Southbend P24N-CC, P16C-X, P24C-CC, P12C-B, P32A-HH User Manual

...

Installation & Operation Manual

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

Platinum Series Sectional Range

Charbroiler Models: P16C-C, P16N-C, P24C-CC, P24N-CC, P32A-CC, P32C-CC, P32D-CC, P32N-CC, P36A-CCC, P36C-CCC, P36D-CCC,

P36N-CCC, P48A-CCCC, P48C-CCCC, P48D-CCCC, & P48N-CCCC

Standard Griddle Models: P16C-G, P16N-G, P32A-GG, P32C-GG, P32D-GG, P32N-GG, P48A-GGG, P48C-GGG, P48D-GGG, & P48N-GGG

Graduated Hot-Top Models: P32A-GRAD, P32C-GRAD, P32D-GRAD, & P32N-GRAD

Uniform Hot-Top Models: P16C-H, P16N-H, P32A-HH, P32C-HH, P32D-HH, & P32N-HH

Thermostatic Griddle Models: P16C-T, P16N-T, P32A-TT, P32C-TT, P32D-TT, P32N-TT, P48A-TTT, P48C-TTT, P48D-TTT, & P48N-TTT

Flush Open-Burner Models: P12C-B, P12N-B, P16C-X, P16N-X, P32A-BBB, P32A-XX, P32C-BBB, P32C-XX, P32D-BBB, P32D-XX,

P32N-BBB, P32N-XX, P48A-BBBB, P48D-BBBB, & P48N-BBBB

Step-Up Open-Burner Models: P32A-BBB-SU, P32C-BBB-SU, P32D-BBB-SU, P32N-BBB-SU

Combination Open-Burner Hot-Top Models: P32A-XH, P32C-XH, P32D-XH, P32N-XH, P32A-XH-RE, P32C-XH-RE, P32D-XH-RE, & P32N-XH-RE Combination Open-Burner Griddle Models: P32A-XG, P32C-XG, P32D-XG, P32N-XG, P32A-XT, P32C-XT, P32D-XT, & P32N-XT

Wood Smoker: P36W-CCC, P48W-CCCC, P60W-CCCCC, P72W-CCCCCC

WARNING

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death. Read installation, operation, and maintenance instructions thoroughly before installing or servicing this equipment.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526 USA • www.southbendnc.com

MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

$18.00 |

MANUAL SECTION SR |

SAFETY PRECAUTIONS |

PLATINUM SERIES SECTIONAL RANGE |

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator, service personnel, or to the equipment.

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury, product damage, or property damage.

This symbol refers to information that needs special attention or must be fully understood, even though not dangerous.

WARNING

WARNING

FIRE HAZARD

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of cooking appliances. Keep area around cooking appliances free and clear of combustibles.

Purchaser of equipment must post in a prominent location detailed instructions to be followed in the event the operator smells gas. Obtain the instructions from the local gas supplier.

WARNING

WARNING

BURN HAZARD

Contact with hot surfaces will cause severe burns. Always use caution when operating cooking appliances.

WARNING

WARNING

EXPLOSION AND ASPHYXIATION HAZARD

In the event a gas odor is detected, shut down equipment at the main gas shut-off valve and immediately call the emergency phone number of your gas supplier.

Improper ventilation can result in headaches, drowsiness, nausea, and could result in death. Do not obstruct the flow of combustion and ventilation air to and from cooking appliances.

WARNING

WARNING

ELECTRIC SHOCK HAZARD

For appliances that use electric power, disconnect the power to the appliance before cleaning. Do not remove panels that require tools to remove.

NOTICE

Southbend appliances are intended for commercial use only. Not for household use.

Warranty will be void if service work is performed by other than a qualified technician, or if other than genuine Southbend replacement parts are installed.

Give this Owner’s Manual and important papers to the proper authority to retain for future reference.

Copyright © 2003 by Southbend. All rights reserved. Published in the United States of America.

PAGE 2 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

INTRODUCTION |

INTRODUCTION

Congratulations! You have purchased one of the finest pieces of heavy-duty commercial cooking equipment on the market.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to meet the toughest standards in the industry. Each piece of Southbend equipment is carefully engineered and designs are verified through laboratory tests and field installations. With proper care and field maintenance, you will experience years of reliable, trouble-free operation. For best results, read this manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

This manual is for Southbend Platinum Series Sectional Range models P12C-B, P12N-B, P16C-C, P16C-G, P16C-H, P16C-T, P16C-X, P16N-C, P16N-G, P16N-H, P16N-T, P16N-X, P24C-CC, P24N-CC, P32A-BBB, P32A-BBB-SU, P32A-CC, P32A-GG, P32A-GRAD, P32A-HH, P32A-TT, P32A-XG, P32A-XH, P32A-XH-RE, P32A-XT, P32A-XX, P32C-BBB, P32C-BBB-SU, P32C-CC, P32C-GG, P32C-GRAD, P32C-HH, P32C-TT, P32C-XG, P32C-XH, P32C-XH-RE, P32C-XT, P32C-XX, P32D-BBB, P32D-BBB-SU, P32D-CC, P32D-GG, P32D-GRAD, P32D-HH, P32D-TT, P32D-XG, P32D-XH, P32D-XH-RE, P32D-XT, P32D-XX, P32N-BBB, P32N-BBB-SU, P32N-CC, P32N-GG, P32N-GRAD, P32N-HH, P32N-TT, P32N-XG, P32N-XH, P32N-XH-RE, P32N-XT, P32N-XX, P36A-CCC, P36C-CCC, P36D-CCC, P36N-CCC, P48A-BBBB, P48A-CCCC, P48A-GGG, P48A-TTT, P48C-BBBB, P48C-CCCC, P48C-GGG, P48C-TTT, P48D-BBBB, P48D-CCCC, P48D-GGG, P48D-TTT, P48N-BBBB, P48N-CCCC, P48N-GGG, P48N-TTT, P36W-CCC, P48W-CCCC,P60W-CCCCC AND P72W-CCCCCC.

This manual does NOT cover Southbend sectional fryers, fryer filter systems, salamander broilers, upright broilers, cheese melters, or refrigerated bases. Those appliances have their own manuals.

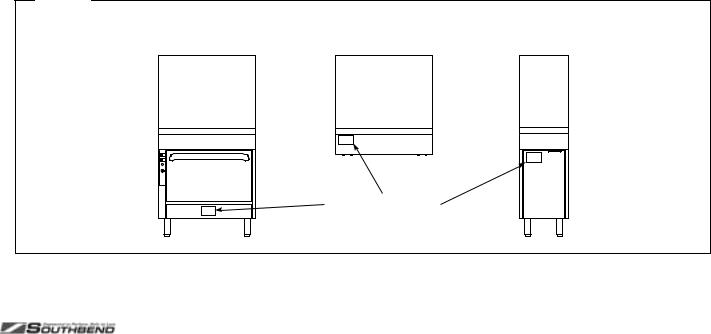

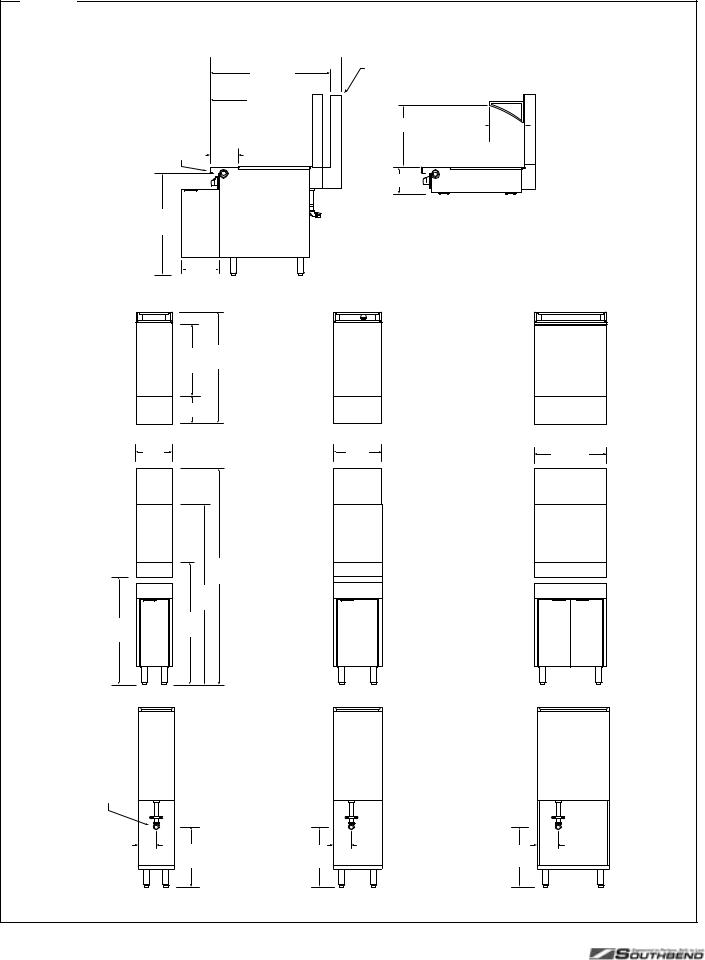

The location of the serial plate depends on the type of base (see Figure 1 below). On models with oven bases, the serial plate is located on the backside of the kick-plate below the oven door (lift the kick-plate straight up and tilt the top edge out and down.) On models with a cabinet base, the serial plate is located inside the left cabinet door. On modular (countertop) models, the serial plate is located inside the front valve panel.

Read these instructions carefully before attempting installation. Installation and initial startup should be performed by a qualified installer. Unless the installation instructions for this product are followed by a qualified service technician (a person experienced in and knowledgeable with the installation of commercial gas and/or electric cooking equipment) then the terms and conditions on the Manufacturer’s Limited Warranty will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Southbend

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

Figure 1

Location of Serial Plate

Location of Serial Plate

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 3 OF 80 |

SPECIFICATIONS |

PLATINUM SERIES SECTIONAL RANGE |

SPECIFICATIONS

NOTICE

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association, Inc., states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to installation requirements for equipment. Therefore, installations should comply with all local codes.

Southbend reserves the right to change specifications and product design without notice. Such revisions do not entitle the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

Southbend appliances are intended for commercial use only, not for household use.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGAB149.2, as applicable, including:

1.The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psi (3.45 kPa).

2.The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.45 kPa).

CLEARANCES

WARNING

WARNING

MINIMUM CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

There must be adequate clearance between the sectional range and combustible construction. Clearance must also be provided for servicing and for operation.

|

Open-Top |

Open-Top |

|

|

Graduated |

|

Standard-Burner |

PyroMax-Burner |

Griddle |

Uniform Hot-Top |

Hot-Top |

|

Models |

Models |

Models |

Models |

Models |

Sides |

10" |

13" |

10" |

10" |

6" |

Back |

6" |

6" |

12" |

12" |

6" |

Floor* |

0" |

0" |

0" |

0" |

0" |

Sectional charbroilers and sectional wood smokers are NOT recommended for installation next to combustible materials

* Models with 6" legs or casters are suitable for installation on combustible floors.

Adequate clearance must be provided in the aisle in front of the unit to permit operation (including opening of doors and/or removal of grease drawers, drippings trays, and/or oven racks), as well as for servicing. No additional clearance is required for servicing as the sectional range is serviceable from the front.

Models with a convection-type oven require a minimum clearance of 2" between the motor on the back and noncombustible construction. Care must be taken to provide adequate air circulation to prevent the motor from overheating.

Minimum clearance from noncombustible construction is zero on the sides and back for all models (except for models with a convection-type oven).

The high-temperature flue products flow out through the top of the flue riser of all models, and from the top of open-top and charbroiler models. Installation under a vented hood is recommended.

Salamander broilers and cheese melters mounted on the flue riser of a sectional range may require additional minimum clearances (see the documentation for those appliances).

PAGE 4 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

SPECIFICATIONS |

VENTILATION

WARNING

WARNING

Improper ventilation can result in personal injury or death. Ventilation which fails to properly remove flue products can cause headaches, drowsiness, nausea, or could result in death.

All gas appliances must be installed in such a manner that the flow of combustion and ventilation air is not obstructed. Provisions for adequate air supply must be provided. Do not obstruct the area under the control panel or below the oven door (on the front), or the area below the flue riser (on the back) as combustion air enters through these areas.

NOTICE

Proper ventilation is the owner’s responsibility. Any problem due to improper ventilation will not be covered by the warranty.

Be sure to inspect and clean the ventilation system according to the ventilation equipment manufacturer’s instructions.

Air for combustion enters from the front below the valve panel, as well as from the rear into the burner box. Ranges with solid tops (griddles and hot-tops) vent their flue products up the flue riser. On units with a base oven, combustion air enters from the front below the oven door. Oven flue products are vented up the flue riser.

Lack of sufficient ventilation will cause poor burner and pilot operating characteristics, resulting in inefficient performance. Such conditions also cause high ambient temperatures at the manifold area and create valve and thermostat problems.

If a ventilation canopy is used, it is recommended that the canopy extend 6" past the sectional range and that the bottom edge be located 6'6" from the floor. Filters should be installed at an angle of 45° or more from the horizontal. This position prevents dripping grease, and facilitates collecting the run-off grease in a drip pan under the filter.

A strong exhaust fan tends to create a vacuum in the room and may interfere with burner performance or may extinguish pilot flames. Fresh air openings approximately equal to the fan area will relieve such a vacuum. The exhaust fan should be installed at least 2" above the top of the flue riser.

If the sectional range is connected directly to an outside flue, a CSA design certified down draft diverter must be installed.

In case of unsatisfactory performance by any gas appliance, check the appliance with the exhaust fan turned OFF. Do this only long enough to check whether doing so corrects any problems with equipment performance. Then turn the exhaust fan back on and let it run to remove any exhaust that may have accumulated during the test.

GAS SUPPLY

The sectional range is design-certified for operation on natural or propane gases. The sectional range is shipped configured and adjusted for the type of gas specified by the purchaser, which is indicated on the serial plate (see Figure 1 on page 3). Connect the sectional range ONLY to the type of gas for which it is configured and adjusted.

Each section has a 1-1/4" front gas manifold that can be coupled to adjacent section(s). Sections can be ordered with an optional 1" rear gas connection with a male NPT connector. Minimum supply pressure is 7" W.C. for natural gas, 11" W.C. for propane. An external pressure regulator and shut off valve must be provided. If using a flexible-hose gas connection, the I.D. of the hose must not be smaller than the connector on the unit and must comply with ANSI Z21.69. Provide an adequate means of restraint to prevent undue strain on the gas connection.

If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in accordance with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGA-B149.2, as applicable.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for satisfactory performance. Fluctuations of more than 25% on natural gas or 10% on propane gas will create problems and affect burner operating characteristics. A 1/8" pressure tap is located on the manifold to measure the manifold pressure. The supply line to the sectional range should be no smaller than the inside diameter of the pipe on the sectional range to which it is connected.

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 5 OF 80 |

SPECIFICATIONS |

PLATINUM SERIES SECTIONAL RANGE |

Figure 2

Dimensions

43-1/2" (1105)

43-1/2" (1105)

40" (1016)

37-1/2" (953)

37-1/2" (953)

34" (864)

Front Gas |

9-1/4" (235) |

Manifold |

Flue riser for “deep” depth-option extends rearward 6" (cooking surface area is same as for “standard” depth).

20-1/2" (521) |

11-3/4" (298) |

8-1/2" (216)

33-3/4"

(859)

12-1/2"  (318)

(318)

SIDE VIEW of Flush-Burner 16"-Wide Cabinet-Base Models

24" |

37-1/2" |

(610) |

(953) |

9-1/4" (235) |

|

12" |

16" |

(305) |

(406) |

36" Flue Riser

24" Flue Riser

5" Flue Riser |

72" |

|

|

(1829) |

|

|

60" |

|

|

(1524) |

|

36" |

41" |

|

(1041) |

||

(914) |

||

|

SIDE VIEW of Flush-Burner Modular-Base Models (with 24" flue riser with single shelf)

24" (610)

Optional

Rear Gas

Connection

6" (152) |

|

|

6" |

|

7" (178) |

|

20" |

20" |

(152) |

20" |

|||

|

|

|||||

|

(508) |

(508) |

|

(508) |

|

PAGE 6 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

|

PLATINUM SERIES SECTIONAL RANGE |

|

|

|

|

SPECIFICATIONS |

||

|

Figure 3 |

|

|

|

|

|

|

|

|

Dimensions (continued) |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

8.00" |

|

|

|

|

SIDE VIEW of Charbroiler/Griddle Modular-Base Models |

|

|

|

|

|

|

|

|

|

|

|

25.77" |

|

|

SIDE VIEW of Charbroiler/Griddle Oven-Base Models |

|

|

|

SIDE VIEW of Optional Equipment Stand |

|||

|

24" |

|

40-1/2" |

|

|

|

|

|

|

(610) |

|

|

|

|

|

|

|

|

|

(1029) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9-1/4" (235) |

|

|

|

|

|

|

|

|

|

32" (813) |

|

|

|

|

|

48" (1219) |

|

36" Flue Riser |

|

|

|

|

|

|

|

|

24" Flue Riser |

|

|

|

|

|

|

|

|

5" Flue Riser |

|

72" |

|

|

|

|

|

|

|

|

(1829) |

|

|

|

|

|

|

|

|

60" |

|

|

|

|

|

|

|

|

(1524) |

|

|

|

|

|

|

36" |

|

41" |

|

|

|

|

|

|

|

(1041) |

|

|

|

|

|

|

|

(914) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Optional |

|

Electrical |

|

Electrical |

|

|

|

|

Rear Gas |

|

|

|

|

|

||

|

|

Connection |

|

Connection |

|

|

|

|

|

Connection |

|

|

|

|

|

||

|

|

for Oven |

|

for Oven |

|

|

|

|

|

|

|

Models |

|

Models |

|

|

|

|

20" |

6" (152) |

18" |

7" (178) |

18" |

20" |

6" (152) |

17-1/2" |

|

1-1/2" (38) |

2-1/2" (64) |

|

(445) |

||||

|

(508) |

|

(457) |

|

(457) |

(508) |

|

|

|

|

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

|

|

|

PAGE 7 OF 80 |

||

7)Electric alConnectionfor OvenModels |

|

|

|

|

|

|

|

|

OptionalR208"83"(FM41-6"/41/2" (216)ear GasConnection o |

n n e c t i o n |

|

|

|

|

|

|

|

SPECIFICATIONS PLATINUM SERIES SECTIONAL RANGE

UTILITY REQUIREMENTS AND CRATED WEIGHT

Model |

Width |

Base Type |

Top Type |

|

GAS |

ELECTRICITY |

Crated Weight |

||

Natural Gas |

|

Propane |

120V |

208/240V |

pounds (kg) |

||||

|

|

|

|

(BTU/hour) |

|

(BTU/hour) |

(amps) |

(amps) |

|

|

|

|

|

|

|

||||

P12C-B |

12" |

cabinet |

2 flush open-burners |

66,000 |

|

60,000 |

- |

- |

200 (91) |

P12N-B |

12" |

modular |

2 flush open-burners |

66,000 |

|

60,000 |

- |

- |

130 (59) |

P16C-C |

16" |

cabinet |

charbroiler |

40,000 |

|

36,000 |

- |

- |

220 (100) |

P16C-G |

16" |

cabinet |

standard griddle |

40,000 |

|

36,000 |

- |

- |

270 (122) |

P16C-H |

16" |

cabinet |

uniform hot top |

40,000 |

|

36,000 |

- |

- |

220 (100) |

P16C-T |

16" |

cabinet |

thermostatic griddle |

40,000 |

|

36,000 |

- |

- |

270 (122) |

P16C-X |

16" |

cabinet |

2 flush PyroMax open-burners |

90,000 |

|

84,000 |

- |

- |

220 (100) |

P16N-C |

16" |

modular |

charbroiler |

40,000 |

|

36,000 |

- |

- |

150 (68) |

P16N-G |

16" |

modular |

standard griddle |

40,000 |

|

36,000 |

- |

- |

240 (108) |

P16N-H |

16" |

modular |

uniform hot top |

40,000 |

|

36,000 |

- |

- |

150 (68) |

P16N-T |

16" |

modular |

thermostatic griddle |

40,000 |

|

36,000 |

- |

- |

240 (108) |

P16N-X |

16" |

modular |

2 flush PyroMax open-burners |

90,000 |

|

84,000 |

- |

- |

150 (68) |

P24C-CC |

24" |

cabinet |

charbroiler |

64,000 |

|

56,000 |

- |

- |

360 (163) |

P24N-CC |

24" |

modular |

charbroiler |

64,000 |

|

56,000 |

- |

- |

360 (163) |

P32A-BBB |

32" |

convection oven |

6 flush open-burners |

243,000 |

|

222,000 |

4.8 |

2.6 |

670 (305) |

P32A-BBB-SU |

32" |

convection oven |

6 open-burners (rear burners raised) |

243,000 |

|

222,000 |

4.8 |

2.6 |

670 (305) |

P32A-CC |

32" |

convection oven |

charbroiler |

125,000 |

|

114,000 |

4.8 |

2.6 |

670 (305) |

P32A-GG |

32" |

convection oven |

standard griddle |

125,000 |

|

114,000 |

4.8 |

2.6 |

740 (336) |

P32A-GRAD |

32" |

convection oven |

graduated hot-top |

107,000 |

|

87,000 |

4.8 |

2.6 |

670 (305) |

P32A-HH |

32" |

convection oven |

uniform hot top |

125,000 |

|

114,000 |

4.8 |

2.6 |

670 (305) |

P32A-TT |

32" |

convection oven |

thermostatic griddle |

125,000 |

|

114,000 |

4.8 |

2.6 |

740 (336) |

P32A-XG |

32" |

convection oven |

2 PyroMax open-burners (left side), |

175,000 |

|

168,000 |

4.8 |

2.6 |

705 (320) |

standard griddle (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32A-XH |

32" |

convection oven |

2 PyroMax open-burners (left side), |

175,000 |

|

168,000 |

4.8 |

2.6 |

670 (305) |

uniform hot-top (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32A-XH-RE |

32" |

convection oven |

2 PyroMax open-burners (front), |

175,000 |

|

168,000 |

4.8 |

2.6 |

670 (305) |

uniform hot-top (rear) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32A-XT |

32" |

convection oven |

2 PyroMax open-burners (left side), |

175,000 |

|

168,000 |

4.8 |

2.6 |

705 (320) |

thermostatic griddle (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32A-XX |

32" |

convection oven |

4 PyroMax flush open-burners |

225,000 |

|

200,000 |

4.8 |

2.6 |

670 (305) |

P32C-BBB |

32" |

cabinet |

6 flush open-burners |

198,000 |

|

180,000 |

- |

- |

450 (205) |

P32C-BBB-SU |

32" |

cabinet |

6 open-burners (rear burners raised) |

198,000 |

|

180,000 |

- |

- |

450 (205) |

P32C-CC |

32" |

cabinet |

charbroiler |

80,000 |

|

72,000 |

- |

- |

450 (205) |

P32C-GG |

32" |

cabinet |

standard griddle |

80,000 |

|

72,000 |

- |

- |

560 (255) |

P32C-GRAD |

32" |

cabinet |

graduated hot-top |

62,000 |

|

45,000 |

- |

- |

490 (223) |

P32C-HH |

32" |

cabinet |

uniform hot top |

80,000 |

|

72,000 |

- |

- |

490 (223) |

P32C-TT |

32" |

cabinet |

thermostatic griddle |

80,000 |

|

72,000 |

- |

- |

560 (255) |

P32C-XG |

32" |

cabinet |

2 PyroMax open-burners (left side), |

130,000 |

|

126,000 |

- |

- |

525 (238) |

standard griddle (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32C-XH |

32" |

cabinet |

2 PyroMax open-burners (left side), |

130,000 |

|

126,000 |

- |

- |

490 (223) |

uniform hot-top (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32C-XH-RE |

32" |

cabinet |

2 PyroMax open-burners (front), |

124,000 |

|

120,000 |

- |

- |

490 (223) |

uniform hot-top (rear) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32C-XT |

32" |

cabinet |

2 PyroMax open-burners (left side), |

130,000 |

|

126,000 |

- |

- |

525 (238) |

thermostatic griddle (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32C-XX |

32" |

cabinet |

4 PyroMax flush open-burners |

180,000 |

|

168,000 |

- |

- |

490 (223) |

P32D-BBB |

32" |

standard oven |

6 flush open-burners |

243,000 |

|

222,000 |

1.0 |

1.0 |

530 (241) |

P32D-BBB-SU |

32" |

standard oven |

6 open-burners (rear burners raised) |

243,000 |

|

222,000 |

1.0 |

1.0 |

530 (241) |

P32D-CC |

32" |

standard oven |

charbroiler |

125,000 |

|

114,000 |

1.0 |

1.0 |

530 (241) |

P32D-GG |

32" |

standard oven |

standard griddle |

125,000 |

|

114,000 |

1.0 |

1.0 |

700 (318) |

P32D-GRAD |

32" |

standard oven |

graduated hot-top |

107,000 |

|

87,000 |

1.0 |

1.0 |

630 (286) |

P32D-HH |

32" |

standard oven |

uniform hot top |

125,000 |

|

114,000 |

1.0 |

1.0 |

630 (286) |

P32D-TT |

32" |

standard oven |

thermostatic griddle |

125,000 |

|

114,000 |

1.0 |

1.0 |

700 (318) |

P32D-XG |

32" |

standard oven |

2 PyroMax open-burners (left side), |

175,000 |

|

168,000 |

1.0 |

1.0 |

665 (302) |

standard griddle (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32D-XH |

32" |

standard oven |

2 PyroMax open-burners (left side), |

175,000 |

|

168,000 |

1.0 |

1.0 |

630 (286) |

uniform hot-top (right side) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

P32D-XH-RE |

32" |

standard oven |

2 PyroMax open-burners (front), |

169,000 |

|

165,000 |

1.0 |

1.0 |

630 (286) |

uniform hot-top (rear) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

table continues on next page |

|

|

|

|

|

|

|

|

|

PAGE 8 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

|

|

|

|

|

|

SPECIFICATIONS |

||||

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Width |

Base Type |

Top Type |

|

|

GAS |

ELECTRICITY |

Crated Weight |

|

||

|

Natural Gas |

|

Propane |

120V |

208/240V |

pounds (kg) |

|

||||

|

|

|

|

|

(BTU/hour) |

|

(BTU/hour) |

(amps) |

(amps) |

|

|

|

|

|

|

|

|

|

|

||||

P32D-XT |

32" |

standard oven |

2 PyroMax open-burners (left side), |

175,000 |

|

168,000 |

1.0 |

1.0 |

665 (302) |

|

|

thermostatic griddle (right side) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

P32D-XX |

32" |

standard oven |

4 PyroMax flush open-burners |

225,000 |

|

200,000 |

1.0 |

1.0 |

630 (286) |

|

|

P32N-BBB |

32" |

modular |

6 flush open-burners |

198,000 |

|

180,000 |

- |

- |

260 (118) |

|

|

P32N-BBB-SU |

32" |

modular |

6 open-burners (rear burners raised) |

198,000 |

|

180,000 |

- |

- |

260 (118) |

|

|

P32N-CC |

32" |

modular |

charbroiler |

80,000 |

|

72,000 |

- |

- |

260 (118) |

|

|

P32N-GG |

32" |

modular |

standard griddle |

80,000 |

|

72,000 |

- |

- |

400 (182) |

|

|

P32N-GRAD |

32" |

modular |

graduated hot-top |

62,000 |

|

45,000 |

- |

- |

315 (143) |

|

|

P32N-HH |

32" |

modular |

uniform hot top |

80,000 |

|

72,000 |

- |

- |

315 (143) |

|

|

P32N-TT |

32" |

modular |

thermostatic griddle |

80,000 |

|

72,000 |

- |

- |

400 (182) |

|

|

P32N-XG |

32" |

modular |

2 PyroMax open-burners (left side), |

130,000 |

|

126,000 |

- |

- |

358 (162) |

|

|

standard griddle (right side) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

P32N-XH |

32" |

modular |

2 PyroMax open-burners (left side), |

130,000 |

|

126,000 |

- |

- |

315 (143) |

|

|

uniform hot-top (right side) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

P32N-XH-RE |

32" |

modular |

2 PyroMax open-burners (front), |

124,000 |

|

120,000 |

- |

- |

315 (143) |

|

|

uniform hot-top (rear) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

P32N-XT |

32" |

modular |

2 PyroMax open-burners (left side), |

130,000 |

|

126,000 |

- |

- |

358 (162) |

|

|

thermostatic griddle (right side) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

P32N-XX |

32" |

modular |

4 PyroMax flush open-burners |

180,000 |

|

168,000 |

- |

- |

315 (143) |

|

|

P36A-CCC |

36" |

convection oven |

charbroiler |

173,000 |

|

154,000 |

4.8 |

2.6 |

621 (281) |

|

|

P36C-CCC |

36" |

cabinet |

charbroiler |

128,000 |

|

112,000 |

- |

- |

462 (209) |

|

|

P36D-CCC |

36" |

standard oven |

charbroiler |

173,000 |

|

154,000 |

1.0 |

1.0 |

568 (257) |

|

|

P36N-CCC |

36" |

modular |

charbroiler |

128,000 |

|

112,000 |

- |

- |

276 (125) |

|

|

P36W-CCC |

36” |

modular |

wood smoker |

96,000 |

|

84,000 |

- |

- |

330(150) |

|

|

P48A-BBBB |

48" |

convection oven |

8 flush open burners |

309,000 |

|

282,000 |

4.8 |

2.6 |

621 (281) |

|

|

and cabinet |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

P48A-CCCC |

48" |

convection oven |

charbroiler |

165,000 |

|

150,000 |

4.8 |

2.6 |

621 (281) |

|

|

and cabinet |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

P48A-GGG |

48" |

convection oven |

standard griddle |

|

165,000 |

150,000 |

4.8 |

2.6 |

840 (378) |

|

|

and cabinet |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 9 OF 80 |

OPERATION |

PLATINUM SERIES SECTIONAL RANGE |

OPERATION

DANGER

DANGER

EXPLOSION HAZARD

In the event a gas odor is detected, shut down equipment at the main shut off valve. Immediately call the emergency phone number of your gas supplier.

CAUTION

CAUTION

If a pilot flame pilot should go out, the flow of gas to the corresponding burner is NOT interrupted. Consequently, it is the responsibility of the operator to check the ignition of each burner immediately EVERY TIME a burner is turned on. Should ignition fail after 10 seconds, turn off the burner, wait 5 minutes, and then try again.

LIGHTING AFTER GAS HAS BEEN SHUT OFF

When turning on the main gas supply to a sectional range, do the following:

1.Make sure that all the control knobs and power switches of all the connected appliances are in the OFF position.

2.Turn on the gas-supply shut-off valve(s).

3.Light the standing pilots of each connected appliance.

4.Turn on the ovens of the sectional range first, then wait six minutes before turning on the top sections. This enables all air to be purged from the sectional-range gas piping.

SHUTDOWN OF ENTIRE RANGE

To place the range in a standby state (ready for use), turn all burner control knobs to OFF, set all thermostats to their lowest position, and switch all ovens OFF. The pilots will remain lit.

To completely shut down the range for an extended period (or prior to disconnecting the gas supply), place the range in a standby state (as described in the previous paragraph), then turn OFF the manual shut-off valves of all gas supply connections. This will extinguish the pilots.

PAGE 10 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

OPERATION |

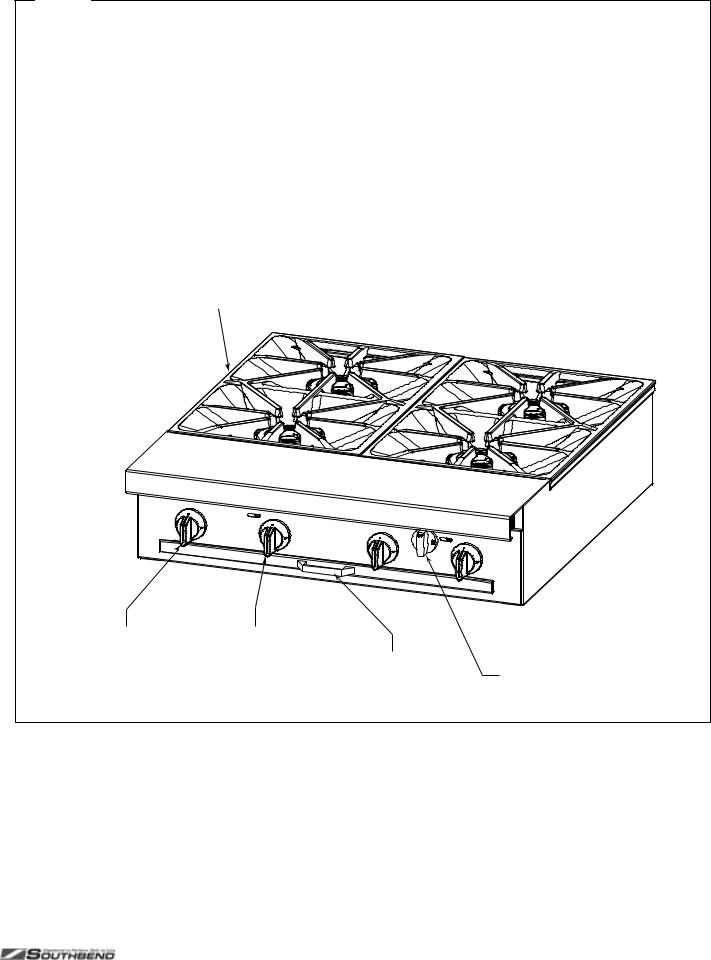

Figure 4

Operation of Open-Burner Sections

Each 12"-wide or 16"-wide section has two control knobs. The left knob controls the rear burner, while the right knob controls the front burner. Each knob can be turned to OFF or to any position in the range from LOW to HIGH.

To start cooking, turn the appropriate control knob to HIGH. Visually check that the burner ignites. The gas does NOT automatically shut off if the burner does not ignite! If the burner does not ignite, check and/or light the pilots (see procedure at right). When the burner is hot, the burner flame should appear blue and steady (some slight yellowing of the flame tips may occur when using propane gas).

While cooking, do not allow excessive drippings and/or debris to accumulate on or below the burners. When necessary, pull out and clean the drippings tray.

Burner Grate (lifts out for cleaning)

When done cooking, turn the appropriate control knob to OFF. (The pilot should remain lit).

Each burner has a pilot located beside the burner. To light a pilot, do the following:

1.Check that the burner control knob is in the OFF position.

2.Check that the pilot is in the correct position beside the burner.

3.Turn on the gas supply to the sectional range (if not already on).

4.Light the pilot with a match or a pilot-lighting device. The pilot flame should be blue and steady.

Rear-Burner |

Front-Burner |

|

|

Control Knob |

Control Knob |

Drippings Tray |

|

(OFF, HIGH-to-LOW) |

(OFF, HIGH-to-LOW) |

||

(slides out for cleaning) |

|||

|

|

Base-Oven Gas Shut-Off Valve (has no effect on range-top burners)

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 11 OF 80 |

OPERATION |

PLATINUM SERIES SECTIONAL RANGE |

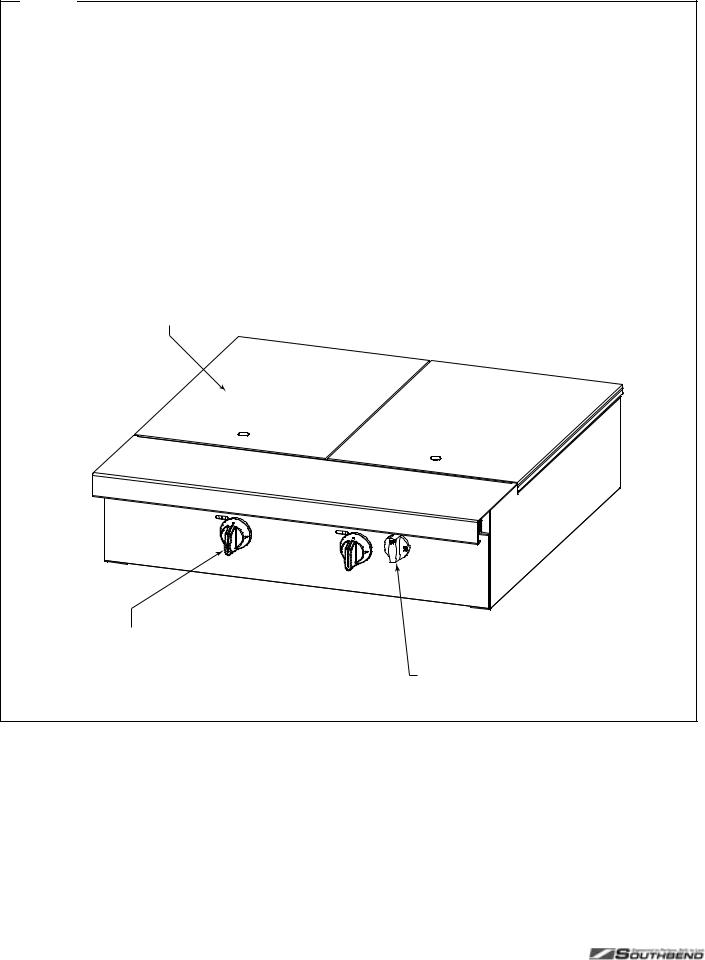

Figure 5

Operation of Uniform Hot-Top Section

Each 16"-wide section has one control knob, which can be turned to OFF or to any position in the range from LOW to HIGH. When the control is set to HIGH, the hot top surface will heat to about 700°F (370°C).

To start cooking, turn the appropriate control knob to HIGH. Visually check that the burner ignites. The gas does NOT automatically shut off if the burner does not ignite! If the burner does not ignite, check and/or light the pilots (see procedure at right). When the burner is hot, the burner flame should appear blue and steady (some slight yellowing of the flame tips may occur when using propane gas).

Do not waste gas and abuse equipment by leaving the burner on HIGH all the time. During idling periods, turn the control to LOW to keep the top warm.

Uniform Hot Top Plate (lifts out for cleaning and lighting pilot)

When done cooking, turn the appropriate control knob to OFF. (The pilot should remain lit).

Each 16"-wide section has two burners, each of which has a pilot located near the front of the burner. To light the pilots, do the following:

1.Check that the control knob is in the OFF position.

2.Lift up a hot-top section plate in order to expose the two pilots.

3.Check that each pilot is in the correct position.

4.Turn on the gas supply to the sectional range (if not already on).

5.Light the pilots with a match or a pilot-lighting device. The pilot flames should be blue and steady.

Burner Control Knob

(OFF, HIGH-to-LOW)

Base-Oven Gas Shut-Off Valve (has no effect on hot-top)

PAGE 12 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

OPERATION |

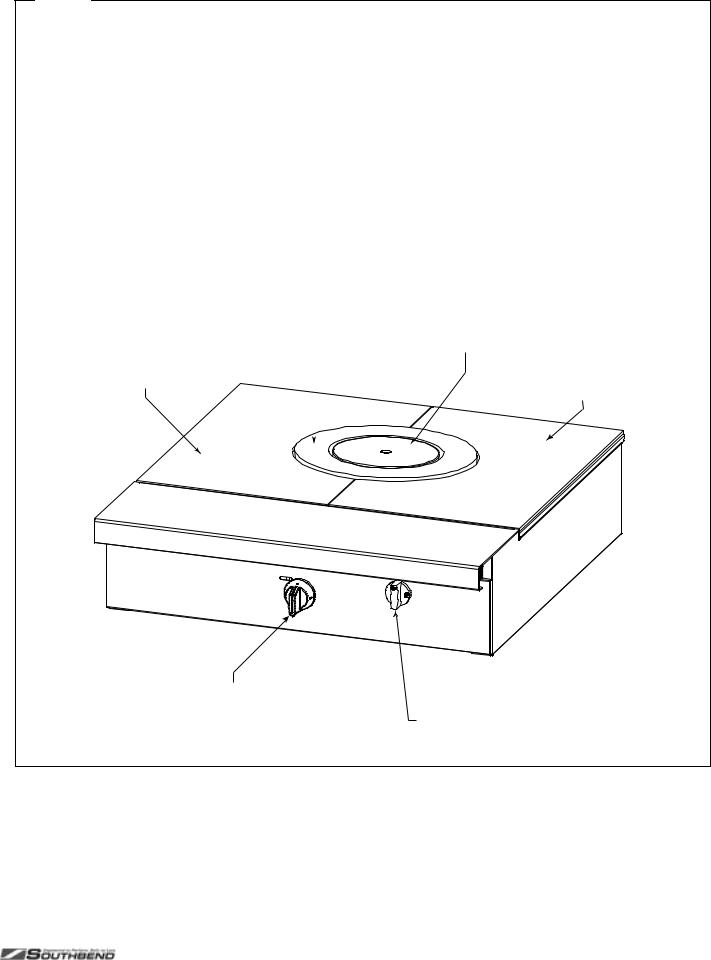

Figure 6

Operation of Graduated Hot-Top Section

Each 32"-wide section has one control knob, which can be turned to OFF or to any position in the range from LOW to HIGH. When the control is set to HIGH, the round center section will heat to about 725°F (385°C), the ring-shaped section will heat to about 625°F (330°C), and the outer areas will heat to about 500°F (260°C).

To start cooking, turn the control knob to HIGH. Visually check that the burner ignites. The gas does NOT automatically shut off if the burner does not ignite! If the burner does not ignite, check and/or light the pilots (see procedure at right). When the burner is hot, the burner flame should appear blue and steady (some slight yellowing of the flame tips may occur when using propane gas).

Do not waste gas and abuse equipment by leaving the control on HIGH all the time. During idling periods, turn the control to LOW to keep the top warm.

When done cooking, turn the control knob to OFF. (The pilot should remain lit).

Each 32"-wide section has one burner. The pilot is located adjacent to the burner. To light the pilot, do the following:

1.Check that the control knob is in the OFF position.

2.Lift out the round center plate in order to expose the pilot.

3.Check that the pilot is in the correct position.

4.Turn on the gas supply to the sectional range (if not already on).

5.Light the pilot with a match or a pilot-lighting device. The pilot flame should be blue and steady.

|

|

|

HighTemperature Area |

|

|

|

(plate lifts out for cleaning |

|

Medium Temperature Area |

and lighting pilot) |

|

|

|

||

Lower Temperature Area |

(plate lifts out for cleaning) |

Lower Temperature Area |

|

(plate lifts out for cleaning) |

|

|

|

|

|

(plate lifts out for cleaning) |

|

|

|

|

|

|

|

|

|

Burner Control Knob |

Base-Oven Gas |

(OFF, HIGH-to-LOW) |

Shut-Off Valve |

|

(has no effect |

|

on hot-top) |

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 13 OF 80 |

OPERATION |

PLATINUM SERIES SECTIONAL RANGE |

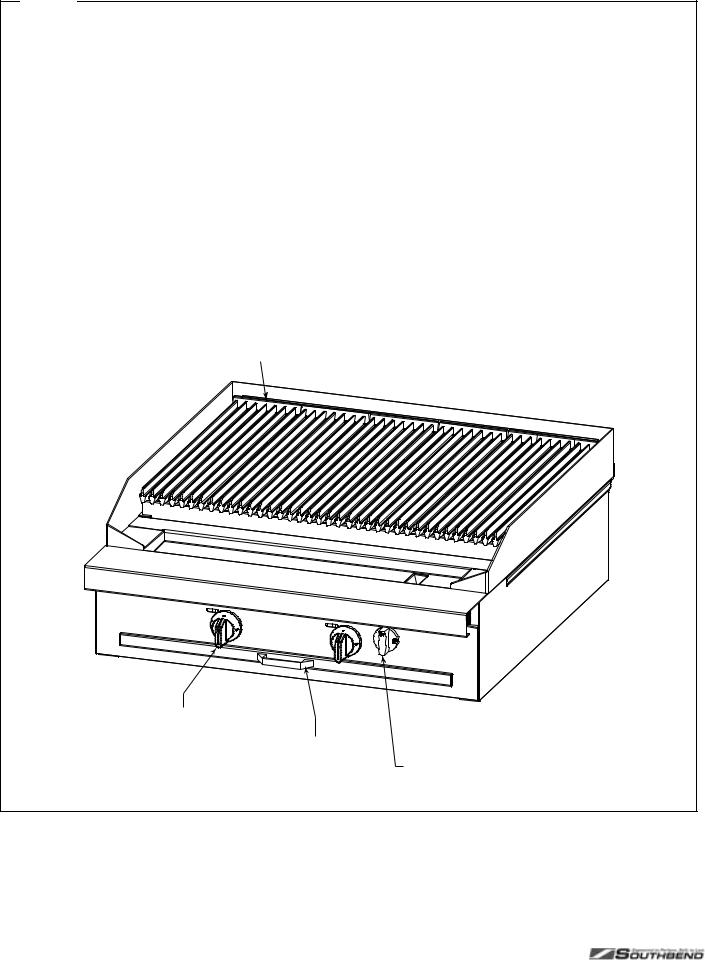

Figure 7

Operation of Charbroiler Section

Each 12"-wide or 16"-wide section has one control knob, which can be turned to OFF, HIGH, or LOW. Each 6"-wide burner top-grate can be turned over to provide either wide branding marks or narrower branding marks with channels to carry away drippings (and so reduce flare up). The back-to- front slope of each top-grate is adjusted by positioning the back end of the top-grate on either the lower or the higher grate-support rail. The radiants (just above the burners) can be reversed front-and-back to provide higher heat toward the back than the front, or vice versa. “Lava rock” briquettes can be placed on grates located above the radiants.

To start cooking, turn the appropriate control knob to HIGH. Visually check that the burner ignites. The gas does NOT automatically shut off if the burner does not ignite! If the burner does not ignite, check and/or light the pilots (see procedure at right). When the burner is hot, the burner flame should appear blue and steady (some slight yellowing of the flame tips may occur when using propane gas).

When done cooking, turn the appropriate control knob to OFF. (The pilot should remain lit).

Each 12"-wide or 16"-wide section has two burners, each of which has a pilot located near the front of the burner. To light the pilots, do the following:

1.Check that the burner control knob is in the OFF position.

2.Lift up a grate in order to expose the two pilots. They are accessible through a slot near the front end of the radiant plate.

3.Check that each pilot is in the correct position.

4.Turn on the gas supply to the sectional range (if not already on).

5.Light the pilots with a match or a pilot-lighting device. The pilot flames should be blue and steady.

Grates

(lift out for cleaning)

Burner Control Knob

(OFF, HIGH, or LOW)

Drippings Tray (slides out for cleaning)

Base-Oven Gas Shut-Off Valve (has no effect on charbroiler)

PAGE 14 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

OPERATION |

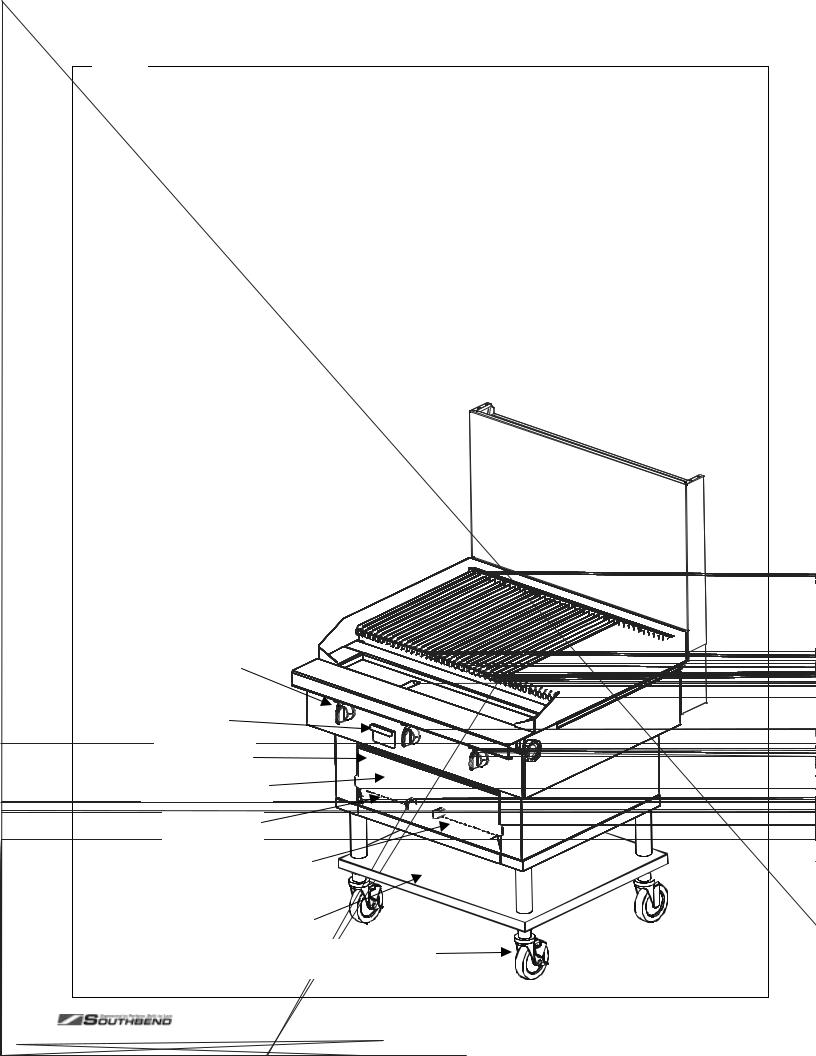

Figure 8

Operation of Wood Smoker Section

Wood Type(s): Split or Chunk Wood.

Wood Chunks:

Hickory Chunks, 10 lb bag, Southbend P/N 1188495 Mesquite Chunks, 10 lb bag Southbend P/N 1188496

Split Wood:

4” diameter X 20” long or smaller

Operation:

a.) |

Fill WATER/CATCH tray with water to bottom of wood |

|

grate. |

b.) |

Place even layer of selected wood on wood grate inside |

|

smoker box. |

c.) |

Turn control knobs to high position. Wood will then self |

|

ignite. |

|

(Ignition time for wood in smoker will vary due to |

|

moisture content and type of wood used) |

d.) |

Wood life can be extended by pre-soaking wood in |

|

water for a couple of hours prior to use. |

e.) |

It is not recommended to soak wood overnight. Wood |

|

will become too saturated and delay ignition. |

f.) |

Smoker box door should remain closed during normal |

|

operation. |

Shutdown: |

|

a.) |

Extinguish all remaining embers, or allow all wood to |

|

burnout. |

b.) |

Place all remaining wood in a fire-safe container. |

c.) |

Remove wood grate for cleaning. |

d.) |

Remove Water/Catch tray and dispose of content in a |

|

fire-safe container. |

WARNING / CAUTION

a.) Never use treated wood. When burned, treated wood can release pollutants harmful to your health into the air.

Burner Control Knob

(OFF, HIGH, LOW)

Grease Drawer

Smoker Box

Smoker Box Door

Wood Grate

Water/Catch Tray

Optional Lower Shelf

Optional Casters

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 15 OF 80 |

OPERATION |

PLATINUM SERIES SECTIONAL RANGE |

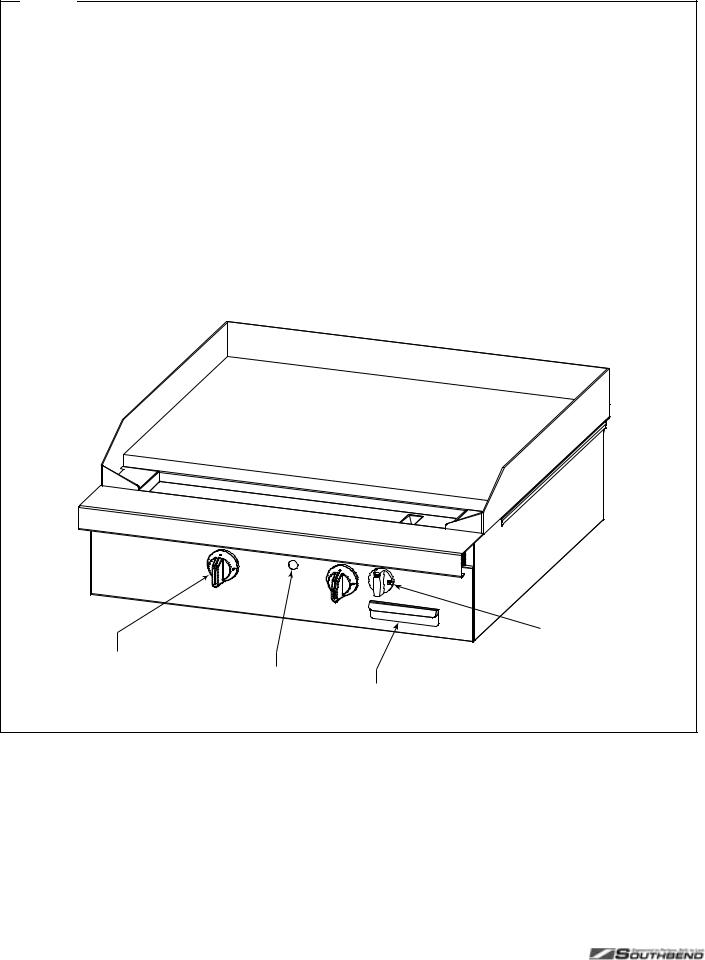

Figure 9

Operation of Standard (Non-Thermostatic) Griddle Sections

Each 16"-wide section has one control knob, which can be turned to OFF, HIGH, or LOW.

To start cooking, turn the appropriate control knob to HIGH. Check that the burner ignites. The gas does NOT automatically shut off if the burner does not ignite! If the burner does not ignite, check and/or light the pilots (see procedure at right). When the burner is hot, the burner flame should appear blue and steady (some slight yellowing of the flame tips may occur when using propane gas).

Always remember to heat the griddle slowly because quick heating may cause costly damage. Never place utensils on the griddle.

Do not waste gas and abuse equipment by leaving the controls on HIGH all the time. During idling periods, turn the control to LOW to keep the griddle warm. (Do not allow the griddle to overheat above 550°F (288°C), as this will cause warping or breakage.)

When necessary while cooking, pull out and empty the grease drawer.

When done cooking, turn the appropriate control knob to OFF. (The pilot should remain lit).

Each 16" or 32" griddle section has a single pilot that is lit using a long match inserted thorough a hole in the front valve panel. (A 48"-wide griddle has two pilots.) To light the pilot, do the following:

1.Check that all the control knobs are in the OFF position.

2.Turn on the gas supply to the sectional range (if not already on).

3.Light the pilot by inserting a long match (at least 11" long) or pilot-lighting device straight into the hole on the front valve panel of the griddle.

Burner Control Knob (OFF, HIGH, or LOW)

Pilot-Lighting

Opening

Base-Oven Gas Shut-Off Valve (has no effect on griddle)

Grease Drawer (slides out for cleaning)

PAGE 16 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

|

OPERATION |

|||

|

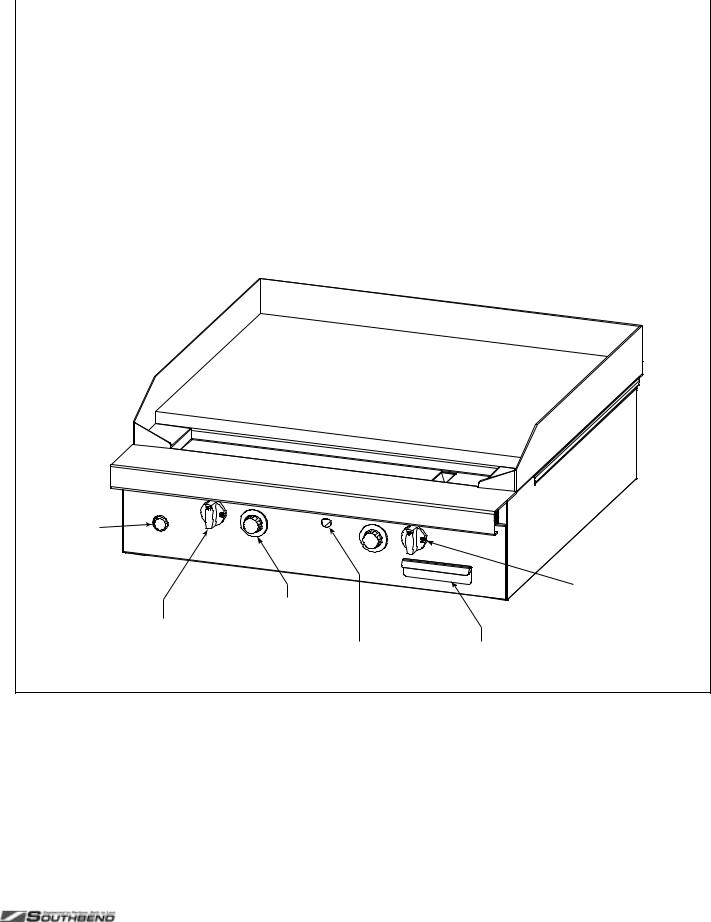

Figure 10 |

|

|

|

|

|

|

|

|

||

Operation of Thermostatic Griddle Sections |

|

|

|||

Each 16"-wide section has one control knob that can be |

Each 16" or 32" griddle section has a single pilot that is lit |

||||

turned to OFF, or to any temperature in the range 150°F to |

using a long match inserted thorough a hole in the front |

||||

400°F (66°C to 204°C). |

valve panel. (A 48"-wide griddle has two pilots.) To light the |

||||

To start cooking, turn on the appropriate control knob. Check |

pilot, do the following: |

||||

that the burner ignites. If the burner does not ignite, check |

1. |

Check that all control knobs are in the OFF position. |

|||

and/or light the pilots (see procedure at right). |

2. |

Turn on the gas supply to the sectional range (if not |

|||

Never place utensils on the griddle. |

|

already on). |

|||

Do not waste gas and abuse equipment by leaving the |

3. |

Turn on the Griddle Gas Shut-Off Valve (if not already |

|||

thermostat at a high temperature all the time. During idling |

|

on). |

|||

periods, turn the thermostat to a low temperature to keep the |

4. |

Press and hold in the Safety Switch Button. |

|||

griddle warm. (Do not allow the griddle to overheat above |

|||||

5. |

Light the pilot by inserting a long match (at least 11" long) |

||||

550°F (288°C), as this will cause warping or breakage.) |

|||||

|

or pilot-lighting device straight into the hole on the front |

||||

When necessary while cooking, pull out and empty the |

|

||||

|

valve panel of the griddle. |

||||

grease drawer. |

|

||||

6. |

After about a minute, release the Safety Switch Button. |

||||

When done cooking, turn the appropriate control knob to |

|||||

|

The pilot should remain lit. |

||||

OFF. (The pilot should remain lit). |

|

||||

|

|

||||

Safety

Switch

Button

Base-Oven Gas Shut-Off Valve (has no effect

|

Burner Control Knob |

on griddle) |

Griddle Gas |

(OFF, temperature) |

|

|

|

|

Shut-Off Valve |

Pilot-Lighting |

Grease Drawer |

|

||

|

Opening |

(slides out for cleaning) |

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 17 OF 80 |

OPERATION |

PLATINUM SERIES SECTIONAL RANGE |

Figure 11

Operation of Oven

Each oven has a thermostatic control that can be set in the range 150°F to 500°F (66°C to 260°C). Convection ovens have a fan that can be set to either HI speed or LO speed.

For advice on using a convection oven, see the information on the following two pages of this manual.

To start cooking, do the following:

1.Turn the Oven Gas Shut-Off Valve to ON.

2.Set the Oven Power Switch to ON. The Cooking Light will come on, and the pilot will light automatically. (You will hear a “snapping” sound until the pilot ignites.)

3.For convection ovens, select the fan speed appropriate for the food to be cooked.

Oven Gas Shut-Off Valve

Oven Power Switch

Fan-Speed Switch

(for Convection Ovens)

4.Select the cooking temperature appropriate for the food to be cooked.

5.When the oven reaches the set temperature, the Cooking Light will go out.

While cooking, if the door is opened on a convection oven, the fan and heat will temporarily stop until the door is closed.

Do not allow excessive drippings and/or debris to accumulate on the interior of the oven. When necessary, pull out and clean the oven-bottom tray.

When done cooking, turn the Oven Power Switch to OFF and turn the Oven Gas Shut-Off Valve to OFF.

Cooking Light

Cooking Temperature

WARNING

WARNING

THE USE OF ALUMINUM FOIL CAN CAUSE HEAT DISTRIBUTION PROBLEMS IN OVENS. EXTREME CARE MUST BE USED WHEN PLACING ALUMINUM FOIL IN THE OVEN TO ENSURE THAT IT DOES NOT BLOCK OR CHANGE THE AIR FLOW. THE USE OF ALUMINUM FOIL MAY VOID THE PRODUCT WARRANTY IF ITS USE IS ASCERTAINED TO BE A PROBLEM.

PAGE 18 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

OPERATION |

SUGGESTIONS FOR COOKING USING A CONVECTION OVEN

As a guide, set oven temperatures 25 to 50 degrees lower than called for in recipes using conventional (nonconvection) ovens.

FROZEN ENTREE PRODUCTS: Punch holes in lid before heating. Tent lid if product has a tendency to stick, i.e., lasagna or macaroni and cheese. Use manufacturer’s convection oven directions for time and temperature or reduce conventional oven temperature 50 degrees for a 6-1/2 size pan load. Some products may cook in 10 to 15 minutes less time than recommended for convection ovens if prepared from frozen in a 6 pan load.

Time and temperatures will vary depending upon load, mix, size of portion, and other factors. Use the following chart to develop your own cooking techniques:

|

Timing |

Temperature |

Number of |

Count per |

Product |

(minutes) |

Setting |

Racks Used |

Pan/Rack |

|

|

|

|

|

Hamburger buns, 3 oz. - 4" |

18 |

375° |

3 |

24 |

|

|

|

|

|

Yeast rolls - 1 oz. |

10 |

400° |

3 |

48 |

Use temperature and time recommended by |

|

|

|

|

manufacturer for convection ovens for a 3 pan load. |

|

|

|

|

|

|

|

|

|

Fruit pies, 46 oz. frozen |

50 |

375° |

3 |

4 |

Use temperature and time from manufacturer’s directions |

|

|

|

|

for convection ovens for a 12 pie load placed on 3 bun |

|

|

|

|

pans. |

|

|

|

|

|

|

|

|

|

Egg custard pies, 44 oz. frozen |

60 |

325° |

3 |

4 |

|

|

|

|

|

Dutch apple pies, 46 oz. frozen |

50 |

350° |

3 |

4 |

|

|

|

|

|

Baked potatoes, 8 oz. |

60 |

400° |

3 |

30 (wrapped) |

Wash and wrap in potato foil. Place 30 potatoes on 18 x |

|

|

|

|

24 bun pan — 3 pans per load. Bake in 400°F oven for 1 |

|

|

|

|

hour. |

|

|

|

|

|

|

|

|

|

Pre-blanched potatoes, frozen |

16 |

400° |

3 |

5 lb. |

Spread on ungreased bun pans, 3 pans per load. Bake |

|

|

|

|

at 400°F, stirring once, for 15 to 18 minutes. |

|

|

|

|

|

|

|

|

|

Fish portions, pre-cooked, breaded, 3 oz. |

16 |

400° |

3 |

32 |

Use manufacturer’s recommended temperature and time |

|

|

|

|

for convection oven for a 3 pan load. |

|

|

|

|

|

|

|

|

|

Macaroni & cheese, 6 lbs. - 40° temp. |

45 |

400° |

3 |

2-6 lbs. |

|

|

|

|

|

Lasagna w/meat sauce, 6 lb. - 40° temp. |

60 |

350° |

3 |

2 - 6 lbs. |

|

|

|

|

|

Lasagna w/meat sauce, 6 lb. - frozen |

75 |

350° |

3 |

2-6 lbs. |

|

|

|

|

|

Salisbury steak w/gravy, 6 lb. - 40° temp. |

45 |

400° |

3 |

2-6 lbs. |

|

|

|

|

|

Top round of beef No. 168 |

|

|

|

|

14 lb. - rare |

140° internal |

250° |

1 |

1 - 2 |

|

14 min./lb. |

|

|

|

14 lb. - medium |

150° internal |

250° |

1 |

1 - 2 |

|

14 min./lb. |

|

|

|

14 lb. - well done |

160° internal |

250° |

1 |

1 - 2 |

|

14 min./lb. |

|

|

|

|

|

|

|

|

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 19 OF 80 |

OPERATION PLATINUM SERIES SECTIONAL RANGE

CORRECTING PROBLEMS WHEN COOKING WITH A CONVECTION OVEN

If… |

then… |

Cakes are dark on the sides and not done in the center… |

lower oven temperature. |

|

|

Cake edges are too brown… |

reduce number of pans or lower oven temperature. |

|

|

Cakes have light outer color… |

raise temperature. |

|

|

Cake settles slightly in the center… |

bake longer or raise oven temperature slightly. Do not open |

|

doors too often for long periods. |

|

|

Pies have uneven color… |

reduce number of pies per rack. |

|

|

Meats are browned, but not done in center… |

lower oven temperature and roast longer. |

|

|

Meats are well done and not browned… |

raise temperature. Limit amount of moisture. |

|

|

Cakes ripple… |

pans are overloaded or batter is too thin. |

|

|

There is excessive meat shrinkage… |

lower oven temperature. |

|

|

Cakes are too coarse… |

lower oven temperature. |

|

|

PAGE 20 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

CLEANING & MAINTENANCE |

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 21 OF 80 |

CLEANING & MAINTENANCE |

PLATINUM SERIES SECTIONAL RANGE |

CLEANING & MAINTENANCE

WARNING

WARNING

Shut off the gas supply to the appliance before cleaning or performing maintenance on any gas appliance.

The appliance may be equipped with a restraint device to limit its movement in order to prevent damage to the gas connection. If disconnection of this restraint is necessary to move the appliance for cleaning or maintenance, reconnect the restraint when the appliance is moved back to its original installed position.

Southbend appliances are sturdily constructed of the best materials and are designed to provide durable service when treated with ordinary care. To expect the best performance, your equipment must be maintained in good condition and cleaned daily. Naturally, the periods for this care and cleaning depend on the amount and degree of usage.

Following daily and periodic maintenance procedures will enhance long life for your equipment. Climatic conditions (such as salt air) may require more thorough and frequent cleaning or the life of the equipment could be adversely affected.

Keep exposed, cleanable areas clean at all times.

DAILY CLEANING AND MAINTENANCE

The daily cleaning procedure is as follows:

1.Shut off the main gas supply and allow the sectional range to cool.

2.Pull out, empty, and clean all drippings trays and grease drawers.

3.Remove and clean all oven racks and oven-bottom trays. Wipe clean the interior of the oven.

4.Visually check for any food and/or debris that may have fallen down into the burner areas.

5.Wipe clean all exterior surfaces.

6.Replace the cleaned and dried drippings trays, grease drawers, and oven components.

7.Check that nothing has been left on or near the sectional range that might block the entry of combustion air or the escape of combustion exhaust.

MONTHLY CLEANING AND MAINTENANCE

The following tasks should be performed monthly:

1.Clean around burner air mixers and orifices if lint has accumulated in these areas.

2.Check for proper pilot operation. Check that the pilot flames are blue (with little or no yellow in the flame tips), stable (not lifting off the pilots), and not producing carbon. If adjustment is necessary, call for service.

3.Check for proper burner operation. The burner flames should be blue and stable. If adjustment is necessary, call for service.

SEMIANNUAL CLEANING AND MAINTENANCE

At least twice a year the venting system should be examined and cleaned.

STAINLESS-STEEL SURFACES

To remove normal dirt, grease and product residue from stainless steel surfaces that operate at LOW temperature, use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth.

To remove BAKED-ON grease and food splatter, or condensed vapors; apply cleanser to a damp cloth or sponge and rub cleanser on the metal in the direction of the polishing lines on the metal. Rubbing cleanser, as gently as possible, in the direction of the polished lines will not mar the finish of the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits which do not respond to the above procedure can usually be removed by rubbing the surface with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO NOT USE ORDINARY STEEL

PAGE 22 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PLATINUM SERIES SECTIONAL RANGE |

CLEANING & MAINTENANCE |

WOOL as any particles left on the surface will rust and further spoil the appearance of the finish. NEVER USE A WIRE BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS. Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also increases the possibility of corrosive attack. Refinishing may then be required.

“Heat tint” is darkened areas that sometimes appear on stainless steel surfaces where the area has been subjected to excessive heat. These darkened areas are caused by thickening of the protective surface of the stainless steel and are not harmful. Heat tint can normally be removed by the foregoing, but tint which does not respond to this procedure calls for a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE scouring pads or a STAINLESS scouring pad in combination with a powered cleanser. Heat tint may be lessened by reducing heat to equipment during slack periods.

BLACK BAKED-ENAMEL SURFACES

Allow appliance to cool somewhat after use and wash black baked-enamel surfaces with a hot, mild detergent or soap solution. In particular, clean off all grease deposits. Dry thoroughly with a dry cloth.

OPEN-BURNERS AND GRATES

The grates can be removed and cleaned with a solution of hot water and strong soap or detergent. The burners themselves require little attention, but if spillage should occur, it may be necessary to clean around pilot areas, air mixer and under burners. Use a wire brush if necessary. Periodically, open-burners should be removed and cleaned. Allow the interior of the burner to drain, and dry thoroughly before replacing.

HOT-TOP SURFACES

Before cleaning hot-top surfaces, allow them to cool. If water is used on hot-tops while they are still hot, they may crack, so avoid this practice. The hot-top plates can be removed and cleaned with hot water and detergent. A wire brush may be used on the underside of the hot top plate. It is recommended not to clean tops while still on the range, even if cooled, as excess water will drip into the burner box and deteriorate the metal.

CARE OF GRIDDLES

A griddle should be carefully cared for in order to avoid possible damage. (The griddle should have been tempered as part of the installation procedure, see page 31). Use a Norton Alundum Griddle Brick to clean the griddle. Do not use any type of steel wool. Small particles may be left on the surface and get into food products. Do not clean spatula by hitting the edge on the griddle plate. Such action will only cut and pit the griddle plate, leaving it rough and hard to clean.

OVEN INTERIOR

WARNING

WARNING

FOR YOUR SAFETY, DISCONNECT THE POWER SUPPLY TO THE SECTIONAL RANGE BEFORE CLEANING THE OVEN. WHEN CLEANING THE BLOWER WHEEL OF A CONVECTION OVEN, BE SURE TO HAVE THE POWER SWITCH IN THE “OFF” POSITION.

To clean the oven interior, first allow the oven to cool. Remove oven bottom and clean it by rubbing with strong detergent and a Brillo pad or similar scrubber. “Spillovers” should be cleaned from the bottom as soon as possible to prevent carbonizing and a “burnt-on” condition. For stubborn accumulations, commercial oven cleaners are recommended.

The porcelain oven door lining can be cleaned in a similar manner. The side, rear and top lining should be wiped only with a cloth dampened with a mild detergent and water. Avoid using excessive amounts of water, as this may drip into burner compartment and deteriorate the metal in that area. Do not use strong commercial cleaners or abrasive pads on the side, rear or top linings, as they may damage the finish or leave gray residue.

INSTALL AND OPERATIONS MANUAL 1185836 REV 3 (07/06) |

PAGE 23 OF 80 |

INSTALLATION |

PLATINUM SERIES SECTIONAL RANGE |

INSTALLATION

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association, Inc., states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to installation requirements for equipment. Therefore, installations should comply with all local codes.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGAB149.2, as applicable, including:

1. The appliance and its individual shutoff valve must be

PAGE 24 OF 80 |

INSTALL & OPERATIONS MANUAL 1185836 REV 3 (07/06) |

Loading...

Loading...