify circled swing number when ordering.

TECHNICAL DATA:

• STANDARD FINISH: US32D

• LOCK BODY: Stainless steel

• FACE PLATE: Stainless steel

• LATCHBOLT: Stainless steel

• DEADLOCK ACTUATOR:

Stainless steel

• ELECTRICAL: 24 VDC,

1.5 watt continuous duty

Frame Preparation

for specific Information.

• AIR REQUIREMENT:

Consumption: .44 cubic

inches per operation

Supply pressure:

80 - 100 P.S.I. at the door

• LOCK SIZE:

10 -5/8"H x 1-1/2"W x 1- 3/4"D

• LOCK WEIGHT: 3.2 lbs.

• LATCHBOLT SIZE:

1- 5/8"H x 5/8"TK

• LATCHBOLT THROW: 3/4"

• BUILDER’S CYLINDER:

1- 5/32" diameter with

standard Yale cam or equal

• UL Listed for use on threehour fire doors

• UL Listed as burglary

resistant

• ASTM F 1577 Certified

Impact Test-Grade 1

P.O. Box 2021, San Antonio, TX 78297 ■Ph: 210 . 533.1231 ■Fx: 210 . 533.2211

Web: www.SouthernFolger.com ■Email: info@southernfolger.com

C6 Printed in USA SS Rev. 04-14

Loading...

Loading...