Sony Ericsson W880I Diagram

Trouble Shooting Guide, Mechanical

Trouble Shooting Guide, Mechanical

Applicable for W880i

Contents

1 General ................................................................................................................................. 2

Service functions in the software ................................................................................... 3

Misuse and other no warranty issues ............................................................................ 4

2 Power Problems.................................................................................................................... 6

3 Network/Signal Problems......................................................................................................7

4 Audio Problems.....................................................................................................................8

Receiver:........................................................................................................................ 8

Rear Speaker:.............................................................................................................. 10

Microphone: ................................................................................................................. 12

5 Key Problems...................................................................................................................... 13

Keypad:........................................................................................................................ 13

Volume key: ................................................................................................................. 14

Camera key .................................................................................................................15

Music Key .................................................................................................................... 15

6 Display Problems ................................................................................................................17

7 Illumination Problems..........................................................................................................18

Keypad Illumination: The entire keypad will not illuminate .........................................18

Keypad Illumination: A portion of the keypad does not illuminate .............................18

Display Illumination:..................................................................................................... 19

8 Alert Problems..................................................................................................................... 20

Vibrator: .......................................................................................................................20

Rear speaker: .............................................................................................................. 20

9 Charging/Capacity Problems ..............................................................................................22

10 SIM Problems...................................................................................................................... 23

11 Data Transfer Problems using a Data Cable ......................................................................24

12 Hands-Free Problems ......................................................................................................... 24

13 Rear Camera Problems ......................................................................................................25

14 Video Call Camera Problems (W880 Only)......................................................................... 27

15 Bluetooth Problems.............................................................................................................29

16 Revision History .................................................................................................................. 30

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

Trouble Shooting Guide, Mechanical

1 General

This document outlines the mechanical repairs that should be made in an attempt to fix the common failures that are seen in the

field. To gain a complete understanding of how to test and repair a unit, this document should be used in conjunction with the Test

Instructions, Mechanical and the Working Instructions, Mechanical.

NOTE! A unit should always be inspected for liquid damage and flashed with latest software before using the

Mechanical Trouble Shooting Guide. Refer to the Mechanical Test Instructions for details regarding upgrading

software.

NOTE! If all of the repair actions listed in this document for addressing a problem have been performed and a unit still

is not working, handle the unit according to your local Sony Ericsson Representative

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

2(30)

Trouble Shooting Guide, Mechanical

Service functions in the software

The service menu will be accessed with the following key combination. Use the joystick.

⇒*⇐⇐*⇐*

The service menu options are:

Service info

Service tests

Text labels

Under the “Service tests” option, the phone’s software has a built in service functionality that allows you to test some of

the phones functions. It looks like this:

Main display

LED/illumination

Keyboard

Speaker

Earphone

Microphone

Vibrator

Camera

Video Call Camera

Memory Stick

Real time clock

Total call time

Security

NOTE: Different names may occur depending on language setting and customization.

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

3(30)

Trouble Shooting Guide, Mechanical

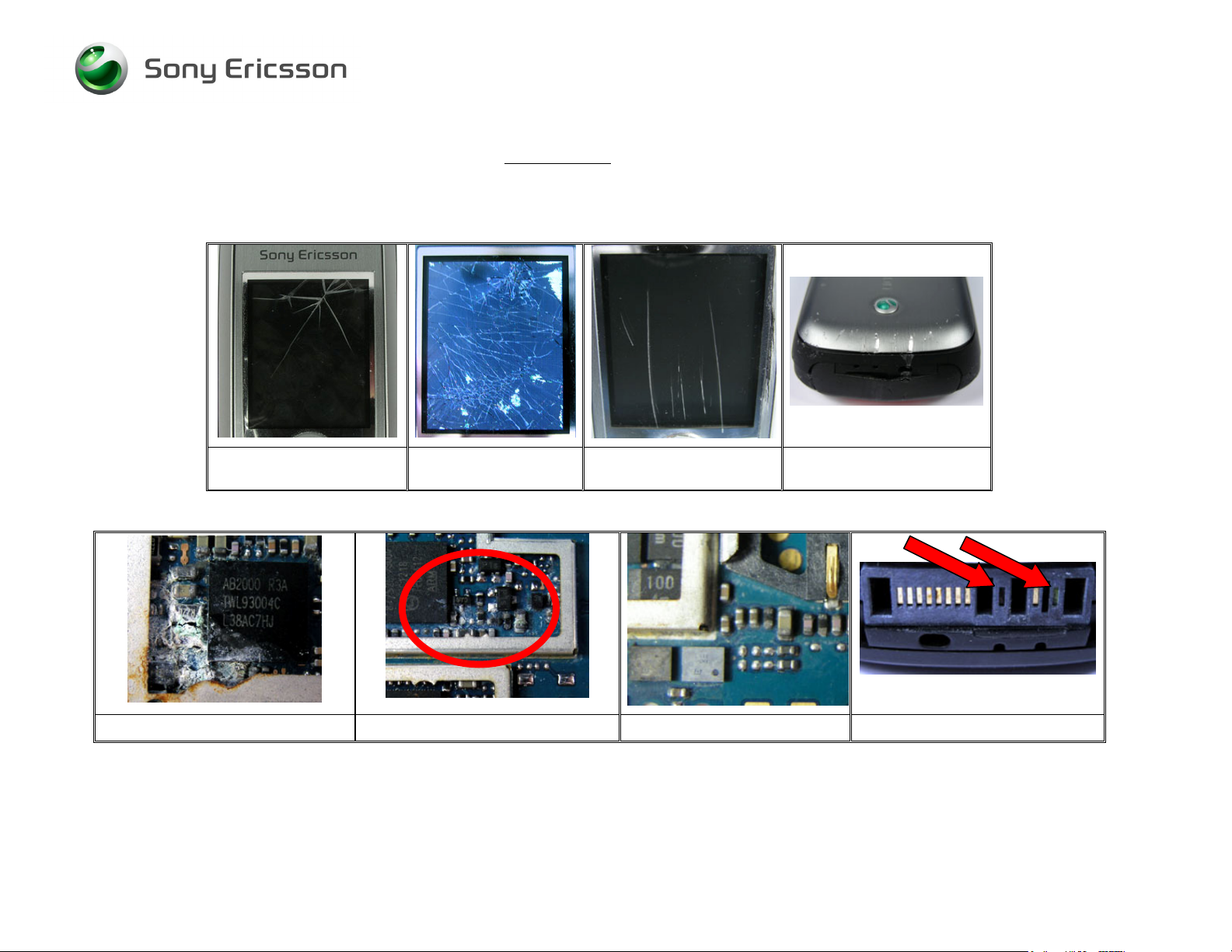

Misuse and other no warranty issues

A phone that is damaged due to misuse is not covered by warranty. This section shows many of the signs of misuse that

are seen in the field. Please refer to local directives on how a phone that appears to be damaged due to misuse should

be handled.

Below are some examples of damage due to misuse that are not covered by warranty.

Front window broken due to

misuse.

LCD cracked due to drop. Clear scratches Mark after drop

Corrosion components on the PCB. Corrosion components on the PCB. Components damaged by liquid System connector damaged by liquid

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

4(30)

Trouble Shooting Guide, Mechanical

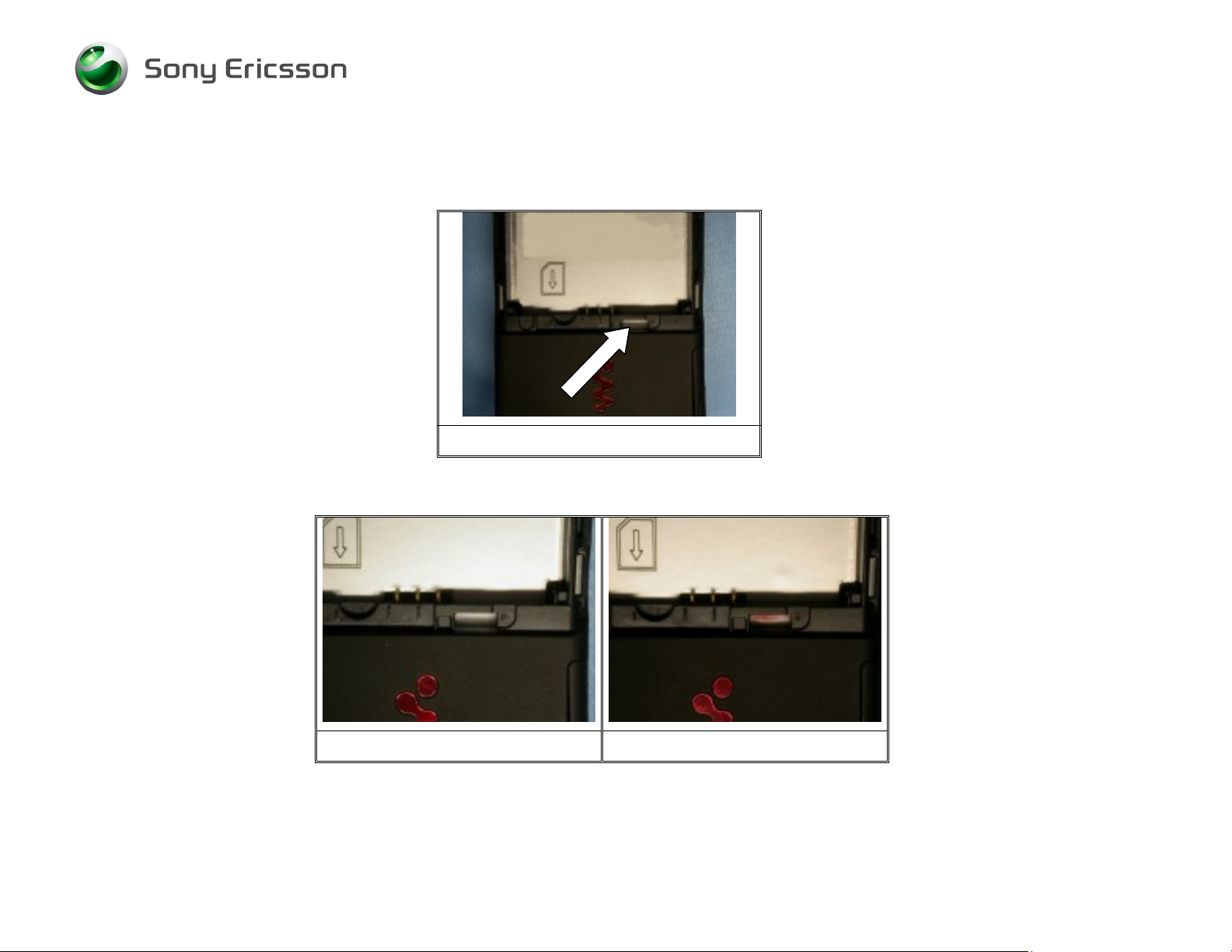

1.1.1 Liquid Damage Inspection

Before any tests are performed, an inspection of the liquid intrusion indicator should be made. If the liquid intrusion

indicator is red this is an indication of possible liquid exposure. If the liquid intrusion indicator suggests liquid exposure

please consult your local SEMC representative for handling instructions.

Location of the liquid intrusion indicator

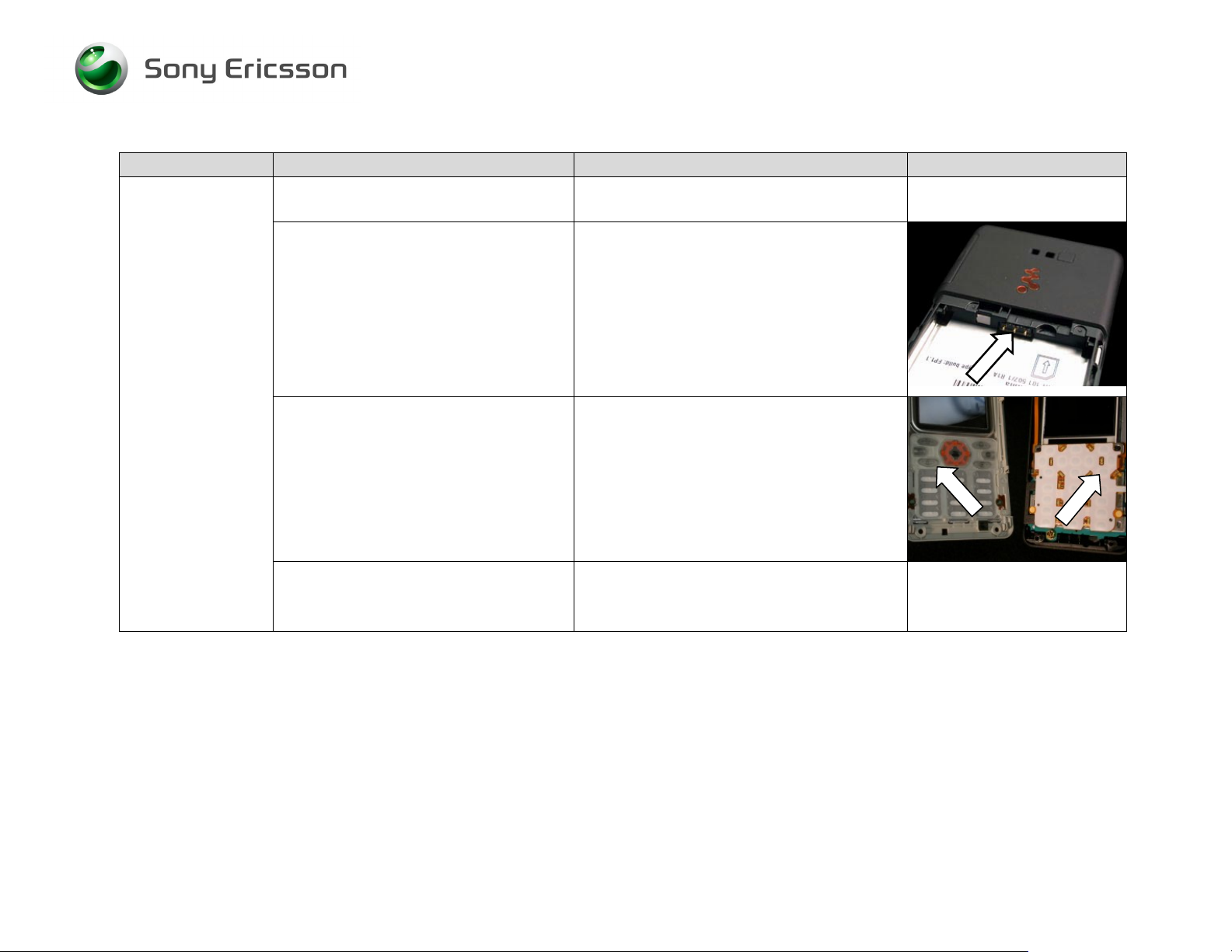

The following pictures show the different between an indicator that has been in contact with liquid and one that has not.

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

Not Exposed to Liquid Exposed to Liquid

5(30)

Trouble Shooting Guide, Mechanical

2 Power Problems

Problem Area

Unit will not

Power On

Items to Inspect

Check whether the phone vibrates

when you press the power key

Inspect battery connector

Inspect the area between the power

key portion of the keypad and the

dome foil assembly

If the issue is still not resolved!

Repair Action

If activation of the vibrator is detected,

refer to the “Display Problems” section

• If dirty or oxidized – Clean the

connector’s contact pins

• If adhesive is detected on the contact

pins – use an eraser to rub off the

adhesive

• If damaged – Send to a repair

location allowed to perform electrical

repairs on this product

• If the keypad is damaged, replace it

• Replace the dome foil assembly

• Send to a repair location allowed to

perform electrical repairs on this

product

Inspection Reference

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

6(30)

Trouble Shooting Guide, Mechanical

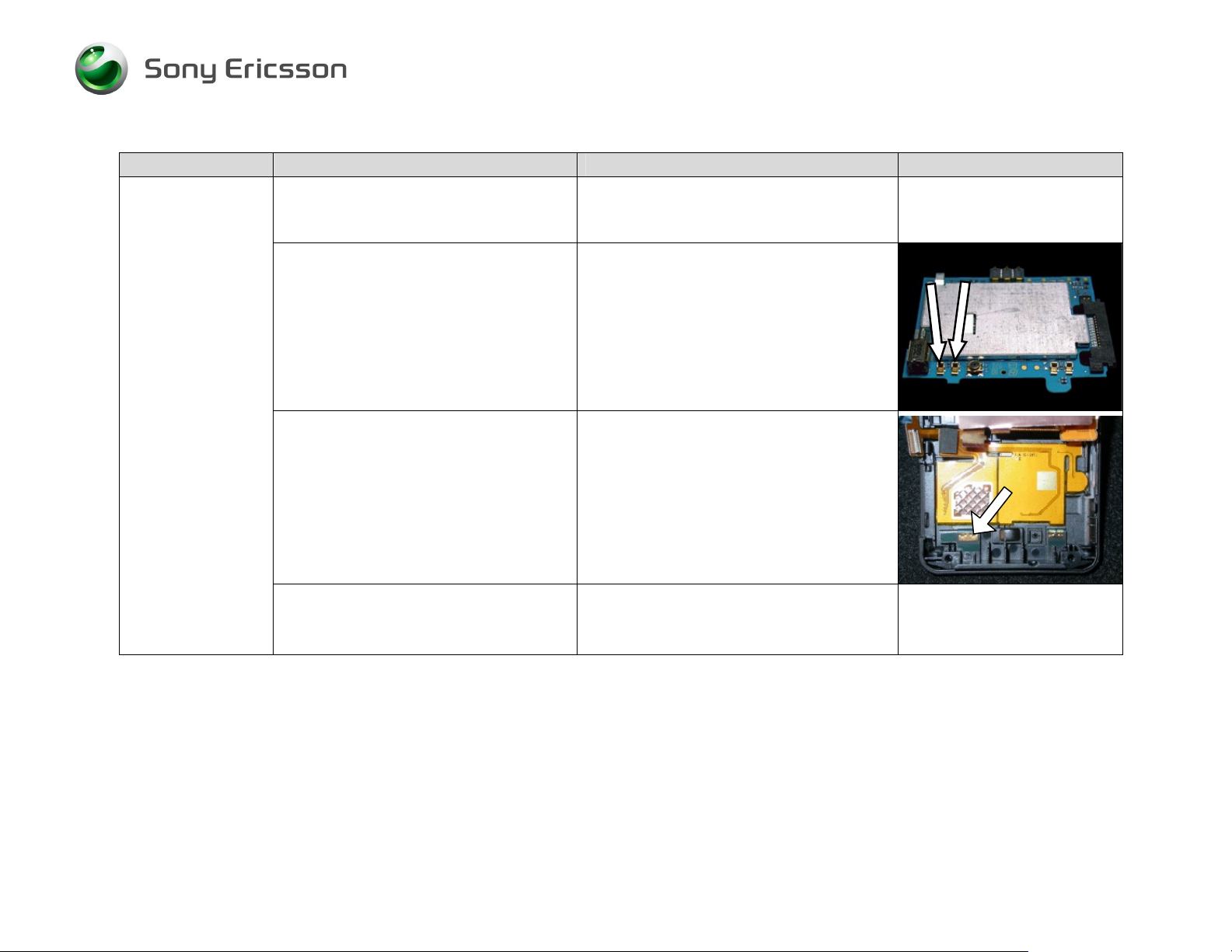

3 Network/Signal Problems

Problem Area

No Signal or Poor

Signal

Items to Inspect

Before proceeding !

Inspect antenna-to-board spring

connectors

If the issue has not been resolved !

If the issue is still not resolved!

Repair Action Inspection Reference

• Ensure the correct SIM (GSM) or

USIM (UMTS) is installed. See Test

Instruction for details.

• If dirty or oxidized – Clean the

antenna-to-board spring connectors

• If damaged - Send to a repair

location allowed to perform

electrical repairs on this product

• Replace the antenna

• Send to a repair location allowed to

perform electrical repairs on this

product

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

7(30)

Trouble Shooting Guide, Mechanical

4 Audio Problems

Problem Area

Receiver:

No sound or poor

quality sound

Items to Inspect

Before proceeding !

Inspect the receiver’s external ports

Inspect the receiver’s dust cloth

Repair Action

• Perform a setting reset

• If clogged – Clean the ports and

receiver’s dust cloth

• If dirty – Clean

• If damaged – Replace the camera flex

assembly

Inspection Reference

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

8(30)

Trouble Shooting Guide, Mechanical

Problem Area

Items to Inspect

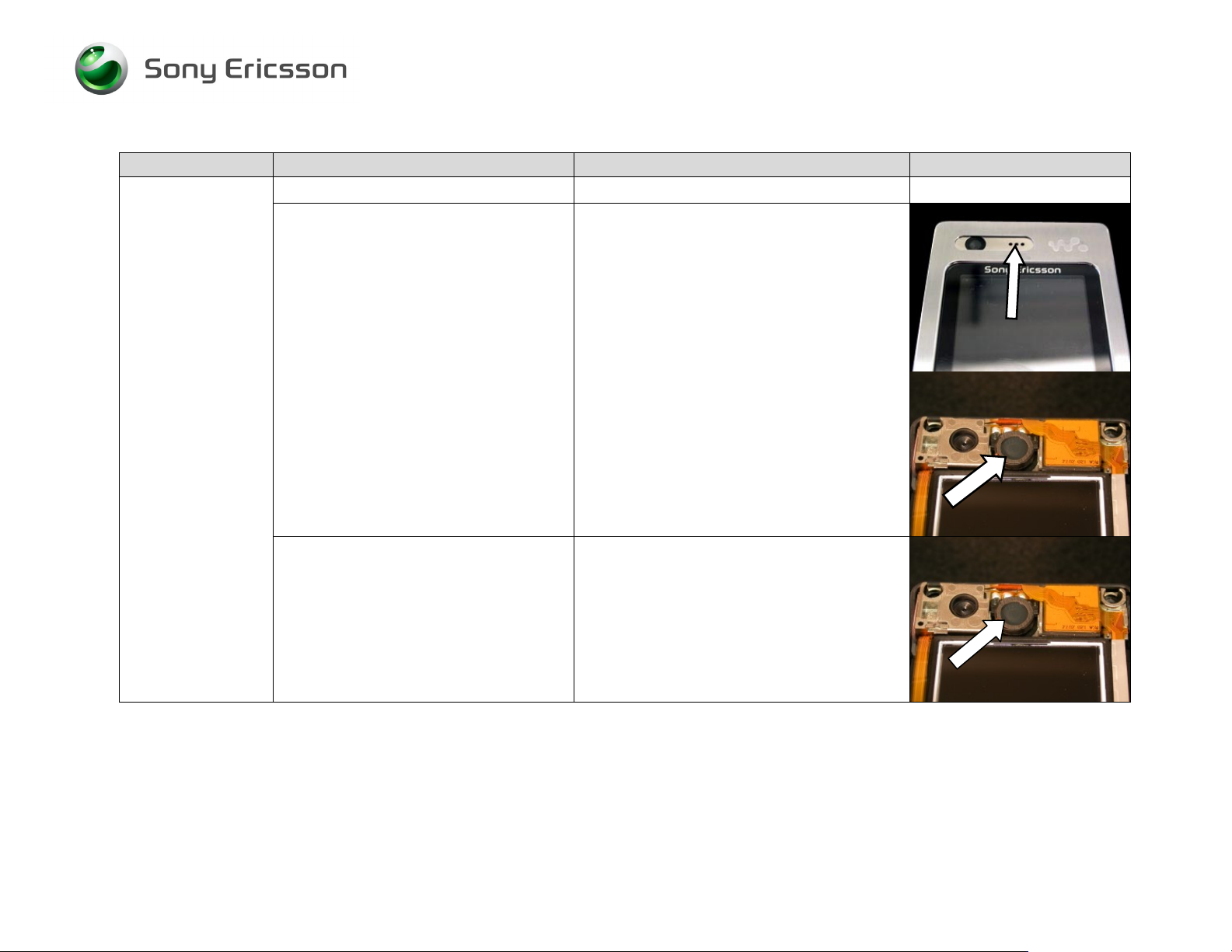

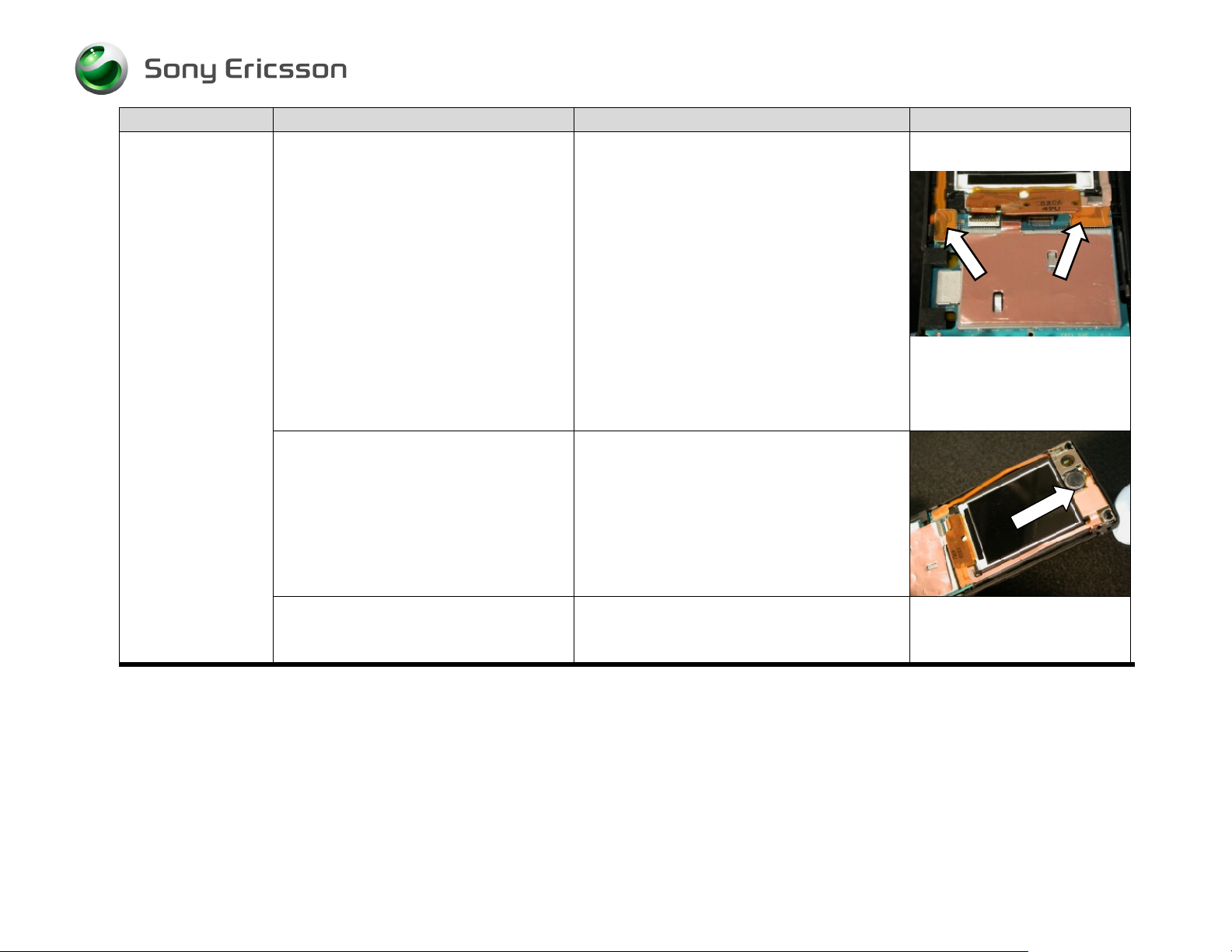

Inspect the two connections where

the camera flex assembly connects

to the circuit board

• If either connection is improperly

connected - Reestablish proper

connection

Repair Action

Inspection Reference

• If one or both of the connections is

dirty or oxidized – Clean both halves

of the connection(s)

• If any portion on the camera assembly

flex film is damaged – replace the

camera flex assembly

• If either of the camera flex assembly

connections on the circuit board is

damaged – Send to a repair location

allowed to perform electrical repairs

on this product

If the issue has not been resolved !

• Replace the camera assembly, if it

has not been replaced

4/000 21-1/FEA 209 544/123 A

Company Internal

© Sony Ericsson Mobile Communications AB

If the issue is still not resolved !

• Send to a repair location allowed to

perform electrical repairs on this

product

9(30)

Loading...

Loading...